1. Introduction

Transportation is an inseparable part of the world, from the simplest methods used in the past (so-called nonmotorized land transport, i.e., transportation in wagons, using animals, carriers, rickshaws, etc.), through to conventional types of transportation used nowadays (road, rail, water, and air), to space transportation. Each type of transportation requires an appropriate technical base, a so-called mobile base (i.e., means of transport) and a stable technical base (i.e., transport infrastructure and equipment). These bases must coexist so that they do not negatively influence each other, and thus form a comprehensive, functioning, and long-term sustainable system. An example related to the focus of this study is the design of intersections (roundabouts); if the dimensions or geometric layout of an intersection are such that motor vehicles have difficulty passing through the intersection safely, dangerous situations may occur (i.e., traffic conflicts [

1,

2,

3,

4,

5] or even accidents [

6,

7]). For example, an intersection with a small corner radius can be a problem, if it forces a driver who is turning right to enter the opposite direction when exiting the intersection. Drivers of ordinary vehicles, as well as drivers of oversized cargoes could encounter problems while passage through the intersection [

8,

9]. There are so-called backbone routes in road networks, for the transport of various large machine parts, construction machinery, etc. On such a route there is often an intersection (e.g., a roundabout), however, which does not contain elements for the passage of large cargoes.

The capacity of an intersection is often unsatisfactory. The simplest solution seems to be to reconstruct the intersection into an intersection with better dimensions, and thus increase its capacity; however, this does not always happen, and if it does, it is often at the expense of traffic safety [

10,

11]. Microsimulation traffic models [

10,

12] are suitable means for evaluating the capacity of an intersection solution, which complement traditional capacity calculations and often are reliable for pointing out possible problems.

Another possible solution is to reconstruct the intersection into a different type of intersection. Uncontrolled intersections are frequently reconstructed into roundabouts. There are many types of roundabouts, from standard single-lane ones, to turbo roundabouts, and other special types (double, “hamburger”, etc.) (see examples [

13,

14,

15]). As previously mentioned, reconstruction of an intersection often involves building an intersection with larger dimensions, which is not always appropriate, or sometimes is even impossible.

The abovementioned consideration is only part of what a designer must take into account when designing intersections. This issue is very closely related to sustainable transportation, or to sustainability in general [

16,

17,

18,

19,

20], because new and larger transportation construction is not endlessly possible and it is always at the expense of our environment, which also has its limits. The primary goal of a traditional approach to transportation planning is to enable the greatest possible mobility of the population. However, we see the negative impacts of this way of planning around us every day in terms of a worsened environment, accident rates, etc. As mentioned in the Introduction, transportation is an inseparable part of humanity, and therefore it is necessary to find a sustainable compromise.

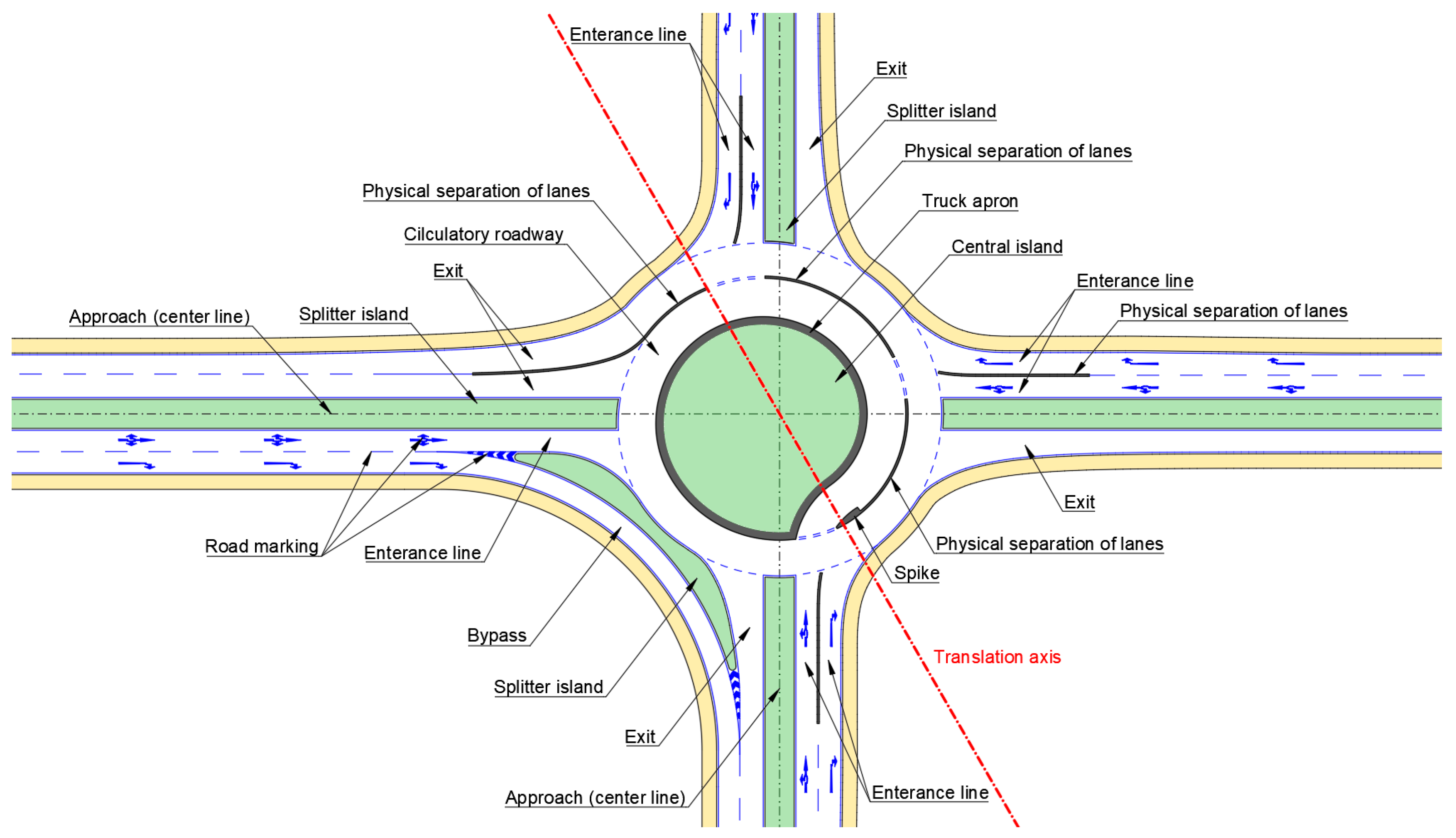

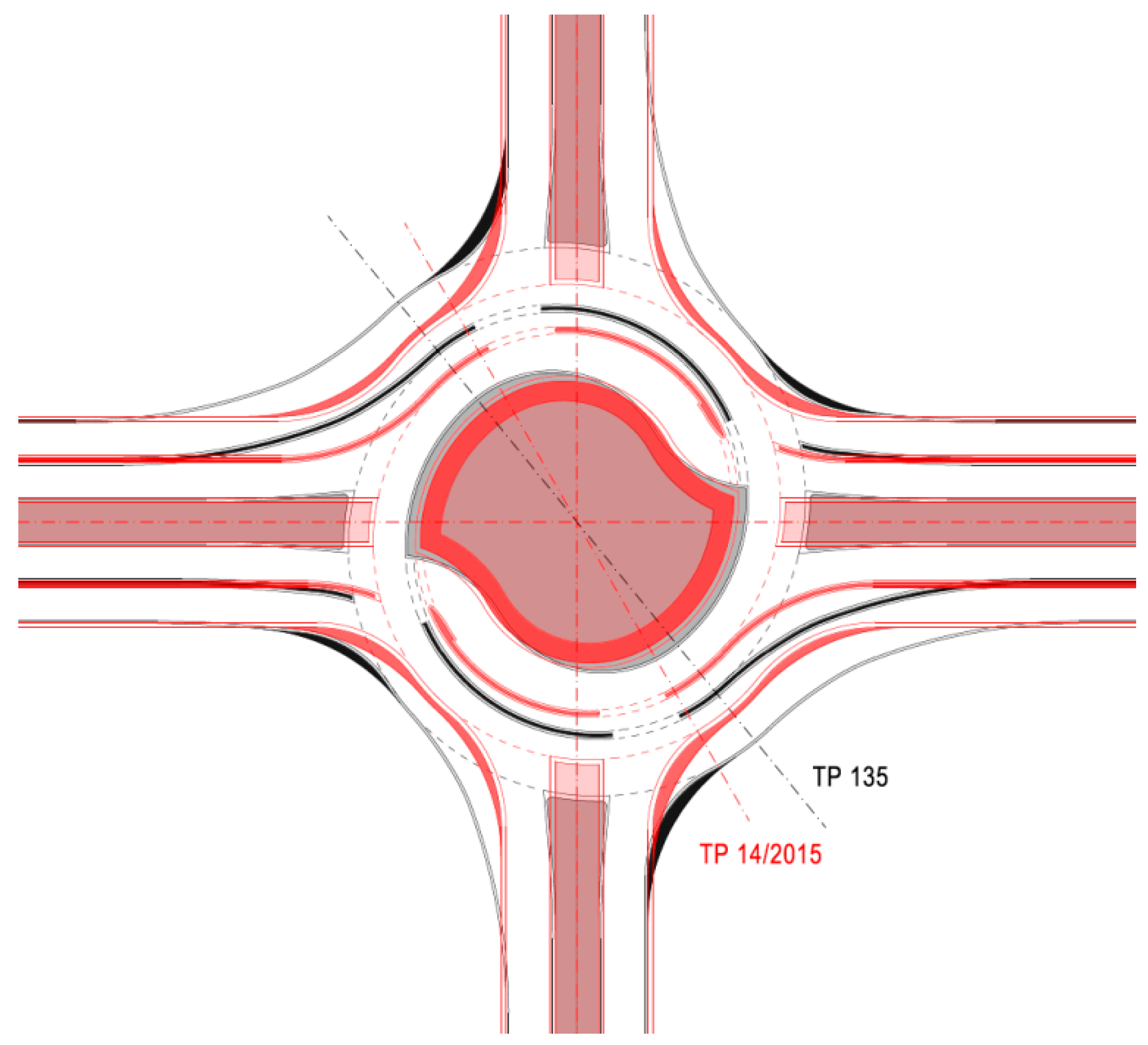

This issue is also related to the proper design and construction of transportation structures. In this article, we deal with a specific type of intersection, i.e., turbo roundabouts (see

Figure 1).

Turbo roundabouts, as reported by the current research, are generally considered to be safe [

11,

21,

22]. An important element is the capacity of the turbo roundabout [

11,

22,

23,

24,

25]. They are considered to have more capacity than single-lane roundabouts, but some may have less capacity than two-lane roundabouts [

22,

23]; however, they are safer than two-lane roundabouts. There are also traffic conflicts or accidents in turbo roundabouts [

5,

20,

26]. Another aspect to be considered in the design of turbo roundabouts is their sustainability, including their influence on the environment, in particular, their life cycle assessment (LCA) [

27] and the influence of emissions at turbo roundabouts in urban areas [

28,

29]. A specific element of turbo roundabouts is the physical separation of lanes and whether these lanes should be separated or not [

13,

15,

22,

23,

30]. In addition, the influence of the geometry of the turbo roundabout on safe passage of vehicles through it and the influence of physical separation on traffic safety [

22,

30] should be considered. Another specific element is the representation of traffic signs, including how signs should inform road users for safe passage through the turbo roundabout [

3,

23,

31,

32].

Because turbo roundabouts are still evolving as traffic and transportation infrastructures change, there are more and more questions to be answered. The development and design elements also differ significantly among countries, where the turbo roundabout design takes place separately for each area. For the reasons mentioned above, we conducted our study on 105 turbo roundabouts in Europe (the Czech Republic, Luxembourg, Hungary, Germany, the Netherlands, Poland, Austria, Slovenia, and the UK) from 2014 to 2019 [

5]. The aim of the research was to analyze the regulations for designing turbo roundabouts and the geometric design elements, as well as traffic signs, and to determine the behavior of drivers in a given type of turbo roundabout to identify conflict situations and analyze their causes. For example, whether these conflicts were caused only by the mistakes by drivers who did not follow traffic rules, or whether they were caused by inappropriately designed building elements of the given turbo roundabout. The main goal of the study was to optimize the design of a turbo roundabout and to determine if following all the design parameters in the existing regulations would avoid errors in the design of a turbo roundabout.

In this paper, our aim is to, first, review the European regulations for the geometric design of turbo roundabouts for the professional public and to confirm the hypothesis that correctly designed turbo roundabouts could partially contribute to road sustainability. If the geometrical and building elements of a turbo roundabout are correct, traffic on it should be smoother and safer. This would help to achieve the required capacity, to ensure a minimum number of traffic conflicts or accidents, and to reduce negative influences on the environment.

2. An Analysis of Regulations for the Design of Turbo Roundabouts

From the point of view of sustainable and safe transportation, an understanding of the design procedures of a turbo roundabout is essential. The regulations in this area differ among European countries, and therefore it is necessary to analyze individual regulations and design procedures in detail. Our findings focus on the initial approach for designing a sustainable transport infrastructure from the perspective of the coexistence of individual transports and the impact on the environment, the evaluation of effectiveness of individual procedures, and possible recommendations for adjustments to increase the effectiveness of this type of roundabout.

We chose countries that have had experience designing turbo roundabouts (the Czech Republic, The Netherlands, Slovenia, Germany, Croatia, and Serbia) for the analysis. The analysis of regulations summarizes the findings regarding regulations for the design of a turbo roundabout from the perspective of individual elements of the roundabout (geometry, central island, physical separation, verification of swept paths, etc.).

2.1. Design Vehicles

The individual elements of an intersection and, subsequently, the intersection as a whole must enable the passage of a relevant design vehicle [

31,

32,

33,

34,

35,

36,

37,

38,

39,

40,

41,

42]. The choice of the design vehicle and its swept path have a major influence on the geometry of a turbo roundabout [

43] and should be based on the composition of the traffic flow (personal vehicles, trucks, etc.) and on the percentage share of the given vehicle types within the total traffic flow of the area where the intersection is located.

The design parameters of a vehicle affect its subsequent behavior when verifying the swept paths. The width and length of a vehicle affect the resulting curve; the front and rear overhang, the distance of the individual axles, the wheelbase, etc. also influence the final design. The usage of a design vehicle is guaranteed to achieve more accurate results for the design of a turbo roundabout for vehicle passage with the most unfavorable parameters.

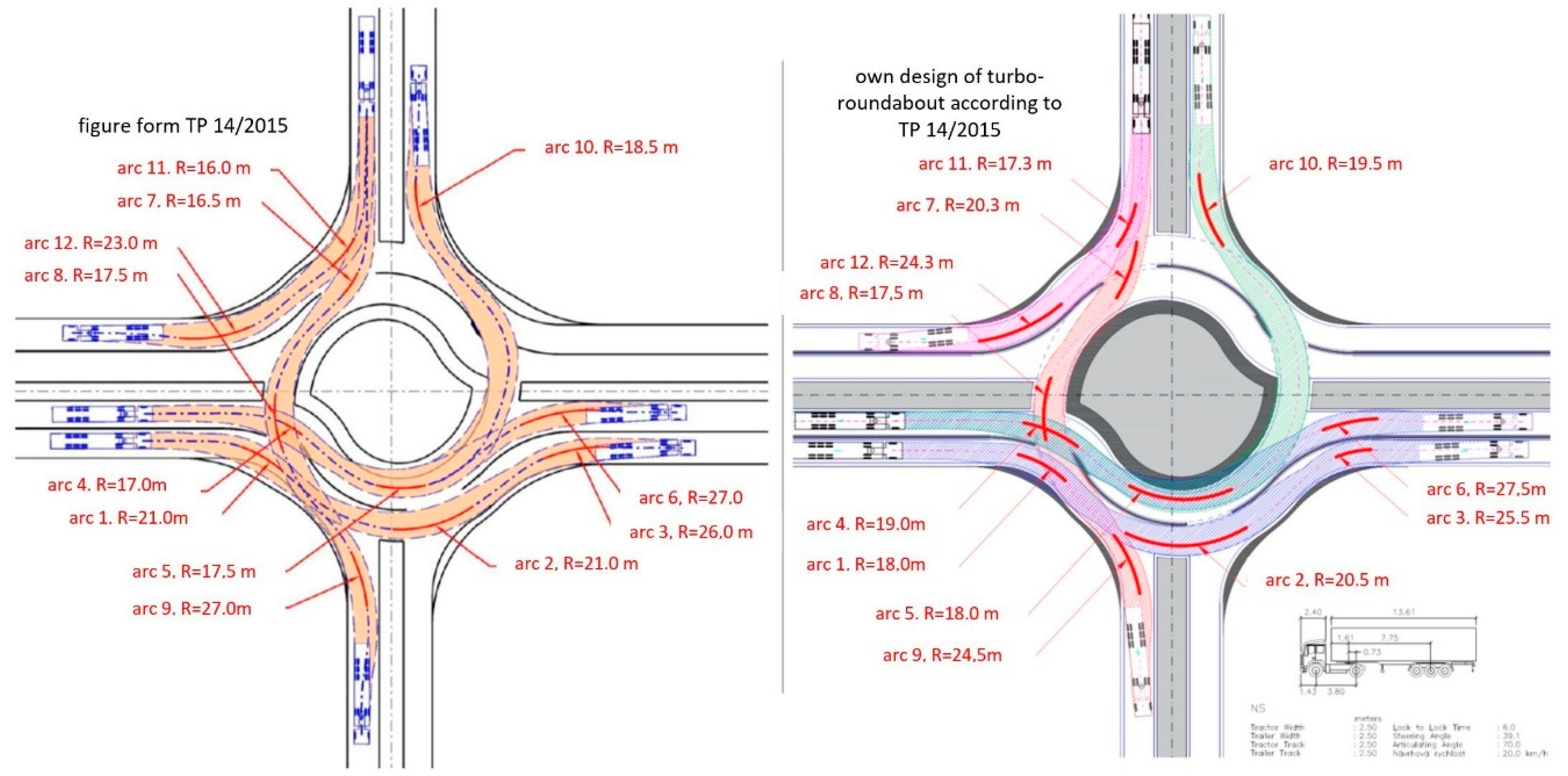

Figure 2 shows a design vehicle; an example of technical data for chosen countries is shown in

Table 1.

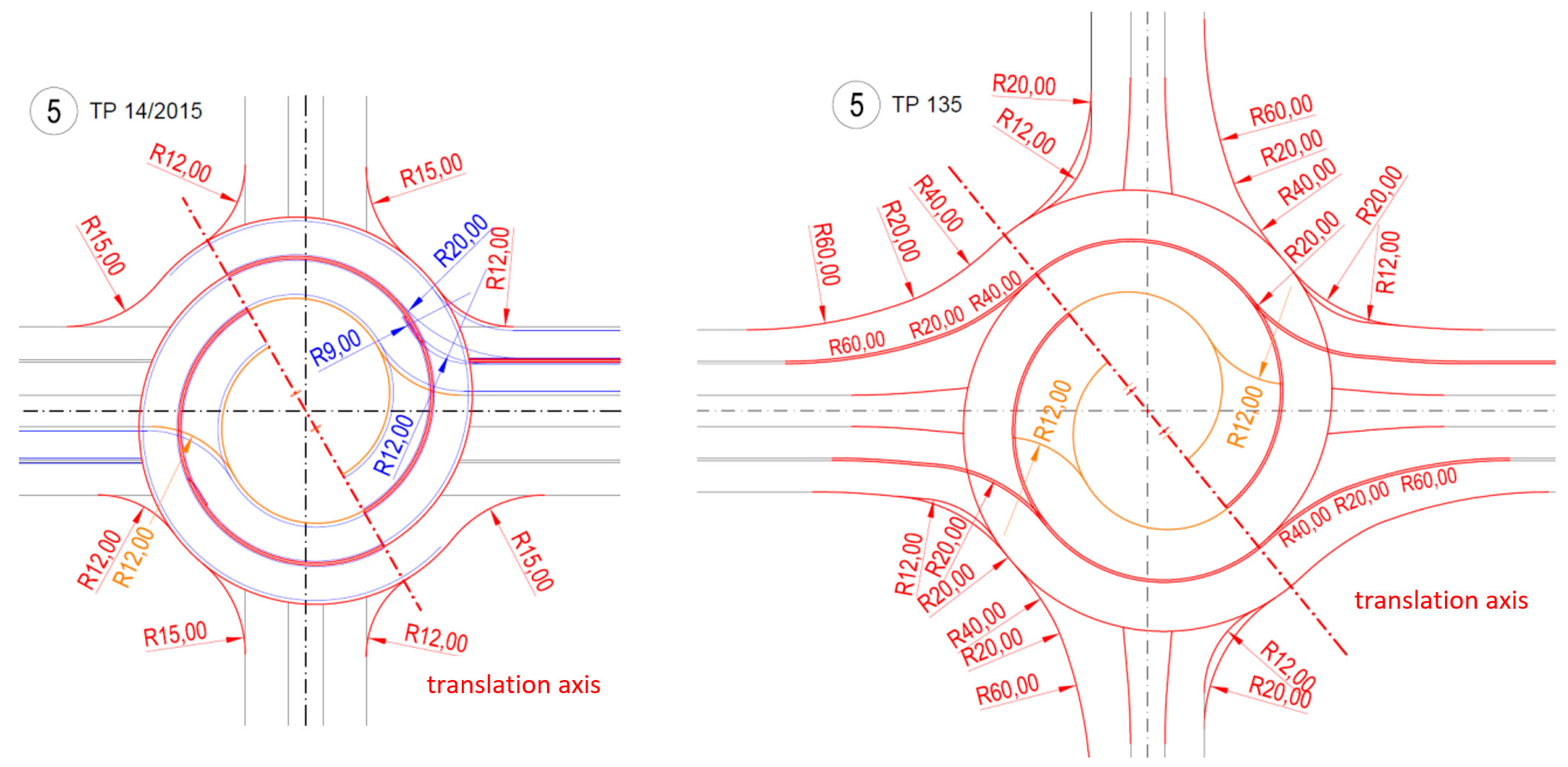

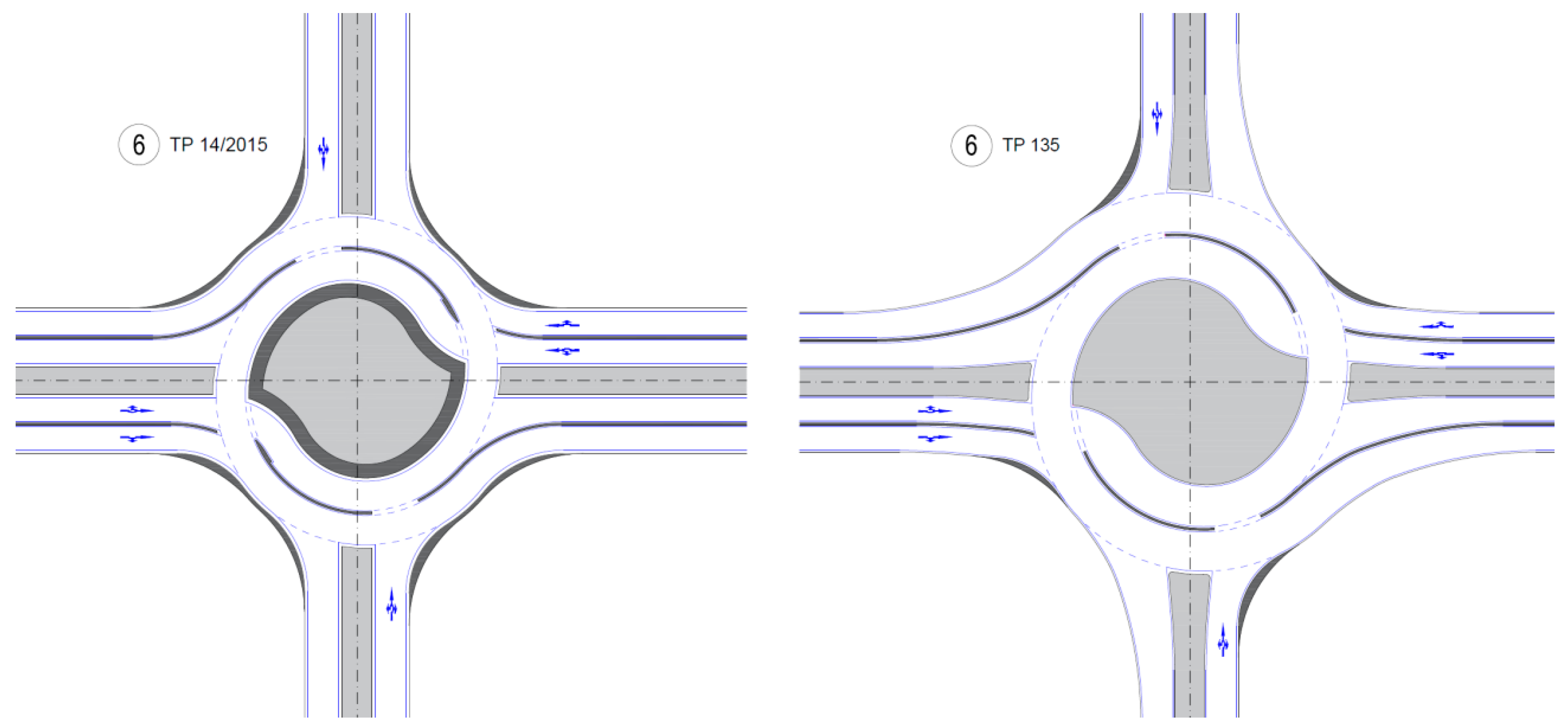

2.2. A Turbo Block

The basic design of the geometry of a turbo roundabout is the so-called turbo block (

Figure 3), which is a set of lines used for the design of lanes on the circulatory roadway. The turbo block is formed by mutually adjoining arcs of given radii. Their points of connection and mutually rotated centers lie on the rotated translation axis. A turbo roundabout can consist of one, two, or three lanes on the circulatory roadway, as can be seen from

Figure 3. A new lane is created at the entrance and is adjacent on the inside to the continuous lane of the circulatory roadway. New lanes are proposed at the main entrances in the traffic-dominant directions of traffic flows (i.e., flows with higher traffic intensities). The direction of the dominant flows, thus, becomes the basic criterion for choosing a suitable type of turbo roundabout.

The analyzed regulations differ significantly in the construction approach for turbo roundabouts. In some documents, the turbo block is defined by predetermined dimensions, other documents do not provide information about the parameters (templates) of the turbo block.

The Czech Republic, the Netherlands, Slovakia, Slovenia, Croatia, and Serbia are among the countries that have regulations that determine the parameters for the turbo block, whereas Germany is among the countries with regulations where there is no turbo block.

The basic geometric arrangement of the turbo block is shown in

Figure 3. The turbo block consists of two spirals, which represent the edges of the lanes (road). The individual spirals consist of four semicircles of different radii. These radii increase gradually (from R1 to R4). The centers of these radii lie on the so-called translation axis. The arcs, R1 and R2, represent the inner and outer edges of the inner lane L1 on the circulatory roadway, while the arcs, R3 and R4, represent the inner and outer edges of the outer lane L2 on the circulatory roadway.

At the beginning of the inner lane L1, an extension is made, which gradually decreases towards the end of the lane. This extension is achieved precisely by designing four centers of circular arcs located on the translation axis. The centers of the individual arcs have various positions on the translation axis. The arcs on the right side of the translation axis have centers above the general center of the turbo roundabout, and the arcs on the left side have centers below the general center of the turbo roundabout. The distance between these centers of arcs is called the offset from the translation axis. The deflection of the arcs is, then, the distance from its center to the general center of the turbo roundabout; at the same time, this value is equal to half the offset along the translation axis. For the continuous spiral, it is necessary for the offset along the translation axis to be equal to the change in radius. Not with all regulations it is about continuous spiral. Ideally, the offset along the translation axis is equal to the width of the lane [

44].

The physical separation of the lanes is achieved with the help of 0.30 m wide elements (concrete curbs, assembly parts, setts, etc.).

An example of a comparison of turbo block parameters in relation to the size of the turbo roundabout from the analyzed regulations is shown in

Table 2. The table shows the dimensions of the turbo block elements for countries that have extensive experience with the design of turbo roundabouts, i.e., the Netherlands, Slovenia, Serbia, Croatia, Slovakia, and the Czech Republic. As can be seen in the Czech Republic, the dimensions of the turbo block, the turbo roundabout signs, and the categorization according to the outer diameter differs significantly from other regulations. The German regulations do not define the parameters of the turbo block, for these reasons they are not listed in the table.

According to Dutch regulations [

37], the design of a turbo roundabout should always start by choosing a turbo block with respect to its suitability for the area and in terms of vehicle speed. The optimal value of the inner radius depends on the dimensions of the dividing islands of the approach centerline. For an island width of 3 m, the optimal value of the inner radius is 12 m. For dividing islands of 7 m width, this value increases to 15 m [

45]. The use of smaller inner radii is only recommended in places with significant space constraints and the usage of larger inner radii when traffic characteristics require it. In the Slovenian [

38] and Serbian regulations [

40], a turbo roundabout with an inner radius is classified as a roundabout of “regular” size. In the Croatian regulations [

41], a roundabout of “regular” size has a radius of 12 m and is the most frequently used typed of roundabout. The Slovak regulations [

44] recommend a 12 m radius and 15 m at the exit of the roundabout. The Czech regulations [

31] recommended value of the corner of the roundabout at the entrance is 12 m, and the exit consists of a compound arc with radius of arcs 2:1:3 (R = 40, 20, and 60 m).

On the basis of the values from

Table 2, it is obvious that almost all the above stated dimensions of regulations from the Netherlands, Slovenia, and Serbia differ by 0.05 m from the regulations from Croatia and Slovakia. This difference results from the different widths of the outer lane on the circulatory roadway of the roundabout. The edge of carriageway markings is 0.45 m wide (possible is also 0.40 m) in the Netherlands, Slovenia, and Serbia, while, in Slovakia and Croatia, the edge of carriageway markings is 0.50 m wide. The inner markings are the same width, i.e., 0.20 m. We further analyze the fundamental difference in the size of the widths of individual lanes on the circulatory roadway in the Czech Republic. The individual widths can be seen in

Figure 4.

Most documents recommended a width of 5.25 m for a lane on the circulatory roadway. This width should represent the value of the standard width of a lane in the circulatory roadway of a single-lane roundabout. In the Netherlands, a turbo roundabout is considered to be a single lane due to the physical separation of lanes [

46].

As previously mentioned, the turbo block should be designed so that the individual radii of the arcs on both sides of the translation axis touch, that is, the inner radius of the lane on one side of the translation axis continues smoothly on the other side [

47]. The turbo blocks based on the regulations from the Netherlands, Slovenia, and Serbia do not fully meet this requirement. The parameters of the turbo block include a 0.05 m offset of circular arcs on the translation axis (

Figure 5). In the regulations from Croatia, Slovakia, and the Czech Republic, this offset is excluded by using 0.05 m wider outer edges of the markings. The circular arcs overlap on the translational axis.

An analysis of European regulations describing the turbo block shows that the Dutch, Slovenian, and Serbian regulations recommend rotor and star-shaped turbo roundabouts. The parameters for these variants are given only in the regulations from the Netherlands. According to the German regulations [

39], a turbo block consists of three pairs of circular arcs (R1, R2, R3) and only two centers on the translation axis (

Figure 6).

The recommended position of the translation axis is given as “five minutes to five” for the intersection of four approach centerlines and “ten after eight” for the intersections of three approach centerlines. The first center represents the centers of the arcs on one side of the translation axis and the second center represents the centers of the arcs on the other side of the translation axis. As a result, the width of the lanes on the roundabout is constant. The German regulations for turbo roundabouts [

39] do not provide turbo block parameters with predetermined dimensions. According to the regulation, the width of the circulatory roadway depends on the diameter of the turbo roundabout and on the design trajectory of the vehicle. The recommended values for turbo roundabouts range from 45 to 70 m and the width of the lane on the circulatory roadway should be from 5.0 to 6.0 m. The position of the translation axis should be determined interactively in relation to the position of the approaches of the turbo roundabout and the vehicle path (passage of a vehicle through the turbo roundabout).

After creating the turbo block, other remaining elements of turbo roundabouts can be designed including a central island, lanes on the approach centerline of the turbo roundabout, a dividing strip, traffic islands, etc. The definitions of the elements differ from one regulation to another. The same elements are named differently and have different purposes. Different dimensions are assigned to them and the definition of their geometry differs significantly.

2.3. Central Island

The central island of a turbo roundabout consists of a truck apron and a central island area (

Figure 7). According to the Dutch regulations [

37], the truck apron of the island allows passage of vehicles longer than 22 m through the inner lane of the circulatory roadway. The recommended width of the truck apron is 5.00 m. In the Croatian [

41], Slovenian [

38], and Serbian regulations [

40], the truck apron is defined as an area on which only special emergency vehicles and ordinary vehicles in an emergency can stop. The recommended width of the truck apron is from 2.0 to 2.5 m. In the Slovak technical regulations [

44], the paved part is intended for a smoother passage of heavy trucks and the width of the truck apron is from 2.0 to 2.5 m. In the Czech regulations, the truck apron is not a necessary part of the turbo roundabout and is seldom designed, especially for the passage of large vehicles [

31].

Regulations also vary considerably in the parameters of the central island. In the Netherlands, traffic signs are placed here. They reduce the view of the opposite approach in the direction of travel. This is a requirement for the safety of roundabouts. According to the Croatian, Slovenian, and Serbian regulations, this element is irrelevant. In the German regulations, the central island is an important element of a turbo roundabout, but its parameters are not given. In the Slovak regulations, the central island of a turbo roundabout has no function, and it represents a redundant space. However, it should be designed to prevent a direct view through the turbo roundabout. The Czech regulations state that if a part or all of the central island is outside the field of view, its height arrangement is solved at that point so that it prevents a view through the roundabout from the approach crossing the turbo roundabout [

31].

The beginning of a central island can be flat or spiral (

Figure 7). In the Netherlands, it was first implemented as a spiral. In the new regulations, it is also recommended as flat, as the spiral is ambiguous for drivers coming to the entrance of the turbo roundabout Consequently, it can lead to a potential traffic conflict on the circulatory roadway of the turbo roundabout. The Croatian, German, Slovak, and Czech regulations have all examples designed as spiral. In the Slovenian and Serbian regulations, both types of the beginning of the island are listed, i.e., flat and spiral. Apart from the Czech and Slovak regulations, other regulations do not provide more detailed information on the design of the spiral beginning of the central island.

2.4. An Approach Centerline of a Turbo Roundabout

According to the analysis of the Dutch regulations, the approach centerlines should form an angle of 90° with each other (due to the driving of long vehicles). It should be noted that 90° entrances to a turbo roundabout are very difficult to plan. Achieving the required angle in the case of reconstructions of existing two-lane roundabouts with significant space restrictions is almost unrealistic. Furthermore, the approaches should be designed so that the speed of the car during the passage through the turbo roundabout does not exceed the maximum recommended value [

45]. According to the German regulation, the approaches should intersect at the geometric center of the roundabout, but it is not defined at what angles.

Many European regulations state detailed instructions for the verification of the vehicle passage through a roundabout. The main parameters defining vehicle passage are the width of the entry and exit lanes, the width of the dividing islands, and the radii of the corner of the turbo roundabout. All these parameters should be chosen on the basis of the size of the roundabout, the relevant design trajectory of the vehicle, and the required speed of driving through the roundabout.

The width of the entry and exit lanes to a turbo roundabout is not precisely defined in many regulations (the Netherlands, Croatia, Slovenia, Slovakia, Serbia, and the Czech Republic). The regulations refer to other regulations for the design of roads, local roads, legislation, etc.

Dividing islands on the approaches of a turbo roundabout have, in the regulations, also different roles and definitions of geometry. In the Netherlands, the minimum width of the dividing island is 2.50 m; in the Croatian, Slovenian, and Serbian regulations, this value is 2.0 m; the German regulations do not have recommendation.

The radii of the entrance to a turbo roundabout have previously been mentioned. In the Czech regulations [

41], the recommended value of the corner of the turbo roundabout at the entrance is 12 m and the exit is formed by a compound arc with a ratio of arcs of 2:1:3 (R = 40, 20, and 60 m).

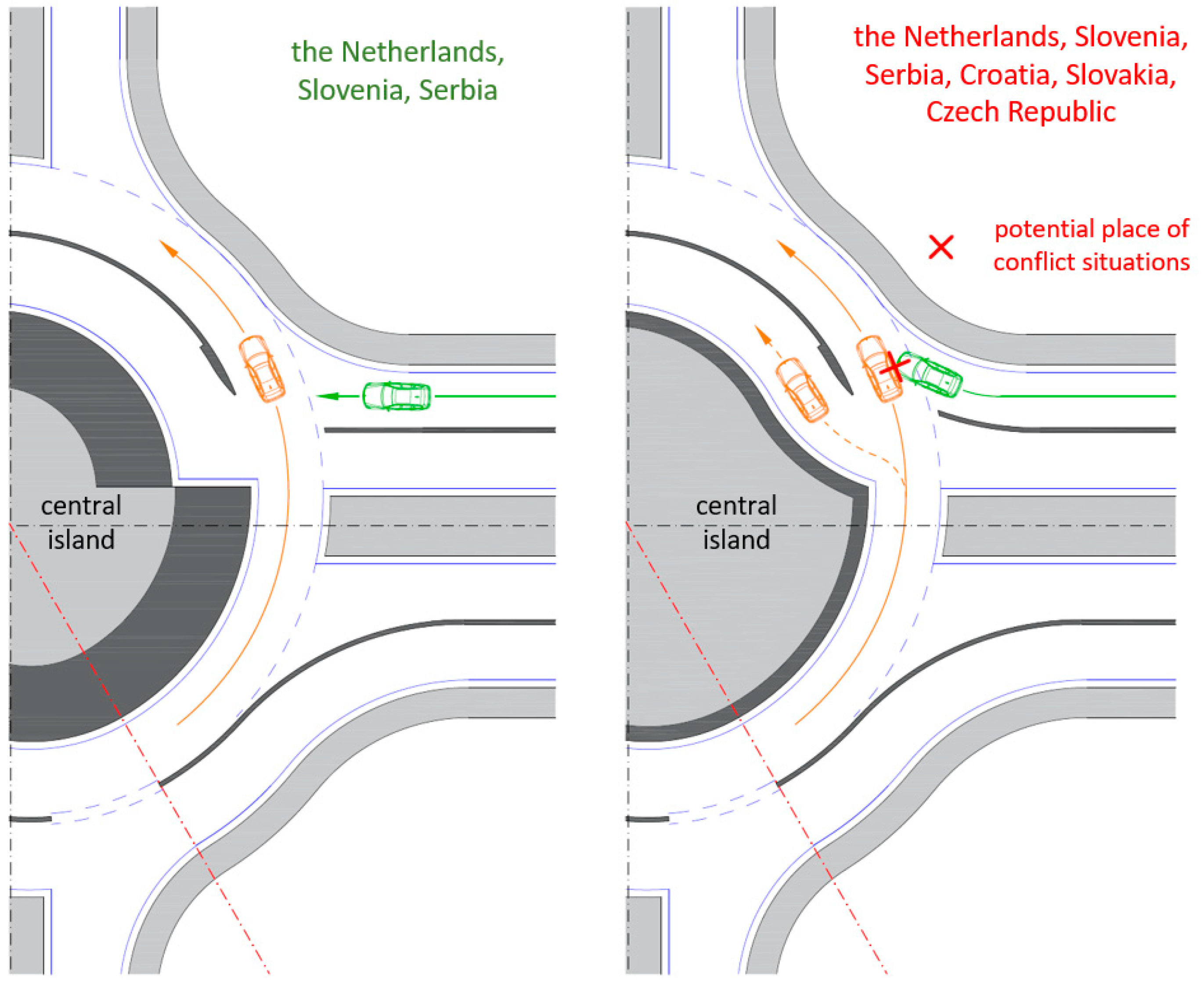

2.5. Physical Separation of Lanes

According to Slovenian experts, countries can be divided into two groups with respect to designing turbo roundabouts [

48], i.e., countries where physical separation of lanes is used (see

Figure 8) and countries where physical separation of lanes is avoided. The main reason why these countries have fewer satisfactory experiences with turbo roundabouts is that “traffic signs do not prevent lane change” [

48]. The author of [

49] claimed that the use of physical separation of lanes is unacceptable due to the requirements for safety of motorcycles, winter service and maintenance, and that the absence of these elements does not have a major impact on the safety and capacity of a turbo roundabout. Regulations from the Netherlands, Croatia, Slovenia, Serbia, Slovakia, and the Czech Republic recommend implementation of physical separation of lanes. For turbo roundabouts in cities, the use of a specially designed “spike” is recommended, which should prevent unacceptable driving and enable the passage of long trucks through the turbo roundabouts (

Figure 8).

In the Netherlands, a spike has fixed dimensions [

49], while other countries (Croatia, Slovenia, and Slovakia) do not have a defined length, rather the length depends on the radii used and the swept path of the vehicle. This element is not defined in the Serbian, Czech, and German regulations.

2.6. Geometry Check

After designing all elements of a turbo roundabout, it should be checked and, here, the analyzed regulations also differ. Regulations from the Netherlands, Croatia, Slovenia, Serbia, Slovakia, and the Czech Republic use some of the following analyses for the final design: an analysis of the swept paths of the design vehicle; an analysis of the fastest trajectory of the vehicle; and an analysis of the speed of the vehicle at the entrance, on the circulatory roadway and at the exit of the turbo roundabout. If these analyses show negative results, the geometry of the designed turbo roundabout must be adjusted.

In the German regulations, the basis for defining all elements of a roundabout is the analysis of the passage of the vehicle (swept paths). The difference between the German regulation and the other analyzed regulations is the fact that the fastest trajectory of the vehicle through the turbo roundabout is not required. The design procedure described in this regulation may lead to higher speeds through the turbo roundabout; however, the speed can be regulated by traffic signs in this case. These design procedures are mainly used for turbo roundabouts located in places with significant spatial limitations, where it is not often possible to rebuild the elements of the roundabout (increase in diameter).

2.7. An Analysis of Other Regulations

The regulations of other European countries were also analyzed. Full versions of documents for designing turbo roundabouts were not available for some countries, and therefore these countries were not included in the analyses.

For example, in the UK, there are numerous roundabouts, which are not a traditional design, but a modification of the horizontal traffic signs on the circulatory roadway in the form of a spiral. Other countries, such as Belgium, Italy, Hungary, and Poland have designed turbo roundabouts following the Dutch or Slovenian regulations.

2.8. Partial Conclusions from the Analysis of the Regulations

The analysis of regulations for designing turbo roundabouts showed that they differ in several aspects such as the number of variants, information about relevant structural elements, dimensions of a turbo block and other elements, the definition of the design, and the input and output parameters for checking the design.

Despite these differences, some regulations have a common basis (i.e., they are based on the same regulation) and they define the procedure for creating a turbo roundabout. These are, in particular, the design procedure for a turbo block, the subsequent analysis of the speed of the vehicles and the analysis of the route (swept paths). This approach to design procedures is highly dependent on a follow-up check. If the subsequent check of the design is not performed properly, there is a risk of designing an excessive or an inadequate turbo roundabout. Giving a designer some freedom to consider satisfactorily evaluated elements in the design, may ultimately be fundamental for proper functioning of a turbo roundabout.

First, we analyzed regulations for evaluating the effectiveness of a turbo roundabout that, subsequently, have a major impact on the safety and sustainability of transport infrastructure. We also considered different designs of a turbo block; an evaluation of the physical separation of lanes, including the design of the spike; an analysis of the fastest vehicle trajectory; and an evaluation of the swept paths based, among other things, on the performed measurements of existing turbo roundabouts in Europe. The observed elements of 105 turbo roundabouts were analyzed.

4. Discussion and Conclusions

In this paper, we analyze the geometric designs of turbo roundabouts and in order to verify their effectiveness one needs to know (understand) all the issues of traffic in turbo roundabouts. Therefore, we investigated, from 2014 to 2019, 105 turbo roundabouts in Europe (the Czech Republic, Luxembourg, Hungary, Germany, the Netherlands, Poland, Austria, Slovenia, and the UK). The aims of the study were to analyze the regulations for designing turbo roundabouts, as well as the geometric design elements and traffic signs, and to determine the behavior of drivers on particular types of turbo roundabouts, identify conflict situations, and analyze their causes. The main focus of the study was to optimize the design of a turbo roundabout.

A variety of technical equipment was used to conduct the analyses such as special recording devices (cameras, cameras with “super slow motion” shooting mode, cameras mounted on the vehicle, 360° cameras, etc.) [

5,

40]. These devices were installed at individual turbo roundabouts (a total of 105 turbo roundabouts). Data were recorded for a minimum of four hours up to a few days. For further evaluation of the analysis of vehicle movement on the turbo roundabout, it was necessary to have records from above (bird’s eye perspective). UAV “drones” were used for this purpose [

9,

20]. On the selected turbo roundabout, shots from the drone and recording devices were supplemented by counting devices. There were several types (counting cards NU-METRICS NC-200, VIACOUNT II, and ICOMS TMS-SA) [

20]. For verification, the obtained data were supplemented with values from measurements by handheld radar. Special data processing programs GOODVISION [

49] and DATA FROM SKY [

50] were used for data processing, especially data from cameras (recording devices and drones).

The analysis and evaluation of the given hypotheses of the research also involved computational procedures from Czech standards and regulations [

33,

51,

52] and foreign standards and regulations [

37,

38,

44,

53,

54,

55], technical conditions [

2], methodologies [

30] for designing of turbo roundabouts, and calculations for turbo roundabout capacity [

56,

57,

58,

59,

60,

61]. For the evaluation, our own procedures were designed, where simulations of the passage of a vehicle through a turbo roundabout, the probability of analysis in terms of the use of lanes, the passage of the vehicle through physical separation elements, etc. were performed, including verification with data from real traffic (data obtained and evaluated from measurements). On the basis of the processed data and the evaluated results, we reliably verified the geometry of an intersection with the help of a design vehicle, and we determined the accuracy of the design, whether modifications were needed or not, as well as if the regulations for the design needed modifications.

The comparison of two sets of regulations (Czech and Slovak) for the design of a turbo roundabout, shows that there are different movements (behaviors) of traffic at each turbo roundabout. This fundamental difference in the design and geometry of a turbo roundabout may subsequently affect the safety of the traffic, the capacity of the turbo roundabout or its section (delay time, congestion), or the behavior of the traffic participants themselves. The driver of the vehicle may choose an unsuitable lane when passing through the turbo roundabout, may be confused when entering the roundabout, may be influenced by other road users, and may be misled due to traffic signs or the geometry of the turbo roundabout. These aspects can be evaluated independently using the method of conflict situations [

3,

5,

20]. Incorrectly designed geometry can also have a major influence on the life cycle assessment (LCA) of a turbo roundabout [

27] and on the increased emission share [

28,

29].

In this study, on the basis of the evaluated data we analyzed the issue of designing turbo roundabouts, including an approach for verification. Therefore, the aim was to draw attention to the fundamental differences and non-negligible influence of the geometric design. This hypothesis was confirmed on the abovementioned example of the Czech regulations. Large differences in the radii of individual circles in a turbo block, based on the Czech regulations, resulted in an undesirable increase in the width of the lanes, which resulted in an unsatisfactory width arrangement. Vehicles, especially on the circulatory roadway, could significantly increase speed. This subsequently affected the entry of other vehicles into the turbo roundabout and had a negative impact on capacity and safety. Furthermore, based on the geometric design, we found that the rotation of the translation axis by a predetermined value paradoxically enhanced the entry speed of vehicles into the turbo roundabout. This fact was also confirmed by a diversion (towards the axis of the approach) of 5° at the central island. This 5° diversion is difficult for a designer to implement, therefore, during the design process, they can evaluate the distance at which the diversion is to be made and how this element will subsequently influence the geometry. The Czech regulations use compound arches at the corners as compared with other regulations. Although the corner in a given type of turbo roundabouts is a negative element in its construction, it can be suitable for differently arranged turbo roundabout, which are mainly turbo roundabouts where the axes of the individual lanes are not perpendicular to each other, or different sizes of turbo roundabouts (turbo block). Then, this element of the compound corner suitably guides the vehicles at the exit. Therefore, this is a very important geometric element that could be incorporated into foreign regulations.

An essential element for correct geometric design and verification of the design is the physical separation of the lanes. This element should be increased in the design, with regard to the trajectory of the vehicle passing through the turbo roundabout, the safety of traffic, and the sustainability of this type of traffic constructions in terms of structural elements of individual parts of the turbo roundabout. If the physical separation of the lanes is not realized, it is not possible to force the vehicles to pass through the turbo roundabout in the intended geometric trajectory, and this turbo roundabout can be a dangerous element in the road network. Furthermore, on the basis of the verification of the geometry, the usage of the so-called “spike” element is essential in the design. This element significantly influences the geometry at the point of entry into the turbo roundabout. The spike has a fundamental influence on the direction of vehicles, their speed and, especially in cooperation with the physical separation of lanes, the use of the effective width of the lane on the circulatory roadway. The functionality of the truck apron for the usage of entry/exit of larger vehicles to/from the turbo roundabout was confirmed. This is a standard feature that is used in multiple types of intersections. In conclusion, it should be noted that the Czech regulations, as currently proposed, contain shortcomings in the design of the geometry of turbo roundabouts. In some areas, it can be difficult for designers to understand and ambiguous for the design of the overall geometry.

Although the chosen Slovak regulations are one of the most recent regulations for the design of turbo roundabouts, the results show that the geometry of the turbo roundabouts must still be developed with regard to the passage of vehicles and the behavior of drivers in the turbo roundabout. One of the points of possible adjustment of the regulations is a slight increase in the radii of the turbo block, as vehicles move in close proximity to the curbs at some points in the turbo roundabout (a greater distance of the vehicle from the curb could be maintained here). Furthermore, it would be appropriate to allow the use of a compound corner in some types of turbo roundabouts, which would give the designer more options at the wrong crossing angle. Alternatively, it should be possible to increase the width of the truck apron in turbo roundabouts with smaller radii, i.e., it is necessary that this width is specified in the regulations. We can also apply this conclusion to other regulations that were mentioned in

Section 2. The correct design and its verification in terms of geometry and swept paths is the first step in terms of safety and durability of a turbo roundabout, followed by verification of capacities, microsimulation models, etc.

In summary, overall, this study and especially the in-depth analysis of the design of turbo roundabouts, including the geometric design, helps us to identify possible problems. These are differences in the design and approach to designing turbo roundabouts and their subsequent impact on traffic infrastructure. Transport infrastructure is a system in which one negative element (e.g., an unsuitably designed roundabout) can fundamentally influence the behavior of transportation and its subsequent sustainability. In particular, it has an impact on transport safety, public health, and the environment.