2.1.1. Product Types

Spare parts are stocked and used for keeping equipment in operating conditions. The management of spare parts is a critical element in the after-sales service supply chain. Capital goods and consumer durable goods are two important product types which have a long lifetime and require after-sales services [

11]. The former are high-value tangible assets used by a company as an input for producing other goods or services, and are also referred to as capital assets. The latter refer to the products purchased by individual customers and are not used for producing another good or service. Examples of consumer durable goods include automobiles, household appliances, and consumer electronics. Normally, capital goods are essential to the operation processes of the owner company. Therefore, a high availability of capital goods needs to be ensured [

12]. Examples of capital goods include computer networks, medical and defense systems, and aircrafts.

There are several differences between these two categories. Capital goods directly involve producing goods or providing services, while consumer durable goods do not. Second, they are supported by distinct after-sales services. Service contracts are provided by the OEMor a third party maintenance company for capital goods. Warranties are usually provided for consumer durable goods. Third, these two goods have different spare parts demand patterns. Consumer durable goods are purchased by a large number of individuals, leading to significant variations in spare parts demand because product usage varies among customers. For capital goods, owners usually purchase a fleet of identical products in use and these products normally have the same usage levels and work under the same environment. On the other hand, for consumer durable goods, the law of large numbers holds for spare parts demand because the product’s installed base is sufficiently large, meaning that the OEM is able to take advantage of this property to make inventory decisions. In contrast, the installed base of capital goods is usually not large enough, especially for the network managed by the equipment owner, who is more likely to be faced with irregular spare parts demand patterns.

According to

Table 1, the studies on spare parts of capital goods prevail in this research area: 109 out of 142 studies focus on the spare parts of capital goods, and only 18 studies consider the spare parts of consumer durable goods. Meanwhile, we cannot identify the product types in 15 papers. This result indicates a notable research gap in managing spare parts of consumer durable goods, and such a gap will be discussed in part b of

Section 4.1.2.

2.1.2. Product Life-Cycle Phases

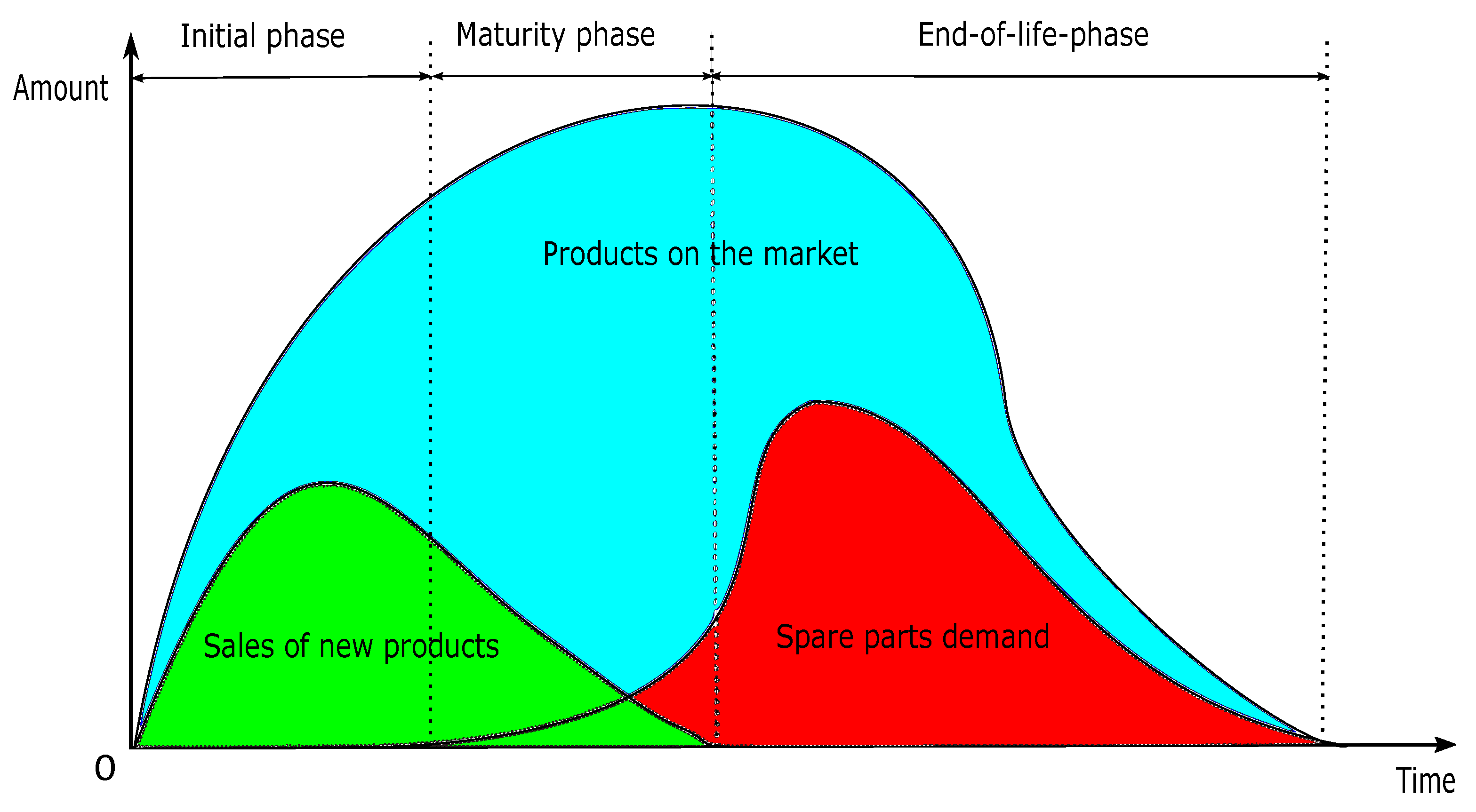

The product life-cycle consists of three phases, including the initial phase, maturity phase, and end-of-life (EOL) phase [

10]. The demands for products and those for spare parts behave differently throughout the life-cycle. The initial phase begins when a new product is launched. The product demand increases sharply during the initial phase and the number of products on the market surges as well. In contrast, the product failure due to deterioration is very low, implying that the spare parts demand is not significant during this phase. After the initial phase, the maturity phase starts when the number of products on the market becomes stable. Such stability is caused not only by the declining product demand, but also by the increasing product failures, which also incur increasing spare parts demands. The EOL phase usually starts when the manufacturing of products and spare parts stops and when the last warranty or service contract period expires [

13]. During this phase, product sales cease and on-market product quantity starts to decrease, while the supply of spare parts stops. However, products on the market still need to retain functionality when they fail, requiring spare parts be procured and then stocked at the beginning of this phase.

Figure 1 illustrates the life-cycle phases. Importantly, spare parts demand follows product demand but with a time lag, called the “life-cycle mismatch” phenomenon [

14]. Such mismatch indicates that spare parts demand is correlated with on-market product quantity [

15].

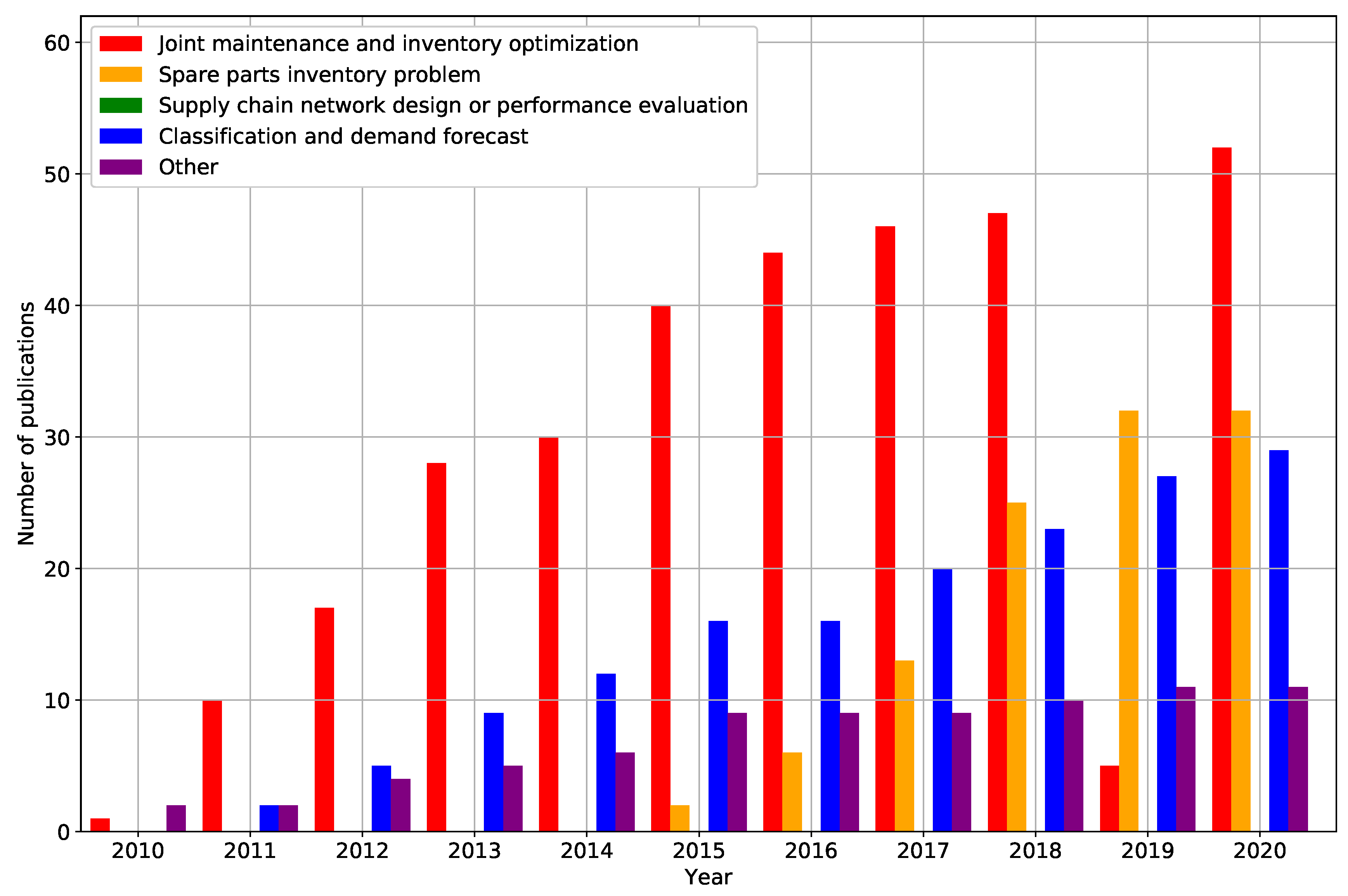

As shown in the second column of

Table 1, most studies in the spare parts inventory management literature focus on the inventory problems arising during the maturity phase when on-market product quantity is stable. There are nine studies focusing on the final order problem or last-time-buy problem occurring in the EOL phase. Additionally, four studies focus their efforts on spare parts inventory management over the entire life-cycle. The other 40 studies cannot be classified because they do not indicate the life-cycle phases they focus on. It is clear that the extant studies lack the life-cycle planning perspective, and we will present the discussion on this research gap in part b of

Section 4.1.2.

2.1.3. Spare Part Types

The spare parts in the reviewed studies mainly include two types, i.e., repairable parts and non-repairable parts. Repairable parts are items which are replaced by new ones and then sent to repair when failure occurs [

12]. After being repaired, the parts are restocked as ready-for-use units (RFUs), which are used to replace faulty ones in the future. Non-repairable parts, also referred to as consumables, are items which cannot be repaired after replacement and are usually discarded. The inventory management of repairable parts is more complex than that of consumables. For repairable parts, supply sources include not only suppliers, but also repair workshops, whose operations are affected by repair capacity, repair time, etc.

As shown in the third column of

Table 1, there are 41 studies focusing on repairable parts, while there are three studies considering both repairable and non-repairable parts. More than half of the studies focus on non-repairable parts. Ten studies do not specify the types of spare parts. However, such emphasis on non-repairable parts is not able to satisfy the urgent need for managing repairable parts among practitioners, especially when the concept of supply chain sustainability has prevailed in industry recently. Based on such an observation, the research gaps regarding reverse logistics of spare parts will be presented in

Section 4.1.1.

2.1.5. Performance Measures

In the literature, various performance measures are used to evaluate the outcomes brought by different inventory policies, maintenance schedules, etc. In the following, three different measures are introduced. These performance measures are adopted by the inventory network owners to manage the spare parts inventory for different products. Typically, if OEMs manage the spare parts inventory network to provide after-sales services, they are interested in the life-cycle cost of the manufactured product, because it is an important factor to consider when designing products and deciding after-sales services strategies. For the product users who build up their own spare parts inventory networks for maintaining the purchased products, the total cost of ownership is one of their main concerns, because it helps them understand the true cost of buying the products from a particular OEM. In addition, both OEM and product users may focus on the supply chain performance metrics to meet their specified operation requirements for the spare parts supply chain. In the following context, three different measures including life-cycle cost, total cost of ownership, and supply chain performance metrics, are introduced and the reviewed literature is classified based on these measures.

Life-cycle cost (LCC) is referred to as the summation of all cost components for manufacturers, users, and society during the product lifetime. The breakdown structure is shown in

Table 2, adapted from [

18].

The difference between this table and that of [

18] is that OEM may also have disposal or recycling costs if reverse logistics (RL) are implemented. Detailed discussions on the relationship between RL and spare parts inventory management are given in

Section 4.2. More importantly, when conducting LCC analysis, the cost categories considered are different for OEM, users, and society, because they are only interested in the cost components that they can control. For example, ref [

19] studied a problem in which an OEM provides the performance-based contract (PBC) to the customer who purchased a set of equipment. The life-cycle cost considered in their study includes the design costs, production costs, and usage costs, and is affected by the product’s reliability level and spare parts inventory level.

- b.

Total cost of ownership

Total cost of ownership (TCO) is a concept which helps customers to understand the true cost of buying a particular good or service from a supplier [

20]. In addition to product price, TCO normally contains the costs incurred by product maintenance, downtime, disposal, and other activities that occur during the usage of the product. Note that the maintenance-related cost may account for a large portion (70–80%) of the TCO for complicated technical systems [

19]. Hence, spare parts inventory management is important due to its critical role in maintenance operations.

It should be highlighted that the maintenance-related cost may account for a very large portion (70–80%) of the TCO for some complicated technical products, such as military, medical, and power generation equipment. Therefore, spare parts inventory management is important due to its critical role in maintenance operations. The studies that adopt the TCO as the performance measure for evaluating the spare parts inventory system generally seek to find the optimal inventory policy, such that the TCO is minimized.

- c.

Supply chain performance metrics

In the literature, the Supply Chain Operation Reference (SCOR) model is widely used to measure supply chain performance. This model measures supply chain performance from four perspectives, i.e., lead time metrics, cost metrics, service/quality metrics, and assets metrics [

21], illustrated in

Table 3.

The number of reviewed studies which use different performance measures are listed in the final column of

Table 1. It is worth mentioning that more than one performance measure can be used to evaluate the system performance. For example, an OEM who provides performance-based contracts to the customer has to not only consider the cost metrics of the maintenance and inventory system, but also ensure that the requested service metrics in the contract be satisfied (e.g., the required product availability level). In this case, one can use the total cost induced by managing spare parts as an objective, while the agreed service level acts as the constraints in optimization models. Consequently, we consider the number of usages of different performance measures in the reviewed literature.

The last column of

Table 1 clearly shows that supply chain performance metrics are dominantly used in the literature. In contrast, eight studies adopt the LCC measure and two studies use the TCO measure, respectively. There are four studies using other measures such as company profits of selling products and providing warranty services [

11,

22], profits of using spare parts inventory pooling among different companies [

23], and warranty cost [

24]. This observation indicates that research on spare parts inventory management should consider advanced warranty types.