On the Road to Circular Public Procurement: Case, Variations, and Potential Actions in Germany

Abstract

:1. Introduction

1.1. Sustainable Development, Public Procurement, and Specific Product Considerations

1.2. Research Gaps and Research Questions

- The GPP discussion ‘has mostly focused so far on the specific impacts of GPP implementation’ [25]. Strategies to implement GPP for specific product areas are analysed less frequently. As shown in Section 1.1, sustainable, circular tyres make an interesting study case in this context.

- Circular public procurement is underrepresented in GPP research. In this context, Cheng et al. [25] refer to the environmental impacts of proposed projects, which may include ‘recycled material’. Apart from the brief mentioning of one circularity aspect, [25] does not consider any other circularity aspects in-depth, not even in the state of the art.

- Cheng et al. [25] also provide information on the countries where GPP studies took place. Germany is not mentioned in their list.

- (1)

- What is the current state of circular public tyre procurement in Germany?

- (2)

- How could circular public procurement of these products be promoted?

2. Materials and Methods

2.1. Status of Sustainable Public Procurement in Germany

2.1.1. Public Procurement in Germany

Public Procurement Processes

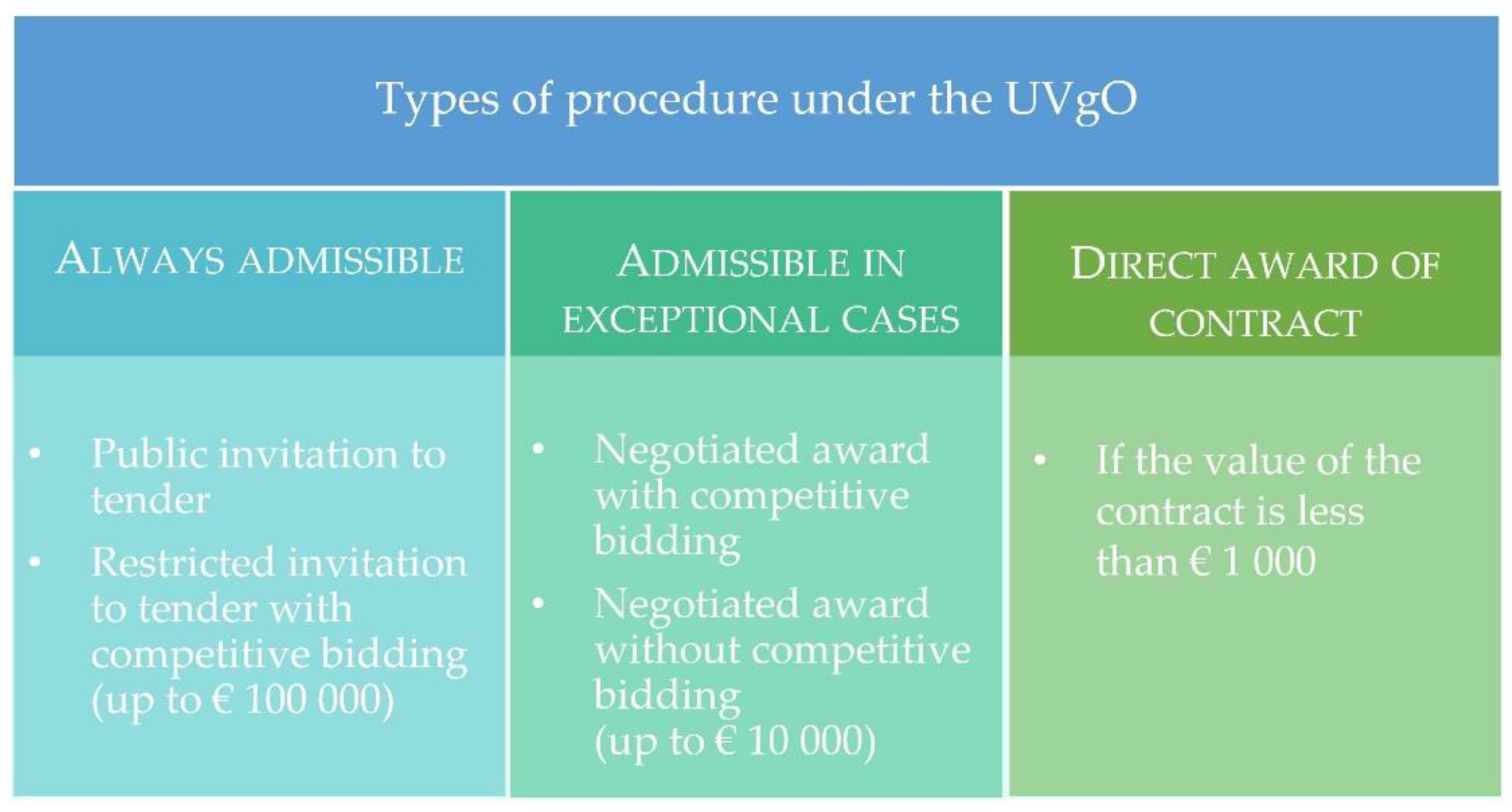

Types of Public Procurement Procedure

Bid Evaluation Methods and Benchmarks

2.1.2. Legal Framework and Support for Sustainable, Circular Public Procurement

European Law

National Law

- the Act against Restraints of Competition (GWB),

- the Regulation on the Award of Contracts for Subthreshold Contracts (UVgO),

- the Public Procurement Ordinance (VgV),

- the Recycling Management Act (Kreislaufwirtschaftsgesetz, KrWG),

- the Klimaschutzgesetz (Climate Protection Act, KSG), added by additional, federal Climate Protection Acts in several Federal States

- Regulations on the Award of Public Contracts for Construction Works, Parts A and B (VOB/A and VOB/B) (not relevant in the context of car tyres)

- Sector regulations (awarding of contracts in the fields of transport, drinking water supply, and energy supply by sector contracting authorities).

Law of Germany’s Federal States

Support for Sustainable Public Procurement: The Competence Centre for Sustainable Procurement and the Sustainability Compass

2.1.3. Initiation of Sustainable Public Procurement for a Product Group

2.2. Research Method

- Procedures used for tyre procurement

- Software used for the procurement processes

- Decision criteria and indicators for the procurement of tyres

- Market analyses for the preparation of tenders

- Procurement of retreaded tyres

- United Nations Sustainable Development Goals and the Circular Economy Act in the procurement of car tyres

- Incentives that could stimulate the procurement of circular tyres

- Legal aspects

- Application scenarios for a tyre configuration software

- Priorities regarding a circular tyre value chain

- Information on the environmental and social performance of sustainable tyres

- Standards and labels/certification for sustainable tyres

- Request for further advice for the project

- Supplementary information on the organisations interviewed and their tyre pur-chasing volumes

- Formal structuring: wants to filter out the inner structure of the material according to certain formal structuring aspects.

- Content structuring: wants to extract and summarise material on certain topics, on certain content areas.

- Typifying structuring wants to find individual distinctive characteristics in the material on a typifying dimension and describe them in more detail.

- Scaling structuring: wants to define characteristics in the form of scale points for individual dimensions and assess the material on this basis.

3. Results

3.1. General Observations

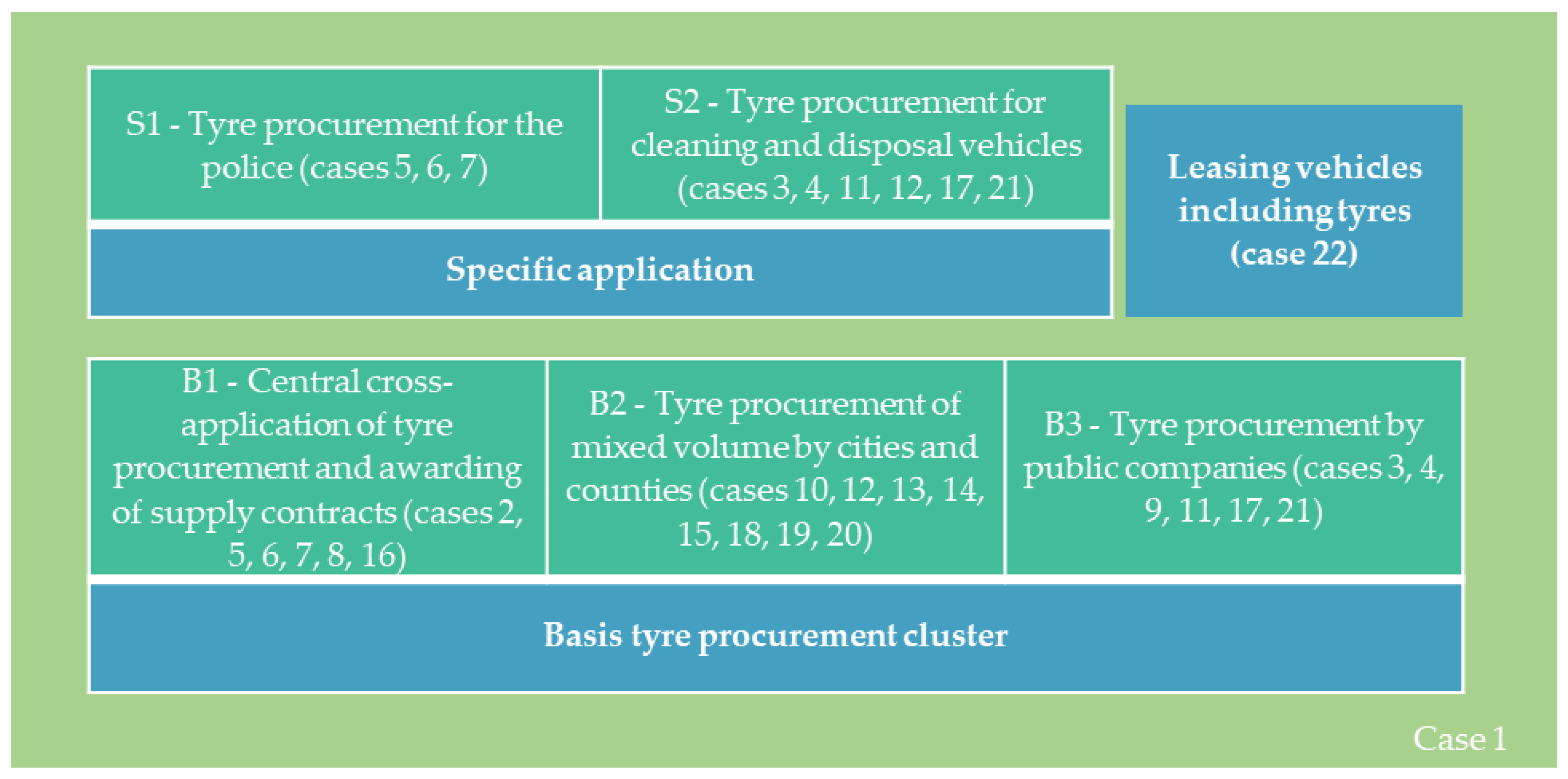

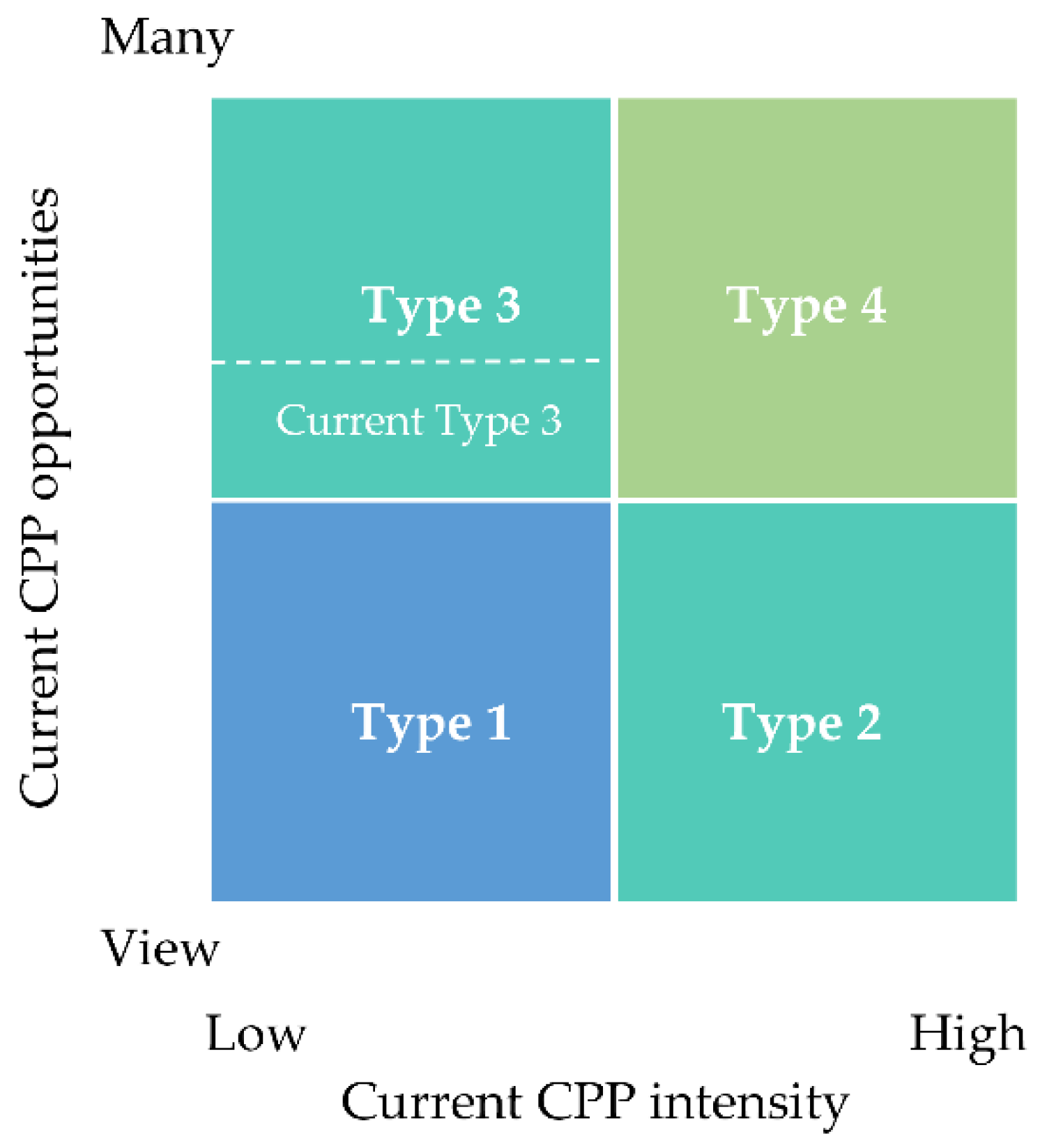

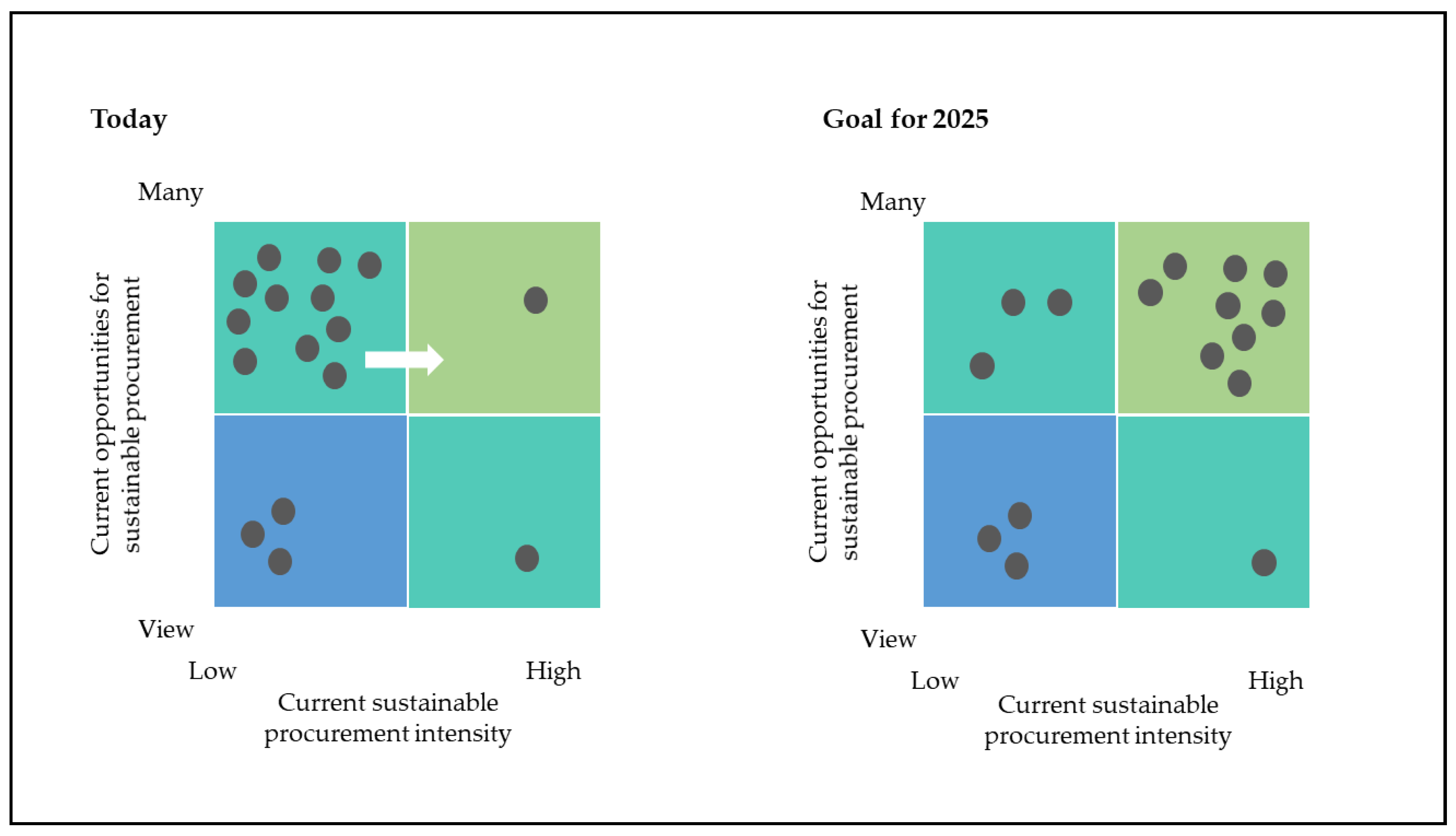

3.2. Classification of Procurement Situations

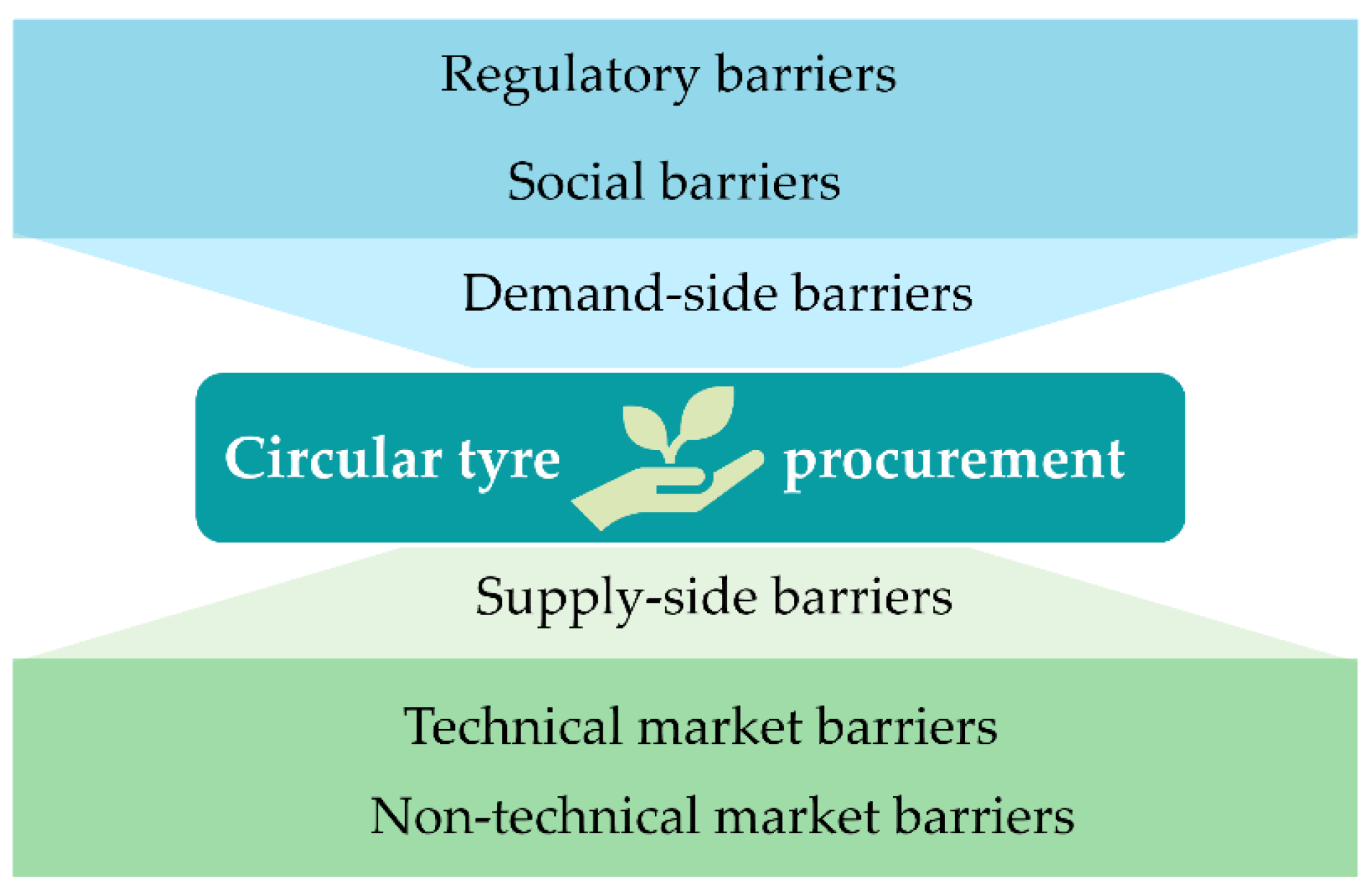

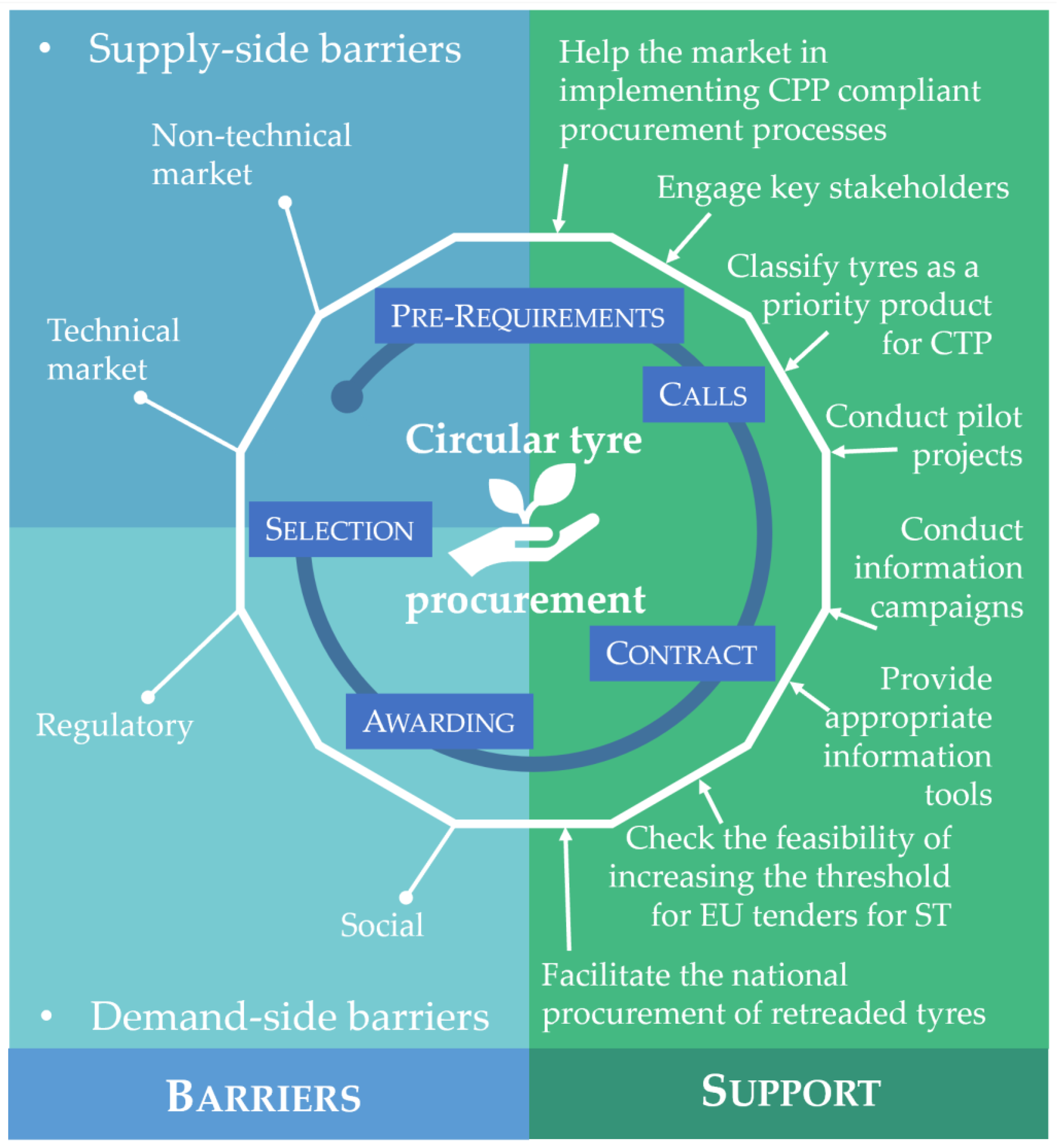

3.3. Barriers to the Implementation of a Circular Economy

3.3.1. Supply-Side Barriers

3.3.2. Demand-Side Barriers

3.3.3. Occurrence of the Barriers in the Clusters

3.4. Policy Recommendations to Promote Tyre CPP Derived from the Interviews

4. Discussion

4.1. Summary of Findings

4.2. Way Forward: Draft of a National Tyre CE Pilot Project

4.2.1. Ensuring Alignment and Commitment

4.2.2. Market Signalling

4.2.3. Strategic Partnerships with the Business Community

4.2.4. Implementation of Aspirations and Capabilities

4.2.5. Finalisation of Specifications and Criteria

4.2.6. Evaluation

5. Discussion and Conclusions

5.1. Contribution to Research and Practice

5.2. Limitations and Further Research Directions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- European Commission; Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. A New Circular Economy Action Plan: For a Cleaner and More Competitive Europe. 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52020DC0098&from=EN (accessed on 27 September 2021).

- United Nations Sustainable Development Goals. Goal 12: Ensure Sustainable Consumption and Production Patterns. Available online: https://www.un.org/sustainabledevelopment/sustainable-consumption-production/ (accessed on 30 September 2021).

- Kirchherr, J.; Reike, D.; Hekkert, M. Conceptualizing the circular economy: An analysis of 114 definitions. Resour. Conserv. Recycl. 2017, 127, 221–232. [Google Scholar] [CrossRef]

- Acatech/Circular Economy Initiative Deutschland/SYSTEMIQ. Circular Economy Roadmap für Deutschland. 2021. Available online: https://www.acatech.de/publikation/circular-economy-roadmap-fuer-deutschland/ (accessed on 27 September 2021).

- Karagoz, S.; Aydin, N.; Simic, V. End-of-life vehicle management: A comprehensive review. J. Mater. Cycles Waste Manag. 2020, 22, 416–442. [Google Scholar] [CrossRef] [Green Version]

- Campbell-Johnston, K.; Calisto Friant, M.; Thapa, K.; Lakerveld, D.; Vermeulen, W.J. How circular is your tyre: Experiences with extended producer responsibility from a circular economy perspective. J. Clean. Prod. 2020, 270, 122042. [Google Scholar] [CrossRef]

- Lapkovskis, V.; Mironovs, V.; Kasperovich, A.; Myadelets, V.; Goljandin, D. Crumb Rubber as a Secondary Raw Material from Waste Rubber: A Short Review of End-Of-Life Mechanical Processing Methods. Recycling 2020, 5, 32. [Google Scholar] [CrossRef]

- European Commission. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. Critical Raw Materials Resilience: Charting a Path towards Greater Security and Sustainability. COM 474 Final. 2020. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:52020DC0474&from=EN (accessed on 27 September 2021).

- Van Beilen, J.B.; Poirier, Y. Guayule and Russian Dandelion as Alternative Sources of Natural Rubber. Crit. Rev. Biotechnol. 2007, 27, 217–231. [Google Scholar] [CrossRef]

- Fraunhofer. Better than Natural Rubber BISYKA Biomimetic Synthetic Rubber. 2019. Available online: https://www.polymer-pilotanlagen.de/content/dam/polymer-pilotanlagen/en/documents/Fraunh-fer_Brosch%C3%BCre%20BISYKA_Englisch_WEB.pdf (accessed on 27 September 2021).

- Fraunhofer-Gesellschaft Kreislaufwirtschaft. Carbon Black aus Autoreifen Recyceln. Forschung Kompakt. 2021. Available online: https://www.fraunhofer.de/de/presse/presseinformationen/2021/juli-2021/carbon-black-aus-autoreifen-recyceln.html (accessed on 27 September 2021).

- Recovered Carbon Black. Hightech-Rohstoff Carbon Black. Available online: https://recovered-carbon-black.com/ (accessed on 27 September 2021).

- BVSE. bvse-Ausschuss Recycling von Reifen und Gummi Gegründet. 2020. Available online: https://www.bvse.de/reifen-und-gummi/themen-meldungen-ausschuss-reifen/6593-bvse-ausschuss-recycling-von-reifen-und-gummi-gegruendet.html (accessed on 27 September 2021).

- Michelin. 100% Sustainable: Disruptive Innovation in Biosourced and Recycled Materials. 2021. Available online: https://www.michelin.com/en/innovation/vision-concept/sustainable/ (accessed on 27 September 2021).

- ETRMA. Management Systems of End-of-Life Tyres. 2019. Available online: https://www.etrma.org/key-topics/circular-economy/ (accessed on 27 September 2021).

- Reifen. Optimiert. 2012. Available online: https://azur-netzwerk.de/wp-content/uploads/Spritsparreifen.pdf (accessed on 27 September 2021).

- Araujo-Morera, J.; Verdejo, R.; López-Manchado, M.A.; Santana, M.H. Sustainable mobility: The route of tires through the circular economy model. Waste Manag. 2021, 126, 309–322. [Google Scholar] [CrossRef]

- ZARE. Used Tire Recovery & Recycling in Germany. Used Tire Recovery and Recycling in Germany 2019 (Tonnage) as of August 2020. Available online: https://zertifizierte-altreifenentsorger.de/nachhaltige-altreifenentsorgung/altreifenverwertung-in-deutschland/ (accessed on 27 September 2021).

- Sienkiewicz, M.; Kucinska-Lipka, J.; Janik, H.; Balas, A. Progress in used tyres management in the European Union: A review. Waste Manag. 2012, 32, 1742–1751. [Google Scholar] [CrossRef]

- Walter, C. PS WELT Materialcheck. Was Taugen Runderneuerte Reifen Wirklich? 2015. Available online: https://www.welt.de/motor/article138565689/Was-taugen-runderneuerte-Reifen-wirklich.html (accessed on 27 September 2021).

- Wurster, S.; Schulze, R.; Simon, R.G.; Hoyer, S. A Grounded Theory on Sustainable Circular Public Procurement in Germany: Specific Product Case and Strategies. Sustainability. 2021, 13, 13525. [Google Scholar] [CrossRef]

- European Commission. Policy: Public Procurement. 2021. Available online: https://ec.europa.eu/info/policies/public-procurement (accessed on 27 September 2021).

- European Union. Public Procurement for a Circular Economy: Good Practice and Guidance. 2021. Available online: https://ec.europa.eu/environment/gpp/pdf/CP_European_Commission_Brochure_webversion_small.pdf (accessed on 4 November 2021).

- Commission of the European Communities. Communication from the Commission to the European Parliament, the Council, the European Economic and Social Committee and the Committee of the Regions. Public Procurement for a Better Environment. COM 2008. Available online: https://eur-lex.europa.eu/LexUriServ/LexUriServ.do?uri=COM:2008:0400:FIN:EN:PDF (accessed on 4 November 2021).

- Cheng, W.; Appolloni, A.; D’Amato, A.; Zhu, Q. Green Public Procurement, missing concepts and future trends—A critical review. J. Clean. Prod. 2018, 176, 770–784. [Google Scholar] [CrossRef]

- Liu, J.; Ma, Y.; Appolloni, A.; Cheng, W. How external stakeholders drive the green public procurement practice? An organizational learning perspective. J. Oncol. Pharm. Pract. 2021, 21, 138–166. [Google Scholar] [CrossRef]

- Ma, Y.; Liu, Y.; Appolloni, A.; Liu, J. Does green public procurement encourage firm’s environmental certification practice? The mediation role of top management support. Corp Soc. Responsib. Environ. Manag. 2021, 28, 1002–1017. [Google Scholar] [CrossRef]

- Rainville, A. Stimulating a more Circular Economy through Public Procurement: Roles and dynamics of intermediation. Res. Policy 2021, 50, 104193. [Google Scholar] [CrossRef]

- Neessen, P.C.M.; Caniëls, M.C.J.; Vos, B.; de Jong, J.P. How and when do purchasers successfully contribute to the implementation of circular purchasing: A comparative case-study. J. Purch. Supply Manag. 2021, 27, 100669. [Google Scholar] [CrossRef]

- Hald, K.S.; Wiik, S.; Larssen, A. Sustainable procurement initiatives and their risk-related costs: A framework and a case study application. Mol. Biol. Evol. 2021, 25, 230–243. [Google Scholar] [CrossRef]

- Siminica, M.; Avram, M.; Roxana, L.P.; Avram, L. The Adoption of the National Green Procurement Plans from the Perspective of Circular Economy. Amfiteatru Econ. 2020, 22, 15–27. [Google Scholar] [CrossRef]

- Gåvertsson, I.; Milios, L.; Dalhammar, C. Quality Labelling for Re-used ICT Equipment to Support Consumer Choice in the Circular Economy. J. Consum. Policy 2020, 43, 353–377. [Google Scholar] [CrossRef] [Green Version]

- Al Hosni, I.S.; Amoudi, O.; Callaghan, N. An Exploratory Study on Challenges of Circular Economy in the Built Environment in Oman. In Proceedings of the Institution of Civil Engineers Management, Procurement and Law; ICE Virtual Library: London, UK, 2020; Volume 173, pp. 104–113. [Google Scholar] [CrossRef]

- Zaidi, S.A.H.; Mirza, F.M.; Hou, F.; Ashraf, R.U. Addressing the sustainable development through sustainable procurement: What factors resist the implementation of sustainable procurement in Pakistan? Socio-Econ. Plan. Sci. 2019, 68, 100671. [Google Scholar] [CrossRef]

- Dalhammar, C. The Application of ‘life cycle thinking’ in European environmental law: Theory and practice. J. Eur. Environ. Plan. Law 2015, 12, 97–127. [Google Scholar] [CrossRef]

- Umweltbundesamt. Leitfaden zur Umweltfreundlichen Öffentlichen Beschaffung von Fahrzeugreifen. 2012. Available online: https://www.nachhaltige-beschaffung.info/DE/DokumentAnzeigen/dokument-anzeigen.html?idDocument=45&view=knbdownload (accessed on 26 November 2021).

- BMU. Umweltfreundliche Öffentliche Beschaffung. 2020. Available online: https://www.bmu.de/themen/wirtschaft-produkte-ressourcen-tourismus/produkte-und-konsum/umweltfreundliche-beschaffung/ (accessed on 27 September 2021).

- FEMNET. Möglichkeiten einer Ökologisch und Sozial Nachhaltigen Öffentlichen Beschaffung. Leitfaden Erstellt im Auftrag von FEMNET e.V. 2019. Available online: https://femnet.de/download/send/22-beschaffung/98-moeglichkeiten-einer-oekologischen-sozial-nachhaltigen-beschaffung-femnet-leitfaden.html (accessed on 27 September 2021).

- BMJV/BfJ. Verordnung über die Vergabe Öffentlicher Aufträge (Vergabeverordnung—VgV). 2016. Available online: https://www.gesetze-im-internet.de/vgv_2016/ (accessed on 27 September 2021).

- BMWI. Bundesministerium für Wirtschaft und Energie Bekanntmachung der Verfahrensordnung für die Vergabe Öffentlicher Liefer und Dienstleistungsaufträge Unterhalb der EU-Schwellenwerte (Unterschwellenvergabeordnung—UVgO)—Ausgabe. 2017. Available online: https://www.bmwi.de/Redaktion/DE/Downloads/U/unterschwellenvergabeordnung-uvgo.pdf?__blob=publicationFile&v=6 (accessed on 27 September 2021).

- Siedenberg, A. Erfahrungen aus der Praxis Nachhaltiger Beschaffung in Kommunen. In Proceedings of the Wer Zahlt Bestimmt die Musik, Web-Seminar of the EnergieAgentur, NRW and Prosperkolleg, Online, 25 March 2021. [Google Scholar]

- Besch, A. Vergaberecht und Nachhaltigkeit. 2020. Available online: http://www.nachhaltige-beschaffung.info/DE/VergaberechtundNachhaltigkeit/neuesvergaberecht_node.html (accessed on 27 September 2021).

- Witzel, A. The Problem-centered Interview. Forum Qualitative Sozialforschung / Forum: Qualitative Social Research. Qual. Res. Natl. Discip. Methodical Empir. Ex. 2000, 1, 22. [Google Scholar] [CrossRef]

- Merten, K. Inhaltsanalyse: Einführung in Theorie, Methode und Praxis; Westdeutscher Verlag: Opladen, Germany, 1983. [Google Scholar]

- Mayring, P. Qualitative Inhaltsanalyse. In Qualitative Forschung in der Psychologie, Grundfragen, Verfahrensweisen, Anwendungsfelder; Jüttemann, G., Ed.; Beltz: Weinheim, Germany, 1985; pp. 187–211. [Google Scholar]

- European Union. Directive 2014/24/EU of the European Parlament and of the Council on Public Procurement and Repealing Directive 2004/18/EC. 2014. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:32014L0024&from=DE (accessed on 1 November 2021).

- Forum Vergabe. Anhang XIV zu RL 2014/24/EU: Dienstleistungen nach Artikel 74. 2016. Available online: http://www.forum-vergabe.de/fileadmin/user_upload/Gesetzestexte/2016.05_ANHANG_XIV_RL_2014-24-EU_A5.pdf (accessed on 29 October 2021).

- Niese, N.; Pieper, C.; Arora, A.; Xie, A. The Case for a Circular Economy in Electric Vehicle Batteries. 2020. Available online: https://www.bcg.com/publications/2020/case-for-circular-economy-in-electric-vehicle-batteries (accessed on 4 November 2021).

- Qiao, D.; Wang, G.; Gao, T.; Wen, B.; Dai, T. Potential impact of the end-of-life batteries recycling of electric vehicles on lithium demand in China: 2010–2050. Sci. Total Environ. 2021, 764, 142835. [Google Scholar] [CrossRef]

- Businesswire. Global Bio-Based Polyurethane Market Report 2021: Increasing Product Demand from the Automotive Industry—Forecast to 2028. ResearchAndMarkets.com. 2021. Available online: https://www.businesswire.com/news/home/20211103005954/en/Global-Bio-based-Polyurethane-Market-Report-2021-Increasing-Product-Demand-from-the-Automotive-Industry---Forecast-to-2028---ResearchAndMarkets.com (accessed on 4 November 2021).

- Vreugdenhil, H.; Taljaard, S.; Slinger, J.H. Pilot projects and their diffusion: A case study of integrated coastal management in South Africa. Int. J. Sustain. Dev. 2012, 15, 148–172. [Google Scholar] [CrossRef]

- 320° Ein Reifen, der aus Recyclingmaterial Besteht und CO2 Absorbiert. 2021. Available online: https://320grad.de/ein-reifen-der-aus-recyclingmaterial-besteht-und-co2-absorbiert/ (accessed on 3 February 2020).

- Sönnichsen, S.D.; Clement, J. Review of green and sustainable public procurement: Towards circular public procurement. J. Clean. Prod. 2020, 245, 118901. [Google Scholar] [CrossRef]

| Type of Public Organisation * | Tyre Demand Per Year or Contract Period (Range) | Interview Length (Range) |

|---|---|---|

| Organisation with overarching expertise | NA | 31–60 min |

| Public procurement office | >10,000 | ≤30 min |

| Central procurement office | 5001–10,000 | 31–60 min |

| Central procurement office | 5001–10,000 | 31–60 min |

| A municipal waste management company | Several thousand tyres in 3 years | ≤30 min |

| Central procurement office | 1001–5000 | ≤30 min |

| The central fleet of a Federal State’s police | 1001–5000 | 31–60 min |

| Central fleet management of a big city | 501–1000 | 31–60 min |

| Procurer for municipalities | 251–500 | ≤30 min |

| The waste management company of a district | 251–500 | ≤30 min |

| A municipal company for street cleaning and waste disposal | 251–500 | ≤30 min |

| The waste management company of a municipality | 101–250 | 31–60 min |

| Office for waste disposal, street cleaning, and vehicle fleet of a city | 101–250 | ≤30 min |

| Public utility | <100 | ≤30 min |

| Technical service of a city | <100 | ≤30 min |

| Central garage of a district | <100 | ≤30 min |

| A city’s company for waste, streets, and greenery | <100 | ≤30 min |

| A district office | <100 | 31–60 min |

| A district office | <100 | >60 min |

| A district office | <100 (sustainable procurement unit) | ≤30 min |

| Major city | N.a. but approx. 700 vehicles | 31–60 min |

| Procurement unit of a public institution | -(≈100 leased vehicles) | ≤30 min |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Wurster, S.; Schulze, R.; Simon, R.G. On the Road to Circular Public Procurement: Case, Variations, and Potential Actions in Germany. Sustainability 2021, 13, 13784. https://doi.org/10.3390/su132413784

Wurster S, Schulze R, Simon RG. On the Road to Circular Public Procurement: Case, Variations, and Potential Actions in Germany. Sustainability. 2021; 13(24):13784. https://doi.org/10.3390/su132413784

Chicago/Turabian StyleWurster, Simone, Rita Schulze, and Ramona G. Simon. 2021. "On the Road to Circular Public Procurement: Case, Variations, and Potential Actions in Germany" Sustainability 13, no. 24: 13784. https://doi.org/10.3390/su132413784

APA StyleWurster, S., Schulze, R., & Simon, R. G. (2021). On the Road to Circular Public Procurement: Case, Variations, and Potential Actions in Germany. Sustainability, 13(24), 13784. https://doi.org/10.3390/su132413784