A Life-Cycle Approach to Integrate Environmental and Mechanical Properties of Blended Cements Containing Seashell Powder

Abstract

1. Introduction

2. Experimental Program

2.1. Introduction of the Developed Blended Cements

2.2. Materials and Methods

3. Environmental Assessment

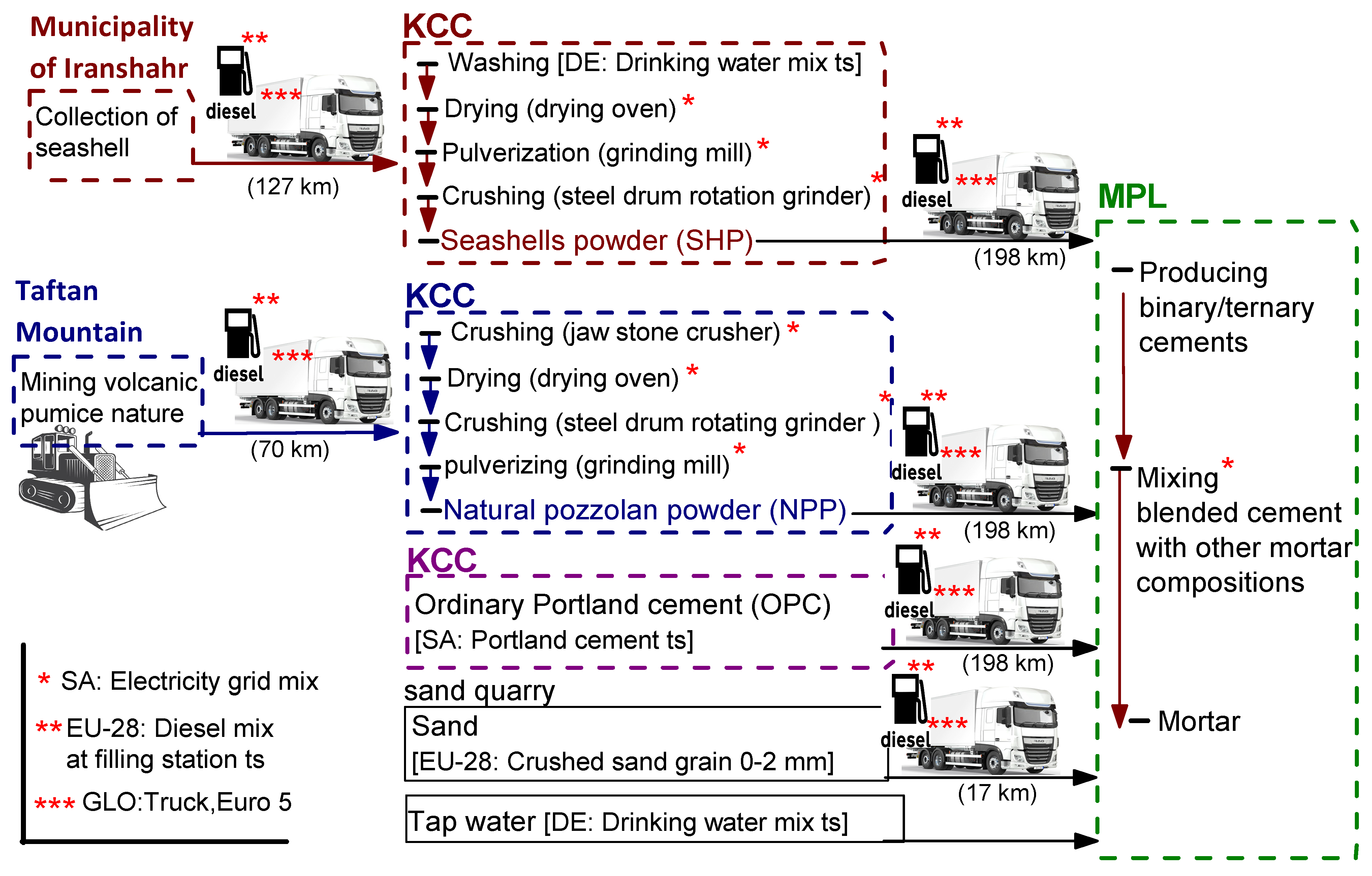

3.1. Goal and Scope Definition of the LCA

3.2. Life Cycle Inventory

3.3. Impact Assessment

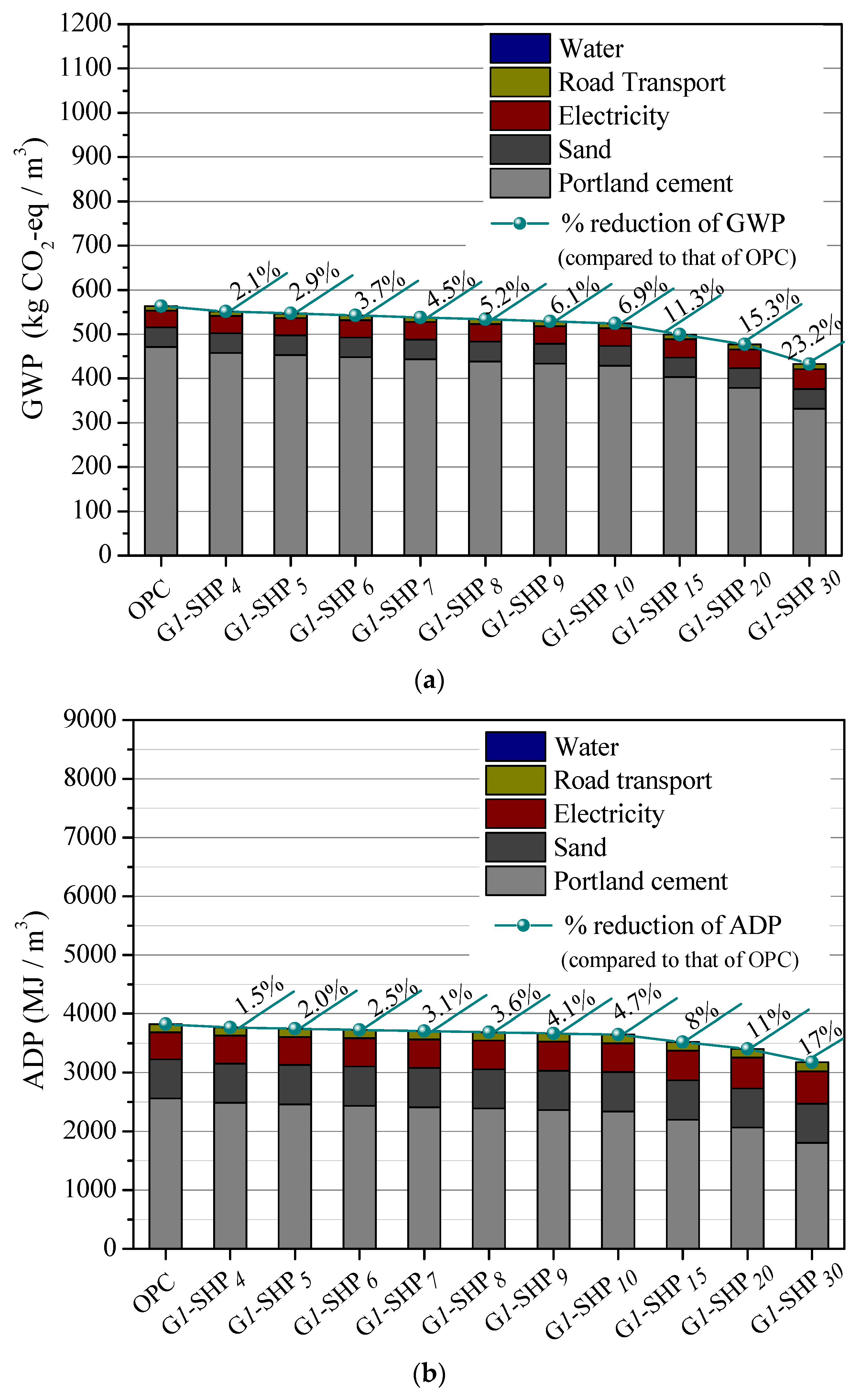

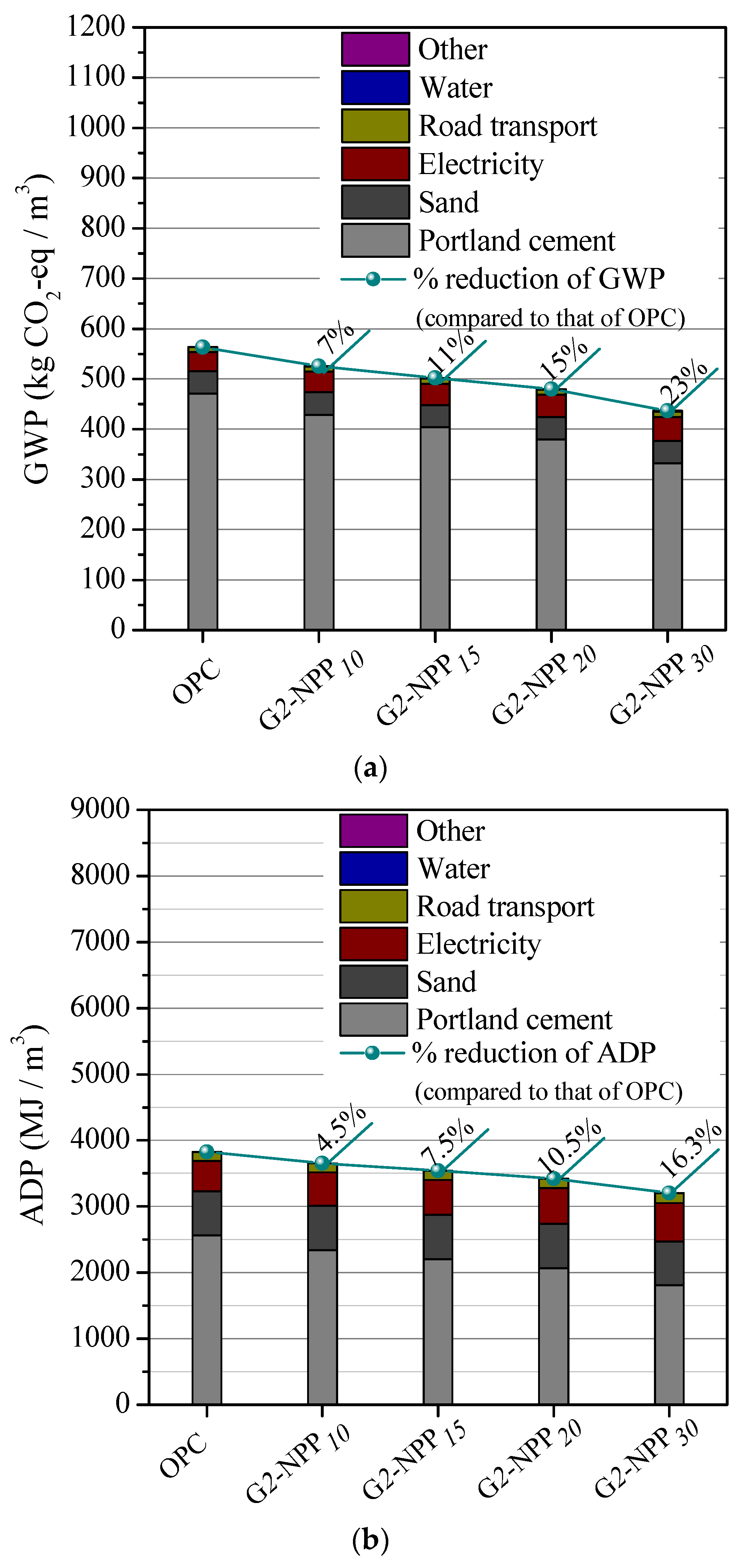

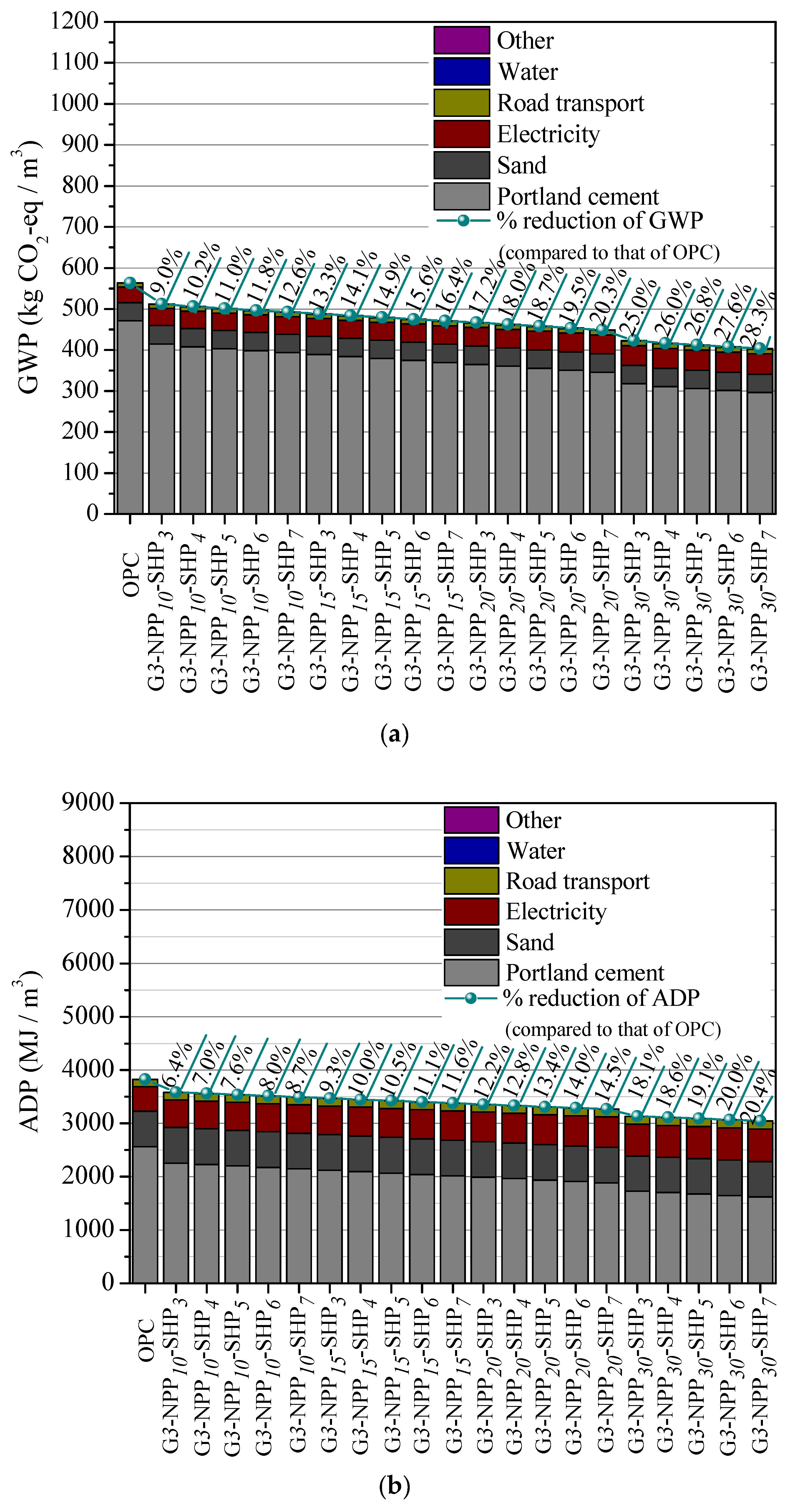

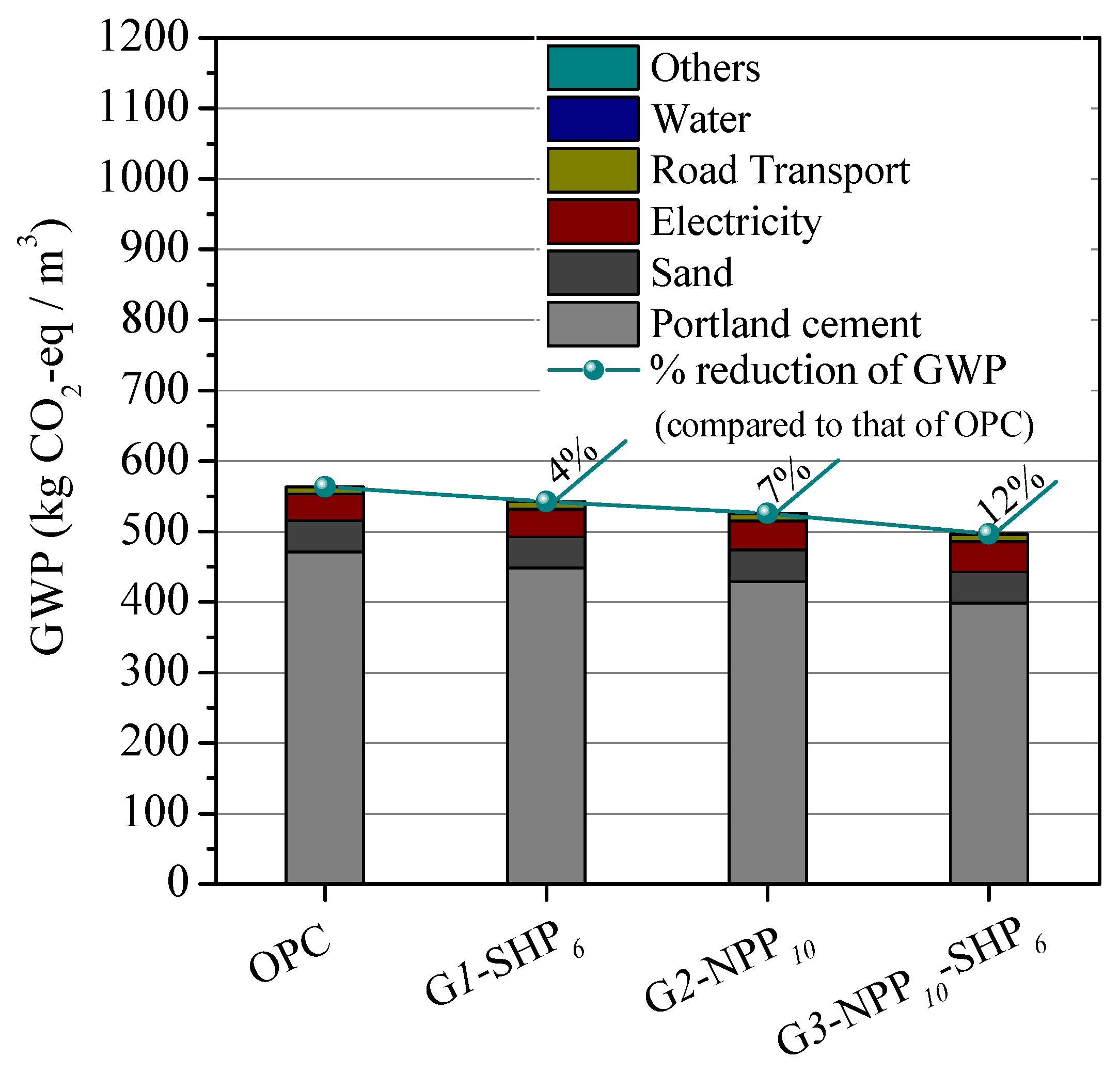

3.4. Interpretation

4. Modified Life Cycle Approach Integrating Environmental and Mechanical Performances (MLCAiEM)

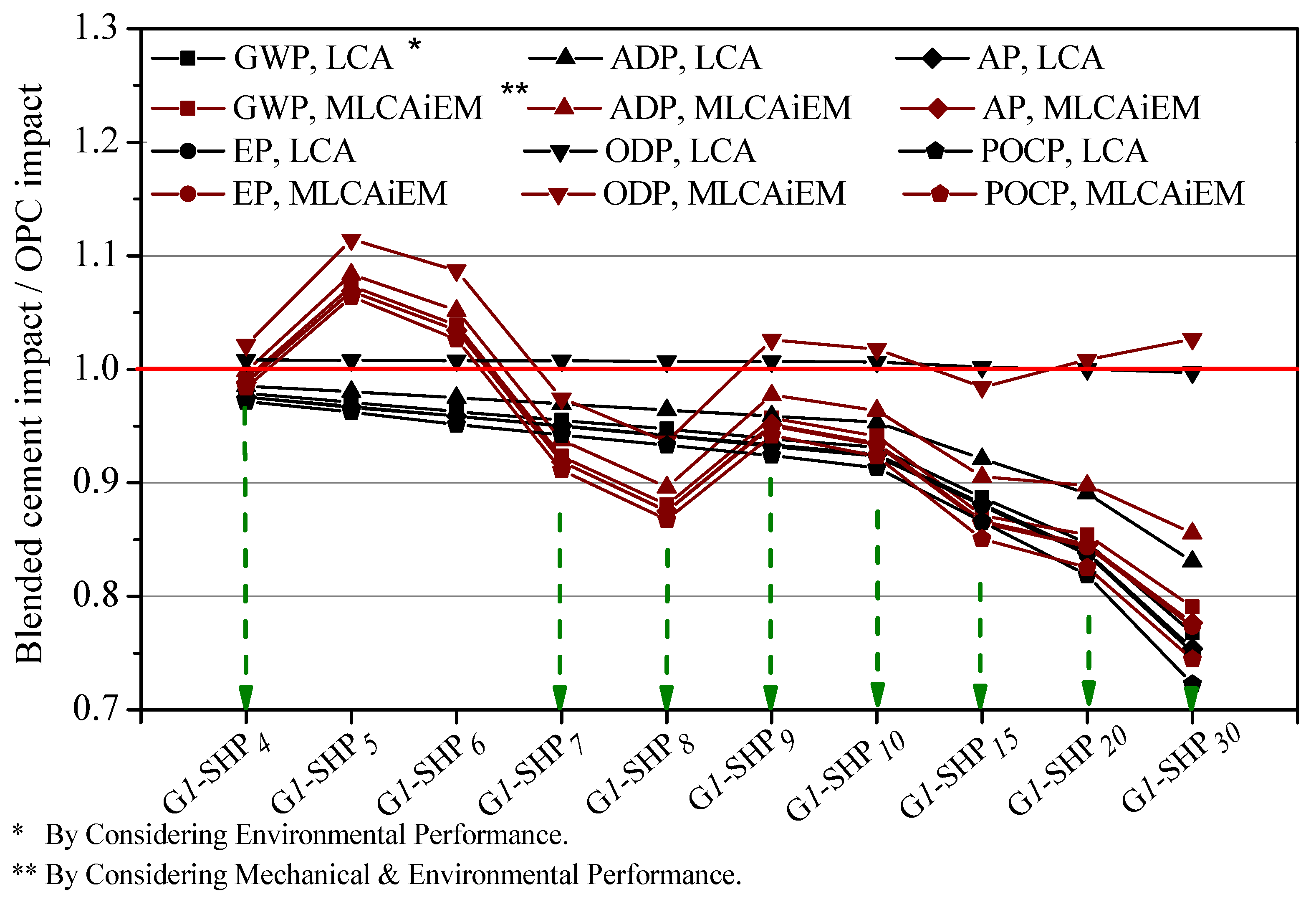

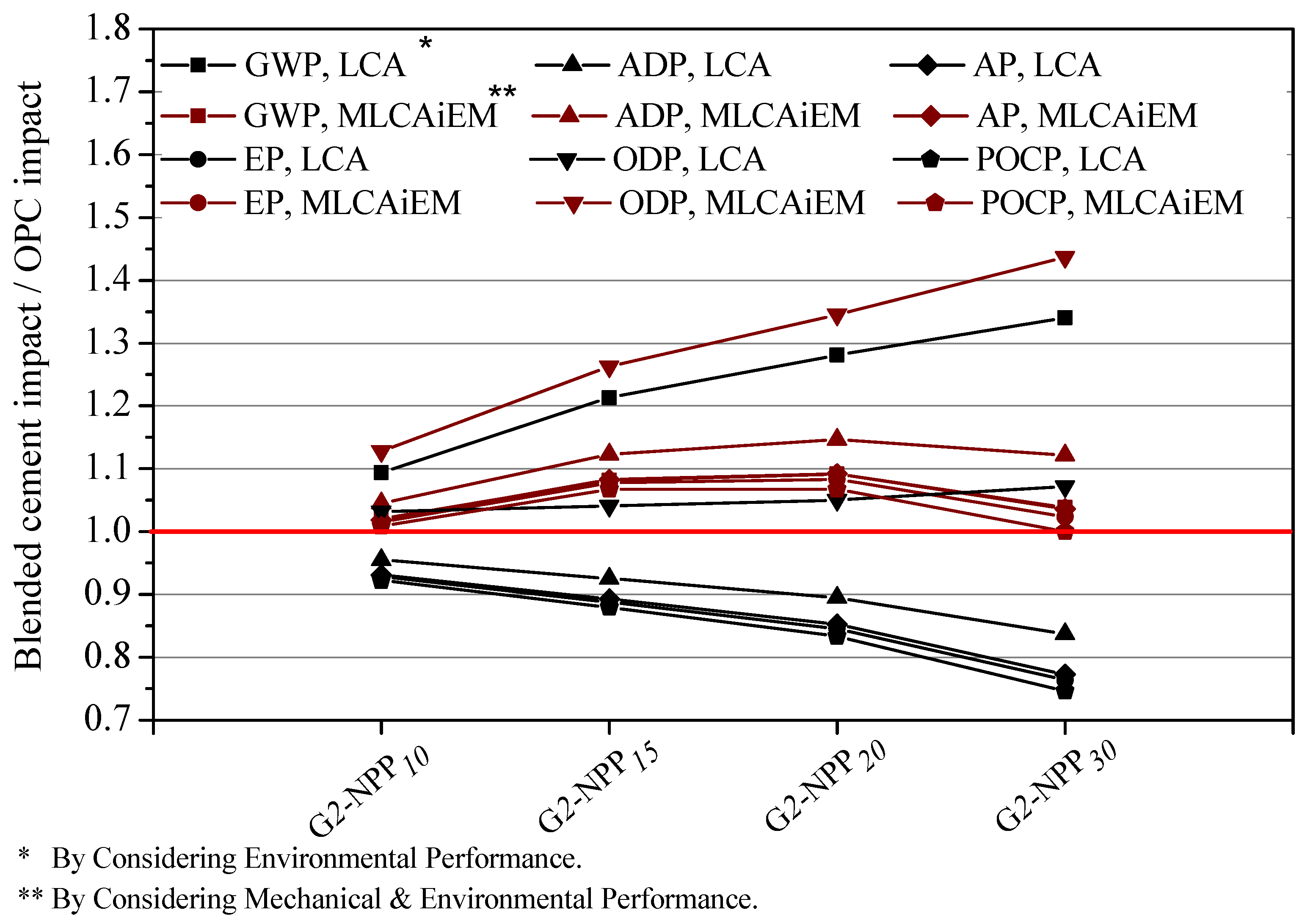

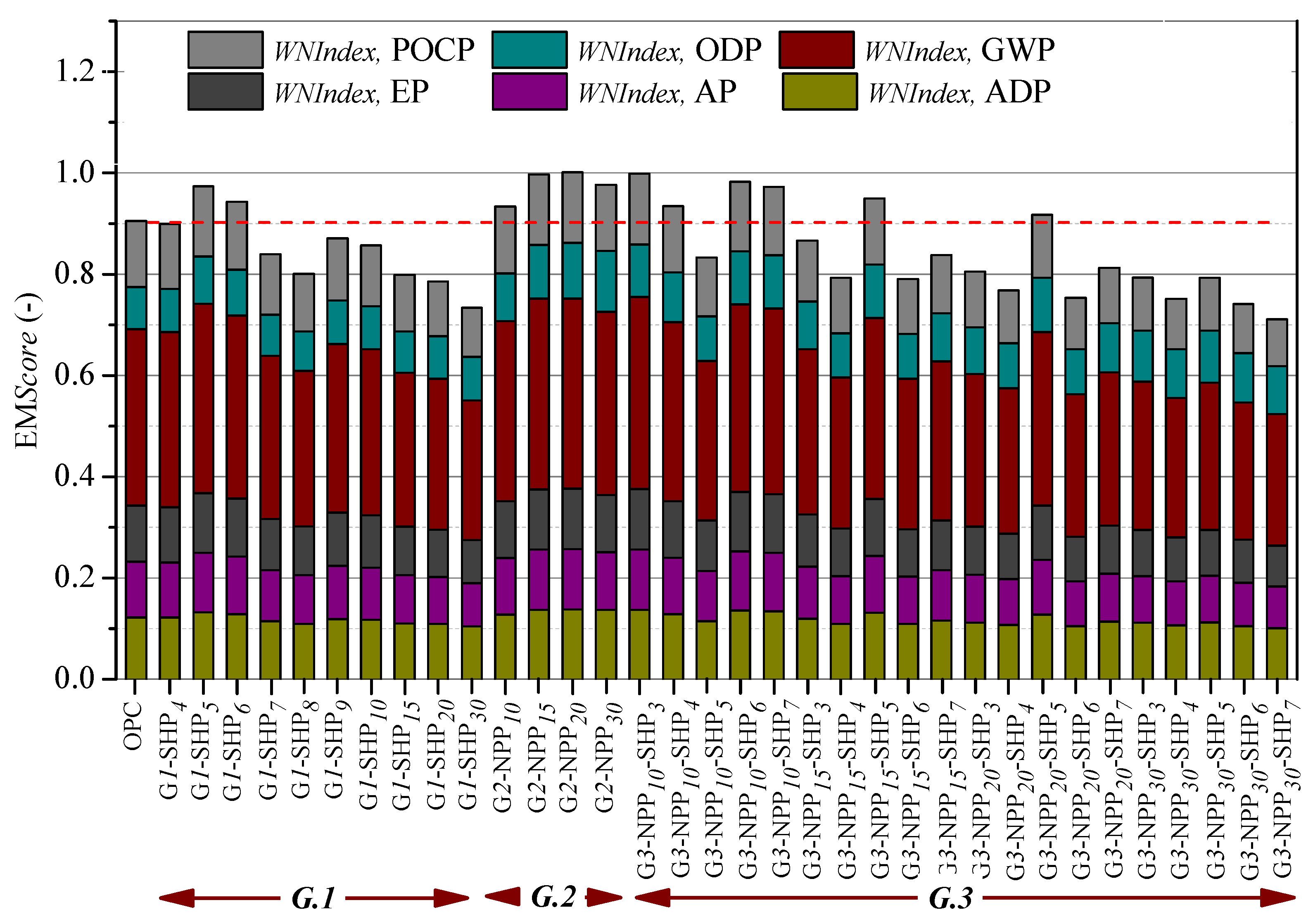

4.1. Results and Discussion

4.2. Consolidated Environmental and Mechanical Evaluation

5. Conclusions

- -

- The production of SHP caused the lowest environmental impacts, whereas the highest environmental impacts were related to the development of OPC. The reason is that the OPC production consumes considerable quantities of resources and releases huge amounts of CO2 to the atmosphere. Thus, by increasing the dosage of the OPC substitution (using SHP) the potential environmental impacts of developing mortar have effectively decreased.

- -

- Among 34 introduced cements, 22 developed binary and ternary ones could be successfully replaced by OPC with a lower environmental impact and similar compressive strength. Application of these cements for developing mortar can reduce the GWP in the range of 1% to 25.5%, ADP in the range of 0.2% to 17.2% and POCP in the range of 1.5% to 29%. The AP could be reduced in the range of 1.2% to 25.4% and the range of reducing EP was between 1.1% and 26.6% by using the abovementioned cements. The maximum reduction of ODP was evaluated as 6.4% compared to that produced by the reference mortar.

- -

- Among all the binary cements, the application of respectively G1-SHP30, G1-SHP20, and G1-SHP15 for developing mortar provided the lowest impact ratios. Despite the marginally lower compressive strength of the mortar obtained with the introduced binary cements compared to that of the reference, these cements have contributed to reduce the environmental impacts, since these cements were produced by replacing a relatively high dosage of OPC with SHP.

- -

- Among all the binary and ternary cements, the application of G2-NPP30-SHP7 for developing mortar resulted in the lowest environmental impacts. Substituting a high dosage of OPC (37% by mass) by the more sustainable materials (i.e., NPP and SHP) in developing G2-NPP30-SHP7, as well as the compressive strength of the mortar made of G2-NPP30-SHP7 which have almost equaled that of the reference, made this cement the most environmentally friendly and sustainable alternative to OPC.

- -

- The objective decision process that leads to the optimal option should take into consideration both the environmental impact indicators and mechanical performance indicators; the use of either of these indicators isolated may be misleading and lead to less sustainable options. Further research is necessary to identify additional mechanical performance indicators to the overall sustainability equation of cements and concretes.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Symbol | Remark |

|---|---|

| AHP | Analytical hierarchy process |

| EMR | Eco-mechanical ratios |

| EPI | environmental performance index |

| MPI | Mechanical performance index |

| MLCAiEM | Modified life cycle approach integrating environmental and mechanical performances |

| EIC | Environmental impact categories |

| Ej | Emission “j” per functional unit |

| CFi,j | Characterization factor for emission “j” contributing to i-th environmental impact category. |

| Fref | Uniaxial load corresponding to compressive strength of the reference mortar |

| VOS | Volume of original specimen |

| AOS | Cross-section of original specimen |

| hOS | Height of original specimen |

| Cross-section area of the fictitious specimen corresponding to the alternative mortar k | |

| Uniaxial compressive strength of alternative mortar k at the age of 28 days | |

| VFS | Volume of fictitious specimens |

| Non-dimensional score, integrating both environmental and mechanical performance of the mortar alternative k | |

| Weighted and normalized score of environmental impact category of i for the alternative k | |

| Raw score of an environmental impact category as per functional unit of VFS | |

| Importance weight for the impact category i, | |

| m | Number of mortar alternatives (equal to 34 in the present study) |

References

- USGS (US Geological Survey). Cement Statistics and Information. 2019. Available online: https://www.usgs.gov/centers/nmic/cement-statistics-and-information (accessed on 2 October 2021).

- International Energy Agency (IEA); World Business Council for Sustainable Development (WBCSD). Cement Technology Roadmap 2009-Carbon Emissions Reductions Up to 2050. 2009. Available online: https://cement.mineralproducts.org/documents/wbcsd-iea%20cement%20roadmap%202009.pdf. (accessed on 2 October 2021).

- Black, L.; Purnell, P. Is carbon dioxide pricing a driver in concrete mix design? Mag. Concr. Res. 2016, 68, 561–567. [Google Scholar] [CrossRef]

- UN Environment; Scrivener, K.L.; John, V.M.; Gartner, E.M. Eco-efficient cements: Potential economically viable solutions for a low-CO2 cement-based materials industry. Cem. Concr. Res. 2018, 114, 2–26. [Google Scholar] [CrossRef]

- Miller, S.A.; John, V.M.; Pacca, S.A.; Horvath, A. Carbon dioxide reduction potential in the global cement industry by 2050. Cement. Concr. Res. 2018, 114, 115–124. [Google Scholar] [CrossRef]

- Taylor, H.F.W. Cement Chemistry, 2nd ed.; Thomas Telford: London, UK, 1997. [Google Scholar]

- Ramezanipour, A.A.; Ghiasvand, E.; Nickseresht, I.; Mahdikhani, M.; Moodi, F. Influence of various amounts of limestone powder on performance of Portland limestone cement concretes. Cem. Concr. Compos. 2009, 31, 715–720. [Google Scholar] [CrossRef]

- Lertwattanaruk, P.; Makul, N.; Siripattarapravat, C. Utilization of ground waste seashells in cement mortars for masonry and plastering. J. Environ. Manag. 2012, 111, 133–141. [Google Scholar] [CrossRef]

- Soltanzadeh, F.; Emamjomeh, M.; Edalat-Behbahani, A.; Soltanzadeh, Z. Development and characterization of blended cements containing seashell powder. J. Constr. Build. Mater. 2018, 161, 292–304. [Google Scholar] [CrossRef]

- Martínez-García, C.; González-Fonteboa, B.; Carro-López, D.; Martínez-Abella, F. Impact of mussel shell aggregates on air lime mortars. Pore structure and carbonation. J. Clean. Prod. 2019, 215, 650–668. [Google Scholar] [CrossRef]

- Martínez-García, C.; González-Fonteboa, B.; Carro-López, D.; Martínez-Abella, F. Design and properties of cement coating with mussel shell fine aggregate. Constr. Build. Mater. 2019, 215, 494–507. [Google Scholar] [CrossRef]

- FAO (Food and Agriculture Organization of the United Nations). The State of World Fisheries and Aquaculture. Contributing to Food Security and Nutrition for All; FAO: Rome, Italy, 2016; Available online: http://www.fao.org/publications/sofia/2016/en/ (accessed on 2 October 2021).

- Soltanzadeh, F.; Emamjomeh, M. Optimization of Cement and Concrete Using Oman Sea Chalky Conches. IRI-Iran Patent No. 35259, 6 June 2006. [Google Scholar]

- Wang, J.; Liu, E.; Li, L. Characterization on the recycling of waste seashells with Portland cement towards sustainable cementitious materials. J. Clean. Prod. 2019, 220, 235–252. [Google Scholar] [CrossRef]

- Edalat-Behbahani, A.; Soltanzadeh, F.; Emam-Jomeh, M.; Soltan-Zadeh, Z. Sustainable approaches for developing concrete and mortar using waste seashell. Eur. J. Environ. Civ. Eng. 2019, 25, 1874–1893. [Google Scholar] [CrossRef]

- Wang, J.; Liu, E.; Li, L. Upcycling waste seashells with cement: Rheology and early-age properties of Portland cement paste. Resour. Conserv. Recycl. 2020, 155, 104680. [Google Scholar] [CrossRef]

- Damineli, B.L.; Kemeid, F.M.; Aguiar, P.S.; John, V.M. Measuring the eco-efficiency of cement use. Cem. Concr. Compos. 2010, 32, 555–562. [Google Scholar] [CrossRef]

- Abrão, P.S.R.A.; Cardoso, F.A.; John, V.M. Efficiency of Portland-pozzolana cements: Water demand, chemical reactivity and environmental impact. Constr. Build. Mater. 2020, 247, 118546. [Google Scholar] [CrossRef]

- Habert, G.; Roussel, N. Study of two concrete mix design strategies to reach carbon mitigation objectives. Cem. Concr. Compos. 2009, 31, 397–402. [Google Scholar] [CrossRef]

- Celik, K.; Meral, C.; Petek Gursel, A.; Mehta, P.K.; Horvath, A.; Monteiro, P.J.M. Mechanical properties, durability, and life-cycle assessment of self-consolidating concrete mixtures made with blended Portland cements containing fly ash and limestone powder. Cem. Concr. Compos. 2015, 56, 59–72. [Google Scholar] [CrossRef]

- Gursel, A.P.; Maryman, H.; Ostertag, C. A life-cycle approach to environmental, mechanical, and durability properties of “green” concrete mixes with rice huskash. J. Clean. Prod. 2016, 112, 823–836. [Google Scholar] [CrossRef]

- Fantilli, A.P.; Chiaia, B. Eco-mechanical performances of cement-based materials: An application to self-consolidating concrete. Constr. Build. Mater. 2013, 40, 189–196. [Google Scholar] [CrossRef]

- Chiaia, B.; Fantilli, A.P.; Guerini, A.; Volpatti, G.; Zampini, D. Eco-mechanical index for structural concrete. Constr. Build. Mater. 2014, 67, 386–392. [Google Scholar] [CrossRef]

- Vandewalle, L. Vandewalle, L. RILEM TC 162-TDF, Test and design methods for steel fibre reinforced concrete design method–Final Recommendation. Mater. Struct. 2003, 36, 560–567. [Google Scholar] [CrossRef]

- Khodabakhshian, A.; Brito, J.D.; Ghalehnovi, M.; Shamsabadi, E.A. Mechanical, environmental and economic performance of structural concrete containing silica fume and marble industry waste powder. Constr. Build. Mater. 2018, 169, 237–251. [Google Scholar] [CrossRef]

- CEN, British Standard Institution, BS EN 197-1 Cement. Composition, Specifications Conformity Criteria for Common Cements; BSI: London, UK, 2004; Available online: http://www.rucem.ru/yabbfiles/Attachments/EN-197-1.pdf (accessed on 2 October 2021).

- ASTM. Standard Specification for Portland Cement (ASTM C150); ASTM: West Conshohocken, PA, USA, 2017. [Google Scholar]

- ASTM. Standard Test Method for Density of Hydraulic Cement (ASTM C188); ASTM: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM. Standard Test Method for Fineness of Hydraulic Cement by the 45-lm (No. 325) Sieve (ASTM C430); ASTM: West Conshohocken, PA, USA, 2015. [Google Scholar]

- ASTM. Standard Test Methods for Fineness of Hydraulic Cement by Air-Permeability Apparatus (ASTM C204); ASTM: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM. Standard Test Method for Compressive Strength of Hydraulic Cement Mortars (Using 2-in. or [50-mm] Cube Specimens) (ASTM C109); ASTM: West Conshohocken, PA, USA, 2016. [Google Scholar]

- ASTM. Standard Test Method for Flexural Strength of Hydraulic-Cement Mortars (ASTM C348); ASTM: West Conshohocken, PA, USA, 2014. [Google Scholar]

- Habert, G.; Billard, C.; Rossi, P.; Chen, C.; Roussel, N. Cement production technology improvement compared to factor 4 objectives. Cem. Concr. Res. 2010, 40, 820–826. [Google Scholar] [CrossRef]

- Huntzinger, D.N.; Eatmon, T.D. A life-cycle assessment of Portland cement manufacturing: Comparing the traditional process with alternative technologies. J. Clean. Prod. 2009, 17, 668–675. [Google Scholar] [CrossRef]

- ISO 14040. Environmental Management–Life Cycle Assessment–Principles and Framework; ISO: Geneva, Switzerland, 2006; Available online: https://www.iso.org/standard/37456.html (accessed on 2 October 2021).

- ISO 14044. Environmental Management–Life Cycle Assessment–Requirements and Guidelines; ISO: Geneva, Switzerland, 2006; Available online: https://www.iso.org/obp/ui/#iso:std:iso:14044:ed-1:v1:en (accessed on 2 October 2021).

- Sala, S.; Beylot, A.; Corrado, S.; Crenna, E.; Sanyé-Mengual, E.; Secchi, M. Indicators and Assessment of the Environmental Impact of EU Consumption, JRC 2016. Available online: https://eplca.jrc.ec.europa.eu/uploads/Science_for_policy_report_final_on_line.pdf (accessed on 2 October 2021).

- Thinkstep GaBi Software, Version 6.2. ThinkStep: Leinfelden-Echterdingen, Germany, 2017.

- ISO 15000. International Organization for Standardization, Energy Management Systems—Requirements with Guidance for Use; ISO: Geneva, Switzerland, 2011; Available online: https://www.iso.org/standard/51297.html (accessed on 2 October 2021).

- ISO 14001. International Organization for Standardizati, Environmental Management Systems—Requirements with Guidance for Use; ISO: Geneva, Switzerland, 2011; Available online: https://www.iso.org/standard/31807.html (accessed on 2 October 2021).

- ISO 9001. International Organization for Standardization, Quality Management Systems; ISO: Geneva, Switzerland, 2015; Available online: https://www.iso.org/standard/46486.html (accessed on 2 October 2021).

- Fernández-Muñiz, B.; Montes-Peón, J.M.; Vázquez-Ordás, C.J. Vázquez-Ordás, Safety climate in OHSAS 18001-certified organisations: Antecedents and consequences of safety behaviour. Accid. Anal. Prev. 2012, 45, 745–758. [Google Scholar] [CrossRef]

- Guinée, J.B. Handbook on LCA, Operational Guide to the ISO Standards; Kluwer Academic Publishers: Dordrecht, The Netherlands, 2002. [Google Scholar]

- Havukainen, J.; Zhan, M.; Dong, J.; Liikanen, M.; Deviatkin, I.; Li, X.; Horttanainen, M. Environmental impact assessment of municipal solid waste management incorporating mechanical treatment of waste and incineration in Hangzhou, China. J. Clean. Prod. 2017, 141, 453–461. [Google Scholar] [CrossRef]

- Strange, A.; Park, J.; Bennett, R.; Phipps, R. The use of life-cycle assessment to evaluate the environmental impacts of growing genetically modified, nitrogen use-efficient canola. Plant Biotechnol. J. 2008, 6, 337–345. [Google Scholar] [CrossRef]

- Siegl, S.; Laaber, M.; H, P. Green Electricity from Biomass, Part I: Environmental Impacts of Direct Life Cycle Emissions. Waste Biomass Valor. 2011, 2, 267–284. [Google Scholar] [CrossRef]

- Shi, J.; Li, T.; Zhang, H.; Peng, S.; Liu, Z.; Jiang, Q. Energy consummation and environmental emissions assessment of a refrigeration compressor based on life cycle assessment methodology. Int. J. Life Cycle Assess 2015, 20, 947–956. [Google Scholar] [CrossRef]

- Teixeira, E.R.; Mateus, R.; Camoes, A.F.; Bragança, L.; Branco, F.G. Comparative environmental life-cycle analysis of concretes using biomass and coal fly ashes as partial cement replacement material. J. Clean. Prod. 2016, 112, 2221–2230. [Google Scholar] [CrossRef]

- Taehyoung, K.; Sungho, T.; Chang, U.C. Analysis of Environmental Impact for Concrete Using LCA by Varying the Recycling Components, the Compressive Strength and the Admixture Material Mixing. J. Sustain. 2016, 8, 389. [Google Scholar] [CrossRef]

- Worrell, E.; Price, L.; Martin, N.; Hendriks, C.; Meida, L.O. Carbon dioxide emissions from the global cement industry. Annu. Rev. Energy Environ. 2001, 26, 303–329. [Google Scholar] [CrossRef]

- CEN 2004, Eurocod 2. Design of Concrete Structures -Part 1-1: General Rules and Rules for Buildings; UNI-ENV 1992-1-2; British-Adopted European Standard: London, UK, 2004.

- Fib–International Federation for Structural Concrete, Fib Model Code for Concrete Structures 2010; Verlag Ernst & Sohn: Berlin, Germany, 2013; Available online: https://onlinelibrary.wiley.com/doi/epdf/10.1002/suco.201200062 (accessed on 2 October 2021).

- Edalat Bahbahani, A.; Barros, J.A.O.; Ventura-Gouveia, A. Plastic-damage smeared crack model to simulate the behaviour of structures made by cement based materials. J Solid Struct. 2015, 73–74, 20–40. [Google Scholar] [CrossRef]

- Edalat-Behbahani, A.; Barros, J.A.O.; Ventura-Gouveia, A. Application of plastic-damage multidirectional fixed smeared crack model in analysis of RC structures. Eng. Struct. 2016, 125, 374–391. [Google Scholar] [CrossRef][Green Version]

- Edalat-Behbahani, A.; Barros, J.A.O.; Ventura-Gouveia, A. Three dimensional plastic-damage multidirectional fixed smeared crack approach for modelling concrete structures. Int. J. Solids. 2017, 115–116, 104–125. [Google Scholar] [CrossRef]

- Soltanzadeh, F.; Edalat-Behbahani, A.; Mazaheripour, H.; Barros, J.A.O. Shear resistance of SFRSCC short-span beams without transversal reinforcements. J. Compos. Struct. 2016, 139, 42–61. [Google Scholar] [CrossRef]

- Soltanzadeh, F.; Edalat-Behbahani, A.; Barros, J.A.O.; Mazaheripour, H. Effect of fiber dosage and prestress level on shear behavior of hybrid GFRP-steel reinforced concrete I-shape beams without stirrups. J. Compos. Part B 2016, 102, 57–77. [Google Scholar] [CrossRef]

- Ranaivomanan, N.; Multon, S.; Turatsinze, A. Basic creep of concrete under compression, tension and bending. J. Constr. Build. Mater. 2013, 38, 173–180. [Google Scholar] [CrossRef]

- Abrishambaf, A.; Barros, J.A.O.; Cunha, V. Tensile stress-crack width law for steel fibre reinforced self-compacting concrete obtained from indirect (splitting) tensile tests. Cem. Concr. Compos. J. 2015, 57, 153–165. [Google Scholar] [CrossRef]

- Soltanzadeh, F.; Barros, J.A.O.; Santos, R.F.C. High performance fiber reinforced concrete for the shear reinforcement: Experimental and numerical research. J. Constr. Build. Mater. 2015, 77, 94–109. [Google Scholar] [CrossRef]

- Soltanzadeh, F.; Cunha, V.; Barros, J. Assessment of different methods for characterization and simulation of post-cracking behavior of self-compacting steel fiber reinforced concrete. J. Constr. Build. Mater. 2019, 227, 116704. [Google Scholar] [CrossRef]

| Group | ID | SH | PZ | OPC | Density | Blaine | Setting Time | Fineness | W/c | Comp. Str. | Flex. Str. | |

|---|---|---|---|---|---|---|---|---|---|---|---|---|

| (%) | (%) | (%) | (gr/cm3) | (cm2/gr) | Initial (Min) | Final (Min) | (%) | (MPa) | (MPa) | |||

| Ref. | OPC | 0 | - | 100 | 3.120 | 3118 | 60 | 90 | 94.50 | 0.46 | 32.03 | 9.88 |

| Group 1 | G1-SHP4 | 4 | - | 96 | 3.099 | 3118 | 75 | 105 | 94.50 | 0.44 | 31.61 | 8.62 |

| G1-SHP5 | 5 | - | 95 | 3.094 | 3172 | 75 | 90 | 94.60 | 0.44 | 28.97 | 8.70 | |

| G1-SHP6 | 6 | - | 94 | 3.088 | 3172 | 75 | 90 | 94.60 | 0.43 | 29.68 | 8.26 | |

| G1-SHP7 | 7 | - | 93 | 3.084 | 3172 | 75 | 105 | 94.60 | 0.43 | 33.12 | 8.75 | |

| G1-SHP8 | 8 | - | 92 | 3.078 | 3199 | 90 | 105 | 94.64 | 0.43 | 34.46 | 9.56 | |

| G1-SHP9 | 9 | - | 91 | 3.073 | 3225 | 105 | 135 | 94.69 | 0.43 | 31.42 | 8.91 | |

| G1-SHP10 | 10 | - | 90 | 3.068 | 3278 | 105 | 120 | 94.78 | 0.43 | 31.67 | 8.68 | |

| G1-SHP15 | 15 | - | 85 | 3.042 | 3330 | 105 | 135 | 94.87 | 0.43 | 32.59 | 8.55 | |

| G1-SHP20 | 20 | - | 80 | 3.016 | 3355 | 120 | 135 | 94.92 | 0.43 | 31.76 | 8.00 | |

| G1-SHP30 | 30 | - | 70 | 2.964 | 3431 | 120 | 135 | 95.05 | 0.43 | 31.10 | 7.81 | |

| Group 2 | G2-NPP10 | - | 10 | 90 | 3.073 | 3330 | 105 | 120 | 94.63 | 0.44 | 29.28 | 8.95 |

| G2-NPP15 | - | 15 | 85 | 3.050 | 3430 | 135 | 150 | 94.70 | 0.44 | 26.39 | 8.24 | |

| G2-NPP20 | - | 20 | 80 | 3.026 | 3480 | 135 | 165 | 94.77 | 0.44 | 25.00 | 8.75 | |

| G2-NPP30 | - | 30 | 70 | 2.979 | 3694 | 135 | 165 | 94.90 | 0.44 | 23.89 | 9.14 | |

| Group 3 | G3-NPP10-SHP3 | 3 | 10 | 87 | 3.057 | 3381 | 90 | 105 | 94.73 | 0.43 | 26.75 | 8.31 |

| G3-NPP10-SHP4 | 4 | 10 | 86 | 3.052 | 3406 | 105 | 120 | 94.77 | 0.43 | 28.33 | 8.38 | |

| G3-NPP10-SHP5 | 5 | 10 | 85 | 3.047 | 3406 | 105 | 120 | 94.77 | 0.43 | 31.53 | 9.03 | |

| G3-NPP10-SHP6 | 6 | 10 | 84 | 3.042 | 3431 | 105 | 120 | 94.82 | 0.43 | 26.53 | 8.86 | |

| G3-NPP10-SHP7 | 7 | 10 | 83 | 3.037 | 3455 | 105 | 120 | 94.86 | 0.43 | 26.60 | 9.58 | |

| G3-NPP15-SHP3 | 3 | 15 | 82 | 3.034 | 3455 | 90 | 105 | 94.74 | 0.43 | 29.64 | 7.74 | |

| G3-NPP15-SHP4 | 4 | 15 | 81 | 3.029 | 3455 | 105 | 120 | 94.74 | 0.43 | 32.17 | 8.44 | |

| G3-NPP15-SHP5 | 5 | 15 | 80 | 3.024 | 3480 | 105 | 120 | 94.79 | 0.43 | 26.62 | 8.00 | |

| G3-NPP15-SHP6 | 6 | 15 | 79 | 3.018 | 3582 | 120 | 150 | 94.87 | 0.43 | 31.73 | 9.59 | |

| G3-NPP15-SHP7 | 7 | 15 | 78 | 3.013 | 3529 | 120 | 150 | 94.88 | 0.43 | 29.70 | 6.91 | |

| G3-NPP20-SHP3 | 3 | 20 | 77 | 3.010 | 3529 | 135 | 165 | 94.85 | 0.43 | 30.68 | 8.62 | |

| G3-NPP20-SHP4 | 4 | 20 | 76 | 3.005 | 3624 | 120 | 135 | 95.02 | 0.43 | 31.88 | 8.84 | |

| G3-NPP20-SHP5 | 5 | 20 | 75 | 3.000 | 3648 | 120 | 150 | 95.06 | 0.43 | 26.49 | 9.14 | |

| G3-NPP20-SHP6 | 6 | 20 | 74 | 2.995 | 3694 | 105 | 135 | 95.14 | 0.43 | 31.98 | 8.17 | |

| G3-NPP20-SHP7 | 7 | 20 | 73 | 2.990 | 3717 | 105 | 150 | 95.18 | 0.43 | 29.41 | 9.33 | |

| G3-NPP30-SHP3 | 3 | 30 | 67 | 2.963 | 3785 | 120 | 135 | 95.07 | 0.43 | 28.66 | 8.58 | |

| G3-NPP30-SHP4 | 4 | 30 | 66 | 2.958 | 3830 | 120 | 135 | 95.15 | 0.43 | 29.94 | 9.62 | |

| G3-NPP30-SHP5 | 5 | 30 | 65 | 2.953 | 3852 | 120 | 135 | 95.19 | 0.43 | 28.13 | 9.14 | |

| G3-NPP30-SHP6 | 6 | 30 | 64 | 2.948 | 3874 | 120 | 150 | 95.23 | 0.43 | 29.82 | 9.60 | |

| G3-NPP30-SHP7 | 7 | 30 | 63 | 2.943 | 3940 | 120 | 150 | 95.35 | 0.43 | 30.81 | 9.39 | |

| Binder | GWP (100 Years) | ODP | AP | EP | POCP | ADP (Fossil Fuels) |

|---|---|---|---|---|---|---|

| kg CO2 eq | kg R11 eq | kg SO2 eq | kg PO4 eq | kg C2H4 eq | MJ eq | |

| SHP | 0.068 | 1.50 × 10−16 | 0.00019 | 2.14 × 10−5 | −1.07 × 10−5 | 0.872 |

| NPP | 0.089 | 4.87 × 10−16 | 0.00045 | 3.63 × 10−5 | 7.57 × 10−5 | 0.999 |

| OPC | 0.875 | 1.63 × 10−16 | 0.00360 | 0.00031 | 0.00021 | 4.890 |

| Binder | GWP (100 Years) | ODP | AP | EP | POCP | ADP (Fossil Fuels) | |

|---|---|---|---|---|---|---|---|

| kg CO2 eq | kg R11 eq | kg SO2 eq | kg PO4 eq | kg C2H4 eq | MJ eq | ||

| OPC | 563.206 | 7.48 × 10−13 | 2.273 | 0.188 | 0.131 | 3825.740 | |

| G1-SHi | G1-SHP4 | 551.264 | 7.54 × 10−13 | 2.217 | 0.183 | 0.127 | 3770. 098 |

| G1-SHP5 | 546.819 | 7.54 × 10−13 | 2.198 | 0.182 | 0.126 | 3750.111 | |

| G1-SHP6 | 542.282 | 7.54 × 10−13 | 2.178 | 0.180 | 0.125 | 3729.226 | |

| G1-SHP7 | 537.820 | 7.54 × 10−13 | 2.160 | 0.179 | 0.123 | 3709. 025 | |

| G1-SHP8 | 533.531 | 7.54 × 10−13 | 2.140 | 0.177 | 0.122 | 3688.304 | |

| G1-SHP9 | 528.807 | 7.53 × 10−13 | 2.121 | 0.175 | 0.121 | 3667.790 | |

| G1-SHP10 | 524.336 | 7.53 × 10−13 | 2.102 | 0.174 | 0.120 | 3647.262 | |

| G1-SHP15 | 499.493 | 7.50 × 10−13 | 2.004 | 0.165 | 0.113 | 3523.461 | |

| G1-SHP20 | 477.038 | 7.48 × 10−13 | 1.906 | 0.157 | 0.107 | 3407.089 | |

| G1-SHP30 | 432.465 | 7.46 × 10−13 | 1.713 | 0.141 | 0.095 | 3178.080 | |

| G2-NPPi | G2-NPP10 | 525.625 | 7.72 × 10−13 | 2.116 | 0.175 | 0.121 | 3655.065 |

| G2-NPP15 | 502.189 | 7.79 × 10−13 | 2.028 | 0.167 | 0.115 | 3540.556 | |

| G2-NPP20 | 479.749 | 7.86 × 10−13 | 1.937 | 0.159 | 0.109 | 3423.592 | |

| G2-NPP30 | 436.420 | 8.02 × 10−13 | 1.756 | 0.144 | 0.098 | 3201.841 | |

| G3-SHPi-NPPj | G3-NPP10-SHP3 | 512.259 | 7.76 × 10−13 | 2.061 | 0.170 | 0.117 | 3582.536 |

| G3-NPP10-SHP4 | 505.684 | 7.78 × 10−13 | 2.042 | 0.168 | 0.116 | 3560.777 | |

| G3-NPP10-SHP5 | 501.219 | 7.78 × 10−13 | 2.025 | 0.166 | 0.115 | 3536.715 | |

| G3-NPP10-SHP6 | 496.758 | 7.80 × 10−13 | 2.006 | 0.165 | 0.114 | 3514.961 | |

| G3-NPP10-SHP7 | 492.415 | 7.82 × 10−13 | 1.989 | 0.163 | 0.112 | 3492.830 | |

| G3-NPP15-SHP3 | 488.370 | 7.84 × 10−13 | 1.970 | 0.162 | 0.111 | 3470.052 | |

| G3-NPP15-SHP4 | 483.935 | 7.86 × 10−13 | 1.954 | 0.160 | 0.110 | 3448.896 | |

| G3-NPP15-SHP5 | 479.432 | 7.86 × 10−13 | 1.935 | 0.159 | 0.109 | 3424.708 | |

| G3-NPP15-SHP6 | 475.172 | 7.88 × 10−13 | 1.918 | 0.157 | 0.108 | 3402.977 | |

| G3-NPP15-SHP7 | 470.751 | 7.90 × 10−13 | 1.899 | 0.156 | 0.107 | 3380.912 | |

| G3-NPP20-SHP3 | 466.603 | 7.92 × 10−13 | 1.882 | 0.154 | 0.106 | 3357.903 | |

| G3-NPP20-SHP4 | 462.153 | 7.92 × 10−13 | 1.863 | 0.153 | 0.104 | 3336.383 | |

| G3-NPP20-SHP5 | 457.880 | 7.94 × 10−13 | 1.846 | 0.151 | 0.103 | 3312.325 | |

| G3-NPP20-SHP6 | 453.416 | 7.96 × 10−13 | 1.827 | 0.149 | 0.102 | 3290.828 | |

| G3-NPP20-SHP7 | 448.988 | 7.98 × 10−13 | 1.808 | 0.148 | 0.101 | 3269.190 | |

| G3-NPP30-SHP3 | 423.314 | 8.06 × 10−13 | 1.702 | 0.139 | 0.094 | 3134.316 | |

| G3-NPP30-SHP4 | 416.592 | 8.08 × 10−13 | 1.685 | 0.137 | 0.093 | 3113.022 | |

| G3-NPP30-SHP5 | 412.359 | 8.10 × 10−13 | 1.666 | 0.136 | 0.092 | 3091.509 | |

| G3-NPP30-SHP6 | 407.908 | 8.12 × 10−13 | 1.649 | 0.134 | 0.091 | 3067.497 | |

| G3-NPP30-SHP7 | 403.680 | 8.12 × 10−13 | 1.631 | 0.133 | 0.089 | 3046.147 |

| Binder | GWP (100 Years) | ODP | AP | EP | POCP | ADP (Fossil Fuels) | ||

|---|---|---|---|---|---|---|---|---|

| kg CO2 eq | kg R11 eq | kg SO2 eq | kg PO4 eq | kg C2H4 eq | MJ eq | - | ||

| OPC | 563.206 | 7.48 × 10−13 | 2.273 | 0.188 | 0.131 | 3825.740 | 0.905 | |

| G1-SHi | G1-SHP4 | 558.523 | 7.64 × 10−13 | 2.246 | 0.186 | 0.129 | 3819.744 | 0.899 |

| G1-SHP5 | 604.458 | 8.34 × 10−13 | 2.430 | 0.201 | 0.139 | 4145.406 | 0.974 | |

| G1-SHP6 | 585.068 | 8.13 × 10−13 | 2.350 | 0.194 | 0.134 | 4023.459 | 0.943 | |

| G1-SHP7 | 520.013 | 7.29 × 10−13 | 2.088 | 0.173 | 0.119 | 3586.216 | 0.839 | |

| G1-SHP8 | 495.900 | 7.00 × 10−13 | 1.989 | 0.164 | 0.114 | 3428.161 | 0.801 | |

| G1-SHP9 | 538.947 | 7.68 × 10−13 | 2.162 | 0.179 | 0.123 | 3738.121 | 0.871 | |

| G1-SHP10 | 530.155 | 7.62 × 10−13 | 2.125 | 0.176 | 0.121 | 3687.741 | 0.857 | |

| G1-SHP15 | 490.844 | 7.37 × 10−13 | 1.969 | 0.163 | 0.111 | 3462.454 | 0.798 | |

| G1-SHP20 | 480.947 | 7.55 × 10−13 | 1.921 | 0.159 | 0.108 | 3435.013 | 0.785 | |

| G1-SHP30 | 445.378 | 7.68 × 10−13 | 1.764 | 0.145 | 0.097 | 3272.971 | 0.734 | |

| G2-NPi | G2-NPP10 | 574.940 | 8.44 × 10−13 | 2.315 | 0.191 | 0.132 | 3997.988 | 0.934 |

| G2-NPP15 | 609.296 | 9.45 × 10−13 | 2.461 | 0.202 | 0.140 | 4295.688 | 0.997 | |

| G2-NPP20 | 614.655 | 1.01 × 10−12 | 2.482 | 0.204 | 0.140 | 4386.306 | 1.000 | |

| G2-NPP30 | 584.905 | 1.08 × 10−12 | 2.354 | 0.192 | 0.131 | 4291.217 | 0.976 | |

| G3-SHi-NPj | G3-NPP10-SHP3 | 613.199 | 9.29 × 10−13 | 2.467 | 0.203 | 0.140 | 4288.476 | 0.999 |

| G3-NPP10-SHP4 | 571.601 | 8.79 × 10−13 | 2.308 | 0.190 | 0.131 | 4024.929 | 0.934 | |

| G3-NPP10-SHP5 | 509.035 | 7.9 × 10−13 | 2.057 | 0.169 | 0.117 | 3591.867 | 0.833 | |

| G3-NPP10-SHP6 | 599.588 | 9.41 × 10−13 | 2.421 | 0.199 | 0.137 | 4242.571 | 0.982 | |

| G3-NPP10-SHP7 | 592.748 | 9.41 × 10−13 | 2.394 | 0.197 | 0.135 | 4204.515 | 0.972 | |

| G3-NPP15-SHP3 | 527.651 | 8.47 × 10−13 | 2.129 | 0.175 | 0.120 | 3749.162 | 0.867 | |

| G3-NPP15-SHP4 | 481.803 | 7.83 × 10−13 | 1.945 | 0.160 | 0.110 | 3433.706 | 0.793 | |

| G3-NPP15-SHP5 | 576.758 | 9.45 × 10−13 | 2.327 | 0.191 | 0.131 | 4119.932 | 0.950 | |

| G3-NPP15-SHP6 | 479.600 | 7.95 × 10−13 | 1.936 | 0.159 | 0.109 | 3434.683 | 0.791 | |

| G3-NPP15-SHP7 | 507.523 | 8.52 × 10−13 | 2.047 | 0.168 | 0.115 | 3645.013 | 0.838 | |

| G3-NPP20-SHP3 | 486.977 | 8.27 × 10−13 | 1.964 | 0.161 | 0.110 | 3504.527 | 0.805 | |

| G3-NPP20-SHP4 | 464.235 | 7.95 × 10−13 | 1.871 | 0.153 | 0.105 | 3351.417 | 0.768 | |

| G3-NPP20-SHP5 | 553.583 | 9.6 × 10−13 | 2.232 | 0.183 | 0.125 | 4004.648 | 0.917 | |

| G3-NPP20-SHP6 | 454.063 | 7.97 × 10−13 | 1.830 | 0.150 | 0.102 | 3295.521 | 0.753 | |

| G3-NPP20-SHP7 | 488.984 | 8.69 × 10−13 | 1.969 | 0.161 | 0.110 | 3560.410 | 0.813 | |

| G3-NPP30-SHP3 | 473.009 | 9.01 × 10−13 | 1.901 | 0.155 | 0.105 | 3502.274 | 0.793 | |

| G3-NPP30-SHP4 | 445.604 | 8.64 × 10−13 | 1.802 | 0.147 | 0.099 | 3329.818 | 0.751 | |

| G3-NPP30-SHP5 | 469.441 | 9.22 × 10−13 | 1.897 | 0.155 | 0.105 | 3519.462 | 0.793 | |

| G3-NPP30-SHP6 | 438.108 | 8.72 × 10−13 | 1.772 | 0.144 | 0.097 | 3294.610 | 0.741 | |

| G3-NPP30-SHP7 | 419.657 | 8.44 × 10−13 | 1.695 | 0.138 | 0.093 | 3166.713 | 0.711 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Soltanzadeh, F.; Behbahani, A.E.; Pereira, E.N.B.; Teixeira, C.A. A Life-Cycle Approach to Integrate Environmental and Mechanical Properties of Blended Cements Containing Seashell Powder. Sustainability 2021, 13, 13120. https://doi.org/10.3390/su132313120

Soltanzadeh F, Behbahani AE, Pereira ENB, Teixeira CA. A Life-Cycle Approach to Integrate Environmental and Mechanical Properties of Blended Cements Containing Seashell Powder. Sustainability. 2021; 13(23):13120. https://doi.org/10.3390/su132313120

Chicago/Turabian StyleSoltanzadeh, Fatemeh, Ali E. Behbahani, Eduardo N. B. Pereira, and Carlos A. Teixeira. 2021. "A Life-Cycle Approach to Integrate Environmental and Mechanical Properties of Blended Cements Containing Seashell Powder" Sustainability 13, no. 23: 13120. https://doi.org/10.3390/su132313120

APA StyleSoltanzadeh, F., Behbahani, A. E., Pereira, E. N. B., & Teixeira, C. A. (2021). A Life-Cycle Approach to Integrate Environmental and Mechanical Properties of Blended Cements Containing Seashell Powder. Sustainability, 13(23), 13120. https://doi.org/10.3390/su132313120