1. Introduction

Seismic and energetic retrofit interventions are one of the main challenges to ensure adequate building safety and comfort. Safety, in a more comprehensive sense, shall include sustainability, in the perspective of contrast to climate change and related risks. Most of existing buildings in the European Union were built without any energy performance requirement: 35% is over 50 years old, and almost 75% are inadequate to the current building standards in terms of energy efficiency, according to the Joint Research Centre report [

1]. Improving energy efficiency of buildings is an essential component to fulfil the EU Commission’s purpose to cut net greenhouse gas emissions by 55% by 2030, respect to 1990, in the EU. With about 34 million Europeans who reported an inability to afford keeping their homes adequately heated in 2018 [

2] renovation and retrofit interventions are also important to tackling energy poverty. In addition, the structural reliability of aged buildings is often inadequate, especially with regards to seismic actions, as observed after recent seismic events in EU seismic-prone countries (e.g., Athens, Greece 1999 [

3,

4]; L’ Aquila, Italy 2009 [

5,

6,

7]; Lorca, Spain 2011 [

8,

9,

10]; Emilia, Italy 2012 [

11,

12]; and Central Italy 2016 [

13,

14]). The observed building collapses due to seismic events resulted in significant economic losses, severe injuries, and loss of human lives.

Both energetic and seismic retrofit present specific aspects that often lead to difficulties in defining intervention solutions that fulfil both targets. Thus, the development and optimization of integrated intervention technologies is a theme of growing importance and interest at international level. Recently, in Italy, a series of fiscal incentives in form of tax credit have been approved and financed in order to ease the implementation of both energetic, seismic and, above all, integrated interventions. It is the case of the so-called “Ecobonus” [

15], for energetic retrofit, “Sismabonus” [

16], for seismic improvements, and the more recent “Superbonus” [

17], which increases the tax credit value up to 110% of the intervention costs.

In this framework, an innovative intervention strategy is proposed. It is defined by the Nested Building (NB) approach, which enables to retrofit and reuse existing buildings by (i) preserving the external envelope, (ii) removing the internal elements, and (iii) inserting a new inner coat layer with high structural and thermal performances. This intervention allows for the integrated design and optimization of both structural and energy retrofit maintaining the façade, so that it can be suitable in presence of historical constraints requiring external preservation [

18].

The feasibility and the efficiency of NBs, in terms of both energy efficiency and seismic performance are here analyzed by taking into consideration the retrofit of unreinforced masonry (URM) existing buildings by means of cross-laminated timber (CLT) panels. CLT is a quasi-rigid composite, commonly formed by an uneven number of timber layers arranged orthogonally to each other; due to its capability to bear both in-plane and out-of-plane loads, CLT can be used for planar elements (floors and walls) [

19,

20,

21,

22]. The integrated intervention requires to couple the external existing walls with CLT panels, in order to improve the global seismic strength, with a new inner insulation system to achieve high thermal efficiency and comfort standard. In addition, the substitution of slabs with lighter CLT floors reduces seismic masses, thus providing an advantage in terms of mechanical behavior of the retrofitted structure.

Figure 1 illustrates a scheme of the NB intervention phases.

The usage of timber elements within masonry buildings dates back to the origin of ancient civilizations, due to the spread of wood sources, the high workability of timber, and the mechanical compatibility of wooden and masonry elements. Timber elements (such as beams, lintels, floors, and roofs) were widely used in the built heritage until the advent of steel and reinforced concrete (r.c.), that restricted them to traditional or handcrafted solutions. The use of r.c. slabs in unreinforced masonry buildings, in place of traditional timber diaphragms, had dire consequences in seismic prone areas, as shown after earthquakes occurred in Italy since 90s [

23,

24].

Then, research has moved towards the rehabilitation of traditional timber components and the improvement of their mechanical characteristics through compatible techniques, whose main lines regard (i) the stiffening of timber diaphragms and (ii) the strengthening of masonry walls through timber frames or panels [

25,

26].

Traditional and innovative strengthening techniques of timber beams were assessed by Valluzzi et al. [

27,

28,

29]: diaphragms strengthening and stiffening techniques above traditional floors (composed by support beams and one simple transverse boarding) were tested in laboratory and good performances were obtained with superimposition of 45° double planking. Experimental and analytical studies on vintage timber floors performances were made by Giongo et al. [

30]. The influence of strengthened timber floors on the dynamic behavior of URM structures were assessed, by means of numerical simulations, in Scotta et al. [

31] and in Salvalaggio et al. [

32]; results showed the importance of floors improvement in the seismic capacity of URM buildings. Nevertheless, the improvements of seismic response due to floors stiffening rely on proper quality of masonry walls and of wall-to-diaphragm connections, which are often a weakness of existing buildings [

33]. Non-retrofitted vintage timber-steel connections and retrofitted ones with new nails were compared in Schiro et al. [

34]. Furthermore, vintage wall-to-diaphragm plate anchors were tested in situ by Dizhur et al. [

35] and Giaretton et al. [

36]. All these last three studies showed that lower performances of vintage specimens can be related, case by case, to both steel connectors and timber status.

Strengthening techniques aimed ai increasing URM walls capacity by coupling with wooden elements rely on (i) the capacity of connectors to bear the loads and (ii) the embedment strength of masonry unit in preventing splitting phenomena. The efficiency of seismic retrofitting of URM walls by means of timber strong-backs were tested and described in [

37,

38], while CLT-URM coupling solutions are shown in [

39], where connections between the two leaves were lumped at the floor levels of the building. An integrated seismic and energetic retrofit intervention with CLT panels was proposed for both URM and r.c. frames in Sustersic et al. [

40,

41]. The intervention consisted in the application of a novel outer shell made of aerogel insulation and CLT and was further investigated through shaking-table tests on two-stories r.c. frames, with, and without, masonry infills [

42]. In Riccadonna et al. [

43], the study of dry connections joining timber and URM suggested the use of mild steel fasteners for clay brick units, whereas hardened carbon steel elements were recommended to prevent brittle failure in stone elements. In this regard, stone masonry-timber elements connections strengthened with injection anchors were tested in Moreira et al. [

44], while a study about tension and shear failure of anchorage systems in limestone, usually found in the heritage built, is described in Shedde et al. [

45]. Very recently, Damiani et al. [

46] proposed a new seismic retrofit technique to strengthen cavity walls by means of timber frames investigated through an extensive experimental campaign. A combined energetic and seismic retrofit intervention that applies CLT panels on existing r.c. frames was proposed by Margani et al. [

47].

Focusing on energy-efficiency, retrofit interventions can be bound to operate only on the inner part of the building envelope, thus preserving the façade (e.g., for historical buildings) and providing an internal insulation system that changes the building hygrothermal conditions. Indeed, several studies focused on the effects and optimization of inner thermal insulation systems by means of experimental tests, monitoring, and simulations [

48,

49,

50,

51]. Moradias et al. [

52] studied the hygrothermal behavior of retrofit solutions applied to the inner surface of old stone masonry rural buildings. The study highlighted the importance of repairing in order to minimize the risk of condensation. Abdul et al. [

53] carried out a hygrothermal analysis on solid brick masonry panels of two case studies, with, and without, an inner thermal insulation system. The research pointed out the increasing risk of mold growth due to solar-driven vapor in case of biological materials on the exterior surface of the vapor barrier. Furthermore, the precipitation uptake was demonstrated to be the strongest factor to favor biological growth.

Focusing on CLT, in new building construction, the good thermal characteristics of timber, coupled with insulation materials, provide excellent energy performance rate, even though, as for most wood products, CLT is subjected to durability problems when exposed to prolonged moisture [

54]. Thus, to guarantee an adequate service life to CLT buildings, hygrothermal performances shall be deeply investigated and fast drying shall be ensured [

55,

56]. Numerical simulations validated by means of small-scale experimental tests also showed that mineral wood insulation shall be avoided to reduce mold growth risk [

57]. In addition, the lack of thermal mass together with the thermal transmittance of CLT increase the risk of overheating in hot season, which shall be taken into account in the design, especially in terms of expected increase in risk of overheating due to climate change [

58,

59].

Nevertheless, currently, the hygrothermal properties of the combined CLT-masonry system have not been fully investigated, due to the strong innovation of the solution.

In this paper, the integrated solution was studied by means of hygrothermal simulations, and of numerical finite element (FE) modelling through two validated software (Dartwin Mold Simulator [

60] and Straus7 [

61]) on an idealized wall panel representing a slender pier. The analyzed configuration allowed the evaluation of both the energetic performance of the section of the hybrid system and the seismic behavior of a single structural element, thus reducing parameters which affect the results. Both stone and clay block masonry were taken into consideration for the existing URM wall; steel bars were used to connect the CLT panel to the masonry wall to improve the seismic response avoiding, at the same time, the development of thermal bridges and the consequent drop in hygrothermal performance.

2. Research Methods

Nested buildings represent an innovative approach to the reuse of existing buildings that permit to reach technological, energy saving and indoor comfort levels comparable to new-built ones. The intervention strategy provides the preservation of the original façades while floor slabs and internal partitions are demolished, and a new inner structure is built up improving both seismic and energy-efficiency performances. Hence, NB intervention is compatible with buildings whose façades have high historical value while it is unsuitable for other heritage buildings subjected to specific limitations. It must be observed that construction phases and construction site planning are fundamental for this type of intervention.

Various solutions are available to create the new internal structure: reinforced concrete, steel, timber frames, and CLT panels. For each type, a brief description of the main features is presented in the following.

R.c. offers high stiffness and adaptability and permits effective structural connections between the new and the existing structure, due to reinforcing bars embedded in the existing wall. Nevertheless, concrete has high thermal transmittance, which causes significant thermal bridges if the structure is not adequately designed. Furthermore, construction site planning for installation and casting can become very complex in presence of the existing structure.

Steel frames also offer effective structural performances but, due to their high slenderness, they tend to develop greater displacements than masonry under seismic actions, especially in the case of historic buildings with very thick walls. To overcome the stiffness difference between the old structure and the new one, steel may need to be prestressed [

62]. The strong precast level of steel structures permits easier installations, thus reducing both construction time and employed labor, even though the structural element dimension strongly affects handling and construction site. In this case, disadvantages refer to the high costs and hygrothermal properties of steel, which has a very high thermal conductivity and could create important variations in the thermal flow.

Timber solutions present the advantages of lightweight and good thermal properties. Timber frames present low stiffness, making them suitable to strengthen thin masonry panels [

46], but it could be insufficient to strengthen thick masonry walls. Instead, CLT panels, thanks to their elevated stiffness, permit to combine the advantages of installation of prefabricated elements with both structural and energetic efficiency, making the intervention very competitive. Moreover, the CLT recyclability guarantees a good sustainability of the intervention lifecycle from both the environmental and economic points of view.

Table 1 summarizes the main features of the above-mentioned available solutions (i.e., reinforced concrete frame, steel frame, wooden frame, and cross-laminated panel).

2.1. Intervention Layout and Configurations

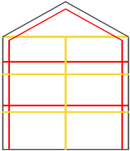

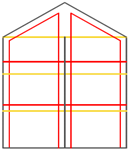

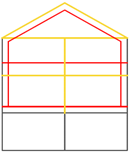

The proposed intervention strategy may have a significant impact, but it guarantees a good degree of adaptability in the recovery and refurbishment phases. A series of intervention schemes were developed and shown in

Table 2 with demolition phases (in yellow) and the assembly of novel structural elements (in red). The intervention can be applied to the entire building envelope or to only a portion of the floors. In the latter case, the portion excluded from the intervention shall be adequately verified to ensure the seismic improvement of the whole structural system. Indeed, the seismic performance improvement is favored by the reduction in seismic masses given by slab substitution with lighter CLT floors. In case of intervention at the ground floor, a foundation system shall be provided to the new inner structure; in other cases, an adequate load transfer system between the new and the existing structures shall be devised. Various retrofitted configurations are provided whether the roof and the internal walls are removed, or they are maintained. Each configuration requires a detailed evaluation of the construction site and installation phases, for instance, the evolution of the structural static scheme (e.g., thrusting roof no longer constrained by the upper floor) or the size of CLT panels that can be managed within the encumbrance of the standing structure. Possibly, provisional structures can be adopted.

The analyzed configurations here presented concern both stone and clay masonry walls connected to a 100 mm thick CLT panel by means of stainless-steel bars grouted with epoxy resin and fastened to CLT by a bolted plate. The mechanical properties of CLT and of Glue Laminated Timber (i.e., the material of the laminate layers), refer to EN 14080:2013 [

63], whereas its hygrothermal properties were in agreement with the Italian code UNI 10351:2015 [

64].

Stainless steel EN 1.4016 (corresponding to AISI 430, according to the Italian code) was used for the connectors, whose mechanical properties refer to EN 10088-3:2014 [

65].

As regards the stone masonry, both an “as-built” wall with weak mortar and a stone masonry consolidated by means of well executed grout injections were taken into consideration. The masonry mechanical characteristics were defined following the Italian seismic code [

66,

67]; according to it, effective grout injections in stonework increase both Young’s modulus and compression strength up to 50%. Wall thickness values were assigned according to the masonry types, as representative of common ranges of the Italian building heritage, resulting in a stone masonry wall 65 cm thick and a hollow clay block masonry wall 30 cm thick. Masonry hygrothermal properties referred to the above-mentioned UNI 10351:2015 [

64].

Table 3,

Table 4 and

Table 5 show the geometric, hygrothermal and mechanical properties of timber elements, steel connectors, and masonry types, respectively.

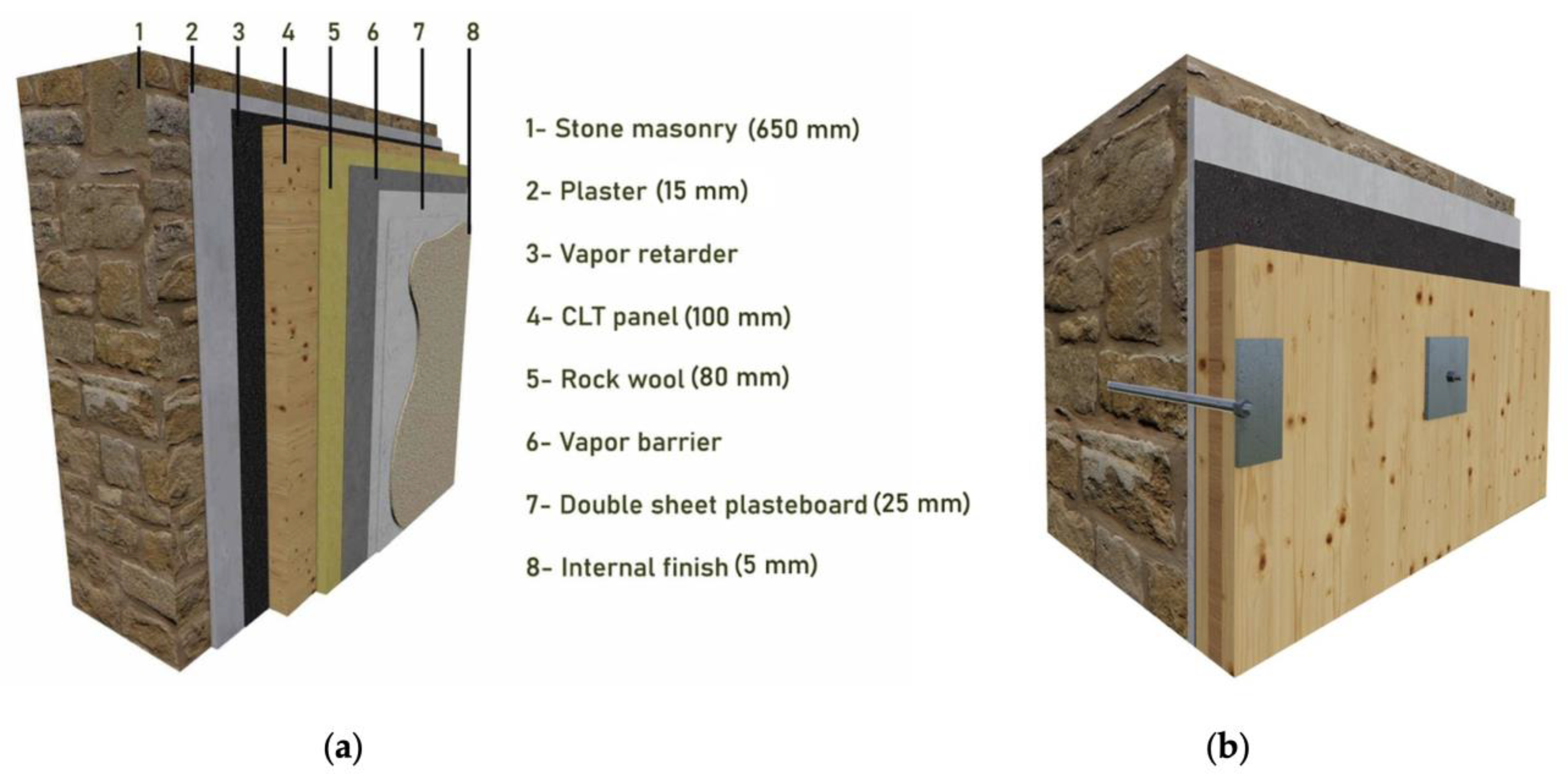

The energy-efficiency retrofit required the realization of an insulation system at the intrados of the CLT panel. The inner stratigraphy analyzed here consisted in a rock wool layer 80 mm thick, a vapor barrier and a double plasterboard sheet. To avoid moisture and mold growth, a vapor retarder was also inserted at the interface between the existing masonry and the wooden panel;

Figure 2 represents, as an example, the intervention on a stone masonry wall. The properties of the inner insulation system components (

Table 6) were assigned according to UNI 10351:2015 [

64].

2.2. Hygrothermal Simulations

Numerical simulations were carried out by means of Dartwin Mold Simulator 4 software [

60], which provides analyses of both bidimensional and tridimensional models of stratigraphy and construction nodes, respectively. This software is based on the parameters and methodologies defined by EN ISO 6946:2017 [

68] and by EN ISO 13786:2017 [

69]. It subdivides the geometric model into a triangular mesh and then the energy conservation laws are applied to the model, resulting in a system of equations depending on the temperature at the mesh nodes. The iterative solution of the system provides the node temperatures. Then, the heat flow through the modelled surface is determined applying the Fourier’s law to the temperature distribution.

For the model implemented in this study, both steady-state and dynamic analyses were carried out. A 2D-model with quadratic elements was developed of the external wall, which was 3 m high, representative of an average interstory height. As boundary conditions, the internal temperature, the minimum external temperature, and the relative humidity were set to 20 °C, 0 °C, and 65%, respectively, as required by current energy saving regulations [

70,

71]. Both the initial and the post-intervention configurations were analyzed. In the latter, four steel connectors 60 cm spaced were applied. The following parameters (with their unit of measurement according to IS) were calculated for each configuration, as defined by EN ISO codes [

68,

69], and used as comparators:

Thermal transmittance under steady-state boundary conditions U (W/m2K)

Periodic thermal transmittance Ymn (W/m2K)

Internal areal heat capacity K1 (kJ/m2K)

Decrement factor f (-)

Thermal time lag Δt (h)

The steady-state thermal transmittance U describes the heat flow through a unit area, in unit time for a unit difference in temperature, assuming steady-state boundary conditions. It is calculated as the reciprocal of the sum of the thermal resistance of each layer of the building partition (R1, R2, … Rn), including external and internal surfaces (Rse, Rsi), and air layers or cavities (Ra).

The periodic thermal transmittance Ymn expresses the thermal transmittance recorded over a 24-h period. This parameter quantifies the ability of a building component to limit the heat flow rate () with dynamic-state boundary conditions, such as the variation of temperature during the day ().

The internal areal heat capacity K

1 describes the capacity of a partition of absorbing heat flowing from its internal to its external side, assuming a unit area per unit difference in temperature in the span of 24 h. This value takes into account the temperature swings on both sides of the surface. The detailed calculation of K

1 was implemented according to Annex C of EN ISO 13786:2017 [

69]. The formulation (

Table 7) is based on the elements (Z

mn) of the heat transfer matrix Z, which relates the complex amplitude of temperature and heat flow rate on one side of a component to that on the other side. Index 1 conventionally refers to the innermost layer, while index 2 indicates the external side. T is the period of the variations.

The decrement factor f is calculated as the ratio between the modulus Ymn and U.

At last, the thermal time lag Δt corresponds to the time delay between the peak of the heat flux and the maximum amplitude of its effects, i.e., the time it takes for the heat waves to pass through each layer of the building partition. This lag occurs because of the heat buffering effect of the wall surfaces and it is proportional to the heat capacity of the building partition.

Table 7 reports the equations of the above-described parameters.

The temperature of the inner surface was also computed for the analyzed configurations, in order to assess the chance of moisture and mold growth and the relative mitigation given by the intervention.

The phenomenon of mold growth and moisture mainly depends on three parameters: the inner temperature, the internal humidity, and the inner surface temperature [

72,

73]. The development of condensation and mold occurs when the surface temperature is lower than the related dew temperature, which represent the saturation point of air [

74]. The dew temperature can be evaluated through the psychrometric chart [

75], also known as Carrier’s chart, which is a graphical representation of the main parameters of humid air at a constant pressure (i.e., dry-bulb temperature, humidity ratio, wet bulb, or saturation temperature). It is commonly used in the literature to evaluate the dew point temperature [

76,

77]. Assuming a relative humidity equal to 65% and an inner dry-bulb temperature [

78,

79] of 20 °C, the resulting dew temperature is 13.2 °C, which represent the minimum threshold value of the inner surface temperature to avoid condensation.

Molds tend to grow in environments with a greater relative humidity equal to 80% [

72]. However, these conditions cannot be neglected, as they represent common humidity peaks linked to various human activities. According to the psychrometric chart, the dew point for the mold growth (with a relative humidity equal to 80% and an inner temperature of 20 °C) corresponds to 16.5 °C.

Section 3.1 shows the results of the hygro-thermal analyses for the “as built” and the retrofitted configurations.

2.3. FE Modeling for Parametric Seismic Analyses

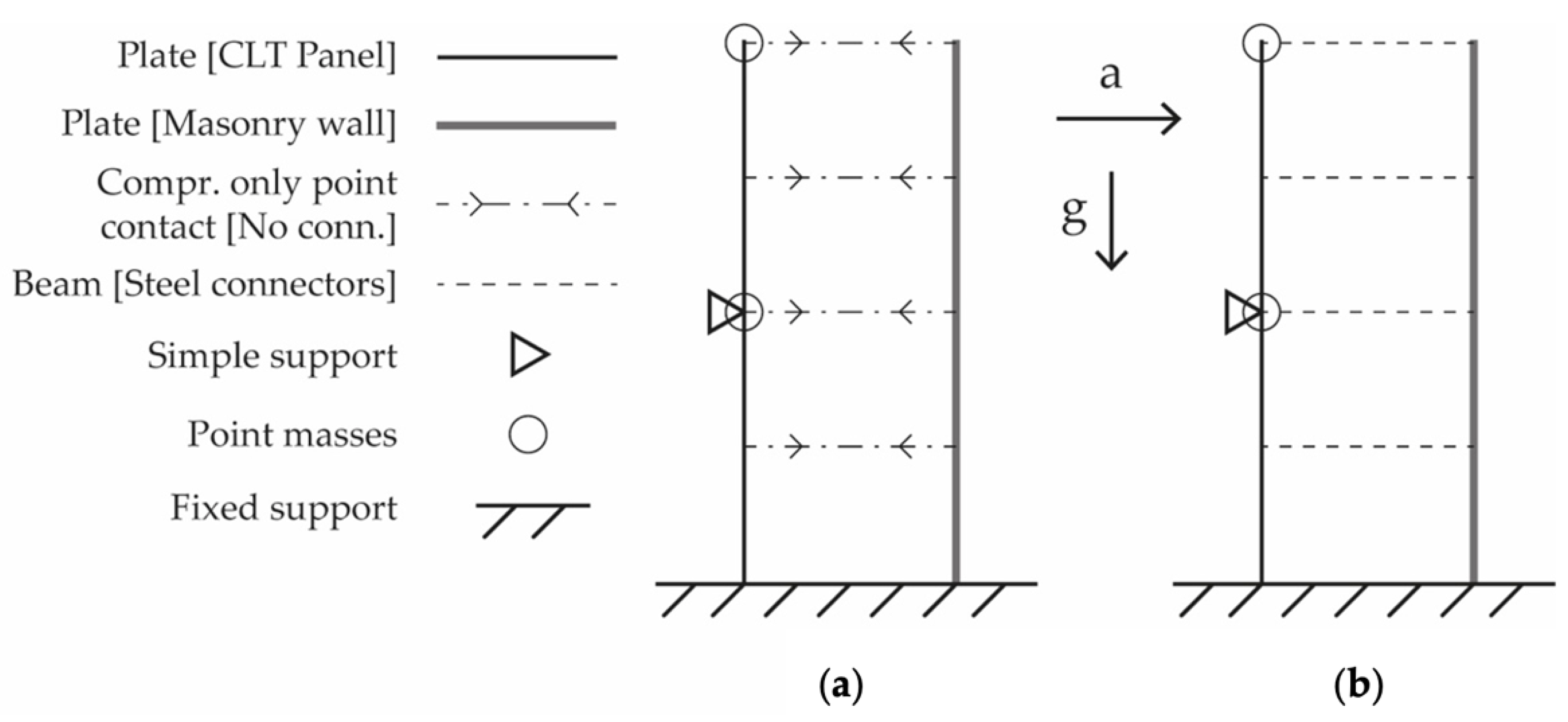

The seismic behavior of the innovative solution was analyzed both in-plane (IP) and out-of-plane (OOP) by a finite element (FE) model of a slender masonry wall, combined with a CLT panel. In addition, a parametric analysis was implemented to evaluate the effectiveness of various degrees of connection, taking into account both masonry types and spacing of the steel connectors. The masonry panel was 6 m high, corresponding to a two-story wall, and 1.2 m wide, to represent a slender pier. This can be traced back to a regular building with a large number of nearby openings.

The FE model was implemented in Straus7 2.4 software [

61] by means of 2D plate elements for the walls, using 8-node quadrilateral elements (QUAD8), and beam elements for connectors; link elements were overlapped to connectors in order to concentrate the shear deformations at the interface between the masonry wall and the CLT panel. The CLT panel OOP displacements were constrained at the floor levels. To evaluate the possible degree of connection, the foundation was considered fixed and the connection to CLT were the only boundaries for the masonry walls. In this configuration, the seismic actions acted from floor masses to CLT panels, while masonry walls bore only self-weight and the consequent seismic inertial forces.

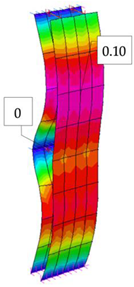

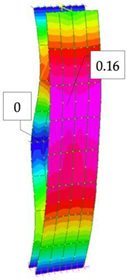

The parametric analysis also took into consideration various modeling schemes and boundary conditions between the CLT panel and the masonry pier (

Figure 3). First, interface contact with no connector was modelled as base configuration, to be used as control model and evaluate the benefits of timber-masonry connections. Then, steel connectors were modelled considering two spacing values, i.e., 120 cm and 60 cm.

An equivalent linear static analysis was implemented accounting for geometric non-linearity, for both IP and OOP directions considering inertial forces compliant with a uniform acceleration of 0.2 g, corresponding to a moderate seismic hazard [

80], applied in 10 steps.

3. Results

3.1. Improvement of Hygrothermal Performance

The numerical simulations provided results to evaluate the thermal improvement given by the proposed intervention.

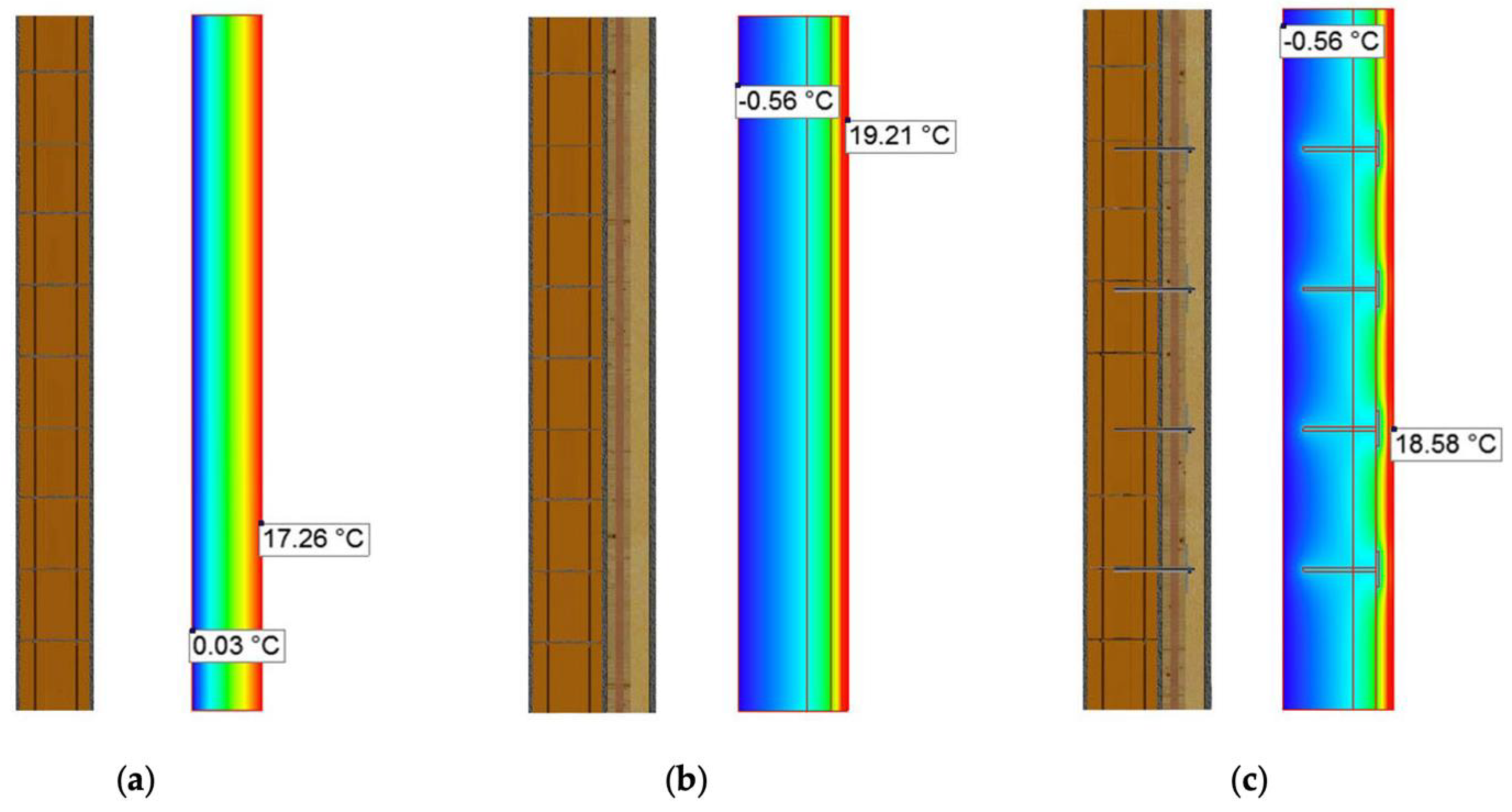

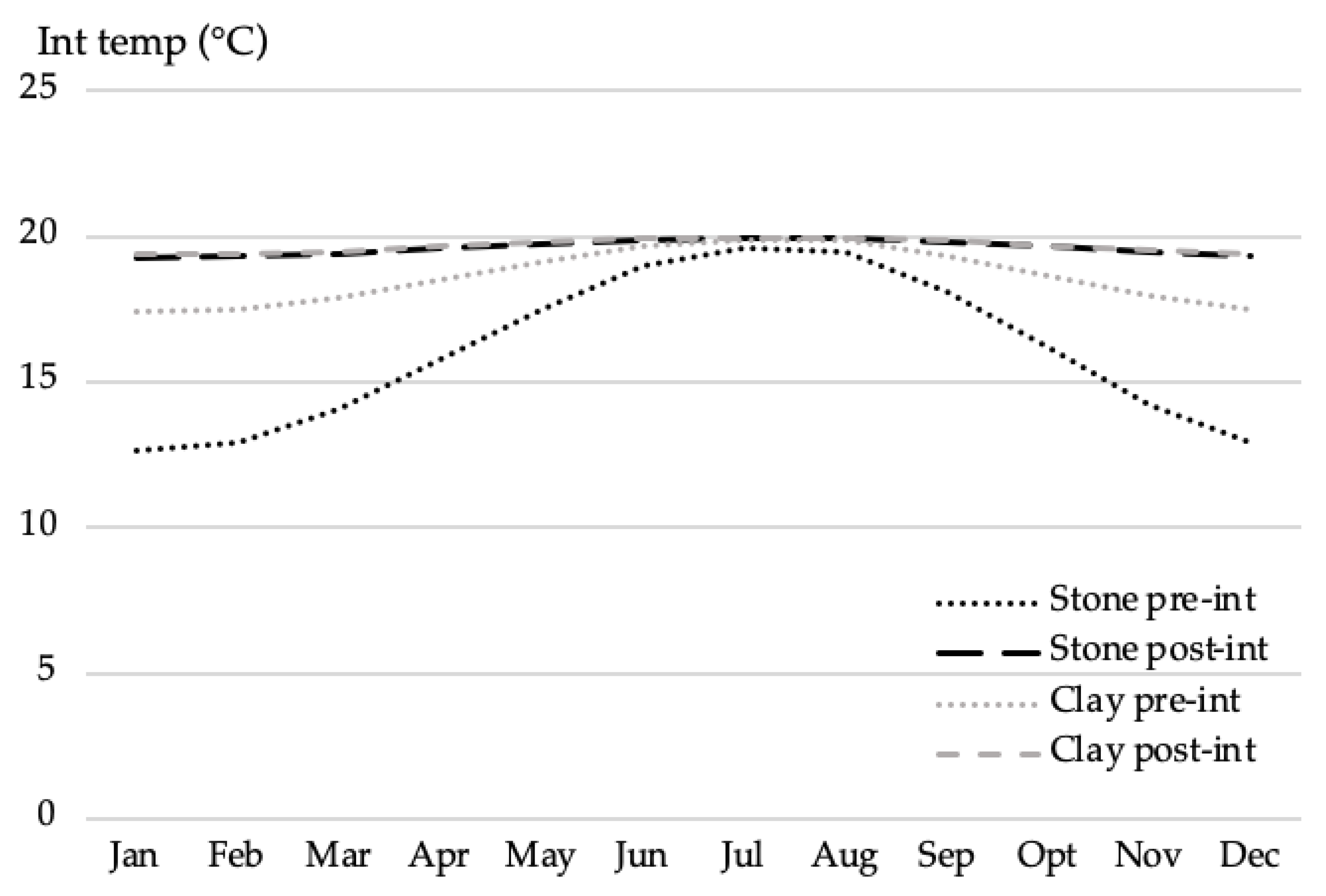

Figure 4 and

Figure 5 show the isotherm distributions for the stone and the hollow clay block walls, respectively. The surface temperature is reported before and after the intervention for the minimum external temperature (0 °C) are reported, whereas

Figure 6 shows its annual trend.

The increase in the internal surface temperature improved the thermal comfort in the heating seasons, and, as mentioned before, avoids moisture and mold growth, thus preserving the wooden structure. In both masonry types, the inner surface temperature increased to around 19 °C, greater than the dew temperatures related to the condensation and to the mold growth, as described in

Section 2.1. In terms of surface temperature, the intervention appeared to be especially effective for the stone masonry wall, which in the “as built” configuration showed a value (12.64 °C) below the calculated minimum threshold (13 °C), with a significant risk in the formation of condensation and in the mold growth.

In addition, in the post-intervention configurations, steel connectors did not affect the hygrothermal performance, with neither significant variation in the isotherm distribution nor presence of mold and interstitial condensation, due to their low thermal transmittance and not dense structural mesh.

The performance of the retrofitted building envelope was significantly improved compared to the initial configuration, as shown in

Table 8.

The steady thermal transmittance U of the envelope significantly decreased, and, in both masonry configurations, the outcome values were smaller than 0.338 W/m

2K. This is the threshold provided by the Italian code DM 26/06/2015 [

81], starting from 2021, for vertical opaque elements in existing buildings subjected to energy-efficiency retrofit by means of inner insulation system. Indeed, in case of internal intervention, the thresholds of thermal transmittance can be incremented by 30%. This confirms that the proposed intervention meets the requirements given by the current codes [

81].

Similarly, those codes limit the periodic thermal transmittance up to 0.10 W/m2K for the walls subjected to solar irradiation, with the aim of cutting energy need for the cooling conditioning. This also confirms that the proposed intervention fulfils this provision.

Due to the lightweight of the inner layers, the intervention led to a decrement in the internal areal heat capacity, which is strongly linked to the inner thermal mass. Indeed, the intervention aims at providing an integrated solution which improve both the energy efficiency and the seismic performance. Thus, for the latter, a decrease in the inertial masses is desirable, with the consequence decrease in the inner layer thermal masses. The performances of the retrofit solution in the heating season, compared to those in the cooling season, suggest the application of the intervention in climatic zones with mild summertime.

Nevertheless, the thermal time lag quadrupled, for both stone and clay masonry, approaching or overtaking the ideal value of 12 h. A significant reduction in the decrement factor was observed; in case of stone masonry the retrofitted value was a quarter of the initial one, while the clay masonry showed a greater decrease in the decrement factor to less than a tenth of the “as built” value. The thermal time lag improvement and the reduction in the decrement factor, denoted the better comfort offered by the retrofitted solutions.

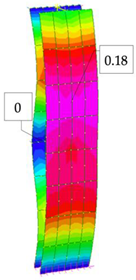

3.2. Parametric Seismic Analysis on Numerical Model

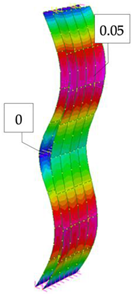

The seismic micro-model of the coupled wall was analyzed in term of system of deformations and maximum displacements both in the in-plane (IP) and in the out-of-plane (OOP) directions. Seismic action was represented in terms of acceleration; hence, results were affected not only by the stiffness of the system but also by the inertial masses, which are higher in case of thicker stone masonry.

Figure 7 shows the results in terms of IP maximum displacements for the control model (CM), so as to compare them with the outcomes of the other models and thereby to evaluate the IP displacement reduction given by the steel connectors. The stone masonry wall with weak mortar, which has large inertial mass and a low Young’s modulus, reached the greatest IP maximum displacement, while the stone masonry wall with injections developed smaller displacements due to its higher stiffness. The hollow clay block masonry showed the lowest amplitude of deformations, mainly due to its small inertial mass, given its small thickness (and therefore stiffness). The CM cannot provide significant results in the OOP direction, for which the overturning mechanism of the masonry wall would be observed.

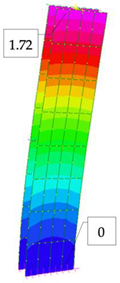

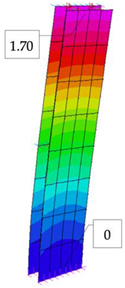

Table 9 and

Table 10 show results obtained for the models with steel connectors, in terms of deformed shapes and maximum displacements, respectively. Moreover,

Table 10 reports the percentage reduction in IP displacement for the analyzed models compared to the CM.

Results showed that the degree of coupling ensured by connectors reduced the IP displacements. Connectors in the sparse configuration (120 cm spacing) significantly reduced the IP displacements with respect to the CM; no significant benefit was detected by increasing the number of connectors, halving spacing. The intervention increased the global stiffness of the system with a reduction in the IP displacements ranging from 20% to 30% (

Table 10). The IP maximum displacement of the post-intervention configuration with sparse connectors applied to a stone masonry wall with injections was also compared to the one obtained from the control model of the stone masonry wall with weak mortar. The former developed an IP displacement of 1.72 mm, while the latter reached 3.34 mm. Thus, a combined intervention on a stone masonry wall, which comprised a preliminary grout injection and then the connection of the CLT panel to the masonry wall by means of sparse connectors, may decrease the IP maximum displacement of almost 50%.

Results in terms of OOP maximum displacements showed the benefit of decreasing the connector spacing even though (see

Table 9 for the developed deformed configurations), for the stone wall-CLT system, a satisfactory degree of coupling was yet to be reached, even in the denser configuration of steel connectors.

For the thinner clay block panel, good coupling was already reached with the largest connector spacing (120 cm). In this case, the thickening of connectors improved the effectiveness of the intervention in terms of deformed shape.

The OOP deformed configurations also pointed out the importance to provide a good connection of the masonry wall to the floors, which cannot be always ensured by the connectors to CLT walls. Thus, to avoid masonry OOP overturning mechanisms, it is fundamental to pay attention to all construction details to be designed case by case.

4. Conclusions

An innovative intervention on URM buildings by means of CLT panels has been proposed among Nested Building strategies. This intervention permits the integration and optimization of both energetic and seismic improvements by coupling the external existing masonry walls with inner CLT panels, which are able to enhance the global mechanical behavior and, by adding a new insulation system, to increase the energy efficiency. The coupled system was investigated by means of hygrothermal simulation and structural micro-modeling, with respect to two types of URM walls, i.e., stone masonry and hollow clay block masonry.

In case of a stone masonry wall (65 cm thick), the integrated retrofit intervention showed, in terms of hygrothermal performance, a significant reduction in both the steady and the periodic thermal transmittance, reaching values of 0.278 W/m

2K and 0.007 W/m

2K, respectively, both smaller than the reference values given by the Italian code [

81]. The thermal time lag quadrupled reaching a value of 12.43 h, while the retrofitted decrement factor was a quarter of the initial one, both indices of a better comfort offered by the retrofitted solution. In terms of seismic response, the simulation of the NB intervention showed an increment in the structural stiffness demonstrated by the significant reduction of the 30% in the IP maximum displacements. The results in terms of IP maximum displacements suggest that a combined intervention on a stone masonry wall, which comprised a preliminary grout injection and then the connection of the CLT panel to the masonry wall by means of sparse connectors, may decrease the IP maximum displacement of almost 50%. However, the coupling in the OOP direction was not fully reached even with the minimum spacing of the connectors. Thus, the CLT-stone masonry connection may not be sufficient to exclude OOP mechanisms and a careful evaluation of construction details able to ensure the connection of masonry walls at floor levels is needed.

In case of application of the intervention to a hollow clay block masonry wall (30 cm thick), the improvement in the hygrothermal performance was demonstrated by a significant reduction in both the steady and the periodic thermal transmittance, reaching values of 0.235 W/m

2K and 0.006 W/m

2K, respectively, both smaller than the reference values given by the Italian code [

81]. The thermal time lag increased up to 13.90 h and the decrement factor was less than a tenth of its “as built” estimation, which both indicate a significant improvement in the comfort of the retrofitted configuration. In terms of seismic response, the hollow clay block masonry showed a reduction of the 25% in the IP maximum displacements. The clay wall, which is characterized by smaller thickness, and thus OOP stiffness, besides a smaller inertial mass, seemed to be satisfactorily coupled with the CLT panel in the OOP direction.

Regardless of the type of masonry, in the post-intervention configurations, the internal areal heat capacity decreased due to the lower inner thermal mass, which was strongly related to the system inertial mass. In general, reducing inertial masses is desirable in terms of seismic behavior. Considering that the intervention aims to fulfil both the energetic and the seismic retrofit targets, it resulted in being optimized for the application in climatic zones with mild summertime.

This research presented a methodological approach to determine the feasibility and the potential improvement given by a new integrated intervention. The results of this parametric study can be used to design and assess optimized solutions in case studies.