Towards Effective Safety Cost Budgeting for Apartment Construction: A Case Study of Occupational Safety and Health Expenses in South Korea

Abstract

1. Introduction

2. Literature Review

3. Materials and Methods

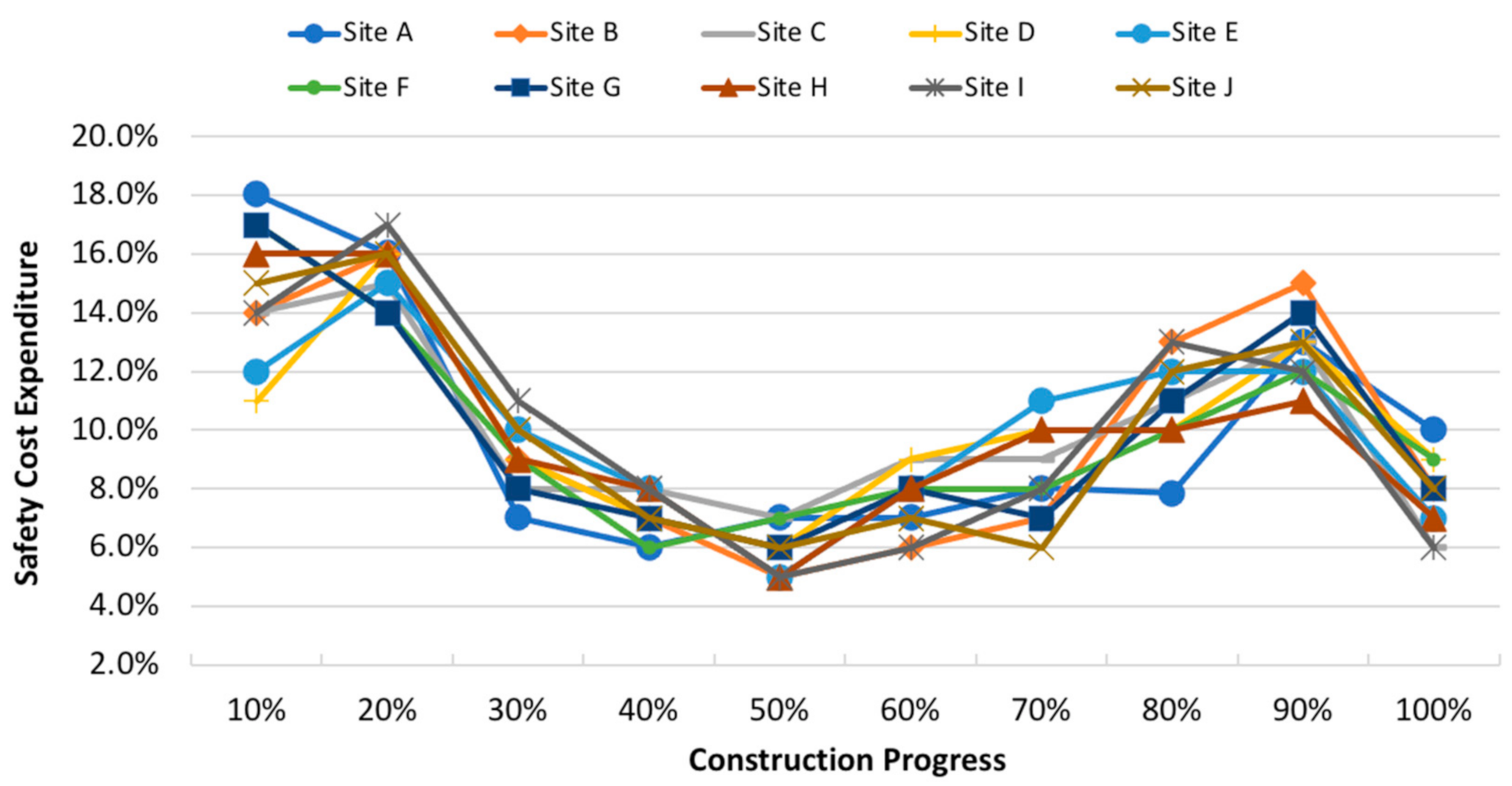

3.1. Occupational Safety and Health Expenses in Case Study

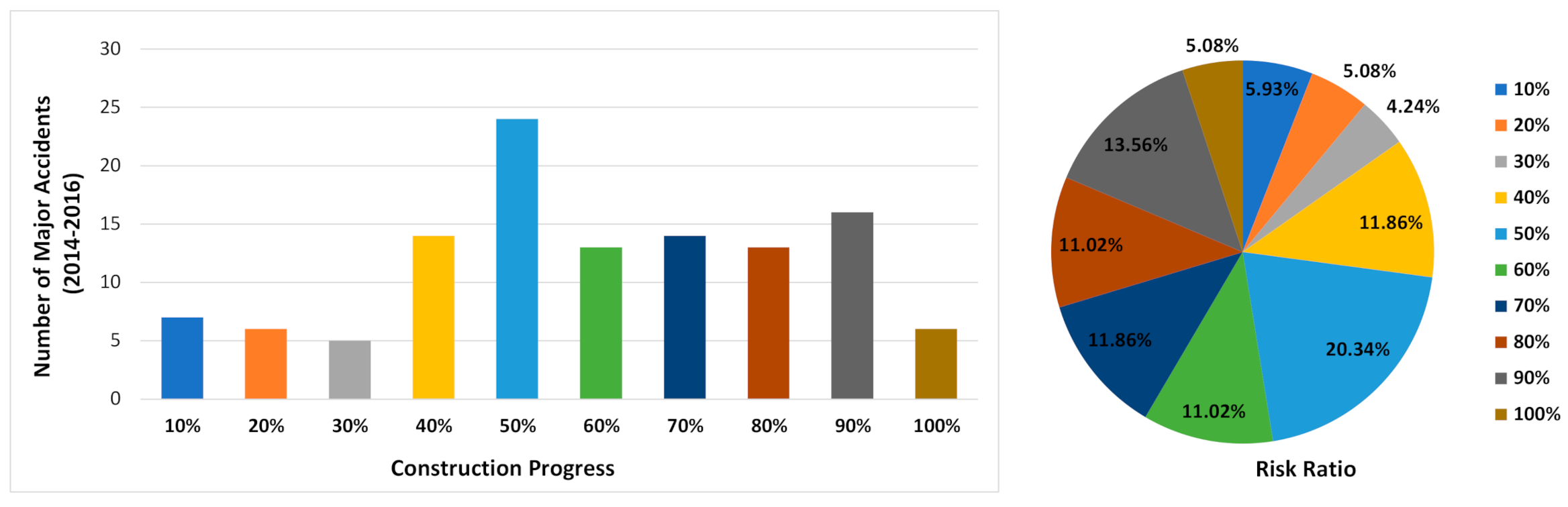

3.2. Accident Risk Index

4. Case Study Data Analysis

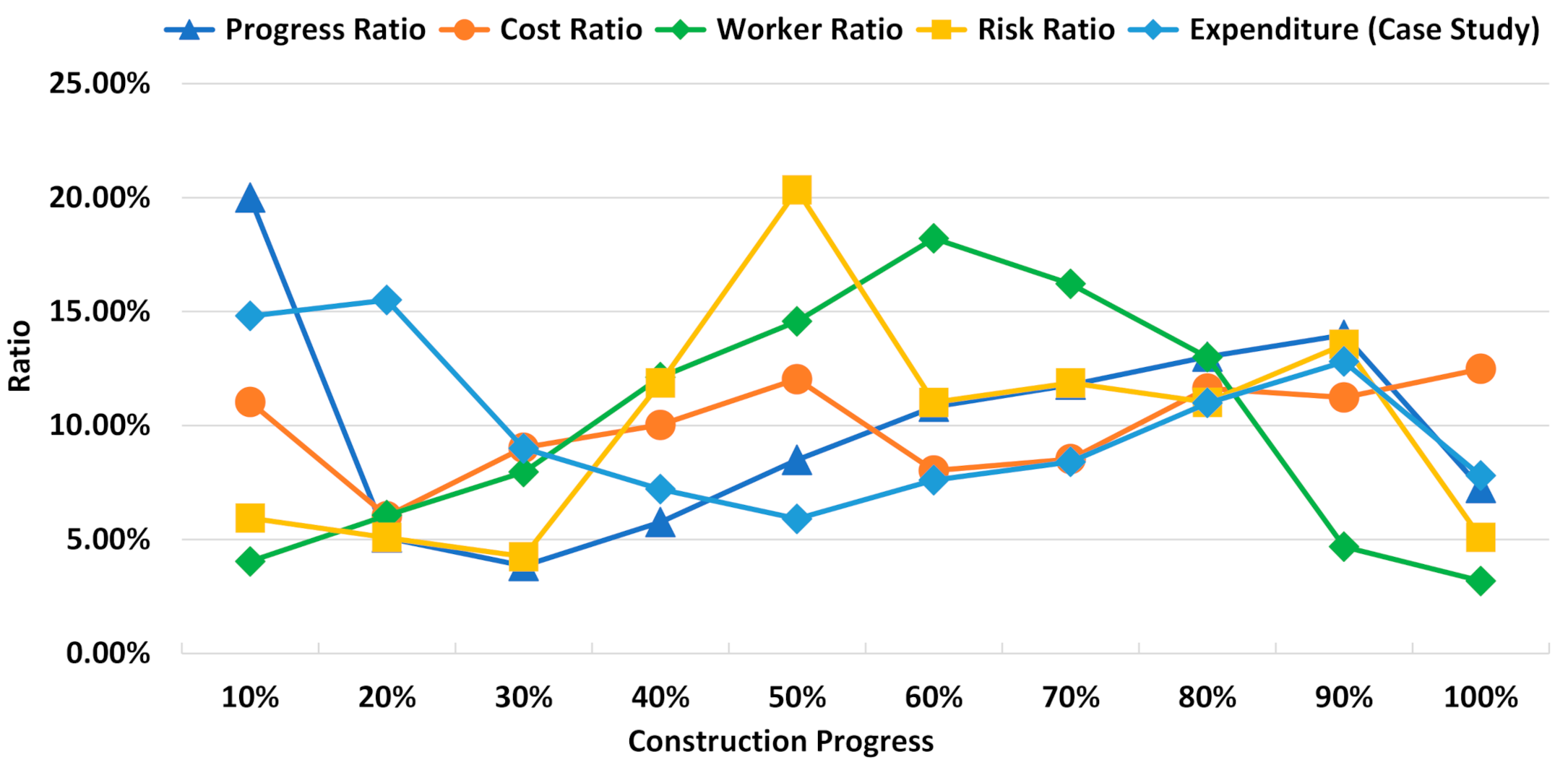

4.1. Trends of Safety Expenditures and Computations for Progress, Cost, Worker, and Risk Ratios

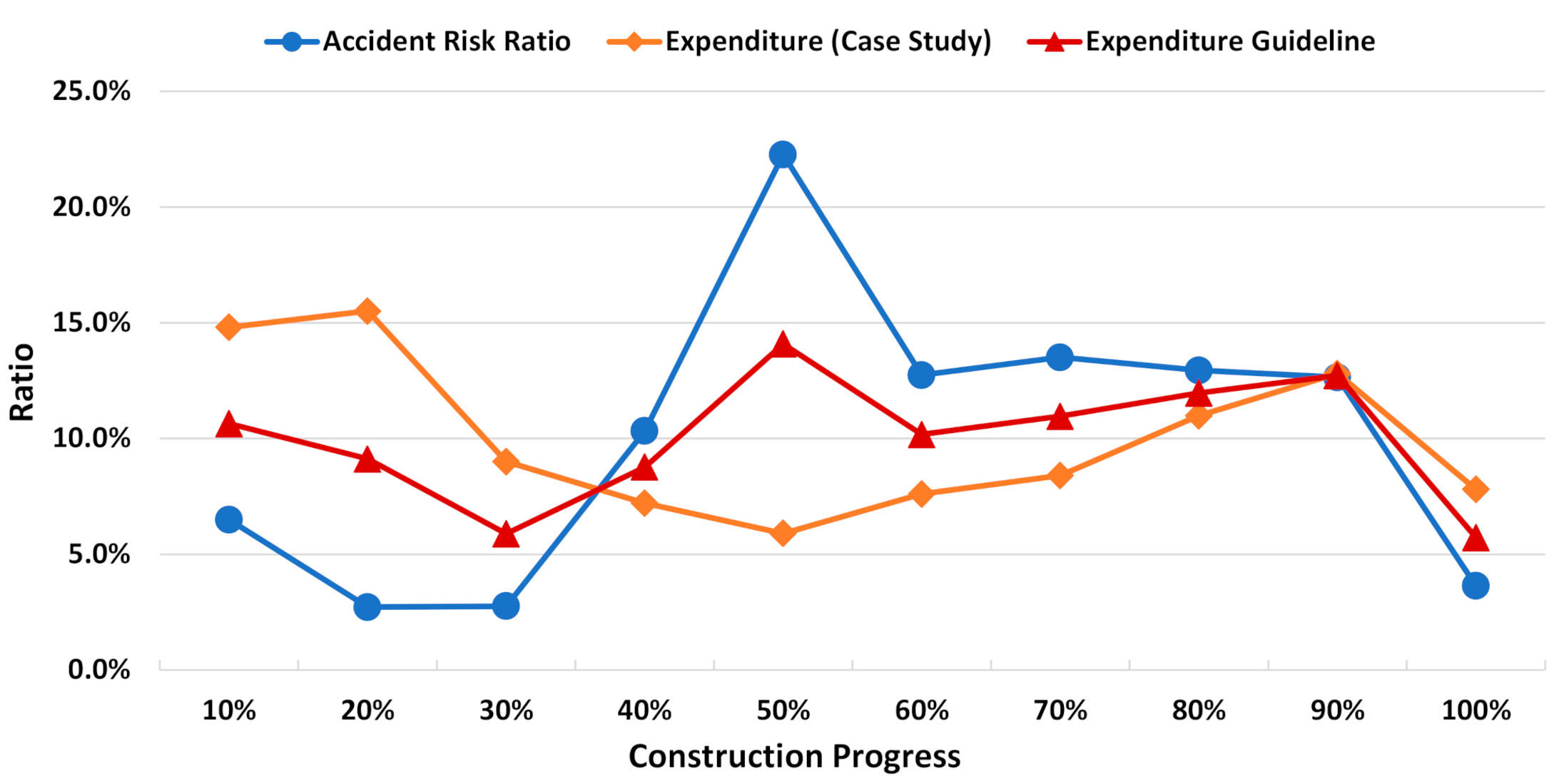

4.2. Accident Risk Index for Safety Cost Budgeting

5. Conclusions

Author Contributions

Funding

Data Availability Statement

Conflicts of Interest

References

- Choi, S.D.; Guo, L.; Kim, J.; Xiong, S. Comparison of Fatal Occupational Injuries in Construction Industry in the United States, South Korea, and China. Int. J. Ind. Erg. 2019, 71, 64–74. [Google Scholar] [CrossRef]

- Fang, D.; Wu, H. Development of a Safety Culture Interaction (SCI) Model for Construction Projects. Saf. Sci. 2013, 57, 138–149. [Google Scholar] [CrossRef]

- Wanberg, J.; Harper, C.; Hallowell, M.; Rajendran, S. Relationship between Construction Safety and Quality Performance. J. Constr. Eng. Manag. 2013, 139, 04013003. [Google Scholar] [CrossRef]

- Fang, D.; Wu, C.; Wu, H. Impact of the Supervisor on Worker Safety Behavior in Construction Projects. J. Manag. Eng. 2015, 31, 04015001. [Google Scholar] [CrossRef]

- Korea Occupational Safety and Health Agency Statistics of Occupational Accidents in 2018. Available online: http://www.kosha.or.kr/kosha/data/industrialAccidentStatus.do?mode=view&articleNo=410303&article.offset=0&articleLimit=10 (accessed on 19 October 2020).

- Sunindijo, R.Y.; Zou, P.X. Political Skill for Developing Construction Safety Climate. J. Constr. Eng. Manag. 2012, 138, 605–612. [Google Scholar] [CrossRef]

- Chang, D.-S.; Tsai, Y.-C. Investigating the Long-Term Change of Injury Pattern on Severity, Accident Types and Sources of Injury in Taiwan’s Manufacturing Sector between 1996 and 2012. Saf. Sci. 2014, 68, 231–242. [Google Scholar] [CrossRef]

- Fabiano, B.; Parentini, I.; Ferraiolo, A.; Pastorino, R. A Century of Accidents in the Italian Industry: Relationship with the Production Cycle. Saf. Sci. 1995, 21, 65–74. [Google Scholar] [CrossRef]

- Dong, X.S.; Choi, S.D.; Borchardt, J.G.; Wang, X.; Largay, J.A. Fatal Falls from Roofs among US Construction Workers. J. Saf. Res. 2013, 44, 17–24. [Google Scholar] [CrossRef]

- Sawacha, E.; Naoum, S.; Fong, D. Factors Affecting Safety Performance on Construction Sites. Int. J. Proj. Manag. 1999, 17, 309–315. [Google Scholar] [CrossRef]

- Yi, K.-J. Preventive Occupational Health and Safety Expense Estimation Method Based on Fatality Statistics and Progress Model. J. Korea Inst. Build. Constr. 2017, 17, 191–197. [Google Scholar] [CrossRef][Green Version]

- Baek, Y.; Wee, K.; Baek, I.; Kim, J. A Study on Improvement of Occupational Safety and Health Management Cost Accounting Standards. Korean J. Constr. Eng. Manag. 2020, 21, 39–46. [Google Scholar]

- Durdyev, S.; Mohamed, S.; Lay, M.L.; Ismail, S. Key Factors Affecting Construction Safety Performance in Developing Countries: Evidence from Cambodia. Constr. Econ. Build. 2017, 17, 48. [Google Scholar] [CrossRef]

- Mohamed, S. Empirical Investigation of Construction Safety Management Activities and Performance in Australia. Saf. Sci. 1999, 33, 129–142. [Google Scholar] [CrossRef]

- Shafique, M.; Rafiq, M. An Overview of Construction Occupational Accidents in Hong Kong: A Recent Trend and Future Perspectives. Appl. Sci. 2019, 9, 2069. [Google Scholar] [CrossRef]

- Jo, B.W.; Lee, Y.S.; Kim, J.H.; Khan, R.M.A. Trend Analysis of Construction Industrial Accidents in Korea from 2011 to 2015. Sustainability 2017, 9, 1297. [Google Scholar] [CrossRef]

- Yang, K.; Ahn, C.R.; Vuran, M.C.; Aria, S.S. Semi-Supervised near-Miss Fall Detection for Ironworkers with a Wearable Inertial Measurement Unit. Autom. Constr. 2016, 68, 194–202. [Google Scholar] [CrossRef]

- Yang, K.; Ahn, C.R.; Vuran, M.C.; Kim, H. Collective Sensing of Workers’ Gait Patterns to Identify Fall Hazards in Construction. Autom. Constr. 2017, 82, 166–178. [Google Scholar] [CrossRef]

- Kim, H.; Ahn, C.R.; Yang, K. Identifying Safety Hazards Using Collective Bodily Responses of Workers. J. Constr. Eng. Manag. 2017, 143, 04016090. [Google Scholar] [CrossRef]

- Jebelli, H.; Ahn, C.R.; Stentz, T.L. Fall Risk Analysis of Construction Workers Using Inertial Measurement Units: Validating the Usefulness of the Postural Stability Metrics in Construction. Saf. Sci. 2016, 84, 161–170. [Google Scholar] [CrossRef]

- Iverson, R.D.; Erwin, P.J. Predicting Occupational Injury: The Role of Affectivity. J. Occup. Organ. Psychol. 1997, 70, 113–128. [Google Scholar] [CrossRef]

- Sheehy, N.P.; Chapman, A.J. Industrial accidents. In International Review of Industrial and Organizational Psychology 1987; John Wiley & Sons: Oxford, UK, 1987; pp. 201–227. [Google Scholar]

- Oliver, A.; Cheyne, A.; Tomas, J.M.; Cox, S. The Effects of Organizational and Individual Factors on Occupational Accidents. J. Occup. Organ. Psychol. 2002, 75, 473–488. [Google Scholar] [CrossRef]

- Choudhry, R.M.; Fang, D. Why Operatives Engage in Unsafe Work Behavior: Investigating Factors on Construction Sites. Saf. Sci. 2008, 46, 566–584. [Google Scholar] [CrossRef]

- Heinrich, H.W. Industrial Accident Prevention. A Scientific Approach; McGraw-Hill Book Company Inc.: New York, NY, USA; London, UK, 1941. [Google Scholar]

- Blackmon, R.B.; Gramopadhye, A.K. Improving Construction Safety by Providing Positive Feedback on Backup Alarms. J. Constr. Eng. Manag. 1995, 121, 166–171. [Google Scholar] [CrossRef]

- Fleming, M.; Lardner, R. Strategies to Promote Safe Behaviour as Part of a Health and Safety Management System; HSE Books: London, UK, 2002. [Google Scholar]

- Choudhry, R.M. Behavior-Based Safety on Construction Sites: A Case Study. Accid. Anal. Prev. 2014, 70, 14–23. [Google Scholar] [CrossRef] [PubMed]

- Pinto, A.; Nunes, I.L.; Ribeiro, R.A. Occupational Risk Assessment in Construction Industry–Overview and Reflection. Saf. Sci. 2011, 49, 616–624. [Google Scholar] [CrossRef]

- Everett, J.G.; Frank, P.B., Jr. Costs of Accidents and Injuries to the Construction Industry. J. Constr. Eng. Manag. 1996, 122, 158–164. [Google Scholar] [CrossRef]

- Aminbakhsh, S.; Gunduz, M.; Sonmez, R. Safety Risk Assessment Using Analytic Hierarchy Process (AHP) during Planning and Budgeting of Construction Projects. J. Saf. Res. 2013, 46, 99–105. [Google Scholar] [CrossRef]

- Hariri-Ardebili, M.A. Risk, Reliability, Resilience (R3) and beyond in Dam Engineering: A State-of-the-Art Review. Int. J. Disaster Risk Reduct. 2018, 31, 806–831. [Google Scholar] [CrossRef]

- Zacchei, E.; Molina, J.L. Reviewing Arch-Dams’ Building Risk Reduction Through a Sustainability–Safety Management Approach. Sustainability 2020, 12, 392. [Google Scholar] [CrossRef]

- Saaty, T.L. How to Make a Decision: The Analytic Hierarchy Process. Eur. J. Oper. Res. 1990, 48, 9–26. [Google Scholar] [CrossRef]

- Badri, A.; Nadeau, S.; Gbodossou, A. Proposal of a Risk-Factor-Based Analytical Approach for Integrating Occupational Health and Safety into Project Risk Evaluation. Accid. Anal. Prev. 2012, 48, 223–234. [Google Scholar] [CrossRef] [PubMed]

- Padma, T.; Balasubramanie, P. Knowledge Based Decision Support System to Assist Work-Related Risk Analysis in Musculoskeletal Disorder. Knowl. Based Syst. 2009, 22, 72–78. [Google Scholar] [CrossRef]

- Gurcanli, G.E.; Bilir, S.; Sevim, M. Activity Based Risk Assessment and Safety Cost Estimation for Residential Building Construction Projects. Saf. Sci. 2015, 80, 1–12. [Google Scholar] [CrossRef]

| Construction Types | Sizes of Construction Projects | Projects Required to Hire a Safety Manager ** | ||

|---|---|---|---|---|

| Smaller Than 500 million KRW * | Between 500 million KRW * and 5000 million KRW * (Baseline Cost) | More Than 5000 million KRW * | ||

| General Construction (A) | 2.93% | 1.86% (5.349 million KRW *) | 1.97% | 2.15% |

| General Construction (B) | 3.09% | 1.99% (5.499 million KRW *) | 2.10% | 2.29% |

| Heavy Construction | 3.43% | 2.35% (5.4 million KRW *) | 2.44% | 2.66% |

| Railway Construction | 2.45% | 1.57% (4.411 million KRW *) | 1.66% | 1.83% |

| Special Construction | 1.85% | 1.20% (3.25 million KRW *) | 1.27% | 1.31% |

| Median | Min | Max | |

|---|---|---|---|

| Number of Housing Units (EA) | 356 | 303 | 410 |

| Construction Periods (Months) | 28 | 24 | 32 |

| Construction Costs (million KRW) | 37,900 | 32,500 | 45,000 |

| Completion Date (YYYY-MM) | 2016-05 | 2015-02 | 2017-11 |

| Case Study (10 Sites) | Safety Cost Budgeting (Million KRW) | Safety Cost Expenditure Ratio (%) | |||||

|---|---|---|---|---|---|---|---|

| Labor Costs | Material Costs | Safety and Health Expenses | Labor Costs | Protective Device/Safety Facility | Personal Protective Equipment | Other Safety Activities | |

| Site A | 12,478 | 13,212 | 588.3 | 48.7 | 32.6 | 11.2 | 7.5 |

| Site B | 11,700 | 11,700 | 535.9 | 46.3 | 35.7 | 11.9 | 6.1 |

| Site C | 12,639 | 12,639 | 622.7 | 44.9 | 35.4 | 13.2 | 6.5 |

| Site D | 15,750 | 15,750 | 721.4 | 50.3 | 31.8 | 12.7 | 5.2 |

| Site E | 12,032 | 12,032 | 611.3 | 46.2 | 34.5 | 14.5 | 4.8 |

| Site F | 15,365 | 15,365 | 723.8 | 47.4 | 32.3 | 12.5 | 6.8 |

| Site G | 11,154 | 11,154 | 557.3 | 51.8 | 30.6 | 11.4 | 6.2 |

| Site H | 14,580 | 14,580 | 677.1 | 46.1 | 33.2 | 14.6 | 6.1 |

| Site I | 12,578 | 12,578 | 560.9 | 46.5 | 32.0 | 13.9 | 7.6 |

| Site J | 14,972 | 14,972 | 658.6 | 50.4 | 33.6 | 11.1 | 4.7 |

| Case Study (10 Sites) | Construction Progress | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10% | 20% | 30% | 40% | 50% | 60% | 70% | 80% | 90% | 100% | |

| Site A | 105.89 | 94.13 | 41.18 | 35.30 | 41.18 | 41.18 | 47.06 | 46.06 | 76.48 | 58.83 |

| Site B | 75.02 | 85.74 | 48.23 | 37.51 | 26.79 | 32.15 | 37.51 | 69.66 | 80.38 | 42.87 |

| Site C | 87.18 | 93.41 | 49.82 | 49.82 | 43.59 | 56.04 | 56.04 | 68.50 | 80.95 | 37.36 |

| Site D | 79.35 | 115.42 | 64.92 | 50.49 | 43.28 | 64.92 | 72.14 | 72.14 | 93.78 | 64.92 |

| Site E | 73.36 | 91.70 | 61.13 | 48.91 | 30.57 | 48.91 | 67.25 | 73.36 | 73.36 | 42.79 |

| Site F | 123.05 | 101.34 | 65.14 | 43.43 | 50.67 | 57.91 | 57.91 | 72.38 | 86.86 | 65.14 |

| Site G | 94.74 | 78.02 | 44.58 | 39.01 | 33.44 | 44.58 | 39.01 | 61.30 | 78.02 | 44.58 |

| Site H | 108.33 | 108.33 | 60.93 | 54.16 | 33.85 | 54.16 | 67.70 | 67.70 | 74.47 | 47.39 |

| Site I | 78.53 | 95.36 | 61.70 | 44.87 | 28.05 | 33.65 | 44.87 | 72.92 | 67.31 | 33.65 |

| Site J | 98.80 | 105.38 | 65.86 | 46.11 | 39.52 | 46.11 | 39.52 | 79.04 | 85.62 | 52.69 |

| Case Study (10 Sites) | Construction Progress | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10% | 20% | 30% | 40% | 50% | 60% | 70% | 80% | 90% | 100% | |

| Site A | 30 | 45 | 56 | 90 | 110 | 136 | 120 | 91 | 29 | 23 |

| Site B | 25 | 33 | 53 | 75 | 89 | 95 | 108 | 92 | 24 | 22 |

| Site C | 33 | 50 | 58 | 91 | 113 | 141 | 121 | 95 | 30 | 25 |

| Site D | 36 | 51 | 67 | 103 | 119 | 156 | 127 | 101 | 49 | 28 |

| Site E | 28 | 42 | 55 | 85 | 108 | 135 | 115 | 92 | 39 | 21 |

| Site F | 33 | 47 | 63 | 96 | 101 | 142 | 119 | 97 | 42 | 26 |

| Site G | 26 | 38 | 52 | 76 | 94 | 115 | 102 | 83 | 31 | 19 |

| Site H | 35 | 51 | 59 | 95 | 117 | 153 | 127 | 98 | 32 | 25 |

| Site I | 26 | 36 | 51 | 72 | 91 | 99 | 104 | 90 | 30 | 20 |

| Site J | 21 | 49 | 62 | 98 | 115 | 158 | 131 | 99 | 35 | 21 |

| Attributes | Construction Progress | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 10% | 20% | 30% | 40% | 50% | 60% | 70% | 80% | 90% | 100% | ||

| Progress | Avg. (days) | 146 | 37 | 28 | 42 | 62 | 79 | 86 | 95 | 102 | 53 |

| Ratio (%) | 20.00 | 5.07 | 3.84 | 5.75 | 8.49 | 10.82 | 11.78 | 13.01 | 13.97 | 7.26 | |

| Cost | Avg. (million KRW) | 3872 | 2112 | 3168 | 3520 | 4224 | 2816 | 2992 | 4083 | 3942 | 4370 |

| Ratio (%) | 11.03 | 6.02 | 9.02 | 10.03 | 12.03 | 8.02 | 8.52 | 11.63 | 11.23 | 12.48 | |

| Worker | Avg. (workers) | 29 | 44 | 58 | 88 | 106 | 133 | 117 | 94 | 34 | 23 |

| Ratio (%) | 4.04 | 6.06 | 7.95 | 12.12 | 14.57 | 18.20 | 16.21 | 13.00 | 4.68 | 3.17 | |

| Risk | Events | 7 | 6 | 5 | 14 | 24 | 13 | 14 | 13 | 16 | 6 |

| Ratio (%) | 5.93 | 5.08 | 4.24 | 11.86 | 20.34 | 11.02 | 11.86 | 11.02 | 13.56 | 5.08 | |

| Construction Progress | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10% | 20% | 30% | 40% | 50% | 60% | 70% | 80% | 90% | 100% | |

| Accident Risk Index | 207.97 | 87.12 | 88.23 | 330.89 | 713.73 | 408.18 | 433.01 | 414.79 | 405.17 | 116.38 |

| Accident Risk Ratio | 6.49 | 2.72 | 2.75 | 10.32 | 22.27 | 12.73 | 13.51 | 12.94 | 12.64 | 3.63 |

| Rank | 7 | 10 | 9 | 6 | 1 | 4 | 2 | 3 | 5 | 8 |

| Construction Progress | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| 10% | 20% | 30% | 40% | 50% | 60% | 70% | 80% | 90% | 100% | |

| Accident Risk Ratio | 6.49 | 9.21 | 11.96 | 22.28 | 44.55 | 57.28 | 70.79 | 83.73 | 96.37 | 100 |

| Expenditure Ratio (Case Study) | 14.80 | 30.31 | 39.31 | 46.51 | 52.41 | 60.01 | 68.41 | 79.40 | 92.20 | 100 |

| Expenditure Guideline (Law) | 50 | 50 | 70 | 70 | 90 | |||||

| Expenditure Guideline (Recommended) | 10.65 | 19.76 | 25.63 | 34.39 | 48.48 | 58.65 | 69.60 | 81.56 | 94.28 | 100 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Yang, K.; Kim, K.; Go, S. Towards Effective Safety Cost Budgeting for Apartment Construction: A Case Study of Occupational Safety and Health Expenses in South Korea. Sustainability 2021, 13, 1335. https://doi.org/10.3390/su13031335

Yang K, Kim K, Go S. Towards Effective Safety Cost Budgeting for Apartment Construction: A Case Study of Occupational Safety and Health Expenses in South Korea. Sustainability. 2021; 13(3):1335. https://doi.org/10.3390/su13031335

Chicago/Turabian StyleYang, Kanghyeok, Kiltae Kim, and Seongseok Go. 2021. "Towards Effective Safety Cost Budgeting for Apartment Construction: A Case Study of Occupational Safety and Health Expenses in South Korea" Sustainability 13, no. 3: 1335. https://doi.org/10.3390/su13031335

APA StyleYang, K., Kim, K., & Go, S. (2021). Towards Effective Safety Cost Budgeting for Apartment Construction: A Case Study of Occupational Safety and Health Expenses in South Korea. Sustainability, 13(3), 1335. https://doi.org/10.3390/su13031335