Carbon Impact and Cost of Mass Timber Beam–Column Gravity Systems

Abstract

:1. Introduction

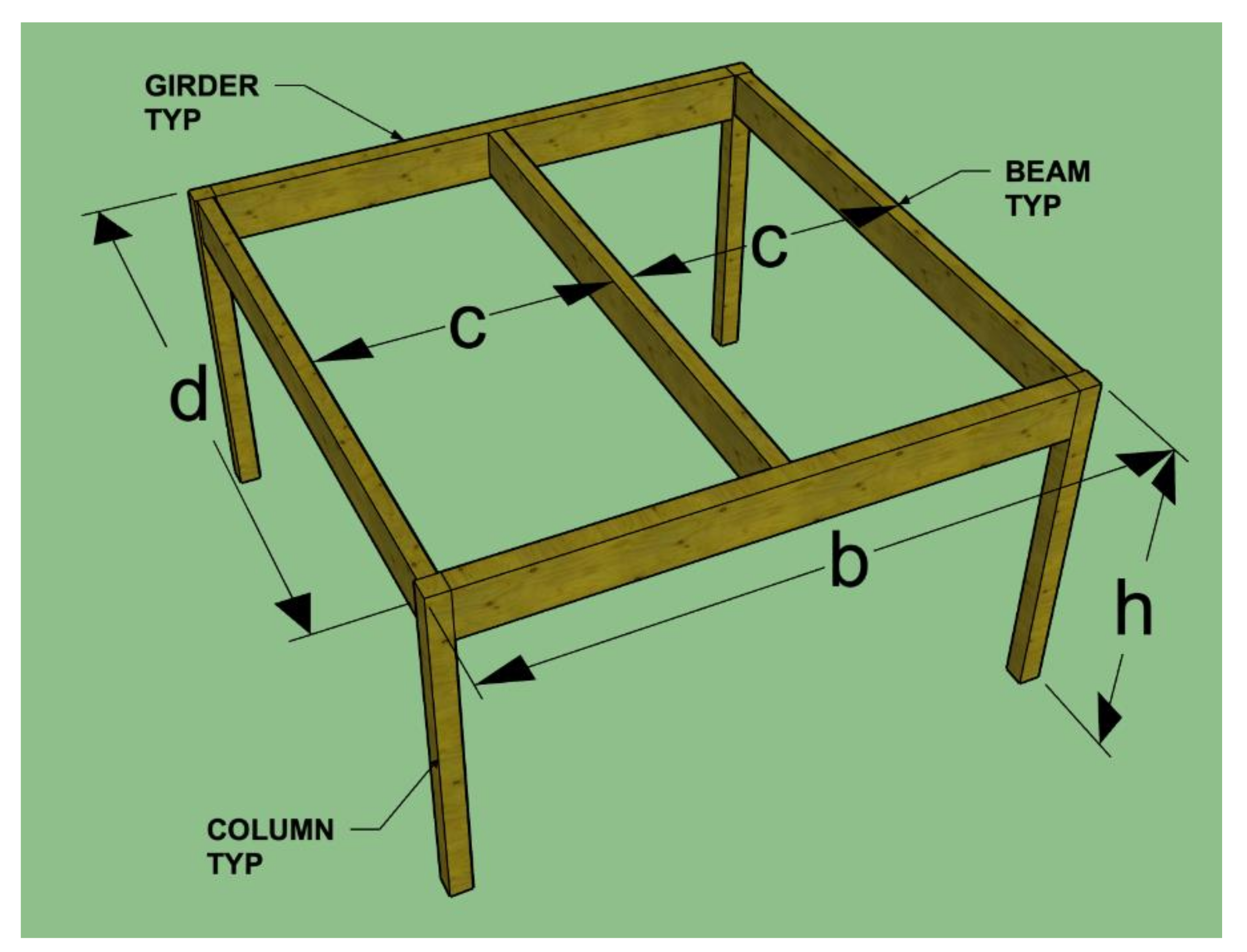

2. Materials and Methods

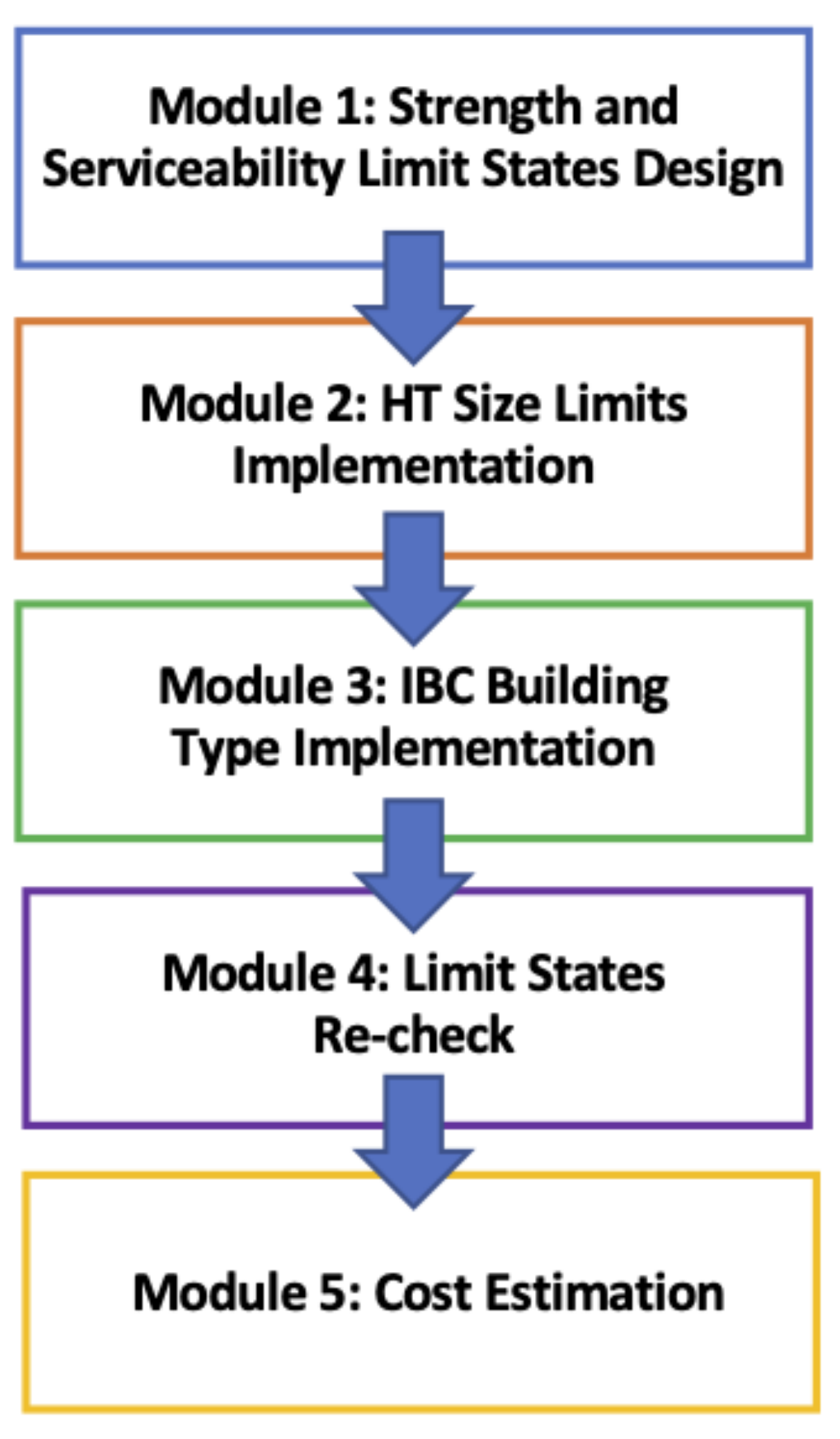

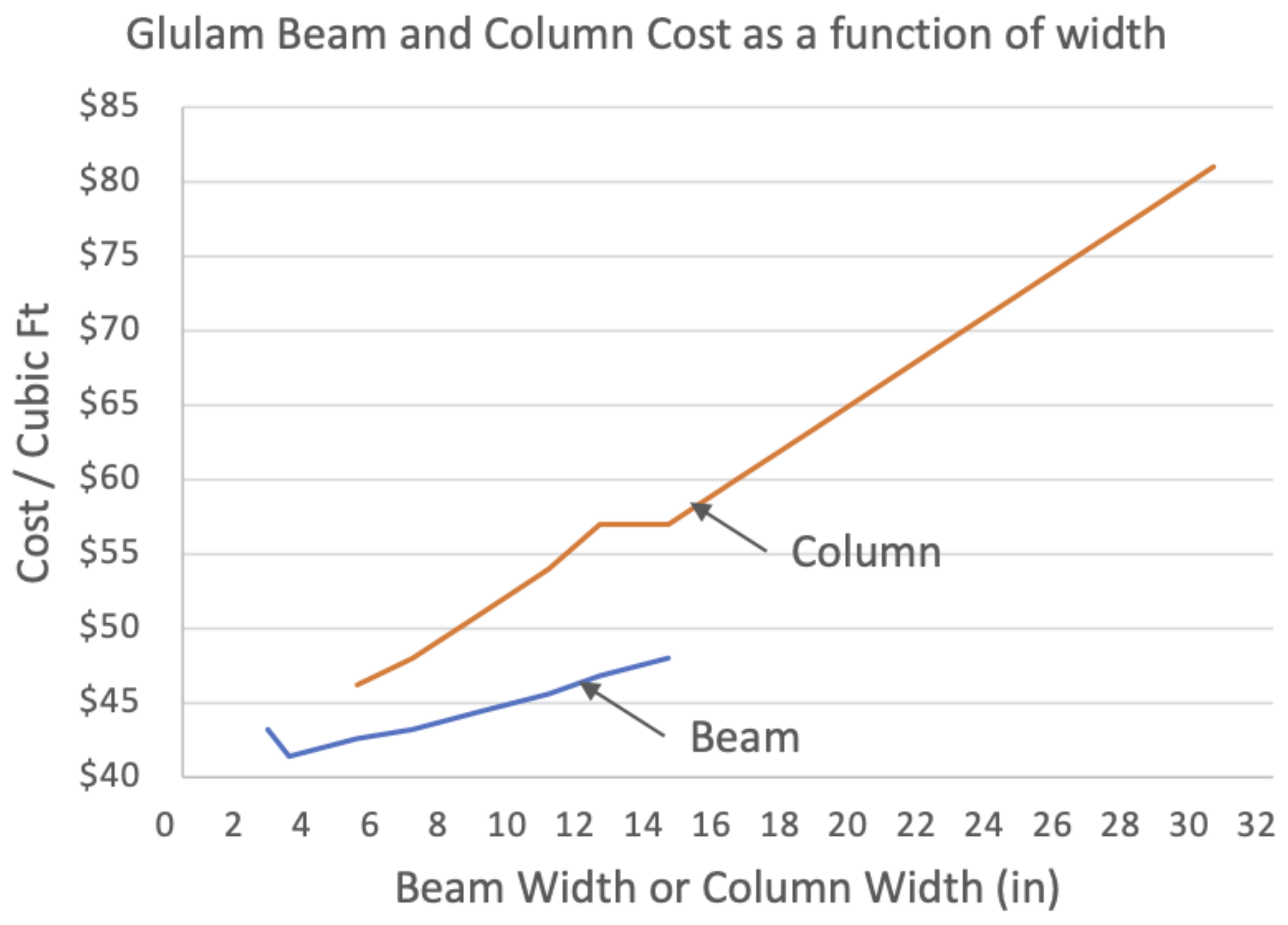

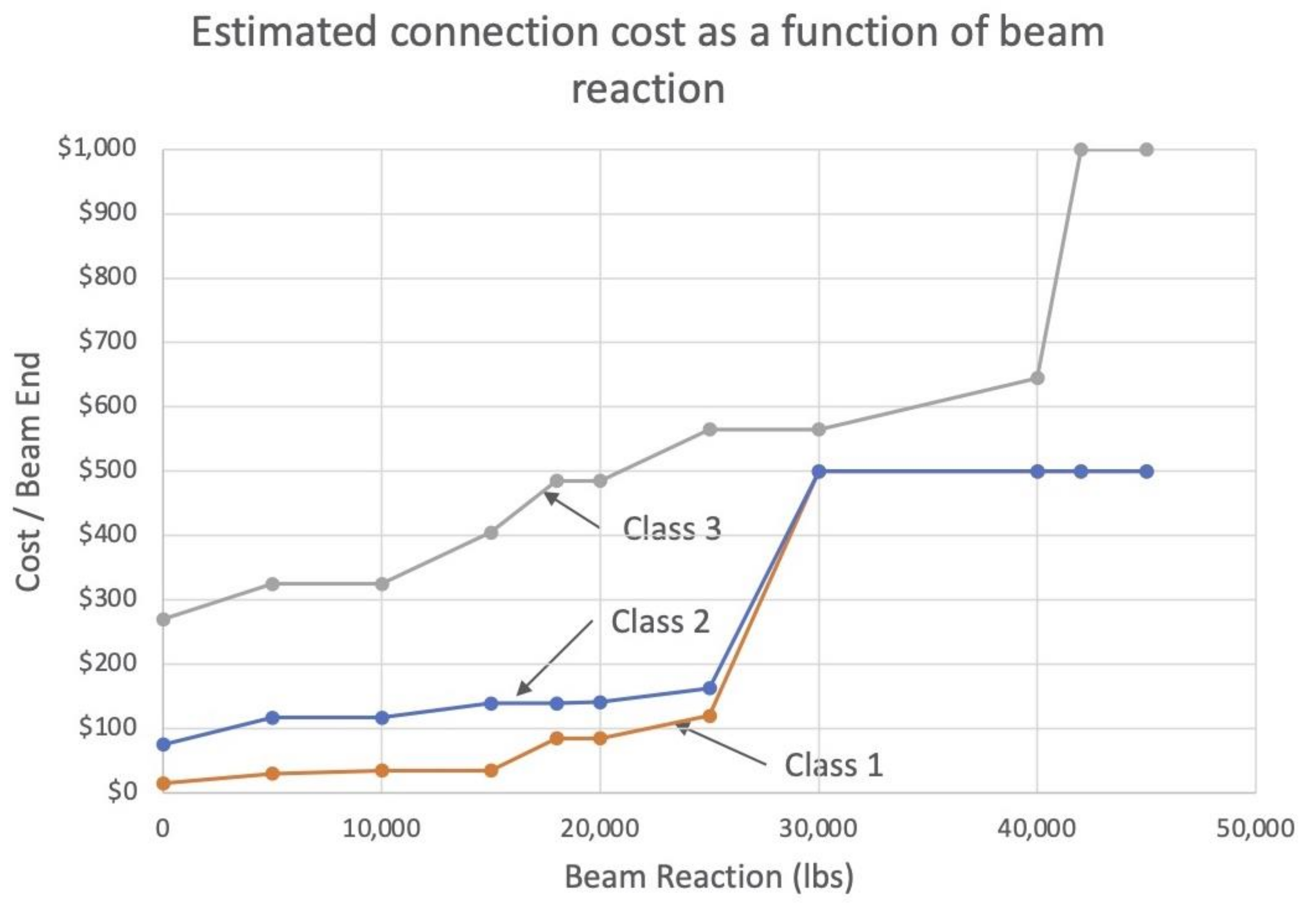

Automated Design and Cost Estimation Process

3. Results

3.1. Sensitivity Analysis Cases

3.2. Sensitivity Analysis Results

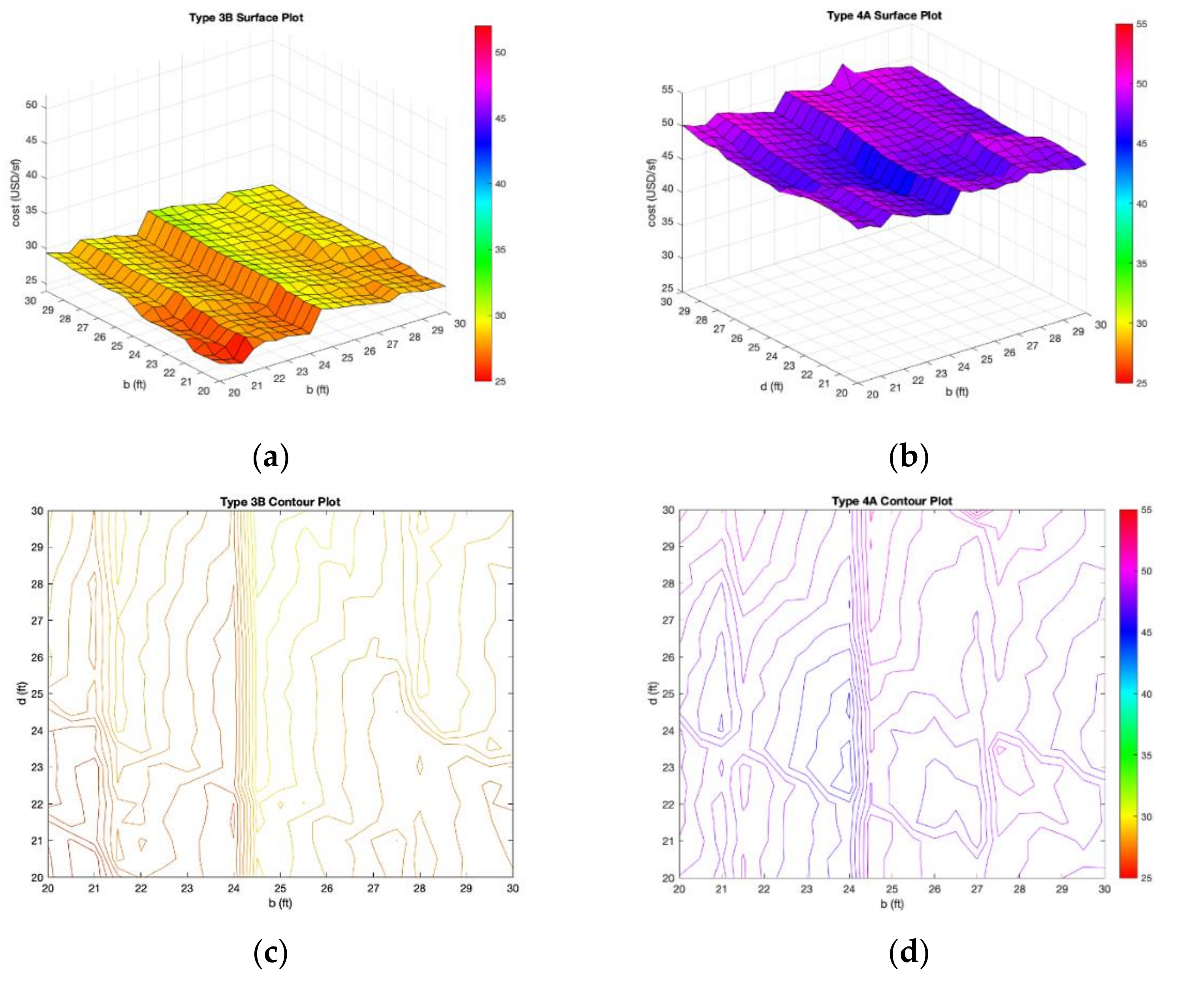

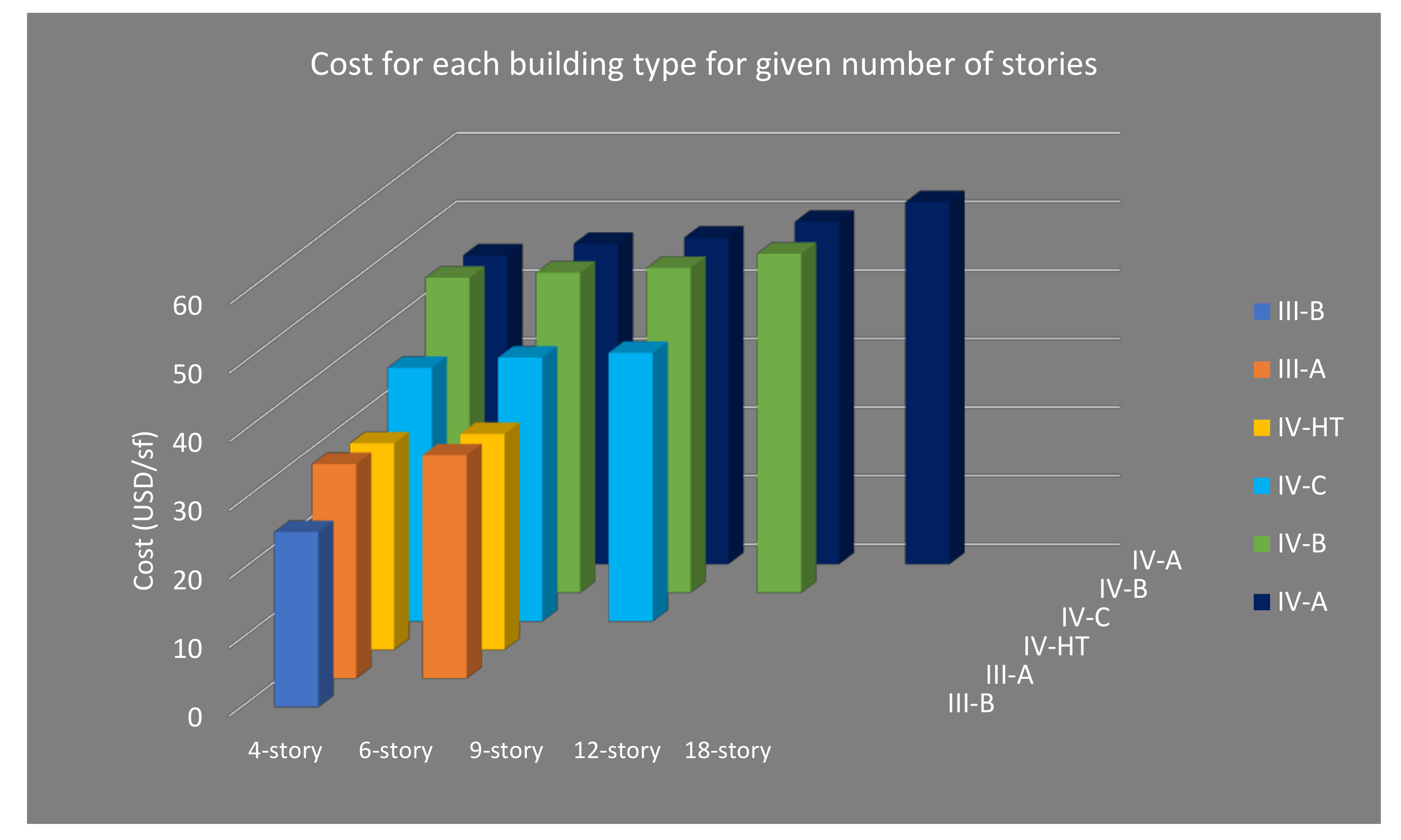

3.2.1. Cost Comparison: General Trends

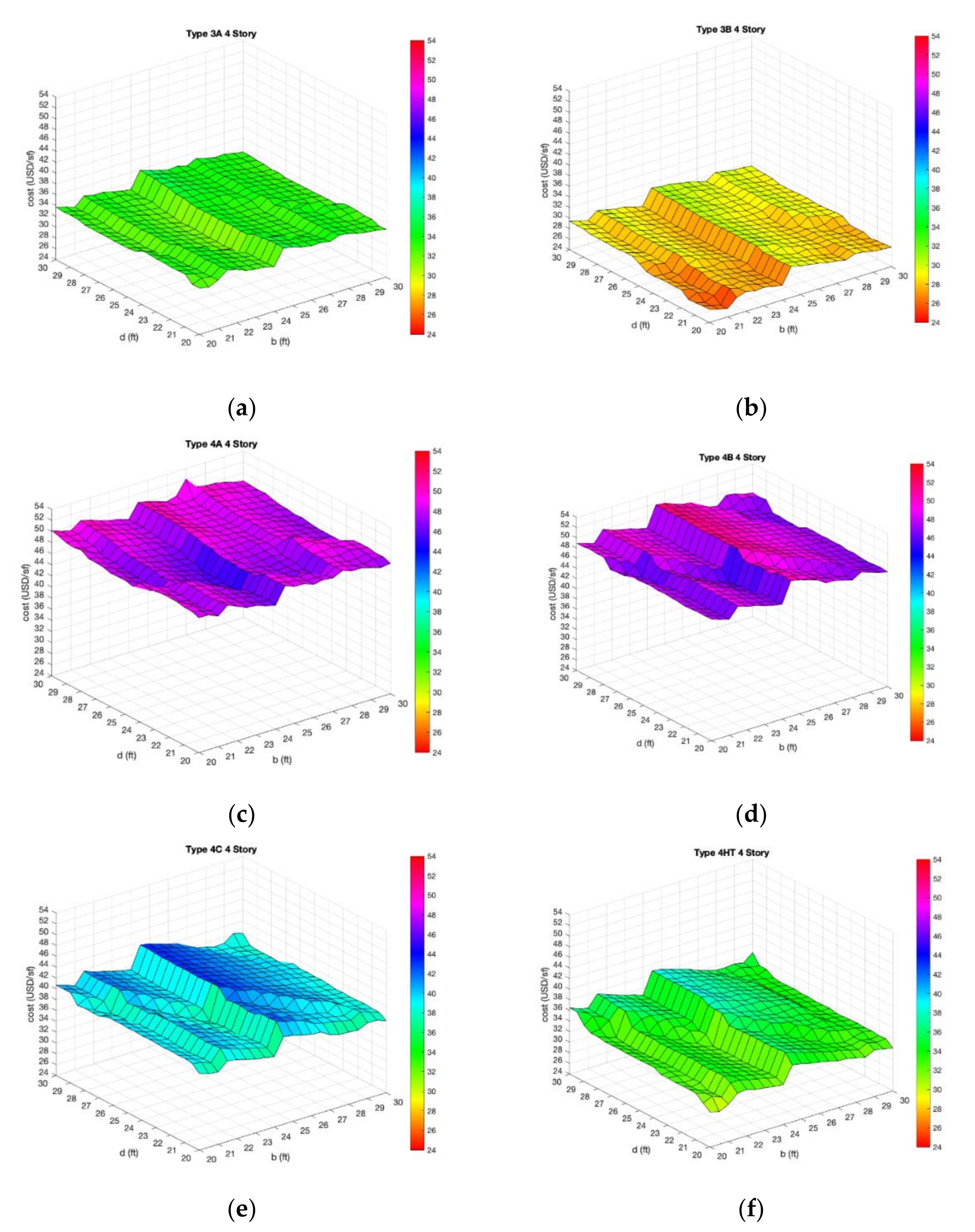

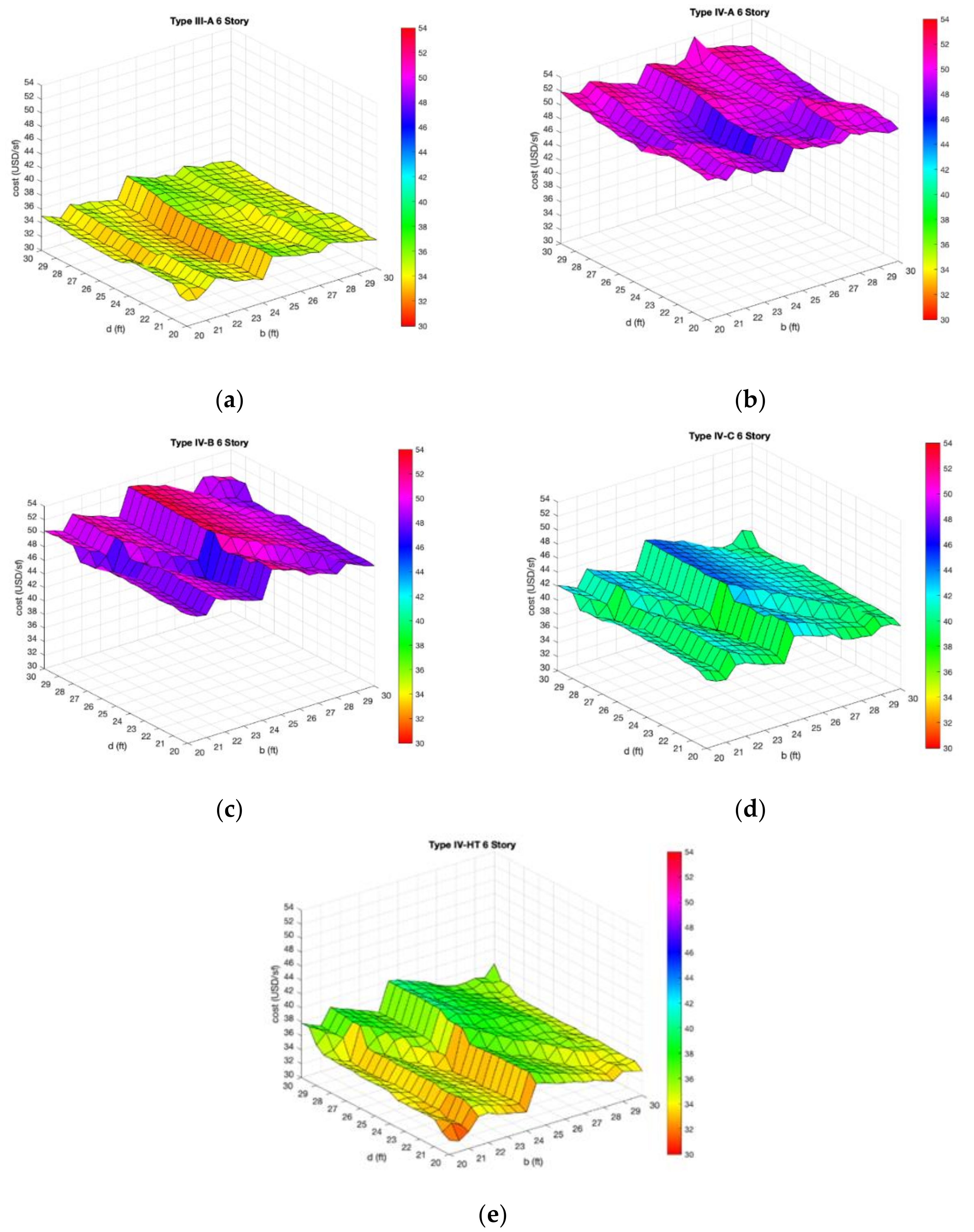

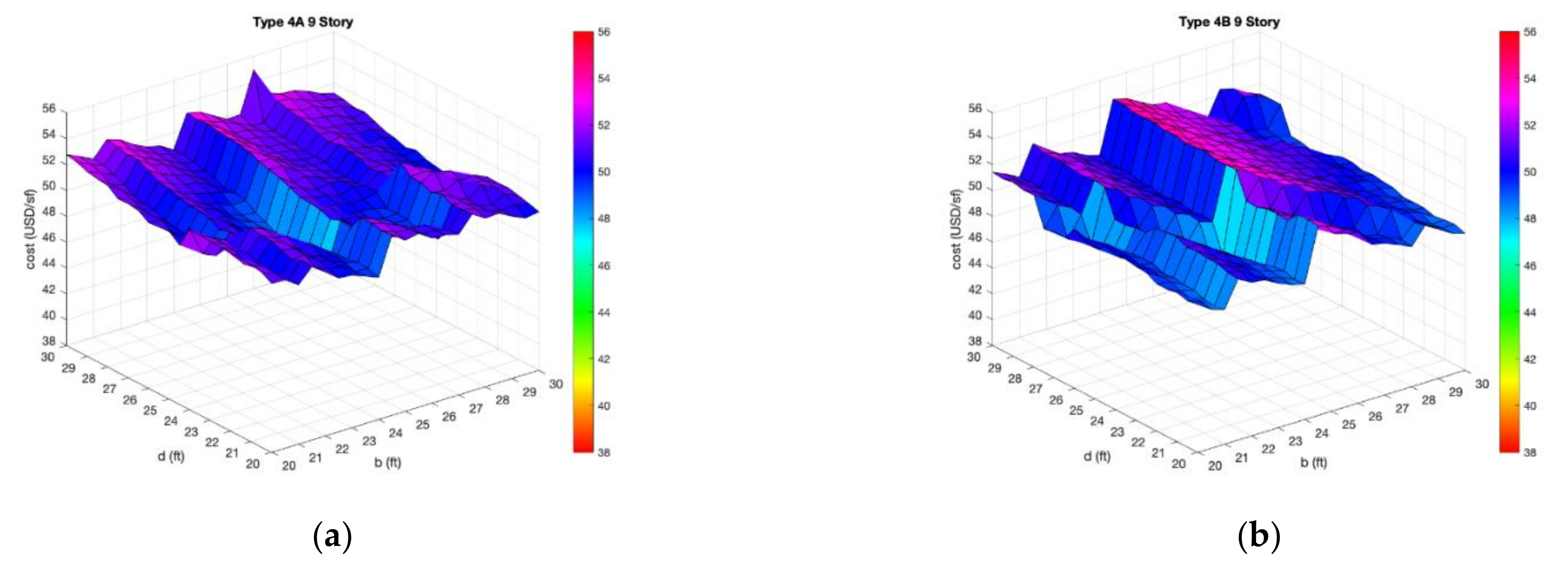

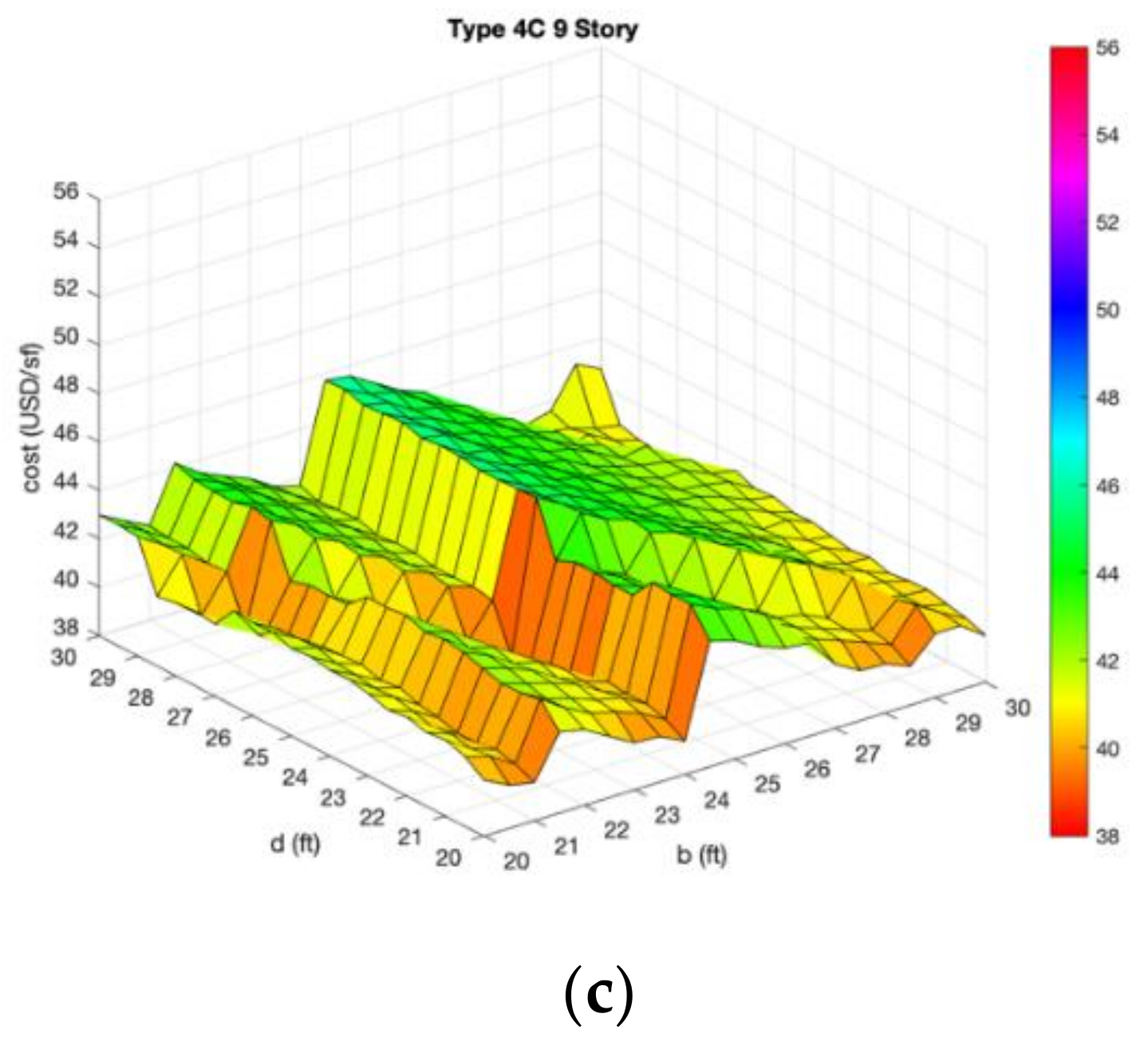

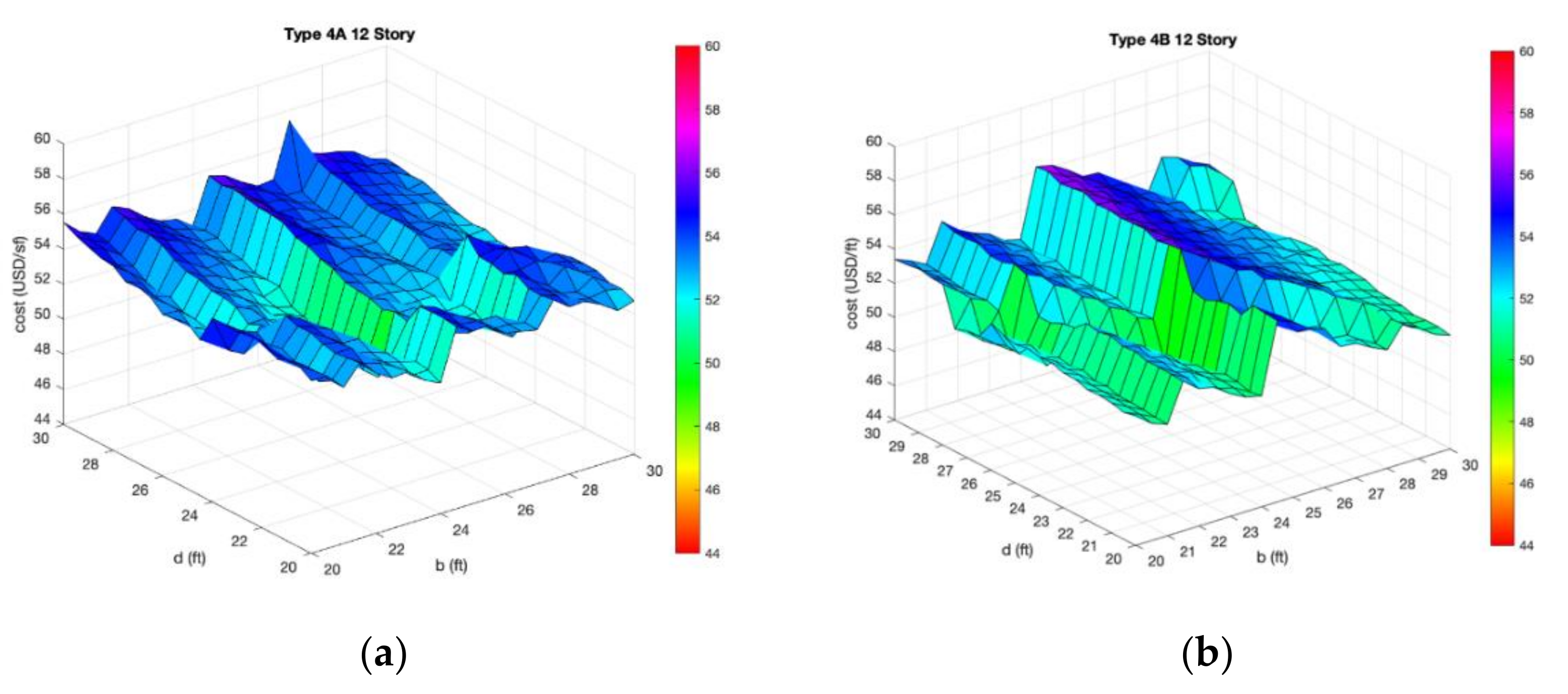

3.2.2. Cost Comparison: IBC Type Cost Performance at Different Building Heights

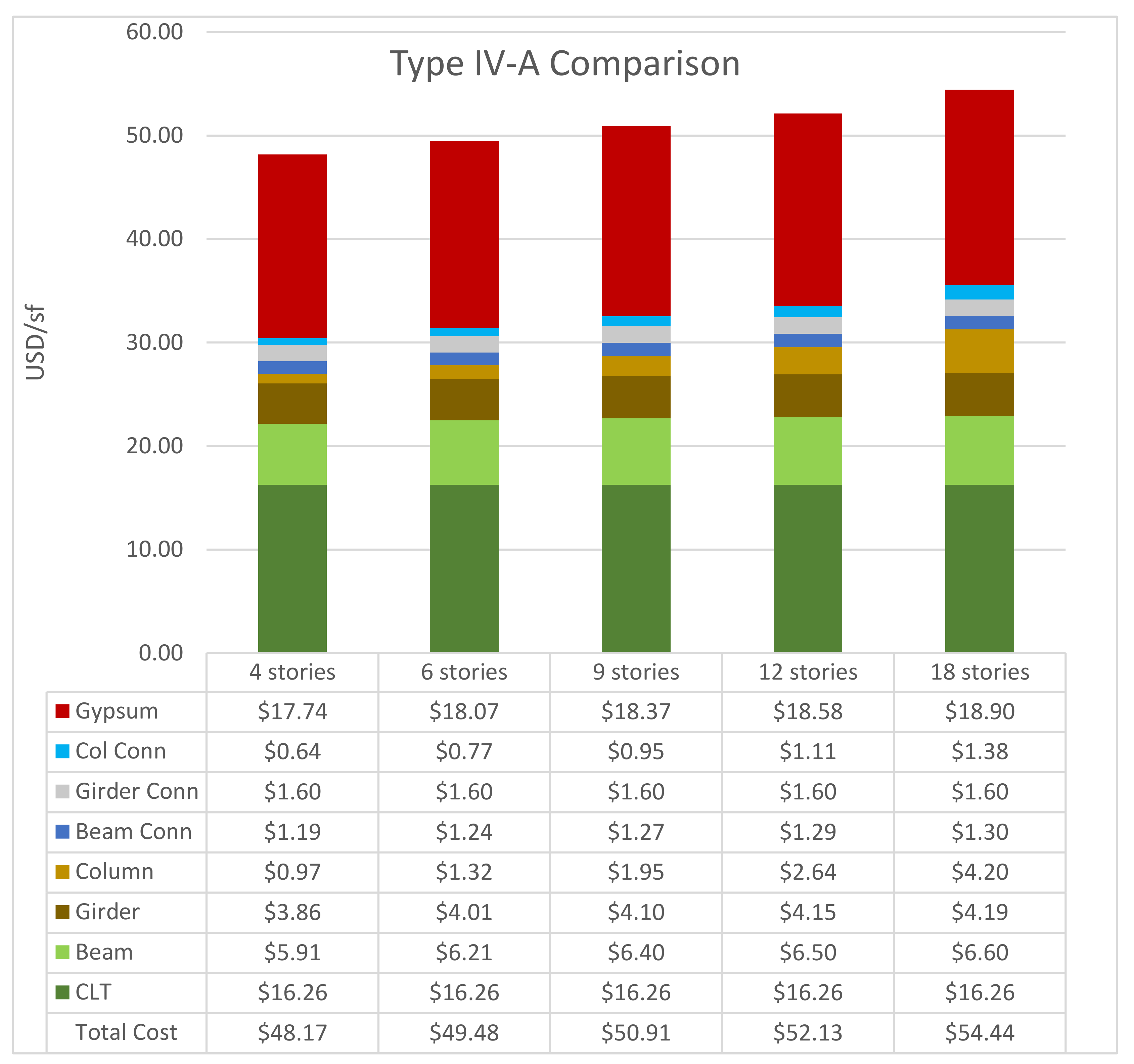

3.2.3. Cost Comparison: Type IV-A with Increasing Building Heights

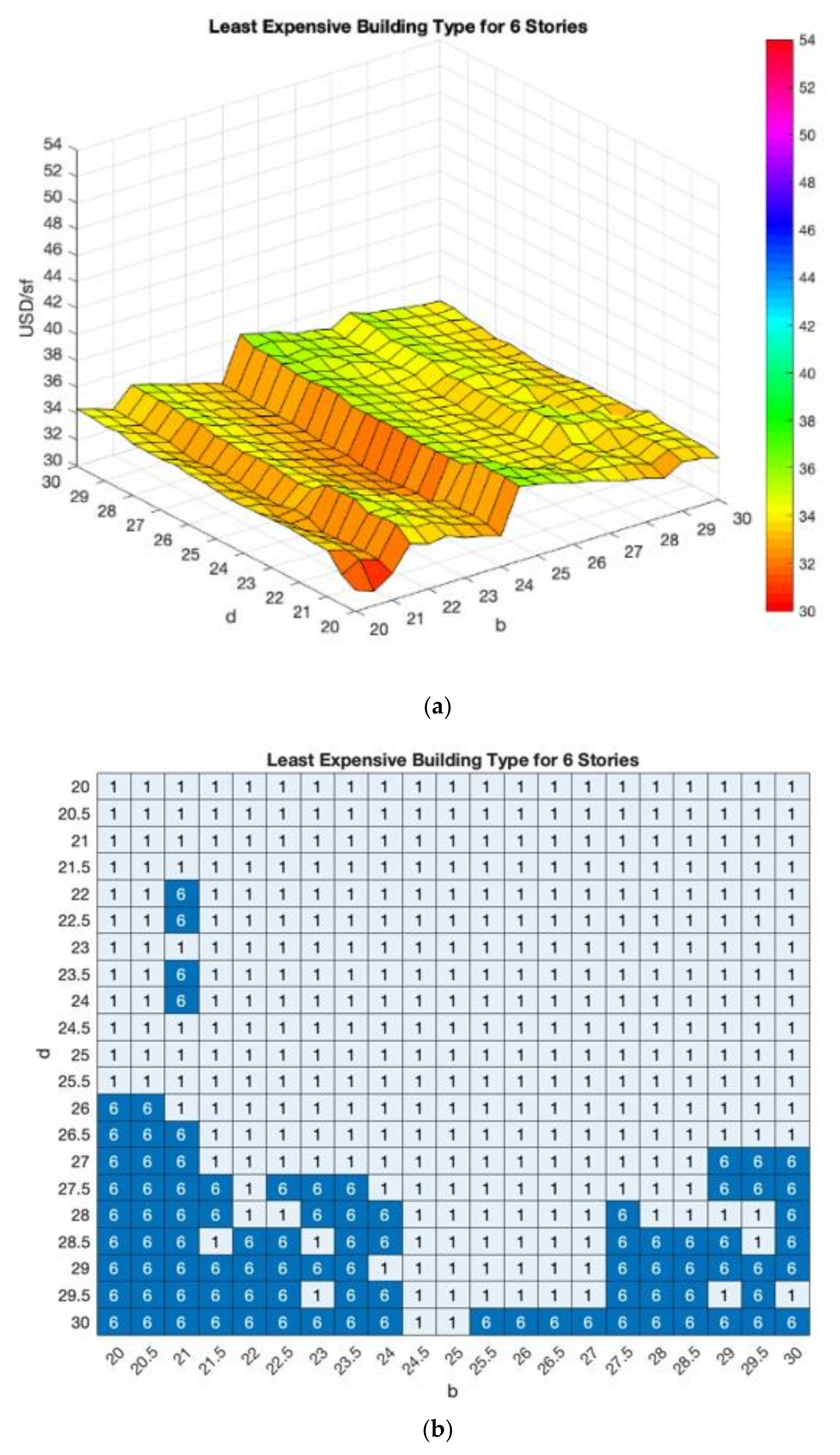

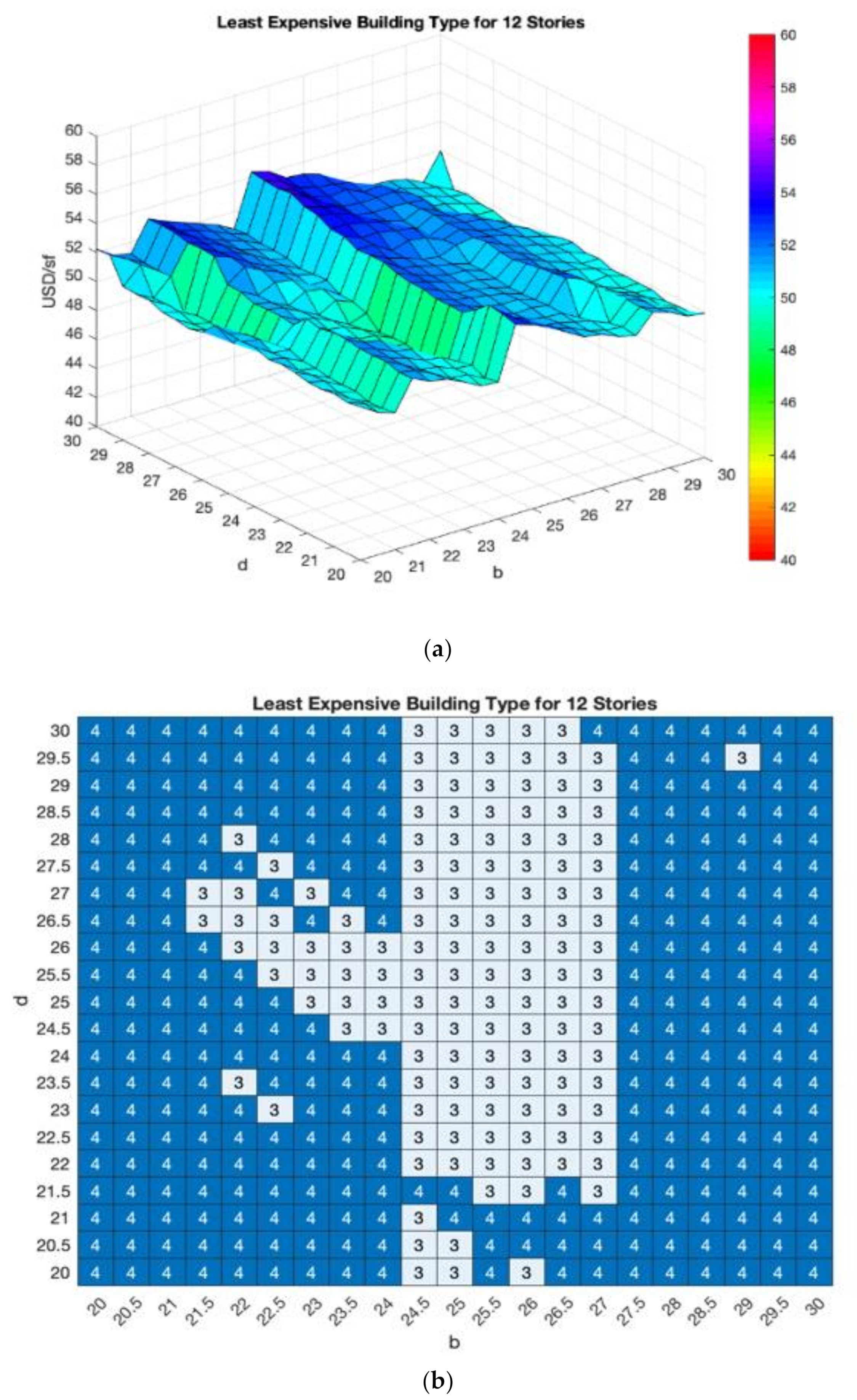

3.2.4. Cost Comparison: Overall Most Economical Design

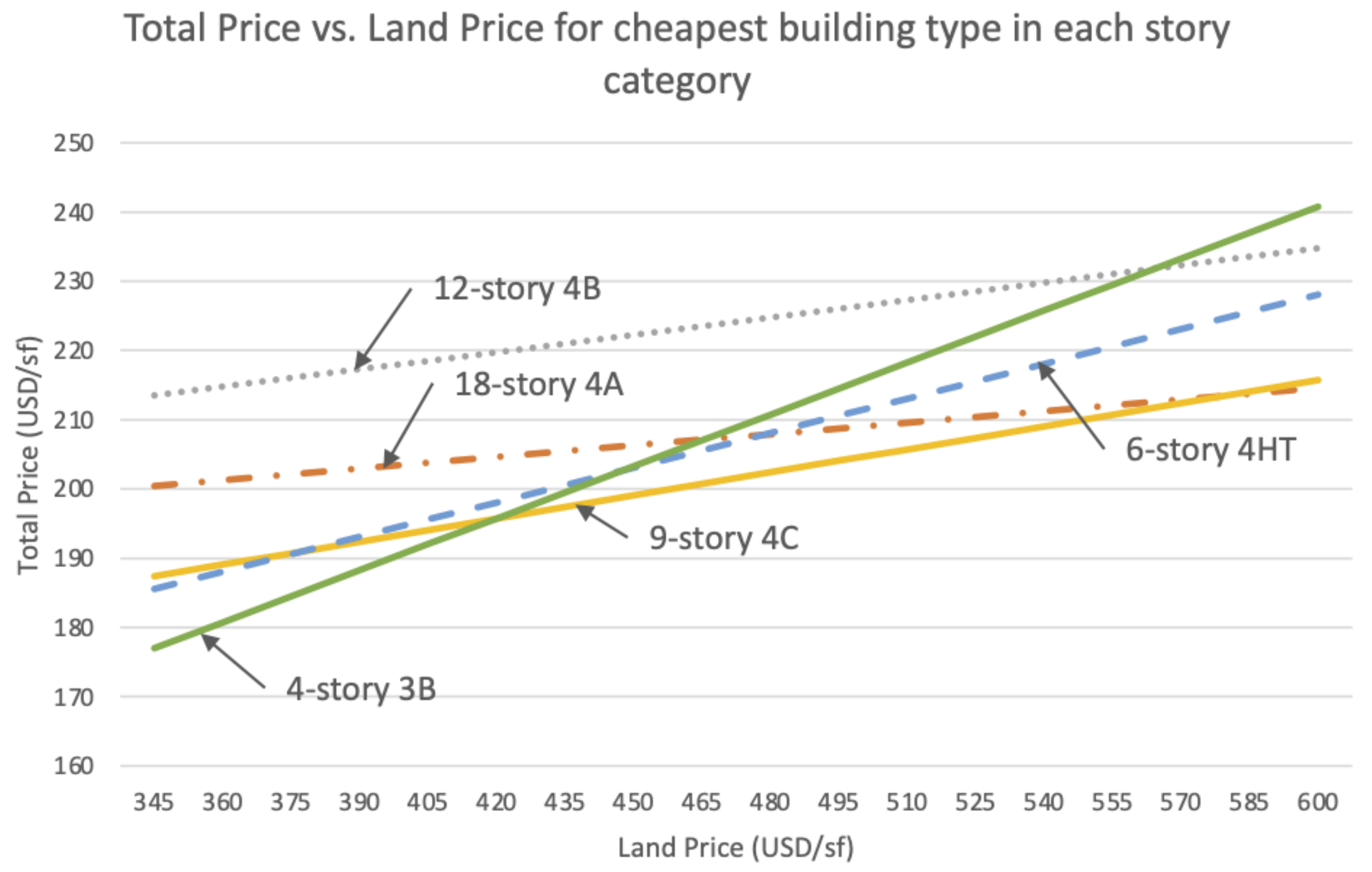

3.2.5. Sensitivity Study: Tall Wood Competitiveness against Land Price

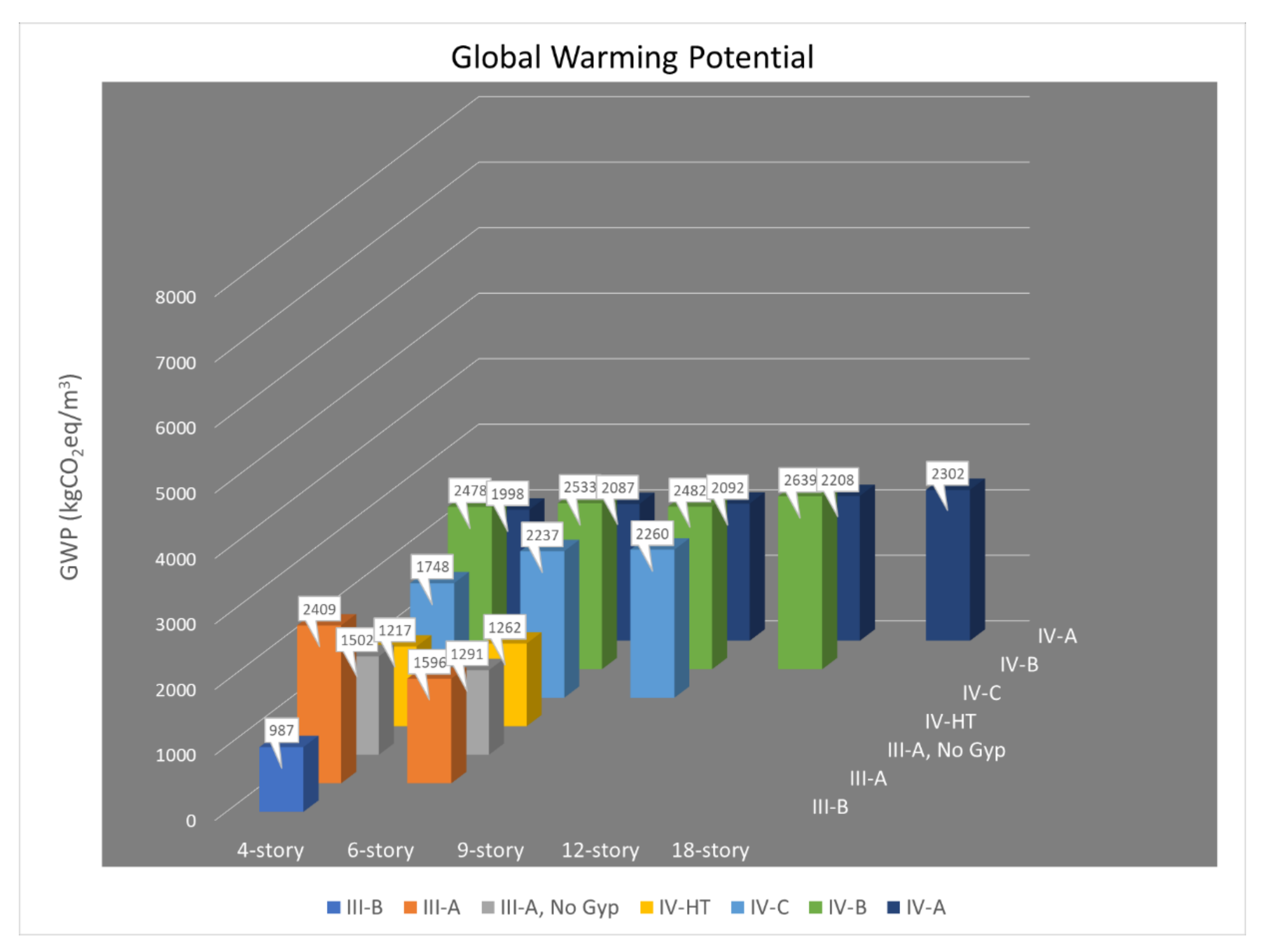

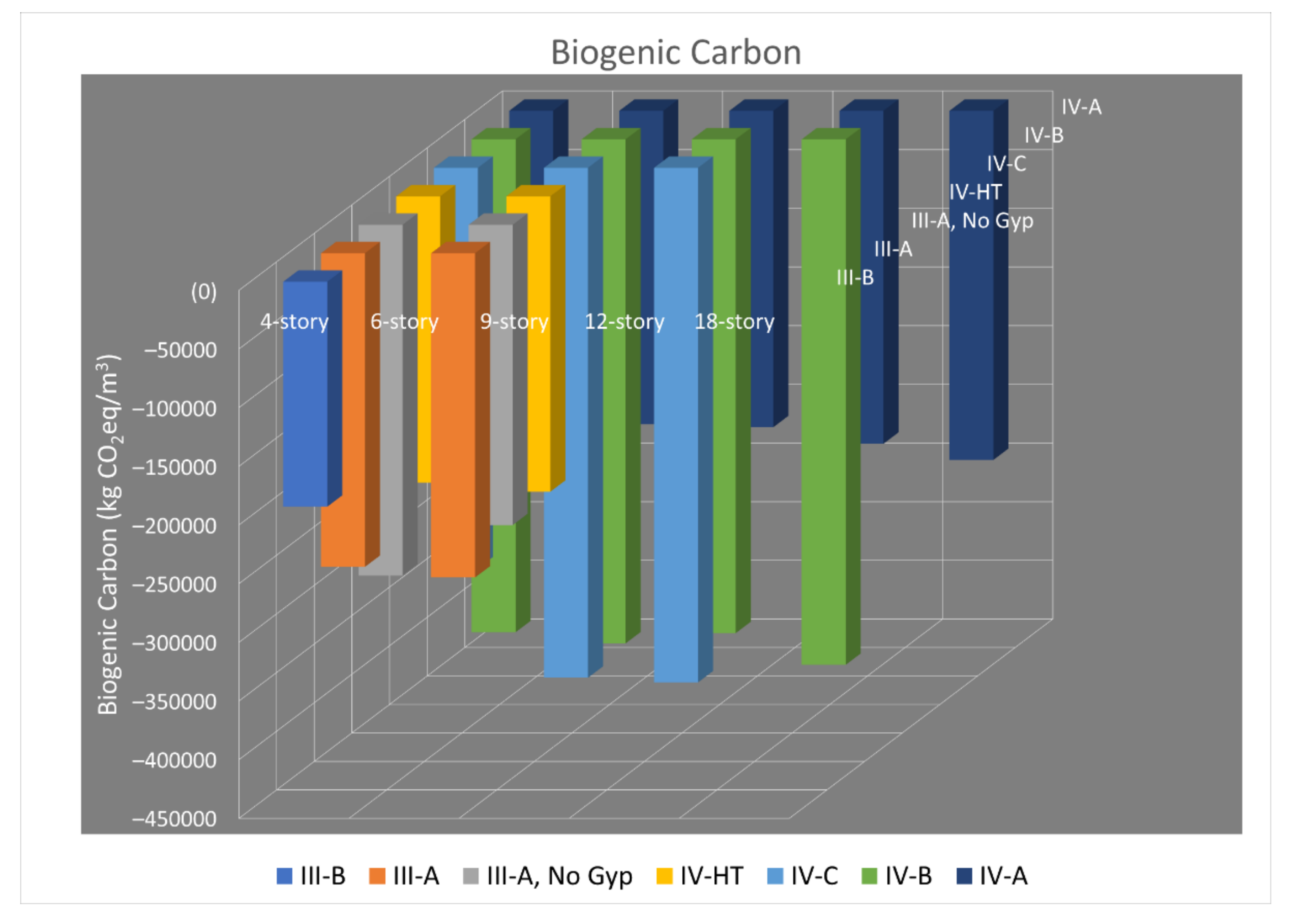

3.2.6. Sensitivity Study: Carbon Impact

4. Conclusions

- The cost of CLT floor material and gypsum board for non-combustible protection (when needed) tend to dominate the material cost for mass timber gravity systems regardless of building type;

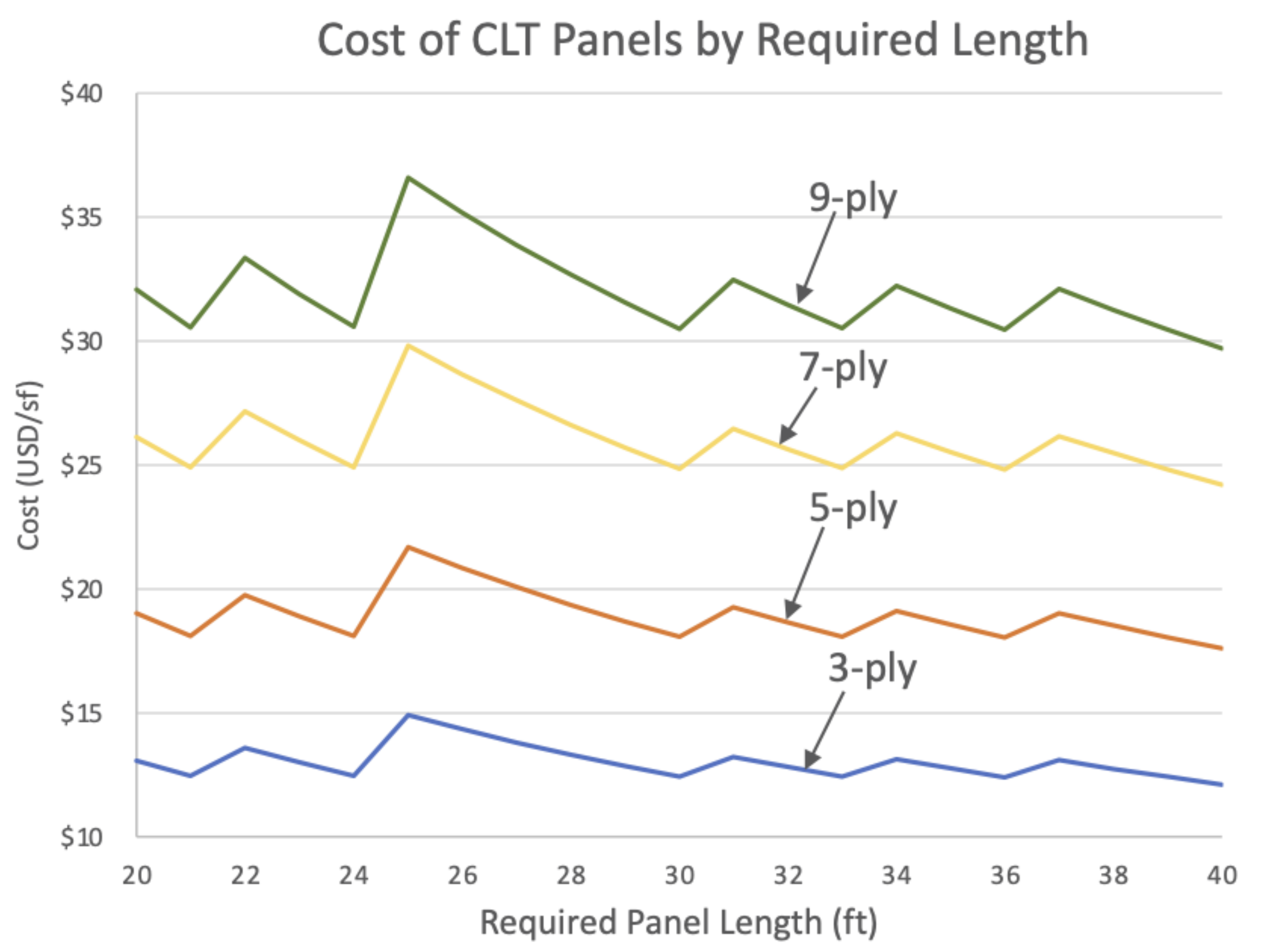

- The unit cost of CLT is greatly affected by the pressed lengths used by the manufacturer (dictated by the manufacturing process and equipment unique to each manufacturer). There is a non-linear relationship between required panel length and cost that the designer must be aware of because this trend will transfer to the overall building system cost;

- For a four-story building, the most economical building type is Type III-B because no FRR or non-combustible protection is required for this building type;

- For a six-story building, Type III-A and Type IV-HT have fairly close price performances, with Type III-A requiring FRR that can be addressed with limited gypsum board coverage or increased wood member sizes;

- For a nine-story building, Type IV-C is the least expensive building type as it does not require any gypsum board. Type IV-A and IV-B both require gypsum board;

- For a 12-story building, Type IV-B is a cheaper option than Type IV-A for most of the bay sizes investigated in this study. However, this cost-effectiveness is highly dependent on the unit price of CLT that is available to the project. Thus, the Type IV-B option might become more attractive once the CLT market becomes more mature and production capacity increases. In addition to cost consideration, Type IV-B is the only option to enable exposed wood at this height level;

- As the only wood option above 12 stories, the cost of the Type IV-A gravity system is high mainly due to the gypsum protection costs. Great innovations in non-combustible fire protection could greatly increase the competitiveness of this building type. Even with the current method of fire-proofing, Type IV-A could become favorable once other costs are factored in, such as the cost of the land;

- Goals to sequester carbon using wood products can be at odds with goals for cost, because, in general, both increase as the volume of wood increases. This study has shown that the interplay of wood volume and noncombustible covering must be considered together to obtain a realistic understanding of both cost and embodied carbon impact;

- The rise of viable platforms to provide embodied carbon credits [12] may ultimately alter the dynamic between monetary cost and carbon sequestration goals.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- International Energy Agency; United Nations Environment Programme. 2018 Global Status Report: Towards a Zero-Emission, Efficient and Resilient Buildings and Construction Sector; UN Environment and International Energy Agency: Paris, France, 2018. [Google Scholar]

- Churkina, G.; Organschi, A.; Reyer, C.P.O.; Ruff, A.; Vinke, K.; Zhu, L.; Reck, B.K.; Graedel, T.E.; Schellnhuber, H.J. Buildings as a global carbon sink. Nat. Sustain. 2020, 3, 269–276. [Google Scholar] [CrossRef]

- Borjen, Y.; Gagnon, S.; Williamson, T.; Pirvu, C. The cross-laminated timber standard in north America. In Proceedings of the World Conference on Timber Engineering, Auckland, New Zealand, 15–19 July 2012. [Google Scholar]

- Muszyński, L.; Gupta, R.; Hong, S.H.; Osborn, N.; Pickett, B. Fire resistance of unprotected cross-laminated timber floor assemblies produced in the USA. Fire Saf. J. 2019, 107, 126–136. [Google Scholar] [CrossRef]

- Breneman, S.; Timmers, M.; Richardson, D. Tall Wood Buildings in the 2021 IBC Up to 18 Stories of Mass Timber. WoodWorks. Available online: https://www.woodworks.org/wp-content/uploads/wood_solution_paper-TALL-WOOD.pdf (accessed on 19 September 2020).

- Mallo, M.F.L.; Espinoza, O. Outlook for cross-laminated timber in the United States. BioResources 2014, 9, 4. [Google Scholar]

- Mallo, M.F.L.; Espinoza, O. Cross-laminated timber vs. concrete/steel: Cost comparison using a case study. In Proceedings of the World Conference on Timber Engineering, Vienna, Austria, 22–25 August 2016. [Google Scholar]

- Kremer, O.D.; Symmons, M.A. Mass timber construction as an alternative to concrete and steel in Australia building industry: A PESTEL evaluation of the potential. Int. Wood Prod. J. 2015, 6, 3. [Google Scholar] [CrossRef]

- Chaggaris, R.; Pei, S.; Kingsley, G.; Kinder, E. Cost effectiveness of mass timber beam–column gravity systems. J. Archit. Eng. 2021, 27, 3. [Google Scholar] [CrossRef]

- ANSI/AWC (American National Standards Institute/American Wood Council). National Design Specification for Wood Construction (NDS). 2018. Available online: https://www.awc.org/pdf/codes-standards/publications/nds/AWC-NDS2018-ViewOnly-171117.pdf (accessed on 19 September 2020).

- International Code Council (ICC). International Building Code (IBC). 2018. Available online: https://codes.iccsafe.org/content/IBC2018 (accessed on 19 September 2020).

- Srubar, W.; Barnes, S.; Grieshaber, M.; Orens, A. A Methodology for Building-Based Embodied Carbon Offsetting. A white paper, Aureus Earth, Inc. 2021. Available online: http://www.aureusearth.com (accessed on 19 September 2020).

- Environmental Product Declaration: Nordic X-Lam. FPInnovations. August 2018. Available online: https://library.fpinnovations.ca/en/permalink/fpipub7910?utm_source=blog&utm_medium=blogpost&utm_campaign=20210204Recentpublications. (accessed on 23 February 2021).

- Environmental Product Declaration: North American Glued Laminated Timbers. American Wood Council and Canadian Wood Council. April 2013. Available online: https://www.awc.org/pdf/greenbuilding/epd/AWC-EPD-Glulam-1307.pdf (accessed on 23 February 2021).

- An Environmental Product Declaration. Gypsum Association. April 2020. Available online: https://www.pabcogypsum.com/sites/default/files/EPD_Type_X_Gypsum_Board_2020.pdf (accessed on 23 February 2021).

| Construction Type | FRR (hours) | Non-Combustible Protection | Story Limit | Maximum Height (m(ft)) | ||

|---|---|---|---|---|---|---|

| Primary Structural Frame | Floor | Roof | ||||

| III-A | 1 | 1 | 1 | Not required | 6 | 26 (85) |

| III-B | 0 | 0 | 0 | Not required | 4 | 23 (75) |

| IV-A | 3 | 2 | 1.5 | Fully Covered | 18 | 82 (270) |

| IV-B | 2 | 2 | 1 | Partially Covered | 12 | 55 (180) |

| IV-C | 2 | 2 | 1 | Not Required | 9 | 26 (85) |

| IV-HT | HT 1 | HT 1 | HT 1 | Not Required | 6 | 26 (85) |

| Product | GWP (kg CO2 eq/m3) | EPD |

|---|---|---|

| Cross Laminated Timber | 137.19 | Nordic X-Lam, Nordic Structures (2018) |

| Glulam Beams and Columns | 197.97 | North American Glued Laminated Timber, American Wood Council (2020) |

| Gypsum Wallboard | 187.82 | 5/8″ Type X Conventional Gypsum Board, Gypsum Association (2020) |

| Stories | Viable Building Types | Maximum FTF [m(ft)] |

|---|---|---|

| 4 | III-A, III-B, IV-A, IV-B, IV-C, IV-HT | 3.5 (11.5) |

| 6 | III-A, IV-A, IV-B, IV-C, IV-HT | 3.5 (11.5) |

| 9 | IV-A, IV-B, IV-C | 2.7 (9) |

| 12 | IV-A, IV-B | 3.5 (11.5) |

| 18 | IV-A | 3.5 (11.5) |

| Design Load Type | Design Load Quantity [kPa (psf)] |

|---|---|

| Dead | Calculated 1 |

| Office Live | 2.4 (50) |

| Partition | 0.7 (15) |

| Superimposed Dead—Office | 2.3 (47.5) |

| Superimposed Dead—Roof | 0.5 (10) |

| Roof Live | 1 (20) |

| Building Type | |||||||

|---|---|---|---|---|---|---|---|

| Stories | III-B | III-A | IV-HT | IV-C | IV-B | IV-A | |

| 4 | Grid | 21 × 20.5 | 24 × 23.5 | 20.5 × 20 | 24 × 20 | 24 × 24 | 24 × 22.5 |

| Cost | $25.53 | $31.28 | $30.14 | $36.97 | $45.49 | $45.04 | |

| 6 | Grid | -- | 24 × 23.5 | 20.5 × 20 | 24 × 24.5 | 24 × 24 | 24 × 22 |

| Cost | $32.56 | $31.50 | $38.47 | $46.68 | $46.72 | ||

| 9 | Grid | -- | -- | -- | 24 × 24.5 | 24 × 24 | 24 × 22.5 |

| Cost | $39.16 | $47.37 | $47.64 | ||||

| 12 | Grid | -- | -- | -- | -- | 24 × 24 | 24 × 22 |

| Cost | $49.44 | $49.93 | |||||

| 18 | Grid | -- | -- | -- | -- | -- | 24 × 22 |

| Cost | $52.81 | ||||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Chaggaris, R.; Pei, S.; Kingsley, G.; Feitel, A. Carbon Impact and Cost of Mass Timber Beam–Column Gravity Systems. Sustainability 2021, 13, 12966. https://doi.org/10.3390/su132312966

Chaggaris R, Pei S, Kingsley G, Feitel A. Carbon Impact and Cost of Mass Timber Beam–Column Gravity Systems. Sustainability. 2021; 13(23):12966. https://doi.org/10.3390/su132312966

Chicago/Turabian StyleChaggaris, Rachel, Shiling Pei, Greg Kingsley, and Alexis Feitel. 2021. "Carbon Impact and Cost of Mass Timber Beam–Column Gravity Systems" Sustainability 13, no. 23: 12966. https://doi.org/10.3390/su132312966

APA StyleChaggaris, R., Pei, S., Kingsley, G., & Feitel, A. (2021). Carbon Impact and Cost of Mass Timber Beam–Column Gravity Systems. Sustainability, 13(23), 12966. https://doi.org/10.3390/su132312966