Multi-Objective Optimization for Sustainable Supply Chain and Logistics: A Review

Abstract

1. Introduction

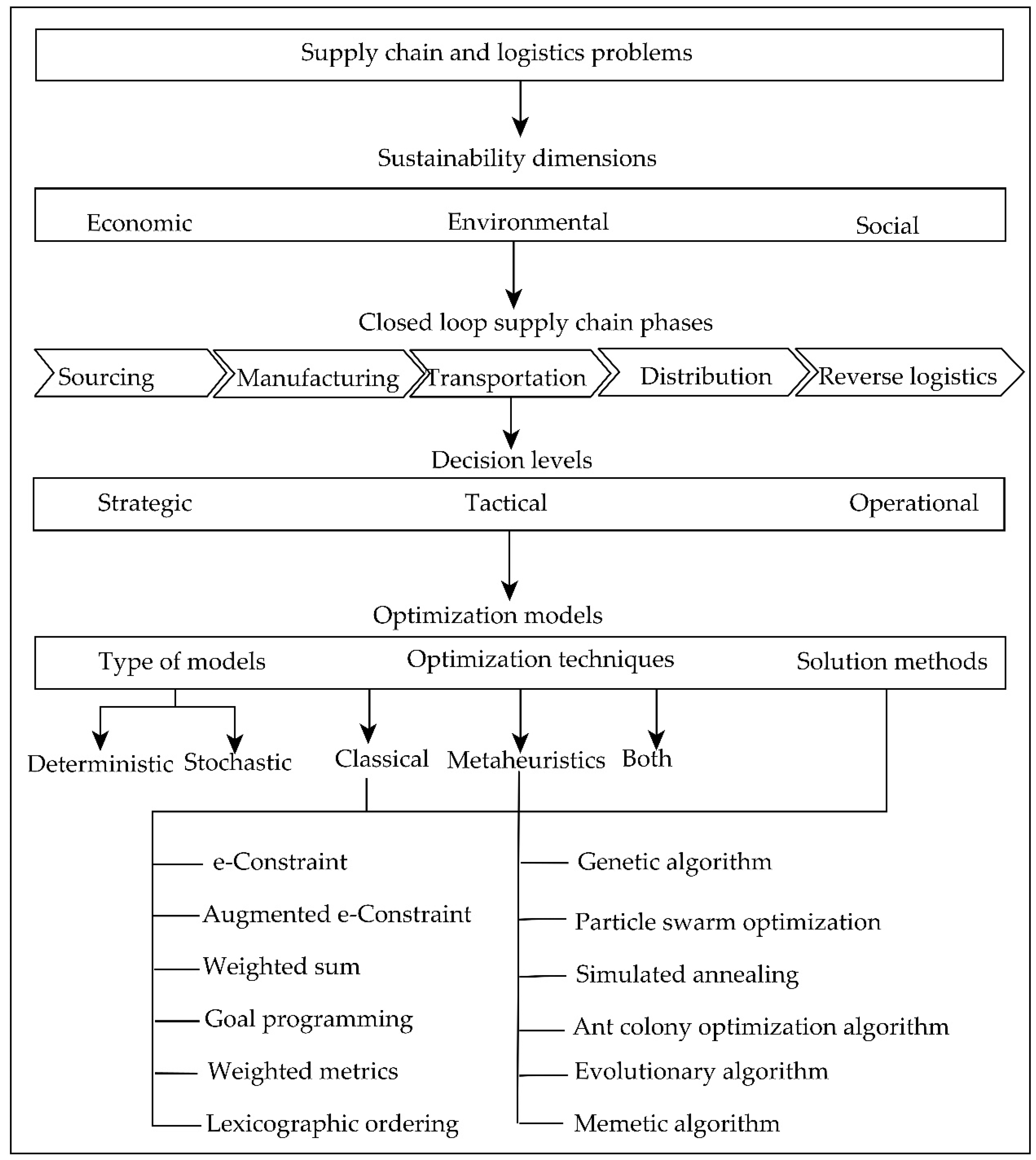

2. Methodology

- Step 1: Formulation of research questions

- (i)

- What dimensions and indicators of sustainability are over-presented in MOO of supply chain and logistics models?

- (ii)

- Which supply chain phases and decision levels are discussed in the SSCLM?

- (iii)

- Which type of optimization technique and solution method is used to address SSCLM?

- (iv)

- To what extent uncertainty has been incorporated into SSCLM and what optimization techniques and solution methods are used to address uncertainty in SSCLM?

- Step 2: Locating studies

- Step 3: Screening and selection

- Step 4: Reviewing and analyzing

Framework of the Study

3. Data Analysis

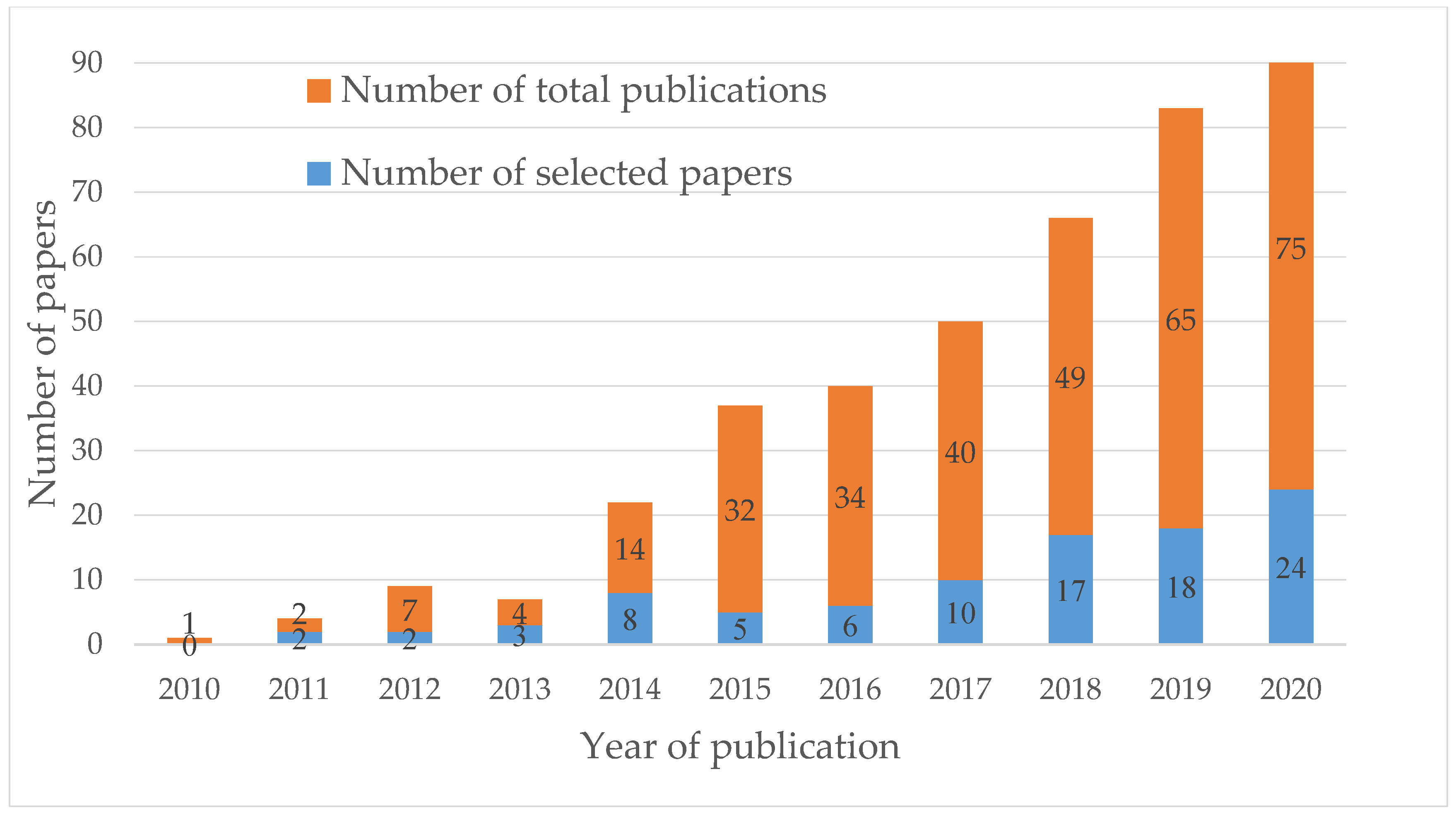

3.1. Distribution of Articles by Time and Outlet

3.2. Analysis of Articles by Sustainability Dimensions and Indicators

3.3. Supply Chain Phases and Decision Levels from a Sustainable Perspective

3.4. Optimization Techniques and Solution Methods

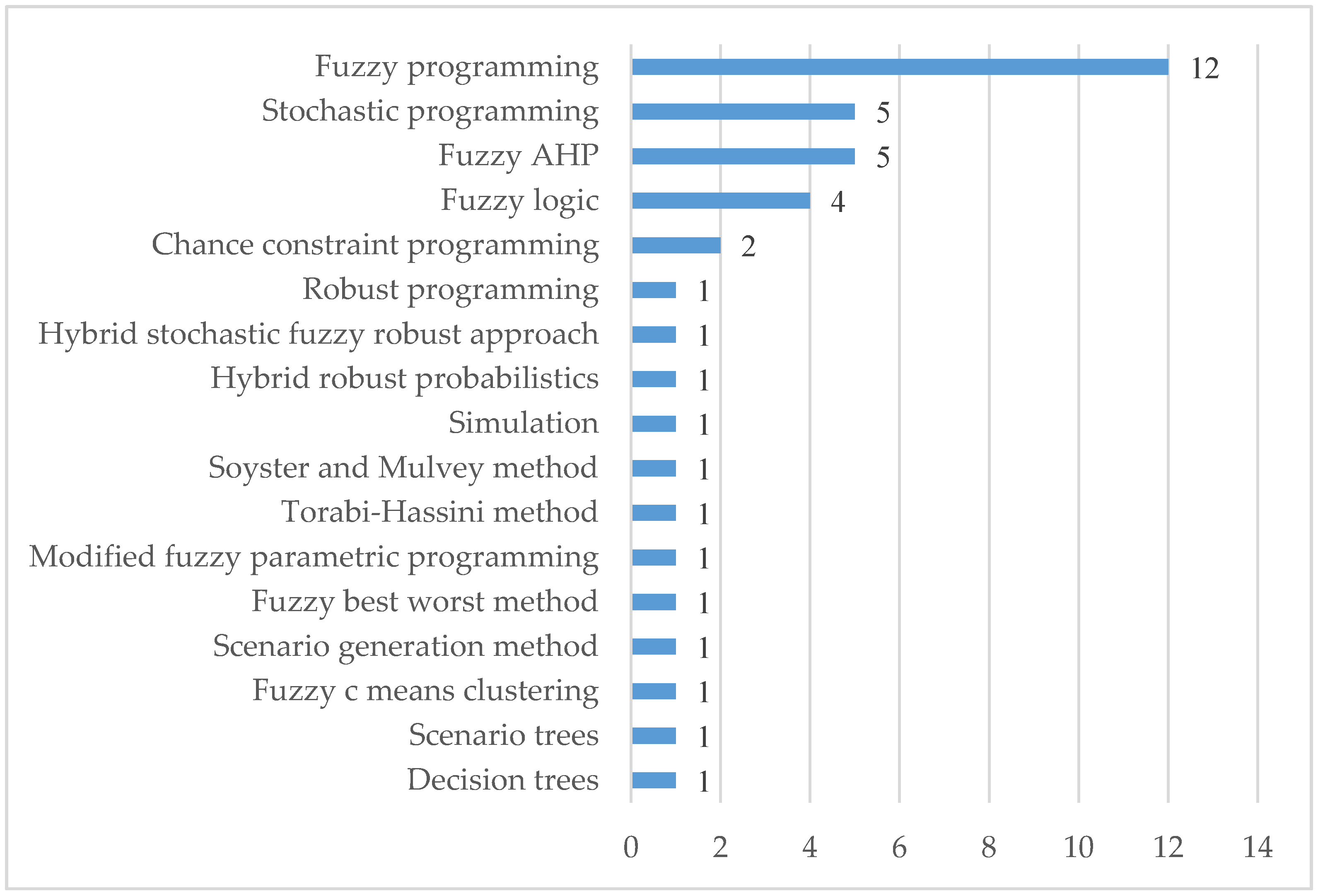

3.5. Uncertainty in Supply Chains

4. Results and Discussion

5. Conclusions and Recommendations for Future Research

- In the absence of broad indicators of sustainability assessment and limited focus on the social dimension, the authors suggest incorporating more social aspects and integrating economic, environmental, and social indicators into the future of SSCLM. For example, innovation can be considered as an economic indicator in addition to cost, quality, and delivery flexibility to maximize competitive advantage [90], which is one of the main economic objectives in supply chain modeling. As indicated in the GRI (Global Reporting Initiative) standard [91], indirect economic impact, anti-corruption, and anti-competitive behavior from economic aspects, the material used, biodiversity, supplier environmental assessment from environmental aspects, training and development, non-discrimination, human rights, and supplier social assessment from social aspects can be considered as sustainability indicators. Comprehensive economic, environmental, and social indicators proposed by [92] can also be used in SSCLM.

- To incorporate the sustainability indicators into the optimization models, quantification is a barrier. Direct and indirect economic benefits can be quantified using the cost of implementing green practices, cost savings of using reverse logistics practices, and return on environmental and social investment. Social impact can be quantified using factors, including the number of health and safety training, cost of health and safety training, average hours of training on anti-corruption policies and procedures, reported cases of corruption and bribery, employee happiness index, community satisfaction rate, and number of CSR initiatives. The use of comprehensive techniques, including LCA and S-LCA, for measuring environmental and social impact have more research potential in this case. The authors propose to combine social science research techniques, including surveys and case research, especially for social sustainability assessment in optimization models, to avoid its limitations and ensure data quality.

- More SSCLMs for sourcing, distribution, and transportation phases of the supply chain are required. Of these phases, the transportation phase requires more focus on strategic decisions, for example, a decision to use electric vehicles to reduce Co2 emissions. The integration of all levels of decision with uncertainty factors to the model is also emphasized as a solution method to address uncertainty is limited to fuzzy programming. Incorporating more demand and supply-related uncertainty factors in a model can lead to exploring other solution methods, such as simulation, scenario and robust programming. Dividing the optimization model into different phases, including decision levels or supply chain phases, is recommended as it will help reduce problem space and the solution time. As all these considerations make optimization models more complex and larger, more sophisticated techniques and solution methods, the inclusion of hybrid metaheuristics approaches will be more useful in SSCLM. Furthermore, the authors propose the use of more hybrid and decomposed optimization methods that have direct implications for solving many real-world cases. Other OR methods, including simulation and system dynamics modeling, can also be applied and combined in future research, which facilitates decision-makers to acquire a more comprehensive picture of the sustainable supply chain and logistics issues.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Reference | Min. Cost/ Max. Profit/ Max. Oper. Performance | Min. Lead Time/ Travel Time | Max. Eco. Benefits | Max. NPV/ Min. PV of Cost | Max. Resilience | Max. Total Quality | Min. Financial Risk | Min. Travel Distance | Max. Reliability | Max. Responsiveness | Max. Supplier Performance |

|---|---|---|---|---|---|---|---|---|---|---|---|

| [5] | * | ||||||||||

| [6] | * | ||||||||||

| [9] | * | ||||||||||

| [10] | * | * | |||||||||

| [14] | * | ||||||||||

| [39] | * | ||||||||||

| [40] | * | * | |||||||||

| [41] | * | ||||||||||

| [42] | * | * | |||||||||

| [43] | * | ||||||||||

| [44] | * | ||||||||||

| [45] | * | ||||||||||

| [46] | * | ||||||||||

| [47] | * | ||||||||||

| [48] | * | ||||||||||

| [49] | * | ||||||||||

| [50] | * | * | |||||||||

| [51] | * | ||||||||||

| [52] | * | ||||||||||

| [53] | * | ||||||||||

| [54] | * | ||||||||||

| [55] | * | ||||||||||

| [56] | * | * | |||||||||

| [57] | * | ||||||||||

| [58] | * | ||||||||||

| [59] | * | ||||||||||

| [60] | * | ||||||||||

| [61] | * | ||||||||||

| [62] | * | ||||||||||

| [63] | * | ||||||||||

| [64] | * | ||||||||||

| [65] | * | ||||||||||

| [66] | * | ||||||||||

| [67] | * | ||||||||||

| [68] | * | ||||||||||

| [69] | * | ||||||||||

| [70] | * | ||||||||||

| [71] | * | ||||||||||

| [72] | * | ||||||||||

| [73] | * | ||||||||||

| [74] | * | * | |||||||||

| [75] | * | * | |||||||||

| [76] | * | ||||||||||

| [77] | * | * | |||||||||

| [78] | * | ||||||||||

| [79] | * | ||||||||||

| [80] | * | ||||||||||

| [87] | * | ||||||||||

| [88] | * | * | |||||||||

| [93] | * | ||||||||||

| [94] | * | ||||||||||

| [95] | * | ||||||||||

| [96] | * | * | |||||||||

| [97] | * | ||||||||||

| [98] | * | ||||||||||

| [99] | * | ||||||||||

| [100] | * | ||||||||||

| [101] | * | ||||||||||

| [102] | * | ||||||||||

| [103] | * | ||||||||||

| [104] | * | ||||||||||

| [105] | * | * | |||||||||

| [106] | * | ||||||||||

| [107] | * | ||||||||||

| [108] | * | ||||||||||

| [109] | * | ||||||||||

| [110] | * | ||||||||||

| [111] | * | * | |||||||||

| [112] | * | * | |||||||||

| [113] | * | ||||||||||

| [114] | * | ||||||||||

| [115] | * | ||||||||||

| [116] | * | * | |||||||||

| [117] | * | * | |||||||||

| [118] | * | ||||||||||

| [119] | * | ||||||||||

| [120] | * | ||||||||||

| [121] | * | ||||||||||

| [122] | * | ||||||||||

| [123] | * | ||||||||||

| [124] | * | ||||||||||

| [125] | * | * | |||||||||

| [126] | * | ||||||||||

| [127] | * | ||||||||||

| [128] | * | ||||||||||

| [129] | * | ||||||||||

| [130] | * | ||||||||||

| [131] | * | * | * | ||||||||

| [132] | * | * | * | ||||||||

| [133] | * | ||||||||||

| [134] | * | ||||||||||

| [135] | * | * | |||||||||

| [136] | * | ||||||||||

| [137] | * | ||||||||||

| [138] | * | * | |||||||||

| 85 | 12 | 5 | 4 | 3 | 2 | 1 | 1 | 2 | 1 | 1 |

Appendix B

| Environmental Objectives | Social Objectives | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Reference | Min. GHG/CO2 Emission/GWP | Min. env. Impact/ Max. env. Performance | Min. Energy Consumption/ Max. Energy Recovery | Min. Waste | Min. Noise Pollution | Min. Water Consumption | Max. Social Benefits/ Min. Social Impact | Max. Job OPPORTUNITIES | Min. emp. Injuries | Min. Human Resource Variations | Min. Lost Working Days | Max. Community Development |

| [5] | * | |||||||||||

| [6] | * | * | ||||||||||

| [9] | * | * | ||||||||||

| [10] | * | * | ||||||||||

| [14] | * | |||||||||||

| [39] | * | |||||||||||

| [40] | * | |||||||||||

| [41] | * | * | ||||||||||

| [42] | * | |||||||||||

| [43] | * | * | * | |||||||||

| [44] | * | |||||||||||

| [45] | * | |||||||||||

| [46] | * | |||||||||||

| [47] | * | |||||||||||

| [48] | * | * | ||||||||||

| [49] | * | * | ||||||||||

| [50] | * | |||||||||||

| [51] | * | |||||||||||

| [52] | * | * | ||||||||||

| [53] | * | |||||||||||

| [54] | * | * | * | * | ||||||||

| [55] | * | |||||||||||

| [56] | * | |||||||||||

| [57] | * | |||||||||||

| [58] | * | * | ||||||||||

| [59] | * | * | ||||||||||

| [60] | * | * | ||||||||||

| [61] | * | * | ||||||||||

| [62] | * | * | ||||||||||

| [63] | * | * | ||||||||||

| [64] | * | * | ||||||||||

| [65] | * | * | ||||||||||

| [66] | * | * | * | * | * | |||||||

| [67] | * | * | ||||||||||

| [68] | * | * | ||||||||||

| [69] | * | * | ||||||||||

| [70] | * | |||||||||||

| [71] | * | |||||||||||

| [72] | * | * | ||||||||||

| [73] | * | * | ||||||||||

| [74] | * | * | ||||||||||

| [75] | * | * | ||||||||||

| [76] | * | |||||||||||

| [77] | * | |||||||||||

| [78] | * | |||||||||||

| [79] | * | |||||||||||

| [80] | * | * | ||||||||||

| [87] | * | * | ||||||||||

| [88] | * | |||||||||||

| [94] | * | |||||||||||

| [95] | * | |||||||||||

| [96] | * | |||||||||||

| [97] | * | * | ||||||||||

| [98] | * | |||||||||||

| [99] | * | |||||||||||

| [100] | * | |||||||||||

| [101] | * | * | ||||||||||

| [102] | * | |||||||||||

| [103] | * | |||||||||||

| [104] | * | * | * | * | ||||||||

| [105] | * | |||||||||||

| [106] | * | |||||||||||

| [107] | * | |||||||||||

| [108] | * | * | ||||||||||

| [109] | * | * | * | |||||||||

| [110] | * | * | * | |||||||||

| [111] | * | * | ||||||||||

| [112] | * | |||||||||||

| [113] | * | |||||||||||

| [114] | * | * | ||||||||||

| [115] | * | * | ||||||||||

| [116] | * | |||||||||||

| [117] | * | * | ||||||||||

| [118] | * | |||||||||||

| [119] | * | * | ||||||||||

| [120] | * | |||||||||||

| [121] | * | * | ||||||||||

| [122] | * | |||||||||||

| [123] | * | * | ||||||||||

| [124] | * | * | ||||||||||

| [125] | * | |||||||||||

| [126] | * | * | ||||||||||

| [127] | * | * | ||||||||||

| [128] | * | |||||||||||

| [129] | * | |||||||||||

| [130] | * | |||||||||||

| [131] | * | * | ||||||||||

| [132] | * | |||||||||||

| [133] | * | |||||||||||

| [134] | * | * | ||||||||||

| [135] | * | |||||||||||

| [136] | * | * | ||||||||||

| [137] | * | |||||||||||

| [138] | * | |||||||||||

| 48 | 42 | 8 | 3 | 1 | 5 | 26 | 12 | 2 | 1 | 1 | 1 | |

Appendix C

| Reference | Sustainability Dimension | Supply Chain (SC) Phases | SC Decision Level | SC Environment | Optimization Technique | Solution Method |

|---|---|---|---|---|---|---|

| [5] | Eco/Env | Overall Supply Chain | Strategic | Uncertainty | Classical | Weighted sum/Torabi-Hassini method |

| [6] | Eco/Env/ Soc | Overall Supply Chain | Strategic | Certain | Metaheuristic | PSO |

| [9] | Eco/Env/ Soc | Overall Supply Chain | Strategic/ Tactical | Uncertainty | Classical | Fuzzy goal programming/Fuzzy best worst method |

| [10] | Eco/Env/ Soc | Overall Supply Chain | Strategic | Certain | Classical | Augmented e-Constraint |

| [14] | Eco/Env | Overall Supply Chain | Strategic | Certain | Metaheuristic | PSO |

| [39] | Eco/Soc | Reverse Logistics | Tactical | Certain | Classical/Metaheuristic | e-Constraint/NSGA-II |

| [40] | Eco/Soc | Overall Supply Chain | Strategic | Uncertainty | Classical | Weighted sum/hybrid stochastic fuzzy-robust |

| [41] | Eco/Env/ Soc | Overall Supply Chain | Strategic | Certain | Classical | Augmented e-Constraint |

| [42] | Eco/Env | Overall Supply Chain | Strategic | Uncertainty | Classical | e-Constraint/Soyster and Mulvey method |

| [43] | Eco/Env/ Soc | Overall Supply Chain | Strategic | Certain | Classical | AHP and Ordered weighted averaging (OWA) |

| [44] | Eco/Env | Manufacturing | Tactical | Uncertainty | Classical | Weighted sum/Fuzzy logic |

| [45] | Eco/Env | Manufacturing | Tactical | Certain | Classical | weighted sum |

| [46] | Eco/Env | Manufacturing | Tactical | Uncertainty | Metaheuristic | Lagrangian relaxation (LR) algorithm/stochastic programming |

| [47] | Eco/Env | Manufacturing | Tactical | Certain | Classical | Weighted goal programming |

| [48] | Eco/Env/ Soc | Manufacturing/Distribution | Operational | Certain | Classical | Weighted sum |

| [49] | Eco/Env/ Soc | Distribution | Operational/Strategic | Certain | Metaheuristic | Hybrid swarm intelligence meta-heuristic |

| [50] | Eco/Env/ Soc | Overall Supply Chain | Tactical/ Operational | Certain | Metaheuristic | NSGA II/PSO |

| [51] | Eco/Env | Overall Supply Chain | Strategic/ Tactical | Uncertainty | Classical | Augmented e-Constraint/Decision trees |

| [52] | Eco/Env/ Soc | Overall Supply Chain | Strategic/ Tactical | Uncertainty | Metaheuristic | Fuzzy possibilistic programming/Simulated annealing |

| [53] | Eco/Env | Overall Supply Chain | Strategic/ Tactical | Uncertainty | Metaheuristic | EA/Fuzzy programming |

| [54] | Eco/Env/ Soc | Overall Supply Chain | Strategic/ Tactical | Certain | Classical | Goal programming/e-Constraint method |

| [55] | Eco/Env | Overall Supply Chain | Strategic/Tactical | Uncertainty | Classical | e-Constraint/Fuzzy logic |

| [56] | Eco/Env | Overall Supply Chain | Strategic/Tactical/Operational | Uncertainty | Classical | Fuzzy programming/Weighted min max |

| [57] | Eco/Env | Overall Supply Chain | Strategic/Tactical/Operational | Certain | Metaheuristic | Mematic algorithm/Taguchi |

| [58] | Eco/Env/ Soc | Manufacturing | Strategic/Tactical/Operational | Certain | Classical | Exact solution approach (Non dominated points) |

| [59] | Eco/Env | Manufacturing | Strategic | Certain | Classical | e-Constraint |

| [60] | Eco/Env/ Soc | Manufacturing | Strategic | Uncertainty | Classical | Meta goal programming/simulation |

| [61] | Eco/Env/ Soc | Manufacturing | Strategic | Uncertainty | Classical | Fuzzy AHP/Max-min |

| [62] | Eco/Env/ Soc | Reverse Logistics | Strategic | Certain | Classical | Augmented e-Constraint |

| [63] | Eco/Env/ Soc | Reverse Logistics | Strategic | Uncertainty | Classical | Weighted goal programming/chance constraint method |

| [64] | Eco/Env/ Soc | Reverse Logistics | Strategic | Certain | Classical | Weighted sum/Augmented e-Constraint |

| [65] | Eco/Env/ Soc | Reverse Logistics | Tactical | Certain | Classical | e-Constraint |

| [66] | Eco/Env/ Soc | Reverse Logistics | Strategic | Uncertainty | Classical | Fuzzy programming |

| [67] | Eco/Env/ Soc | Reverse Logistics | Strategic | Certain | Metaheuristic | NSGA II/PSO |

| [68] | Eco/Env/ Soc | Reverse Logistics | Tactical | Uncertainty | Metaheuristic | PSO/Fuzzy programming |

| [69] | Eco/Env | Reverse Logistics | Strategic | Uncertainty | Classical | Fuzzy AHP/Weighted comprehensive criterian method |

| [70] | Eco/Env | Reverse Logistics | Strategic | Certain | Metaheuristic | Centre of gravity/K means clustering |

| [71] | Eco/Env | Reverse Logistics | Strategic | Uncertainty | Classical | e-Constraint/Senario generation method |

| [72] | Env/Soc | Overall Supply Chain | Strategic | Certain | Classical | PROMTHEE/Goal programming |

| [73] | Eco/Env/ Soc | Overall Supply Chain | Strategic/ Tactical | Uncertainty | Metaheuristic | NSGA II/Fuzzy programming |

| [74] | Eco/Env | Manufacturing | Strategic | Uncertainty | Classical | e-Constraint/Fuzzy AHP |

| [75] | Eco/Env/ Soc | Sourcing | Strategic | Uncertainty | Classical | e-Constraint/Fuzzy AHP |

| [76] | Eco/Env/ Soc | Manufacturing/Distribution | Strategic | Uncertainty | Classical | e-Constraint/stochastic programming |

| [77] | Eco/Env | Sourcing/Distribution | Strategic | Uncertainty | Classical | e-Constraint/stochastic programming |

| [78] | Eco/Env | Manufacturing | Tactical | Uncertainty | Classical | e-Constraint/stochastic programming |

| [79] | Eco/Env | Overall Supply Chain | Strategic | Uncertainty | Classical | LP metric based compromising/Robust programming |

| [80] | Eco/Env/ Soc | Manufacturing/ Distribution | Tactical | Uncertainty | Classical | Improved Augmented e-Constraint method/Hybrid robust probabilistic programming (HRPP II) |

| [87] | Eco/Env/ Soc | Distribution | Tactical | Uncertainty | Metaheuristic | GA/PSO/Chance constraint method |

| [88] | Eco/Env | Overall Supply Chain | Strategic | Uncertainty | Classical | Augmented e-Constraint/Senario tree approach |

| [93] | Eco/Env/ Soc | Overall Supply Chain | Strategic | Uncertainty | Classical | Augmented e-Constraint/Fuzzy logic |

| [94] | Eco/Env | Manufacturing | Strategic | Uncertainty | Classical | e-Constraint/Fuzzy logic |

| [95] | Eco/Env | Manufacturing/ Distribution | Tactical | Certain | Classical | e-Constraint |

| [96] | Eco/Env | Distribution | Tactical | Certain | Classical | Normalized normal constraint method |

| [97] | Eco/Env/ Soc | Overall Supply Chain | Strategic | Certain | Metaheuristic | Hybrid meta-huristic algorithms (AICA/HIV/NIV) |

| [98] | Eco/Env | Manufacturing/Distribution | Strategic | Certain | Classical | e-Constraint |

| [99] | Eco/Env | Overall Supply Chain | Strategic | Certain | Metaheuristic | Hybrid meta-huristic algorithm (MOHEV) |

| [100] | Eco/Env | Distribution/Transportation | Strategic | Certain | Metaheuristic | Hybrid meta-huristic algorithm (MOHEV) |

| [101] | Eco/Env/ Soc | Sourcing/Distribution | Strategic | Uncertainty | Classical | Augmented e-Constraint/Fuzzy c-means clustering |

| [102] | Eco/Env | Overall Supply Chain | Strategic | Certain | Metaheuristic | PSO |

| [103] | Eco/Env | Manufacturing/Distributing | Strategic | Certain | Classical | e-Constraint |

| [104] | Eco/Env/ Soc | Sourcing | Strategic/ Tactical | Uncertainty | Classical | Fuzzy AHP/Weighted sum |

| [105] | Eco/Env | Transportation | Tactical | Certain | Metaheuristic | Ant colony optimization (IACO) algorithm |

| [106] | Eco/Env | Transportation/Reverse Logistics | Tactical | Certain | Metaheuristic | GA |

| [107] | Eco/Env | Sourcing/Manufacturing/Distribution | Strategic/ Tactical | Certain | Classical | Senario method |

| [108] | Eco/Env | Transportation/Distribution | Strategic | Certain | Classical | e-Constraint |

| [109] | Eco/Env | Overall Supply Chain | Strategic | Certain | Classical | Goal programming MINMAX |

| [110] | Eco/Env/ Soc | Overall Supply Chain | Strategic | Certain | Classical | Lexicographic ordering |

| [111] | Eco/Env/ Soc | Overall Supply Chain | Strategic | Uncertainty | Classical | Modified fuzzy parametric programming (MFPP)/weighted metrics |

| [112] | Eco/Env | Transportation/Distribution | Strategic | Certain | Classical | e-Constraint |

| [113] | Eco/Env | Sourcing | Strategic | Uncertainty | Classical | Fuzzy AHP/Weighted sum |

| [114] | Eco/Env/ Soc | Overall Supply Chain | Strategic/ Tactical | Uncertainty | Metaheuristic | NSGA II/Fuzzy programming |

| [115] | Eco/Env/ Soc | Overall Supply Chain | Strategic/ Tactical | Certain | Classical | Augmented e-Constraint and TOPSIS. |

| [116] | Eco/Env | Transportation | Tactical | Certain | Classical | e-Constraint |

| [117] | Eco/Env | Sourcing | Strategic | Certain | Metaheuristic | GA/PSO |

| [118] | Eco/Env | Sourcing/Manufacturing/ Transportation | Strategic/Tactical | Certain | Classical | e-Constraint |

| [119] | Eco/Env/ Soc | Sourcing | Strategic | Certain | Metaheuristic | Hybrid meta-heuristic algoritham (MOHEV) |

| [120] | Eco/Env | Overall Supply Chain | Strategic | Certain | Metaheuristic | GA |

| [121] | Eco/Env /Soc | Transportation | Tactical | Uncertainty | Classical | Fuzzy programming |

| [122] | Eco/Env | Overall Supply Chain | Tactical | Certain | Classical | e-Constraint |

| [123] | Eco/Env/ Soc | Manufacturing/ Distribution | Strategic | Certain | Classical | Normalized normal constraint method |

| [124] | Eco/Env/ Soc | Overall Supply Chain | Strategic | Certain | Metaheuristic | AugMathFix |

| [125] | Eco/Env | Distribution | Tactical | Certain | Metaheuristic | Simulated-annealing Algorithm (MOSA)/NSGA-II |

| [126] | Eco/Env/ Soc | Manufacturing/ Distribution | Strategic/ Tactical | Uncertainty | Classical | Fuzzy programming |

| [127] | Eco/Env/ Soc | Sourcing/Manufacturing/ Distribution | Strategic | Certain | Classical | Augmented e-Constraint |

| [128] | Eco/Env | Distributing | Tactical | Certain | Metaheuristic | GA |

| [129] | Eco/Env | Distributing | Strategic | Certain | Metaheuristic | Non-dominated generic algorithm (NRGA) |

| [130] | Eco/Env | Overall Supply Chain | Strategic | Certain | Classical | Normalized normal constraint |

| [131] | Eco/Env | Manufacturing | Strategic | Certain | Classical | e-Constraint |

| [132] | Eco/Env | Sourcing | Strategic | Certain | Metaheuristic | GA |

| [133] | Eco/Env | Overall Supply Chain | Strategic | Certain | Classical | e-Constraint |

| [134] | Eco/Env | Overall Supply Chain | Strategic/ Tactical | Uncertainty | Classical | Fuzzy programming |

| [135] | Eco/Env/ Soc | Sourcing/Manufacturing/ Transportation | Tactical | Uncertainty | Metaheuristic | Hybrid meta-heuristic algorithm/stochastic programming |

| [136] | Eco/Env | Distribution | Strategic | Uncertainty | Metaheuristic | Hybrid meta-heuristic algorithm/Fuzzy programming |

| [137] | Eco/Env | Distribution | Strategic | Certain | Metaheuristic | Swarm intelligence/ABC |

| [138] | Eco/Env | Overall Supply Chain | Strategic | Certain | Classical | e-Constraint |

References

- Naidelage, C.; Agdas, D.; Rose, T.; Yigitcanlar, T. Stakeholder perception of reverse logistics practices on supply chain performance. Bus. Strategy Environ. 2020, 30, 60–70. [Google Scholar] [CrossRef]

- Zandieh, M.; Aslani, B. A hybrid MCDM approach for order distribution in a multiple-supplier supply chain: A case study. J. Ind. Inf. Integr. 2019, 16, 100104. [Google Scholar] [CrossRef]

- Liu, S.; Papageorgiou, L.G. Multi-objective optimization of production, distribution and capacity planning of global supply chains in the process industry. Omega 2013, 41, 369–382. [Google Scholar] [CrossRef]

- Dekker, R.; Bloemhof, J.; Mallidis, I. Operations Research for green logistics-An overview of aspects, issues, contributions and challenges. Eur. J. Oper. Res. 2012, 219, 671–679. [Google Scholar] [CrossRef]

- Darestani, S.A.; Hemmati, M. Robust optimization of a bi-objective closed-loop supply chain network for perishable goods considering queue system. Comput. Ind. Eng. 2019, 136, 277–292. [Google Scholar] [CrossRef]

- Mota, B.; Gomes, M.I.; Carvalho, A.; Barbosa-Povoa, A.P. Towards supply chain sustainability: Economic, environmental and social design and planning. J. Clean. Prod. 2015, 105, 14–27. [Google Scholar] [CrossRef]

- Jassim, S.; Al-Mubarak, M.; Hamdan, A. The Impact of Green Supply Chain Management on Firm’s Performance. J. Inf. Knowl. Manag. 2020, 19, 2040026. [Google Scholar] [CrossRef]

- Tukamuhabwa, B.; Mutebi, H.; Isabirye, D. Supplier performance in the public healthcare: Internal social capital, logistics capabilities and supply chain risk management capabilities as antecedents in a developing economy. J. Bus. Socio-Econ. Dev. 2021. [Google Scholar] [CrossRef]

- Nasr, K.A.; Tavana, M.; Alavi, B.; Mina, H. A novel fuzzy multi-objective circular supplier selection and order allocation model for sustainable closed-loop supply chains. J. Clean. Prod. 2020, 287, 124994. [Google Scholar] [CrossRef]

- Resat, H.G.; Unsal, B. A novel multi-objective optimization approach for sustainable supply chain: A case study in packaging industry. Sustain. Prod. Consum. 2019, 20, 29–39. [Google Scholar] [CrossRef]

- Barbosa-Póvoa, A.P.; da Silva, C.; Carvalho, A. Opportunities and challenges in sustainable supply chain: An operations research perspective. Eur. J. Oper. Res. 2018, 268, 399–431. [Google Scholar] [CrossRef]

- Banasik, A.; Bloemhof-Ruwaard, J.M.; Kanellopoulos, A.; Claassen, G.D.H.; van der Vorst, J.G.A.J. Multi-criteria decision-making approaches for green supply chains: A review. Flex. Serv. Manuf. J. 2018, 30, 366–396. [Google Scholar] [CrossRef]

- Crainic, T.G.; Perboli, G.; Rosano, M. Simulation of intermodal freight transportation systems: A taxonomy. Eur. J. Oper. Res. 2018, 270, 401–418. [Google Scholar] [CrossRef]

- Chen, L.; Zhao, X.; Tang, O.; Price, L.; Zhang, S.; Zhu, W. Supply chain collaboration for sustainability: A literature review and future research agenda. Int. J. Prod. Econ. 2017, 194, 73–87. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C. An analysis of metrics used to measure performance in green and sustainable supply chains. J. Clean. Prod. 2015, 86, 360–377. [Google Scholar] [CrossRef]

- Brandenburg, M.; Govindan, K.; Sarkis, J.; Seuring, S. Quantitative models for sustainable supply chain management: Developments and directions. Eur. J. Oper. Res. 2014, 233, 299–312. [Google Scholar] [CrossRef]

- Rajeev, A.; Pati, R.K.; Padhi, S.S. Sustainable supply chain management in the chemical industry: Evolution, opportunities, and challenges. Resour. Conserv. Recycl. 2019, 149, 275–291. [Google Scholar] [CrossRef]

- Taticchi, P.; Garengo, P.; Nudurupati, S.S.; Tonelli, F.; Pasqualino, R. A review of decision-support tools and performance measurement and sustainable supply chain management. Int. J. Prod. Res. 2015, 53, 6473–6494. [Google Scholar] [CrossRef]

- Seuring, S. A review of modeling approaches for sustainable supply chain management. Decis. Support Syst. 2013, 54, 1513–1520. [Google Scholar] [CrossRef]

- Denyer, D.; Tranfield, D. Producing a systematic review. In The Sage Handbook of Organizational Research Methods; Buchanan, D.A., Ed.; Sage: London, UK, 2009; Volume 738, pp. 671–689. [Google Scholar]

- Snyder, H. Literature review as a research methodology: An overview and guidelines. J. Bus. Res. 2019, 104, 333–339. [Google Scholar] [CrossRef]

- Trisna, T.; Marimin, M.; Arkeman, Y.; Sunarti, T. Multi-objective optimization for supply chain management problem: A literature review. Decis. Sci. Lett. 2016, 5, 283–316. [Google Scholar] [CrossRef]

- Moreno-Camacho, C.A.; Montoya-Torres, J.R.; Jaegler, A.; Gondran, N. Sustainability metrics for real case applications of the supply chain network design problem: A systematic literature review. J. Clean. Prod. 2019, 231, 600–618. [Google Scholar] [CrossRef]

- Van Engeland, J.; Beliën, J.; De Boeck, L.; De Jaeger, S. Literature review: Strategic network optimization models in waste reverse supply chains. Omega 2020, 91, 102012. [Google Scholar] [CrossRef]

- Zahraee, S.M.; Shiwakoti, N.; Stasinopoulos, P. Biomass supply chain environmental and socio-economic analysis: 40-Years comprehensive review of methods, decision issues, sustainability challenges, and the way forward. Biomass Bioenergy 2020, 142, 105777. [Google Scholar] [CrossRef]

- Ilgin, M.A.; Gupta, S.M. Environmentally conscious manufacturing and product recovery (ECMPRO): A review of the state of the art. J. Environ. Manag. 2010, 91, 563–591. [Google Scholar] [CrossRef]

- Ashby, A. Making connections: A review of supply chain management and sustainability literature. Supply Chain Manag. Int. J. 2012, 17, 497–516. [Google Scholar] [CrossRef]

- Hassini, E.; Surti, C.; Searcy, C. A literature review and a case study of sustainable supply chains with a focus on metrics. Int. J. Prod. Econ. 2012, 140, 69–82. [Google Scholar] [CrossRef]

- Tang, C.S.; Zhou, S. Research advances in environmentally and socially sustainable operations. Eur. J. Oper. Res. 2012, 223, 585–594. [Google Scholar] [CrossRef]

- Alexander, A. Decision theory in sustainable supply chain management: A literature review. Supply Chain Manag. Int. J. 2014, 19, 504–522. [Google Scholar] [CrossRef]

- Brandenburg, M.; Rebs, T. Sustainable supply chain management: A modeling perspective. Ann. Oper. Res. 2015, 229, 213–252. [Google Scholar] [CrossRef]

- Ilgin, M.A.; Gupta, S.M.; Battaïa, O. Use of MCDM techniques in environmentally conscious manufacturing and product recovery: State of the art. J. Manuf. Syst. 2015, 37, 746–758. [Google Scholar] [CrossRef]

- Eskandarpour, M.; Dejax, P.; Miemczyk, J.; Péton, O. Sustainable supply chain network design: An optimization-oriented review. Omega 2015, 54, 11–32. [Google Scholar] [CrossRef]

- Ahi, P.; Searcy, C.; Jaber, M.Y. Energy-related performance measures employed in sustainable supply chains: A bibliometric analysis. Sustain. Prod. Consum. 2016, 7, 1–15. [Google Scholar] [CrossRef]

- Rajeev, A.; Pati, R.K.; Padhi, S.S.; Govindan, K. Evolution of sustainability in supply chain management: A literature review. J. Clean. Prod. 2017, 162, 299–314. [Google Scholar] [CrossRef]

- Malladi, K.T.; Sowlati, T. Sustainability aspects in Inventory Routing Problem: A review of new trends in the literature. J. Clean. Prod. 2018, 197, 804–814. [Google Scholar] [CrossRef]

- Thies, C.; Kieckhäfer, K.; Spengler, T.S.; Sodhi, M.S. Operations research for sustainability assessment of products: A review. Eur. J. Oper. Res. 2019, 274, 1–21. [Google Scholar] [CrossRef]

- Nematollahi, M.; Tajbakhsh, A. Past, present, and prospective themes of sustainable agricultural supply chains: A content analysis. J. Clean. Prod. 2020, 271, 122201. [Google Scholar] [CrossRef]

- Farrokhi-Asl, H.; Makui, A.; Ghousi, R.; Rabbani, M. Developing a hazardous waste management system with consideration of health, safety, and environment. Comput. Electr. Eng. 2020, 82, 106553. [Google Scholar] [CrossRef]

- Sharifi, M.; Hosseini-Motlagh, S.-M.; Samani, M.R.G.; Kalhor, T. Novel resilient-sustainable strategies for second-generation biofuel network design considering Neem and Eruca Sativa under hybrid stochastic fuzzy robust approach. Comput. Chem. Eng. 2020, 143, 107073. [Google Scholar] [CrossRef]

- Varsei, M.; Polyakovskiy, S. Sustainable supply chain network design: A case of the wine industry in Australia. Omega 2017, 66, 236–247. [Google Scholar] [CrossRef]

- Abdolazimi, O.; Salehi Esfandarani, M.; Salehi, M.; Shishebori, D. Robust design of a multi-objective closed-loop supply chain by integrating on-time delivery, cost, and environmental aspects, case study of a Tire Factory. J. Clean. Prod. 2020, 264, 121566. [Google Scholar] [CrossRef]

- Allaoui, H.; Guo, Y.; Choudhary, A.; Bloemhof, J. Sustainable agro-food supply chain design using two-stage hybrid multi-objective decision-making approach. Comput. Oper. Res. 2018, 89, 369–384. [Google Scholar] [CrossRef]

- Rout, C.; Paul, A.; Kumar, R.S.; Chakraborty, D.; Goswami, A. Cooperative sustainable supply chain for deteriorating item and imperfect production under different carbon emission regulations. J. Clean. Prod. 2020, 272, 122170. [Google Scholar] [CrossRef]

- Tiammee, S.; Likasiri, C. Sustainability in corn production management: A multi-objective approach. J. Clean. Prod. 2020, 257, 120855. [Google Scholar] [CrossRef]

- Zheng, M.; Li, W.; Liu, Y.; Liu, X. A Lagrangian heuristic algorithm for sustainable supply chain network considering CO2 emission. J. Clean. Prod. 2020, 270, 122409. [Google Scholar] [CrossRef]

- Sarkar, B.; Omair, M.; Choi, S.-B. A Multi-Objective Optimization of Energy, Economic, and Carbon Emission in a Production Model under Sustainable Supply Chain Management. NATO Advanced Science Institutes Series E. Appl. Sci. 2018, 8, 1744. [Google Scholar] [CrossRef]

- Chen, Z.; Andresen, S. A Multi-objective Optimization Model of Production-Sourcing for Sustainable Supply Chain with Consideration of Social, Environmental, and Economic Factors. Math. Probl. Eng. 2014, 2014, 616107. [Google Scholar] [CrossRef]

- Govindan, K.; Jafarian, A.; Nourbakhsh, V. Designing a sustainable supply chain network integrated with vehicle routing: A comparison of hybrid swarm intelligence metaheuristics. Comput. Oper. Res. 2019, 110, 220–235. [Google Scholar] [CrossRef]

- Wang, Y.; Shi, Q.; Hu, Q.; You, Z.; Bai, Y.; Guo, C. An efficiency sorting multi-objective optimization framework for sustainable supply network optimization and decision making. J. Clean. Prod. 2020, 272, 122842. [Google Scholar] [CrossRef]

- Mohebalizadehgashti, F.; Zolfagharinia, H.; Amin, S.H. Designing a green meat supply chain network: A multi-objective approach. Int. J. Prod. Econ. 2020, 219, 312–327. [Google Scholar] [CrossRef]

- Eskandari-Khanghahi, M.; Tavakkoli-Moghaddam, R.; Taleizadeh, A.A.; Amin, S.H. Designing and optimizing a sustainable supply chain network for a blood platelet bank under uncertainty. Eng. Appl. Artif. Intell. 2018, 71, 236–250. [Google Scholar] [CrossRef]

- Arampantzi, C.; Minis, I. A new model for designing sustainable supply chain networks and its application to a global manufacturer. J. Clean. Prod. 2017, 156, 276–292. [Google Scholar] [CrossRef]

- Saffar, M.; Razmi, J. A new multi objective optimization model for designing a green supply chain network under uncertainty. Int. J. Ind. Eng. Comput. 2015, 6, 15–32. [Google Scholar] [CrossRef][Green Version]

- Azadeh, A.; Shafiee, F.; Yazdanparast, R.; Heydari, J.; Fathabad, A.M. Evolutionary multi-objective optimization of environmental indicators of integrated crude oil supply chain under uncertainty. J. Clean. Prod. 2017, 152, 295–311. [Google Scholar] [CrossRef]

- Govindan, K.; Darbari, J.D.; Agarwal, V.; Jha, P.C. Fuzzy multi-objective approach for optimal selection of suppliers and transportation decisions in an eco-efficient closed loop supply chain network. J. Clean. Prod. 2017, 165, 1598–1619. [Google Scholar] [CrossRef]

- Jamshidi, R.; Fatemi Ghomi, S.M.T.; Karimi, B. Multi-objective green supply chain optimization with a new hybrid memetic algorithm using the Taguchi method. Sci. Iran. 2012, 19, 1876–1886. [Google Scholar] [CrossRef]

- Rasmi, S.A.B.; Kazan, C.; Türkay, M. A multi-criteria decision analysis to include environmental, social, and cultural issues in the sustainable aggregate production plans. Comput. Ind. Eng. 2019, 132, 348–360. [Google Scholar] [CrossRef]

- Nujoom, R.; Mohammed, A.; Wang, Q. Drafting a cost-effective approach towards a sustainable manufacturing system design. Comput. Ind. Eng. 2019, 133, 317–330. [Google Scholar] [CrossRef]

- Motevalli-Taher, F.; Paydar, M.M.; Emami, S. Wheat sustainable supply chain network design with forecasted demand by simulation. Comput. Electron. Agric. 2020, 178, 105763. [Google Scholar] [CrossRef]

- Ozgen, D.; Gulsun, B. Combining possibilistic linear programming and fuzzy AHP for solving the multi-objective capacitated multi-facility location problem. Inf. Sci. 2014, 268, 185–201. [Google Scholar] [CrossRef]

- Budak, A. Sustainable reverse logistics optimization with triple bottom line approach: An integration of disassembly line balancing. J. Clean. Prod. 2020, 270, 122475. [Google Scholar] [CrossRef]

- Dutta, P.; Mishra, A.; Khandelwal, S.; Katthawala, I. A multiobjective optimization model for sustainable reverse logistics in Indian E-commerce market. J. Clean. Prod. 2020, 249, 119348. [Google Scholar] [CrossRef]

- Gao, X.; Cao, C. A novel multi-objective scenario-based optimization model for sustainable reverse logistics supply chain network redesign considering facility reconstruction. J. Clean. Prod. 2020, 270, 122405. [Google Scholar] [CrossRef]

- Huang, L.; Zhen, L.; Yin, L. Waste material recycling and exchanging decisions for industrial symbiosis network optimization. J. Clean. Prod. 2020, 276, 124073. [Google Scholar] [CrossRef]

- Pourmehdi, M.; Paydar, M.M.; Asadi-Gangraj, E. Scenario-based design of a steel sustainable closed-loop supply chain network considering production technology. J. Clean. Prod. 2020, 277, 123298. [Google Scholar] [CrossRef]

- Rabbani, M.; Heidari, R.; Farrokhi-Asl, H.; Rahimi, N. Using metaheuristic algorithms to solve a multi-objective industrial hazardous waste location-routing problem considering incompatible waste types. J. Clean. Prod. 2018, 170, 227–241. [Google Scholar] [CrossRef]

- Govindan, K.; Paam, P.; Abtahi, A.-R. A fuzzy multi-objective optimization model for sustainable reverse logistics network design. Ecol. Indic. 2016, 67, 753–768. [Google Scholar] [CrossRef]

- Abdallah, M.; Hamdan, S.; Shabib, A. A multi-objective optimization model for strategic waste management master plans. J. Clean. Prod. 2020, 284, 124714. [Google Scholar] [CrossRef]

- Mohamed Sultan, A.A.; Mativenga, P.T. Sustainable Location Identification Decision Protocol (SuLIDeP) for determining the location of recycling centres in a circular economy. J. Clean. Prod. 2019, 223, 508–521. [Google Scholar] [CrossRef]

- Yu, H.; Solvang, W.D. Incorporating flexible capacity in the planning of a multi-product multi-echelon sustainable reverse logistics network under uncertainty. J. Clean. Prod. 2018, 198, 285–303. [Google Scholar] [CrossRef]

- de Vivas, R.C.; Sant’Anna, A.M.O.; Esquerre, K.P.S.O.; Freires, F.G.M. Integrated method combining analytical and mathematical models for the evaluation and optimization of sustainable supply chains: A Brazilian case study. Comput. Ind. Eng. 2020, 139, 105670. [Google Scholar] [CrossRef]

- Pourjavad, E.; Mayorga, R.V. Multi-objective Fuzzy Programming of Closed-Loop Supply Chain Considering Sustainable Measures. Int. J. Fuzzy Syst. 2019, 21, 655–673. [Google Scholar] [CrossRef]

- Mohammed, A.; Harris, I.; Soroka, A.; Nujoom, R. A hybrid MCDM-fuzzy multi-objective programming approach for a G-resilient supply chain network design. Comput. Ind. Eng. 2019, 127, 297–312. [Google Scholar] [CrossRef]

- Mohammed, A.; Setchi, R.; Filip, M.; Harris, I.; Li, X. An integrated methodology for a sustainable two-stage supplier selection and order allocation problem. J. Clean. Prod. 2018, 192, 99–114. [Google Scholar] [CrossRef]

- Rahimi, M.; Ghezavati, V.; Asadi, F. A stochastic risk-averse sustainable supply chain network design problem with quantity discount considering multiple sources of uncertainty. Comput. Ind. Eng. 2019, 130, 430–449. [Google Scholar] [CrossRef]

- Ebrahimi, S.B. A stochastic multi-objective location-allocation-routing problem for tire supply chain considering sustainability aspects and quantity discounts. J. Clean. Prod. 2018, 198, 704–720. [Google Scholar] [CrossRef]

- Ruiz-Femenia, R.; Guillén-Gosálbez, G.; Jiménez, L.; Caballero, J.A. Multi-objective optimization of environmentally conscious chemical supply chains under demand uncertainty. Chem. Eng. Sci. 2013, 95, 1–11. [Google Scholar] [CrossRef]

- Wang, L.-C.; Chen, T.-L.; Chen, Y.-Y.; Chen, Y.-W.; Wang, A. Closed-Loop Sustainable Supply Chain Design under Uncertainties. In Advances in Sustainable and Competitive Manufacturing Systems; Springer: Berlin/Heidelberg, Germany, 2013; pp. 799–812. [Google Scholar] [CrossRef]

- Rabbani, M.; Hosseini-Mokhallesun, S.A.A.; Ordibazar, A.H.; Farrokhi-Asl, H. A hybrid robust possibilistic approach for a sustainable supply chain location-allocation network design. Int. J. Syst. Sci. Oper. Logist. 2020, 7, 60–75. [Google Scholar] [CrossRef]

- Mavrotas, G. Effective implementation of the ε-constraint method in Multi-Objective Mathematical Programming problems. Appl. Math. Comput. 2009, 213, 455–465. [Google Scholar] [CrossRef]

- Atoei, F.; Teimory, E.; Amiri, A. Designing reliable supply chain network with disruption risk. Int. J. Ind. Eng. Comput. 2013, 4, 111–126. [Google Scholar] [CrossRef]

- Chiandussi, G.; Codegone, M.; Ferrero, S.; Varesio, F.E. Comparison of multi-objective optimization methodologies for engineering applications. Comput. Math. Appl. 2012, 63, 912–942. [Google Scholar] [CrossRef]

- Ingrao, C.; Messineo, A.; Beltramo, R.; Yigitcanlar, T.; Ioppolo, G. How can life cycle thinking support sustainability of buildings? Investigating life cycle assessment applications for energy efficiency and environmental performance. J. Clean. Prod. 2018, 201, 556–569. [Google Scholar] [CrossRef]

- Ioppolo, G.; Cucurachi, S.; Salomone, R.; Shi, L.; Yigitcanlar, T. Strategic environmental assessment and material flow accounting: A novel approach for moving towards sustainable urban futures. Int. J. Life Cycle Assess. 2019, 24, 1269–1284. [Google Scholar] [CrossRef]

- Bertsimas, D.; Nohadani, O.; Teo, K.M. Robust Optimization for Unconstrained Simulation-Based Problems. Oper. Res. 2010, 58, 161–178. [Google Scholar] [CrossRef]

- Biuki, M.; Kazemi, A.; Alinezhad, A. An integrated location-routing-inventory model for sustainable design of a perishable products supply chain network. J. Clean. Prod. 2020, 260, 120842. [Google Scholar] [CrossRef]

- Silva, W.H.; Guarnieri, P.; Carvalho, J.M.; Farias, J.S.; Reis, S.A.D. Sustainable Supply Chain Management: Analyzing the Past to Determine a Research Agenda. Logistics 2019, 3, 14. [Google Scholar] [CrossRef]

- Cardoso, S.R.; Barbosa-Póvoa, A.P.; Relvas, S. Integrating financial risk measures into the design and planning of closed-loop supply chains. Comput. Chem. Eng. 2016, 85, 105–123. [Google Scholar] [CrossRef]

- Tukamuhabwa, B.; Mutebi, H.; Kyomuhendo, R. Competitive advantage in SMEs: Effect of supply chain management practices, logistics capabilities and logistics integration in a developing country. J. Bus. Socio-Econ. Dev. 2021. [Google Scholar] [CrossRef]

- GRI Standard. GRI 103 Management Approach. 2016. Available online: www.globalreporting.org/standards/download-the-standards/ (accessed on 30 November 2021).

- Jayarathna, C.P.; Agdas, D.; Dawes, L.; Miska, M. Exploring sector-specific sustainability indicators: A content analysis of sustainability reports in the logistics sector. Eur. Bus. Review. 2021. ahead-of-print. [Google Scholar] [CrossRef]

- Ahmed, W.; Sarkar, B. Management of next-generation energy using a triple bottom line approach under a supply chain framework. Resour. Conserv. Recycl. 2019, 150, 104431. [Google Scholar] [CrossRef]

- Balaman, Ş.Y. Investment planning and strategic management of sustainable systems for clean power generation: An ε-constraint based multi objective modeling approach. J. Clean. Prod. 2016, 137, 1179–1190. [Google Scholar] [CrossRef]

- Banasik, A.; Kanellopoulos, A.; Claassen, G.D.H.; Bloemhof-Ruwaard, J.M.; van der Vorst, J.G.A.J. Closing loops in agricultural supply chains using multi-objective optimization: A case study of an industrial mushroom supply chain. Int. J. Prod. Econ. 2017, 183, 409–420. [Google Scholar] [CrossRef]

- Bortolini, M.; Faccio, M.; Ferrari, E.; Gamberi, M.; Pilati, F. Fresh food sustainable distribution: Cost, delivery time and carbon footprint three-objective optimization. J. Food Eng. 2016, 174, 56–67. [Google Scholar] [CrossRef]

- Devika, K.; Jafarian, A.; Nourbakhsh, V. Designing a sustainable closed-loop supply chain network based on triple bottom line approach: A comparison of metaheuristics hybridization techniques. Eur. J. Oper. Res. 2014, 235, 594–615. [Google Scholar] [CrossRef]

- Eskandarpour, M.; Dejax, P.; Péton, O. Multi-directional local search for sustainable supply chain network design. Int. J. Prod. Res. 2019, 1–17. [Google Scholar] [CrossRef]

- Govindan, K.; Jafarian, A.; Nourbakhsh, V. Bi-objective integrating sustainable order allocation and sustainable supply chain network strategic design with stochastic demand using a novel robust hybrid multi-objective metaheuristic. Comput. Operat. Res. 2015, 62, 112–130. [Google Scholar] [CrossRef]

- Govindan, K.; Jafarian, A.; Khodaverdi, R.; Devika, K. Two-echelon multiple-vehicle location–routing problem with time windows for optimization of sustainable supply chain network of perishable food. Int. J. Prod. Econ. 2014, 152, 9–28. [Google Scholar] [CrossRef]

- Jabbarzadeh, A.; Fahimnia, B.; Sabouhi, F. Resilient and sustainable supply chain design: Sustainability analysis under disruption risks. Int. J. Prod. Res. 2018, 56, 5945–5968. [Google Scholar] [CrossRef]

- Kadambala, D.K.; Subramanian, N.; Tiwari, M.K.; Abdulrahman, M.; Liu, C. Closed loop supply chain networks: Designs for energy and time value efficiency. Int. J. Prod. Econ. 2017, 183, 382–393. [Google Scholar] [CrossRef]

- Kostin, A.; Guillén-Gosálbez, G.; Jiménez, L. Dimensionality reduction applied to the simultaneous optimization of the economic and life cycle environmental performance of supply chains. Int. J. Prod. Econ. 2015, 159, 223–232. [Google Scholar] [CrossRef]

- Kumar, D.; Rahman, Z.; Chan, F.T.S. A fuzzy AHP and fuzzy multi-objective linear programming model for order allocation in a sustainable supply chain: A case study. Int. J. Comput. Integr. Manuf. 2017, 30, 535–551. [Google Scholar] [CrossRef]

- Li, Y.; Soleimani, H.; Zohal, M. An improved ant colony optimization algorithm for the multi-depot green vehicle routing problem with multiple objectives. J. Clean. Prod. 2019, 227, 1161–1172. [Google Scholar] [CrossRef]

- Lin, C.; Choy, K.L.; Ho, G.T.S.; Ng, T.W. A Genetic Algorithm-based optimization model for supporting green transportation operations. Expert Syst. Appl. 2014, 41, 3284–3296. [Google Scholar] [CrossRef]

- Liotta, G.; Stecca, G.; Kaihara, T. Optimization of freight flows and sourcing in sustainable production and transportation networks. Int. J. Prod. Econ. 2015, 164, 351–365. [Google Scholar] [CrossRef]

- Liu, Z.; Qiu, T.; Chen, B. A study of the LCA based biofuel supply chain multi-objective optimization model with multi-conversion paths in China. Appl. Energy 2014, 126, 221–234. [Google Scholar] [CrossRef]

- Mahjoub, N.; Sahebi, H. The water-energy nexus at the hybrid bioenergy supply chain: A sustainable network design model. Ecol. Indic. 2020, 119, 106799. [Google Scholar] [CrossRef]

- Martins, C.L.; Melo, M.T.; Pato, M.V. Redesigning a food bank supply chain network in a triple bottom line context. Int. J. Prod. Econ. 2019, 214, 234–247. [Google Scholar] [CrossRef]

- Mohebalizadeh, M.; Hafezalkotob, A. Modeling sustainable supply chain management problem with fuzzy demand based on multi-criteria decision-making methods. Int. J. Ind. Syst. Eng. 2018, 30, 267–297. [Google Scholar] [CrossRef]

- Musavi, M.; Bozorgi-Amiri, A. A multi-objective sustainable hub location-scheduling problem for perishable food supply chain. Comput. Ind. Eng. 2017, 113, 766–778. [Google Scholar] [CrossRef]

- Park, K.; Okudan Kremer, G.E.; Ma, J. A regional information-based multi-attribute and multi-objective decision-making approach for sustainable supplier selection and order allocation. J. Clean. Prod. 2018, 187, 590–604. [Google Scholar] [CrossRef]

- Pourjavad, E.; Mayorga, R.V. Optimization of a sustainable closed loop supply chain network design under uncertainty using multi-objective evolutionary algorithms. Adv. Prod. Eng. Manag. 2018, 13, 216–228. [Google Scholar] [CrossRef]

- Rabbani, M.; Saravi, N.A.; Farrokhi-Asl, H.; Lim, S.F.W.T.; Tahaei, Z. Developing a sustainable supply chain optimization model for switchgrass-based bioenergy production: A case study. J. Clean. Prod. 2018, 200, 827–843. [Google Scholar] [CrossRef]

- Resat, H.G.; Turkay, M. A discrete-continuous optimization approach for the design and operation of synchromodal transportation networks. Comput. Ind. Eng. 2019, 130, 512–525. [Google Scholar] [CrossRef]

- Reza, E.R.; Sohanian, M. A multi-objective optimization model for sustainable supply chain network with using genetic algorithm. J. Model. Manag. 2021, 16, 714–727. [Google Scholar] [CrossRef]

- Rohmer, S.U.K.; Gerdessen, J.C.; Claassen, G.D.H. Sustainable supply chain design in the food system with dietary considerations: A multi-objective analysis. Eur. J. Oper. Res. 2019, 273, 1149–1164. [Google Scholar] [CrossRef]

- Sahebjamnia, N.; Fathollahi-Fard, A.M.; Hajiaghaei-Keshteli, M. Sustainable tire closed-loop supply chain network design: Hybrid metaheuristic algorithms for large-scale networks. J. Clean. Prod. 2018, 196, 273–296. [Google Scholar] [CrossRef]

- Samadi, A.; Mehranfar, N.; Fathollahi Fard, A.M.; Hajiaghaei-Keshteli, M. Heuristic-based metaheuristics to address a sustainable supply chain network design problem. J. Ind. Prod. Eng. 2018, 35, 102–117. [Google Scholar] [CrossRef]

- Sepehri, M.; Sazvar, Z. Multi-objective sustainable supply chain with deteriorating products and transportation options under uncertain demand and backorder. Sci. Iran. 2016, 23, 2977–2994. [Google Scholar] [CrossRef]

- Souza, V.D.; Bloemhof-Ruwaard, J.; Borsato, M. Exploring ecosystem network analysis to balance resilience and performance in sustainable supply chain design. Int. J. Adv. Oper. Manag. 2019, 11, 26–45. [Google Scholar] [CrossRef]

- Taheri-Moghadam, A.; Razmi, J.; Baki, M.F. Designing and planning a sustainable supply chain network considering economic aspects, environmental impact, fixed job opportunities and customer service level. Int. J. Process Manag. Benchmark. 2019, 9, 73–100. [Google Scholar] [CrossRef]

- Tautenhain, C.P.S.; Barbosa-Povoa, A.P.; Nascimento, M.C.V. A multi-objective matheuristic for designing and planning sustainable supply chains. Comput. Ind. Eng. 2019, 135, 1203–1223. [Google Scholar] [CrossRef]

- Tirkolaee, E.B.; Goli, A.; Faridnia, A.; Soltani, M.; Weber, G.-W. Multi-objective optimization for the reliable pollution-routing problem with cross-dock selection using Pareto-based algorithms. J. Clean. Prod. 2020, 276, 122927. [Google Scholar] [CrossRef]

- Tsao, Y.-C.; Thanh, V.-V.; Lu, J.-C.; Yu, V. Designing sustainable supply chain networks under uncertain environments: Fuzzy multi-objective programming. J. Clean. Prod. 2018, 174, 1550–1565. [Google Scholar] [CrossRef]

- Vafaeenezhad, T.; Tavakkoli-Moghaddam, R.; Cheikhrouhou, N. Multi-objective mathematical modeling for sustainable supply chain management in the paper industry. Comput. Ind. Eng. 2019, 135, 1092–1102. [Google Scholar] [CrossRef]

- Validi, S.; Bhattacharya, A.; Byrne, P.J. Sustainable distribution system design: A two-phase DoE-guided meta-heuristic solution approach for a three-echelon bi-objective AHP-integrated location-routing model. Ann. Oper. Res. 2018, 290, 191–222. [Google Scholar] [CrossRef]

- Validi, S.; Bhattacharya, A.; Byrne, P.J. A case analysis of a sustainable food supply chain distribution system—A multi-objective approach. Int. J. Prod. Econ. 2014, 152, 71–87. [Google Scholar] [CrossRef]

- Wang, F.; Lai, X.; Shi, N. A multi-objective optimization for green supply chain network design. Decis. Support Syst. 2011, 51, 262–269. [Google Scholar] [CrossRef]

- Xifeng, T.; Ji, Z.; Peng, X. A multi-objective optimization model for sustainable logistics facility location. Transp. Res. Part D Transp. Environ. 2013, 22, 45–48. [Google Scholar] [CrossRef]

- Yeh, W.-C.; Chuang, M.-C. Using multi-objective genetic algorithm for partner selection in green supply chain problems. Expert Syst. Appl. 2011, 38, 4244–4253. [Google Scholar] [CrossRef]

- You, F.; Tao, L.; Graziano, D.J.; Snyder, S.W. Optimal design of sustainable cellulosic biofuel supply chains: Multi-objective optimization coupled with life cycle assessment and input--output analysis. AIChE J. 2012, 58, 1157–1180. [Google Scholar] [CrossRef]

- Zarei, J.; Amin-Naseri, M.R.; Fakehi Khorasani, A.H.; Kashan, A.H. A sustainable multi-objective framework for designing and planning the supply chain of natural gas components. J. Clean. Prod. 2020, 259, 120649. [Google Scholar] [CrossRef]

- Zhalechian, M.; Tavakkoli-Moghaddam, R.; Rahimi, Y.; Jolai, F. An interactive possibilistic programming approach for a multi-objective hub location problem: Economic and environmental design. Appl. Soft Comput. 2017, 52, 699–713. [Google Scholar] [CrossRef]

- Zhalechian, M.; Tavakkoli-Moghaddam, R.; Zahiri, B.; Mohammadi, M. Sustainable design of a closed-loop location-routing-inventory supply chain network under mixed uncertainty. Transp. Res. Part E Logist. Transp. Rev. 2016, 89, 182–214. [Google Scholar] [CrossRef]

- Zhang, S.; Lee, C.K.M.; Wu, K.; Choy, K.L. Multi-objective optimization for sustainable supply chain network design considering multiple distribution channels. Expert Syst. Appl. 2016, 65, 87–99. [Google Scholar] [CrossRef]

- Zhang, Q.; Shah, N.; Wassick, J.; Helling, R.; van Egerschot, P. Sustainable supply chain optimisation: An industrial case study. Comput. Ind. Eng. 2014, 74, 68–83. [Google Scholar] [CrossRef]

| Reference | No of Papers | Time-Period | a | b | c | d | e | f | g | h | i | j |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| [4] | 60 | n/a | * | * | * | |||||||

| [11] | 220 | 1999–2016 | * | * | * | * | * | * | ||||

| [12] | 188 | 2000–2015 | * | * | * | * | * | * | ||||

| [13] | 89 | 2007–2017 | * | * | * | * | * | |||||

| [14] | 174 | 1987–2015 | * | |||||||||

| [15] | 445 | 1989–2012 | * | * | ||||||||

| [16] | 134 | 1994–2012 | * | * | * | |||||||

| [17] | 145 | 1995–2018 | * | * | * | * | ||||||

| [18] | 384 | 2000–2003 | * | * | ||||||||

| [19] | 36 | 1994–2010 | * | * | ||||||||

| [22] | 98 | 2005–2015 | * | * | * | * | * | |||||

| [23] | 113 | 2015–2018 | * | * | * | * | ||||||

| [24] | 207 | 1995 –2017 | * | * | * | * | * | * | * | |||

| [25] | 300 | 1980–2020 | * | * | * | * | * | * | * | |||

| [26] | 540 | 1999–2010 | * | * | * | * | ||||||

| [27] | 134 | 1983–2011 | * | * | ||||||||

| [28] | 87 | 2000–2010 | * | * | ||||||||

| [29] | 56 | n/a | * | * | ||||||||

| [30] | 160 | 1980–2013 | * | * | ||||||||

| [31] | 185 | 1994–2004 | * | * | ||||||||

| [32] | 190 | 1999–2010 | * | * | * | |||||||

| [33] | 87 | 1990–2014 | * | * | * | * | * | |||||

| [34] | 115 | n/a | * | * | ||||||||

| [35] | 190 | 2000–2015 | * | * | * | * | ||||||

| [36] | 40 | 1900–2018 | * | * | * | * | ||||||

| [37] | 142 | 2009–2019 | * | * | * | * | * | * | ||||

| [38] | 247 | 1997–2019 | * | * | * | * | * |

| Economic Objectives (Min./Max) | No. of Papers | Environmental Objectives (Min./Max.) | No. of Papers | Social Objectives (Min./Max.) | No. of Papers |

|---|---|---|---|---|---|

| Total cost/Profit/ Operational performance | 85 | GHG/CO2 emission/Global warming potential | 49 | Social benefit/ social impact | 25 |

| Delivery lead time/ traveling time | 12 | Environmental impact/performance | 41 | Job opportunities | 14 |

| Economic benefits | 5 | Energy consumption/energy recovery | 8 | Employee injuries | 2 |

| NPV/PV of costs | 4 | Water consumption | 5 | Human resource variations | 1 |

| Resilience | 2 | Waste | 4 | Lost working days | 1 |

| Total quality | 2 | Noise pollution | 1 | Community development | 1 |

| Financial risk | 1 | ||||

| Travel distance | 1 | ||||

| Reliability | 2 | ||||

| Responsiveness | 1 | ||||

| Supplier performance | 1 |

| Decision Levels | Total | OSC | S | M | D | T | RL | S/D | M/D | T/RL | T/D | S/M/D | S/M/T |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Strategic | 55 | 23 | 5 | 6 | 3 | - | 8 | 2 | 4 | - | 3 | 1 | - |

| Tactical | 20 | 1 | - | 5 | 4 | 3 | 3 | - | 2 | 1 | - | - | 1 |

| Operational | 1 | - | - | - | - | - | - | - | 1 | - | - | - | - |

| Strategic/Tactical | 14 | 10 | 1 | - | - | - | - | - | 1 | - | - | 1 | 1 |

| Strategic/Operational | 1 | - | - | 1 | - | - | - | - | - | - | - | - | |

| Tactical/Operational | 1 | 1 | - | - | - | - | - | - | - | - | - | - | |

| Strategic/Tactical/Operational | 3 | 2 | - | 1 | - | - | - | - | - | - | - | - | - |

| Total | 95 | 37 | 6 | 12 | 8 | 3 | 11 | 2 | 8 | 1 | 3 | 2 | 2 |

| Sustainability Dimensions | OSC | S | M | D | T | RL | S/D | M/D | T/RL | T/D | S/M/D | S/M/T | Total |

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Eco/Env/Soc | 16 | 3 | 3 | 2 | 1 | 7 | 1 | 5 | - | - | 1 | 1 | 40 |

| Eco/Env | 19 | 3 | 9 | 6 | 2 | 3 | 1 | 3 | 1 | 3 | 1 | 1 | 52 |

| Eco/Soc | 1 | - | - | - | - | 1 | - | - | - | - | - | - | 2 |

| Env/Soc | 1 | - | - | - | - | - | - | - | - | - | - | - | 1 |

| Total | 37 | 6 | 12 | 8 | 3 | 11 | 2 | 8 | 1 | 3 | 2 | 2 | 95 |

| Decision Levels | Total | Eco/Env/Soc | Eco/Env | Eco/Soc | Env/Soc |

|---|---|---|---|---|---|

| Strategic | 55 | 22 | 31 | 1 | 1 |

| Tactical | 20 | 6 | 13 | 1 | - |

| Operational | 1 | 1 | - | - | - |

| Strategic/Operational | 1 | 1 | - | - | - |

| Tactical/Operational | 1 | 1 | - | - | - |

| Strategic/Tactical | 14 | 8 | 6 | - | - |

| Strategic/Tactical/Operational | 3 | 1 | 2 | - | - |

| Total | 95 | 40 | 52 | 2 | 1 |

| Modeling Technique | Number of Papers | Deterministic Models | Stochastic Models |

|---|---|---|---|

| Classical | 63 | 32 | 31 |

| Metaheuristics | 31 | 22 | 9 |

| Hybrid (C/M) | 1 | 1 | - |

| Total | 95 | 55 | 40 |

| Classical Methods | Total | Certain | Uncertain |

|---|---|---|---|

| e-Constraint | 22 | 13 | 9 |

| Augmented e-constraint | 9 | 4 | 5 |

| Weighted sum | 7 | 2 | 5 |

| Fuzzy programming | 5 | - | 5 |

| Normalized normal constraint methods | 3 | 3 | - |

| Weighted goal programming | 2 | 1 | 1 |

| Fuzzy goal programming | 1 | - | 1 |

| Weighted comprehensive criteria method | 1 | - | 1 |

| Weighted min max | 1 | - | 1 |

| Weighted metrics | 1 | - | 1 |

| LP metric based compromising programming | 1 | - | 1 |

| Meta goal programming and simulation | 1 | - | 1 |

| Scenario method | 1 | 1 | - |

| AHP and ordered weighted averaging (OWA) | 1 | 1 | - |

| Augmented e-constraint and TOPSIS. | 1 | 1 | - |

| Exact solution approach (non-dominated points) | 1 | 1 | - |

| Goal programming/e-constraint | 1 | 1 | - |

| Goal programming MINMAX | 1 | 1 | - |

| Lexicographic ordering | 1 | 1 | - |

| PROMTHEE and goal programming | 1 | 1 | - |

| Weighted sum/Augmented e-constraint | 1 | 1 | - |

| Total | 63 | 32 | 31 |

| Metaheuristics Methods | Total | Certain | Uncertain |

|---|---|---|---|

| Hybrid meta-heuristic algorithm | 6 | 4 | 2 |

| Genetic algorithm (GA) * | 4 | 4 | - |

| Particle swarm optimization (PSO) | 4 | 3 | 1 |

| GA/PSO | 2 | 1 | 1 |

| Non-dominated sorting genetic algorithm (NSGA II)/PSO | 2 | 2 | - |

| Non-dominated sorting genetic algorithm (NSGA II) | 2 | - | 2 |

| Simulated-annealing (SA)/NSGA-II | 1 | 1 | - |

| Swarm intelligence | 1 | 1 | - |

| Hybrid swarm intelligence meta-heuristic | 1 | 1 | - |

| Memetic algorithm | 1 | 1 | - |

| Non-dominated ranking generic algorithm (NRGA) | 1 | 1 | - |

| Ant colony optimization (ACO) | 1 | 1 | - |

| AugMathFix | 1 | 1 | - |

| Centre of gravity/K means clustering | 1 | 1 | - |

| Evolutionary Algorithm (EA) | 1 | - | 1 |

| Simulated annealing (SA) | 1 | - | 1 |

| Lagrangian relaxation (LR) | 1 | - | 1 |

| Total | 31 | 22 | 3 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Jayarathna, C.P.; Agdas, D.; Dawes, L.; Yigitcanlar, T. Multi-Objective Optimization for Sustainable Supply Chain and Logistics: A Review. Sustainability 2021, 13, 13617. https://doi.org/10.3390/su132413617

Jayarathna CP, Agdas D, Dawes L, Yigitcanlar T. Multi-Objective Optimization for Sustainable Supply Chain and Logistics: A Review. Sustainability. 2021; 13(24):13617. https://doi.org/10.3390/su132413617

Chicago/Turabian StyleJayarathna, Chamari Pamoshika, Duzgun Agdas, Les Dawes, and Tan Yigitcanlar. 2021. "Multi-Objective Optimization for Sustainable Supply Chain and Logistics: A Review" Sustainability 13, no. 24: 13617. https://doi.org/10.3390/su132413617

APA StyleJayarathna, C. P., Agdas, D., Dawes, L., & Yigitcanlar, T. (2021). Multi-Objective Optimization for Sustainable Supply Chain and Logistics: A Review. Sustainability, 13(24), 13617. https://doi.org/10.3390/su132413617