COVID-19 Challenges: Can Industry 4.0 Technologies Help with Business Continuity?

Abstract

:1. Introduction

1.1. SCs and Epidemic Outbreaks

1.2. Industry 4.0

1.2.1. Industry 4.0 Technologies

- Functional Compatibilities: The intelligent machines are capable of exchanging information between mechanical components and people through the internet and internet of things, forming an intelligent factory, also known as a smart factory.

- Decentralized Controlling Capability: The separate components in the smart factory are capable of making independent decisions in the direction of circumstances without requiring local or individual control [25].

- Virtual Capability: The digital twin of the industry is the virtual replica of the smart factory produced by the big data generated from sensors installed in the production processes. This helps monitor the production and other related metrics for management.

- Data: Data is the most valuable asset for an industry. Industry 4.0 provides the opportunity to gather and analyze data for effective decision-making in real-time scenarios [27].

- Smart Services Orientation: The digitally integrated systems help customers track the data while using the products, and integrates the maintenance and other important checks for smart users.

- Flexible Systems: The smart factories are capable of mass customization in everchanging requirements by using mass production and planning for customized solutions [24].

- Modularity of Systems: The smart factories adapt the changing requirements by expanding or replacing individual modules with respect to the job.

- Rapidly recover revenue.

- Rebuild operations.

- Rethink the organization.

- Accelerate digital adoption to enable reimagination.

1.2.2. Potential Benefits of Using Industry 4.0 Technologies during COVID-19

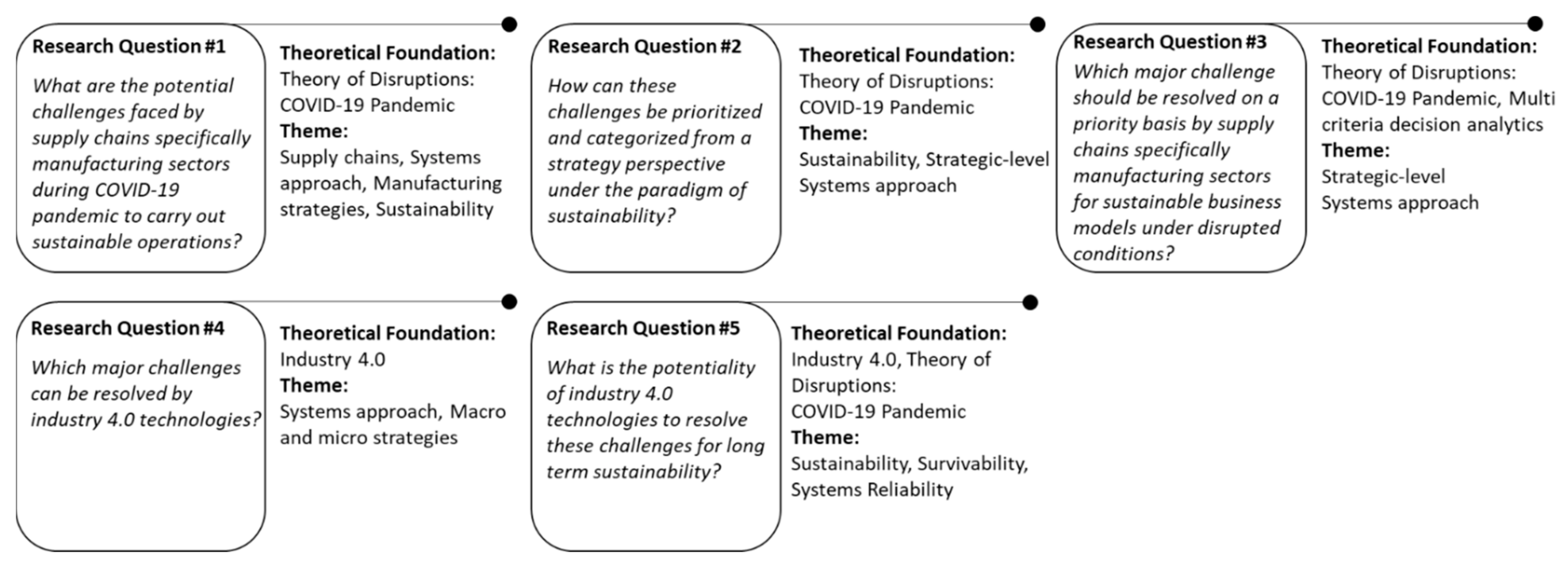

2. Research Problem and Objectives

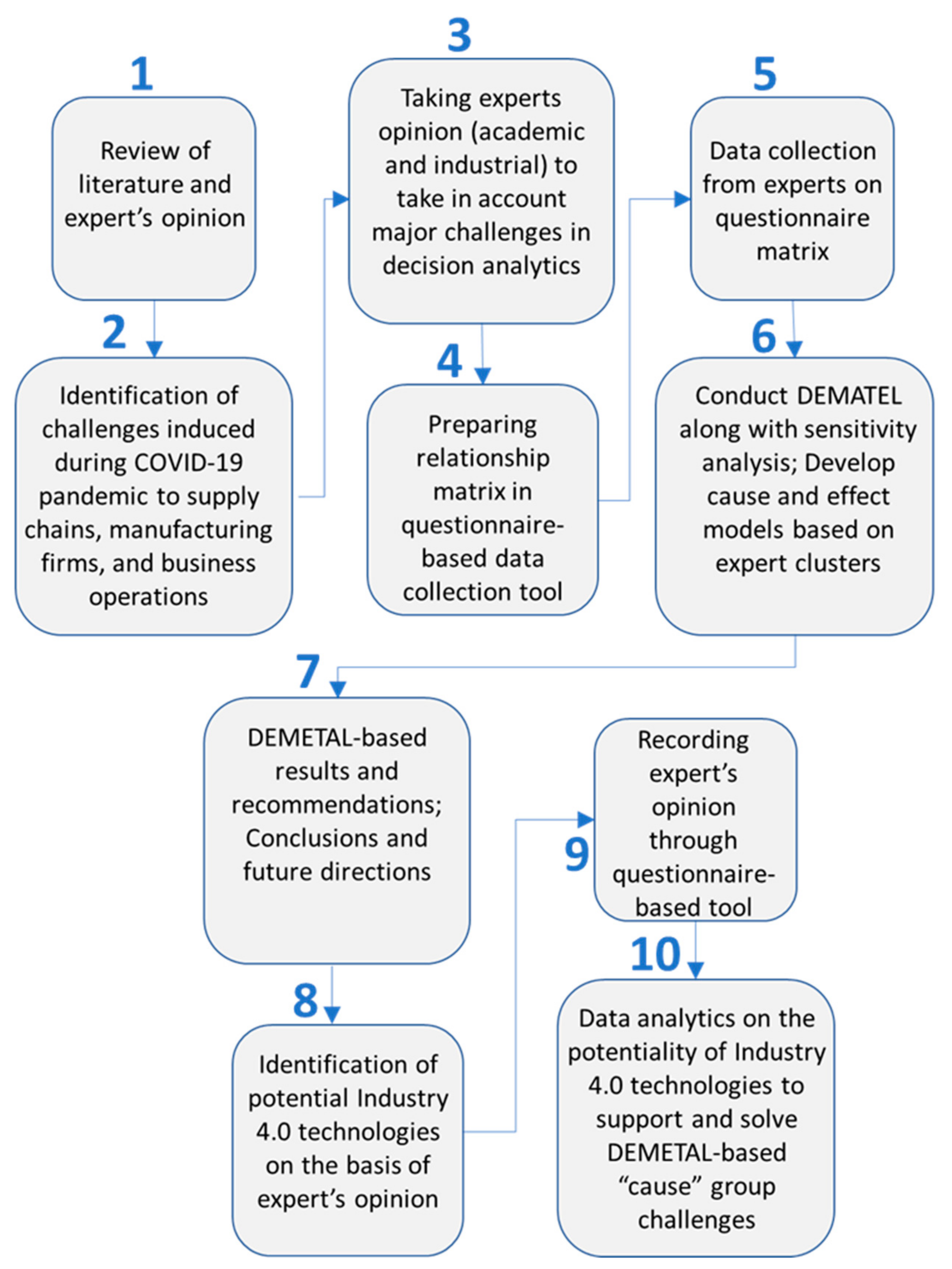

3. Methodology

- Experts’ opinions and the calculation of the arithmetic mean direct relationship matrix.

- Normalize the Direct Relation Matrix (X).

- Develop the full Direct/Indirect Relationship Matrix.

- Calculate the Total Relationship Matrix (T).

- Produce the cause and effect relationship diagram from T.

4. Analysis and Discussion

4.1. Delphi-Based Identification of the Challenges

4.2. DEMATEL-Based Analysis of Challenges

4.3. Domain-Oriented Insights

4.3.1. Strategic-Level Supply Chain Experts

4.3.2. Industry 4.0 and Industrial Systems Experts

5. Conclusions and Related Implications

5.1. Empirical and Theoretical Implications

5.2. Managerial Implications

5.3. Ecological and Social Implications

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Participant ID | Expertise | Current Affiliation |

|---|---|---|

| ID-1 | Workplace design, lean and green production | UET Lahore, Pakistan |

| ID-2 | Engineering management | UET Lahore, Pakistan |

| ID-3 | Supply chain management, network design, sustainability | UET Lahore, Pakistan |

| ID-4 | Industry 4.0, resilience | University of Strathclyde, UK |

| ID-5 | Robotics and automation, Industry 4.0, digital twins | Siemens Energy, Denmark |

| ID-6 | Sustainable manufacturing, industrial automation | Shandong University, China |

| ID-7 | Scheduling in Industry 4.0 | University of Lahore, Islamabad |

| ID-8 | Industrial sensors, energy | Tianjin University, China |

| ID-9 | Supply chain management, network design, sustainability | NUST, Islamabad |

| ID-10 | Lean production in Industry 4.0, decision analytics | LUMS, Lahore |

| ID-11 | Industrial system reliability, predictive maintenance | Beijing Institute of Technology, China |

| ID-12 | Technology road mapping | UNIDO, Islamabad, Pakistan |

| ID-13 | Project planning, supply chain management | TEVTA, Pakistan |

| ID-14 | Industrial waste management, production planning | Al-Aziz Packages, Faisalabad |

| ID-15 | Supply chain management, production planning | Waves, Lahore |

| ID-16 | Applied artificial intelligence in Industry 4.0, big data | KAIST, South Korea |

| ID-17 | Industrial automation, artificial intelligence | UET Lahore, Pakistan |

| ID-18 | Additive manufacturing | Hong Kong University, Hong Kong |

| ID-19 | Project engineering, HSE, operations management | Shell, Islamabad, Pakistan |

| ID-20 | Systems integration, flexible manufacturing | Tsinghua University, China |

| ID-21 | Cloud computing | Saudi Aramco, Saudi Arabia |

| ID-22 | Artificial intelligence, lean transformation | University of Punjab, Lahore |

| ID-23 | Internet of things, big data | General Electric, Canada |

| ID-24 | Cloud computing, augmented/virtual reality | University of Cambridge, UK |

| ID-25 | Lean production system, agile and green manufacturing | Mahmood Group of Textile Industries, Pakistan |

| ID-26 | Flexible manufacturing, engineering management | University of Strathclyde, UK |

| ID-27 | Internet of things, autonomous robotics | Coca Cola International, Pakistan |

| ID-28 | Engineering management, artificial intelligence | Boeing, Canada |

| ID-29 | Autonomous robotics | Vivo, Pakistan |

| ID-30 | Big data analytics, artificial intelligence | University of Cambridge, UK |

| ID-31 | Engineering management, production planning and control | Honda Motor, Japan |

| ID-32 | Artificial intelligence, production planning, engineering management | Style Textile, Pakistan |

| ID-33 | Engineering management, digital planning | IGI Global, Pakistan |

| ID-34 | Additive manufacturing, systems optimization | University of Leeds, UK |

| ID-35 | Robotics and automation, Industry 4.0, digital manufacturing | Hong Kong University, Hong Kong |

References

- Akpan, I.J.; Soopramanien, D.; Kwak, D.-H. Cutting-Edge Technologies for Small Business and Innovation in the Era of COVID-19 Global Health Pandemic. J. Small Bus. Entrep. 2020, 33, 607–617. [Google Scholar] [CrossRef]

- World Health Organization, General’s Opening Remarks at the Media Briefing on COVID-19—11 March 2020. Available online: https://www.who.int/dg/speeches/detail/who-director-general-s-opening-remarks-at-the-media-briefing-on-covid-19---11-march-2020 (accessed on 24 June 2020).

- Worldometers COVID-19. Available online: https://www.worldometers.info/coronavirus/ (accessed on 20 December 2020).

- Fortune 94% of the Fortune 1000 Are Seeing Coronavirus Supply Chain Disruptions. Available online: https://fortune.com/2020/02/21/fortune-1000-coronavirus-china-supply-chain-impact/ (accessed on 2 July 2020).

- Liguori, E.W.; Pittz, T.G. Strategies for Small Business: Surviving and Thriving in the Era of COVID-19. J. Int. Counc. Small Bus. 2020, 1, 106–110. [Google Scholar] [CrossRef]

- Vorfolomeiev, A. Impact of COVID-19 on Ukrainian Manufacturing Companies and Assistance Required for Business Recovery: Report on Survey Delivered by the Resource Efficient and Cleaner Production Centre; Resource Efficient and Cleaner Production Centre: Kyiv, Ukraine, 2020. [Google Scholar]

- World Bank World Bank Open Data. Available online: https://data.worldbank.org/ (accessed on 28 December 2020).

- Papadopoulos, T.; Baltas, K.N.; Balta, M.E. The Use of Digital Technologies by Small and Medium Enterprises during COVID-19: Implications for Theory and Practice. Int. J. Inf. Manag. 2020, 55, 102192. [Google Scholar] [CrossRef]

- Yu, K.D.S.; Aviso, K.B. Modelling the Economic Impact and Ripple Effects of Disease Outbreaks. Integr. Optim. Sustain. 2020, 4, 183–186. [Google Scholar] [CrossRef] [Green Version]

- Keskin, G.A. Using Integrated Fuzzy DEMATEL and Fuzzy C: Means Algorithm for Supplier Evaluation and Selection. Int. J. Prod. Res. 2015, 53, 3586–3602. [Google Scholar] [CrossRef]

- Heizer, J.; Render, B.; Munson, C. Operations Management; Prentice-Hall: London, UK, 2008. [Google Scholar]

- Kamble, S.S.; Gunasekaran, A.; Gawankar, S.A. Sustainable Industry 4.0 Framework: A Systematic Literature Review Identifying the Current Trends and Future Perspectives. Saf. Environ. Prot. 2018, 117, 408–425. [Google Scholar] [CrossRef]

- Shen, W.; Yang, C.; Gao, L. Address Business Crisis Caused by COVID-19 with Collaborative Intelligent Manufacturing Technologies. IET Collab. Intell. Manuf. 2020, 2, 96–99. [Google Scholar] [CrossRef]

- Kumar, A.; Luthra, S.; Mangla, S.K.; Kazançoğlu, Y. COVID-19 Impact on Sustainable Production and Operations Management. Sustain. Oper. Comput. 2020, 1, 1–7. [Google Scholar] [CrossRef]

- Farooq, M.U.; Hussain, A.; Masood, T.; Habib, M.S. Supply Chain Operations Management in Pandemics: A State-of-the-Art Review Inspired by COVID-19. Sustainability 2021, 13, 2504. [Google Scholar] [CrossRef]

- Dolgui, A.; Ivanov, D.; Rozhkov, M. Does the Ripple Effect Influence the Bullwhip Effect? An Integrated Analysis of Structural and Operational Dynamics in the Supply Chain. Int. J. Prod. Res. 2020, 58, 1285–1301. [Google Scholar] [CrossRef]

- Queiroz, M.M.; Ivanov, D.; Dolgui, A.; Wamba, S.F. Impacts of Epidemic Outbreaks on Supply Chains: Mapping a Research Agenda amid the COVID-19 Pandemic through a Structured Literature Review. Ann. Oper. Res. 2020, 1–38. [Google Scholar] [CrossRef] [PubMed]

- Yang, G.-Z.; Nelson, B.J.; Murphy, R.R.; Choset, H.; Christensen, H.; Collins, S.H.; Dario, P.; Goldberg, K.; Ikuta, K.; Jacobstein, N. Combating COVID-19—The Role of Robotics in Managing Public Health and Infectious Diseases. Sci. Robot 2020, 5, eabb5589. [Google Scholar] [CrossRef] [Green Version]

- Czifra, G.; Molnár, Z. Covid-19 and Industry 4.0. Res. Pap. Fac. Mater. Sci. Technol. Slovak Univ. Technol. 2020, 28, 36–45. [Google Scholar] [CrossRef]

- Shepard, W. COVID-19 Undermines China’s Run as the World’s Factory, but Beijing Has a Plan. Available online: https://www.forbes.com/sites/wadeshepard/2020/03/26/covid-19-undermines-chinas-run-as-the-worlds-factory-but-beijing-has-a-plan/ (accessed on 28 July 2020).

- Di Nardo, M. Developing a Conceptual Framework Model of Industry 4.0 for Industrial Management. Ind. Eng. Manag. Syst. 2020, 19, 551–560. [Google Scholar] [CrossRef]

- Sheng, J.; Amankwah-Amoah, J.; Khan, Z.; Wang, X. COVID-19 Pandemic in the New Era of Big Data Analytics: Methodological Innovations and Future Research Directions. Br. J. Manag. 2020, 32, 1164–1183. [Google Scholar] [CrossRef]

- Li, X.; Wang, B.; Liu, C.; Freiheit, T.; Epureanu, B.I. Intelligent Manufacturing Systems in COVID-19 Pandemic and Beyond: Framework and Impact Assessment. Chin. J. Mech. Eng. 2020, 33, 1–5. [Google Scholar] [CrossRef]

- Acioli, C.; Scavarda, A.; Reis, A. Applying Industry 4.0 Technologies in the COVID–19 Sustainable Chains. Int. J. Product. Perform. Manag. 2021, 70, 988–1016. [Google Scholar] [CrossRef]

- Birkel, H.S.; Müller, J.M. Potentials of Industry 4.0 for Supply Chain Management within the Triple Bottom Line of Sustainability–A Systematic Literature Review. J. Clean. Prod. 2020, 289, 125612. [Google Scholar] [CrossRef]

- Chukalov, K. Horizontal and Vertical Integration, as a Requirement for Cyber-Physical Systems in the Context of Industry 4.0. Industry 4.0 2017, 2, 155–157. [Google Scholar]

- Narayanamurthy, G.; Tortorella, G. Impact of COVID-19 Outbreak on Employee Performance–Moderating Role of Industry 4.0 Base Technologies. Int. J. Prod. Econ. 2021, 234, 108075. [Google Scholar] [CrossRef]

- Masood, T.; Sonntag, P. Industry 4.0: Adoption Challenges and Benefits for SMEs. Comput. Ind. 2020, 121, 103261. [Google Scholar] [CrossRef]

- Modrak, V.; Soltysova, Z.; Poklemba, R. Mapping requirements and roadmap definition for introducing I 4.0 in SME environment. In Advances in Manufacturing Engineering and Materials, Lecture Notes in Mechanical Engineering; Springer: Cham, Switzerland, 2019; pp. 183–194. [Google Scholar] [CrossRef]

- Hussain, A.; Jamil, M.; Farooq, M.U.; Asim, M.; Rafique, M.Z.; Pruncu, C.I. Project Managers’ Personality and Project Success: Moderating Role of External Environmental Factors. Sustainability 2021, 13, 9477. [Google Scholar] [CrossRef]

- Advincula, R.C.; Dizon, J.R.C.; Chen, Q.; Niu, I.; Chung, J.; Kilpatrick, L.; Newman, R. Additive Manufacturing for COVID-19: Devices, Materials, Prospects, and Challenges. MRS Commun. 2020, 10, 413–427. [Google Scholar] [CrossRef]

- Egger, J.; Masood, T. Augmented Reality in Support of Intelligent Manufacturing—A Systematic Literature Review. Comput. Ind. Eng. 2020, 140, 106195. [Google Scholar] [CrossRef]

- Kwok, A.O.; Koh, S.G. COVID-19 and Extended Reality (XR). Curr. Issues Tour. 2020, 24, 1935–1940. [Google Scholar] [CrossRef]

- Nee, A.Y.; Ong, S.K.; Chryssolouris, G.; Mourtzis, D. Augmented Reality Applications in Design and Manufacturing. CIRP Ann. 2012, 61, 657–679. [Google Scholar] [CrossRef]

- Rajesh, R. Network Design for Resilience in Supply Chains Using Novel Crazy Elitist TLBO. Neural. Comput. Appl. 2020, 32, 7421–7437. [Google Scholar] [CrossRef]

- Tarfaoui, M.; Nachtane, M.; Goda, I.; Qureshi, Y.; Benyahia, H. Additive Manufacturing in Fighting against Novel Coronavirus COVID-19. Int. J. Adv. Manuf. Technol. 2020, 110, 2913–2927. [Google Scholar] [CrossRef]

- Toba, S.; Tomasini, M.; Yang, Y.H. Supply Chain Management in Hospital: A Case Study. Calif. J. Oper. Manag. 2008, 6, 49–55. [Google Scholar]

- Liu, Y.; Lee, J.M.; Lee, C. The Challenges and Opportunities of a Global Health Crisis: The Management and Business Implications of COVID-19 from an Asian Perspective. Asian Bus. Manag. 2020, 19, 277–297. [Google Scholar] [CrossRef]

- Kaur, J.; Sidhu, R.; Awasthi, A.; Chauhan, S.; Goyal, S. A DEMATEL Based Approach for Investigating Barriers in Green Supply Chain Management in Canadian Manufacturing Firms. Int. J. Prod. Res. 2018, 56, 312–332. [Google Scholar] [CrossRef]

- Govindan, K.; Mina, H.; Alavi, B. A Decision Support System for Demand Management in Healthcare Supply Chains Considering the Epidemic Outbreaks: A Case Study of Coronavirus Disease 2019 (COVID-19). Transp. Res. Part E Logist. Transp. Rev. 2020, 138, 101967. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. Viability of Intertwined Supply Networks: Extending the Supply Chain Resilience Angles towards Survivability. A Position Paper Motivated by COVID-19 Outbreak. Int. J. Prod. Res. 2020, 58, 2904–2915. [Google Scholar] [CrossRef] [Green Version]

- Kumar, R.; Singh, R.K.; Dwivedi, Y.K. Application of Industry 4.0 Technologies in SMEs for Ethical and Sustainable Operations: Analysis of Challenges. J. Clean. Prod. 2020, 275, 124063. [Google Scholar] [CrossRef]

- Yadav, S.; Singh, S.P. Blockchain Critical Success Factors for Sustainable Supply Chain. Resour. Conserv. Recycl. 2020, 152, 104505. [Google Scholar] [CrossRef]

- Rajput, S.; Singh, S.P. Identifying Industry 4.0 IoT Enablers by Integrated PCA-ISM-DEMATEL Approach. Manag. Decis. 2019, 57, 1784–1817. [Google Scholar] [CrossRef]

- Rajput, S.; Singh, S.P. Connecting Circular Economy and Industry 4.0. Int. J. Inf. Manag. 2019, 49, 98–113. [Google Scholar] [CrossRef]

- Singh, R.K.; Luthra, S.; Mangla, S.K.; Uniyal, S. Applications of Information and Communication Technology for Sustainable Growth of SMEs in India Food Industry. Resour. Conserv. Recycl. 2019, 147, 10–18. [Google Scholar] [CrossRef]

- Kumar, A.; Dixit, G. An Analysis of Barriers Affecting the Implementation of E-Waste Management Practices in India: A Novel ISM-DEMATEL Approach. Sustain. Prod. Consum. 2018, 14, 36–52. [Google Scholar] [CrossRef]

- Gazibey, Y.; Kantemir, O.; Demirel, A. Interaction among the Criteria Affecting Main Battle Tank Selection: An Analysis with DEMATEL Method. Def. Sci. J. 2015, 65, 345–355. [Google Scholar] [CrossRef]

- Liu, Z.; Ming, X. A Framework with Revised Rough-DEMATEL to Capture and Evaluate Requirements for Smart Industrial Product-Service System of Systems. Int. J. Prod. Res. 2019, 57, 7104–7122. [Google Scholar] [CrossRef]

- Xia, X.; Govindan, K.; Zhu, Q. Analyzing Internal Barriers for Automotive Parts Remanufacturers in China Using Grey-DEMATEL Approach. J. Clean. Prod. 2015, 87, 811–825. [Google Scholar] [CrossRef]

- Yadav, D.K.; Barve, A. Modeling Post-Disaster Challenges of Humanitarian Supply Chains: A TISM Approach. Glob. J. Flex. Syst. Manag. 2016, 17, 321–340. [Google Scholar] [CrossRef]

- Gehrie, E.A.; Frank, S.M.; Goobie, S.M. Balancing Supply and Demand for Blood during the COVID-19 Pandemic. Anesthesiol. J. Am. Soc. Anesthesiol. 2020, 133, 16–18. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Paul, S.K.; Chowdhury, P. A Production Recovery Plan in Manufacturing Supply Chains for a High-Demand Item during COVID-19. Int. J. Phys. Distrib. Logist. Manag. 2020, 51, 104–125. [Google Scholar] [CrossRef]

- Park, C.-Y.; Kim, K.; Roth, S. Global Shortage of Personal Protective Equipment amid COVID-19: Supply Chains, Bottlenecks, and Policy Implications; Asian Development Bank: Manila, Philippines, 2020. [Google Scholar]

- Paul, S.; Venkateswaran, J. Designing Robust Policies under Deep Uncertainty for Mitigating Epidemics. Comput. Ind. Eng. 2020, 140, 106221. [Google Scholar] [CrossRef]

- Mishra, S.; Singh, S.P. A Stochastic Disaster-Resilient and Sustainable Reverse Logistics Model in Big Data Environment. Ann. Oper. Res. 2020, 1–32. [Google Scholar] [CrossRef]

- Papadopoulos, T.; Gunasekaran, A.; Dubey, R.; Altay, N.; Childe, S.J.; Fosso-Wamba, S. The Role of Big Data in Explaining Disaster Resilience in Supply Chains for Sustainability. J. Clean. Prod. 2017, 142, 1108–1118. [Google Scholar] [CrossRef] [Green Version]

- Kaur, H. Modelling Internet of Things Driven Sustainable Food Security System. Benchmarking Int. J. 2019, 28, 1740–1760. [Google Scholar] [CrossRef]

- Zhang, J.; Feng, P.; Wu, Z.; Yu, D. Automatic identification-enabled traceability in supply chain management. In Proceedings of the 2008 4th International Conference on Wireless Communications, Networking and Mobile Computing, Dalian, China, 12–14 October 2008; pp. 1–4. [Google Scholar]

- Dasaklis, T.K.; Pappis, C.P.; Rachaniotis, N.P. Epidemics Control and Logistics Operations: A Review. Int. J. Prod. Econ. 2012, 139, 393–410. [Google Scholar] [CrossRef]

- He, L.; Wu, Z.; Xiang, W.; Goh, M.; Xu, Z.; Song, W.; Ming, X.; Wu, X. A Novel Kano-QFD-DEMATEL Approach to Optimise the Risk Resilience Solution for Sustainable Supply Chain. Int. J. Prod. Res. 2021, 59, 1714–1735. [Google Scholar] [CrossRef]

- Singh, R.; Bhanot, N. An Integrated DEMATEL-MMDE-ISM Based Approach for Analysing the Barriers of IoT Implementation in the Manufacturing Industry. Int. J. Prod. Res. 2020, 58, 2454–2476. [Google Scholar] [CrossRef]

- Ivanov, D.; Das, A.; Choi, T.-M. New Flexibility Drivers for Manufacturing, Supply Chain and Service Operations. Int. J. Prod. Res. 2018, 56, 1–10. [Google Scholar] [CrossRef] [Green Version]

- Malik, A.A.; Masood, T.; Kousar, R. Reconfiguring and Ramping-up Ventilator Production in the Face of COVID-19: Can Robots Help? J. Manuf. Syst. 2020, 60, 864–875. [Google Scholar] [CrossRef]

- Malik, A.A.; Masood, T.; Kousar, R. Repurposing factories with robotics in the face of COVID-19. Sci. Robot. 2020, 5, abc2782. [Google Scholar] [CrossRef]

- Tao, F.; Cheng, J.; Qi, Q.; Zhang, M.; Zhang, H.; Sui, F. Digital Twin-Driven Product Design, Manufacturing and Service with Big Data. Int. J. Adv. Manuf. Tech. 2018, 94, 3563–3576. [Google Scholar] [CrossRef]

- Masood, T.; Egger, J. Augmented Reality: Focusing on Photonics in Industry 4.0. IEEE J. Sel. Top. Quantum Electron. 2021, 27, 1–11. [Google Scholar] [CrossRef]

- Masood, T.; Egger, J. Augmented reality in support of Industry 4.0—Implementation challenges and success factors. Robot. Comput. Integr. Manuf. 2019, 58, 181–195. [Google Scholar] [CrossRef]

- Masood, T.; Egger, J. Adopting augmented Reality in the age of Industrial Digitalisation. Comput. Ind. 2020, 115, 103112. [Google Scholar] [CrossRef]

- Masood, T.; Yang, M.; Wang, J. Industry 4.0 Technologies for Global Challenges. Sustainability. 2021. Available online: https://www.mdpi.com/journal/sustainability/special_issues/technologies_challenges (accessed on 2 October 2021).

- Masood, T.; Kern, M.; Clarkson, P.J. Characteristics of changeable systems across value chains. Int. J. Prod. Res. 2021, 59, 1626–1648. [Google Scholar] [CrossRef]

- Masood, T.; So, E.; McFarlane, D.C. Disaster management operations–big data analytics to resilient supply networks. In Proceedings of the 24th EurOMA Conference, Edinburgh, UK, 1–5 July 2017; p. 10. [Google Scholar]

| Sr. No. | Industry 4.0 Technologies | Brief Introduction | Potential Benefits in the Pandemic | Ref. |

|---|---|---|---|---|

| 1 | Autonomous robotics |

| In the times of COVID-19 pandemic, robots could be used to serve medication to patients, to affirm that people are maintaining social distancing, in industries perform repetitive tasks to create an environment of collaborative workplace and assist in logistical activities in hospitals as well as in industries. | [18,22] |

| 2 | Big data analytics |

| During pandemic like situations, analytics based on big date helps to analyze and forecast the impacts of disease on people and supply chains. Moreover, it helps in tracking and collecting the real time data which equips medical practitioners, businessmen, analysts, and other personnel. In addition to this, it also improves the policy deployment through sentiment analysis of response of public as well as provides efficient transparency to business and supply chain networks. | [22,31] |

| 3 | System integration |

| Systems integration across different departments backed by artificial intelligence can help in predicting and minimizing the spread of disease. Moreover, it helps to navigate and take down wrong news to refrain the public from panic. Also, the trail phase could be systemized and helped by creating virtual support through investigating medicine effects on tangible implants and analyzing them across the system. Moreover, the merger of physical world, robots, and simulation based virtual environment can help in analyzing more critical situations. It also helps in manufacturing healthcare related equipment at the time of need. | [13,18,23,32] |

| 4 | Internet of things |

| Internet of things is helping by providing drone-based surveillance, mask detection and wearing enforcement, segregating affected ones from business and other operations places and helping medical practitioners through diagnosing the disease. It helps industries by keeping social distancing between employees, partially automating the work, and providing the safe and secure operations environment. Moreover, it helps the medical teams in relief operations to monitor patients remotely and provide them medication. | [13,23,31] |

| 5 | Flexible manufacturing |

| Flexible manufacturing can help in large scale production of essentially required items during pandemics. It happens to support governments through modern technologies such as virtual reality, robots, flexible systems, and industrial designing capabilities. In addition, the systems are backed with the sensors such as biosensor in the time of health crisis (providing essential regulatory measures). These help in carrying out mass production without any hindrance through easily employable, sensitive, and economic support. | [19,23,31] |

| 6 | Augmented reality |

| The technologies of virtual and AR integrate remote groups working on specific tasks. The technology can help during pandemic and lockdown situations when people’s safety is important and can be maintained through social distancing. It also increases group’s productivity, decreases travelling cost, and consequently, the absenteeism of employees.In addition to above benefits, the technology has also helped in the form of holography. The organization of conferences, meetings, educational activities, and other training sessions for employees, it has helped a lot by providing ultra realistic experience. | [23,33,34] |

| 7 | Cloud computing |

| During the term of social isolation during health crisis, all services and business went online providing services on internet on the place of physical support. The data collected and managed through these industries increased exponentially which put them in another challenge to analyze the dynamic and live data. Similar is the case with the industries, due to rise in automated systems, the data exponentially increased. Therefore, cloud computing technologies can help in analyzing real time data and optimizing the services and operations experience. Similarly, the data obtained from various hospitals related to disease diagnostic can also be analyzed remotely and transferred to other units for further processing. | [13,22,35] |

| 8 | Additive manufacturing |

| The additive manufacturing also known as 3D printing can be employed in critically unprecedented conditions. This technology can help in manufacturing the medical aids, providing mass production of surgical masks and ventilator parts, producing medicines, and printing human implants. | [19,31,36] |

| No. | Key Challenge | Brief Narrative | References |

|---|---|---|---|

| 1 | Low system flexibility | Decreased throughput rate, expanded lead time, inadequate responsiveness to market fluctuations | [12,19,23,36,40] |

| 2 | High mismatch between supply and demand | Extremely uncertain demand, decreased logistical activities, delays and supply shortage | [12,17,19,40] |

| 3 | Elevated consumer generated bullwhip effects | Customer behavior, increased stockpiling, retailers selling monopoly, retailers, and consumer behavior with factory outlets | [9,17,29] |

| 4 | No responsibility and trust issues | Competency and integrity within SC stakeholders, mismatched deliverables, double-crossing under uncertain environments, contactless deliveries between consumers and retailers | [14,17,38,40] |

| 5 | Inadequate viability of SC network | Survival during unprecedented circumstances, less resilient systems, low adaptability, inadequate capacity to improve networks to ensure sustainable system | [17,40,41] |

| 6 | Poor access to real customer and lack of infrastructure | Inadequate penetration to market and access to information, inefficient logistical infrastructure, unavailability of capacity enhancement and subsequent storage opportunities | [12,17,23,40] |

| 7 | Insufficient human resource availability and security | Shortage of labor and emergency medical support, inefficient security protocols for employees to ensure safer work environment and consumers’ safety | [12,17,19,23] |

| 8 | Unavailability of medical capabilities for safer workplace | Shortages of disinfectants, safety tools and sanitization amenities | [8,31,38,41] |

| 9 | Governmental policies and support | Inadequate incentives, insufficient support in logistical activities, lockdowns and enforced restrictions on business retails, no cost-sharing opportunities for special production targets | [6,19,20,38,40] |

| 10 | Inadequate system transparency and communication | Openness between SC nodes, miscommunication between organization, governmental authorities, and local bodies | [17,19,33,40] |

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 0 | 3 | 2 | 1.5 | 1 | 2 | 0.5 | 0.5 | 0.5 | 1.5 |

| C2 | 1.67 | 0 | 3 | 2 | 1 | 1 | 1.5 | 0.5 | 0.5 | 1 |

| C3 | 2.33 | 2 | 0 | 1 | 1 | 1.5 | 1 | 1 | 0.5 | 0.5 |

| C4 | 1.33 | 1.67 | 2 | 0 | 1.5 | 1.5 | 0.5 | 1 | 0.5 | 0.5 |

| C5 | 1.33 | 2.33 | 2.33 | 1.5 | 0 | 2.5 | 2 | 1 | 1 | 1 |

| C6 | 2 | 3 | 2 | 2.67 | 2 | 0 | 2.5 | 3 | 0.5 | 2.5 |

| C7 | 1.33 | 2.67 | 1.67 | 2.67 | 2 | 1.33 | 0 | 1 | 0.5 | 1.5 |

| C8 | 0.67 | 0.33 | 1 | 1 | 1.67 | 1.33 | 2 | 0 | 2 | 2 |

| C9 | 1 | 1.67 | 1.67 | 1.67 | 1.33 | 2.67 | 2 | 3 | 0 | 2 |

| C10 | 1 | 1.67 | 1.33 | 1.67 | 2 | 2.67 | 2 | 1 | 1.33 | 0 |

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 0 | 0.148 | 0.099 | 0.074 | 0.049 | 0.099 | 0.024 | 0.024 | 0.024 | 0.074 |

| C2 | 0.082 | 0 | 0.148 | 0.099 | 0.049 | 0.049 | 0.074 | 0.024 | 0.024 | 0.049 |

| C3 | 0.115 | 0.099 | 0 | 0.049 | 0.049 | 0.074 | 0.049 | 0.049 | 0.024 | 0.024 |

| C4 | 0.065 | 0.082 | 0.099 | 0 | 0.074 | 0.074 | 0.024 | 0.049 | 0.024 | 0.024 |

| C5 | 0.065 | 0.115 | 0.115 | 0.074 | 0 | 0.123 | 0.099 | 0.049 | 0.049 | 0.049 |

| C6 | 0.099 | 0.148 | 0.099 | 0.132 | 0.099 | 0 | 0.123 | 0.148 | 0.024 | 0.123 |

| C7 | 0.065 | 0.132 | 0.082 | 0.132 | 0.099 | 0.065 | 0 | 0.049 | 0.024 | 0.074 |

| C8 | 0.033 | 0.016 | 0.049 | 0.049 | 0.082 | 0.065 | 0.099 | 0 | 0.099 | 0.099 |

| C9 | 0.049 | 0.082 | 0.082 | 0.082 | 0.065 | 0.132 | 0.099 | 0.148 | 0 | 0.099 |

| C10 | 0.049 | 0.082 | 0.065 | 0.082 | 0.099 | 0.132 | 0.099 | 0.049 | 0.065 | 0 |

| C1 | C2 | C3 | C4 | C5 | C6 | C7 | C8 | C9 | C10 | |

|---|---|---|---|---|---|---|---|---|---|---|

| C1 | 0.136 | 0.317 | 0.267 | 0.225 | 0.178 | 0.243 | 0.159 | 0.136 | 0.092 | 0.186 |

| C2 | 0.206 | 0.175 | 0.297 | 0.236 | 0.170 | 0.192 | 0.190 | 0.128 | 0.088 | 0.154 |

| C3 | 0.223 | 0.253 | 0.152 | 0.184 | 0.161 | 0.202 | 0.162 | 0.143 | 0.084 | 0.130 |

| C4 | 0.177 | 0.231 | 0.238 | 0.130 | 0.179 | 0.199 | 0.138 | 0.141 | 0.083 | 0.124 |

| C5 | 0.225 | 0.327 | 0.313 | 0.259 | 0.159 | 0.296 | 0.253 | 0.185 | 0.130 | 0.191 |

| C6 | 0.293 | 0.410 | 0.355 | 0.359 | 0.297 | 0.237 | 0.320 | 0.302 | 0.138 | 0.295 |

| C7 | 0.215 | 0.328 | 0.276 | 0.298 | 0.241 | 0.238 | 0.151 | 0.171 | 0.104 | 0.201 |

| C8 | 0.163 | 0.202 | 0.216 | 0.206 | 0.214 | 0.224 | 0.233 | 0.121 | 0.167 | 0.216 |

| C9 | 0.226 | 0.321 | 0.307 | 0.291 | 0.248 | 0.332 | 0.282 | 0.295 | 0.102 | 0.260 |

| C10 | 0.208 | 0.299 | 0.270 | 0.268 | 0.253 | 0.307 | 0.257 | 0.189 | 0.146 | 0.146 |

| Rank | |||||

|---|---|---|---|---|---|

| C1 | 1.944 | 2.076 | −0.132 | 4.020 | 8 |

| C2 | 1.842 | 2.867 | −1.024 | 4.709 | 2 |

| C3 | 1.698 | 2.696 | −0.997 | 4.394 | 4 |

| C4 | 1.644 | 2.461 | −0.816 | 4.106 | 7 |

| C5 | 2.343 | 2.104 | 0.238 | 4.447 | 3 |

| C6 | 3.011 | 2.475 | 0.535 | 5.486 | 1 |

| C7 | 2.227 | 2.151 | 0.075 | 4.378 | 5 |

| C8 | 1.966 | 1.816 | 0.150 | 3.782 | 10 |

| C9 | 2.668 | 1.138 | 1.529 | 3.807 | 9 |

| C10 | 2.349 | 1.908 | 0.441 | 4.257 | 6 |

| Challenges as Causes | Challenges as Effects | ||

|---|---|---|---|

| Challenge No. | Rank | Challenge No. | Rank |

| C9 | 1 | C2 | 1 |

| C6 | 2 | C3 | 2 |

| C10 | 3 | C4 | 3 |

| C5 | 4 | C1 | 4 |

| C8 | 5 | ||

| C7 | 6 | ||

| Case 1 | Case 2 | Case 3 | Case 4 | |

|---|---|---|---|---|

| Expert 1 | 0.33 | 0.25 | 0.25 | 0.50 |

| Expert 2 | 0.33 | 0.25 | 0.50 | 0.25 |

| Expert 3 | 0.33 | 0.50 | 0.25 | 0.25 |

| Challenge No. | Case 1 | Case 2 | Case 3 | Case 4 | ||||

|---|---|---|---|---|---|---|---|---|

| Rank | Rank | Rank | Rank | |||||

| C1 | 4.020 | 8 | 4.120 | 4 | 3.416 | 10 | 3.674 | 6 |

| C2 | 4.709 | 2 | 4.497 | 2 | 4.396 | 3 | 4.308 | 2 |

| C3 | 4.394 | 4 | 4.276 | 3 | 4.251 | 4 | 3.673 | 7 |

| C4 | 4.106 | 7 | 3.598 | 9 | 3.900 | 6 | 3.608 | 8 |

| C5 | 4.447 | 3 | 4.025 | 5 | 3.806 | 8 | 3.705 | 5 |

| C6 | 5.486 | 1 | 4.956 | 1 | 5.079 | 1 | 4.471 | 1 |

| C7 | 4.378 | 5 | 3.834 | 7 | 4.409 | 2 | 3.766 | 4 |

| C8 | 3.782 | 10 | 3.215 | 10 | 3.701 | 9 | 3.299 | 10 |

| C9 | 3.807 | 9 | 3.703 | 8 | 3.831 | 7 | 3.541 | 9 |

| C10 | 4.257 | 6 | 3.836 | 6 | 4.171 | 5 | 3.892 | 3 |

| Research Question | Reference | |

|---|---|---|

| RQ 1 | What are the potential challenges faced by supply chains specifically manufacturing sectors during COVID-19 pandemic to carry out sustainable operations? | The output of Delphi approach stated in Table 2 highlights the potential challenges. |

| RQ 2 | How can these challenges be prioritized and categorized from a strategy perspective under the paradigm of sustainability? | The DEMATEL analysis priortized and categorized the said challenges as termed in Table 7. |

| RQ 3 | Which major challenge should be resolved on a priority basis by supply chains specifically manufacturing sectors for sustainable business models under disrupted conditions? | The ranking shown in Table 9 demonstrats the major challenge. The sensitivity analysis results C6 to be the major challenge in said perspective. |

| RQ 4 | Which major challenges can be resolved by industry 4.0 technologies? | The causal group formed through DEMATEL analysis are the most priortized challenges which need immediate focus and evaluation through Industry 4.0 lens as illustrated in Figure 3. |

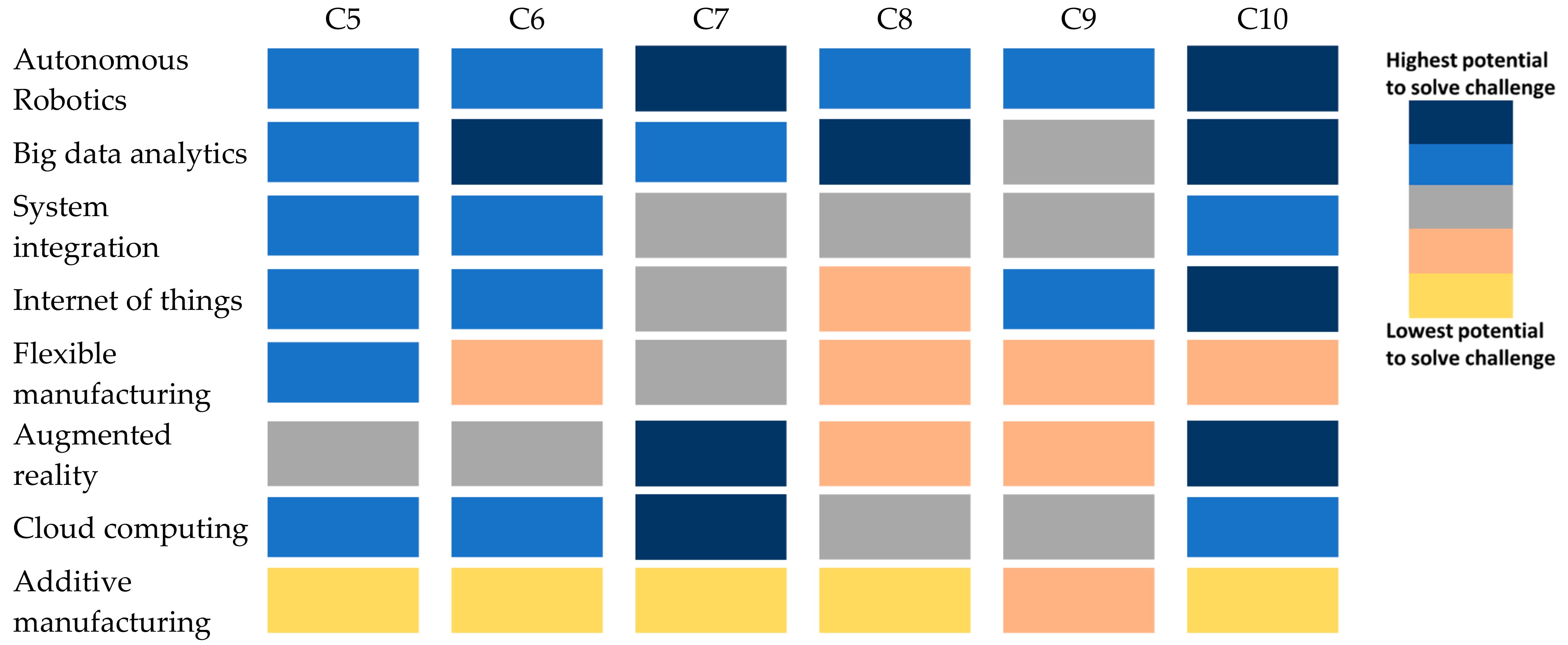

| RQ 5 | What is the potentiality of industry 4.0 technologies to resolve these challenges for long term sustainability? | The output of Domain-experts focus on the potentiality of technologies to resolve the selected challenges as shown in Figure 4 and Figure 5. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Hussain, A.; Farooq, M.U.; Habib, M.S.; Masood, T.; Pruncu, C.I. COVID-19 Challenges: Can Industry 4.0 Technologies Help with Business Continuity? Sustainability 2021, 13, 11971. https://doi.org/10.3390/su132111971

Hussain A, Farooq MU, Habib MS, Masood T, Pruncu CI. COVID-19 Challenges: Can Industry 4.0 Technologies Help with Business Continuity? Sustainability. 2021; 13(21):11971. https://doi.org/10.3390/su132111971

Chicago/Turabian StyleHussain, Amjad, Muhammad Umar Farooq, Muhammad Salman Habib, Tariq Masood, and Catalin I. Pruncu. 2021. "COVID-19 Challenges: Can Industry 4.0 Technologies Help with Business Continuity?" Sustainability 13, no. 21: 11971. https://doi.org/10.3390/su132111971

APA StyleHussain, A., Farooq, M. U., Habib, M. S., Masood, T., & Pruncu, C. I. (2021). COVID-19 Challenges: Can Industry 4.0 Technologies Help with Business Continuity? Sustainability, 13(21), 11971. https://doi.org/10.3390/su132111971