An AHP-Based Procedure for Model Selection for Eco-Efficiency Assessment

Abstract

1. Introduction

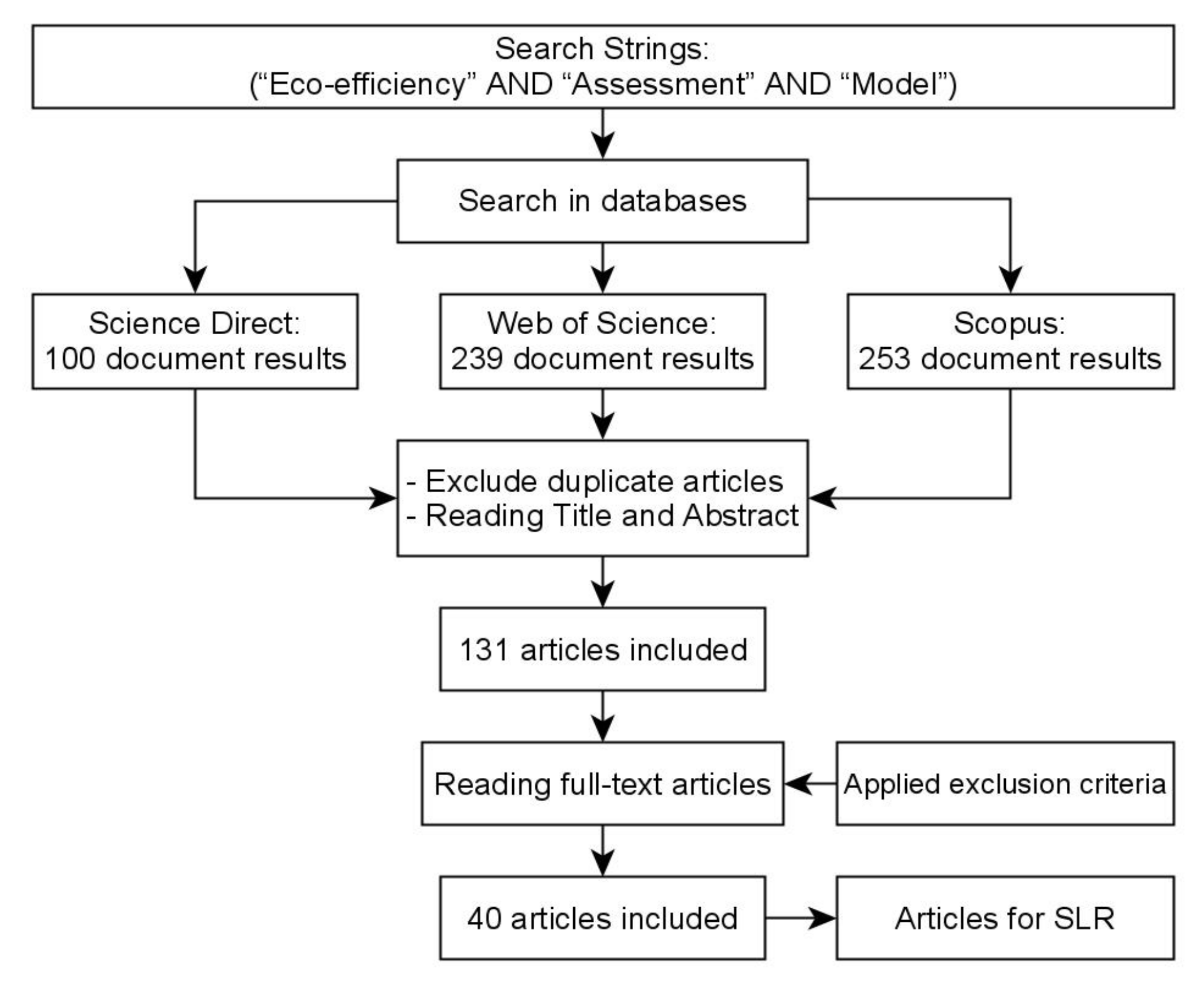

2. Eco-Efficiency

3. Systematic Literature Review (SLR) Methodology and Procedures

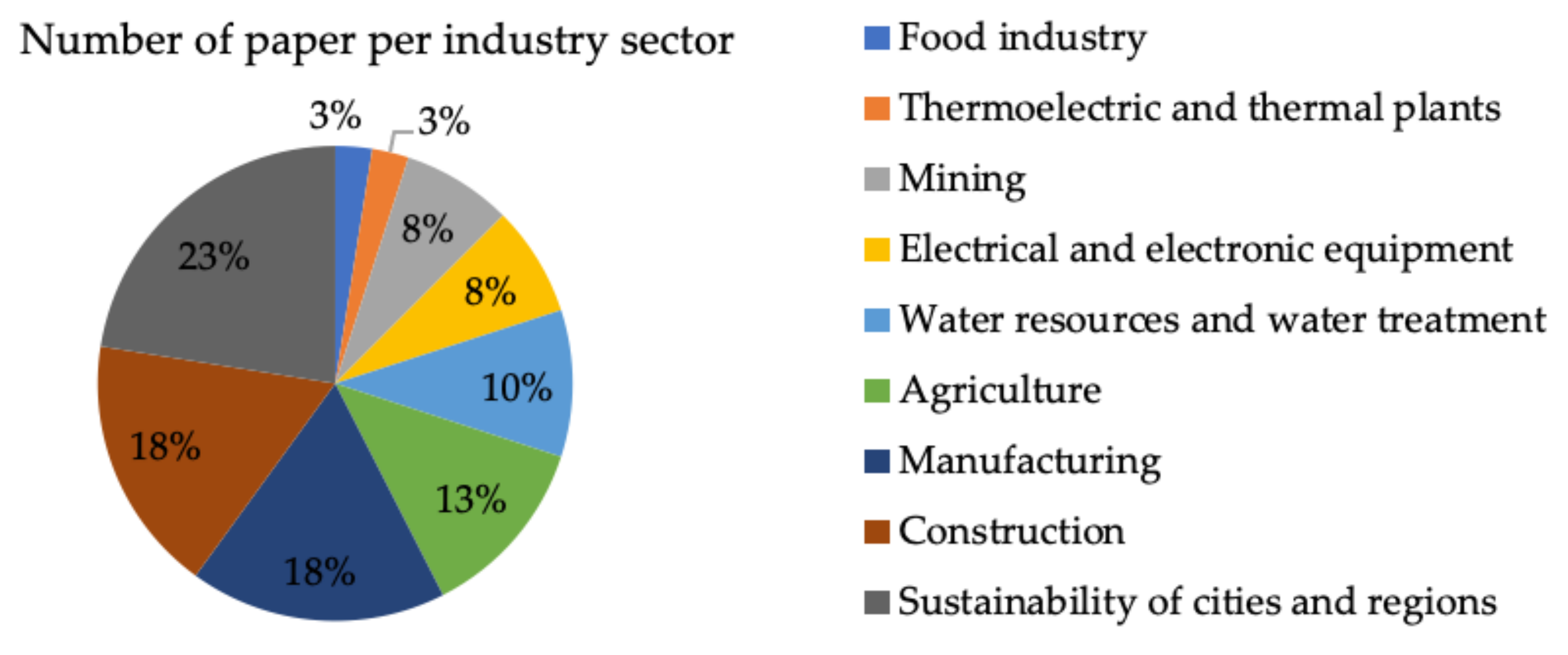

4. Analysis of Eco-Efficiency Assessment Models

Discussion of Eco-Efficiency Assessment Models

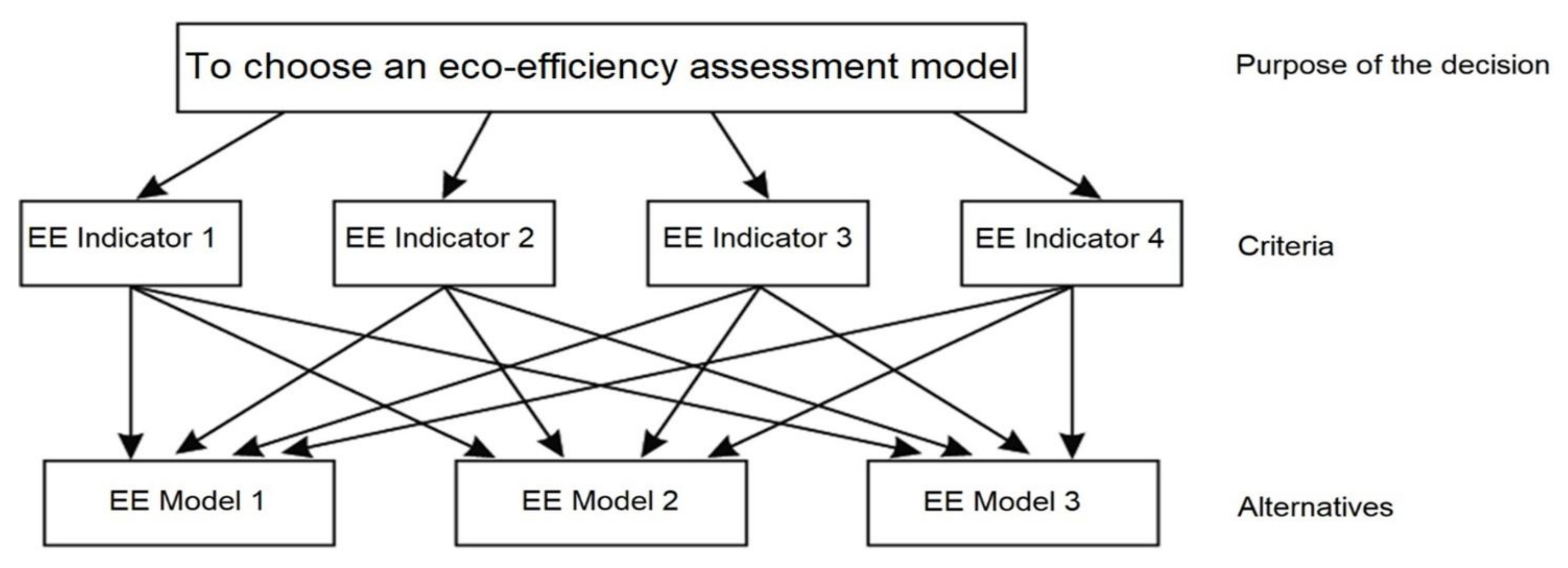

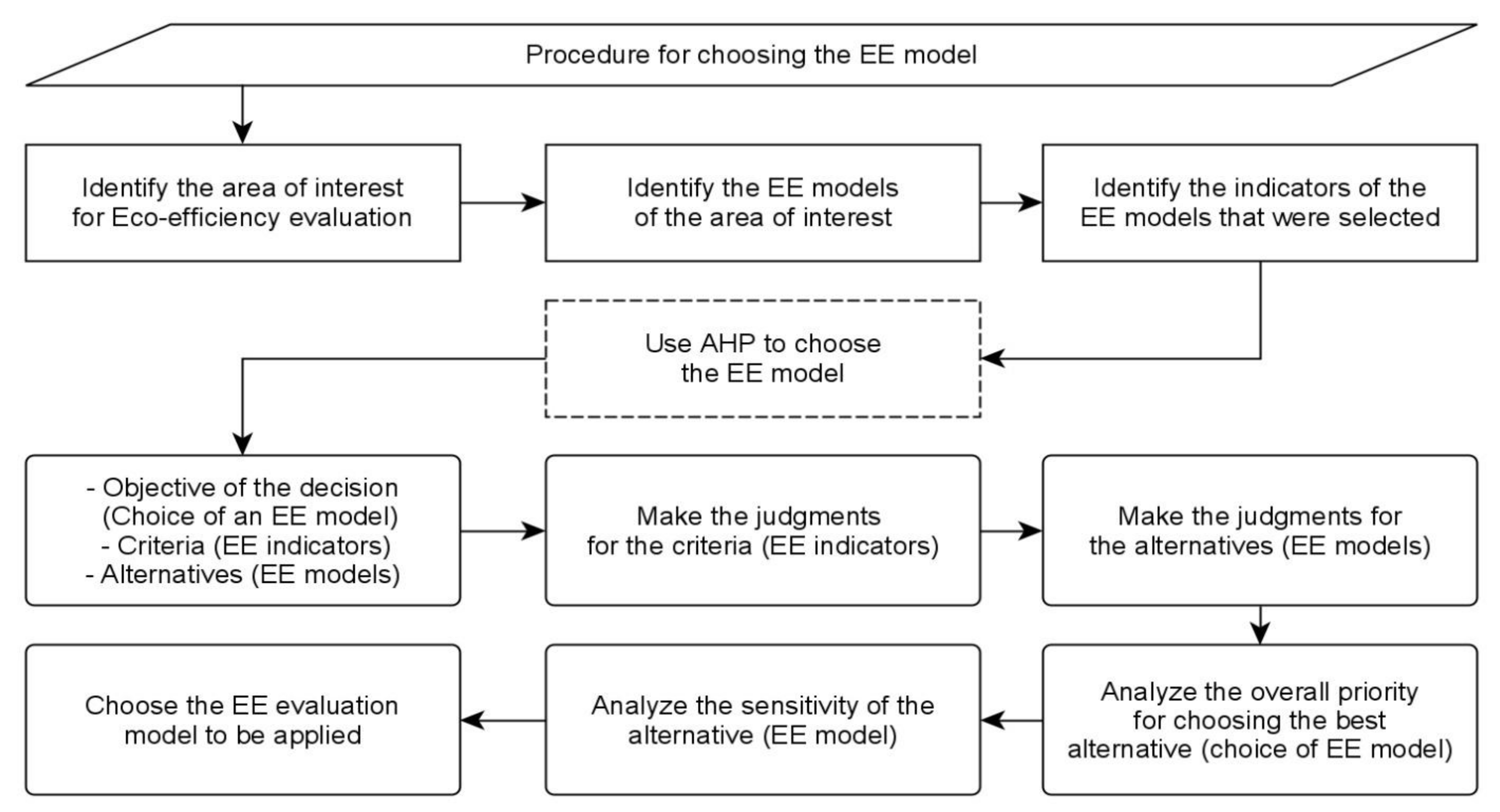

5. AHP-Based Procedure for Selecting an Appropriate Eco-Efficiency Model

5.1. Fundamentals of Analytic Hierarchy Process—AHP

- i.

- Developing a decision model: decision is structured into a hierarchy of objectives, criteria and alternatives;

- ii.

- Derive the priorities (weights) for the established criteria: in this step, the importance of the criteria is made by a pair comparison of criteria to derive their weights. The consistency of the judgments provided by experts is quantified so as to review the judgments and ensure that a reasonable level of consistency with respect to proportionality and transitivity is met;

- iii.

- Derive the local priorities (preferences) for the alternatives: at this point, the derivation of the priorities or the alternatives in relation to each criterion separately is done (this process is like the previous step, since the comparison of the alternatives in pairs with respect to each criterion should be performed). Then, consistency is checked and adjusted when necessary;

- iv.

- Derive the general priorities (this is the model’s synthesis): in this step, all priorities of the alternatives obtained must be combined as a weighted sum, considering the weight of each criterion and establishing the general priorities of the alternatives. By this analysis, the alternative that presents the highest overall priority is considered as the best choice;

- v.

- Sensitivity analysis: a study is conducted to analyze how changes in the weights of the criteria can affect the result. The sensitivity analysis allows us to understand the reason that led to the results obtained;

- vi.

- Final decision making: decision-making is based on the results of the model synthesis and the sensitivity analysis.

5.2. Applying AHP for Selecting the Appropriate Eco-Efficiency Model

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Taheri, K.; Gadow, R.; Killinger, A. Exergy Analysis as a Developed Concept of Energy Efficiency Optimized Processes: The Case of Thermal Spray Processes. Procedia CIRP 2014, 17, 511–516. [Google Scholar] [CrossRef]

- Bidoki, S.M.; Wittlinger, R.; Alamdar, A.A.; Burger, J. Eco-efficiency analysis of textile coating materials. J. Iran. Chem. Soc. 2006, 3, 351–359. [Google Scholar] [CrossRef]

- Saling, P.; Kicherer, A.; Dittrich-Krämer, B.; Wittlinger, R.; Zombik, W.; Schmidt, I.; Schrott, W.; Schmidt, S. Eco-efficiency analysis by basf: The method. Int. J. Life Cycle Assess. 2002, 7, 203–218. [Google Scholar] [CrossRef]

- Uhlman, B.W.; Saling, P. Measuring and communicating sustainability through Eco-efficiency analysis. Chem. Eng. Prog. 2010, 106, 12. [Google Scholar]

- Bradlee, C.A.; Saling, P.; Uhlman, B. Submission for NSF Protocol P352 Validation and Verification of Eco-efficiency Analyses, Part A. BASF’s Eco-Effic. Anal. Methodol. 2009, 1, 1–38. [Google Scholar]

- Wall-Markowski, C.A.; Kicherer, A.; Wittlinger, R. Eco-efficiency: Inside BASF and beyond. Manag. Environ. Qual. An Int. J. 2005, 16, 2. [Google Scholar]

- Lozano, F.J.; Lozano, R. Assessing the potential sustainability benefits of agricultural residues: Biomass conversion to syngas for energy generation or to chemicals production. J. Clean. Prod. 2018, 172, 4162–4169. [Google Scholar] [CrossRef]

- Suter, G.W. Multi-Criteria Decision Analysis: Environmental Applications and Case Studies; CRC Press: Boca Raton, FL, USA, 2011. [Google Scholar]

- Talukder, B.; Blay-Palmer, A.; Hipel, K.W.; VanLoon, G.W. Elimination Method of Multi-Criteria Decision Analysis (MCDA): A Simple Methodological Approach for Assessing Agricultural Sustainability. Sustainability 2017, 9, 287. [Google Scholar] [CrossRef]

- Van Caneghem, J.; Block, C.; Cramm, P.; Mortier, R.; Vandecasteele, C. Improving eco-efficiency in the steel industry: The ArcelorMittal Gent case. J. Clean. Prod. 2010, 18, 807–814. [Google Scholar] [CrossRef]

- Xu, T.; Gao, P.; Yu, Q.; Fang, D. An Improved Eco-Efficiency Analysis Framework Based on Slacks-Based Measure Method. Sustainability 2017, 9, 952. [Google Scholar] [CrossRef]

- Zhou, C.; Shi, C.; Wang, S.; Zhang, G. Estimation of eco-efficiency and its influencing factors in Guangdong province based on Super-SBM and panel regression models. Ecol. Indic. 2018, 86, 67–80. [Google Scholar] [CrossRef]

- Wang, C.-N.; Hsu, H.-P.; Wang, Y.-H.; Nguyen, T.-T. Eco-Efficiency Assessment for Some European Countries Using Slacks-Based Measure Data Envelopment Analysis. Appl. Sci. 2020, 10, 1760. [Google Scholar] [CrossRef]

- Mokarram, M.; Mokarram, M.J.; Gitizadeh, M.; Niknam, T.; Aghaei, J. A novel optimal placing of solar farms utilizing multi-criteria decision-making (MCDA) and feature selection. J. Clean. Prod. 2020, 261, 121098. [Google Scholar] [CrossRef]

- Sarraf, R.; McGuire, M.P. Integration and comparison of multi-criteria decision making methods in safe route planner. Expert Syst. Appl. 2020, 154, 113399. [Google Scholar] [CrossRef]

- Oliveira, M.; Fontes, D.; Pereira, T. Multicriteria Decision Making: A Case Study in the Automobile Industry. Ann. Manag. Sci. 2014, 3, 109–128. [Google Scholar] [CrossRef]

- Ferrari, S.; Zagarella, F.; Caputo, P.; Bonomolo, M. Assessment of tools for urban energy planning. Energy 2019, 176, 544–551. [Google Scholar] [CrossRef]

- Vakilipour, S.; Sadeghi-Niaraki, A.; Ghodousi, M.; Choi, S.-M. Comparison between Multi-Criteria Decision-Making Methods and Evaluating the Quality of Life at Different Spatial Levels. Sustainability 2021, 13, 4067. [Google Scholar] [CrossRef]

- Council for Sustainable Development (WBCSD). Measuring eco-efficiency: A guide to reporting company performance WBCSD. 2000, pp. 1–39. Available online: https://www.gdrc.org/sustbiz/measuring.pdf (accessed on 30 September 2021).

- WBCSD. Introduction to the learning module WBCSD. 2006, pp. 1–231. Available online: https://docs.wbcsd.org/2006/08/EfficiencyLearningModule.pdf (accessed on 30 September 2021).

- Zhang, B.; Bi, J.; Fan, Z.; Yuan, Z.; Ge, J. Eco-efficiency analysis of industrial system in China: A data envelopment analysis approach. Ecol. Econ. 2008, 68, 306–316. [Google Scholar] [CrossRef]

- Diebold, W.; Schmidheiny, S. Changing Course: A Global Business Perspective on Development and the Environment. Foreign Aff. 1992, 71, 202. [Google Scholar] [CrossRef][Green Version]

- Lozano, S.; Adenso-Diaz, B.; Barba-Gutiérrez, Y. Russell non-radial eco-efficiency measure and scale elasticity of a sample of electric/electronic products. J. Frankl. Inst. 2011, 348, 1605–1614. [Google Scholar] [CrossRef]

- Lucato, W.C.; Júnior, M.V.; Santos, J.C.D.S. Measuring the ecoefficiency of a manufacturing process: A conceptual proposal. Manag. Environ. Qual. Int. J. 2013, 24, 755–770. [Google Scholar] [CrossRef]

- Masternak-Janus, A.; Rybaczewska-Błażejowska, M. Comprehensive Regional Eco-Efficiency Analysis Based on Data Envelopment Analysis: The Case of Polish Regions. J. Ind. Ecol. 2016, 21, 180–190. [Google Scholar] [CrossRef]

- Koskela, M.; Vehmas, J. Defining Eco-efficiency: A Case Study on the Finnish Forest Industry. Bus. Strat. Environ. 2012, 21, 546–566. [Google Scholar] [CrossRef]

- Kitchenham, B. Guidelines for performing systematic literature reviews in software engineering. Tech. Rep. EBSE 2007, 1, 1–65. [Google Scholar]

- Brereton, P.; Kitchenham, B.; Budgen, D.; Turner, M.; Khalil, M. Lessons from applying the systematic literature review process within the software engineering domain. J. Syst. Softw. 2006, 80, 571–583. [Google Scholar] [CrossRef]

- Fabbri, S.; Silva, C.; Hernandes, E.M.; Octaviano, F.; Di Thommazo, A.; Belgamo, A. Improvements in the StArt tool to better support the systematic review process. ACM Int. Conf. Proceeding Ser. 2016, 21, 5. [Google Scholar] [CrossRef]

- Yang, L.; Zhang, X. Assessing regional eco-efficiency from the perspective of resource, environmental and economic performance in China: A bootstrapping approach in global data envelopment analysis. J. Clean. Prod. 2018, 173, 100–111. [Google Scholar] [CrossRef]

- Kuosmanen, T.; Kortelainen, M. Measuring Eco-efficiency of Production with Data Envelopment Analysis. J. Ind. Ecol. 2005, 9, 59–72. [Google Scholar] [CrossRef]

- Lorenzo-Toja, Y.; Vázquez-Rowe, I.; Chenel, S.; Marín, D.; Moreira, M.T.; Feijoo, G. Eco-efficiency analysis of Spanish WWTPs using the LCA + DEA method. Water Res. 2015, 68, 651–666. [Google Scholar] [CrossRef]

- Gutiérrez, Y.B.; Adenso-Díaz, B.; Lozano, S. Eco-Efficiency of Electric and Electronic Appliances: A Data Envelopment Analysis (DEA). Environ. Model. Assess. 2008, 14, 439–447. [Google Scholar] [CrossRef]

- Kondo, Y.; Nakamura, S. Waste input–output linear programming model with its application to eco-efficiency analysis. Econ. Syst. Res. 2005, 17, 393–408. [Google Scholar] [CrossRef]

- Tatari, O.; Kucukvar, M. Evaluating Eco-Efficiency of Construction Materials: A Frontier Approach. Congr. Comput. Civ. Eng. Proc. 2011, 736–743. [Google Scholar] [CrossRef]

- Tatari, O.; Kucukvar, M. Eco-Efficiency of Construction Materials: Data Envelopment Analysis. J. Constr. Eng. Manag. 2012, 138, 733–741. [Google Scholar] [CrossRef]

- Hamid, M.S.A.; Shafiq, N. Eco-efficiency index model for reinforced concrete structural design: Malaysia case study. ARPN J. Eng. Appl. Sci. 2016, 11, 8. [Google Scholar]

- Kim, T.; Tae, S.; Chae, C.U.; Lee, K. Proposal for the Evaluation of Eco-Efficient Concrete. Sustainability 2016, 8, 705. [Google Scholar] [CrossRef]

- Perera, P.; Hewage, K.; Alarti, M.S.; Sadiq, R. Eco-efficiency analysis of recycled material for residential construction: A case study of Okanagan (BC). In Proceedings of the 6th CSCE-CRC International Construction Specialty Conference 2017-Held as Part of the Canadian Society for Civil Engineering Annual Conference and General Meeting 2017, Vancouver, BC, Canada, 31 May–3 June 2017; Volume 1. [Google Scholar]

- Hu, X.; Liu, C. Slacks-based data envelopment analysis for eco-efficiency assessment in the Australian construction industry. Constr. Manag. Econ. 2017, 35, 11–12. [Google Scholar]

- Belucio, M.; Rodrigues, C.; Antunes, C.H.; Freire, F.; Dias, L.C. Eco-efficiency in early design decisions: A multimethodology approach. J. Clean. Prod. 2020, 283, 124630. [Google Scholar] [CrossRef]

- Liu, Y.; Sun, C.; Xu, S. Eco-Efficiency Assessment of Water Systems in China. Water Resour. Manag. 2013, 27, 4927–4939. [Google Scholar] [CrossRef]

- Mehmeti, A.; Todorovic, M.; Scardigno, A. Assessing the eco-efficiency improvements of Sinistra Ofanto irrigation scheme. J. Clean. Prod. 2016, 138, 208–216. [Google Scholar] [CrossRef]

- Molinos-Senante, M.; Gémar, G.; Gómez, T.; Caballero, R.; Sala-Garrido, R. Eco-efficiency assessment of wastewater treatment plants using a weighted Russell directional distance model. J. Clean. Prod. 2016, 137, 1066–1075. [Google Scholar] [CrossRef]

- Gómez, T.; Gémar, G.; Molinos-Senante, M.; Sala-Garrido, R.; Caballero, R. Measuring the eco-efficiency of wastewater treatment plants under data uncertainty. J. Environ. Manag. 2018, 226, 484–492. [Google Scholar] [CrossRef]

- Sanjuan, N.; Ribal, J.; Clemente, G.; Fenollosa, M.L. Measuring and Improving Eco-efficiency Using Data Envelopment Analysis: A Case Study of Mahón-Menorca Cheese. J. Ind. Ecol. 2011, 15, 4. [Google Scholar]

- Hengen, T.J.; Sieverding, H.L.; Cole, N.A.; Ham, J.M.; Stone, J.J. Eco-Efficiency Model for Evaluating Feedlot Rations in the Great Plains, United States. J. Environ. Qual. 2016, 45, 4. [Google Scholar]

- Mendoza, J.M.F.; D’Aponte, F.; Gualtieri, D.; Azapagic, A. Disposable baby diapers: Life cycle costs, eco-efficiency and circular economy. J. Clean. Prod. 2019, 211, 455–467. [Google Scholar]

- Rebolledo-Leiva, R.; Angulo-Meza, L.; Iriarte, A.; González-Araya, M.C.; Vásquez-Ibarra, L. Comparing two CF+DEA methods for assessing eco-efficiency from theoretical and practical points of view. Sci. Total. Environ. 2018, 659, 1266–1282. [Google Scholar] [CrossRef]

- Vukelic, D.; Agarski, B.; Budak, I.; Simunovic, G.; Buchmeister, B.; Jakovljevic, Z.; Tadic, B. Eco-Design of Fixtures Based on Life Cycle and Cost Assessment. Int. J. Simul. Model. 2019, 18, 72–85. [Google Scholar] [CrossRef]

- ISO. 14040: Environmental management–life cycle assessment—Principles and framework. Int. Organ. Stand. 2006, 3, 28. [Google Scholar]

- Finnveden, G.; Hauschild, M.Z.; Ekvall, T.; Guinée, J.; Heijungs, R.; Hellweg, S.; Koehler, A.; Pennington, D.; Suh, S. Recent developments in Life Cycle Assessment. J. Environ. Manag. 2009, 91, 1–21. [Google Scholar] [CrossRef]

- Yin, K.; Wang, R.; An, Q.; Yao, L.; Liang, J. Using eco-efficiency as an indicator for sustainable urban development: A case study of Chinese provincial capital cities. Ecol. Indic. 2014, 36, 665–671. [Google Scholar] [CrossRef]

- Zhang, X. Estimation of eco-efficiency and identification of its influencing factors in China’s Yangtze River Delta urban agglomerations. Growth Chang. 2020, 51, 2. [Google Scholar]

- Banker, R.D.; Charnes, A.; Cooper, W.W. Some Models for Estimating Technical and Scale Inefficiencies in Data Envelopment Analysis. Manag. Sci. 1984, 30, 9. [Google Scholar]

- Rybaczewska-Błażejowska, M.; Masternak-Janus, A. Eco-efficiency assessment of Polish regions: Joint application of life cycle assessment and data envelopment analysis. J. Clean. Prod. 2018, 172, 1180–1192. [Google Scholar] [CrossRef]

- Czaplicka-Kolarz, K.; Burchart-Korol, D.; Turek, M.; Borkowski, W. Model of Eco-Efficiency Assessment of Mining Production Processes. Arch. Min. Sci. 2015, 60, 2. [Google Scholar]

- Oliveira, R.; Camanho, A.; Zanella, A. Eco-efficiency assessment at firm level: An application to the mining sector. In Operations Research and Big Data: IO2015-XVII Congress of Portuguese Association of Operational Research (APDIO); Springer: Berlin/Heidelberg, Germany, 2015; Volume 15. [Google Scholar]

- Oliveira, R.; Camanho, A.; Zanella, A. Expanded eco-efficiency assessment of large mining firms. J. Clean. Prod. 2017, 142, 2364–2373. [Google Scholar] [CrossRef]

- Zhong, F.; Jiang, D.; Zhao, Q.; Guo, A.; Ullah, A.; Yang, X.; Cheng, Q.; Zhang, Y.; Ding, X. Eco-efficiency of oasis seed maize production in an arid region, Northwest China. J. Clean. Prod. 2020, 268, 122220. [Google Scholar]

- Cheng, C.Y.; Ren, J.M.; Wang, R.S.; Liu, F. Eco-Efficiency Assessment of Farming Activity in China. Adv. Mater. Res. 2011, 361-363, 1776–1779. [Google Scholar] [CrossRef]

- Charnes, A.; Cooper, W.W.; Rhodes, E. Measuring the efficiency of decision making units. Eur. J. Oper. Res. 1978, 2, 429–444. [Google Scholar] [CrossRef]

- Masuda, K. Optimization Model for Mitigating Global Warming at the Farm Scale: An Application to Japanese Rice Farms. Sustainability 2016, 8, 593. [Google Scholar] [CrossRef]

- Song, J.; Chen, X. Eco-efficiency of grain production in China based on water footprints: A stochastic frontier approach. J. Clean. Prod. 2019, 236. (accessed on 30 September 2021). [Google Scholar] [CrossRef]

- Gumus, S.; Egilmez, G.; Kucukvar, M.; Park, Y.S. Integrating expert weighting and multi-criteria decision making into eco-efficiency analysis: The case of US manufacturing. J. Oper. Res. Soc. 2016, 67, 616–628. [Google Scholar] [CrossRef]

- Zheng, J.; Peng, X. Does an Ecological Industry Chain Improve the Eco-Efficiency of an Industrial Cluster? Based on Empirical Study of an Energy-Intensive Industrial Cluster in China. Sustainability 2019, 11, 1651. [Google Scholar] [CrossRef]

- Ng, R.; Nai, S.; Chan, H.L.I.; Shi, C.W.P.; Song, B. Comparative Eco-efficiency Analyses of Copper to Copper Bonding Technologies. Procedia CIRP 2014, 15, 96–104. [Google Scholar] [CrossRef]

- Leme, R.D.; Nunes, A.O.; Costa, L.B.M.; Silva, D.A.L. Creating value with less impact: Lean, green and eco-efficiency in a metalworking industry towards a cleaner production. J. Clean. Prod. 2018, 196, 517–534. [Google Scholar] [CrossRef]

- Guo, Y.; Liu, W.; Tian, J.; He, R.; Chen, L. Eco-efficiency assessment of coal-fired combined heat and power plants in Chinese eco-industrial parks. J. Clean. Prod. 2017, 168, 963–972. [Google Scholar] [CrossRef]

- Xu, T.; Chen, Y. Eco-efficiency assessment of Wuhan based on data envelopment analysis approach. In Proceedings of the 2015 27th Chinese Control and Decision Conference CCDC, Qingdao, China, 23–25 May 2015. [Google Scholar]

- He, J.; Wan, Y.; Feng, L.; Ai, J.; Wang, Y. An integrated data envelopment analysis and emergy-based ecological footprint methodology in evaluating sustainable development, a case study of Jiangsu Province, China. Ecol. Indic. 2016, 70, 23–34. [Google Scholar]

- Karayalcin, I.I. The analytic hierarchy process: Planning, priority setting, resource allocation. Eur. J. Oper. Res. 1982, 9, 1. [Google Scholar]

- Wang, J.J.; Jing, Y.Y.; Zhang, C.F.; Zhao, J.H. Review on multi-criteria decision analysis aid in sustainable energy decision-making. Renew. Sustain. Energy Rev. 2009, 13, 9. [Google Scholar]

- Ge, Y. Research on green suppliers’ evaluation based on AHP & genetic algorithm. In Proceedings of the 2009 International Conference on Signal Processing Systems, Singapore, 15–17 May 2009. [Google Scholar]

- Sadok, W.; Angevin, F.; Bergez, J.; Bockstaller, C.; Colomb, B.; Guichard, L.; Reau, R.; Doré, T. Ex ante assessment of the sustainability of alternative cropping systems: Implications for using multi-criteria decision-aid methods. A review. Agron. Sustain. Dev. 2008, 28, 163–174. [Google Scholar] [CrossRef]

- Macharis, C.; Springael, J.; de Brucker, K.; Verbeke, A. PROMETHEE and AHP: The design of operational synergies in multicriteria analysis. Eur. J. Oper. Res. 2004, 153, 2. [Google Scholar]

- Jamwal, A.; Agrawal, R.; Sharma, M.; Kumar, V. Review on multi-criteria decision analysis in sustainable manufacturing decision making. Int. J. Sustain. Eng. 2020, 14, 202–225. [Google Scholar] [CrossRef]

- Kurttila, M.; Pesonen, M.; Kangas, J.; Kajanus, M. Utilizing the analytic hierarchy process (AHP) in SWOT analysis—A hybrid method and its application to a forest-certification case. For. Policy Econ. 2000, 1, 41–52. [Google Scholar] [CrossRef]

- Mu, E.; Pereyra-Rojas, M. Practical Decision Making using Super Decisions v3. 2018. In An Introduction to the Analytic Hierarchy Process; Springer: Berlin/Heidelberg, Germany. [CrossRef]

- Saaty, T.; Vargas, L. Models, Methods, Concepts & Applications of the Analytic Hierarchy Process; Springer: Boston, MA, USA, 2012. [Google Scholar]

- Labib, A. Introduction to the Analytic Hierarchy Process. In Learning from Failures; Elsevier: Amsterdam, The Netherlands, 2014; pp. 33–44. [Google Scholar] [CrossRef]

| Aspects for Article Selection | |

|---|---|

| Database | Scopus, Web of Science, Science Direct |

| Search strings used | “Eco-efficiency” AND “Assessment” AND “Model” |

| Research fields | Article title, abstract and keyword |

| Language | English |

| Publication date range | No limit was set for the date range |

| Exclusion Criteria |

|

| Application Sector | Product/Process/Service | Author/Year | Model for EE Evaluation |

|---|---|---|---|

| Electrical and electronic equipment | Product | Barba-Gutierrez; Adenso-Diaz; Lozano (2009) [33] | DEA |

| Product | Lozano et al. (2011) [23] | DEA | |

| Process/Service | Kondo and Nakamura (2006) [34] | WIO-LP | |

| Civil construction | Product | Tatari and Kucukvar (2011) [35] | DEA |

| Product | Tatari and Kucukvar (2012) [36] | DEA | |

| Product/Service | Hu and Liu (2017) [40] | DEA | |

| Product | Hamid and Shafiq (2016) [37] | Economic Score/Environmental Score | |

| Product | Kim et al. (2016) [38] | (EC + MC) /SL | |

| Product | Perera et al. (2017) [39] | Economic Score/Environmental Score | |

| Product/Service | Belucio et al. (2021) [41] | DEA | |

| Water resources and water treatment | Process/Service | Gómez et al. (2018) [45] | DEA |

| Process/Service | Molinos-Senante et al. (2016) [44] | DEA | |

| Food industry | Process | Sanjuan et al. (2011) [46] | Economic Score/Environmental Score |

| Farming | Product/Process | Hengen et al. (2016) [47] | Economic Score/Environmental Score |

| Process/Service | Rebolledo-Leiva et al. (2019) [49] | DEA | |

| Process | Zhong et al. (2020) [60] | DEA | |

| Process/Service | Cheng et al. (2012) [61] | DEA | |

| Service | Song; Chen (2019) [64] | SFA | |

| Process/Service | Masuda (2016) [63] | LP-linear programming | |

| Thermoelectric and thermal power plants | Process/Service | Guo et al. (2017) [69] | DEA-SBM |

| Sustainability of cities and regions | Product/Process/Service | Xu et al. (2017) [11] | DEA |

| Product/Process/Service | Zhou et al. (2018) [12] | DEA | |

| Product/Process/Service | Wang et al. (2020) [13] | DEA | |

| Product/Process/Service | Xu and Chen (2015) [70] | DEA | |

| Product/Process/Service | Yang and Zhang (2018) [30] | DEA | |

| Product/Process/Service | Yin et al. (2014) [53] | DEA | |

| Product/Process/Service | He et al. (2016) [71] | DEA | |

| Product/Process/Service | Zhang (2020) [54] | DEA | |

| Product/Process/Service | Masternak-Janus and Rybaczewska-Błażejowska (2016) [25] | DEA | |

| Product/Process/Service | Rybaczewska-Błażejowska and Masternak-Janus (2018) [56] | DEA | |

| Mining | Process | Czaplicka-Kolarz et al. (2015) [57] | EBIT/LCA |

| Service | Oliveira et al. (2017) [58] | DEA | |

| Service | Oliveira et al. (2015) [59] | DEA | |

| Manufacturing | Process | Ng et al. (2014) [67] | C/CFP |

| Process | Egilmez et al. (2013) [65] | EIO-LCA + DEA | |

| Process/Service | Zheng and Peng (2019) [66] | DEA | |

| Process | Lucato et al. (2013) [24] | Product value/Ecological influence | |

| Product/Process | Mendoza et al. (2019) [48] | Economic Score/Environmental Score | |

| Product/Process | Vukelic et al. (2019) [50] | TFC/TEI | |

| Process | Leme Jr. et al. (2018) [68] | Lean-Green Model: SMED/CF |

| Author/Year | Model for EE Evaluation (Alternatives) | Composition of EE Indicators (Criteria) | |

|---|---|---|---|

| Ng et al. (2014) [67] | A1 | C/CFP | C is the cost of production CFP is the carbon footprint |

| Egilmez et al. (2013) [65] | A2 | EIO-LCA + DEA (CCR) | EIO is economic input–output (total economic output) GHG emissions, energy use, water use, hazardous waste generation and toxic emissions) |

| Zheng and Peng (2019) [66] | A3 | DEA (CCR) | Resource efficiency (comprehensive energy consumption, unit labor output, unit product capital input) environmental efficiency (gas emission and waste) |

| Leme Jr. et al. (2018) [68] | A4 | Lean-Green Model: SMED/CF | SMED is single minute exchange of die CF is the carbon footprint |

| Lucato et al. (2013) [24] | A5 | Product value/ Ecological influence | number of pieces consumed energy material resources of equipment consumed |

| Mendoza et al. (2019) [48] | A6 | Economic Score/Environmental Score | raw material cost, manufacturing cost, transportation cost and waste management cost) Element abiotic depletion potential (ADP), fossil fuel abiotic depletion potential (ADP), acidification potential (AP), eutrophication potential (EP), freshwater aquatic ecotoxicity potential (FAETP), global warming potential (GWP), human toxicity potential (HTP), marine aquatic ecotoxicity potential (MAETP), ozone depletion potential (ODP), photochemical oxidant creation potential (POCP) and terrestrial ecotoxicity potential (TETP) |

| Vukelic et al. (2019) [50] | A7 | TFC/TEI | TFC is the total fixture cost TEI is the total environmental impact: human health, ecosystem quality, climate change and resources |

| Verbal Judgment | Numeric Value |

|---|---|

| Extremely important | 9 |

| 8 | |

| Very strongly more important | 7 |

| 6 | |

| Strongly more important | 5 |

| 4 | |

| Moderately more important | 3 |

| 2 | |

| Equally important | 1 |

| Indicators | |||||||

|---|---|---|---|---|---|---|---|

| Criteria | C1 | C2 | C3 | C4 | Weight Ci | Normalized Weight Cin | |

| Indicators | C1 | 1 | 1/7 | 1/9 | 1 | 2.25 | 0.05 |

| C2 | 7 | 1 | 1/3 | 7 | 15.33 | 0.37 | |

| C3 | 9 | 3 | 1 | 9 | 22.00 | 0.53 | |

| C4 | 1 | 1/7 | 1/9 | 1 | 2.25 | 0.05 | |

| Total | 41.84 | ||||||

| λmax (Mean) | IR | CI | CR | ||

|---|---|---|---|---|---|

| C1 | 4.06 | 4.16 | 0.90 | 0.053 | 0.058 |

| C2 | 3.54 | ||||

| C3 | 4.94 | ||||

| C4 | 4.06 | ||||

| Alternatives | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | A1 | A2 | A3 | A4 | Weight Ca | Normalized Weight Ci,an | λmax (Mean) | IR | CI | CR | |

| A1 | 1 | 1/5 | 1/2 | 1/7 | 1.84 | 0.06 | 4.13 | 4.12 | 0.90 | 0.040 | 0.045 |

| A2 | 5 | 1 | 2 | 1 | 9.00 | 0.30 | 4.51 | ||||

| A3 | 2 | 1/2 | 1 | 1/6 | 3.67 | 0.12 | 3.91 | ||||

| A4 | 7 | 1 | 6 | 1 | 15.00 | 0.51 | 3.93 | ||||

| Tot | 29.51 | ||||||||||

| Alternatives | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | A1 | A2 | A3 | A4 | Weight Ca | Normalized Weight Ci,an | λmax (Mean) | IR | CI | CR | |

| A1 | 1 | 1/4 | 5 | 2 | 8.25 | 0.22 | 3.67 | 4.10 | 0.90 | 0.033 | 0.037 |

| A2 | 4 | 1 | 9 | 9 | 23.00 | 0.63 | 4.56 | ||||

| A3 | 1/5 | 1/9 | 1 | 1/2 | 1.81 | 0.05 | 4.32 | ||||

| A4 | 1/2 | 1/9 | 2 | 1 | 3.61 | 0.10 | 3.85 | ||||

| Tot | 36.67 | ||||||||||

| Alternatives | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | A1 | A2 | A3 | A4 | Weight Ca | Normalized Weight Ci,an | λmax (Mean) | IR | CI | CR | |

| A1 | 1 | 1/6 | 1/2 | 1/2 | 2.17 | 0.09 | 3.96 | 4.02 | 0.90 | 0.008 | 0.009 |

| A2 | 6 | 1 | 2 | 3 | 12.00 | 0.52 | 3.92 | ||||

| A3 | 2 | 1/2 | 1 | 1 | 4.50 | 0.20 | 4.26 | ||||

| A4 | 2 | 1/3 | 1 | 1 | 4.33 | 0.19 | 3.96 | ||||

| Tot | 23.00 | ||||||||||

| Alternatives | |||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| C1 | A1 | A2 | A3 | A4 | Weight Ca | Normalized Weight Ci,an | λmax (mean) | IR | CI | CR | |

| A1 | 1 | 1/6 | 1/4 | 1/4 | 1.67 | 0.07 | 4.10 | 4.18 | 0.90 | 0.059 | 0.066 |

| A2 | 6 | 1 | 1/2 | 1 | 8.50 | 0.34 | 3.47 | ||||

| A3 | 4 | 2 | 1 | 1 | 8.00 | 0.32 | 4.83 | ||||

| A4 | 4 | 1 | 1 | 1 | 7.00 | 0.28 | 4.31 | ||||

| Tot | 25.17 | ||||||||||

| C1 | C2 | C3 | C4 | Overall Performance | Classification | |

|---|---|---|---|---|---|---|

| A1 | 0.003 | 0.082 | 0.050 | 0.004 | 0.139 | 4 |

| A2 | 0.016 | 0.230 | 0.274 | 0.018 | 0.539 | 1 |

| A3 | 0.007 | 0.018 | 0.103 | 0.017 | 0.145 | 3 |

| A4 | 0.027 | 0.036 | 0.099 | 0.015 | 0.178 | 2 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Xavier Belem, M.J.; Vieira Junior, M.; Mummolo, G.; Facchini, F. An AHP-Based Procedure for Model Selection for Eco-Efficiency Assessment. Sustainability 2021, 13, 12121. https://doi.org/10.3390/su132112121

Xavier Belem MJ, Vieira Junior M, Mummolo G, Facchini F. An AHP-Based Procedure for Model Selection for Eco-Efficiency Assessment. Sustainability. 2021; 13(21):12121. https://doi.org/10.3390/su132112121

Chicago/Turabian StyleXavier Belem, Maria Julia, Milton Vieira Junior, Giovanni Mummolo, and Francesco Facchini. 2021. "An AHP-Based Procedure for Model Selection for Eco-Efficiency Assessment" Sustainability 13, no. 21: 12121. https://doi.org/10.3390/su132112121

APA StyleXavier Belem, M. J., Vieira Junior, M., Mummolo, G., & Facchini, F. (2021). An AHP-Based Procedure for Model Selection for Eco-Efficiency Assessment. Sustainability, 13(21), 12121. https://doi.org/10.3390/su132112121