Life Cycle Impact Assessment of Recycled Aggregate Concrete, Geopolymer Concrete, and Recycled Aggregate-Based Geopolymer Concrete

Abstract

:1. Introduction

2. Materials and Methods

2.1. Goal and Scope

2.2. Study Area

2.3. Mix Design adaptation

2.4. Inventory Analysis

2.5. Questionnaire Survey

2.6. Life Cycle Impact Assessment (LCIA)

3. Results and Discussion

3.1. Life Cycle Inventory Results

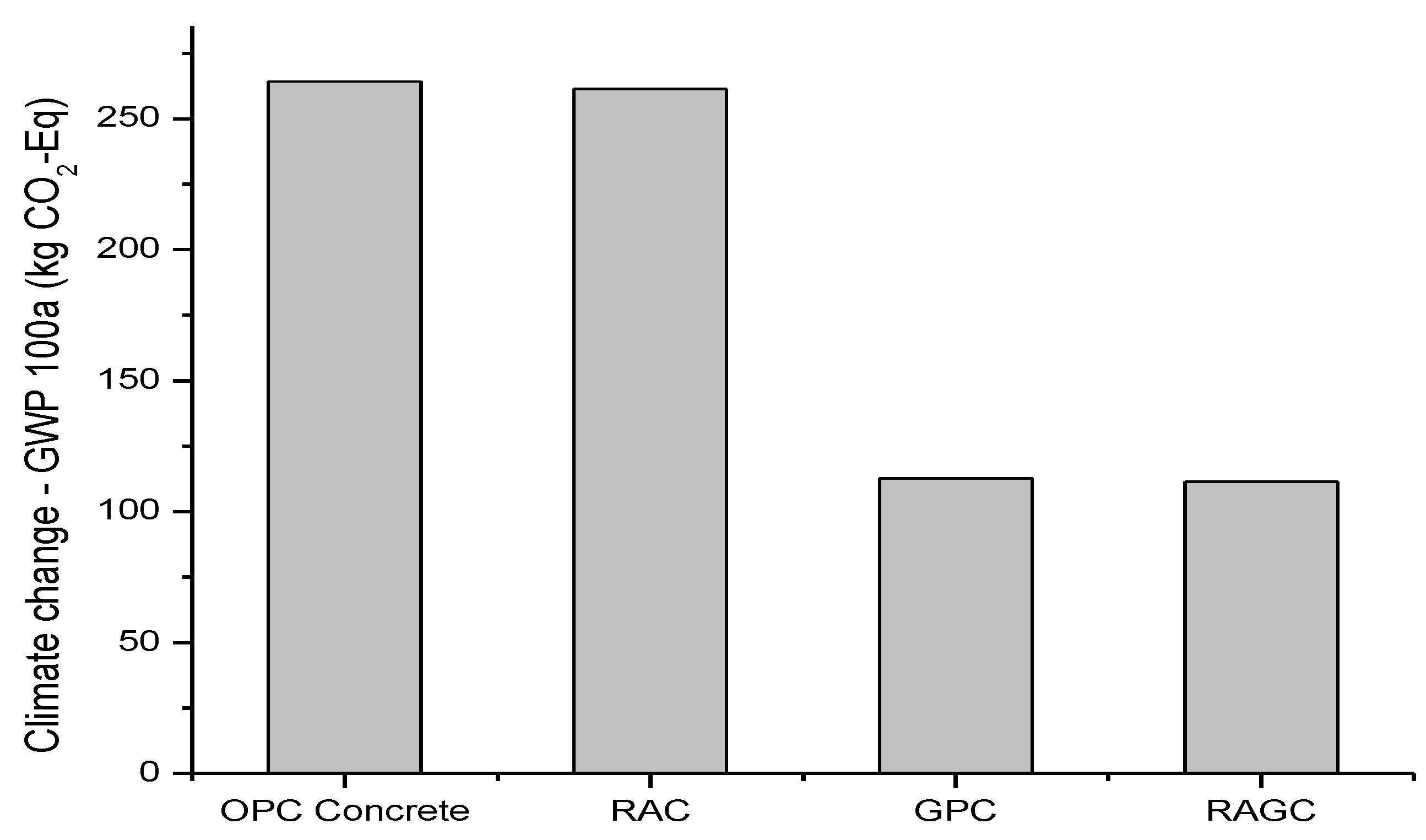

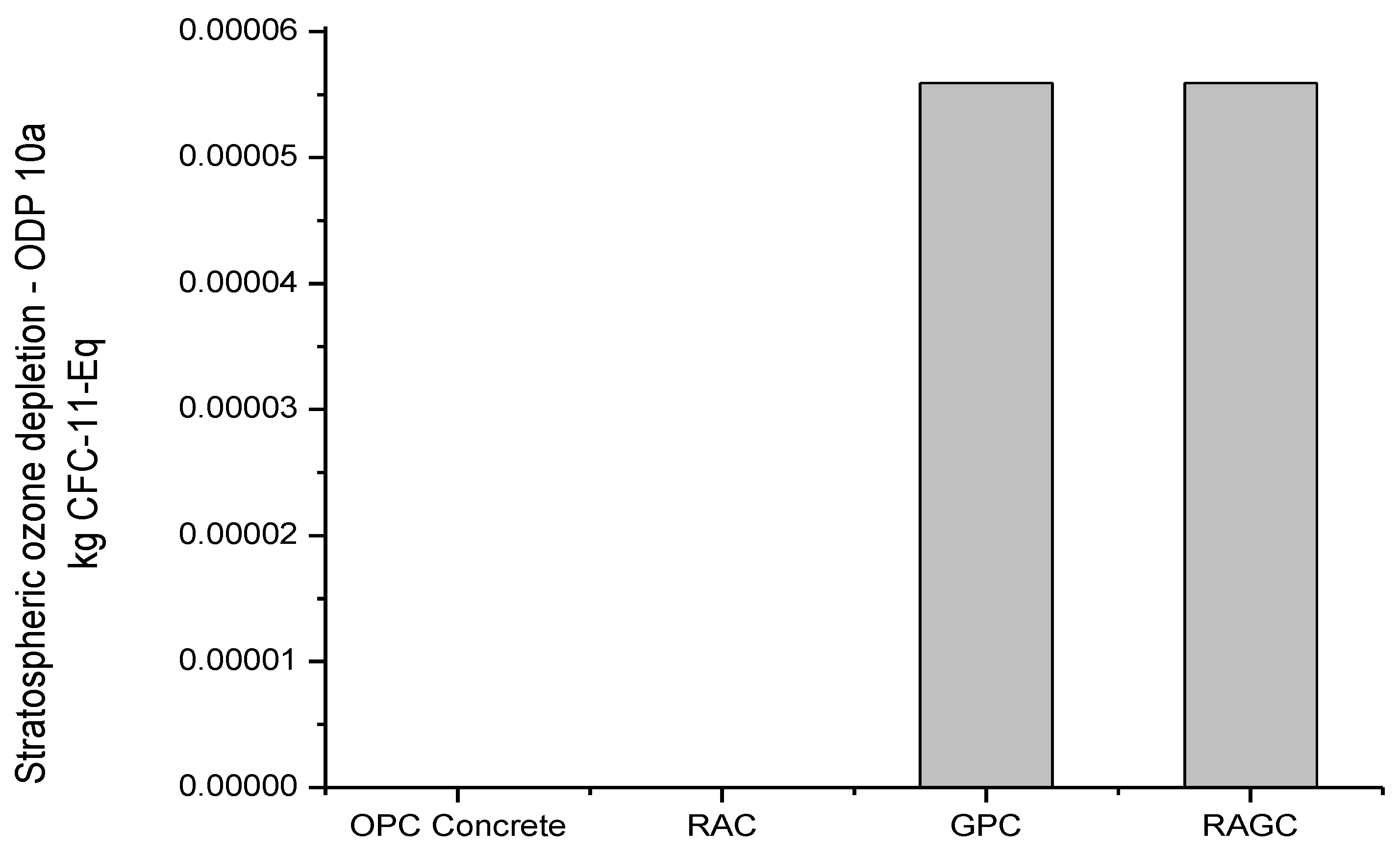

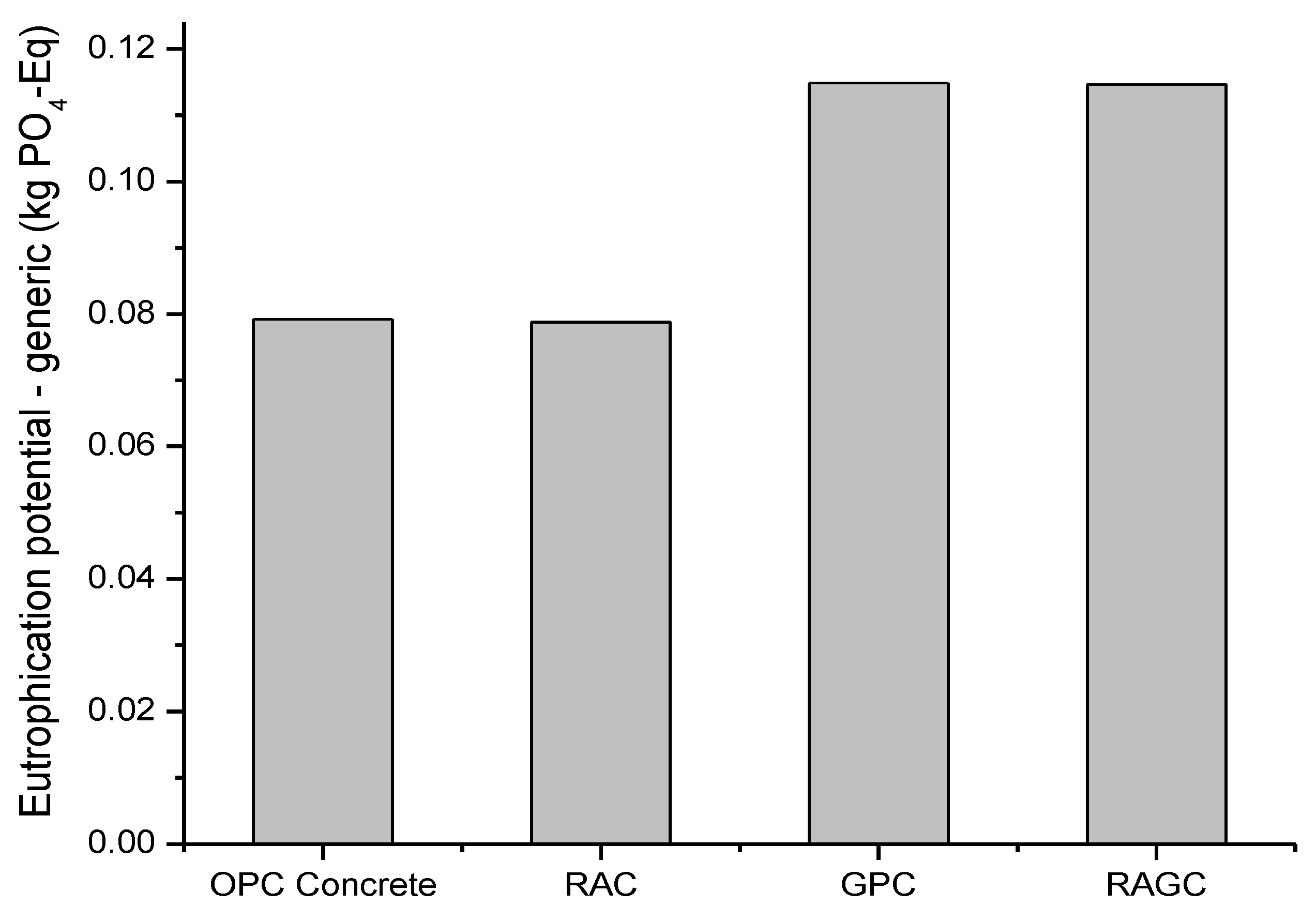

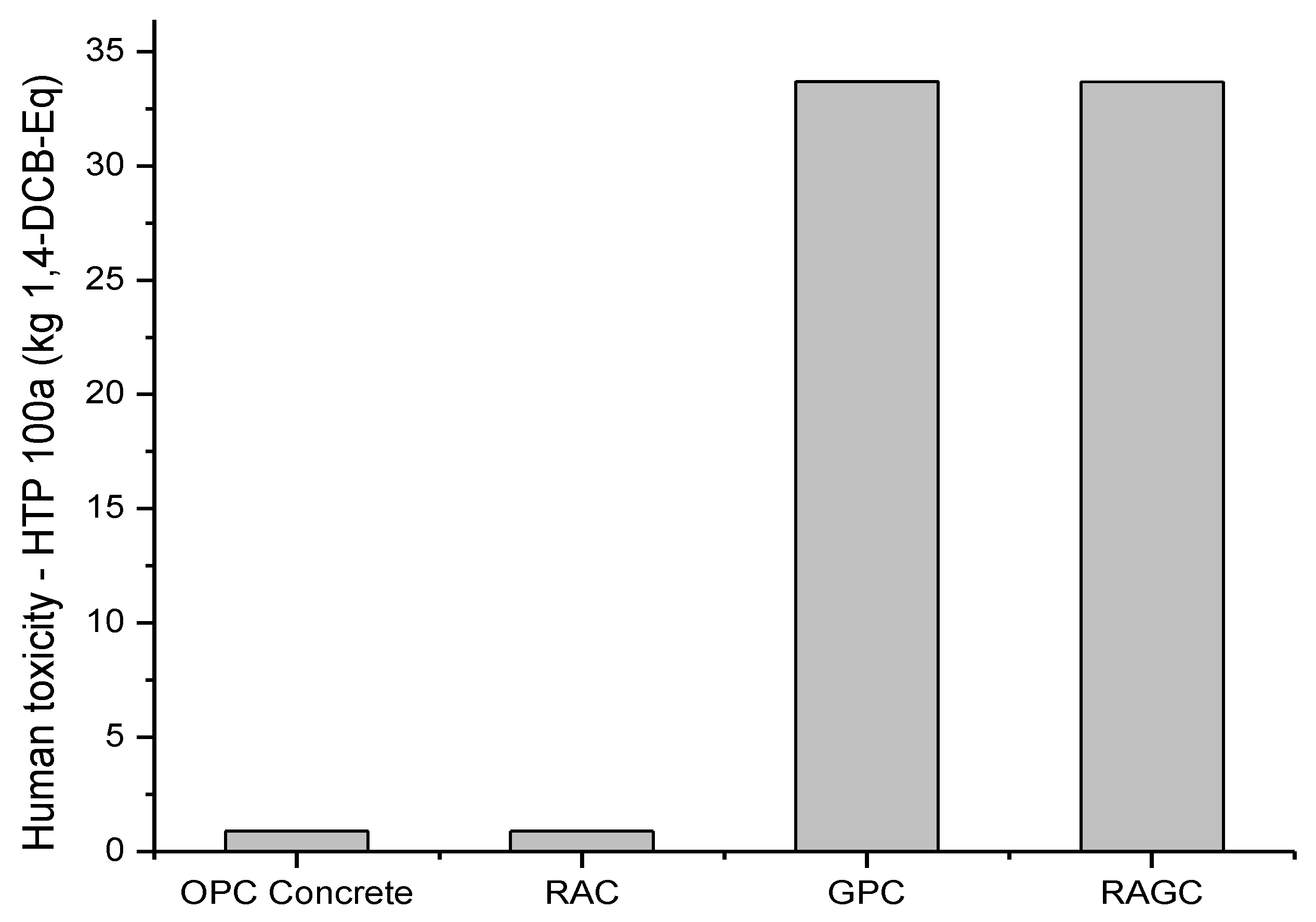

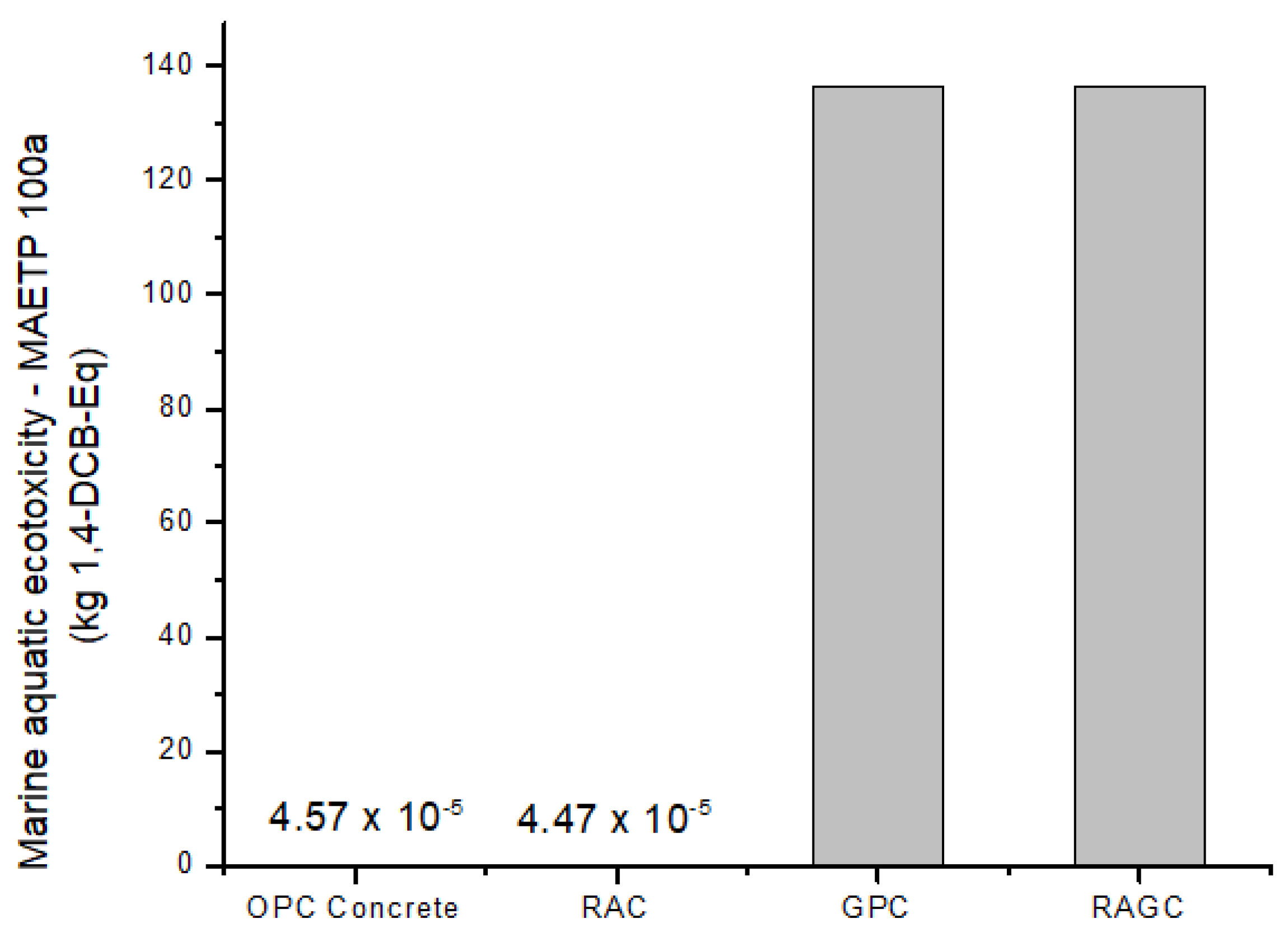

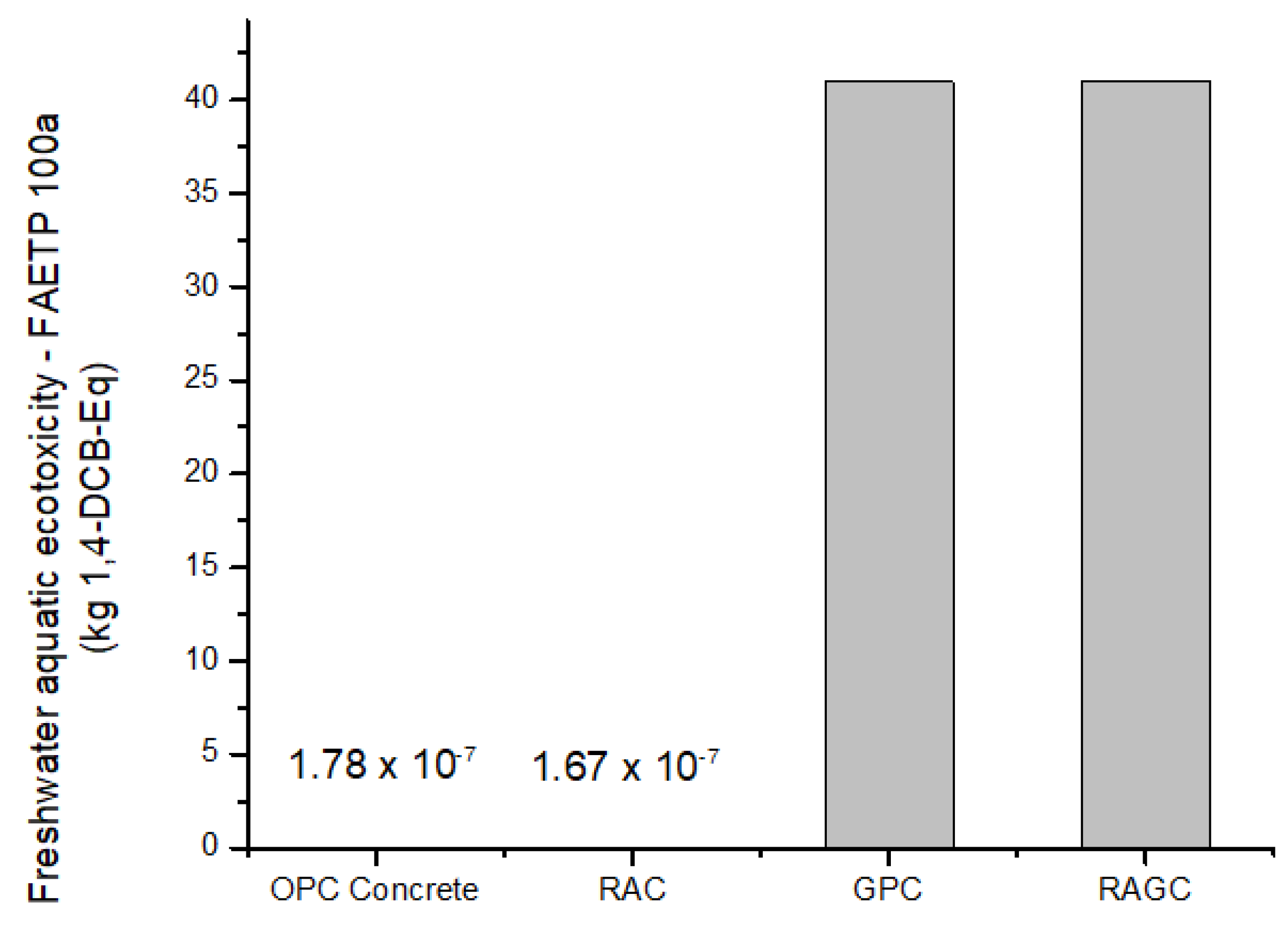

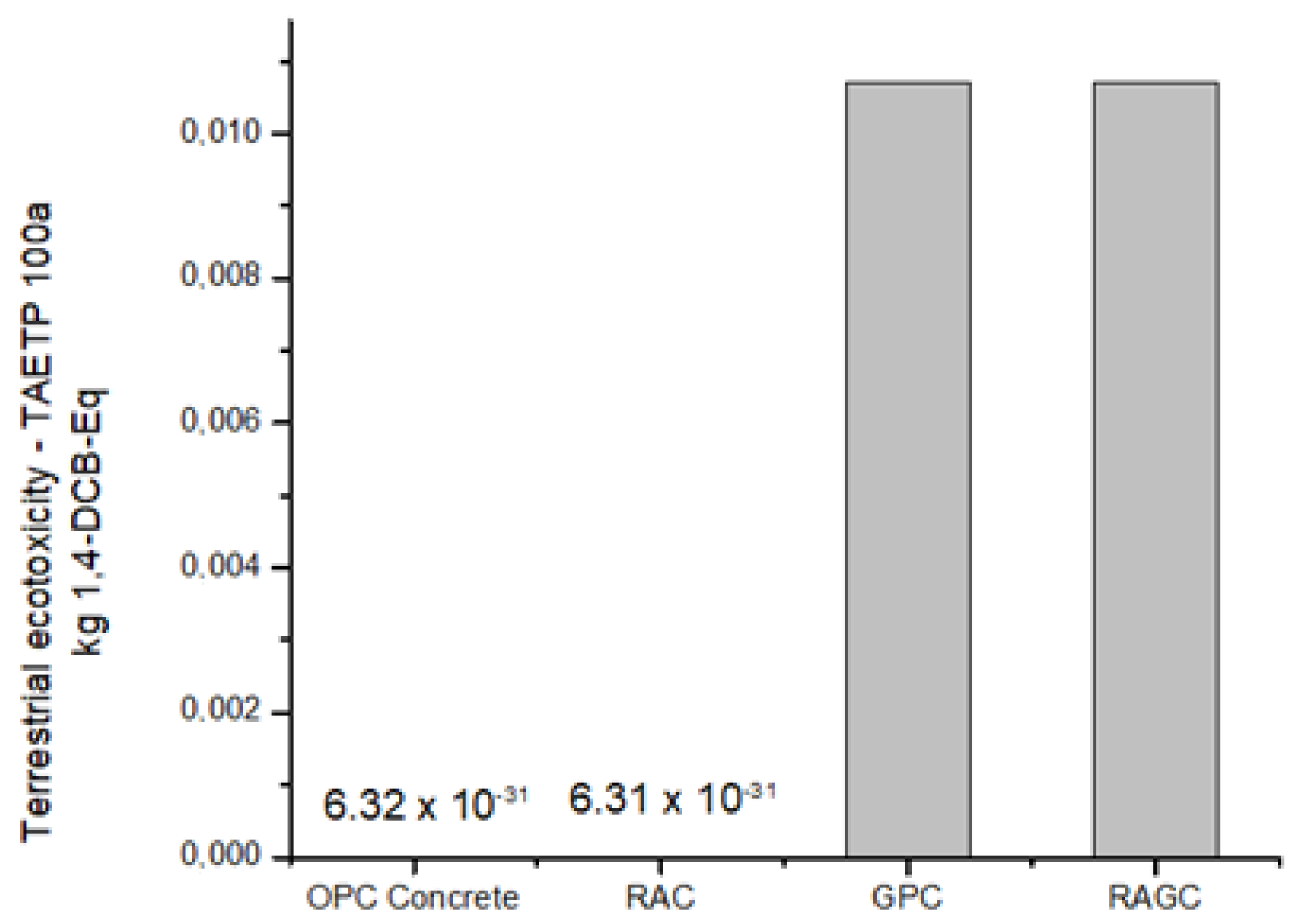

3.2. Environmental Impact Analysis of Four Mixes

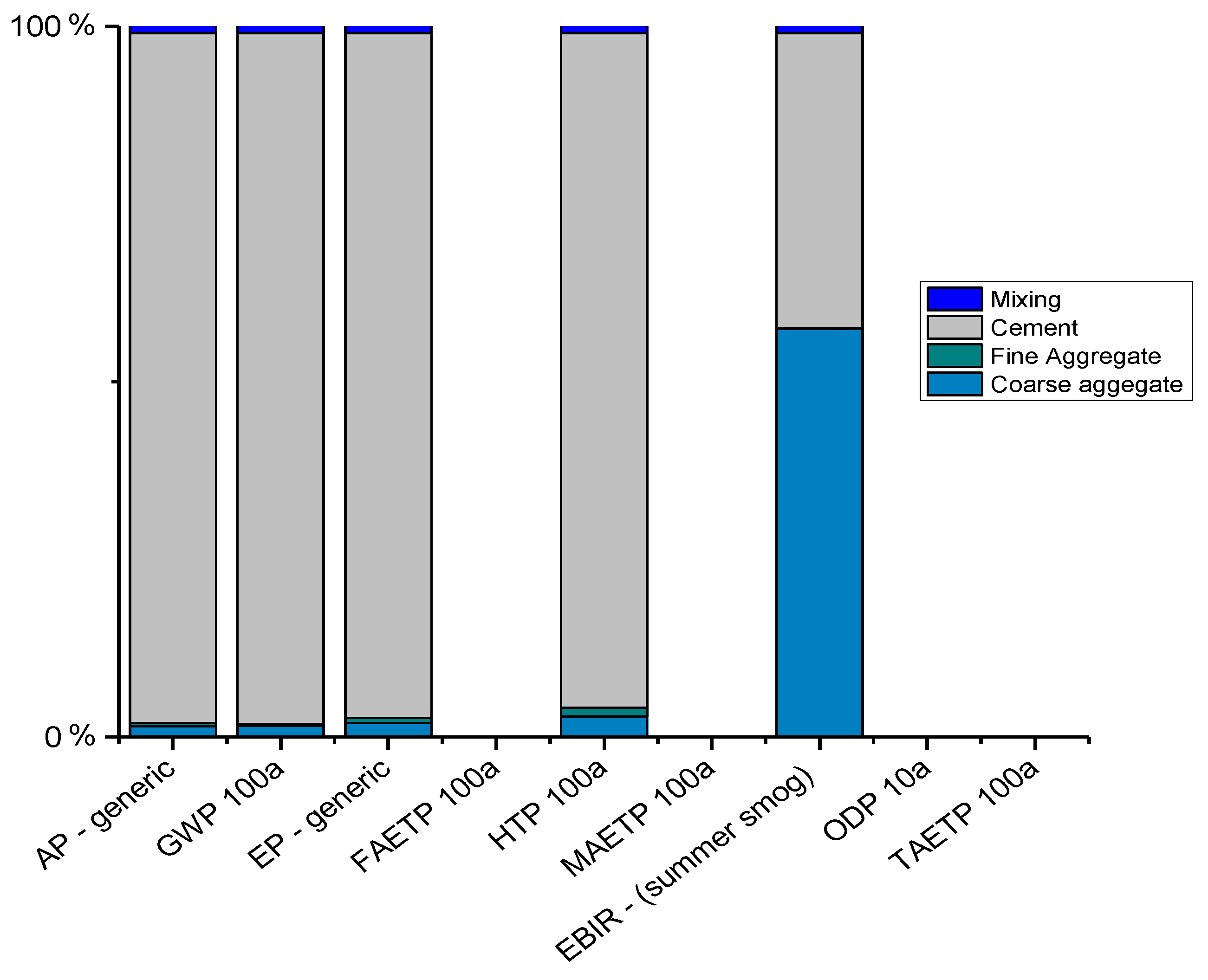

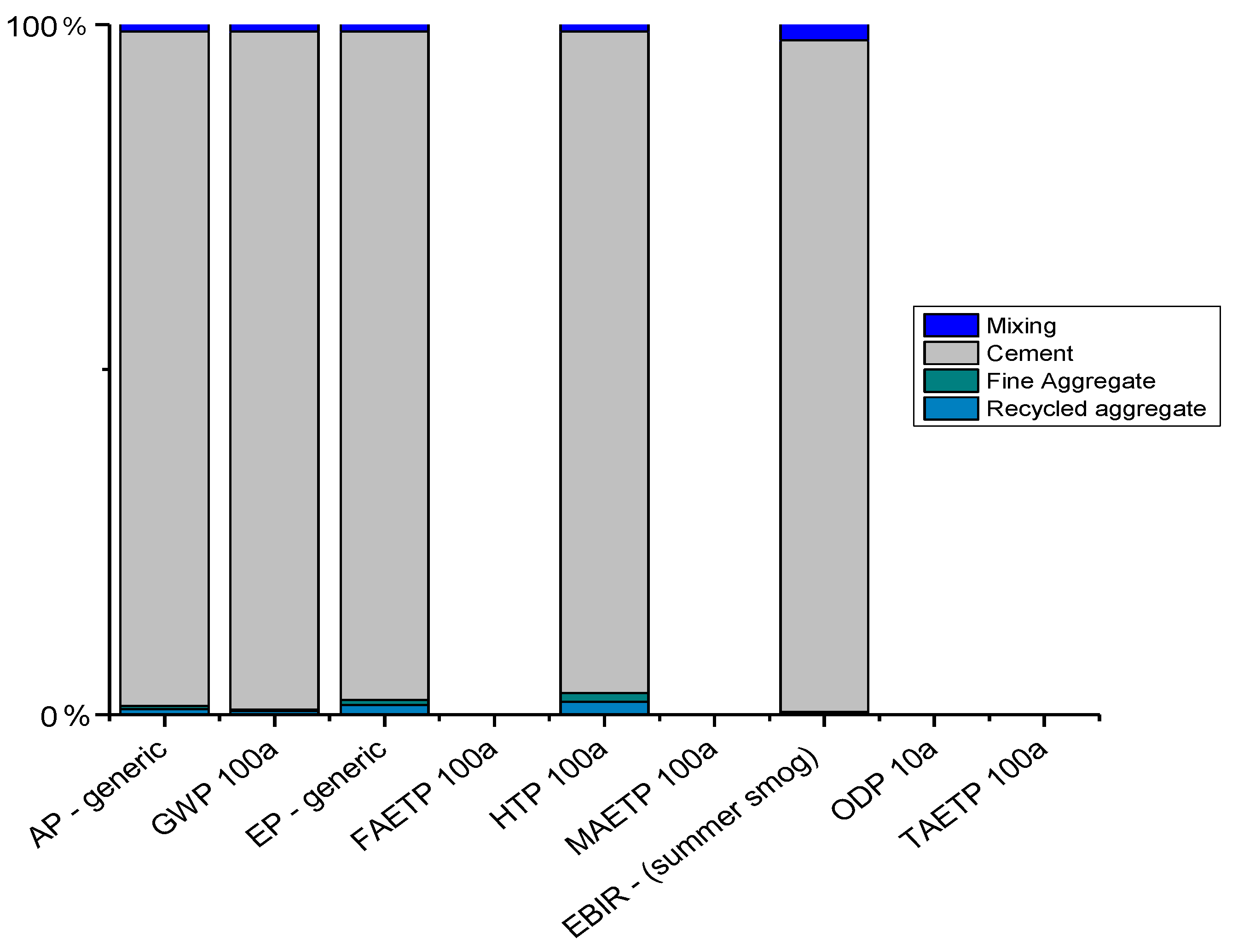

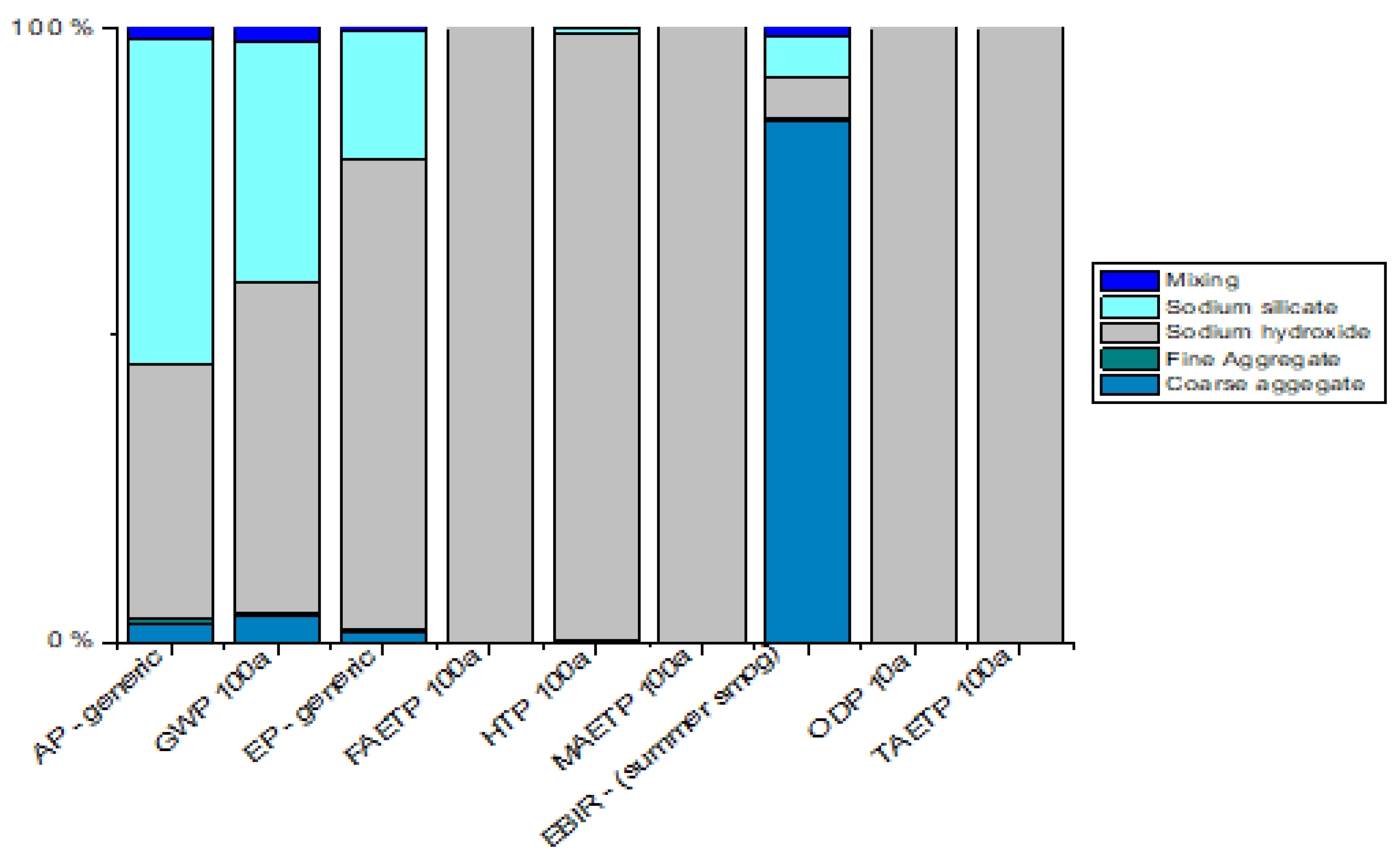

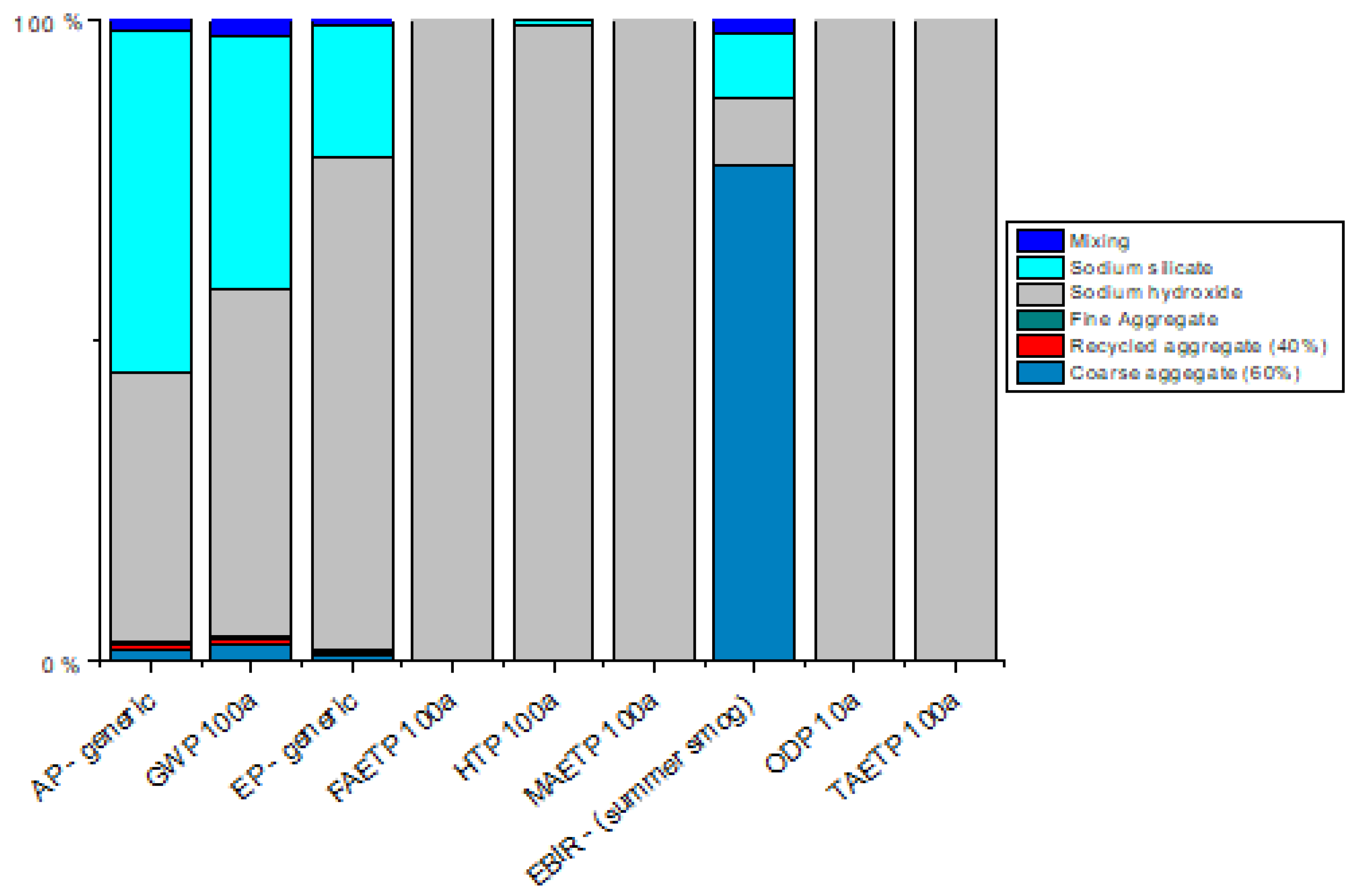

3.3. Contribution Analysis

4. Conclusions and Recommendations

- A questionnaire survey was conducted to calculate the production and transportation energy of all products of concrete mixtures per kilogram. It is reported from the survey that the total energy (the sum of electric, coal, and transportation energy) required for one kilogram of cement is 2.973 MJ. However, the total energy required for coarse aggregate (the sum of mining, crushing, and transportation energy) and RA (the sum of crushing and transportation energy) are 0.0154 MJ and 0.00834 MJ, respectively. The total energy required for sand production and transportation is 0.0136 MJ;

- A LCA analysis was conducted using OpenLCA software with the aid of the CML 2001 baseline method. Nine different impact categories were analyzed and compared for each mixture in order to evaluate the best mixture for the environment. On the basis of the LCA analysis, it is concluded that OPC in concrete mixtures is the major contributor to the production of negative environmental impacts;

- The use of aggregates also contributes to different environmental impacts, such as GWP, EP, ADP, and POF. The use of RA in both RAC and RAGC mixtures help to reduce the overall environmental impacts. However, the use of RA in concrete mixtures depends on the transportation distances;

- The inclusion of FA as an aluminosilicate in GPC concrete reduces some of the environmental impacts, such as GWP, ADP, and photochemical oxidation. However, the use of alkaline activators, such as sodium silicate and sodium hydroxide, is a major contributor to other environmental impacts, such as FAETP, TAETP, MAETP, ODP, and HTP. Hence, it is important to select the suitable and sustainable manufacturing method for alkaline activators;

- The use of GPC and RAGC mixtures is a more suitable option for reducing the GWP produced due to normal concrete cement. It is concluded that use of GPC lowers the GWP impact up to 57.34%, when compared to OPC concrete. However, categories other than GWP are affected by use of GPC mixtures;

- The use of an alkaline activator is a major contributor to environmental impacts, both in the case of GPC and RAGC. Hence, it is important to select the appropriate source of alkaline activators to be used in the GPC mixture. If the sodium hydroxide is taken from the seabed, or the sodium silicate is taken from any sustainable source, then the overall environmental impacts of GPC mixtures can be reduced.

- Research on generating and collecting the LCI data for condition of Pakistan

- The comparison of GPC and RAGC concrete at different percentages of RA

- The comparison of concrete mixtures by using different impact assessment methods

- The investigation of LCA of GPC mixtures by using different manufacturing processes for the alkaline activators

- The investigation of different transportation scenarios while comparing different mixtures of concrete

- The use of normalization and weighting set analysis after the comparison of different concrete mixtures

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Abbreviations

| ADP | Acidification Potential |

| CFC | Chlorofloro Carbons |

| CML | Centrum voor Milieukunde Leiden |

| CO | Carbon Monoxide |

| CO2 | Carbon Dioxide |

| EPD | Environmental Product Declaration |

| ER | Environmental Reports |

| ETP | Eutrophication Potential |

| EBIR | Equal Benefit Incremental Reactivity |

| FA | Fly Ash |

| FAETP | Freshwater Aquatic Ecotoxicity Potential |

| GGBFS | Ground Granulated Blast Furnace Slag |

| GHG’s | Greenhouse Gases |

| GPC | Geopolymer Concrete |

| GWP | Global Warming Potential |

| HTP | Human Toxicity Potential |

| LCA | Life Cycle Assessment |

| LCIA | Life Cycle Impact Assessment |

| MAETP | Marine Aquatic Ecotoxicity Potential |

| MK | Metakaolin |

| MIR | Maximum Incremental Reactivity |

| NOx | Nitrogen Oxides |

| NMVOC | Volatile Organic Compounds |

| PM | Particulate Matter |

| MOIR | Maximum Ozone Incremental Reactivity |

| OPC | Ordinary Portland cement |

| POCP | Photochemical Ozone Creation Potential |

| RA | Recycled Aggregate |

| POF | Photochemical Oxidant Formation |

| RAC | Recycled Aggregate Concrete |

| SF | Silica Fume |

| SOx | Sulphur Oxides |

| RAGC | Recycled Aggregate Geopolymer Concrete |

| SETAC | Society of Environmental Toxicology and Chemistry |

| GWP-100a | 100-year Global warming potential |

| TAETP | Terrestrial Aquatic Ecotoxicity Potential |

| UNEP | United Nations Environmental Program |

| ISO | International Organization for Standardization |

| TRACI | Tool for Reduction and Assessment of Chemical and other Environmental impacts |

References

- Aprianti, E.; Shafigh, P.; Bahri, S.; Farahani, J.N. Supplementary cementitious materials origin from agricultural wastes–A review. Constr. Build. Mater. 2015, 74, 176–187. [Google Scholar] [CrossRef]

- Oss, H.G.; Padovani, A.C. Cement Manufacture and the Environment Part II: Environmental Challenges and Opportunities. J. Ind. Ecol. 2003, 7, 93–126. [Google Scholar] [CrossRef] [Green Version]

- WORLD, H. Rise of Carbon Dioxide in the Atmosphere Continues Unabated. 2020. Available online: https://earthsky.org/earth/rising-carbon-dioxide-co2-record-high-june2020/ (accessed on 25 November 2021).

- Li, N.; Shi, C.; Zhang, Z.; Wang, H.; Liu, Y. A review on mixture design methods for geopolymer concrete. Compos. Part B Eng. 2019, 178, 107490. [Google Scholar] [CrossRef]

- Nuaklong, P.; Sata, V.; Chindaprasirt, P. Influence of recycled aggregate on fly ash geopolymer concrete properties. J. Clean. Prod. 2016, 112, 2300–2307. [Google Scholar] [CrossRef]

- Xie, J.; Wang, J.; Rao, R.; Wang, C.; Fang, C. Effects of combined usage of GGBS and fly ash on workability and mechanical properties of alkali activated geopolymer concrete with recycled aggregate. Compos. Part B Eng. 2019, 164, 179–190. [Google Scholar] [CrossRef]

- Nuaklong, P.; Sata, V.; Chindaprasirt, P. Properties of metakaolin-high calcium fly ash geopolymer concrete containing recycled aggregate from crushed concrete specimens. Constr. Build. Mater. 2018, 161, 365–373. [Google Scholar] [CrossRef]

- E McGrath, T.; Cox, S.; Soutsos, M.; Kong, D.; Mee, L.P.; Alengaram, J.U.J. Life Cycle Assessment of Geopolymer Concrete: A Malaysian Context; IOP Conference Series: Materials Science and Engineering; IOP Publishing: Kuala lumper, Malaysia, 2018. [Google Scholar]

- Salas, D.A.; Ramirez, A.D.; Ulloa, N.; Baykara, H.; Boero, A. Life cycle assessment of geopolymer concrete. Constr. Build. Mater. 2018, 190, 170–177. [Google Scholar] [CrossRef]

- Bajpai, R.; Choudhary, K.; Srivastava, A.; Sangwan, K.S.; Singh, M. Environmental impact assessment of fly ash and silica fume based geopolymer concrete. J. Clean. Prod. 2020, 254, 120147. [Google Scholar] [CrossRef]

- Habert, G.; d’Espinose de Lacaillerie, J.B.; Roussel, N. An environmental evaluation of geopolymer based concrete production: Reviewing current research trends. J. Clean. Prod. 2011, 19, 1229–1238. [Google Scholar] [CrossRef]

- Zain, H.; Abdullah, M.M.A.B.; Hussin, K.; Ariffin, N.; Bayuaji, R. Review on Various Types of Geopolymer Materials with the Environmental Impact Assessment. In MATEC Web of Conferences; EDP Sciences: Perlis, Malaysia, 2017. [Google Scholar]

- Habert, G.; Lacaillerie, J.D.D.; Lanta, E.; Roussel, N. Environmental evaluation for cement substitution with geopolymers. In Proceedings of the 2nd International Conference on Sustainable Construction Materials and Technologies, Ancone, Italy, 28–30 June 2010. [Google Scholar]

- Abbas, R.; Khereby, M.A.; Ghorab, H.Y.; Elkhoshkhany, N. Preparation of geopolymer concrete using Egyptian kaolin clay and the study of its environmental effects and economic cost. Clean Technol. Environ. Policy 2020, 22, 669–687. [Google Scholar] [CrossRef]

- Pozzo, A.D.; Carabba, L.; Bignozzi, M.C.; Tugnoli, A. Life cycle assessment of a geopolymer mixture for fireproofing applications. Int. J. Life Cycle Assess. 2019, 24, 1743–1757. [Google Scholar] [CrossRef]

- Finkbeiner, M.; Inaba, A.; Tan, R.; Christiansen, K.; Klüppel, H.-J. The New International Standards for Life Cycle Assessment: ISO 14040 and ISO 14044. Int. J. Life Cycle Assess. 2006, 11, 80–85. [Google Scholar] [CrossRef]

- Rashid, K.; Rehman, M.U.; de Brito, J.; Ghafoor, H. Multi-criteria optimization of recycled aggregate concrete mixes. J. Clean. Prod. 2020, 276, 124316. [Google Scholar] [CrossRef]

- Wernet, G.; Bauer, C.; Steubing, B.; Reinhard, J.; Moreno-Ruiz, E.; Weidema, B. The ecoinvent database version 3 (part I): Overview and methodology. Int. J. Life Cycle Assess. 2016, 21, 1218–1230. [Google Scholar] [CrossRef]

- Galvin, B.; Lloyd, N. Fly ash based geopolymer concrete with recycled concrete aggregate. In Proceedings of the CONCRETE 2011 Conference, Perth, Australia, 12 October 2011; The Concrete Institute of Australia: Sydney, Australia. [Google Scholar]

- Mohammadi, J.; South, W. Life cycle assessment (LCA) of benchmark concrete products in Australia. Int. J. Life Cycle Assess. 2017, 22, 1588–1608. [Google Scholar] [CrossRef]

- Frischknecht, R. LCI modelling approaches applied on recycling of materials in view of environmental sustainability, risk perception and eco-efficiency. Int. J. Life Cycle Assess. 2010, 15, 666–671. [Google Scholar] [CrossRef] [Green Version]

- Ding, T.; Xiao, J.; Tam, V.W.Y. A closed-loop life cycle assessment of recycled aggregate concrete utilization in China. Waste Manag. 2016, 56, 367–375. [Google Scholar] [CrossRef]

- Guo, Z.; Tu, A.; Chen, C.; Lehman, D.E. Mechanical properties, durability, and life-cycle assessment of concrete building blocks incorporating recycled concrete aggregates. J. Clean. Prod. 2018, 199, 136–149. [Google Scholar] [CrossRef]

- Marinkovic, S.; Ignjatović, I.; Radonjanin, V. Life-cycle assessment (LCA) of concrete with recycled aggregates (RAs). In Handbook of Recycled Concrete and Demolition Waste; Elsevier: Amsterdam, The Netherlands, 2013; pp. 569–604. [Google Scholar]

- Serres, N.; Braymand, S.; Feugeas, F. Environmental evaluation of concrete made from recycled concrete aggregate implementing life cycle assessment. J. Build. Eng. 2016, 5, 24–33. [Google Scholar] [CrossRef]

- Knoeri, C.; Sanyé-Mengual, E.; Althaus, H.-J. Comparative LCA of recycled and conventional concrete for structural applications. Int. J. Life Cycle Assess. 2013, 18, 909–918. [Google Scholar] [CrossRef] [Green Version]

- Shi, X.; Mukhopadhyay, A.; Zollinger, D.; Grasley, Z. Economic input-output life cycle assessment of concrete pavement containing recycled concrete aggregate. J. Clean. Prod. 2019, 225, 414–425. [Google Scholar] [CrossRef]

- Colangelo, F.; Navarro, T.G.; Farina, I.; Petrillo, A. Comparative LCA of concrete with recycled aggregates: A circular economy mindset in Europe. Int. J. Life Cycle Assess. 2020, 25, 1790–1804. [Google Scholar] [CrossRef]

- Marinković, S.; Radonjanin, V.; Malešev, M.; Ignjatović, I. Comparative environmental assessment of natural and recycled aggregate concrete. Waste Manag. 2010, 30, 2255–2264. [Google Scholar] [CrossRef]

- Shan, X.; Zhou, J.; Chang, V.W.-C.; Yang, E.-H. Life cycle assessment of adoption of local recycled aggregates and green concrete in Singapore perspective. J. Clean. Prod. 2017, 164, 918–926. [Google Scholar] [CrossRef]

- Kim, T.; Tae, S.; Chae, C.U. Analysis of Environmental Impact for Concrete Using LCA by Varying the Recycling Components, the Compressive Strength and the Admixture Material Mixing. Sustainability 2016, 8, 389. [Google Scholar] [CrossRef] [Green Version]

- Asadollahfardi, G.; Katebi, A.; Taherian, P.; Panahandeh, A. Environmental life cycle assessment of concrete with different mixed designs. Int. J. Constr. Manag. 2021, 21, 665–676. [Google Scholar] [CrossRef]

- Turner, L.K.; Collins, F.G. Carbon dioxide equivalent (CO2-e) emissions: A comparison between geopolymer and OPC cement concrete. Constr. Build. Mater. 2013, 43, 125–130. [Google Scholar] [CrossRef]

| Ingredients | OPC Concrete (kg/m3) [16] | RAC (kg/m3) [16] | GPC (kg/m3) [17] | RAGC (kg/m3) [17] |

|---|---|---|---|---|

| Cement | 415 | 415 | - | - |

| Fly ash | - | - | 408 | 408 |

| Fine aggregate | 620 | 620 | 554 | 554 |

| Coarse aggregate | 1040 | - | 1243 | 746 |

| Recycled aggregate | - | 1040 | - | 497 |

| Water | 185 | 185 | 20 | 20 |

| Sodium Hydroxide | - | - | 41 | 41 |

| Sodium Silicate | - | - | 103 | 103 |

| Superplasticizer SP (% of cement) | 0.5 | 1.5 | - | - |

| Ingredient | Cement | Coarse Aggregate | Fine Aggregate | Recycled Aggregate |

|---|---|---|---|---|

| Total Energy (MJ/kg) | 2.973 | 0.0154 | 0.0136 | 0.00833 |

| Emissions (kg) | ||||

| CO2 | 0.614 | 0.00173 | 0.00095 | 0.00124 |

| SO2 | 0.0014 | 6.976 × 10−6 | 1.99 × 10−6 | 2.091 × 10−6 |

| CO | 0.0026 | 0.001437 | 3.46 × 10−6 | 2.394 × 10−6 |

| NOx | 0.00141 | 1.128 × 10−5 | 7.25 × 10−6 | 8.202 × 10−6 |

| PM < 10 | 0.000267 | 1.281 × 10−5 | 1.1 × 10−5 | 7.097 × 10−6 |

| NMVOC | 0.000161 | 6.455 × 10−7 | 6.4 × 10−10 | 4.320 × 10−7 |

| NH3 | 1.893 × 10−5 | - | 3.37 × 10−9 | - |

| N2O | 1.357 × 10−6 | 2.813 × 10−8 | 3.29 × 10−7 | 1.535 × 10−8 |

| CH4 | 0.000655 | 6.979 × 10−7 | 1.88 × 10−8 | 3.629 × 10−7 |

| Ingredients | Production Energy (MJ/kg) | Transportation Energy (MJ/kg) |

|---|---|---|

| Cement | 2.918 | 0.055 |

| Fine Aggregate | 0.00565 | 0.00795 |

| Coarse Aggregate | 0.00873 | 0.00630 |

| Recycled Aggregate | 0.00524 | 0.00309 |

| Indicator | OPC Concrete | RAC | GPC | RAGC | Units |

|---|---|---|---|---|---|

| Acidification Potential—Generic | 1.01904 | 1.01165 | 0.60119 | 0.59769 | kg SO2-Eq |

| Climate Change—GWP | 264.181 | 261.315 | 112.743 | 111.377 | kg CO2-Eq |

| Eutrophication Potential | 0.07922 | 0.0788 | 0.11483 | 0.11463 | kg PO4-Eq |

| Freshwater Ecotoxicity | 1.78 × 10−7 | 1.677 × 10−7 | 40.940 | 40.940 | kg 1,4-DCB-Eq |

| Human toxicity | 0.8952 | 0.8860 | 33.70 | 33.68249 | kg 1,4-DCB-Eq |

| Marine aquatic Ecotoxicity | 4.575 × 10−5 | 4.475 × 10−5 | 136.45 | 136.45 | kg 1,4-DCB-Eq |

| Photochemical Oxidation | 0.0963 | 0.0411 | 0.0777 | 0.0513 | kg ozone formed |

| Stratospheric ozone depletion | 0 | 0 | 5.59 × 10−5 | 5.59 × 10−5 | kg CFC-11-Eq |

| Terrestrial Ecotoxicity | 6.32 × 10−31 | 6.30 × 10−31 | 0.0107 | 0.0107 | kg 1,4-DCB-Eq |

| Ranking | Mixture |

|---|---|

| 1st | RAGC |

| 2nd | GPC |

| 3rd | RAC |

| 4th | OPC |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Imtiaz, L.; Kashif-ur-Rehman, S.; Alaloul, W.S.; Nazir, K.; Javed, M.F.; Aslam, F.; Musarat, M.A. Life Cycle Impact Assessment of Recycled Aggregate Concrete, Geopolymer Concrete, and Recycled Aggregate-Based Geopolymer Concrete. Sustainability 2021, 13, 13515. https://doi.org/10.3390/su132413515

Imtiaz L, Kashif-ur-Rehman S, Alaloul WS, Nazir K, Javed MF, Aslam F, Musarat MA. Life Cycle Impact Assessment of Recycled Aggregate Concrete, Geopolymer Concrete, and Recycled Aggregate-Based Geopolymer Concrete. Sustainability. 2021; 13(24):13515. https://doi.org/10.3390/su132413515

Chicago/Turabian StyleImtiaz, Lahiba, Sardar Kashif-ur-Rehman, Wesam Salah Alaloul, Kashif Nazir, Muhammad Faisal Javed, Fahid Aslam, and Muhammad Ali Musarat. 2021. "Life Cycle Impact Assessment of Recycled Aggregate Concrete, Geopolymer Concrete, and Recycled Aggregate-Based Geopolymer Concrete" Sustainability 13, no. 24: 13515. https://doi.org/10.3390/su132413515

APA StyleImtiaz, L., Kashif-ur-Rehman, S., Alaloul, W. S., Nazir, K., Javed, M. F., Aslam, F., & Musarat, M. A. (2021). Life Cycle Impact Assessment of Recycled Aggregate Concrete, Geopolymer Concrete, and Recycled Aggregate-Based Geopolymer Concrete. Sustainability, 13(24), 13515. https://doi.org/10.3390/su132413515