Abstract

The design of passive fire protection is applied to minimize the domino effect when a liquid pool fire occurs due to the facilities inside a process plant. In general, the design of passive fire protection has been applied using the API RP 2218 guideline as the basis regardless of the country or owner of the process plant. However, in Korea, legal regulations dictate that explosive areas should be regarded as fireproofing zones rather than following the API RP 2218 guideline. Because liquid pool fires and explosive gas atmospheres are different concepts, it is wrong from an engineering perspective to regard them as the same. Therefore, when a liquid pool fire occurs in a process plant in Korea, it may be more dangerous than in any other countries. In this study, we investigated three categories of fire risk. Korean safety regulations for the design of passive fire protection and others that are not reasonable from an engineering perspective need to be studied and revised. Specifically, Korea needs to revise the design basis of passive fire protection based on the API RP 2218 guideline as a legal standard in accordance with global trends.

1. Introduction

The purpose of designing passive fire protection is to prevent the domino effect caused by a liquid pool fire and to save time for firefighting activities by reinforcing the loaded structure or support inside the process plant with FENDOLITE or other similar materials [1]. Previously, it was a common practice to pass internationally accepted test standards to verify fire resistance performance. Recently, scientific techniques have been studied beyond the conventional test standards of fire resistance performance, with the development of fire safety engineering for verifying fire resistance performance like the study of physical properties of intumescent coatings in the laboratory scale [2]. However, no matter what engineering technique is applied to passive fire protection, what must proceed is determination of the extent of a pool fire that requires fire resistance.

API RP 2218 has been established as an international practice standard for passive fire protection, although the design criteria varies in detail depending on the country and the owner of the process plant. API RP 2218 suggests grouping fire potential equipment into three types (that is, high, medium, low) depending on the degree of risk of starting a liquid pool fire [3]. The country and owner of the process plant need to determine the specific degree of risk for their own environment. In addition, API RP 2218 suggests that the extent of the fireproofing zone formed to contain liquid pool fires is 6–12 m in both horizontal and vertical directions [3]. Thus, the country and owner of the process plant need to designate a specific extent within this coverage to form a fireproofing zone (Table 1). In other words, the design of passive fire protection has the same basis although there are differences between the degree of risk associated with the specific fire potential equipment in place and the horizontal and vertical extents that should apply to the fireproofing zone.

Table 1.

Example for design criteria of passive fire protection based on API RP 2218.

However, in the case of Korea, the law stipulates the application of passive fire protection regulation different from API RP 2218. The next section introduces this topic in detail.

2. Present Conditions of a Passive Fire Protection Design in Korea

The guideline for designing passive fire protection in Korea is regulated by the law under Article 270 of local rules on occupation safety and health standards [10]. This regulation stipulates that any potential hazard that can cause a gas or dust explosion, not a liquid pool fire, should be regarded as a fireproofing zone. According to this criterion, there is no need to define fire potential equipment in accordance with API RP 2218 because a source that can cause gas or dust explosions would be defined as a source that constitutes a fireproofing zone.

A liquid pool fire indicates that liquid hydrocarbon has been released and formed a pool, and any cause of fire therein is the actuation of an ignition source [11]. However, explosive gas or dust are clearly different concepts, that do not form a liquid pool, but have the potential for explosion [12]. Therefore, in Korea, the law stipulates that fireproofing may be required independently of engineering aspects.

In the following section, the problems arising from the application of the guidelines for designing passive fire protection in Korea are introduced through a case study divided into three categories.

3. Case Study: Defect of a Passive Fire Protection Design in Korea

In this section, we describe two cases where fireproofing is not required from the engineering perspective but are only needed for fireproofing in Korea. We also describe a case where fireproofing should be applied from the engineering perspective, but is not needed in terms of Korean regulations.

Korean regulations stipulate that the design basis of hazardous area classification should be based on IEC 60079 edition 2.0, which is one of the international guidelines for designing hazardous area classification. This is in accordance with Article 230 of the local rules on occupation safety and health standards [10]. IEC 60079-10-1 applies to gas explosions, and IEC 60079-10-2 applies to dust explosions. Therefore, since this study aims to design passive fire protection in Korea, the criteria for designing the hazardous area classification are also considered to apply to IEC 60079.

3.1. Explosive Gas Atmosphere with No Risk of Liquid Pool Fire

In this case, it is not necessary to apply fireproofing from an engineering perspective as there is no risk of a liquid pool fire. However, in Korea, an explosive gas atmosphere is regarded as a fireproofing zone; therefore, fireproofing is legally required. A typical example is a compressor that handles hydrogen gas. Hydrogen gas is remarkably light such that it spreads rapidly to the top of the atmosphere immediately upon release, and because of the physical nature of the gas, it cannot form a liquid pool under ambient conditions. There is therefore no risk of a liquid pool fire. In Korea, however, the hazardous area of a compressor handling hydrogen gas is derived through IEC 60079-10-1 and is regarded as a fireproofing zone. Therefore, fireproofing must be applied in such a hazardous area.

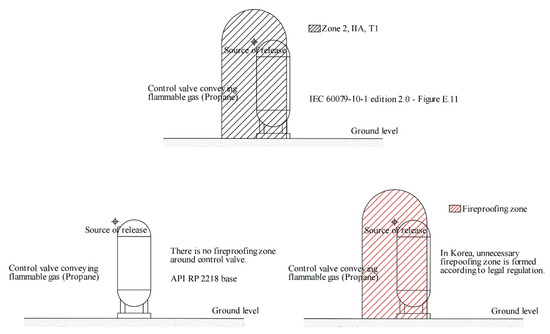

In addition, other process facilities installed in Korea that handle hydrocarbon gases, such as propane, are regarded as fire potential equipment (Figure 1). Compressors are normally operated at high pressure, so they have a wider extent of an explosive gas atmosphere by IEC 60079-10-1. This means that they have a wider fireproofing zone than other low-pressure process facilities, by Korean regulation. Therefore, in Korea, it is necessary to apply more useless fireproofing to structures around high-pressure process facilities like compressors than around low-pressure process facilities.

Figure 1.

Example for applying fireproofing only in Korea, although it is the same process facility.

3.2. Explosive Dust Atmosphere with No Risk of Liquid Pool Fire

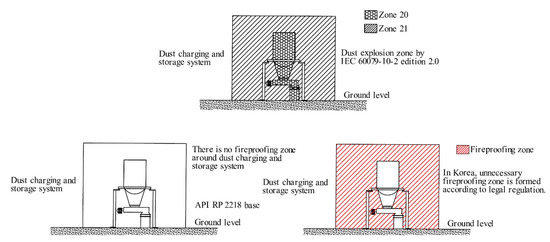

This case also does not require fireproofing from the engineering perspective; however, in Korea, fireproofing is legally required. A typical example may be a factory with flour. Flour can be classified as an explosive dust source in dust group IIIB. The flour does not form a liquid pool owing to its physical characteristics. However, fireproofing should be applied around a factory with flour as the extent of the explosive dust atmosphere derived through IEC 60079-10-2 is considered a fireproofing zone (Figure 2).

Figure 2.

Example for applying fireproofing only in Korea, although it is the same process facility.

For other examples, if facilities such as hoppers and conveyors, which handle polyethylene or polypropylene pellets, are installed in Korea, fireproofing should be applied to all loaded supports.

3.3. No Explosive Gas Atmosphere with Liquid Pool Fire Risk

Unlike the previous two examples, this case may be abused by the owner of the process plant in Korea to reduce the cost of fireproofing. According to NFPA 497, combustible materials in class IIIB with a flash point over 93 °C do not pose a risk of gas explosion, even if operated at a temperature above the flash point. However, they do condense rapidly during their release into the atmosphere [13] and thus can form a liquid pool fire. Therefore, such substances do not form the extent of a hazardous area. However, since API RP 2218 is based on the formation of a liquid pool fire rather than an explosion, the use of such combustible materials can also be classified as fire potential equipment. In other words, if a substance in class IIIB is handled in a process plant, it is not regarded as a fireproofing zone in Korea, but from the engineering perspective and in other countries, a fireproofing zone is needed [3].

Zone 2 NE is a hazardous gas zone derived only in IEC 60079-10-1 and is regarded as non-hazardous for gas explosions [14]. Zone 2 NE is a special grade of hazardous zone type and is not defined in the international guidelines for designing hazardous area classifications [15]. Zone 2 NE can be derived when a normally low volatile flammable liquid is operated at low pressure. If the flammable liquid is released, because of the fluid’s characteristics and the low pressure and ventilation, the evaporation rate is very low; hence, the risk of gas explosion is also very low. However, the low evaporation rate does not prevent the formation of a liquid pool. Therefore fireproofing should be applied, although in Korea there is no legal requirement for fireproofing.

4. Consideration

Legally regulated design criteria for passive fire protection in Korea are difficult to understand, both for safety improvement and from an engineering perspective. Regardless of forming a liquid pool, the regulation to apply fireproofing to gas or dust explosion areas might be thought as strengthening the safety aspects of the process plant. However, studies have shown that excessive application of fireproofing weakens the structure itself by containing moisture in the space between the fireproofing material and the steel frame [16]. This phenomenon is called corrosion under fireproofing (CUF) and the details are introduced in API RP 583 [17]. The best way to prevent CUF is to apply fireproofing only to areas that really need such protection. Therefore, it is difficult to understand how applying unnecessary fireproofing to structures would improve safety.

There is also a problem with not applying fireproofing in an area classified as Zone 2 NE based on IEC 60079-10-1. This does not conform to API RP 2218, which is the only international guideline for designing passive fire protection, although there may be a liquid pool fire risk in Zone 2 NE areas. In addition, this regulation is problematic because it legally protects those wishing to reduce the cost of fireproofing at the expense of safety.

5. Conclusions

Currently, the legal standards for designing passive fire protection in Korea are problematic because they have a logic that cannot be adequately dealt with in the event of an actual liquid pool fire. There is an irony that compliance with legal standards weakens safety due to misguided regulations that confuse the concept of explosion and pool fire in past legislation. Therefore, Korea’s legal guideline for designing passive fire protection needs to be revised based on API RP 2218 in accordance with the international trend.

Typically, a process plant is designed according to the proven technology of the licensor; thus, a similar process plant can be constructed in other countries. Ironically, however, it is a significant problem that process plants in Korea could be more vulnerable to the same liquid pool fire if they are constructed overseas.

Therefore, it is necessary to examine the feasibility of engineering areas where Korean legal regulations and international guidelines are not met. This needs to be expanded not only for passive fire protection but also for other areas of safety design.

Author Contributions

J.-Y.C. and S.-H.B. conceived and designed the experiment; J.-Y.C. performed the task of data processing and coding, analyzed the results, and wrote the manuscript; S.-H.B. edited the manuscript. All authors have read and agreed to the published version of the manuscript.

Funding

This research was supported by Korea University (Grant No. K2017891).

Conflicts of Interest

The authors declare no conflict of interest.

References

- Cafco International Ltd. Largest ever order for spray passive fire protection materials. Fire Saf. Eng. 2007, 14, 42. [Google Scholar]

- De Silva, D.; Bilotta, A.; Nigro, E. Approach for modelling thermal properties of intumescent coating applied on steel members. Fire Saf. J. 2020, 116, 103200. [Google Scholar] [CrossRef]

- API. API RP 2218: Recommended Practice 2218: Fireproofing Practices in Petroleum and Petrochemical Processing Plants, 3rd ed.; American Petroleum Institute: Washington, DC, USA, 2013. [Google Scholar]

- Saudi Aramco. SAES-B-006: Fireproofing for Plants; Saudi Aramco: Dhahran, Saudi Arabia, 2003. [Google Scholar]

- Shell. DEP 80.47.10.30-Gen.: Assessment of the Fire Safety of Onshore Installations; Shell GSI: Hague, The Netherlands, 2010. [Google Scholar]

- Borouge. BGS-CU-012: Fireproofing Requirements (Vessels and Structures); Borouge: Abu Dhabi, United Arab Emirates, 2017. [Google Scholar]

- Kuwait Oil Company. KOC-C-027: Fireproofing of Structural Steelwork; Kuwait Oil Company: Al Ahmadi, Kuwait, 2010. [Google Scholar]

- Kuwait National Petroleum Company. Standard Specification No. 96A4: Fire Protection Design; Kuwait National Petroleum Company: Al Ahmadi, Kuwait, 1984. [Google Scholar]

- British Petroleum. GP 52-20: Passive Fire Protection (PFP); British Petroleum: London, UK, 2005. [Google Scholar]

- Korea Ministry of Employment and Labor (KMOEL). Enforcement Regulation, Local Rule on Occupational Safety and Health Standard; KMOEL: Seoul, Korea, 2011.

- Health and Safety Executive. Modelling of Pool Fires in Offshore Hazard Assessments; HSE: London, UK, 2008. [Google Scholar]

- Salzano, E. Confined Gas and Dust Explosions. Reference Module in Chemistry, Molecular Sciences and Chemical Engineering; Elsevier: Amsterdam, The Netherlands, 2014. [Google Scholar]

- NFPA. NFPA 497: Recommended Practice for the Classification of Flammable Liquids, Gases, or Vapors and of Hazardous (Classified) Locations for Electrical Installations in Chemical Process Areas; National Fire Protection Association: Quincy, MA, USA, 2017. [Google Scholar]

- IEC. IEC 60079-10-1: Explosive Atmospheres–Part 10-1: Classification of Areas–Explosive Gas Atmospheres, 2nd ed.; International Electrotechnical Commission: Geneva, Switzerland, 2015. [Google Scholar]

- Choi, J.Y.; Byeon, S.H. Operating Pressure Conditions for Non-Explosion Hazards in Plants Handling Propane Gas. Korean Chem. Eng. Res. 2020, 58, 493–497. [Google Scholar] [CrossRef]

- Murti, D.G. Design Operations-and-Maintenance-Friendly Pressure Vessels—Part 2. Available online: https://www.hydrocarbonprocessing.com/magazine/2016/september-2016/maintenance-and-reliability/design-operations-and-maintenance-friendly-pressure-vessels-part-2 (accessed on 7 December 2020).

- API. API RP 583: Recommended Practice 583: Corrosion Under Insulation and Fireproofing, 1st ed.; American Petroleum Institute: Washington, DC, USA, 2014. [Google Scholar]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).