Energy Retrofit. A Case Study—Santi Romano Dormitory on the Palermo University

Abstract

:1. Introduction

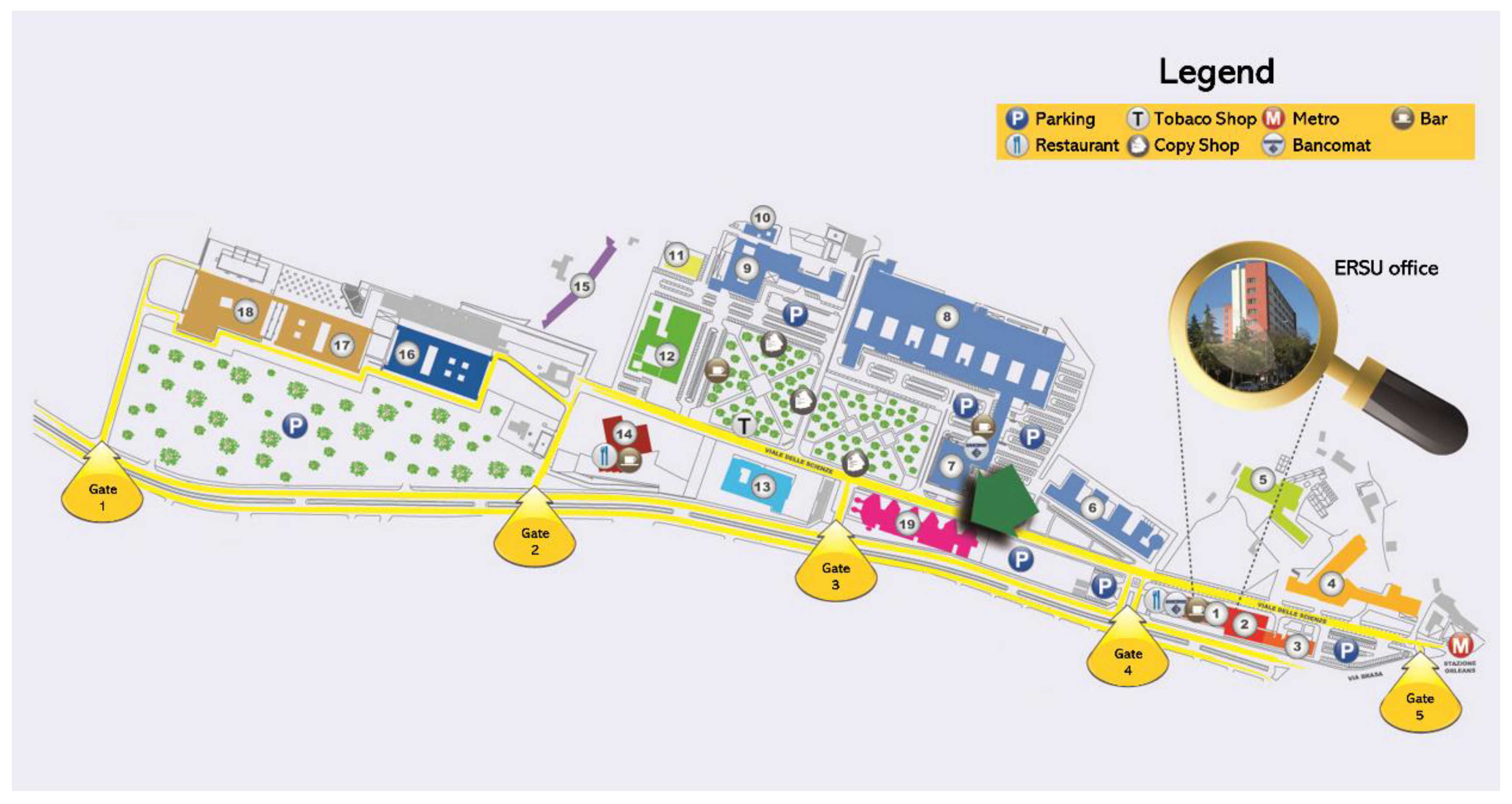

2. Energy Modernization of the Campus

3. Case study

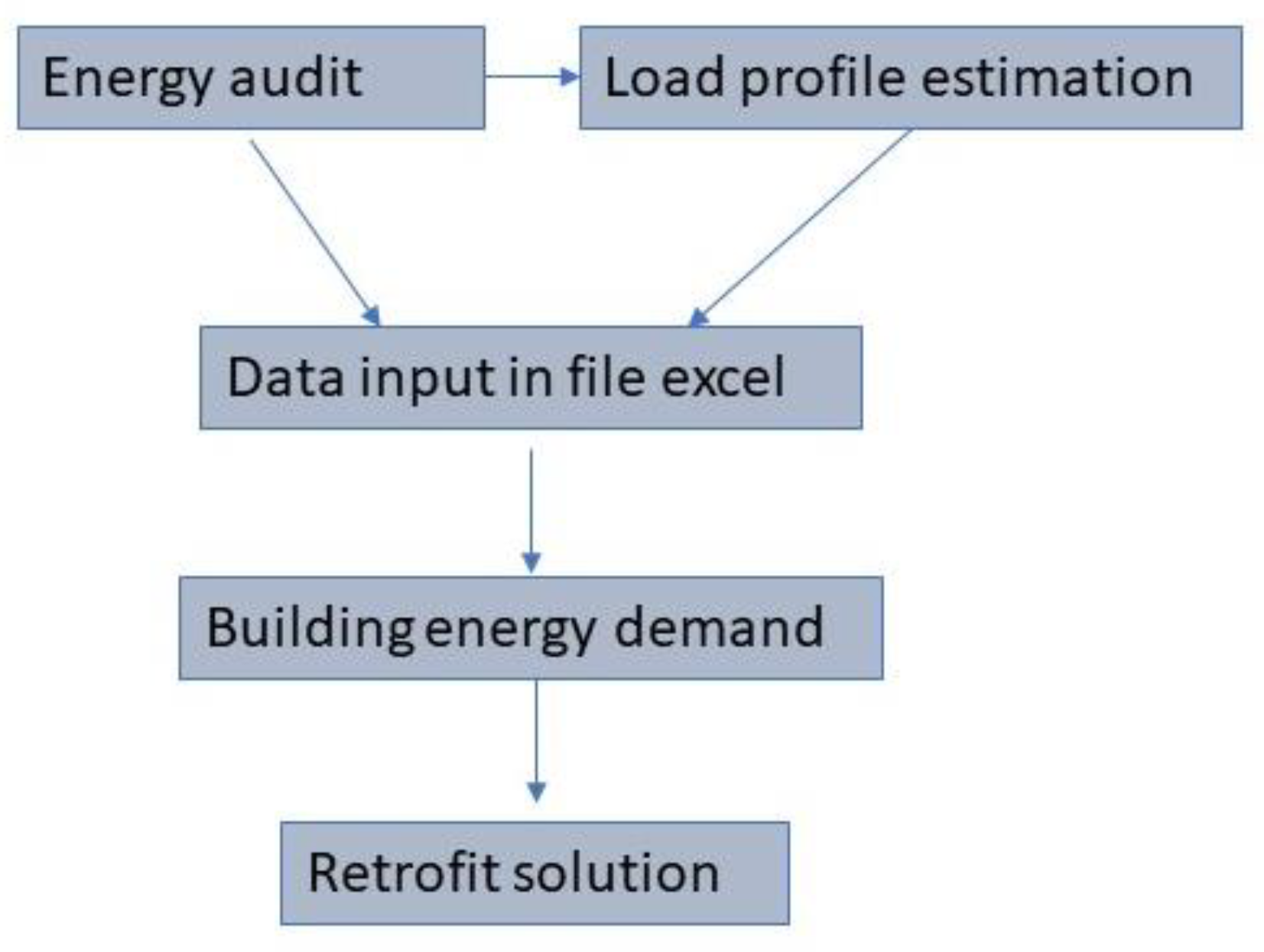

3.1. Research Methodology

3.1.1. Energy Audit

- Building technical description

- Air-conditioning system features

- Thermal features

- Electrical features

3.1.2. Load Profiles

3.1.3. Load Estimation

- WL: winter loads

- SL: summer loads

- S: surface in [m2] of the i-th wall or j-th window

- U: thermal transmittance in [W/m2K] of the i-th wall or j-th window

- DD20: degree day in winter condition [K day/year]

- DD22: degree day in summer condition [K day/year]

- 24/1000: conversion in [kWh/year]

- LL: lighting load

- Plight: power density of lights [W/m2]

- Sfloor: Surface of the floor [m2]

- 1000: conversion in kW.

3.1.4. Energy Saving Measures

- The first solution focuses on the windows. It is important to reduce the heat losses through the windows. For this reason, it was proposed to replace the windows with a thermal transmittance lower than 2 W/m2K. In addition, it was proposed to cover some of the windows with a sunscreen film. The structure has no shading, which means that the sun’s rays penetrate through the windows, specifically those facing south, south-east, and south-west. The energy saving was estimated in the same way as shown in Equations (1) and (2) with the replacement of the old transmittance with new one.

- The second solution focuses on the generation system. It was proposed to replace boilers with modern condensing boilers. The old boilers are characterized by a combustion performance approximately of 85% with very dangerous emission. Due to these reasons, the replacement of them reduces the consumption because the new machines have a combustion performance of 93%, and then cuts the emission of greenhouse gases and NOx. The existing boilers are very old, and their replacement is almost necessary [26]. The energy saving connected to the old boiler replacement was calculated by the difference between the energy, required in the pre-retrofit situation, produced with conventional boilers and the energy, required after the retrofit, versus that produced with condensing boilers. This is shown in Equation (4).

- TES: thermal energy saving (kWh/year)

- WL 1: winter loads ante retrofit (kWh/year)

- WL 2: winter loads post retrofit (kWh/year)

- εreg: efficiency of the regulation system

- εdist: efficiency of the distribution system

- εterm: efficiency of the terminal

- ƞboiler: efficiency of the boiler

- Subscript 1 refers to the ante situation d subscript 2 refers to the post-retrofit situation.

- For the same reason as replacing the old boilers, it was proposed to replace the old heat pump chiller. This renovation increases the COP of chiller unit from the 2.5 of the existing machine to the 3.9 of the new one. Consequently, this intervention significantly reduces the energy consumption because the machine is more efficient than the old one [27]. This also involves savings in terms of emissions into the atmosphere. The electrical energy saving (EES) was calculated in the same way as for the replacement of boiler, i.e., with the difference of efficiency, because the COP ante and post retrofit must be considered. This is shown in Equation (5).

- One of the most effective energy-saving measures is the replacement of fluorescent and halogen luminaires with LEDs [28,29]. The replacement of all the luminaires was proposed based on the requirements of standard UNI EN 12464-1. In fact, it has been estimated that with the new LED luminaires, which provide 300 lux of illuminance [25], the total installed power is practically halved. In this way, the consumption of electrical energy will be very low. To calculate the electrical energy saving (EES), in this case of the energy consumed with LED lamps, it must be subtracted from that calculated in Equation (3). Equation (6) shows how the electrical saving is calculated. Subscript 1 refers to the ante situation and subscript 2 refers to the post-retrofit situation. The power density decreased from 6 (W/m2) to 3 (W/m2). The lighting system was estimated to work about 5000 h per year.

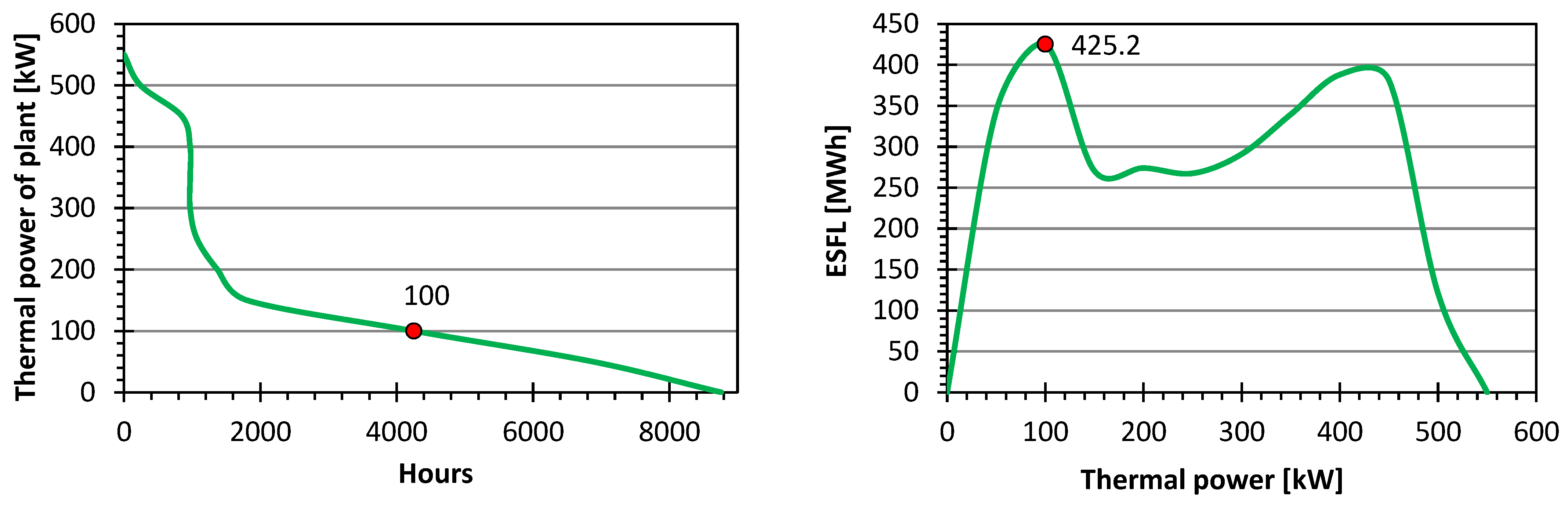

- The ultimate proposal concerned the designing of a cogeneration power plant. Cogeneration attempts to usefully recover a part of the heat produced by the thermal engine, which must then necessarily be discharged to the environment.

3.1.5. Results and Discussion

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

Appendix A

References

- Luomi, M.; Abdullah, K.; Studies, P. Where Are the Leaders? In Proceedings of the Dr Mari Luomi * Analysis of the COP 25 Climate Change Conference, Madrid, Spain, 2–13 December 2019. [Google Scholar]

- Cole, L.B. Green building literacy: A framework for advancing green building education. Int. J. STEM Educ. 2019, 6, 18. [Google Scholar] [CrossRef]

- Staudt, P.; Ludwig, N.; Huber, J.; Hagenmeyer, V.; Weinhardt, C. SCiBER: A new public data set of municipal building consumption. In Proceedings of the e-Energy Ninth International Conference on Future Energy Systems, Karlsruhe, Germany, 12–15 June 2018; pp. 618–621. [Google Scholar] [CrossRef]

- European Commision. Directive 2010/31/EU of the European Parliament and of the Council of 19 May 2010 on the energy performance of buildings (recast). Official Journal of the European Union. 2010, pp. 13–35. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/?uri=celex%3A32010L0031 (accessed on 1 November 2021).

- Miletić, M.; Krstić-Furundzić, A. Energy Refurbishment of a Public Building in Belgrade; University of Belgrade: Belgrade, Serbia, 2018; p. 10. [Google Scholar]

- Tavakolan, M.; Mostafazadeh, F.; Jalilzadeh, S.; Safari, A.; Mirzaei, K. A simulation-based multi-objective optimization framework for economic analysis of building energy retrofit: A case study in Iran. J. Build. Eng. 2021, 103485. [Google Scholar] [CrossRef]

- Lu, Y.; Li, P.; Lee, Y.P.; Song, X. An integrated decision-making framework for existing building retrofits based on energy simulation and cost-benefit analysis. J. Build. Eng. 2021, 43, 103200. [Google Scholar] [CrossRef]

- Li, Q.; Zhang, L.; Zhang, L.; Wu, X. Optimizing energy efficiency and thermal comfort in building green retrofit. Energy 2021, 237. [Google Scholar] [CrossRef]

- Ma, Z.; Cooper, P.; Daly, D.; Ledo, L. Existing building retrofits: Methodology and state-of-the-art. Energy Build. 2012, 55, 889–902. [Google Scholar] [CrossRef]

- Ibañez Iralde, N.S.; Pascual, J.; Salom, J. Energy retrofit of residential building clusters. A literature review of crossover recommended measures, policies instruments and allocated funds in Spain. Energy Build. 2021, 252. [Google Scholar] [CrossRef]

- Seyedzadeh, S.; Pour Rahimian, F.; Oliver, S.; Rodriguez, S.; Glesk, I. Machine learning modelling for predicting non-domestic buildings energy performance: A model to support deep energy retrofit decision-making. Appl. Energy 2020, 279, 115908. [Google Scholar] [CrossRef]

- Li, X.; Yao, R. Modelling heating and cooling energy demand for building stock using a hybrid approach. Energy Build. 2021, 235, 110740. [Google Scholar] [CrossRef]

- Wang, D.; Meng, J.; Zhang, T. Post-evaluation on energy saving reconstruction for hotel buildings, a case study in Jiangsu, China. Energy Build. 2021, 251, 111316. [Google Scholar] [CrossRef]

- Presidente della Repubblica Italiana D.P.R. 26 agosto 1993, n. 412. Regolamento Recante norme per la Progettazione, l’installazione, l’esercizio e la Manutenzione degli impianti termici degli edifici ai fini del Contenimento dei Consumi di Energia, in attuazione dell’art. 4, comma 4, della L. 1993. Available online: https://www.gazzettaufficiale.it/eli/id/1993/10/14/093G0451/sg (accessed on 1 November 2021).

- Braccio, G.; Sharma, V.K. Important Aspects of Green Energy in Italy. 2016. Available online: https://www.researchgate.net/publication/305140317 (accessed on 1 November 2021).

- Ruparathna, R.; Hewage, K.; Sadiq, R. Improving the energy efficiency of the existing building stock: A critical review of commercial and institutional buildings. Renew. Sustain. Energy Rev. 2016, 53, 1032–1045. [Google Scholar] [CrossRef]

- Delmastro, C.; Mutani, G.; Perassi, S. In use monitoring of public buildings. Case study in North Italy. Int. J. Heat Technol. 2016, 34, S266–S276. [Google Scholar] [CrossRef]

- Menezes, A.C.; Cripps, A.; Bouchlaghem, D.; Buswell, R. Predicted vs. actual energy performance of non-domestic buildings: Using post-occupancy evaluation data to reduce the performance gap. Appl. Energy 2012, 97, 355–364. [Google Scholar] [CrossRef] [Green Version]

- Beccali, M.; Bonomolo, M.; Lo Brano, V.; Ciulla, G.; Di Dio, V.; Massaro, F.; Favuzza, S. Energy saving and user satisfaction for a new advanced public lighting system. Energy Convers. Manag. 2019, 195, 943–957. [Google Scholar] [CrossRef]

- Campisi, D.; Gitto, S.; Morea, D. Economic feasibility of energy efficiency improvements in street lighting systems in Rome. J. Clean. Prod. 2018, 175, 190–198. [Google Scholar] [CrossRef]

- Buscemi, A.; Lo Brano, V.; Chiaruzzi, C.; Ciulla, G.; Kalogeri, C. A validated energy model of a solar dish-Stirling system considering the cleanliness of mirrors. Appl. Energy 2020, 260, 114378. [Google Scholar] [CrossRef] [Green Version]

- UNI 10349-3: 2016. Heating and Cooling of Building-Climate Data—Part 3: Accumulated Temperature Differences (Degree-Days) and Other Indices; Italian Organization for Standardization (UNI): Milano, Italy, 2016. [Google Scholar]

- UNI 10349-1: 2016. Heating and Cooling of Building-Climate Data—Part 1: Monthly Means for Evaluation of Energy Need for Space Heating and Cooling and Methods for Splitting Global Solar Irradiance into the Direct and Diffuse Parts and for Calculate the Solar Irradiance on Tilted Planes; Italian Organization for Standardization (UNI): Milano, Italy, 2016. [Google Scholar]

- UNI/TS 11300-2: 2019. Energy Performance of Buildings—Part 2: Evaluation of Primary Energy Need and of System Efficiencies for Space Heating, Domestic Hot Water Production, Ventilation and Lighting for Non-Residential Buildings; Italian Organization for Standardization (UNI): Milano, Italy, 2019. [Google Scholar]

- UNI EN 12464-1: 2011. Light and Lighting—Lighting of Workplaces—Part 1: Indoor Work Places; Italian Organization for Standardization (UNI): Milano, Italy, 2011. [Google Scholar]

- Bǎlǎnescu, D.T.; Homutescu, V.M. Study on condensing boiler technology potential accounting various fuels. Procedia Manuf. 2019, 32, 504–512. [Google Scholar] [CrossRef]

- Namirian, Z. Report on HVAC Design of a Building; University of Mumbai: Mumbai, India, 2021. [Google Scholar]

- Raimondi, F.M.; Curto, D.; Frazitta, V.; Milone, D. Energy savings for indoor lighting in a shopping mall: A case of study. In Proceedings of the 2018 Thirteenth International Conference on Ecological Vehicles and Renewable Energies (EVER), Monte Carlo, Monaco, 10–12 April 2018; pp. 1–6. [Google Scholar]

- Curto, D.; Milone, D. Improvement of Energy Efficiency for Indoor Lighting in a Big Shopping Center. In Proceedings of the 2018 IEEE International Conference on Environment and Electrical Engineering and 2018 IEEE Industrial and Commercial Power Systems Europe (EEEIC/I&CPS Europe), Palermo, Italy, 12–15 June 2018; pp. 1–6. [Google Scholar]

- Catrini, P.; Curto, D.; Franzitta, V.; Cardona, F. Improving energy efficiency of commercial buildings by Combined Heat Cooling and Power plants. Sustain. Cities Soc. 2020, 60, 102157. [Google Scholar] [CrossRef]

| Thermal and Electrical Loads | ||

|---|---|---|

| Thermal losses through the building envelope | 11,250,000 | (kWht/y) |

| Domestic hot water | 363,000 | (kWht/y) |

| Summer heat load | 594,530 | (kWhe/y) |

| Lighting load | 210,000 | (kWhe/y) |

| Proposed Retrofit Solutions | Electrical Energy Saving (kWhe/y) | Thermal Energy Saving (kWht/y) |

|---|---|---|

| Window replacement | 4733 | 29,914 |

| Sunscreen film | 27,661 | /* |

| Boilers replace ** | /* | 46,857 |

| Chiller replacement | 81,623 | /* |

| Relamping | 102,800 | /* |

| Cogeneration plant | 297,660 | 405,900 |

| Total | 514,477 | 482,671 |

| Electrical Consumption (kWhe/y) | Thermal Consumption (kWht/y) | |

|---|---|---|

| Ante-retrofit | 800,000 | 1,488,000 |

| Post-retrofit | 285,523 | 1,005,329 |

| Saving | 514,477 (65%) | 482,671 (33%) |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Curto, D.; Franzitta, V.; Guercio, A.; Panno, D. Energy Retrofit. A Case Study—Santi Romano Dormitory on the Palermo University. Sustainability 2021, 13, 13524. https://doi.org/10.3390/su132413524

Curto D, Franzitta V, Guercio A, Panno D. Energy Retrofit. A Case Study—Santi Romano Dormitory on the Palermo University. Sustainability. 2021; 13(24):13524. https://doi.org/10.3390/su132413524

Chicago/Turabian StyleCurto, Domenico, Vincenzo Franzitta, Andrea Guercio, and Domenico Panno. 2021. "Energy Retrofit. A Case Study—Santi Romano Dormitory on the Palermo University" Sustainability 13, no. 24: 13524. https://doi.org/10.3390/su132413524

APA StyleCurto, D., Franzitta, V., Guercio, A., & Panno, D. (2021). Energy Retrofit. A Case Study—Santi Romano Dormitory on the Palermo University. Sustainability, 13(24), 13524. https://doi.org/10.3390/su132413524