Intelligent Drilling of Oil and Gas Wells Using Response Surface Methodology and Artificial Bee Colony

Abstract

1. Introduction

- A comprehensive review of drill bit selection methodology for drilling oil and gas wells;

- A novel application of RSM and ABC combination has been tested for the selection of suitable drill bit types based on optimum ROP values;

- Comparison of proposed approach with the existing ANN, ANN, and GA-based drill bit selection models to test their efficacies and find a more reliable approach for bit selection.

2. Literature Review

3. Materials and Methods

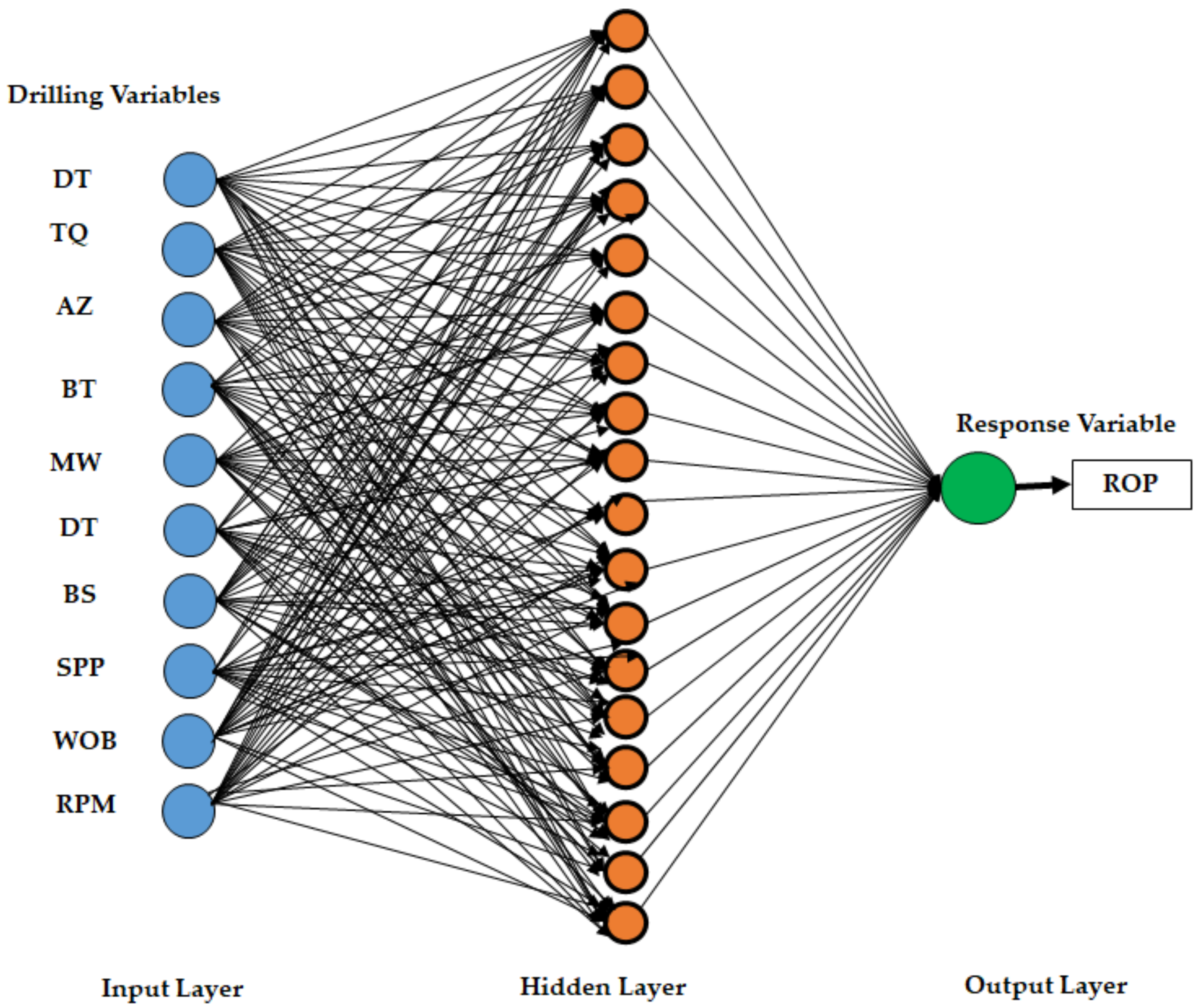

3.1. Artificial Neural Networks

3.2. Response Surface Methodology

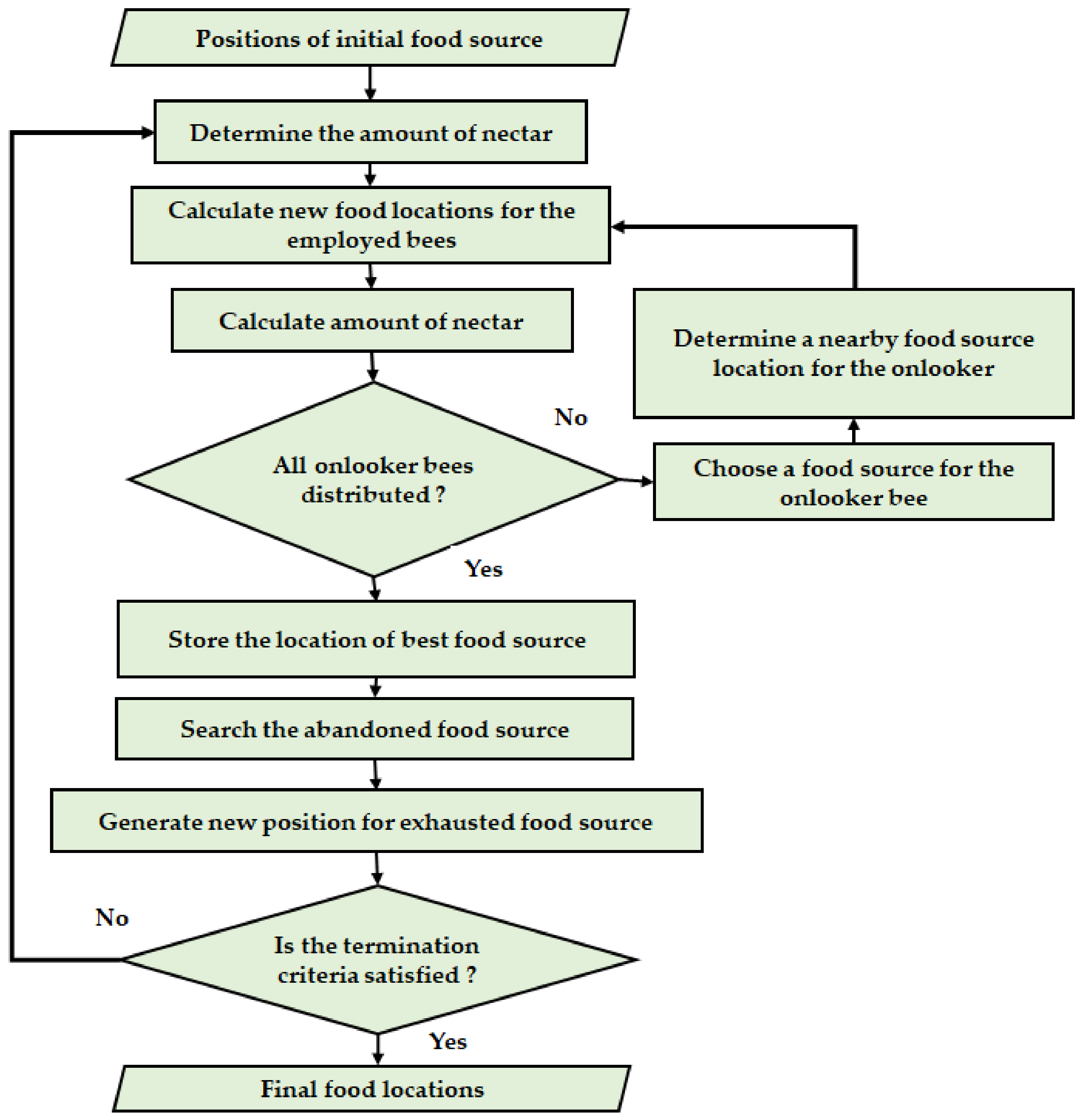

3.3. Artificial Bee Colony

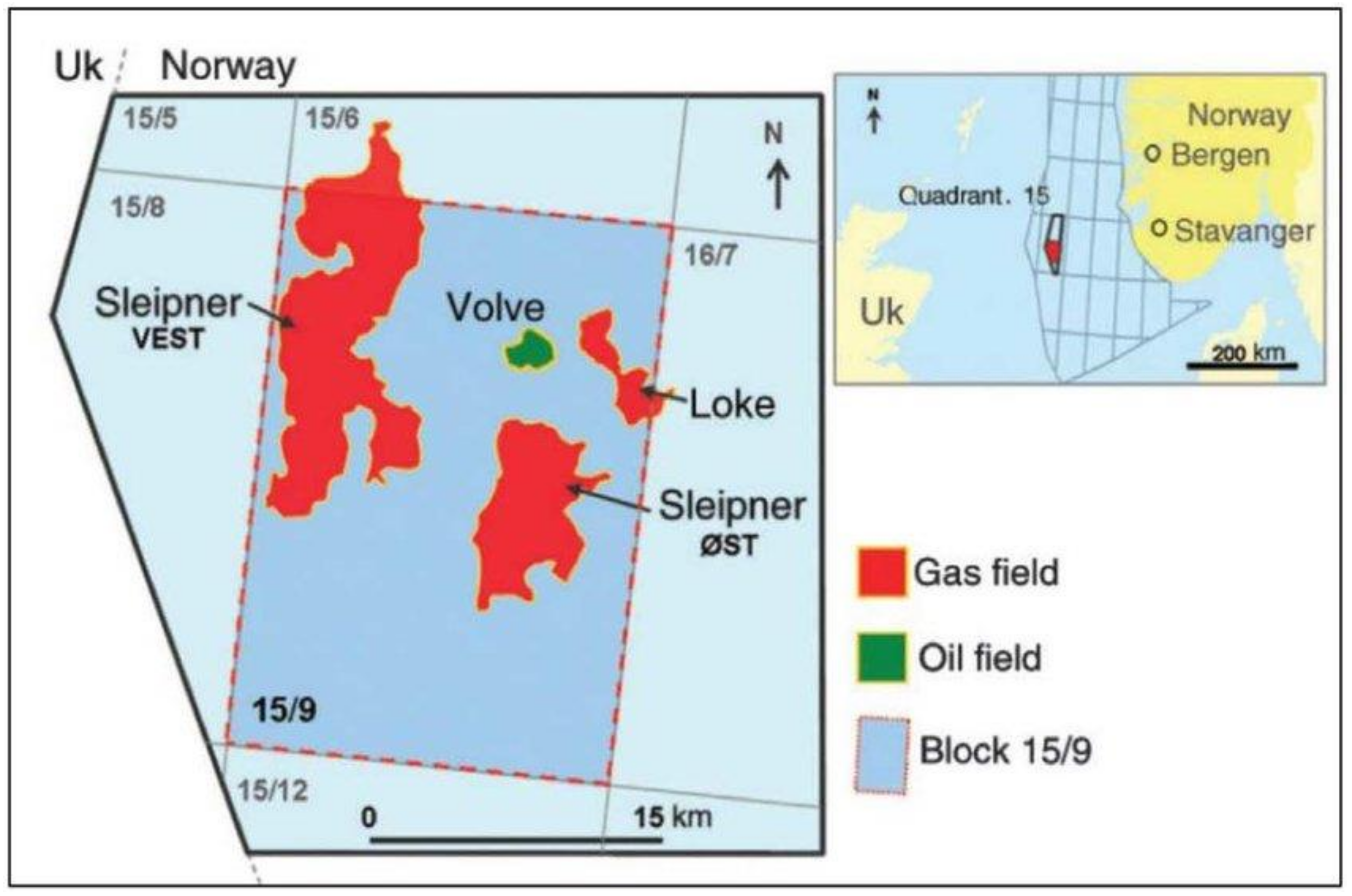

3.4. Data Description

4. Results

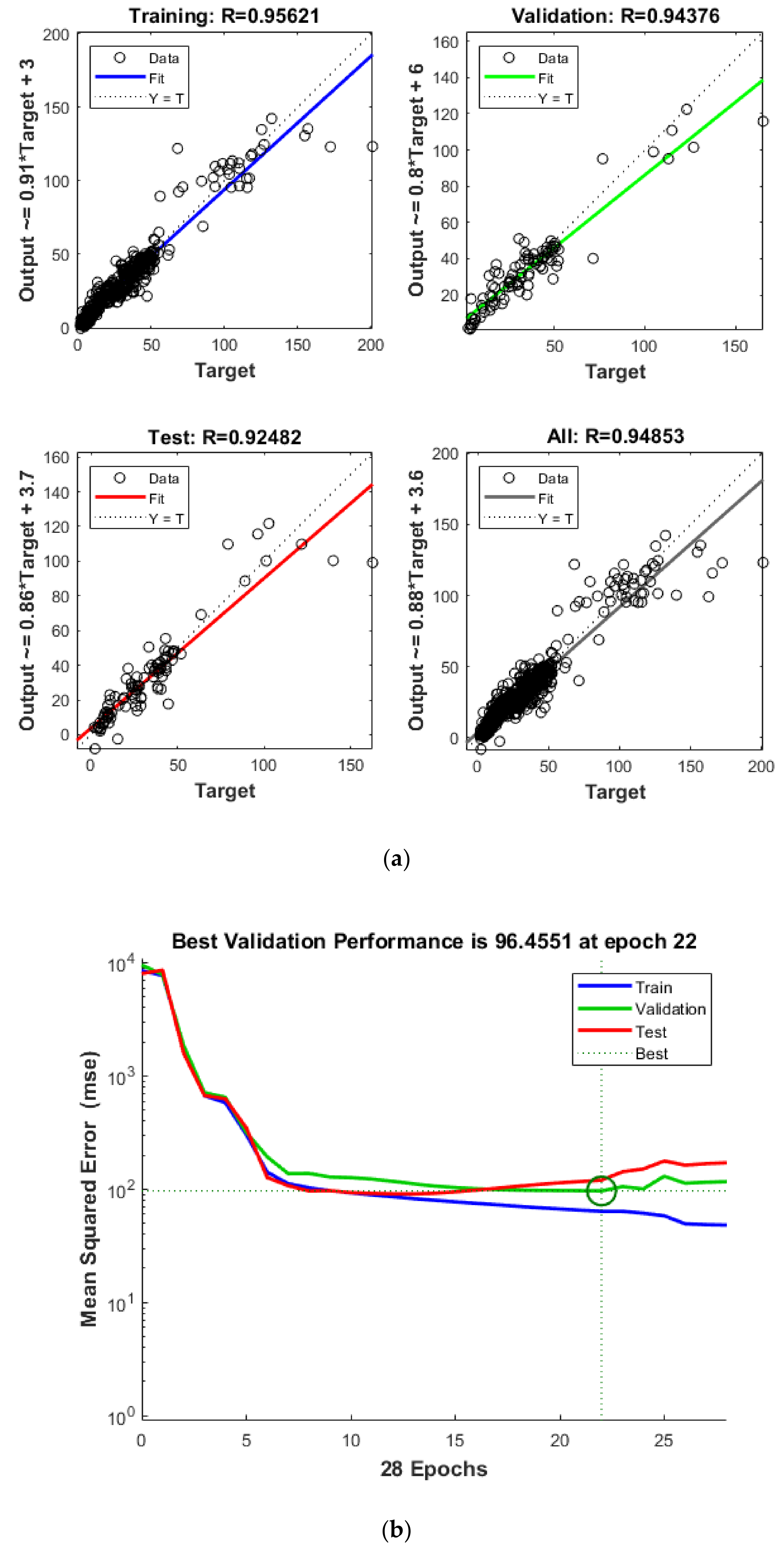

4.1. Development of ROP Objective Function Using ANN

- (a)

- Adjust the model parameters of GA (maximum no of iterations = 3000, crossover probability = 0.5, population size = 100, parents portion = 0.3, crossover-type = uniform, elite ratio = 0.01, variable type = real);

- (b)

- Set the upper and lower bounds for input variables existing in objective Equation (16) using Table 10;

- (c)

- Randomly generate the initial population for GA;

- (d)

- Several combinations of ROP and input variables will be generated during optimization. In the end, GA converges on the best combination of input variables having maximum ROP value;

- (e)

- Record the value of ROP and BT in the final solution produced by GA. GA will provide optimum ROP values along with suitable BT and other control variables.

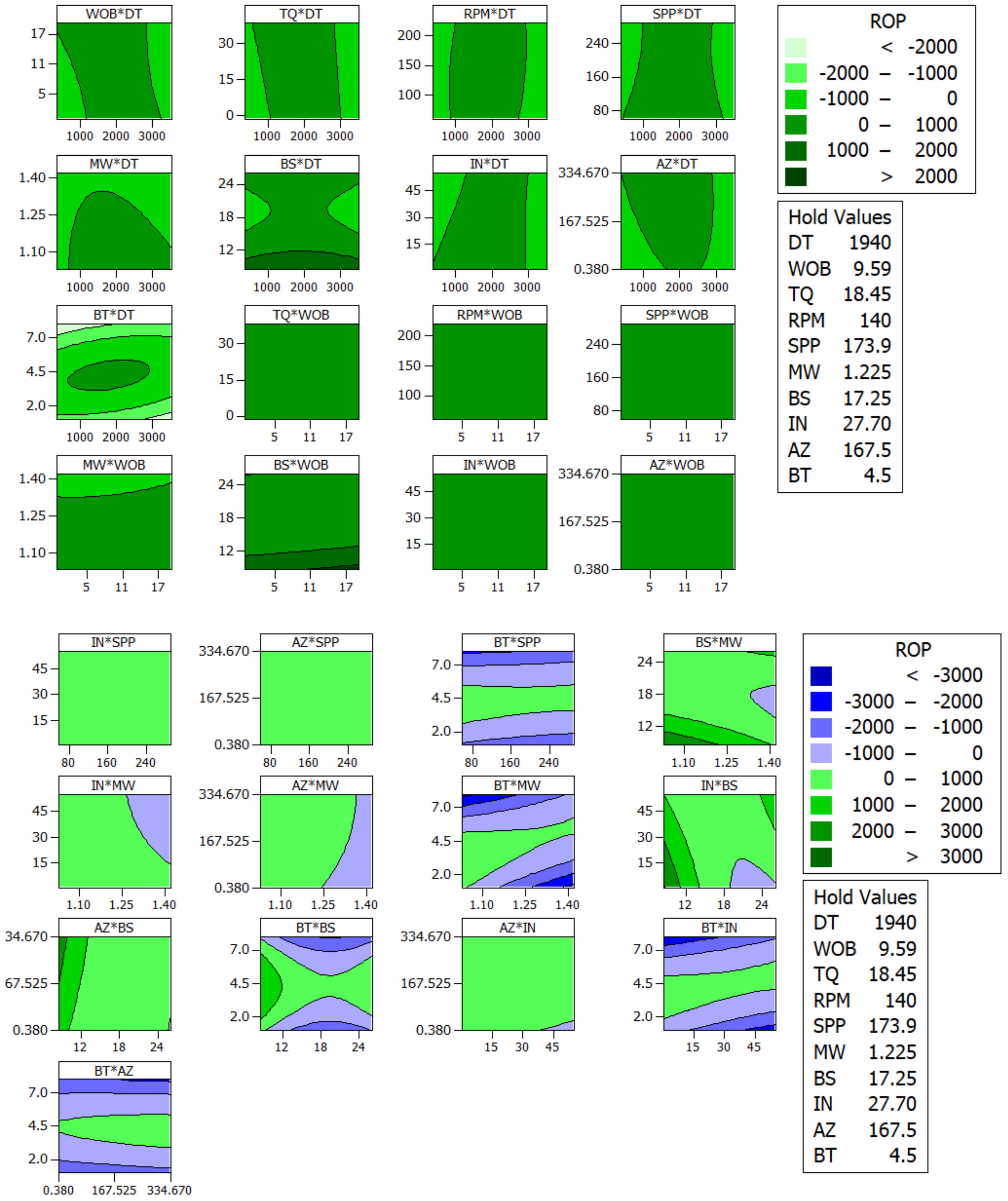

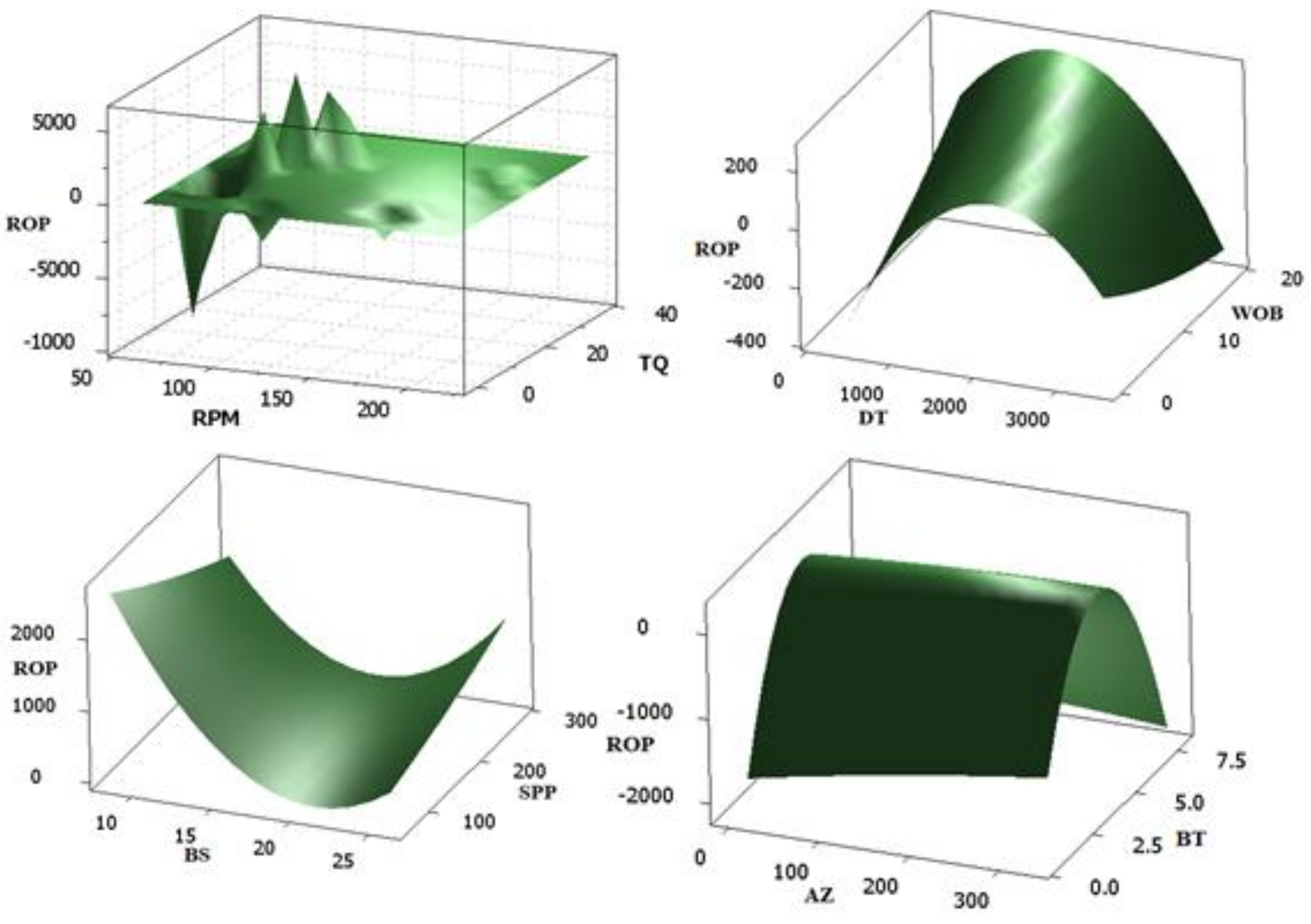

4.2. Development of the ROP Function Using RSM

- (a)

- A normal probability plot is used to verify the normal distribution of residual data. Ideally, the fitted data should follow a straight line. However, it was found to be not true for the studied drilling datasets, as the trend did not follow a straight line. This verifies the complexity of the real field drilling datasets.

- (b)

- Histogram of residuals plot provides details about data skewness or outliers. The skewness is confirmed by a long tail in one direction; however, if a bar is distant away from the other bars, it indicates noise or outlier in the residual data. In the studied drilling datasets, no such problem with data distribution has been found.

- (c)

- The residual vs. fits plot checks the constant variance of the residual. It plots the fitted values on the x-axis and residual on the y-axis and verifies the model assumption of the random distribution of residuals as well as constant variance. It is expected that the data points should lie randomly on both sides of the 0 line with no pattern [26,27], which is true in our case.

- (d)

- The residual vs. order plot checks whether residuals are uncorrelated or not. These graphs are generated to inspect the goodness of fit of fitting Equation (17) and ANOVA test. Normally, a model residual must lies randomly on both sides of the centerline with no patterns, which is true for our drilling data as well. The generated ROP Equation (17) has satisfied all the required standard conditions to be a good fitting equation (approximate function/objective function).

- (a)

- Initialize the search boundaries using the range of parameters provided in Table 10 and code Equation (17) as an objective function;

- (b)

- Adjust the other parameters of ABC (colony size = 50, scouts = 0.5, iterations = 100, min_max = ‘max’, nan_protection = True). Here, the size of the colony determines bees in the algorithm. Half of its values represent food sources, employed bees, and onlooker bees;

- (c)

- The algorithm returns a global optimal solution for the ROP objective function along with the locations of food sources or possible solutions (local maxima);

- (d)

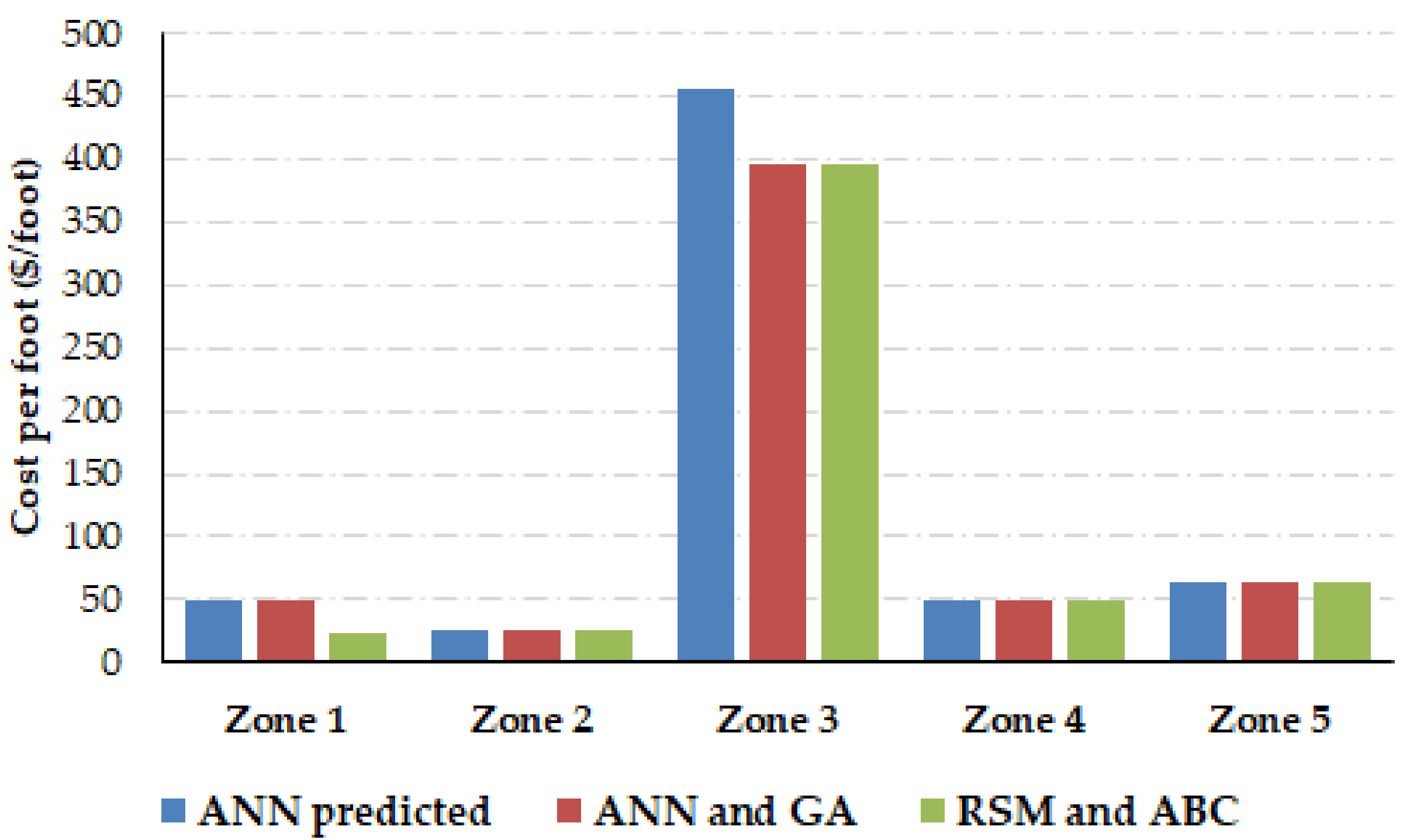

5. Discussion

6. Conclusions

- This study provides an alternate intelligent approach for bit selection based on optimum values of ROP.

- The proposed drill bit selection approach is found to be more accurate than the ANN-based prediction of drill bit types.

- The combination of RSM and ABC provides a more reliable bit selection modeling approach as compared to ANN based on cost per foot comparison.

- The prediction correlation coefficient of the RSM objective function is found to be 81.23%, while 85.5% has been found for ANN during the estimation of ROP.

- The ROP objective function developed through RSM is less complex than the ANN-based objective function due to the absence of an exponential function.

- ANN requires more computational cost for the development of the ROP function and its optimization.

- These models are case-specific data-dependent models and require calibration for other field data.

- The proposed data-driven approach has presented optimism for the sustainable development of more efficient, robust, reliable, and economical technology that has shown potential for drilling optimization and cost reduction.

7. Code Source

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Nomenclature

| DT | Measured Depth |

| TVD | True Vertical Depth |

| ROP | Rate of Penetration |

| WOB | Weight on Bit |

| RPM | Rounds per Minutes |

| TQ | Torque |

| SPP | Standpipe Pressure |

| MW | Mud Weight |

| FR | Flow Rate |

| TG | Total Gas |

| IN | Inclination |

| AZ | Azimuth |

| BT | Bit Type |

| BS | Bit Size |

| RSM | Response Surface Methodology |

| PDC | Polycrystalline Diamond Cutter |

| MT | Milled Tooth |

| MSE | Mean Square Error |

| MAE | Mean Absolute Error |

| RMSE | Root Mean Square Error |

| LM | Levenberg–Marquardt |

| BR | Bayesian Regularization |

| SCG | Scaled Conjugate Gradient |

| IADC | International Association of Drilling Contractors |

| MLP | Multilayer Perceptron Neural Network |

| UNDP | United Nation Development Programme |

| CCD | Central Composite Design |

| BBD | Box Behnken Design |

| CCRD | Central Composite Rotatable Design |

References

- Bahari, A.; Seyed, A.B. Drilling cost optimization in a hydrocarbon field by a combination of comparative and mathematical methods. Pet. Sci. 2009, 6, 451–463. [Google Scholar] [CrossRef]

- Teale, R. The concept of specific energy in rock drilling. Int. J. Rock Mech. Min. Sci. Geomech. Abstr. 1965, 2, 57–73. [Google Scholar] [CrossRef]

- Perrin, V.P.; Mensa-Wilmot, G.; Alexander, W.L. Drilling index-a new approach to bit performance evaluation. In Proceedings of the SPE/IADC Drilling Conference, Amsterdam, The Netherlands, 4–6 March 1997. [Google Scholar]

- Yιlmaz, S.; Demircioglu, C.; Akin, S. Application of artificial neural networks to optimum bit selection. Comput. Geosci. 2002, 28, 261–269. [Google Scholar] [CrossRef]

- Bahari, M.H.; Bahari, A.; Moharrami, F.N.; Naghibi-Sistani, M.B. Determining Bourgoyne and Young model coefficients using genetic algorithm to predict drilling rate. J. Appl. Sci. 2008, 8, 3050–3054. [Google Scholar] [CrossRef][Green Version]

- Edalatkhah, S.; Rasoul, R.; Hashemi, A. Bit selection optimization using artificial intelligence systems. Pet. Sci. Technol. 2010, 28, 1946–1956. [Google Scholar] [CrossRef]

- Momeni, M.S.; Ridha, S.; Hosseini, S.J.; Meyghani, B.; Emamian, S.S. Bit selection using field drilling data and mathematical investigation. In IOP Conference Series: Materials Science and Engineering; IOP Publishing: Bristol, UK, 2018; Volume 328, p. 012008. [Google Scholar]

- Momeni, M.; Hosseini, S.J.; Ridha, S.; Laruccia, M.B.; Liu, X. An optimum drill bit selection technique using artificial neural networks and genetic algorithms to increase the rate of penetration. J. Eng. Sci. Technol. 2018, 13, 361–372. [Google Scholar]

- Abbas, A.K.; Assi, A.H.; Abbas, H.; Almubarak, H.; Al Saba, M. Drill Bit Selection Optimization Based on Rate of Penetration: Application of Artificial Neural Networks and Genetic Algorithms. In Proceedings of the Abu Dhabi International Petroleum Exhibition & Conference, Abu Dhabi, United Arab Emirates, 11–14 November 2019. [Google Scholar]

- Hightower, W.J. Proper selection of drill bits and their use. In Proceedings of the SPE Mechanical Engineering Aspects of Drilling and Production Symposium, Fort Worth, TX, USA, 20–23 March 1964. [Google Scholar]

- Bourgoyne, A.T., Jr.; Young, F.S., Jr. A multiple regression approach to optimal drilling and abnormal pressure detection. Soc. Pet. Eng. J. 1974, 14, 371–384. [Google Scholar] [CrossRef]

- Rabia, H.; Farrelly, M.; Barr, M.V. A new approach to drill bit selection. In Proceedings of the SPE European Petroleum Conference, London, UK, 20 October 1985; pp. 20–22. [Google Scholar]

- Fear, M.J.; Meany, N.C.; Evans, J.M. An expert system for drill bit selection. In Proceedings of the SPE/IADC Drilling Conference, Dallas, TX, USA, 15–18 February 1994. [Google Scholar]

- Uboldi, V.; Civolani, L.; Zausa, F. Rock strength measurements on cuttings as input data for optimizing drill bit selection. In Proceedings of the SPE Annual Technical Conference and Exhibition, Houston, TX, USA, 3–6 October 1999. [Google Scholar]

- Bybee, K. A New Approach for Drill-Bit Selection. J. Pet. Technol. 2000, 52, 27–28. [Google Scholar] [CrossRef]

- Bilgesu, H.I.; Al-Rashidi, A.F.; Aminian, K.; Ameri, S. A new approach for drill bit selection. SPE Eastern Regional Meeting, London, UK, 17–19 October 2000. [Google Scholar]

- Kůrková, V. Kolmogorov’s theorem and multilayer neural networks. Neural Netw. 1992, 5, 501–506. [Google Scholar] [CrossRef]

- Villarrubia, G.; De Paz, J.F.; Chamoso, P.; De la Prieta, F. Artificial neural networks used in optimization problems. Neurocomputing 2018, 272, 10–16. [Google Scholar] [CrossRef]

- Polikar, R. Pattern Recognition. Wiley Encyclopedia of Biomedical Engineering; John Wiley & Sons, Inc.: New York, NY, USA, 2006. [Google Scholar]

- Muthiah, A.; Rajkumar, R. A comparison of artificial bee colony algorithm and genetic algorithm to minimize the makespan for job shop scheduling. Procedia Eng. 2014, 97, 1745–1754. [Google Scholar]

- Alqattan, Z.N.M.; Abdullah, R.A. Comparison between Artificial Bee Colony and Particle Swarm Optimization Algorithms for Protein Structure Prediction Problem. Lect. Notes Comput. Sci. 2013, 827, 331–340. [Google Scholar]

- Karaboga, D.; Basturk, B. A powerful and efficient algorithm for numerical function optimization: Artificial bee colony (ABC) algorithm. J. Glob. Optim. 2007, 39, 459–471. [Google Scholar] [CrossRef]

- Myers, R.H.; Khuri, A.I.; Walter, H.C., Jr. Response Surface Methodology. Technometrics 1989, 31, 137–157. [Google Scholar]

- Montgomery, D.C. Design and Analysis of Experiments; John Wiley & Sons, Inc.: New York, NY, USA, 2014. [Google Scholar]

- Hecht-Nielsen, R. Kolmogorov’s mapping neural network existence theorem. In Proceedings of the IEEE First International Conference on Neural Networks, San Diego, CA, USA, 21–24 June 1987; Volume 989, pp. 11–14. [Google Scholar]

- Box, G.E.P.; Wilson, K.B. On the Experimental Attainment of Optimum Conditions. In Breakthroughs in Statistics. Springer Series in Statistics (Perspectives in Statistics); Kotz, S., Johnson, N.L., Eds.; Springer: New York, NY, USA; Morgantown, WV, USA, 1993. [Google Scholar]

- Myers, R.H.; Montgomery, D.C.; Anderson-Cook, C.M. Response Surface Methodology: Process and Product Optimization Using Designed Experiments; John Wiley & Sons. Inc.: New York, NY, USA, 1995; pp. 134–174. [Google Scholar]

- Karaboga, D. An Idea Based on Honey Bee Swarm for Numerical Optimization. Technical Report-tr06, Erciyes University, Engineering Faculty, Computer Engineering Department. 2005. Available online: http://citeseerx.ist.psu.edu/viewdoc/download;jsessionid=E32274EB05825D919807935CF722606F?doi=10.1.1.714.4934&rep=rep1&type=pdf (accessed on 29 October 2020).

- Zhao, Y.; Noorbakhsh, A.; Koopialipoor, M.; Azizi, A.; Tahir, M.M. A new methodology for optimization and prediction of rate of penetration during drilling operations. Eng. Comput. 2020, 36, 587–595. [Google Scholar] [CrossRef]

- Nozohour-leilabady, B.; Fazelabdolabadi, B. On the application of artificial bee colony (ABC) algorithm for optimization of well placements in fractured reservoirs; efficiency comparison with the particle swarm optimization (PSO) methodology. Petroleum 2016, 2, 79–89. [Google Scholar] [CrossRef]

- Koopialipoor, M.; Ghaleini, E.N.; Haghighi, M.; Kanagarajan, S.; Maarefvand, P.; Mohamad, E.T. Overbreak prediction and optimization in tunnel using neural network and bee colony techniques. Eng. Comput. 2019, 35, 1191–1202. [Google Scholar] [CrossRef]

- Ghaleini, E.N.; Koopialipoor, M.; Momenzadeh, M.; Sarafraz, M.E.; Mohamad, E.T.; Gordan, B. A combination of artificial bee colony and neural network for approximating the safety factor of retaining walls. Eng. Comput. 2018, 35, 647–658. [Google Scholar] [CrossRef]

- Ahmad, A.; Razali, S.F.M.; Mohamed, Z.S.; El-shafie, A. The application of artificial bee colony and gravitational search algorithm in reservoir optimization. Water Resour. Manag. 2018, 30, 2497–2516. [Google Scholar] [CrossRef]

- Ravasi, M.; Vasconcelos, I.; Curtis, A.; Kristi, A. Vector-acoustic reverse time migration of Volve ocean-bottom cable data set without up/down decomposed wavefields. Geophysics 2015, 80, S137–S150. [Google Scholar] [CrossRef]

- Equinor Website Database. Available online: https://www.equinor.com/en/how-and-why/digitalisation-in-our-dna/volve-field-data-village-download.html (accessed on 17 August 2020).

- Hornik, K.; Stinchcombe, M.; White, H. Multilayer feedforward networks are universal approximators. Neural Netw. 1989, 2, 359–366. [Google Scholar] [CrossRef]

- Ripley, B.D. Statistical aspects of neural networks Networks and Chaos: Statistical and Probabilistic Aspects. Chapman Hall 1993, 50, 40–123. [Google Scholar]

- Paola, J.D. Neural Network Classification of Multispectral Imagery. Master’s Thesis, The University of Arizona, Tucson, AZ, USA, 1994. [Google Scholar]

- Wang, C. A Theory of Generalization in Learning Machines with Neural Applications. Ph.D. Thesis, The University of Pennsylvania, Philadelphia, PA, USA, 1994. [Google Scholar]

- Masters, T. Practical Neural Network Recipes in C++; Morgan Kaufmann: Burlington, VT, USA, 1993. [Google Scholar]

- Kanellopoulos, I.; Wilkinson, G.G. Strategies and best practice for neural network image classification. Int. J. Remote Sens. 1997, 18, 711–725. [Google Scholar] [CrossRef]

- Kaastra, I.; Boyd, M. Designing a neural network for forecasting financial and economic time series. Neurocomputing 1996, 10, 215–236. [Google Scholar] [CrossRef]

- Zorlu, K.; Gokceoglu, C.; Ocakoglu, F.; Nefeslioglu, H.A.; Acikalin, S. Prediction of uniaxial compressive strength of sandstones using petrography-based models. Eng. Geol. 2008, 96, 141–158. [Google Scholar] [CrossRef]

- Demuth, H.; Beale, M.; Hagan, M. Artificial Neural Networks & Genetic Algorithms User’s Guide. Revis. Matlab Program. 2007, 5. Available online: http://cda.psych.uiuc.edu/matlab_pdf/nnet.pdf (accessed on 18 January 2021).

- Lindenmayer, D.; Burgman, M.A. Monitoring, assessment, and indicators. Pract. Conserv. Biol. 2005, 401–424. [Google Scholar] [CrossRef]

- Schlotzhauer, S. Elementary Statistics Using JMP; SAS Publishing: Cary, NC, USA, 2007. [Google Scholar]

- Hou, B.; Chen, M.; Yuan, J. Optimization and Application of Bit Selection Technology for Improving the Penetration Rate. Res. J. Appl. Sci. Eng. Technol. 2014, 8, 179–187. [Google Scholar] [CrossRef]

- Tewari, S.; Dwivedi, U.D. Ensemble-based Big Data Analytics of Lithofacies for Automatic Development of Petroleum Reservoirs. Comput. Ind. Eng. 2018, 128, 937–947. [Google Scholar] [CrossRef]

- Ibisworld Website Database. Available online: https://www.ibisworld.com/industry-insider/search/?query=GDP (accessed on 3 December 2020).

- Pessier, R.; Damschen, M. Hybrid bits offer distinct advantages in selected roller-cone and pdc-bit applications. Spe Drill. Complet. 2011, 26, 96–103. [Google Scholar] [CrossRef]

- Tewari, S.; Dwivedi, U.D.; Biswas, S. A Novel Application of Ensemble Methods with Data Resampling Techniques for Drill Bit Selection in the Oil and Gas Industry. Energies 2021, 14, 432. [Google Scholar] [CrossRef]

| Group | Formation | Depth (m) | Description |

|---|---|---|---|

| Nordland | Utsira Top | 892 | Gray claystone, a stringer of sand and siltstone. |

| Utsira Base | 1084 | Well-sorted sandstone, minor silt, and limestone stringers. | |

| Hordaland | Skade Top | 1259 | Claystone, minor limestone/dolomite stringers. |

| Skade Base | 1347 | Medium-grained sorted sandstone. | |

| Grid Top | 2179 | Fine-grained sandstone. | |

| Grid Base | 2245 | Fine-grained sandstone. | |

| Rogaland | Balder Top | 2317 | Colored claystone, partly tuffaceous, and limestone stringers. |

| Sele Top | 2374 | Claystone and limestone stringer. | |

| Lista Top | 2445 | Non-calcareous claystone and minor limestone stringers. | |

| Ty Top | 2531 | Fine to medium sandstone; some interbedded claystone, siltstone, and limestone stringers. | |

| Shetland | Ekofisk Top | 2698 | Limestone with traces of claystone and sandstone. |

| Tor Top | 2715 | White limestone with traces of claystone. | |

| Hod Top | 2839 | Limestone along with gluconate. | |

| Blodoeks Top | 2944 | Marl, argillaceous laminations, and gluconates in parts. | |

| Hidra Top | 2972 | Off-white firm limestone. | |

| Cromer Knoll | Roedby Top | 2981 | Marl along with argillaceous laminations |

| Aasgard Top | 3001 | Interbedded limestone and marl with minor claystone and siltstone. | |

| Viking | Draupne Top | 3036 | Organic-rich claystone, micaceous, carbonaceous with traces of pyrite. |

| Heather Top | 3086 | Claystone with limestone stringers. | |

| Vestland | Hugin Top | 3094 | Sandstone and rare claystone stringers. |

| Sleipner Top | 3266 | Sandstone, grey claystone, and layers of coal. |

| S. No. | Drilling Variables | Ranges | Units | Code Factor |

|---|---|---|---|---|

| 1. | Measured Depth (DT) | 100–3520 | m | |

| 2. | Rate of Penetration (ROP) | 1.73–201.02 | m/h | -- |

| 3. | Weight on bit (WOB) | 0.01–19.17 | Tons | |

| 4. | Rounds per minutes (RPM) | 60–220 | rpm | |

| 5. | Torque (TQ) | 0–5.24 | kN/m | |

| 6. | Standpipe pressure (SPP) | 58.6–289.2 | Bar | |

| 7. | Mud weight (MW) | 1.03–1.42 | S.g. | |

| 8. | Inclination (IN) | 0.46–54.95 | Degree | |

| 9. | Azimuth (AZ) | 0.38–334.67 | Degree | |

| 10. | Bit type (BT) | 1–11 | N/A | |

| 11. | Bit Size (BS) | 8.5–26 | Inch |

| Well Name | Bit Type | Depth In (m) | Depth Out (m) | IADC Code | Bit Size (Inch) |

|---|---|---|---|---|---|

| WELL A (F-4) | 1 | 100 | 310 | PDC M415 | 36″ |

| 2 | 25 | 1360 | MT 115A | 17.5″ | |

| 7 | 1360 | 1410 | PDC M422 | 12.25″ | |

| 8 | 2770 | 2993 | PDC M222 | 8.5″ | |

| 8 | 2993 | 3510 | PDC M222 | 8.5″ | |

| Well B (F-15) | 10 | 144 | 226 | MT 115 | 36″ |

| 6 | 226 | 1378 | PDC M115 | 26″ | |

| 3 | 1378 | 1381 | MT 244 | 17.5″ | |

| 4 | 1381 | 2536 | PDC M332 | 12.25″ | |

| 9 | 2536 | 3670 | PDC M323 | 8.5″ | |

| 9 | 3670 | 4090 | PDC M323 | 8.5″ | |

| 5 | 1378 | 2591 | PDC M322 | 26″ | |

| 4 | 2591 | 2594 | PDC M332 | 12.25″ | |

| 5 | 2591 | 2596 | PDC M322 | 8.5″ | |

| 5 | 2596 | 3180 | PDC M322 | 8.5″ | |

| 5 | 3180 | 4095 | PDC M322 | 8.5″ | |

| 5 | 3185 | 3498 | PDC M322 | 8.5″ | |

| 7 | 2562 | 2665 | PDC M422 | 12.25″ | |

| 7 | 2665 | 2920 | PDC M422 | 12.25″ | |

| WELL C (F-12) | 1 | 251 | 1369 | PDC M415 | 36″ |

| 5 | 1369 | 2513 | PDC M322 | 17.5″ | |

| 6 | 2513 | 2573 | MT 135 | 17.5″ | |

| 7 | 2573 | 3114 | PDC M422 | 12.25″ | |

| 8 | 3114 | 3520 | PDC M222 | 8.5″ |

| Relationships | References |

|---|---|

| [25] | |

| [37] | |

| [38] | |

| [39] | |

| [40] | |

| [41,42] |

| Estimators | Model Parameters | Search Range | Optimum Value |

|---|---|---|---|

| ANNs | Configuration | 2–20 | [10-18-1] |

| Learning rate | 0.0001–0.5 | 0.0001 | |

| Maximum number of iteration | 100–1000 | 200 | |

| Activation function hidden layer | Tangential sigmoid function | N/A | |

| Activation function output layer | purline function | ||

| Training algorithm | Levenberg–Marquardt | N/A | |

| ABC | Iterations | 10–200 | 100 |

| Scouts | 1–100 | 70 | |

| Colony size | 1–100 | 100 | |

| GA | Iterations | 1–5000 | 3000 |

| Crossover probability | 0.1–1 | 0.5 | |

| Population size | 1–200 | 100 | |

| Crossover type | - | Uniform | |

| Elit_ratio | 0.001–1 | 0.001 | |

| Parents portion | 0.1–1 | 0.3 |

| Model No. | No of Neurons | Train R2 | Train RMSE | Test R2 | Test RMSE | Train Rating R2 | Train Rating RMSE | Test Rating R2 | Test Rating RMSE | Total Rank |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 0.793 | 11.76 | 0.597 | 20.414 | 3 | 3 | 1 | 1 | 8 |

| 2 | 4 | 0.640 | 16.20 | 0.634 | 16.233 | 1 | 1 | 2 | 2 | 6 |

| 3 | 6 | 0.839 | 10.94 | 0.720 | 14.975 | 4 | 5 | 3 | 4 | 16 |

| 4 | 8 | 0.894 | 9.283 | 0.850 | 8.298 | 6 | 6 | 9 | 10 | 31 |

| 5 | 10 | 0.843 | 11.18 | 0.801 | 10.475 | 5 | 4 | 6 | 8 | 23 |

| 6 | 12 | 0.930 | 6.930 | 0.831 | 13.635 | 9 | 8 | 8 | 5 | 30 |

| 7 | 14 | 0.908 | 8.332 | 0.761 | 11.786 | 8 | 7 | 4 | 7 | 26 |

| 8 | 16 | 0.952 | 6.319 | 0.825 | 16.392 | 10 | 9 | 7 | 3 | 29 |

| 9 | 18 | 0.9143 | 7.99 | 0.855 | 10.32 | 7 | 10 | 10 | 9 | 36 |

| 10 | 20 | 0.734 | 14.59 | 0.774 | 12.916 | 2 | 2 | 5 | 6 | 15 |

| Model No. | No of Neurons | Train R2 | Train RMSE | Test R2 | Test RMSE | Train Rating R2 | Train Rating RMSE | Test Rating R2 | Test Rating RMSE | Total Rank |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 0.723 | 14.82 | 0.675 | 16.430 | 4 | 4 | 4 | 4 | 16 |

| 2 | 4 | 0.767 | 12.71 | 0.804 | 12.901 | 8 | 8 | 2 | 9 | 27 |

| 3 | 6 | 0.558 | 19.32 | 0.648 | 16.520 | 1 | 2 | 2 | 3 | 8 |

| 4 | 8 | 0.710 | 14.30 | 0.673 | 14.263 | 3 | 6 | 3 | 7 | 19 |

| 5 | 10 | 0.685 | 16.34 | 0.600 | 14.340 | 2 | 3 | 1 | 6 | 12 |

| 6 | 12 | 0.764 | 13.88 | 0.816 | 11.778 | 7 | 7 | 9 | 10 | 33 |

| 7 | 14 | 0.814 | 12.37 | 0.756 | 13.538 | 10 | 9 | 7 | 8 | 34 |

| 8 | 16 | 0.734 | 14.36 | 0.745 | 14.609 | 5 | 5 | 6 | 5 | 21 |

| 9 | 18 | 0.802 | 12.12 | 0.733 | 16.851 | 9 | 10 | 5 | 2 | 26 |

| 10 | 20 | 0.757 | 210.75 | 0.869 | 115.82 | 6 | 1 | 10 | 1 | 18 |

| Model No. | No of Neurons | Train R2 | Train RMSE | Test R2 | Test RMSE | Train Rating R2 | Train Rating RMSE | Test Rating R2 | Test Rating RMSE | Total Rank |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | 2 | 0.855 | 10.84 | 0.714 | 13.376 | 1 | 1 | 3 | 8 | 13 |

| 2 | 4 | 0.890 | 8.90 | 0.819 | 13.520 | 2 | 3 | 7 | 6 | 18 |

| 3 | 6 | 0.927 | 7.58 | 0.751 | 13.375 | 3 | 4 | 5 | 9 | 21 |

| 4 | 8 | 0.9281 | 6.94 | 0.864 | 13.473 | 4 | 5 | 9 | 7 | 25 |

| 5 | 10 | 0.946 | 6.492 | 0.762 | 14.476 | 6 | 6 | 6 | 4 | 22 |

| 6 | 12 | 0.946 | 6.359 | 0.907 | 10.059 | 6 | 7 | 10 | 10 | 33 |

| 7 | 14 | 0.965 | 5.131 | 0.547 | 19.724 | 8 | 9 | 1 | 2 | 20 |

| 8 | 16 | 0.960 | 5.37 | 0.820 | 14.157 | 7 | 8 | 8 | 5 | 28 |

| 9 | 18 | 0.973 | 4.416 | 0.715 | 19.234 | 9 | 10 | 4 | 3 | 26 |

| 10 | 20 | 0.986 | 9.907 | 0.562 | 28.045 | 10 | 2 | 2 | 1 | 15 |

| Connections | Generated Values |

|---|---|

| Bias Hidden Layer | −2.331; −2.775; −0.1308; −0.03132; 1.504; 0.2345; 2.2617; −1.5475; 1.1458; 0.3785; −0.0855; 0.3141; −1.0727; −2.2302; 1.8623; −2.6596; −1.85; 2.721 |

| Connection Weights between Input and Hidden Layer | −0.486; −2.186; 0.151; 1.236; 1.964; 0.920; −0.5052; −0.677; 0.008; 0.570; 1.202; −0.577; 0.269; −2.421; 0.145; −0.654; −0.664; −2.189; 1.061; 0.126; 1.048; 1.962; −0.479; −0.984; −1.578; 0.542; −1.061; −0.900; −0.856; 0.401; 0.108; −0.469; −1.358; −0.818; 0.037; 0.413; 0.484; −1.092; −1.283; 0.109; −0.444; −1.698; −3.35; 0.353; −0.194; −0.038; −0.431; −0.647; −0.0049; −0.225; 0.266; 0.517; −0.0142; 1.035; 0.456; −0.271; 0.6465; −0.568; 1.96; −0.423;−0.594; −0.981; 0.441; −0.363; −0.293; −0.0681; −0.313; −0.996; −2.33; 1.21; −1.033; −0.649; 1.68; −0.859; 0.426; 0.880; −0.425; −1.456; −1.231; 0.436; −1.234; −1.301; 1.712; 1.96; 1.55; 0.53; 1.17; −1.79; 0.66; −0.093; −2.81; 1.47; −1.103; −0.346; −3.252; 0.403; −0.52; 0.426; −1.246; 0.8551; −0.721; −3.845; 0.619; 0.902; 1.909; −0.7886; 0.271; 1.015; −3.98; 0.366; −0.101; −1.257; 2.83; 1.017; 1.185; −0.150; −0.0382; −2.389; −0.740; −1.086; −1.868; −0.573; −0.689; −0.337; −1.414; 1.336; 0.797; −0.853; −2.783; −0.484; −0.252; −1.243; 1.548; 1.508; 0.047; −0.109; 0.699; 0.56544; −0.317; −0.452; 1.35; −0.1153; −0.661; 1.076; 0.436; 0.986; 0.55; 0.5131; −1.026; −0.5348; −0.1402; 0.156; −0.5217; −0.6648; 1.3074; 0.0939; −0.822; −1.814; −0.092; 1.22; 0.242; −1.53; 1.24; −1.493; 0.112; −0.68; −0.342; 0.62; 0.451; −0.179; −1.14; 3.38; 0.66; −0.351; −0.017; 0.098; −0.433; −1.99; −1.40; −0.112 |

| Bias Output Layer | −0.7816 |

| Connection Weights between Hidden Layer and Output Layer | −0.264; −1.214; 0.0348; −0.701; 0.319; 0.410; 0.1114; 0.421; 0.5133; −0.4028; 0.1325; −0.5300; 0.785; −0.475; −0.765; 0.434; 0.376; −0.133 |

| Depth Interval (m) | Predictor Variables Utilized During Optimization |

|---|---|

| 251–1369 | DT = constant, BT = [1, 10], BS = constant, WOB = [0.01, 16.29], RPM = [83, 220], TQ = [−0.15, 15.26]. MW = [1.03, 1.36], IN = constant, AZ = constant, SPP = [59, 153] |

| 1369–2513 | DT = constant, BT = [1, 10], BS = constant, WOB = [0.01, 19.17], RPM = [90, 186], TQ = [7.58, 27.03]. MW = [1.16, 1.4], IN = constant, AZ = constant, SPP = [140, 252] |

| 2513–2573 | DT = constant, BS = constant, BT = [1, 10], WOB = [11.78, 19.07], RPM = [150, 180], TQ = [11.35, 19.07]. MW = [1.39, 1.4], IN = constant, AZ = constant, SPP = [226, 282.4] |

| 2573–3114 | DT = constant, BT = [1, 10], BS = constant, WOB = [1.35, 10.96], RPM = [137, 180], TQ = [1.07, 9.84]. MW = [1.39, 1.42], IN = constant, AZ = constant, SPP = [220, 290] |

| 3114–3520 | DT = constant, BS = constant, BT = [1, 10], WOB = [2.04, 6.87], RPM = [60, 140], TQ = [2.11, 6.15]. MW = [1.39, 1.44], IN = constant, AZ = constant, SPP = [174.6, 233.9] |

| Source | DF | Sum of Squares | Mean Square | F-Value | p-Value | T-Value |

|---|---|---|---|---|---|---|

| Model | 63 | 10.29 | 0.1633 | 48.74 | 0.00 | 0.000 |

| 1 | 0.98 | 0.1022 | 30.51 | 0.00 | 5.524 | |

| 1 | 0.013 | 0.013 | 3.94 | 0.047 | 1.986 | |

| 1 | 0.0158 | 0.0157 | 4.71 | 0.030 | −2.169 | |

| 1 | 0.02 | 0.02 | 5.97 | 0.015 | 2.444 | |

| 1 | 0.0020 | 0.00204 | 0.61 | 0.036 | −1.779 | |

| 1 | 0.022 | 0.020 | 5.98 | 0.015 | −2.445 | |

| 1 | 0.1132 | 0.1132 | 33.77 | 0.000 | 5.811 | |

| 1 | 0.0001 | 0.00005 | 0.02 | 0.897 | −0.129 | |

| 1 | 0.0139 | 0.0139 | 4.15 | 0.042 | −2.038 | |

| 1 | 0.0243 | 0.0243 | 7.24 | 0.007 | 2.691 | |

| 1 | 0.0343 | 0.3433 | 10.24 | 0.001 | −3.200 | |

| 1 | 0.1493 | 0.1493 | 44.57 | 0.00 | −6.676 | |

| 1 | 0.0154 | 0.0154 | 4.61 | 0.032 | −2.146 | |

| 1 | 0.0027 | 0.00271 | 8.09 | 0.005 | −2.844 | |

| 1 | 0.1153 | 0.1153 | 34.4 | 0.000 | −5.865 | |

| 1 | 0.0206 | 0.0206 | 6.15 | 0.013 | 2.480 | |

| 1 | 0.0157 | 0.01565 | 4.67 | 0.031 | −2.161 | |

| 1 | 0.0134 | 0.0133 | 4.01 | 0.046 | −2.002 | |

| 1 | 0.0206 | 0.0206 | 6.15 | 0.013 | 2.480 | |

| 1 | 0.1299 | 0.1298 | 38.75 | 0.000 | −6.225 | |

| 1 | 0.0534 | 0.05303 | 15.82 | 0.000 | 3.978 | |

| 1 | 0.0137 | 0.01366 | 4.08 | 0.044 | 2.019 |

| Bit Selection | Models | Zone 1 | Zone 2 | Zone 3 | Zone 4 | Zone 5 | |

|---|---|---|---|---|---|---|---|

| [47] | ANNs | 3 | 5 | 4 | 3 | 8 | |

| [6]/[9] | ANNs and GA | 3 | 5 | 6 | 7 | 8 | |

| Proposed approach | RSM and ABC | 1 | 5 | 6 | 7 | 8 | |

| Actual BT Data | 1 | 5 | 6 | 7 | 8 | ||

| Target Zones | ANNs Predicted | Cumulative CCF $/ft | ANNs and GA | Cumulative CCF $/ft | Proposed Approach | Cumulative CCF $/ft |

|---|---|---|---|---|---|---|

| Zone 1 | 3 | 50 | 3 | 50 | 1 | 24 |

| Zone 2 | 5 | 25 | 5 | 25 | 5 | 25 |

| Zone 3 | 4 | 456 | 6 | 396 | 6 | 396 |

| Zone 4 | 3 | 50 | 7 | 50 | 7 | 50 |

| Zone 5 | 8 | 64 | 8 | 64 | 8 | 64 |

| DT | WOB | TQ | RPM | SPP | MW | BT | ROP |

|---|---|---|---|---|---|---|---|

| Zone 1 | 3.72 | 0.01 | 90 | 62.6 | 1.03 | 1 | 47.4 |

| Zone 2 | 3.64 | 16.67 | 176 | 247.3 | 1.39 | 5 | 40.35 |

| Zone 3 | 16.01 | 21.8 | 178 | 279.3 | 1.22 | 6 | 10.56 |

| Zone 4 | 6.94 | 31.25 | 139 | 193.8 | 1.41 | 7 | 11.61 |

| Zone 5 | 6.87 | 22.28 | 140 | 205.9 | 1.4 | 8 | 27.54 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Tewari, S.; Dwivedi, U.D.; Biswas, S. Intelligent Drilling of Oil and Gas Wells Using Response Surface Methodology and Artificial Bee Colony. Sustainability 2021, 13, 1664. https://doi.org/10.3390/su13041664

Tewari S, Dwivedi UD, Biswas S. Intelligent Drilling of Oil and Gas Wells Using Response Surface Methodology and Artificial Bee Colony. Sustainability. 2021; 13(4):1664. https://doi.org/10.3390/su13041664

Chicago/Turabian StyleTewari, Saurabh, Umakant Dhar Dwivedi, and Susham Biswas. 2021. "Intelligent Drilling of Oil and Gas Wells Using Response Surface Methodology and Artificial Bee Colony" Sustainability 13, no. 4: 1664. https://doi.org/10.3390/su13041664

APA StyleTewari, S., Dwivedi, U. D., & Biswas, S. (2021). Intelligent Drilling of Oil and Gas Wells Using Response Surface Methodology and Artificial Bee Colony. Sustainability, 13(4), 1664. https://doi.org/10.3390/su13041664