Performance Investigation of 18 Thermoelectric Cooler (TEC) Units to Supply Continuous Daily Fresh Water from Malaysia’s Atmosphere

Abstract

1. Introduction

2. Materials and Methods

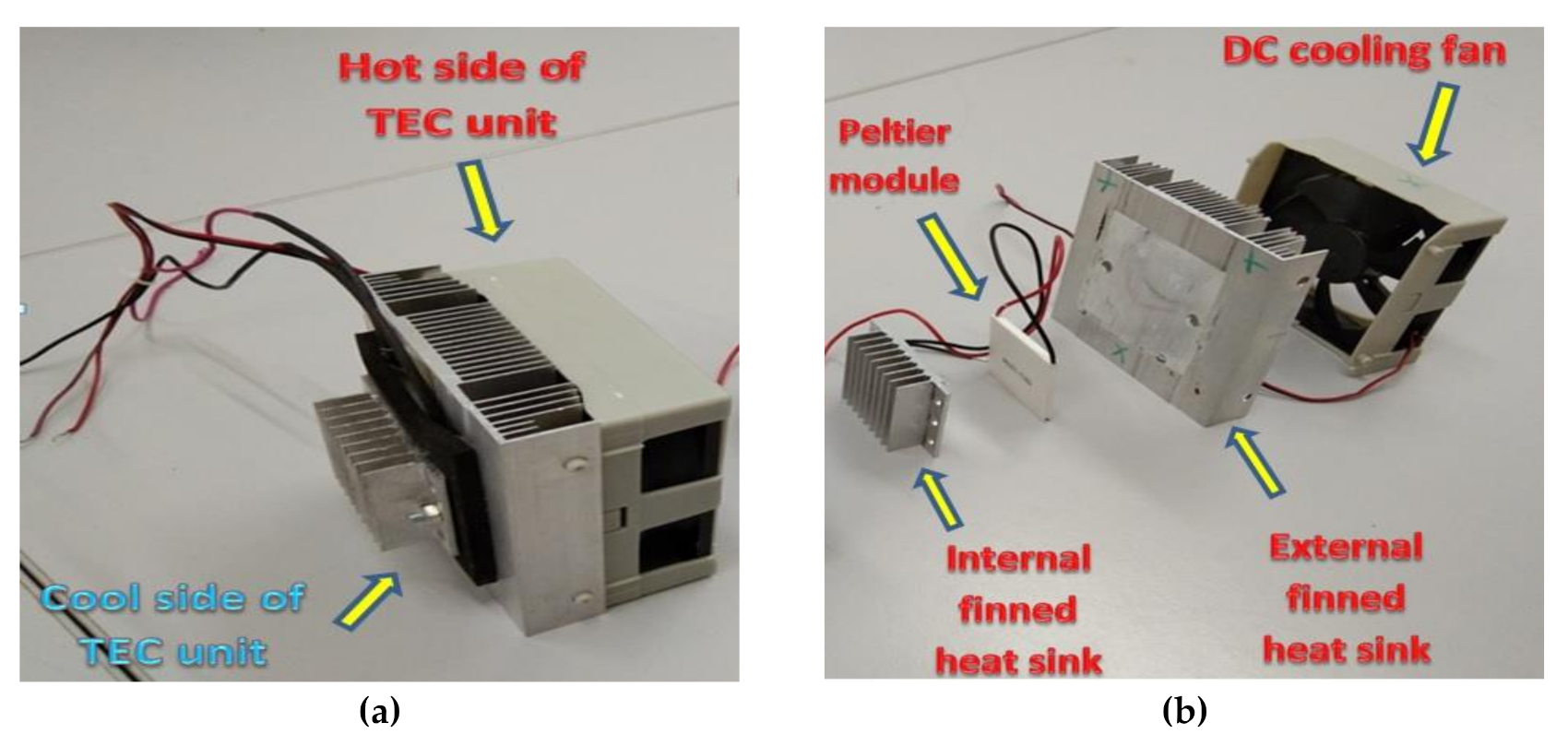

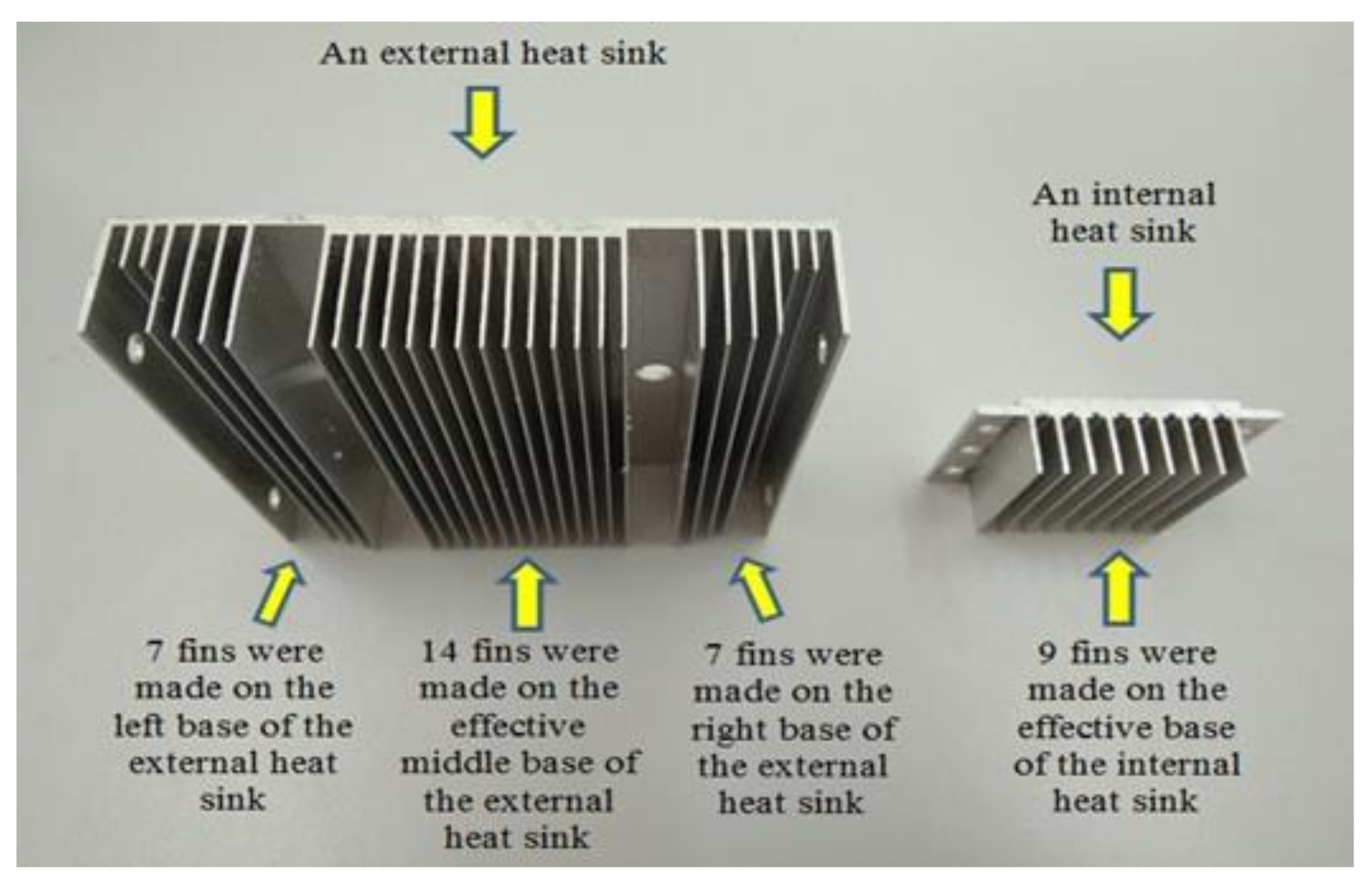

2.1. MSAWG System Materials and Dimensions

2.2. Experimental Set-Up

2.3. Mechanism of Generating Fresh Water by MSAWG

3. Results

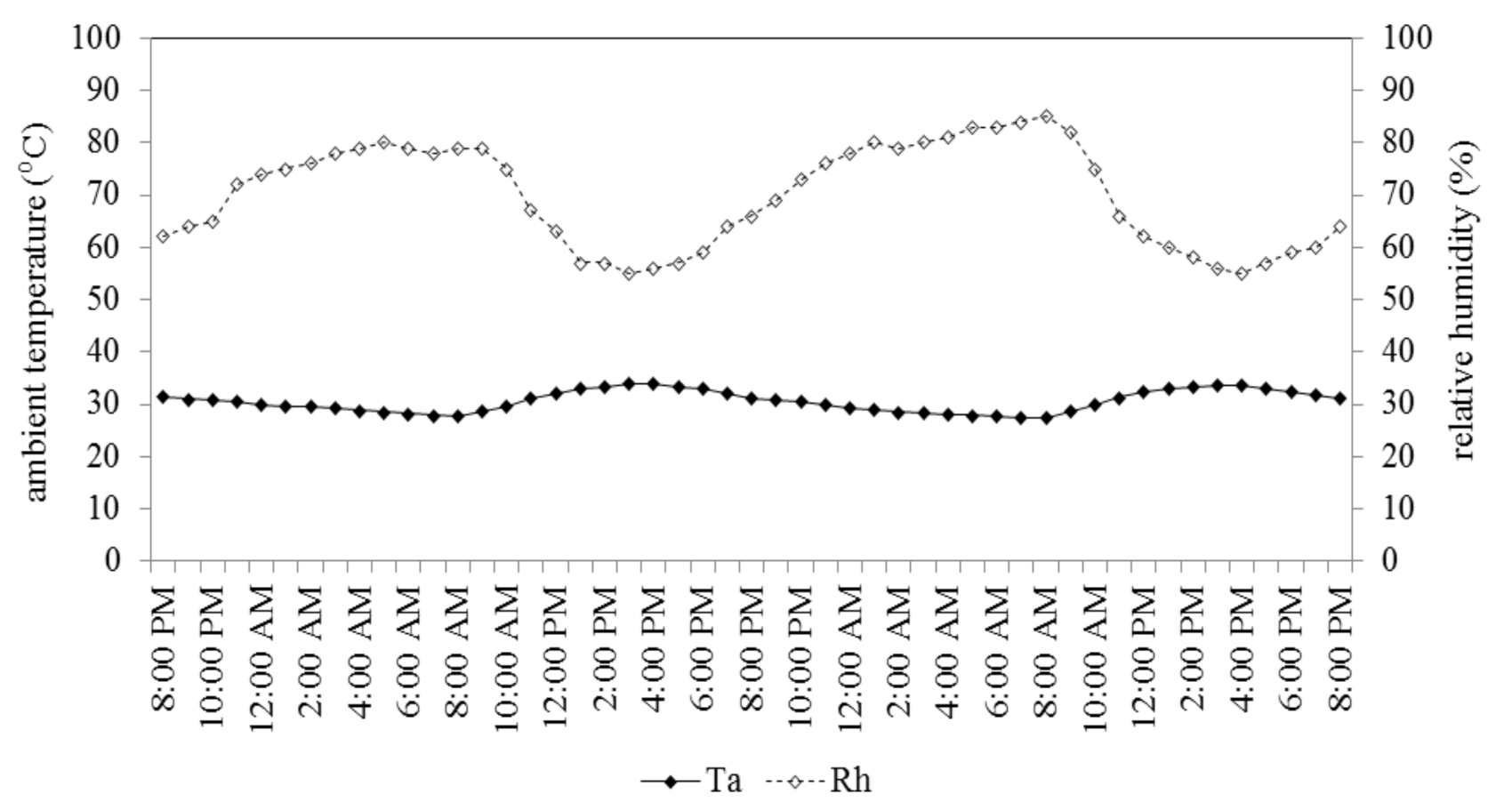

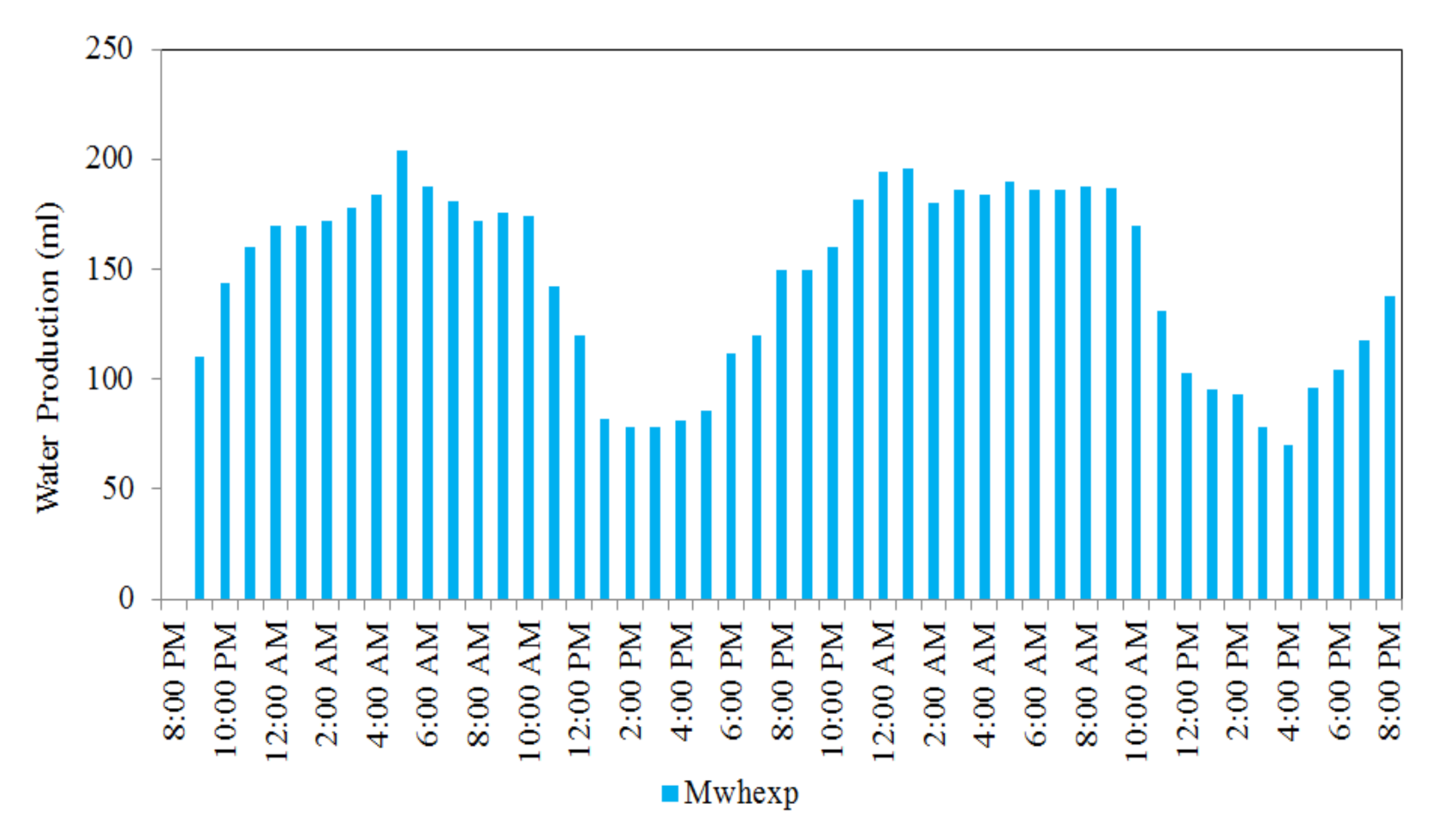

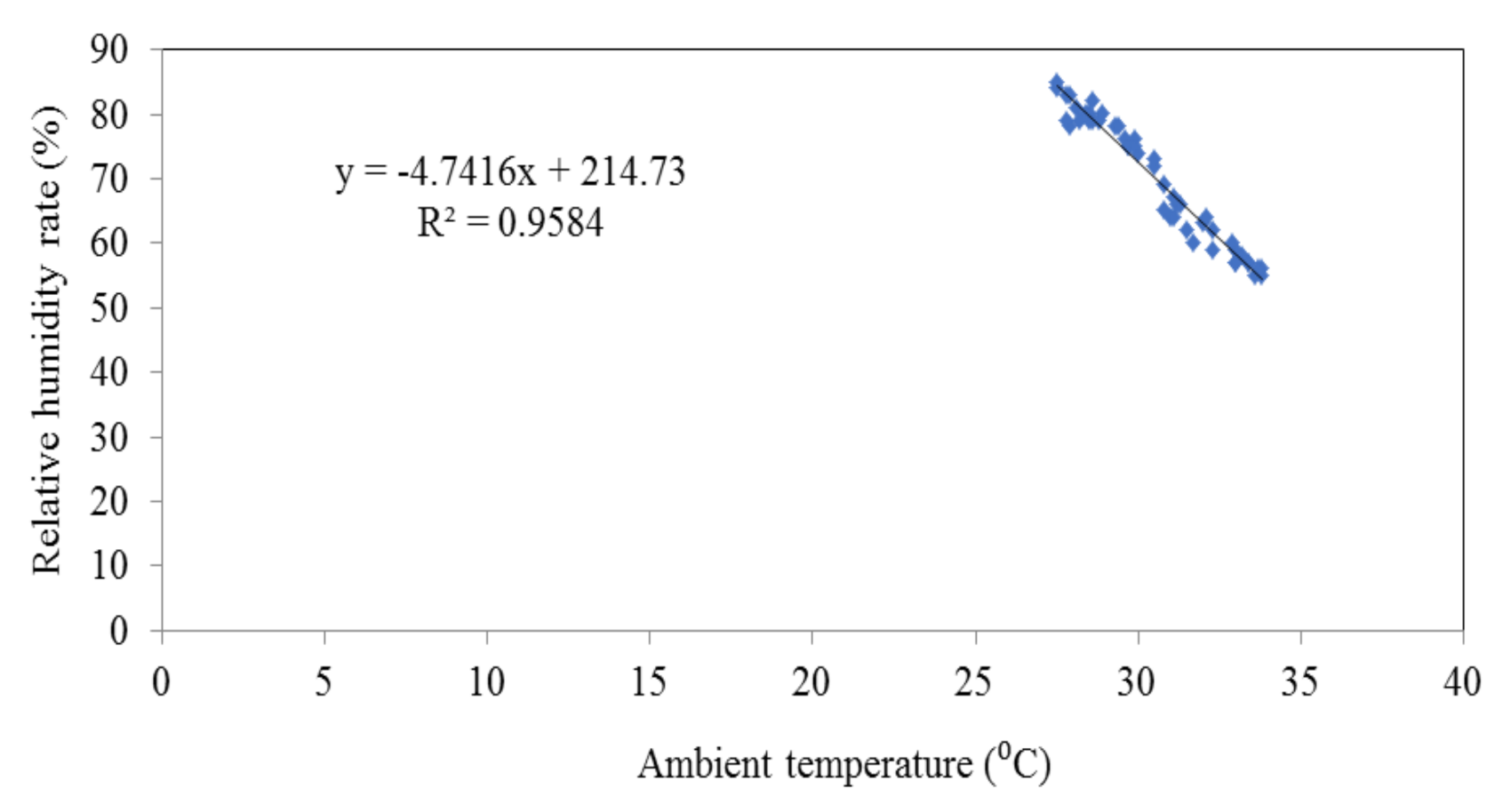

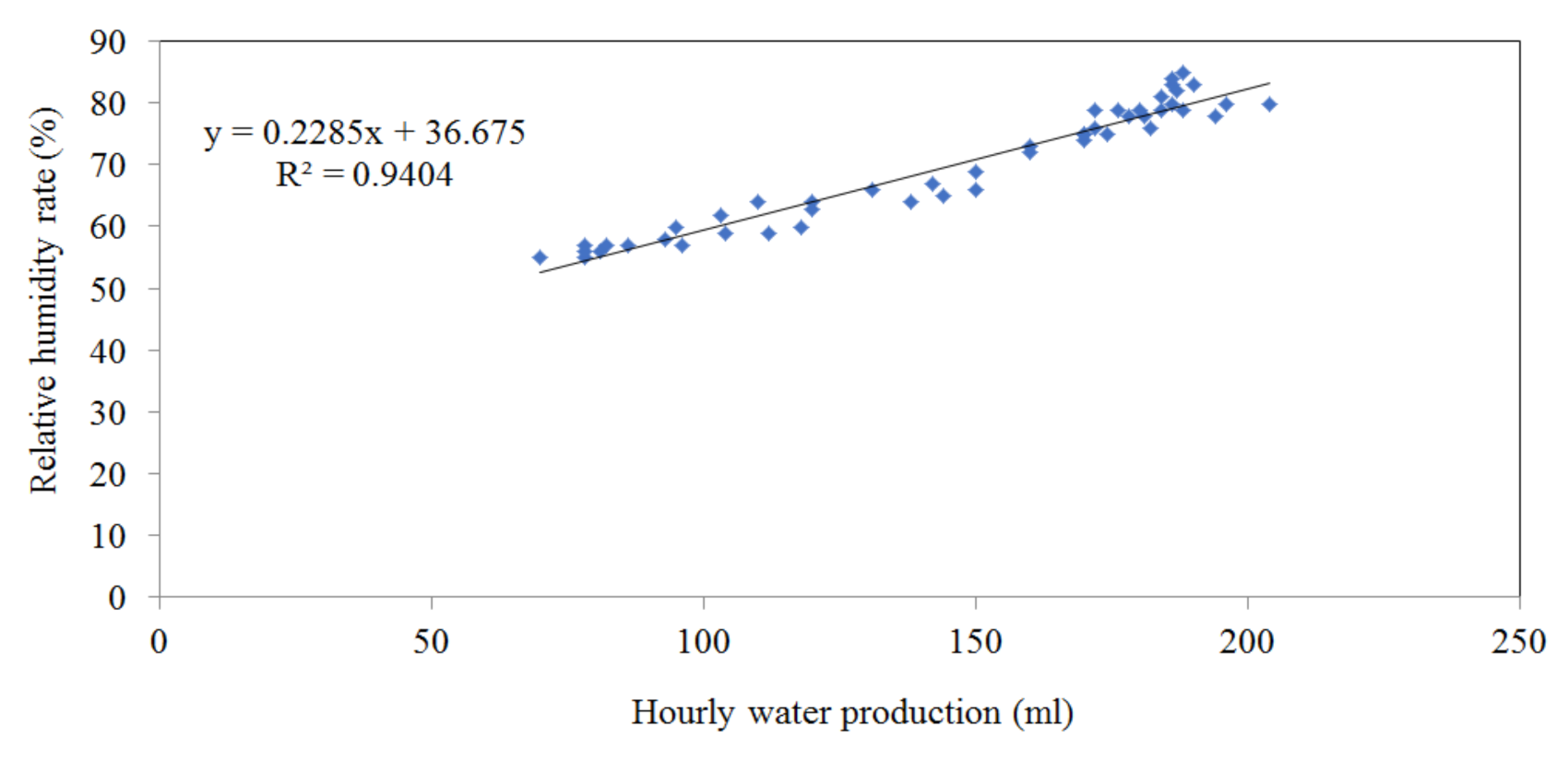

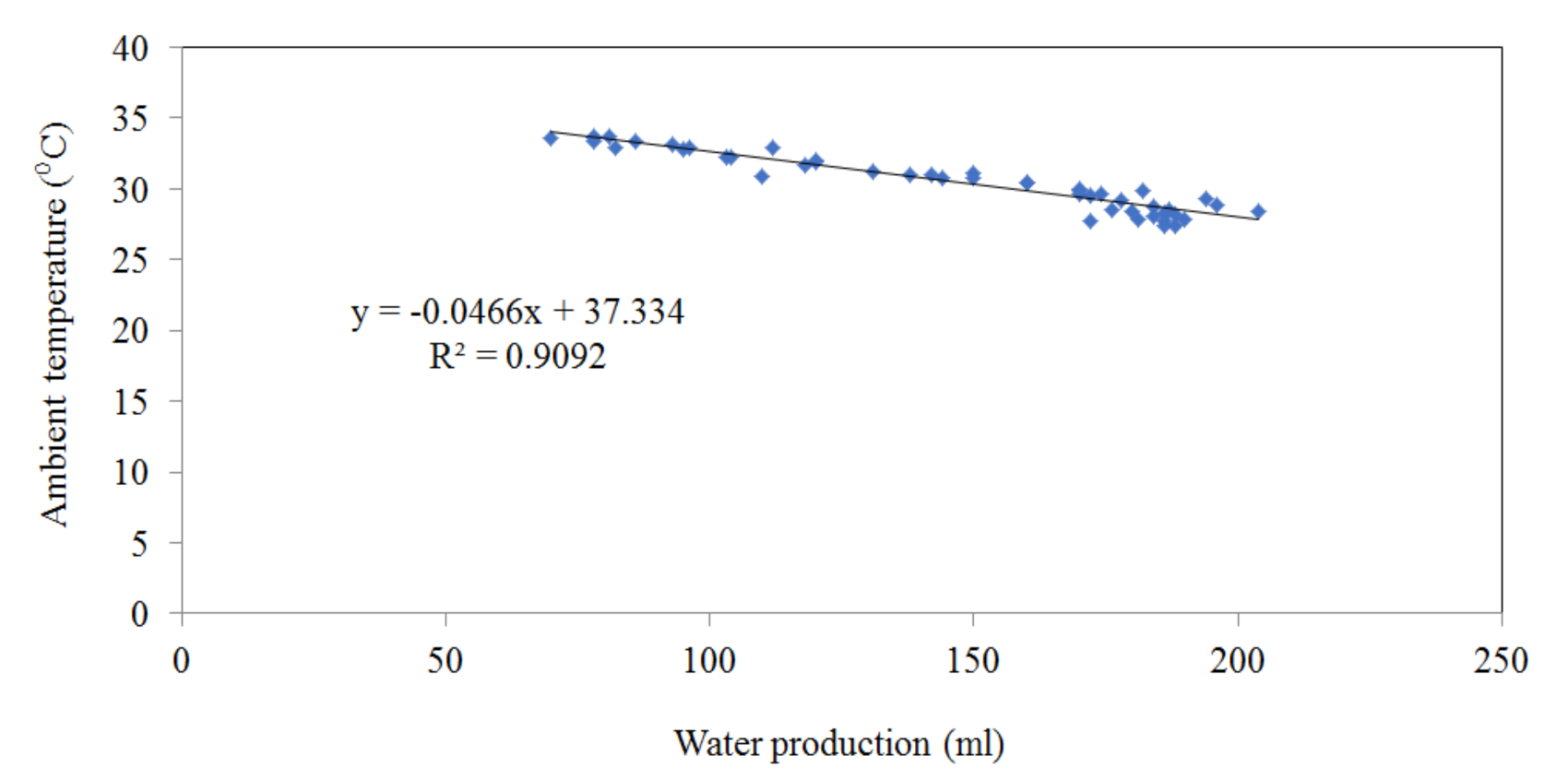

3.1. Impact of the Rates of Relative Humidity and Ambient Temperature on Water Production of the MSAWG

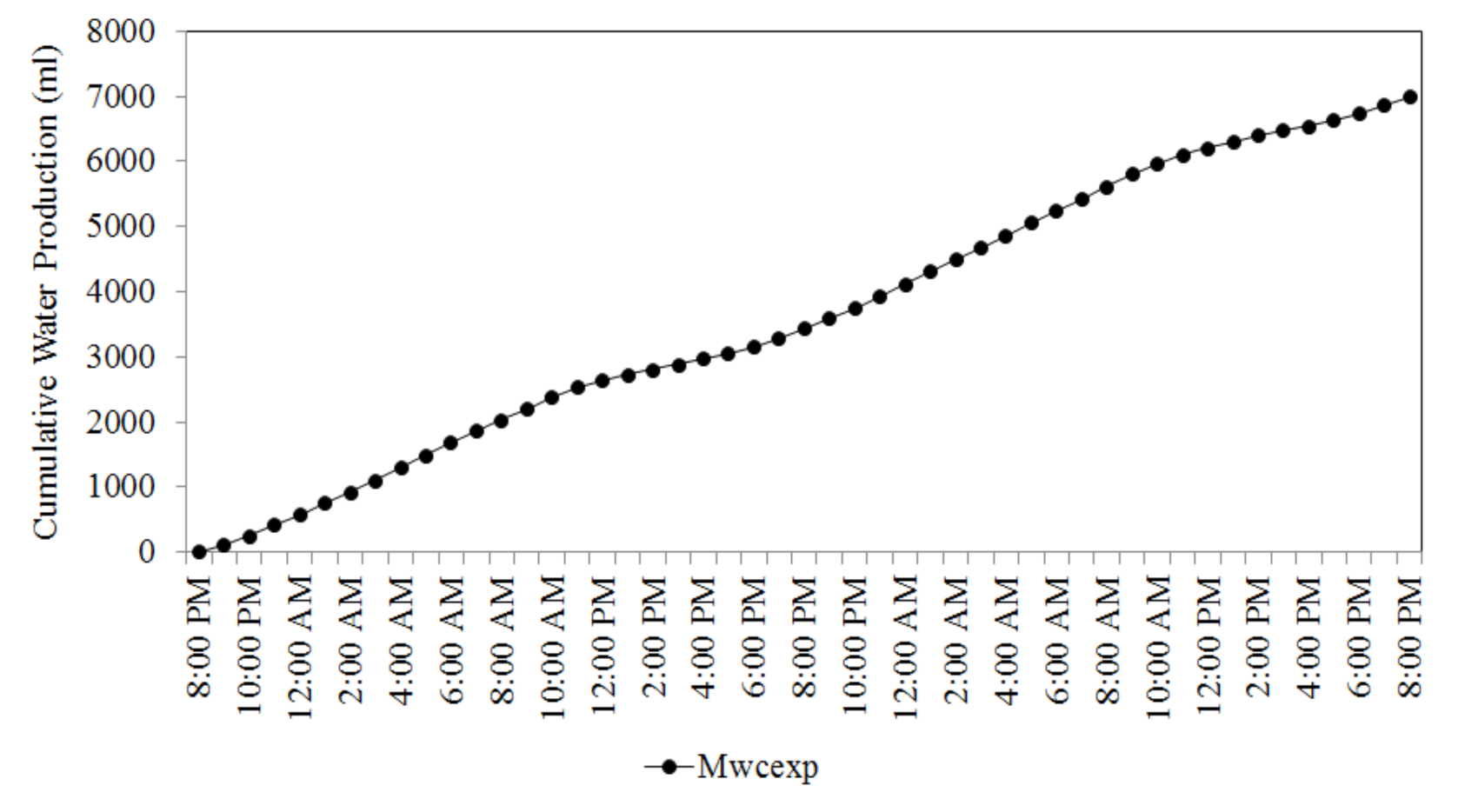

3.2. Cumulative Water Production of MSAWG

3.3. Cost Study and Analysis of the Medium-Scale AWG (MSAWG) in This Work

3.4. Water Quality Analysis

4. Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- World Health Organization. Global Costs and Benefits of Drinking-Water Supply and Sanitation Interventions to Reach the MDG Target and Universal Coverage, 1st ed.; WHO Press: Geneva, Switzerland, 2012; pp. 1–67. [Google Scholar]

- Global Humidity Index Map. Available online: http://watermakerindia.com/images/globel-humidity.jpg (accessed on 15 January 2020).

- Solar Greenhouses. Available online: http://www.roperld.com/science/solargreenhouses.htm?detailedgreenhouses=3496418288#humidity (accessed on 20 March 2019).

- Holiday Weather. Malaysia Weather Overview. Available online: https://www.holiday-weather.com/country/malaysia (accessed on 17 January 2020).

- Milani, D.; Qadir, A.; Vassallo, A.; Chiesa, M.; Abbas, A. Experimentally validated model for atmospheric water generation using a solar assisted desiccant dehumidification system. Energy Build. 2014, 77, 236–246. [Google Scholar] [CrossRef]

- Joshi, V.P.; Joshi, V.S.; Kothari, H.A.; Mahajan, M.D.; Chaudhari, M.B.; Sant, K.D. Experimental Investigations on a Portable Fresh Water Generator Using a Thermoelectric Cooler. Energy Procedia 2017, 109, 161–166. [Google Scholar] [CrossRef]

- Vian, J.G.; Astrain, D.; Dominguez, M. Numerical modelling and a design of a thermoelectric dehumidifier. Appl. Therm. Eng. 2002, 22, 407–422. [Google Scholar] [CrossRef]

- He, W.; Yu, P.; Hu, Z.; Lv, S.; Qin, M.; Yu, C. Experimental study and performance analysis of a portable atmospheric water generator. Energies 2019, 13, 73. [Google Scholar] [CrossRef]

- Tan, F.; Fok, S. Experimental testing and evaluation of parameters on the extraction of water from air using thermoelectric coolers. J. Test. Eval. 2013, 41, 96–103. [Google Scholar] [CrossRef]

- Water harvesting for young trees using Peltier modules powered by photovoltaic solar energy. Comput. Electron. Agric. 2013, 93, 60–67. [CrossRef]

- Liu, S.; He, W.; Hu, D.; Chen, D.; Wu, X.; Xu, F.; Li, S. Experimental analysis of a portable atmospheric water generator by thermoelectric cooling method. Energy Procedia 2017, 142, 1609–1614. [Google Scholar] [CrossRef]

- World Health Organization. Guidelines for Drinking-Water Quality, 4th ed.; WHO Press: Geneva, Switzerland, 2011. [Google Scholar]

| Parameters | Values of a DC Peltier Module | Values of a DC Cooling Fan | Values of the AC Axial Ventilation Fan | Values of a Power Supply of DC to AC Converter (Input) | Values of a Power Supply of DC to AC Converter (Output) |

|---|---|---|---|---|---|

| Working current (Imax) | 5.8A | 0.12A | 0.20A | 1.46A | 33A |

| Rated Voltage | 12V | 12V | 220V | 90V | 12V |

| Maximum Voltage | 15V | 12V | 265V | 275V | 12V |

| Pmax | 60 W | 1.44W | 55W | 400W | 400W |

| Items | Quantity | Unit Cost (RM) | Cost (RM) |

|---|---|---|---|

| Acrylic sheet | 1.5 m2 | 3.00 | 4.50 |

| TEC unit | 18 | 30.00 | 540.00 |

| Axial ventilation fan | 1 | 60.00 | 60.00 |

| Silicon glue | 2 | 5.00 | 10.00 |

| Power supply of DC to AC converter | 6 | 100.00 | 600.00 |

| Metal Frame | 6 m | 2.00 | 12.00 |

| Wooden box | 0.32 m2 | 5.00 | 1.60 |

| Total fixed cost | 1228.10 |

| Items Are Expected to Be Replaced Annually | Expected Quantity of the Items to Be Replaced Annually | Unit Cost (RM) | The Annual Maintenance Cost of Items (RM) | Total Annual Maintenance Cost (RM) |

|---|---|---|---|---|

| Peltier modules | 6 | 10.00 | 60.00 | 368.00 |

| DC cooling fans | 6 | 8.00 | 48.00 | |

| Axial ventilation fan | 1 | 60.00 | 60.00 | |

| Power supply of DC to AC converters | 2 | 100.00 | 200.00 |

| Cost of 1 KWh Power Consumption in Malaysia in 2020 (RM) | The Hourly Power Consumed by MSAWG (KW.hr) | Total Cost of the Power Consumed by MSAWG Annually (RM) |

|---|---|---|

| 0.20 | 1.0 | 1752.00 |

| Instruments | Range | Accuracy |

|---|---|---|

| Digital multimeter | 0–100 °C | ±1 °C |

| Digital humidity meter | 10–99% | ±5% |

| Anemometer | 0.2–30 m/s | ±0.015 m/s |

| Measuring cylinder | ±0.5 ml | 0–50 ml |

| Water Quality Parameter | Generated Water from the MSAWG | WHO Drinking Water Standards [12] |

|---|---|---|

| pH | 7.38 | 6.5–8.0 |

| Total suspended solids (mg/L) | 1 | <250 |

| Ammonia nitrogen (mg/L) | 0.33 | <1.5 |

| Nitrate (mg/L) | 0.2 | <50 |

| Chemical oxygen demand (mg/L) | 0 | <10 |

| Turbidity (NTU) | 0.37 | <5 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Riahi, A.; Zakaria, N.A.; Noh, N.M.; Mat Amin, M.Z.; Mat Jusoh, A.; Mohamad Ideris, M.; Muhammad, M.Z.; Ramli, M.A.; Mohd Arif Zainol, M.R.R.; Shaharuddin, S.; et al. Performance Investigation of 18 Thermoelectric Cooler (TEC) Units to Supply Continuous Daily Fresh Water from Malaysia’s Atmosphere. Sustainability 2021, 13, 1399. https://doi.org/10.3390/su13031399

Riahi A, Zakaria NA, Noh NM, Mat Amin MZ, Mat Jusoh A, Mohamad Ideris M, Muhammad MZ, Ramli MA, Mohd Arif Zainol MRR, Shaharuddin S, et al. Performance Investigation of 18 Thermoelectric Cooler (TEC) Units to Supply Continuous Daily Fresh Water from Malaysia’s Atmosphere. Sustainability. 2021; 13(3):1399. https://doi.org/10.3390/su13031399

Chicago/Turabian StyleRiahi, Ali, Nor Azazi Zakaria, Nasir Md Noh, Mohd Zaki Mat Amin, Azman Mat Jusoh, Marini Mohamad Ideris, Mohd Zharif Muhammad, Mohd Asri Ramli, Mohd Remy Rozainy Mohd Arif Zainol, Syafiq Shaharuddin, and et al. 2021. "Performance Investigation of 18 Thermoelectric Cooler (TEC) Units to Supply Continuous Daily Fresh Water from Malaysia’s Atmosphere" Sustainability 13, no. 3: 1399. https://doi.org/10.3390/su13031399

APA StyleRiahi, A., Zakaria, N. A., Noh, N. M., Mat Amin, M. Z., Mat Jusoh, A., Mohamad Ideris, M., Muhammad, M. Z., Ramli, M. A., Mohd Arif Zainol, M. R. R., Shaharuddin, S., & Yusof, M. F. (2021). Performance Investigation of 18 Thermoelectric Cooler (TEC) Units to Supply Continuous Daily Fresh Water from Malaysia’s Atmosphere. Sustainability, 13(3), 1399. https://doi.org/10.3390/su13031399