Comparative LCAs of Conventional and Mass Timber Buildings in Regions with Potential for Mass Timber Penetration

Abstract

:1. Introduction

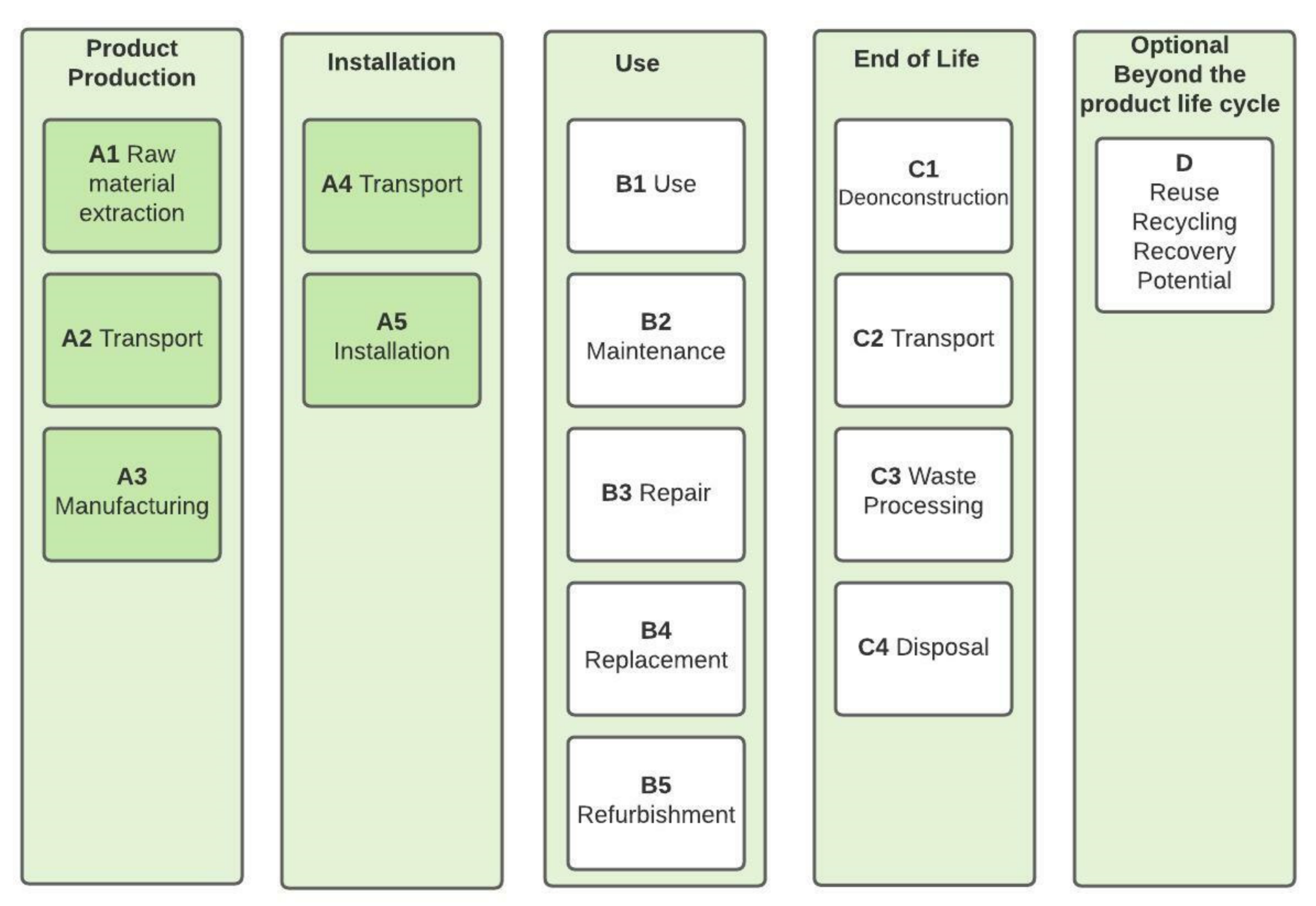

2. Materials and Methods

Architectural Building Designs and Assumptions

| Region | Species | Wood Density 1/ | GWP |

|---|---|---|---|

| kg/m3 | kg CO2e/m3 | ||

| Pacific Northwest | Douglas fir and western hemlock | 467 | 60.97 |

| Northeast | Eastern spruce and white pine | 434 | 46.78 |

| Southeast | Southern pine | 510 | 85.03 |

3. Results

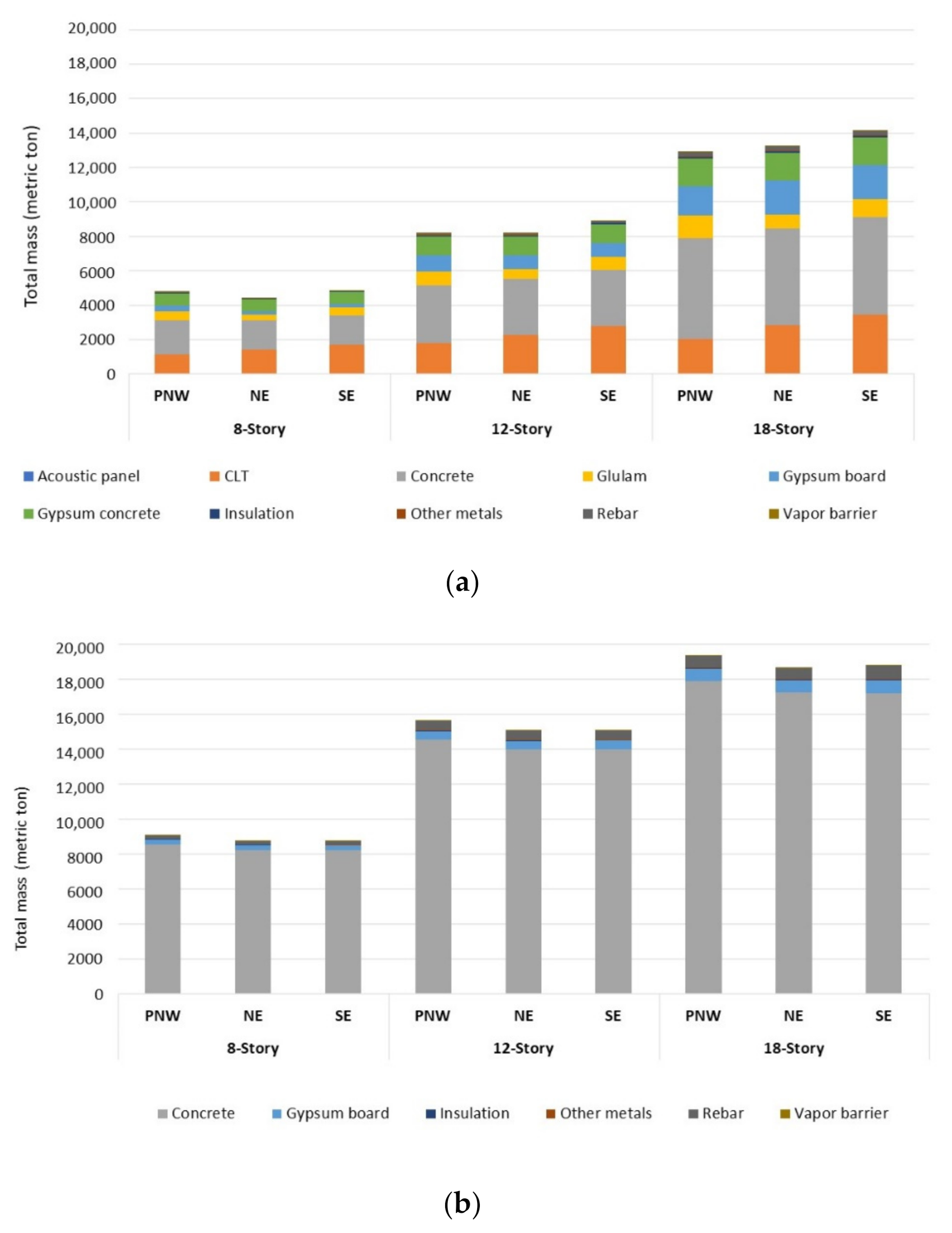

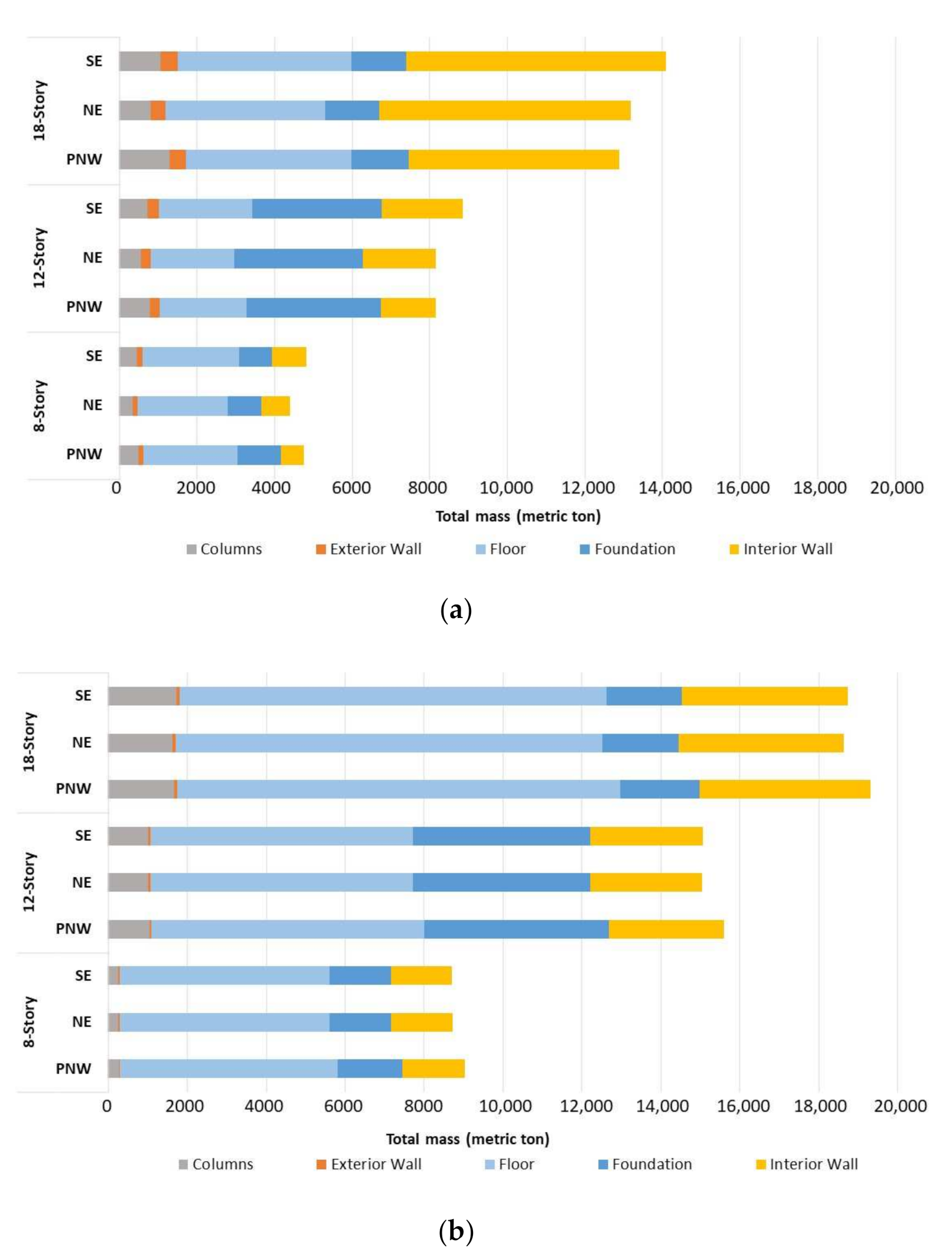

3.1. Building Mass

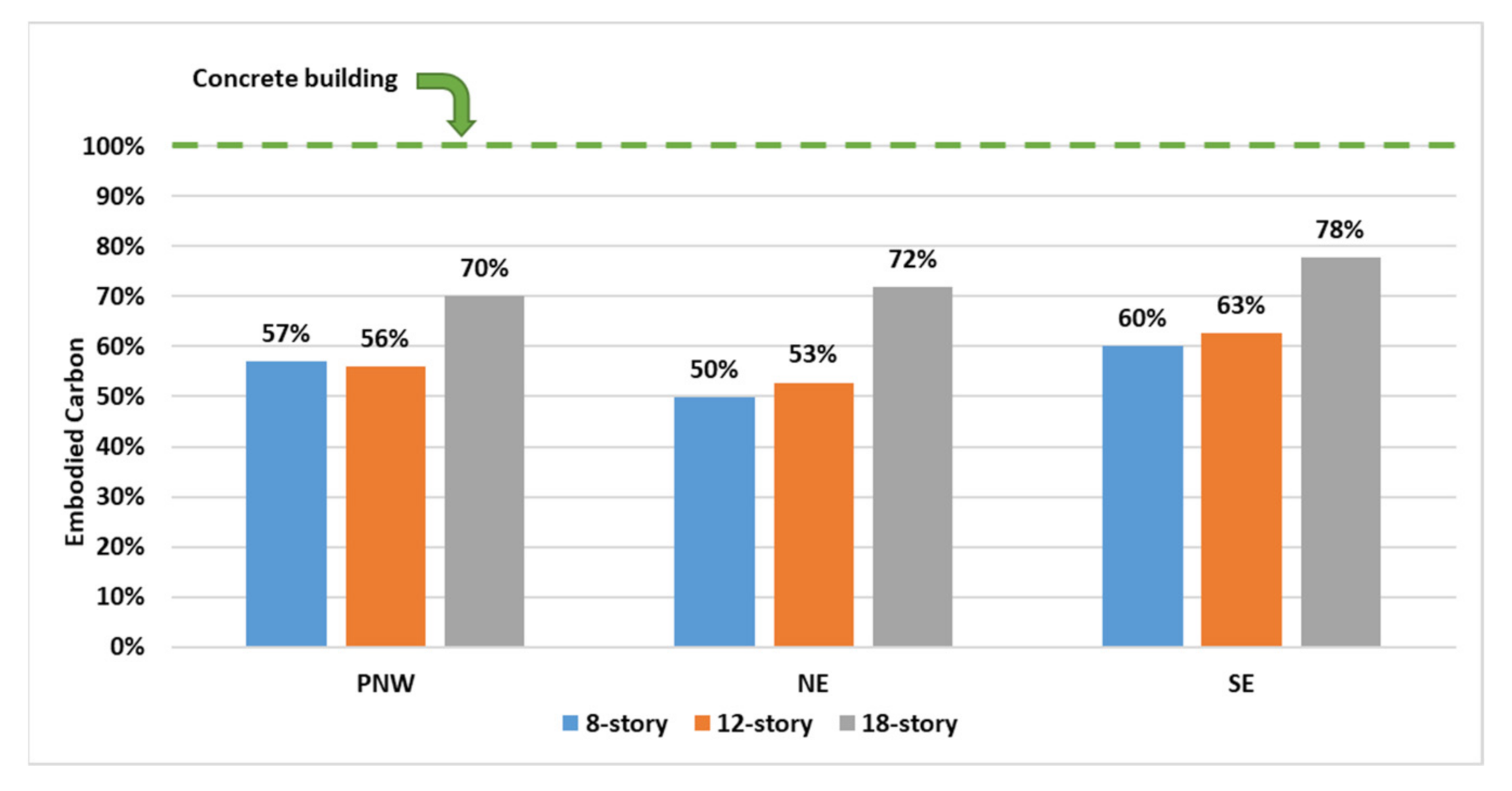

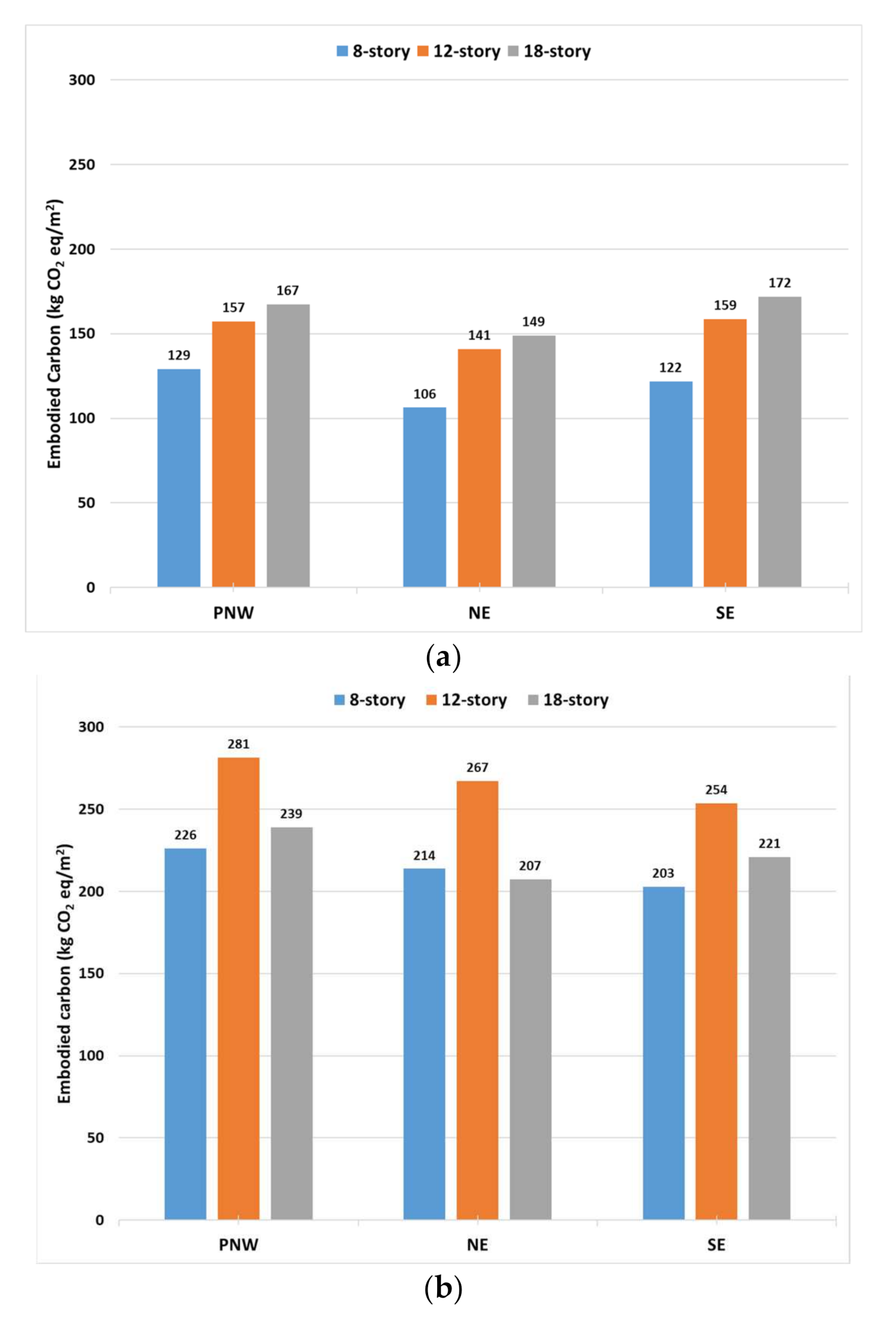

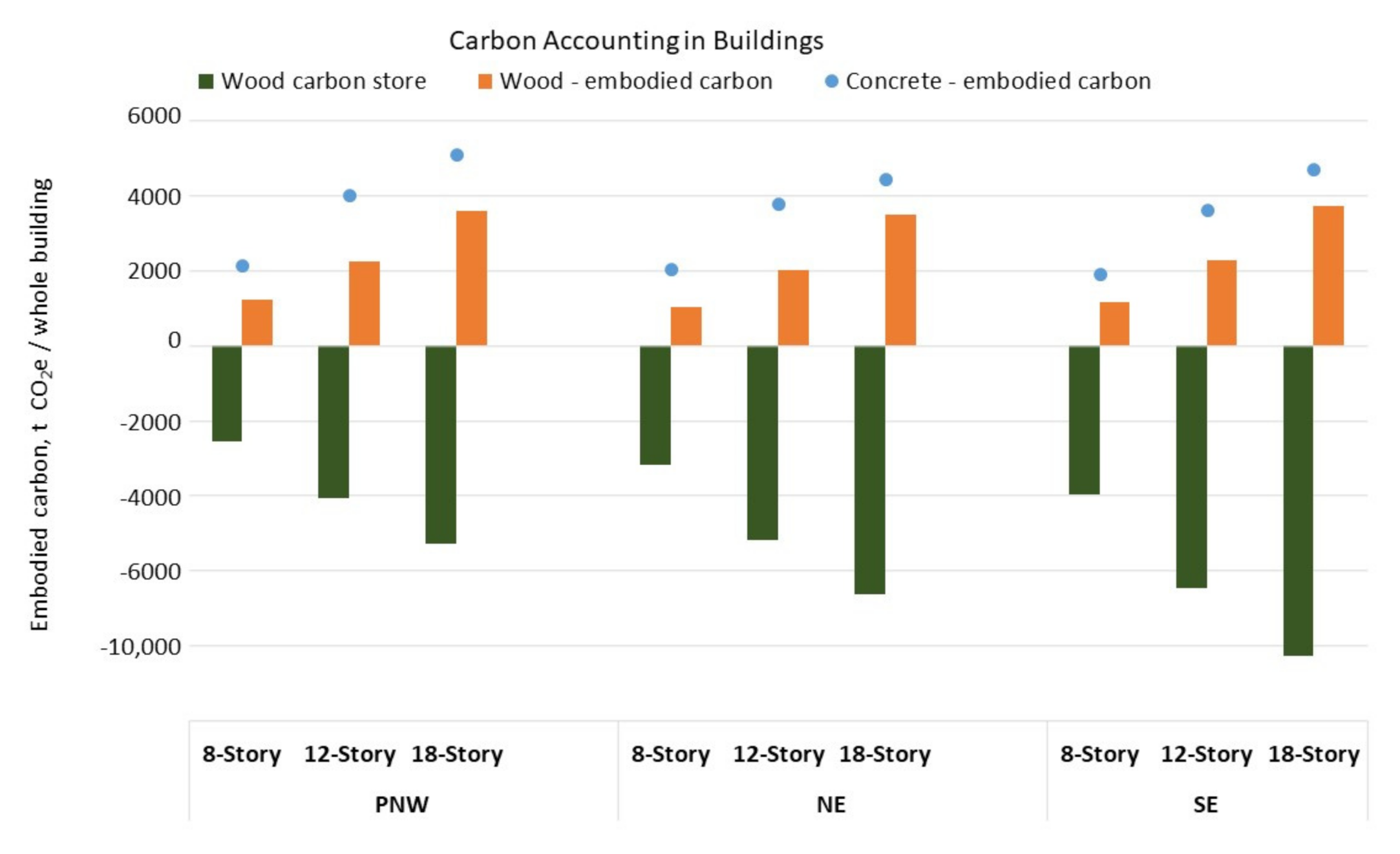

3.2. Embodied Carbon

3.3. Energy Use

4. Discussion

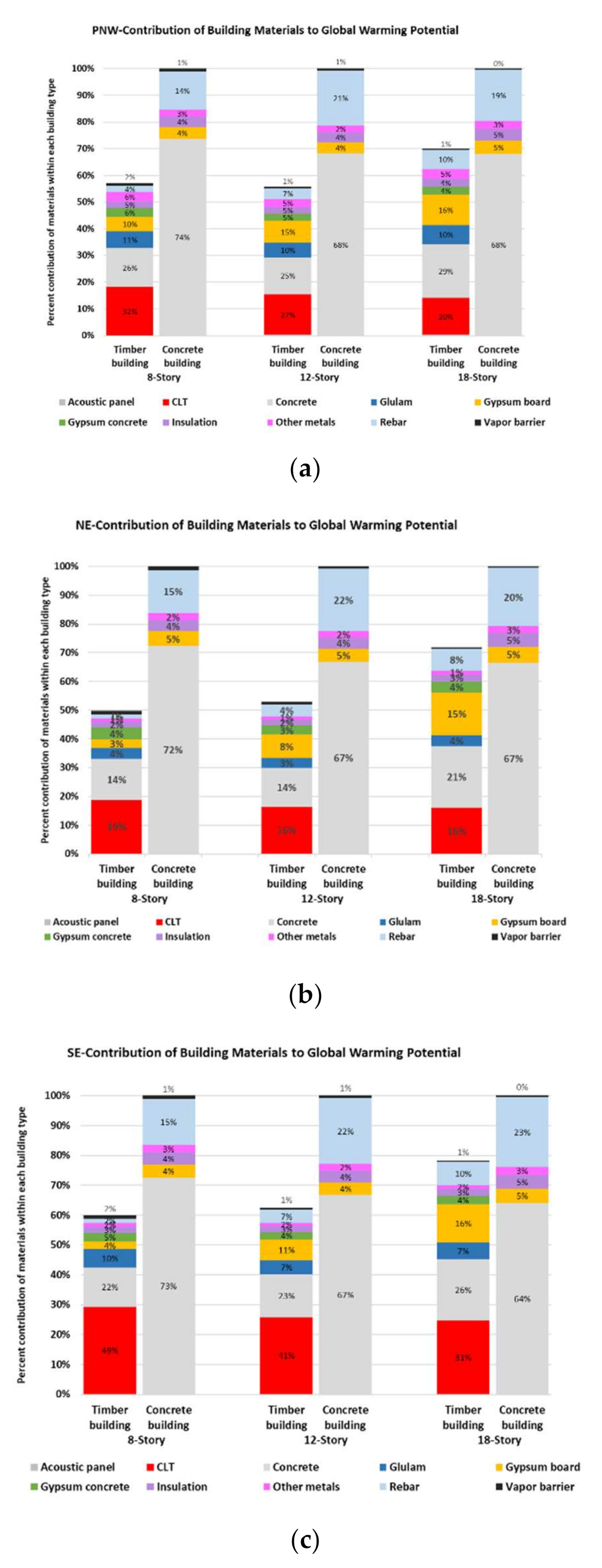

4.1. Embodied Carbon (A1–A5)

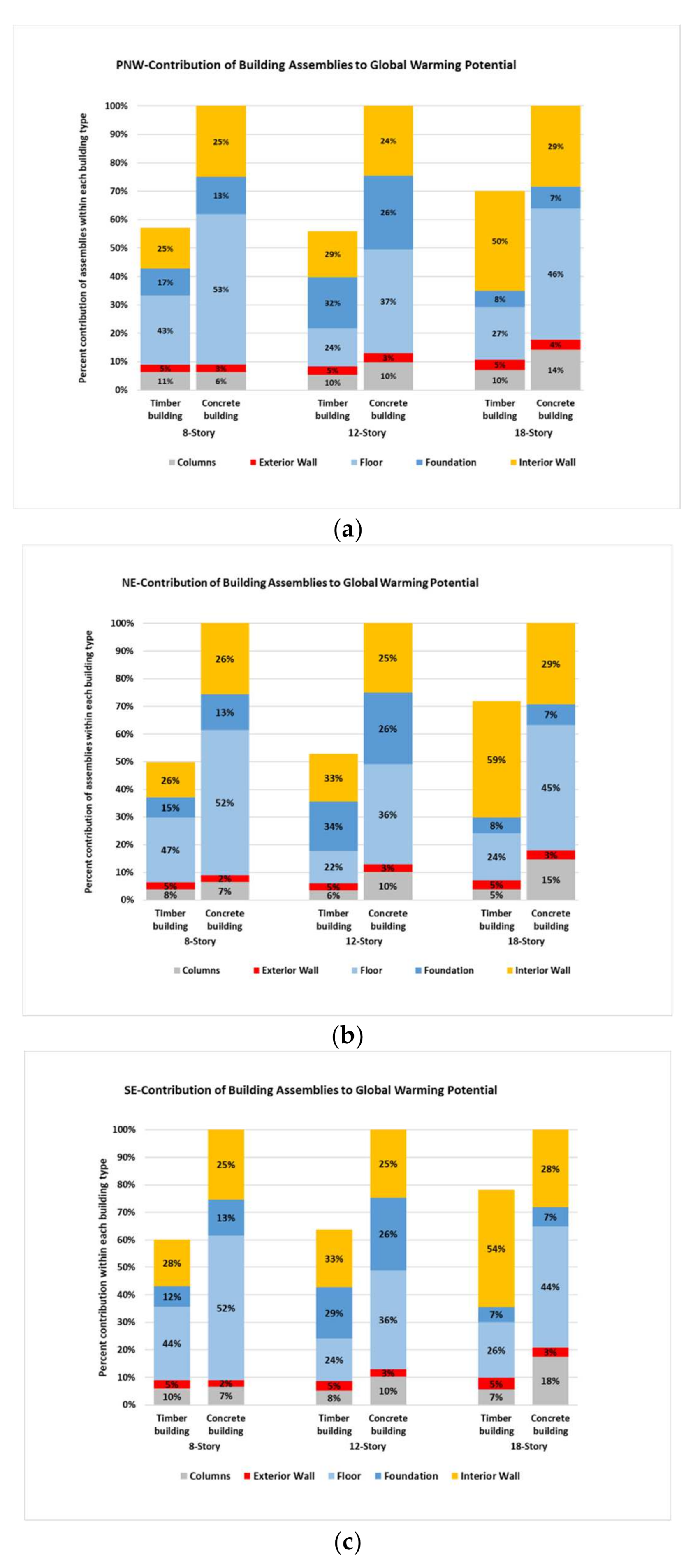

4.2. Embodied Carbon—Assemblies

4.3. Embodied Energy

5. Conclusions

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Bastin, J.-F.; Finegold, Y.; Garcia, C.; Mollicone, D.; Rezende, M.; Routh, D.; Zohner, C.M.; Crowther, T.W. The global tree restoration potential. Science 2019, 365, 76–79. [Google Scholar] [CrossRef]

- Griscom, B.W.; Adams, J.; Ellis, P.W.; Houghton, R.A.; Lomax, G.; Miteva, D.A.; Schlesinger, W.H.; Shoch, D.; Siikamäki, J.V.; Smith, P.; et al. Natural climate solutions. Proc. Natl. Acad. Sci. USA 2017, 114, 11645–11650. [Google Scholar] [CrossRef] [Green Version]

- Lippke, B.; Puettmann, M.; Oneil, E.; Oliver, C.D. The plant a trillion trees campaign to reduce global warming—Fleshing out the concept. J. Sustain. For. 2021, 40, 1–31. [Google Scholar] [CrossRef]

- Food and Agriculture Organization of the United Nations (FAO). FAO Statistics Division (FAOSTAT); FOA: Rome, Italy, 2015; Available online: https://www.fao.org/faostat/en/#home (accessed on 15 December 2021).

- Ganguly, I.; Pierobon, F.; Sonne Hall, E. Global warming mitigating role of wood products from Washington State’s private forests. Forests 2020, 11, 194. [Google Scholar] [CrossRef] [Green Version]

- Hudiburg, T.W.; Law, B.E.; Moomaw, W.R.; Harmon, M.E.; Stenzel, J.E. Meeting GHG reduction targets requires accounting for all forest sector emissions. Environ. Res. Lett. 2019, 14, 095005. [Google Scholar] [CrossRef]

- Stewart, W.C.; Nakamura, G.M. Documenting the full climate benefits of harvested wood products in Northern California: Linking harvests to the US greenhouse gas inventory. For. Prod. J. 2012, 62, 340–353. [Google Scholar] [CrossRef]

- Anderson, R.; Atkins, D.; Beck, B.; Dawson, E.; Gayle, C. State of the Industry North American Mass Timber; Self-Publishing Services LLC: Missoula, MT, USA, 2020; p. 156. [Google Scholar]

- Bengston, D.N. The Revolutionary Role of Wood in Our Future. 2021. Available online: https://www.usda.gov/media/blog/2018/01/05/revolutionary-role-wood-our-future (accessed on 15 December 2021).

- Zelinka, S.L.; Williamson, T.; Martinson, K.L.; Ritter, M.A. Research needs assessment for the mass timber industry. In Proceedings of the 2nd North American Mass Timber Research Needs Workshop, Madison, WI, USA, 13–14 November 2018. [Google Scholar]

- Salazar, J.; Puettmann, M.E. Whole-Building LCA Case Study of a Mid-Rise Office Building in New England; Unpublished Work; New England Forestry Foundations: Littleton, MA, USA, 2019; p. 58. [Google Scholar]

- Chen, C.X.; Pierobon, F.; Ganguly, I. Life cycle assessment (LCA) of cross-laminated timber (CLT) produced in western Washington: The role of logistics and wood species mix. Sustainability 2019, 11, 1278. [Google Scholar] [CrossRef] [Green Version]

- Chen, Z.; Gu, H.; Bergman, R.; Liang, S. Comparative life-cycle assessment of a high-rise mass timber building with an equivalent reinforced concrete alternative using the Athena Impact Estimator for buildings. Sustainability 2020, 12, 4708. [Google Scholar] [CrossRef]

- Liang, S.; Gu, H.; Bergman, R.; Kelley, S. Comparative life-cycle assessment of a mass timber building and concrete alternative. Wood Fiber Sci. 2020, 52, 217–229. [Google Scholar] [CrossRef]

- ASTM. Freres Lumber Environmental Product Declaration Mass Ply Panels. 2020. Available online: https://www.astm.org/CERTIFICATION/DOCS/563.EPD_For_FinalFreres_Lumber_Company.pdf (accessed on 5 October 2021).

- ASTM. Structurlam Mass Timber Environmental Product Declaration. 2020. Available online: https://www.astm.org/CERTIFICATION/DOCS/480.EPD_FOR_Structurlam_CLT_20200113.pdf (accessed on 5 October 2021).

- Puettmann, M.E.; Sinha, A.; Ganguly, I. Life cycle energy and environmental impacts of cross laminated timber made with coastal Douglas-fir. J. Green Build. 2020, 14, 17–33. [Google Scholar] [CrossRef]

- Bowers, T.; Puettmann, M.E.; Ganguly, I.; Eastin, I. Cradle-to-gate life-cycle impact analysis of glued-laminated (glulam) timber: Environmental impacts from glulam produced in the US Pacific Northwest and southeast. For. Prod. J. 2017, 17, 368–380. [Google Scholar] [CrossRef]

- Anderson, R.; (The Beck Group, Portland, OR, USA). Personal communication, 2021.

- United Nations Environment Programme. Emissions Gap Report 2020. 2020. Available online: www.unenvironment.org/emissionsgap (accessed on 15 December 2021).

- Buchanan, A.H.; John, S.; Love, S. LCA and carbon footprint of multi-story timber buildings compared with steel and concrete buildings. N. Z. J. For. 2013, 54, 9–18. [Google Scholar]

- Milaj, K.; Sinha, A.; Miller, T.H.; Tokarczyk, J.S. Environmental utility of wood substitution in commercial buildings using life-cycle analysis. Wood Fiber Sci. 2017, 49, 338–358. [Google Scholar]

- Meil, J.; Lippke, B.; Perez-Garcia, J.; Bowyer, J.; Wilson, J. Environmental Impacts of a Single Family Building Shell—From Harvest to Construction; CORRIM: Corvallis, OR, USA, 2004; p. 44. [Google Scholar]

- Perez-Garcia, J.; Lippke, B.; Briggs, D.; Wilson, J.B.; Bowyer, J.; Meil, J. The environmental performance of renewable building materials in the context of residential construction. Wood Fiber Sci. 2005, 37, 3–17. [Google Scholar]

- Pierobon, F.; Huang, M.; Simonen, K.; Ganguly, I. Environmental benefits of using hybrid CLT structure in midrise non-residential construction: An LCA comparative case study in the US PNW. J. Build. Eng. 2019, 26, 100862. [Google Scholar] [CrossRef]

- Robertson, A.B.; Lam, F.C.F.; Cole, R.J. A comparative cradle-to-gate lifecycle assessment of mid-rise office building construction alternatives: Laminated timber or reinforced concrete. Buildings 2012, 2, 245–270. [Google Scholar] [CrossRef]

- Liang, S.; Gu, H.; Bergman, R. Environmental life-cycle assessment and life-cycle cost analysis of a high-rise mass timber building: A case study in Pacific Northwestern United States. Sustainability 2021, 13, 7831. [Google Scholar] [CrossRef]

- Forterra. Mass Timber: The Innovative Future of Our Built Environment. 2018. Available online: https://forterra.org/editorial/mass-timber (accessed on 11 August 2021).

- Upton, B.; Miner, R.; Spinney, M.; Heath, L.S. The greenhouse gas and energy impacts of using wood instead of alternatives in residential construction in the United States. Biomass Bioenergy 2008, 32, 1–10. [Google Scholar] [CrossRef]

- Schmidt, J.; Griffin, C.T. Barriers to the design and use of cross-laminated timber structures in high-rise multi-family housing in the United States. In Structures and Architecture, 1st ed.; Cruz, P.J., Ed.; CRC Press: Boca Raton, FL, USA, 2013; pp. 2225–2231. [Google Scholar]

- Gu, H.; Nepal, P.; Arvanitis, M.; Alderman, D. Carbon impacts of engineered wood products in construction. In Engineered Wood Products for Construction; InTech Open: London, UK, 2021. [Google Scholar]

- Johnston, C.M.T.; Radeloff, V.C. Global mitigation potential of carbon stored in harvested wood products. Proc. Natl. Acad. Sci. USA 2019, 116, 14526–14531. [Google Scholar] [CrossRef] [Green Version]

- Perez-Garcia, J.; Lippke, B.; Comnick, J.; Manriquez, C. An assessment of carbon pools, storage, and wood products market substitution using life-cycle analysis results. Wood Fiber Sci. 2005, 37, 140–148. [Google Scholar]

- The Consortium for Research on Renewable Industrial Materials. Available online: www.corrim.org (accessed on 10 August 2021).

- National Renewable Energy Laboratory. U.S. Life Cycle Inventory Database. Available online: http://www.nrel.gov/lci/LTS (accessed on 11 August 2021).

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (Part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- LTS. DataSmart. Available online: https://ltsexperts.com/services/software/datasmart-life-cycle-inventory (accessed on 5 October 2021).

- ISO. Environmental Management—Life Cycle Assessment—Requirement and Guidelines; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- European Committee. EN 15978:2011—Sustainability of Construction Works—Assessment of Environmental Performance of Buildings—Calculation Method; European Committee for Standardization: Brussels, Belgium, 2011; 60p. [Google Scholar]

- ISO. Sustainability in buildings and civil engineering works. In Core Rules for Environmental Product Declarations of Construction Products and Services; International Organization for Standardization: Geneva, Switzerland, 2006. [Google Scholar]

- Gu, H.; Liang, S.; Puettmann, M.; Pierobon, F.; Ganguly, I.; Chen, C.; Pasternack, R.; Wishnie, M.; Jones, S.; Maples, I. Mass timber building Life Cycle Assessment methodology for the US regional case studies. Sustainability special issue -Mass Timber and Sustainable Building Construction. Sustainability 2021, in press. [Google Scholar]

- Breneman, S.; Timmers, M.; Richardson, D. Tall Wood Buildings in the 2021 IBC Up to 18 Stories of Mass Timber 12. 2019. Available online: https://www.woodworks.org/wp-content/uploads/wood_solution_paper-TALL-WOOD.pdf (accessed on 11 August 2021).

- Milota, M. Life Cycle Assessment for the Production of Pacific Northwest Softwood Lumber. 2020. Available online: https://corrim.org/wp-content/uploads/2020/06/CORRIM-AWC-PNW-Lumber.pdf (accessed on 10 August 2021).

- Milota, M. Life Cycle Assessment for the Production of Southeastern Softwood Lumber. 2020. Available online: https://corrim.org/wp-content/uploads/2020/06/CORIRM-AWC-SE-Lumber.pdf (accessed on 10 August 2021).

- Puettmann, M.E. Life Cycle Assessment for the Production of Northeast–Northcentral Softwood Lumber. 2020. Available online: https://corrim.org/wp-content/uploads/2020/06/CORRIM-AWC-NENC-Lumber.pdf (accessed on 10 August 2021).

- Bare, J. TRACI 2.0: The tool for the reduction and assessment of chemical and other environmental impacts 2.0. Clean Technol. Environ. Policy 2011, 13, 687–696. [Google Scholar] [CrossRef]

- SimaPro. Simapro 9.1.1.1 Life-Cycle Assessment Software Package; SimaPro: Amersfoort, The Netherlands, 2020. [Google Scholar]

| Stories | Floor Occupancy Ratio | Building Height | Total Floor Area | |

|---|---|---|---|---|

| IBC 1/ for MT buildings | Residential–Commercial | m | m2 | |

| Type IV-C | 8 | 6:2 | 26 | 9476 |

| Type IV-B | 12 | 8:4 | 48 | 14,214 |

| Type IV-A | 18 | 12:6 | 71 | 21,321 1/ |

| Geographic Regions | Species | CLT Production | Glulam Production |

|---|---|---|---|

| Pacific Northwest | Douglas fir and western hemlock | Spokane, Washington 2/ | Veneta, Oregon 2/ |

| Northeast | Eastern spruce and white pine | Lincoln, Maine | Lincoln, Maine |

| Southeast | Southern pine 1/ | Dothan, Alabama 2/ | Greenville, Alabama 2/ |

| Material Used the Interior Walls | Mass of Materials kg/m2 of Floor Area | Composition by Mass | Contribution to Embodied Carbon |

|---|---|---|---|

| Pacific Northwest | |||

| Concrete | 165.4 | 65.0% | 32.8% |

| CLT | 0.0 | 0.0% | 0.0% |

| Gypsum wall board | 75.3 | 29.6% | 31.5% |

| Insulation | 1.5 | 0.6% | 5.7% |

| Other metals | 2.9 | 1.1% | 10.6% |

| Rebar | 9.5 | 3.7% | 19.4% |

| Northeast | |||

| Concrete | 145.3 | 52.3% | 32.9% |

| CLT | 39.4 | 14.2% | 11.0% |

| Gypsum wall board | 81.6 | 29.4% | 32.7% |

| Insulation | 1.8 | 0.6% | 3.3% |

| Other metals | 0.8 | 0.3% | 3.1% |

| Rebar | 8.7 | 3.1% | 17.0% |

| Southeast | |||

| Concrete | 158.7 | 50.7% | 30.2% |

| CLT | 53.0 | 16.9% | 17.3% |

| Gypsum wall board | 89.3 | 28.5% | 30.1% |

| Insulation | 1.9 | 0.6% | 3.1% |

| Other metals | 0.9 | 0.3% | 3.0% |

| Rebar | 9.5 | 3.0% | 16.3% |

| PNW Embodied Carbon kg CO2e/m2 | |||||||||

|---|---|---|---|---|---|---|---|---|---|

| Building System | A1–A3 | A4 | A5 | Total | |||||

| 8-story | Mass timber building | 113.4 | 87.9% | 11.6 | 9.0% | 4.0 | 3.1% | 129.1 | 100.0% |

| Concrete building | 212.5 | 94.0% | 5.5 | 2.5% | 8.0 | 3.5% | 226.0 | 100.0% | |

| 12-story | Mass timber building | 139.2 | 88.5% | 12.8 | 8.1% | 5.3 | 3.4% | 157.3 | 100.0% |

| Concrete building | 264.5 | 94.0% | 6.3 | 2.2% | 10.7 | 3.8% | 281.4 | 100.0% | |

| 18-story | Mass timber building | 146.1 | 87.3% | 14.8 | 8.8% | 6.5 | 3.9% | 167.3 | 100.0% |

| Concrete building | 223.4 | 93.5% | 5.3 | 2.2% | 10.1 | 4.2% | 238.9 | 100.0% | |

| NE Embodied Carbon kg CO2e/m2 | |||||||||

| A1–A3 | A4 | A5 | Total | ||||||

| 8-story | Mass timber building | 90.7 | 85.2% | 12.0 | 11.2% | 3.7 | 3.5% | 106.3 | 100.0% |

| Concrete building | 203.7 | 95.3% | 2.7 | 1.3% | 7.4 | 3.5% | 213.8 | 100.0% | |

| 12-story | Mass timber building | 121.4 | 86.1% | 14.2 | 10.1% | 5.3 | 3.8% | 141.0 | 100.0% |

| Concrete building | 254.0 | 95.1% | 3.1 | 1.2% | 9.9 | 3.7% | 267.0 | 100.0% | |

| 18-story | Mass timber building | 130.0 | 87.2% | 13.0 | 8.7% | 6.1 | 4.1% | 149.1 | 100.0% |

| Concrete building | 196.3 | 94.6% | 2.6 | 1.2% | 8.6 | 4.1% | 207.4 | 100.0% | |

| SE Embodied Carbon kg CO2e/m2 | |||||||||

| A1–A3 | A4 | A5 | Total | ||||||

| 8-story | Mass timber building | 110.0 | 90.4% | 7.62 | 6.3% | 4.09 | 3.4% | 121.7 | 100.0% |

| Concrete building | 194.5 | 95.9% | 0.96 | 0.5% | 7.37 | 3.6% | 202.8 | 100.0% | |

| 12-story | Mass timber building | 144.0 | 90.8% | 8.76 | 5.5% | 5.81 | 3.7% | 158.6 | 100.0% |

| Concrete building | 242.6 | 95.7% | 1.12 | 0.4% | 9.86 | 3.9% | 253.5 | 100.0% | |

| 18-story | Mass timber building | 157.2 | 91.4% | 7.68 | 4.5% | 7.09 | 4.1% | 172.0 | 100.0% |

| Concrete building | 210.5 | 95.3% | 0.96 | 0.4% | 9.43 | 4.3% | 220.9 | 100.0% | |

| PNW Embodied Energy MJ/m2 | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| A1–A3 | A4 | A5 | Total | Total | ||||||

| Building Design | Renewable | Nonrenewable | Renewable | Nonrenewable | Renewable | Nonrenewable | Renewable | Nonrenewable | Energy | |

| 8-story | Mass timber | 1145 | 1526 | 0 | 148 | 0 | 55 | 1146 | 1729 | 2875 |

| Concrete | 62 | 1857 | 0 | 71 | 0 | 109 | 62 | 2037 | 2099 | |

| 12-story | Mass timber | 1217 | 1852 | 0 | 163 | 0 | 73 | 1217 | 2088 | 3305 |

| Concrete | 78 | 2405 | 0 | 80 | 0 | 146 | 78 | 2631 | 2709 | |

| 18-story | Mass timber | 1090 | 1892 | 0 | 188 | 0 | 89 | 1091 | 2169 | 3260 |

| Concrete | 67 | 2016 | 0 | 68 | 0 | 139 | 67 | 2222 | 2289 | |

| NE Embodied Energy MJ/m2 | ||||||||||

| 8-story | Mass timber | 799 | 1448 | 0 | 152 | 0 | 51 | 800 | 1651 | 2451 |

| Concrete | 57 | 1816 | 0 | 34 | 0 | 101 | 58 | 1952 | 2010 | |

| 12-story | Mass Timber | 875 | 1878 | 0 | 181 | 0 | 73 | 875 | 2132 | 3007 |

| Concrete | 72 | 2355 | 0 | 40 | 0 | 135 | 72 | 2530 | 2602 | |

| 18-story | Mass timber | 698 | 1829 | 0 | 165 | 0 | 83 | 698 | 2077 | 2775 |

| Concrete | 56 | 1806 | 0 | 32 | 0 | 118 | 56 | 1956 | 2012 | |

| SE Embodied Energy MJ/m2 | ||||||||||

| 8-story | Mass timber | 869 | 1489 | 0 | 98 | 0 | 56 | 869 | 1643 | 2512 |

| Concrete | 53 | 1735 | 0 | 12 | 0 | 101 | 53 | 1848 | 1901 | |

| 12-story | Mass timber | 952 | 1917 | 0 | 113 | 0 | 79 | 952 | 2109 | 3061 |

| Concrete | 63 | 2236 | 0 | 14 | 0 | 135 | 64 | 2385 | 2449 | |

| 18-story | Mass timber | 827 | 1991 | 0 | 99 | 0 | 97 | 827 | 2186 | 3014 |

| Concrete | 55 | 1962 | 0 | 12 | 0 | 129 | 55 | 2104 | 2158 | |

| PNW Embodied Energy, Relative Basis | ||||||||||

| A1–A3 | A4 | A5 | Total | Total | ||||||

| Building Design | Renewable | Nonrenewable | Renewable | Nonrenewable | Renewable | Nonrenewable | Renewable | Nonrenewable | Energy | |

| 8-story | Mass timber | 39.83% | 53.08% | 0.01% | 5.13% | 0.00% | 1.92% | 39.86% | 60.14% | 100% |

| Concrete | 2.95% | 88.47% | 0.01% | 3.37% | 0.01% | 5.18% | 2.95% | 97.05% | 100% | |

| 12-story | Mass Timber | 36.82% | 56.04% | 0.01% | 4.93% | 0.00% | 2.21% | 36.82% | 63.18% | 100% |

| Concrete | 2.88% | 88.78% | 0.01% | 2.95% | 0.01% | 5.39% | 2.88% | 97.12% | 100% | |

| 18-story | Mass Timber | 33.44% | 58.04% | 0.01% | 5.77% | 0.01% | 2.73% | 33.47% | 66.53% | 100% |

| Concrete | 2.93% | 88.07% | 0.01% | 2.97% | 0.01% | 6.07% | 2.93% | 97.07% | 100% | |

| NE Embodied Energy, Relative basis | ||||||||||

| 8-story | Mass timber | 32.60% | 59.08% | 0.01% | 6.19% | 0.00% | 2.09% | 32.64% | 67.36% | 100% |

| Concrete | 2.84% | 90.35% | 0.00% | 1.71% | 0.01% | 5.04% | 2.89% | 97.11% | 100% | |

| 12-story | Mass Timber | 29.10% | 62.45% | 0.01% | 6.01% | 0.01% | 2.44% | 29.10% | 70.90% | 100% |

| Concrete | 2.77% | 90.51% | 0.00% | 1.53% | 0.01% | 5.19% | 2.77% | 97.23% | 100% | |

| 18-story | Mass Timber | 25.15% | 65.91% | 0.01% | 5.95% | 0.01% | 3.00% | 25.15% | 74.85% | 100% |

| Concrete | 2.78% | 89.76% | 0.00% | 1.61% | 0.01% | 5.84% | 2.78% | 97.22% | 100% | |

| SE Embodied Energy, Relative basis | ||||||||||

| 8-story | Mass timber | 34.59% | 59.28% | 0.00% | 3.91% | 0.00% | 2.23% | 34.59% | 65.41% | 100% |

| Concrete | 2.79% | 91.27% | 0.00% | 0.65% | 0.01% | 5.30% | 2.79% | 97.21% | 100% | |

| 12-story | Mass timber | 31.10% | 62.63% | 0.00% | 3.68% | 0.01% | 2.60% | 31.10% | 68.90% | 100% |

| Concrete | 2.57% | 91.30% | 0.00% | 0.59% | 0.01% | 5.51% | 2.61% | 97.39% | 100% | |

| 18-story | Mass Timber | 27.44% | 66.06% | 0.00% | 3.28% | 0.01% | 3.22% | 27.44% | 72.56% | 100% |

| Concrete | 2.55% | 90.90% | 0.00% | 0.58% | 0.01% | 5.98% | 2.55% | 97.45% | 100% | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Puettmann, M.; Pierobon, F.; Ganguly, I.; Gu, H.; Chen, C.; Liang, S.; Jones, S.; Maples, I.; Wishnie, M. Comparative LCAs of Conventional and Mass Timber Buildings in Regions with Potential for Mass Timber Penetration. Sustainability 2021, 13, 13987. https://doi.org/10.3390/su132413987

Puettmann M, Pierobon F, Ganguly I, Gu H, Chen C, Liang S, Jones S, Maples I, Wishnie M. Comparative LCAs of Conventional and Mass Timber Buildings in Regions with Potential for Mass Timber Penetration. Sustainability. 2021; 13(24):13987. https://doi.org/10.3390/su132413987

Chicago/Turabian StylePuettmann, Maureen, Francesca Pierobon, Indroneil Ganguly, Hongmei Gu, Cindy Chen, Shaobo Liang, Susan Jones, Ian Maples, and Mark Wishnie. 2021. "Comparative LCAs of Conventional and Mass Timber Buildings in Regions with Potential for Mass Timber Penetration" Sustainability 13, no. 24: 13987. https://doi.org/10.3390/su132413987

APA StylePuettmann, M., Pierobon, F., Ganguly, I., Gu, H., Chen, C., Liang, S., Jones, S., Maples, I., & Wishnie, M. (2021). Comparative LCAs of Conventional and Mass Timber Buildings in Regions with Potential for Mass Timber Penetration. Sustainability, 13(24), 13987. https://doi.org/10.3390/su132413987