A Decision Support Tool for Supplier Evaluation and Selection

Abstract

:1. Introduction

2. Literature Review

2.1. The Supplier Selection Problem

2.2. Supplier Selection Criteria

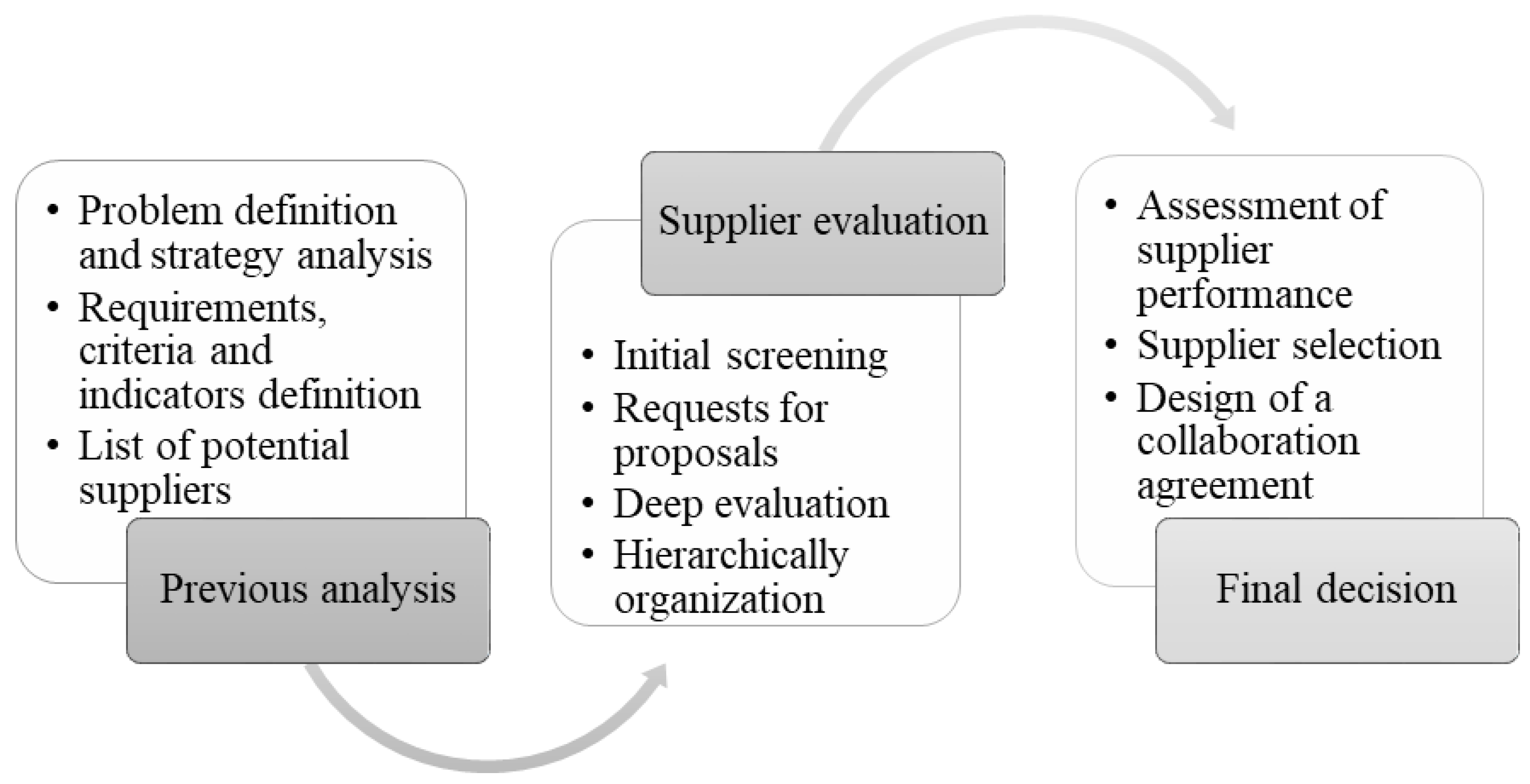

3. Methodology

3.1. PROMETHEE I and II

- –

- Indifference threshold : Two alternatives are indifferent when the difference between evaluations is smaller than the indifference threshold.

- –

- Strict preference threshold : The second alternative is preferred to the first one if the difference between their evaluations is bigger than the preference threshold, (pj).

3.2. The GAIA Interactive Visual Tool

4. Application of PROMETHEE—GAIA to the Supplier Selection Problem

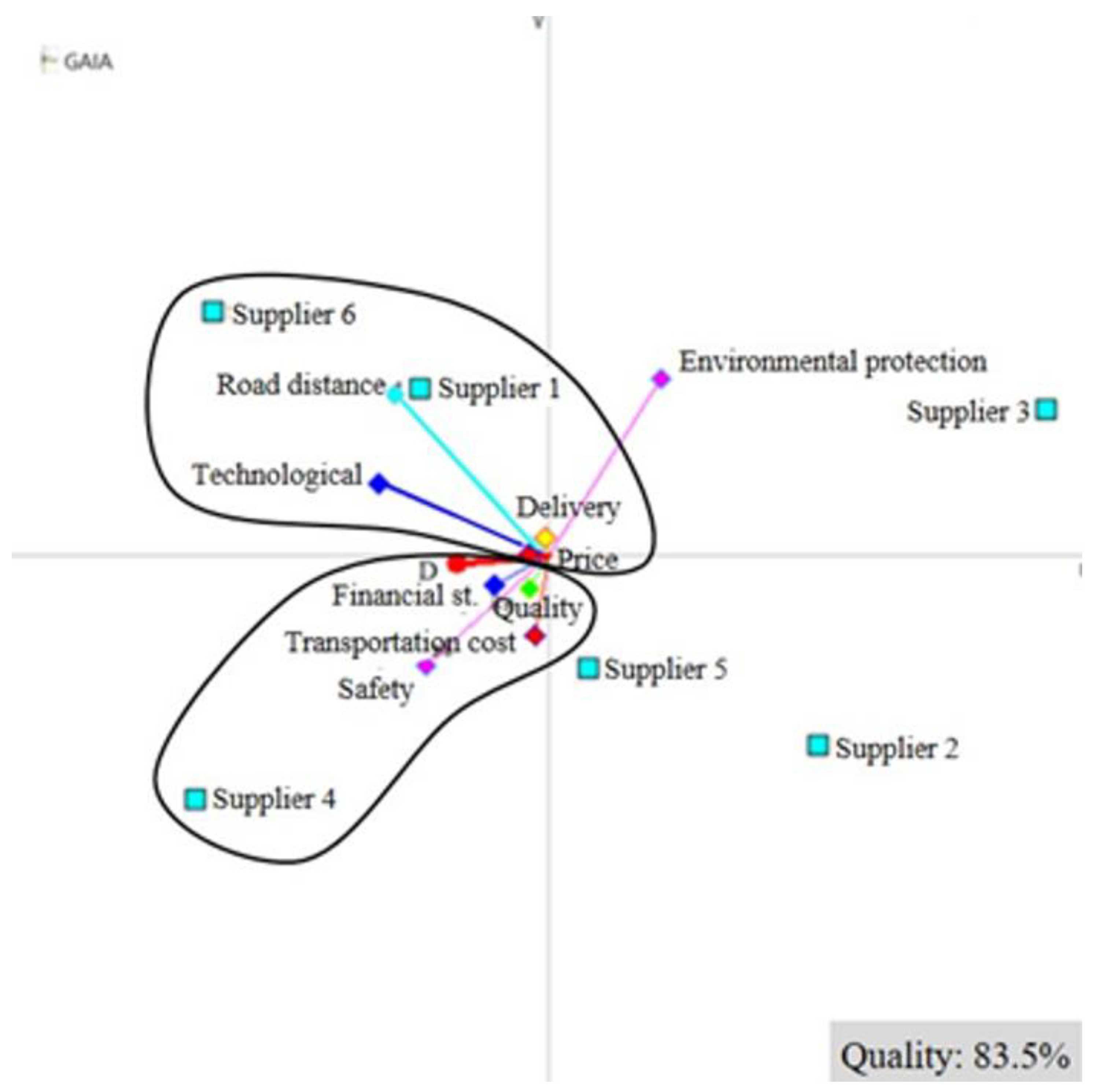

5. Results and Discussion

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- O’Regan, N.; Sims, M.; Ghobadian, A. High performance: Ownership and decision-making in SMEs. Manag. Decis. 2005, 43, 382–396. [Google Scholar] [CrossRef]

- Govindan, K.; Rajendran, S.; Sarkis, J.; Murugesan, P. Multi criteria decision making approaches for green supplier evaluation and selection: A literature review. J. Clean. Prod. 2013, 98, 66–83. [Google Scholar] [CrossRef]

- Banaeian, N.; Mobli, H.; Fahimnia, B.; Nielsen, I.E.; Omid, M. Green supplier selection using fuzzy group decision making methods: A case study from the agri-food industry. Comput. Oper. Res. 2018, 89, 337–347. [Google Scholar] [CrossRef]

- Guarnieri, P. Síntese dos Principais Critérios, Métodos e Subproblemas da Seleção de Fornecedores Multicritério. Synth. Main Criteria Methods Issues Multicriteria Supplier Sel. 2015, 19, 1–25. [Google Scholar] [CrossRef] [Green Version]

- Gupta, H.; Barua, M.K. Supplier selection among SMEs on the basis of their green innovation ability using BWM and fuzzy TOPSIS. J. Clean. Prod. 2017, 152, 242–258. [Google Scholar] [CrossRef]

- Vetschera, R.; de Almeida, A.T. A promethee-based approach to portfolio selection problems. Comput. Oper. Res. 2012, 39, 1010–1020. [Google Scholar] [CrossRef] [Green Version]

- Kizielewicz, B.; Więckowski, J.; Shekhovtsov, A.; Wątróbski, J.; Depczyński, R.; Sałabun, W. Study towards the time-based mcda ranking analysis—A supplier selection case study. Facta Univ. Ser. Mech. Eng. 2021, 19, 381–399. [Google Scholar]

- Biswas, T.K.; Das, M.C. Selection of the barriers of supply chain management in Indian manufacturing sectors due to Covid-19 impacts. Oper. Res. Eng. Sci. Theory Appl. 2020, 3, 1–12. [Google Scholar] [CrossRef]

- Schramm, V.B.; Cabral, L.P.B.; Schramm, F. Approaches for supporting sustainable supplier selection—A literature review. J. Clean. Prod. 2020, 273, 123089. [Google Scholar] [CrossRef]

- Astanti, R.D.; Mbolla, S.E.; Ai, T.J. Raw material supplier selection in a glove manufacturing: Application of AHP and fuzzy AHP. Decis. Sci. Lett. 2020, 9, 291–312. [Google Scholar] [CrossRef]

- Fagundes, M.V.C.; Keler, A.C.; Teles, E.O.; de Melo, S.A.B.V.; Freires, F.G.M. Multicriteria Decision-Making System for Supplier Selection Considering Risk: A Computational Fuzzy AHP-Based Approach. IEEE Lat. Am. Trans. 2021, 19, 1564–1572. [Google Scholar] [CrossRef]

- Solanki, R.; Gulati, G.; Tiwari, A.; Lohani, Q.D. A correlation based Intuitionistic fuzzy TOPSIS method on supplier selection problem. In Proceedings of the 2016 IEEE International Conference on Fuzzy Systems, FUZZ-IEEE, Vancouver, BC, Canada, 24–29 July 2016; pp. 2106–2112. [Google Scholar]

- Jain, V.; Sangaiah, A.K.; Sakhuja, S.; Thoduka, N.; Aggarwal, R. Supplier selection using fuzzy AHP and TOPSIS: A case study in the Indian automotive industry. Neural Comput. Appl. 2016, 29, 555–564. [Google Scholar] [CrossRef]

- Jadidi, O.; Firouzi, F.; Bagliery, E. TOPSIS method for supplier selection problem. World Acad. Sci. Eng. Technol. 2010, 47, 956–958. [Google Scholar]

- Utama, D.M.; Maharani, B.; Amallynda, I. Integration Dematel and ANP for the Supplier Selection in the Textile Industry: A Case Study. J. Ilm. Tek. Ind. 2021, 20, 119–130. [Google Scholar]

- Önder, E.; Kabadayi, N. Supplier Selection in Hospitality Industry Using ANP. Int. J. Acad. Res. Bus. Soc. Sci. 2015, 1, 166–185. [Google Scholar]

- Zaied, A.N.H.; Ismail, M.; Gamal, A. An Integrated of Neutrosophic-ANP Technique for Supplier Selection; Infinite Study: West Conshohocken, PA, USA, 2019; Volume 72, pp. 237–244. [Google Scholar]

- Kilaparthi, S.; Sambana, N. Fuzzy kano—Vikor integrated approach for supplier selection—A case study. Int. J. Mech. Prod. Eng. Res. Dev. 2018, 8, 337–348. [Google Scholar]

- Parkouhi, S.V.; Ghadikolaei, A.S. A resilience approach for supplier selection: Using Fuzzy Analytic Network Process and grey VIKOR techniques. J. Clean. Prod. 2017, 161, 431–451. [Google Scholar] [CrossRef]

- Szmelter-Jarosz, A. DEMATEL Method in Supplier Evaluation and Selection. Transp. Econ. Logist. 2019, 82, 129–142. [Google Scholar] [CrossRef]

- Kumar, M.; Garg, D.; Agarwal, A. Fuzzy DEMATEL approach for agile supplier selections performance criteria. J. Phys. Conf. Ser. 2019, 1240, 012157. [Google Scholar] [CrossRef]

- Fahmi, A.; Kahraman, C.; Bilen, Ü. ELECTRE I Method Using Hesitant Linguistic Term Sets: An Application to Supplier Selection. Int. J. Comput. Intell. Syst. 2016, 9, 153–167. [Google Scholar] [CrossRef] [Green Version]

- Tham, T.T.; Le, D.T.H. An integrated approach of fuzzy ELECTRE I for supplier selection. Int. J. Appl. Manag. Sci. 2021, 13, 240–274. [Google Scholar] [CrossRef]

- Wan, S.-P.; Xu, G.-L.; Dong, J.-Y. Supplier selection using ANP and ELECTRE II in interval 2-tuple linguistic environment. Inf. Sci. 2017, 385–386, 19–38. [Google Scholar] [CrossRef]

- Peide, L. Research on the supplier selection of supply chain based on the improved ELECTRE-II method. In Proceedings of the Workshop on Intelligent Information Technology Application, IITA, Zhangjiajie, China, 2–3 December 2007. [Google Scholar]

- Liu, P.; Zhang, X. Research on the supplier selection of a supply chain based on entropy weight and improved ELECTRE-III method. Int. J. Prod. Res. 2011, 49, 637–646. [Google Scholar] [CrossRef]

- Guarnieri, P.; Trojan, F. Decision making on supplier selection based on social, ethical, and environmental criteria: A study in the textile industry. Resour. Conserv. Recycl. 2018, 141, 347–361. [Google Scholar] [CrossRef]

- Agrawal, N. Multi-criteria decision-making toward supplier selection: Exploration of PROMETHEE II method. Benchmarking Int. J. 2021. ahead-of-print. [Google Scholar] [CrossRef]

- Isa, M.A.M.; Saharudin, N.S.; Anuar, N.B.; Mahad, N.F. The application of AHP-PROMETHEE II for supplier selection. J. Phys. Conf. Ser. 2021, 1988, 012062. [Google Scholar] [CrossRef]

- Abdullah, L.; Chan, W.; Afshari, A. Application of PROMETHEE method for green supplier selection: A comparative result based on preference functions. J. Ind. Eng. Int. 2018, 15, 271–285. [Google Scholar] [CrossRef] [Green Version]

- Madić, M.; Marković, D.; Petrović, G.; Radovanović, M. Application of COPRAS method for supplier selection. In Proceedings of the Fifth International Conference Transport and Logistics-TIL, Niš, Serbia, 5–6 June 2014. [Google Scholar]

- Sałabun, W.; Watróbski, J.; Shekhovtsov, A. Are MCDA methods benchmarkable? A comparative study of TOPSIS, VIKOR, COPRAS, and PROMETHEE II methods. Symmetry 2020, 12, 1549. [Google Scholar] [CrossRef]

- Chai, J.; Liu, J.N.; Ngai, E.W. Application of decision-making techniques in supplier selection: A systematic review of literature. Expert Syst. Appl. 2013, 40, 3872–3885. [Google Scholar] [CrossRef]

- Chai, J.; Ngai, E.W. Decision-making techniques in supplier selection: Recent accomplishments and what lies ahead. Expert Syst. Appl. 2019, 140, 112903. [Google Scholar] [CrossRef]

- Wątróbski, J.; Jankowski, J.; Ziemba, P.; Karczmarczyk, A.; Zioło, M. Generalised framework for multi-criteria method selection. Omega 2018, 86, 107–124. [Google Scholar] [CrossRef]

- Wątróbski, J.; Jankowski, J.; Ziemba, P.; Karczmarczyk, A.; Zioło, M. Generalised framework for multi-criteria method selection: Rule set database and exemplary decision support system implementation blueprints. Data Brief 2018, 22, 639–642. [Google Scholar] [CrossRef] [PubMed]

- Agarwal, G.; Vijayvargy, L. Modeling of Intangibles: An Application in Supplier Selection in Supply Chain—A Case Study of Multinational Food Industry. Int. J. Manag. Innov. 2013, 5, 61–80. [Google Scholar] [CrossRef]

- Voss, M.D.; Closs, D.J.; Calantone, R.J.; Helferich, O.K.; Speier, C. The role of security in the food supplier selection decision. J. Bus. Logist. 2009, 30, 127–155. [Google Scholar] [CrossRef]

- Azadfallah, M. Supplier Selection using MADM Method under Uncertainty. J. Supply Chain Manag. Syst. 2016, 5, 1–8. [Google Scholar] [CrossRef]

- de Santis, R.B.; Golliat, L.; de Aguiar, E.P. Multi-Criteria Supplier Selection Using Fuzzy Analytic Hierarchy Process: Case Study from a Brazilian Railway Operator. Braz. J. Oper. Prod. Manag. 2017, 14, 428–437. [Google Scholar] [CrossRef] [Green Version]

- Lima-Junior, F.R.; Carpinetti, L.C.R. A multicriteria approach based on fuzzy QFD for choosing criteria for supplier selection. Comput. Ind. Eng. 2016, 101, 269–285. [Google Scholar] [CrossRef]

- Ortiz-Barrios, M.A.; Kucukaltan, B.; Carvajal-Tinoco, D.; Neira-Rodado, D.; Jiménez, G. Strategic hybrid approach for selecting suppliers of high-density polyethylene. J. Multi-Criteria Decis. Anal. 2017, 24, 296–316. [Google Scholar] [CrossRef]

- Hamdan, S.; Cheaitou, A. Supplier selection and order allocation with green criteria: An MCDM and multi-objective optimization approach. Comput. Oper. Res. 2017, 81, 282–304. [Google Scholar] [CrossRef]

- Sarkar, S.; Pratihar, D.K.; Sarkar, B. An integrated fuzzy multiple criteria supplier selection approach and its application in a welding company. J. Manuf. Syst. 2018, 46, 163–178. [Google Scholar] [CrossRef]

- Wetzstein, A.; Hartmann, E.; Benton, W.C., Jr.; Hohenstein, N.-O. A systematic assessment of supplier selection literature–State-of-the-art and future scope. Int. J. Prod. Econ. 2016, 182, 304–323. [Google Scholar] [CrossRef]

- Weber, C.A.; Current, J.R.; Benton, W. Vendor selection criteria and methods. Eur. J. Oper. Res. 1991, 50, 2–18. [Google Scholar] [CrossRef]

- Yazdani, M.; Chatterjee, P.; Zavadskas, E.K.; Zolfani, S.H. Integrated QFD-MCDM framework for green supplier selection. J. Clean. Prod. 2017, 142, 3728–3740. [Google Scholar] [CrossRef]

- Asadabadi, M.R. A customer based supplier selection process that combines quality function deployment, the analytic network process and a Markov chain. Eur. J. Oper. Res. 2017, 263, 1049–1062. [Google Scholar] [CrossRef]

- Luthra, S.; Govindan, K.; Kannan, D.; Mangla, S.K.; Garg, C.P. An integrated framework for sustainable supplier selection and evaluation in supply chains. J. Clean. Prod. 2017, 140, 1686–1698. [Google Scholar] [CrossRef]

- de Boer, L.; Labro, E.; Morlacchi, P. A review of methods supporting supplier selection. Eur. J. Purch. Supply Manag. 2001, 7, 75–89. [Google Scholar] [CrossRef]

- de Boer, L. Procedural rationality in supplier selection. Manag. Decis. 2017, 55, 32–56. [Google Scholar] [CrossRef] [Green Version]

- Chen, Y.-J. Structured methodology for supplier selection and evaluation in a supply chain. Inf. Sci. 2011, 181, 1651–1670. [Google Scholar] [CrossRef]

- Ho, W.; Xu, X.; Dey, P. Multi-criteria decision making approaches for supplier evaluation and selection: A literature review. Eur. J. Oper. Res. 2010, 202, 16–24. [Google Scholar] [CrossRef]

- Karsak, E.E.; Dursun, M. Taxonomy and review of non-deterministic analytical methods for supplier selection. Int. J. Comput. Integr. Manuf. 2015, 29, 263–286. [Google Scholar] [CrossRef]

- Izadikhah, M.; Saen, R.F.; Ahmadi, K. How to Assess Sustainability of Suppliers in the Presence of Dual-Role Factor and Volume Discounts? A Data Envelopment Analysis Approach. Asia-Pac. J. Oper. Res. 2017, 34, 1740016. [Google Scholar] [CrossRef]

- Ranjan, R.; Chatterjee, P.; Chakraborty, S. Performance evaluation of Indian states in tourism using an integrated PROMETHEE-GAIA approach. OPSEARCH 2015, 53, 63–84. [Google Scholar] [CrossRef]

- Amorim, P.; Curcio, E.; Almada-Lobo, B.; Barbosa-Póvoa, A.P.; Grossmann, I.E. Supplier selection in the processed food industry under uncertainty. Eur. J. Oper. Res. 2016, 252, 801–814. [Google Scholar] [CrossRef]

- Sahraei, L. Providing a Structured Method for Supplier Evaluation and Ranking under Agility Approach and based on MODM Techniques. Int. J. Sci. Manag. Dev. 2017, 5, 266–273. [Google Scholar]

- Degraeve, Z.; Labro, E.; Roodhooft, F. An evaluation of vendor selection models from a total cost of ownership perspective. Eur. J. Oper. Res. 2000, 125, 34–58. [Google Scholar] [CrossRef] [Green Version]

- Brans, J.P. L’ingénierie de la Décision: Élaboration D’instruments D’aide à la Décision. La Méthode PROMETHEE; Presses de l’Université Laval: Québec, QC, Canada, 1982. [Google Scholar]

- Brans, J.; Vincke, P. A preference ranking organization method: The PROMETHEE method for MCDM. Manag. Sci. 1985, 31, 647–656. [Google Scholar] [CrossRef] [Green Version]

- Brans, B.; Mareschal, J.P. Promethee Methods: Multiple Criteria Decision Analysis: State of the Art Surveys; Springer: New York, NY, USA, 2005; Volume 78, pp. 163–186. [Google Scholar]

- Behzadian, M.; Kazemzadeh, R.; Albadvi, A.; Aghdasi, M. PROMETHEE: A comprehensive literature review on methodologies and applications. Eur. J. Oper. Res. 2010, 200, 198–215. [Google Scholar] [CrossRef]

- Anahas, A.M.P.; Muralitharan, G. Characterization of heterocystous cyanobacterial strains for biodiesel production based on fatty acid content analysis and hydrocarbon production. Energy Convers. Manag. 2018, 157, 423–437. [Google Scholar] [CrossRef]

- de Almeida-Filho, A.T.; Monte, M.; Morais, D.C. A Voting Approach Applied to Preventive Maintenance Management of a Water Supply System. Group Decis. Negot. 2016, 26, 523–546. [Google Scholar] [CrossRef]

- Andreopoulou, Z.; Koliouska, C.; Galariotis, E.; Zopounidis, C. Renewable energy sources: Using PROMETHEE II for ranking websites to support market opportunities. Technol. Forecast. Soc. Chang. 2018, 131, 31–37. [Google Scholar] [CrossRef]

- Kilic, H.S.; Zaim, S.; Delen, D. Selecting ‘the best’ ERP system for SMEs using a combination of ANP and PROMETHEE methods. Expert Syst. Appl. 2015, 42, 2343–2352. [Google Scholar] [CrossRef]

- Yilmaz, B.; Daǧdeviren, M. A combined approach for equipment selection: F-PROMETHEE method and zero-one goal programming. Expert Syst. Appl. 2011, 38, 11641–11650. [Google Scholar] [CrossRef]

- Albadvi, A.; Chaharsooghi, S.K.; Esfahanipour, A. Decision making in stock trading: An application of PROMETHEE. Eur. J. Oper. Res. 2007, 177, 673–683. [Google Scholar] [CrossRef]

- Lolli, F.; Ishizaka, A.; Gamberini, R.; Rimini, B.; Ferrari, A.M.; Marinelli, S.; Savazza, R. Waste treatment: An environmental, economic and social analysis with a new group fuzzy PROMETHEE approach. Clean Technol. Environ. Policy 2016, 18, 1317–1332. [Google Scholar] [CrossRef] [Green Version]

- Peng, A.-H.; Xiao, X.-M. Material selection using PROMETHEE combined with analytic network process under hybrid environment. Mater. Des. 2013, 47, 643–652. [Google Scholar] [CrossRef]

- Nemery, P.; Ishizaka, A.; Camargo, M.; Morel, L. Enriching descriptive information in ranking and sorting problems with visualizations techniques. J. Model. Manag. 2012, 7, 130–147. [Google Scholar] [CrossRef]

- Alencar, L.H.; de Almeida, A.T. A model for selecting project team members using multicriteria group decision making. Pesqui. Oper. 2010, 30, 221–236. [Google Scholar] [CrossRef]

- Brans, J.-P.; Mareschal, B. The PROMCALC & GAIA decision support system for multicriteria decision aid. Decis. Support Syst. 1994, 12, 297–310. [Google Scholar]

- .Lopes, A.P.F.; Muñoz, M.M.; Alarcón-Urbistondo, P. Regional tourism competitiveness using the PROMETHEE approach. Ann. Tour. Res. 2018, 73, 1–13. [Google Scholar] [CrossRef]

- Faizi, S.; Sałabun, W.; Nawaz, S.; Rehman, A.U.; Wątróbski, J. Best-Worst method and Hamacher aggregation operations for intuitionistic 2-tuple linguistic sets. Expert Syst. Appl. 2021, 181, 115088. [Google Scholar] [CrossRef]

- Tian, Z.-P.; Zhang, H.-Y.; Wang, J.-Q.; Wang, T.-L. Green Supplier Selection Using Improved TOPSIS and Best-Worst Method Under Intuitionistic Fuzzy Environment. Informatica 2018, 29, 773–800. [Google Scholar] [CrossRef] [Green Version]

- Shahroudi, K.; Tonekaboni, S.S. Application of topsis method to supplier selection in iran auto supply chain. J. Glob. Strat. Manag. 2012, 2, 123. [Google Scholar] [CrossRef]

- Rouyendegh, B.D.; Yildizbasi, A.; Üstünyer, P. Intuitionistic Fuzzy TOPSIS method for green supplier selection problem. Soft Comput. 2020, 24, 2215–2228. [Google Scholar] [CrossRef]

- Pınar, A.; Erdebilli, B.; Özdemir, Y. q-Rung Orthopair Fuzzy TOPSIS Method for Green Supplier Selection Problem. Sustainability 2021, 13, 985. [Google Scholar] [CrossRef]

- Taqi, H.M.M.; Ahmed, S. Fuzzy TOPSIS and Fuzzy ELECTRE-I Approach for Selecting the Best Suppliers by Multiple Criteria. Int. J. Appl. Fuzzy Sets Artif. Intell. 2018, 8, 155–173. [Google Scholar]

- Rani, P.; Mishra, A.R.; Krishan Kumar, R.; Mardani, A.; Cavallaro, F.; Ravichandran, K.S.; Balasubramanian, K. Hesitant Fuzzy SWARA-Complex Proportional Assessment Approach for Sustainable Supplier Selection (HF-SWARA-COPRAS). Symmetry 2020, 12, 1152. [Google Scholar] [CrossRef]

- Rajesh, G.; Malliga, P. Selection of suppliers using Swara and Copras-G. Int. J. Enterp. Netw. Manag. 2018, 9, 169–185. [Google Scholar] [CrossRef]

| Criteria | Description | Authors |

|---|---|---|

| ECONOMIC | ||

| Quality | The capability to offer products that conform to specifications, meet customer requirements and government regulations. It relates to the use of quality systems and continuous improvement programs, material and process control, maintenance and calibration, planning, and staff training. | [3,19,40,41,42,48,50,51,52,56,57] |

| Delivery | Refers to the duration of time from placing to receiving an order (lead time), on-time delivery (as per time scheduled), and delivery reliability. In addition, the delivery conditions are also important, that is, product presentation, cleanliness and packaging, and provision of the standard documentation required throughout the process. | [3,16,19,41,44,48,50,51,52,56,57,58] |

| Cost | Includes the costs of transportation, inventory, material, maintenance, labour, and other elements related to product manufacturing. Thus, this attribute considers the total estimated cost for each alternative.Can be represented by productivity. Higher productivity indicate a greater supply, cost, and production control ability, better operating management efficiency, and better customer acceptance. | [3,16,40,41,42,44,48,50,51,52,56,57,58] |

| Relationship | Concerns to the ability of the buyer and the supplier to complement each other’s capabilities in order to maintain a long-term partnership with few reliable suppliers. The ability to maintain a good communication channel and a long-term relationship buyer-supplier is essential and they can even present a differential advantage when selecting a supplier. | [19,40,41,42,51,57] |

| Facilities and capacity | Evaluates the capacity of the firm to provide specific solutions to achieve the technical requirements and the company’s desired specification. To this end, a proper infrastructure and resources, an undated assets maintenance (vehicles and equipment), and suitable work stations and physical location are required. | [3,40,44,50,51,57,58] |

| Service | Indicates the after-sales service level provided by the seller. It can include the supplier’s service level in terms of lead time, flexibility, and customer service. | [3,42,44,48,51,57] |

| Flexibility | Indicates the ability to adjust product volume, product mix, product characteristics, or manufacturing processes as demanded by the buyer, using existing machines or equipment. | [19,41] |

| Culture | Relates to the generation of trust, both within the organization and among members in the supply chain, and to the management attitude towards the supplier, which allows him/her to successfully face unexpected future events. | [19,41] |

| Geographical location | It indicates how far the supplier is located from the company. | [42,44,48,50] |

| Performance history | Previous experiences in providing the service can influence future firm performance. | [40,48,58] |

| Financial status | The supplier’s financial situation and stability and payment conditions are important factors to consider in this category. | [40,42,51,59] |

| Innovation | The capability of develop R&D activities in order to improve differentiation while reducing costs. Usually, a higher R&D expense on sales denotes stronger technology ability [57]. | [42,51] |

| ENVIRONMENTAL | The presence of environmental controls and programs that ensure environment-friendly product characteristics. Hamdan and Cheaitou [43] classify these factors into two groups: product-related and organization-related. The first group relates to the use of environment-friendly resources and materials, as well as advanced technologies for recycling materials, to produce environment-friendly items. The second group relates to awareness about the environmental issues pertaining to the operations, structure, and culture of the organization. It refers to the existence of policies that enable the vendor to follow environmental norms. | [19,41,43,44,51] |

| SOCIAL (safety) | The supplier’s concern about accidents, and the provision of a safe and healthy working environment. Security is one of the most important criteria, because accidents have a significant social, environmental, and financial impact. | [19,40,41,51] |

| f1 | f2 | … | fj | … | fk | |

|---|---|---|---|---|---|---|

| a1 | f1(a1) | f2(a1) | … | fj(a1) | … | fk(a1) |

| a2 | f1(a2) | f2(a2) | … | fj(a2) | … | fk(a2) |

| … | … | … | … | … | … | … |

| ai | f1(ai) | f2(ai) | … | fj(ai) | … | fk(ai) |

| … | … | … | … | … | … | … |

| an | f1(an) | f2(an) | … | fj(an) | … | fk(an) |

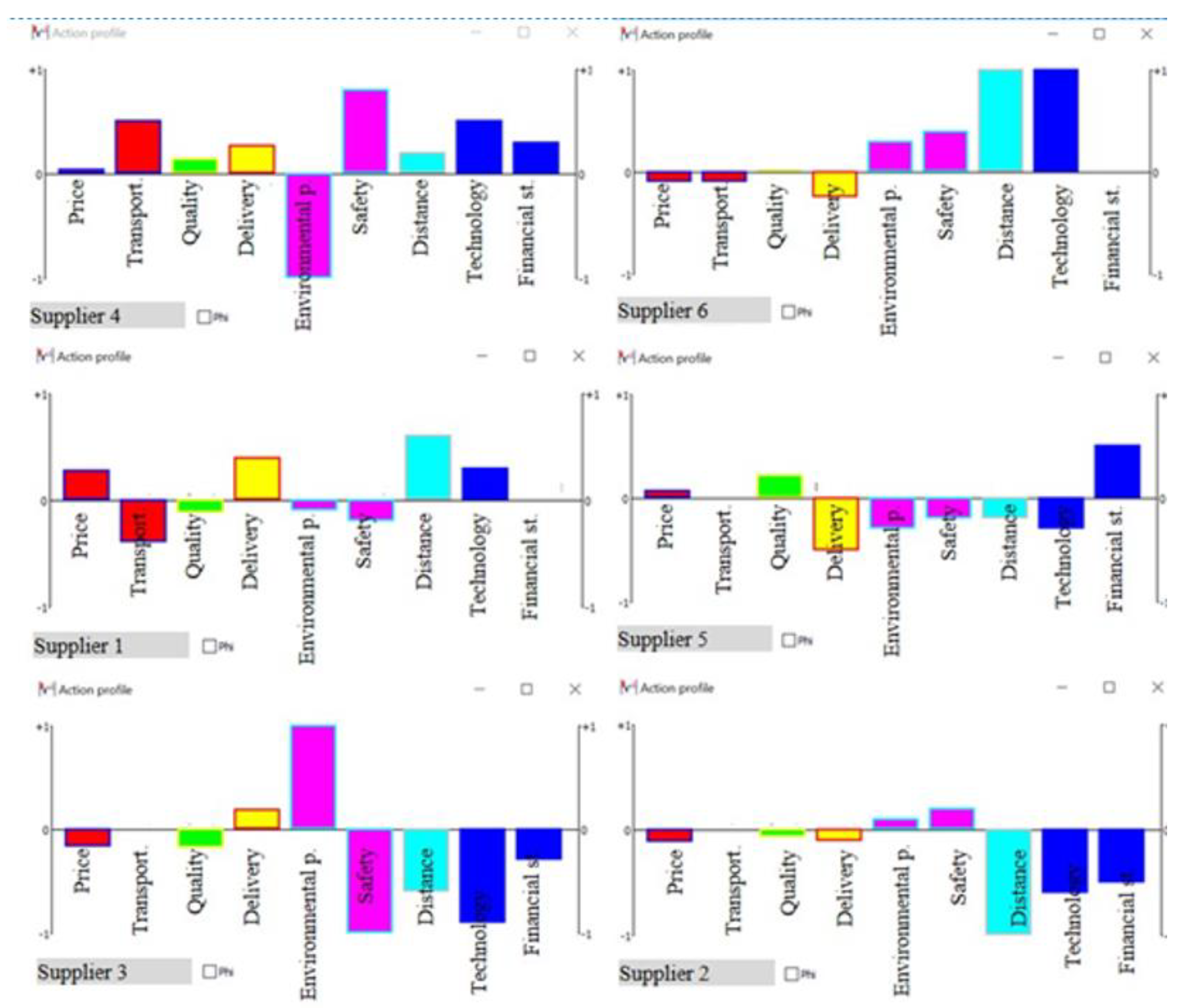

| Main Criteria | Indicator | Description |

|---|---|---|

| C1—Cost | C11—Product Price | Lower fresh fruit price without compromising the quality |

| C12—Transportation Cost | Fixed transportation cost of the fresh fruit | |

| C2—Quality | C21—Quality Assurance | Ensure superior quality control of the fruit, and provide quality related certificates such as ISO 9000 |

| C22—Reject Rate | The percentage of supplied fruit that is rejected by quality control | |

| C3—Delivery | C31—Delivery Capability | The ability of the supplier to fulfil the delivery schedule |

| C32—Order Fulfilment Rate | Conformity with the predefined order quantities | |

| C4—Protection | C41—Environmental Protection System | Environmental protection system specification, such as ISO 14001 (contributes to the environmental pillar of sustainability) |

| C42—Safety | Use of protective equipment, accidents record | |

| C5—Distance | C51—Road distance | Road distance between the supplier and the company |

| C6—Technology | C61—Technological capability | Related to product and process improvement; ownership of infrastructure for research and innovation |

| C7—Financial Position | C71—Financial Stability | Refers to financial stability and credit rating |

| E1 | E2 | E3 | E4 | E5 | E6 | Mean | |

|---|---|---|---|---|---|---|---|

| C11—Product Price | - | - | - | - | - | - | - |

| C12—Transportation Cost | 0.11 | 0.10 | 0.11 | 0.09 | 0.10 | 0.11 | 0.10 |

| C21—Quality Assurance | 0.21 | 0.18 | 0.19 | 0.20 | 0.20 | 0.19 | 0.20 |

| C22—Reject Rate | 0.07 | 0.07 | 0.06 | 0.06 | 0.07 | 0.08 | 0.07 |

| C31—Delivery Capability | 0.06 | 0.05 | 0.08 | 0.07 | 0.06 | 0.07 | 0.07 |

| C32—Order Fulfillment Rate | 0.07 | 0.06 | 0.07 | 0.05 | 0.05 | 0.07 | 0.06 |

| C41—Environmental Protection System | 0.04 | 0.03 | 0.05 | 0.04 | 0.03 | 0.03 | 0.04 |

| C42—Safety | 0.04 | 0.07 | 0.04 | 0.05 | 0.04 | 0.04 | 0.05 |

| C51—Road distance | 0.07 | 0.08 | 0.07 | 0.07 | 0.10 | 0.11 | 0.08 |

| C61—Technological capability | 0.02 | 0.04 | 0.04 | 0.04 | 0.03 | 0.02 | 0.03 |

| C71—Financial Stability | 0.12 | 0.11 | 0.09 | 0.12 | 0.12 | 0.10 | 0.11 |

| S1 | S2 | S3 | S4 | S5 | S6 | |

|---|---|---|---|---|---|---|

| C11—Product Price | - | - | - | - | - | - |

| C12—Transportation Cost | 3.6 | 4.2 | 4.1 | 4.8 | 4 | 3.9 |

| C21—Quality Assurance | 3.9 | 3.7 | 4 | 4.5 | 4.8 | 3.8 |

| C22—Reject Rate | 4 | 3.4 | 4.1 | 4.7 | 4.2 | 3.1 |

| C31—Delivery Capability | 4.1 | 3.6 | 3.9 | 4.5 | 3.3 | 3.6 |

| C32—Order Fulfilment Rate | 4.7 | 4 | 4.2 | 4 | 3.4 | 3.9 |

| C41—Environmental Protection System | 4 | 4.1 | 4.8 | 3.4 | 3.9 | 4.2 |

| C42—Safety | 3.8 | 3.9 | 2.7 | 4.1 | 3.8 | 4 |

| C51—Road distance | 3.1 | 4.9 | 4.6 | 3.8 | 4.2 | 2.7 |

| C61—Technological | 3.7 | 3.2 | 3.1 | 3.8 | 3.4 | 4.2 |

| C71—Financial Stability | 4 | 3.3 | 3.8 | 4.1 | 4.5 | 4 |

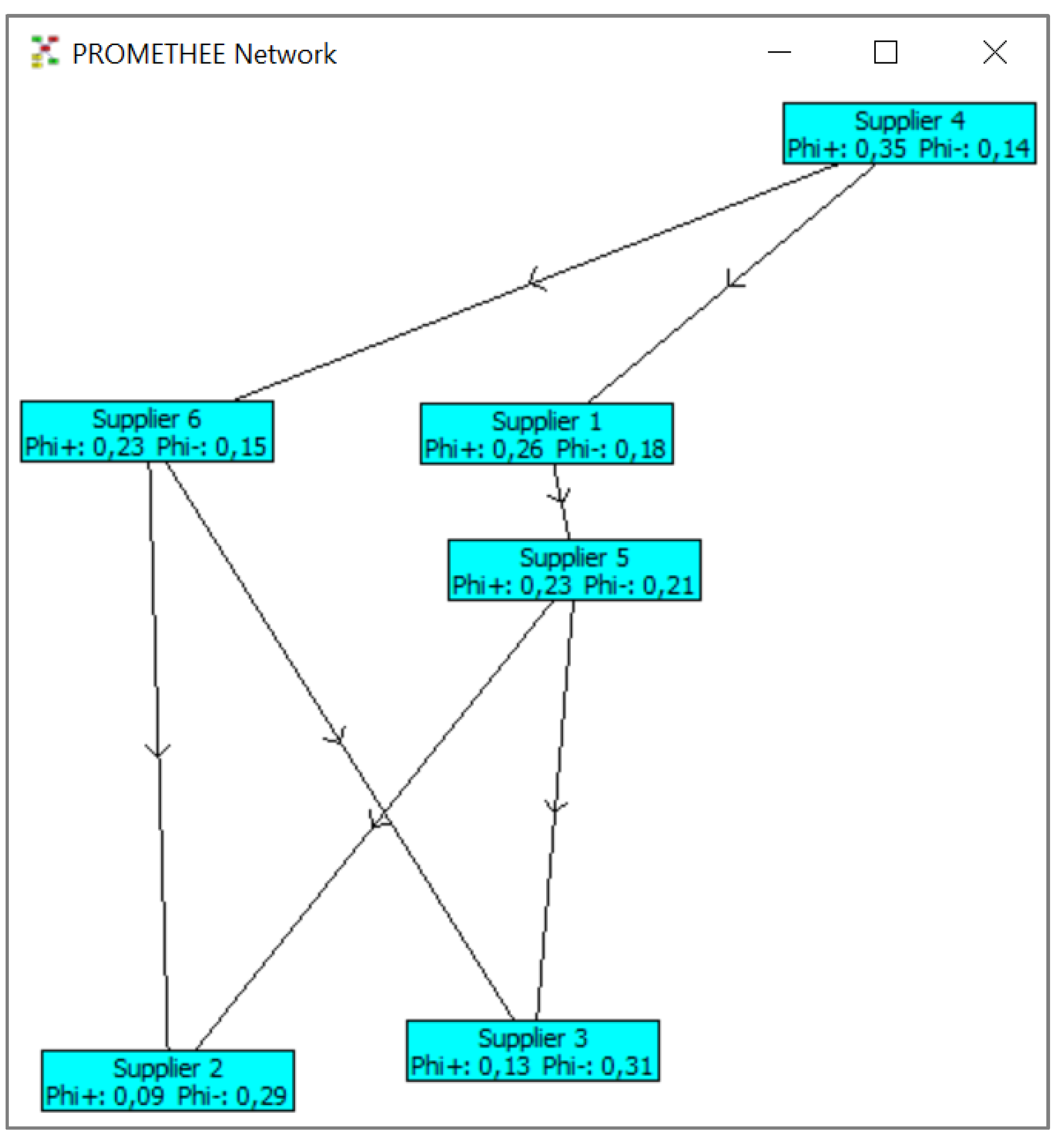

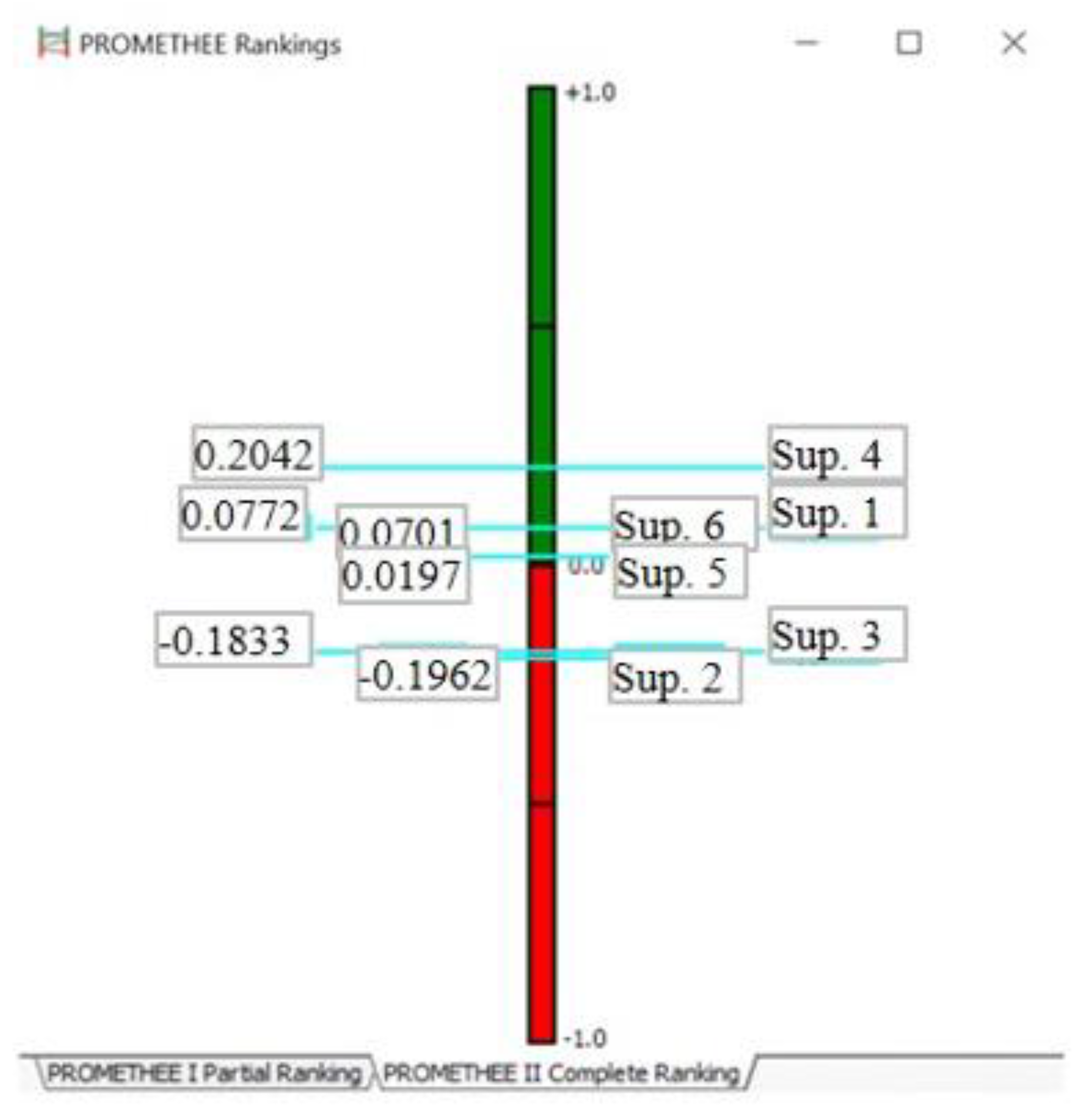

| Rank | Actions | Net Flow (Phi) | Positive Flow (Phi+) | Negative Flow (Phi−) |

|---|---|---|---|---|

| 1 | Supplier 4 (S4) | 0.2042 | 0.3464 | 0.1423 |

| 2 | Supplier 6 (S6) | 0.0784 | 0.2295 | 0.1512 |

| 3 | Supplier 1 (S1) | 0.0772 | 0.2572 | 0.1800 |

| 4 | Supplier 5 (S5) | 0.0197 | 0.2305 | 0.2107 |

| 5 | Supplier 3 (S3) | −0.1833 | 0.1260 | 0.3093 |

| 6 | Supplier 2 (S2) | −0.1962 | 0.0937 | 0.2898 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lopes, A.P.; Rodriguez-Lopez, N. A Decision Support Tool for Supplier Evaluation and Selection. Sustainability 2021, 13, 12387. https://doi.org/10.3390/su132212387

Lopes AP, Rodriguez-Lopez N. A Decision Support Tool for Supplier Evaluation and Selection. Sustainability. 2021; 13(22):12387. https://doi.org/10.3390/su132212387

Chicago/Turabian StyleLopes, Ana Paula, and Nuria Rodriguez-Lopez. 2021. "A Decision Support Tool for Supplier Evaluation and Selection" Sustainability 13, no. 22: 12387. https://doi.org/10.3390/su132212387

APA StyleLopes, A. P., & Rodriguez-Lopez, N. (2021). A Decision Support Tool for Supplier Evaluation and Selection. Sustainability, 13(22), 12387. https://doi.org/10.3390/su132212387