Location-Routing Optimization with Renting Social Vehicles in a Two-Stage E-Waste Recycling Network

Abstract

:1. Introduction

- Under the background of sharing economy, we introduce the application of social vehicles with rental cost into the classical integrated recycling cite location and vehicle routing problem in an e-waste recycling network. There are two stages of e-waste collection, where in the first stage, e-waste recycling demands are processed by either self-delivery or door-to-door pickup and, in the second stage, the collected e-wastes are delivered to the unique processing centre.

- An MILP model is established, in which it is assumed that different recycling sites are equipped with an unequal number of vehicles, and each vehicle shall depart from and return to its respective recycling site in the first collection stage.

- An improved genetic algorithm and a two-stage cyclic optimization-based heuristic algorithm are developed to solve the considered problem.

2. Literature Review

3. Model Formulation

3.1. Problem Description

3.2. Assumptions

- The capacities of recycling sites and the processing centre are infinite ([23]).

- Rented vehicles and the smaller owned vehicles have the same capacity.

3.3. Notations

- -

- i: index of demand node;

- -

- m: index of recycling site;

- -

- j: index of demand node and recycling site;

- -

- p: index of processing centre;

- -

- v: index of vehicle;

- -

- : set of demand nodes, , where is the number of demand nodes;

- -

- : set of candidate recycling sites, , where is the number of candidate recycling sites;

- -

- : set of demand nodes and recycling sites, where ;

- -

- : set of processing centres;

- -

- : number of recycling sites selected;

- -

- : set of own vehicles of each recycling site;

- -

- , , : time between demand node i and demand node j, between demand node i and recycling site m, between recycling site m and processing centre p;

- -

- : capacity of vehicle which processes pick-up tasks;

- -

- : capacity of vehicle which processes transportation tasks;

- -

- : uniform speed of any vehicle;

- -

- : amount of e-waste at demand node i;

- -

- , : cost of transportation per minute and renting cost per time;

- -

- , : the earliest and latest start time acceptable for serving demand node i;

- -

- : amount of self-delivered e-waste received by customers at recycling site m;

- -

- : processing time required by demand node i;

- -

- , : two sufficiently large real numbers.

- -

- : equals 1, if e-waste in demand node i is picked up by an outside vehicle, and 0 otherwise;

- -

- : equals 1, if e-waste in demand node i is picked up by an outside vehicle to recycling site m, and 0 otherwise;

- -

- : equals 1, if an own vehicle travels from node i to node j, and 0 otherwise;

- -

- : equals 1, if candidate recycling site m is selected, and 0 otherwise;

- -

- : equals 1, if e-waste in demand node i is picked up by own vehicle v of recycling site m, and 0 otherwise;

- -

- : equals 1, if an own vehicle v of recycling site m travels form recycling site m to demand node i, and 0 otherwise;

- -

- : equals 1, if an own vehicle v of recycling site m travels form demand node i to recycling site m, and 0 otherwise.

- -

- : equals 1, if e-waste in demand node i is picked up by an own vehicle of recycling site m, and 0 otherwise;

- -

- : arrival time of a vehicle in demand node i;

- -

- : departure time of an own vehicle v in recycling site m.

- -

- : an intermediate variable, equals 1 if , and 0 otherwise.

3.4. Mathematical Model

4. Solutions

4.1. Genetic Algorithm

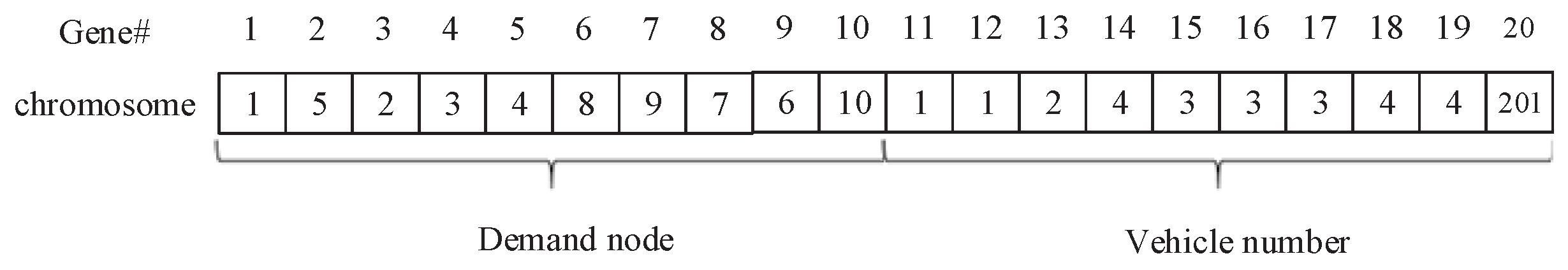

4.1.1. Chromosome Coding

4.1.2. Population Initialization

4.1.3. Calculation of Objective Value

4.1.4. Fitness Function

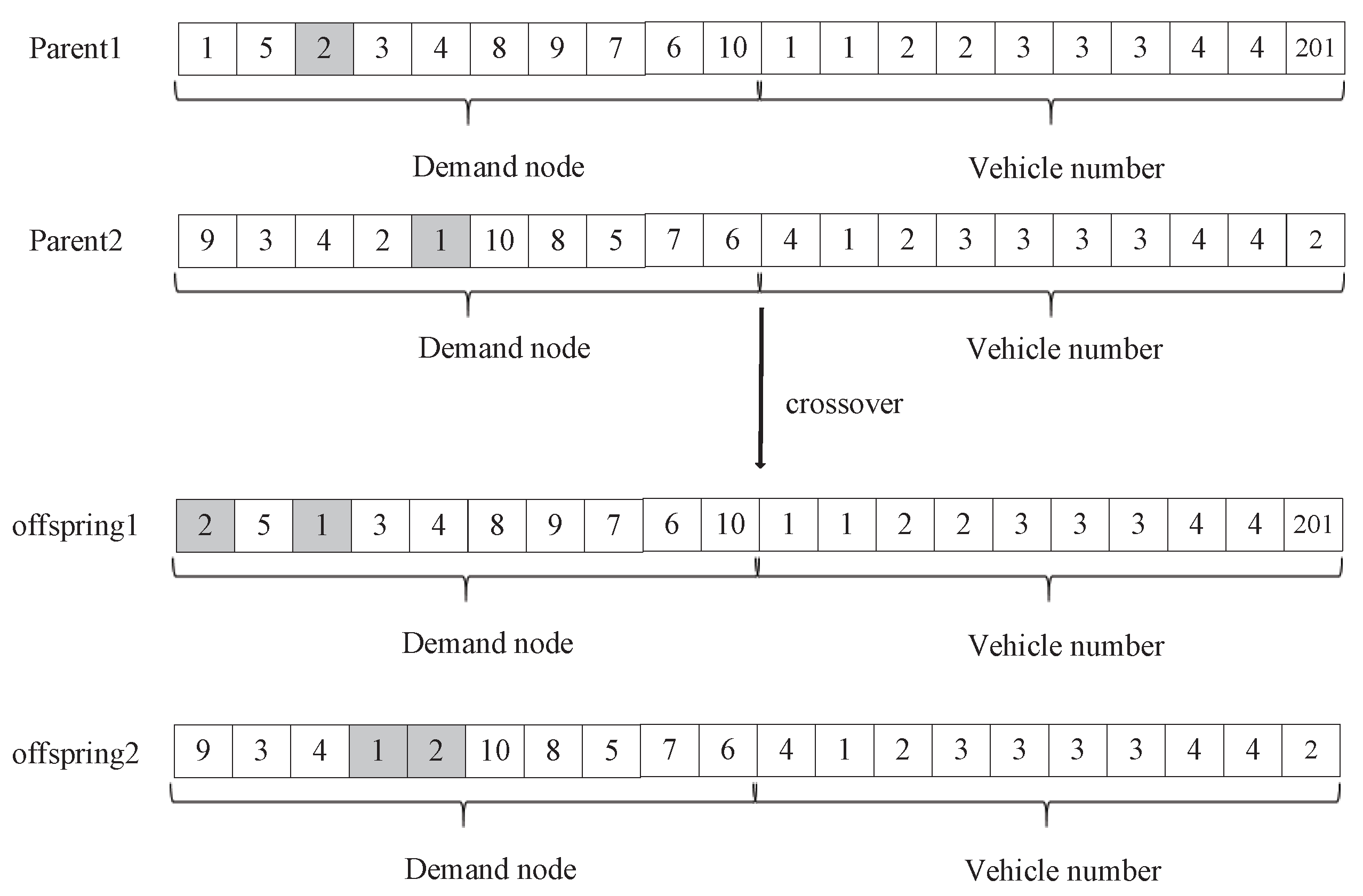

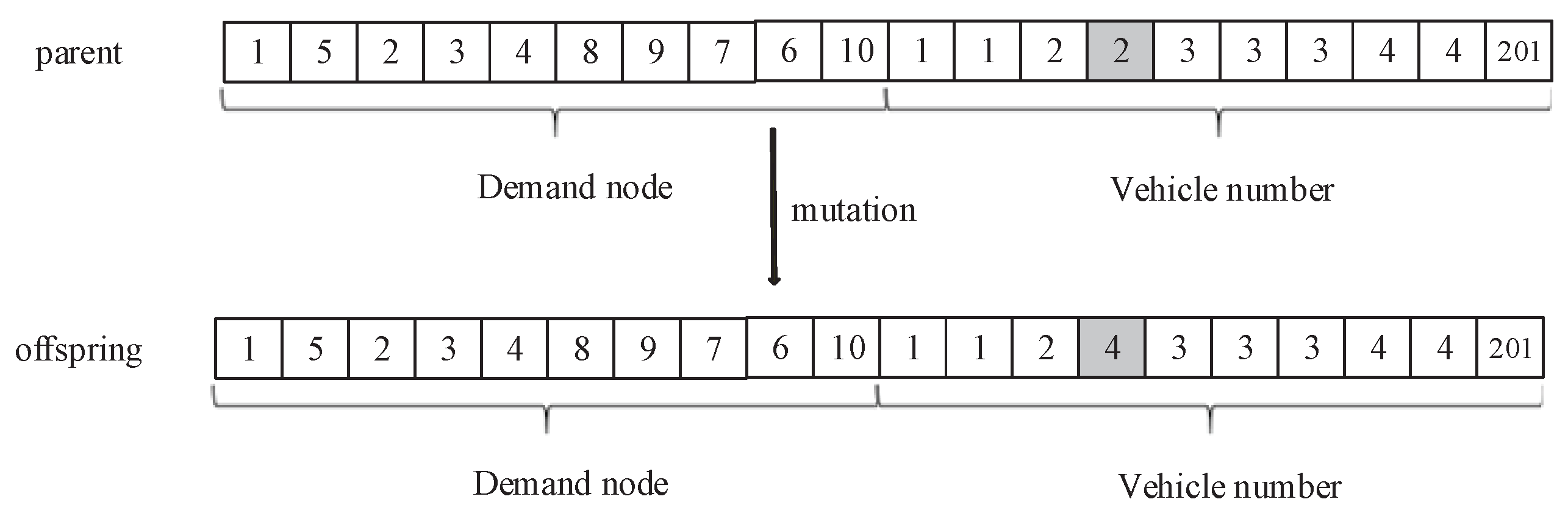

4.1.5. Genetic Operations

4.1.6. Feasibility Judgment

4.1.7. Termination Condition

4.2. Heuristic Algorithm

4.2.1. The Location Sub-Problem

4.2.2. The Routing Sub-Problem

5. Computational Experiments

5.1. Experimental Parameters

- -

- speed of vehicles: = 1 km/min ([35]);

- -

- cost of transporation per minute: = 0.5 CNY/km ([18]);

- -

- renting cost per time: = 200 CNY/km ([36]);

- -

- capacity of small vehicles: = 1800 kg;

- -

- capacity of large vehicles: = 6000 kg;

- -

- coordinate range of demand nodes and recycling sites: randi([10,100],,2)

- -

- coordinate range of the recycling centre: randi([110,150],1,2);

- -

- time window of demand node i: =randi(300,1,), = randi([20,70],1,), and = + ;

- -

- processing time of demand node i: = randi(120, 1, );

- -

- amount of e-waste in demand node i: = randi([50,1000], 1, );

- -

- amount of e-waste sent by customers in m: = randi([2000,3000], 1, );

5.2. Numerical Results

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Acknowledgments

Conflicts of Interest

References

- Li, W.; Achal, V. Environmental and health impacts due to e-waste disposal in china—A review. Sci. Total Environ. 2020, 737, 139745. [Google Scholar] [CrossRef] [PubMed]

- Thompson, R.G.; Nassir, N.; Frauenfelder, P. Shared freight networks in metropolitan areas. Transp. Res. Procedia 2020, 57, 204–211. [Google Scholar] [CrossRef]

- Salhofer, S.; Steuer, B.; Ramusch, R.; Beigl, P. WEEE management in Europe and China—A comparison. Waste Manag. 2016, 57, 27–35. [Google Scholar] [CrossRef] [PubMed]

- Singh, N.; Li, J.; Zeng, X. Solutions and challenges in recycling waste cathode-ray tubes. J. Clean. Prod. 2016, 133, 188–200. [Google Scholar] [CrossRef]

- Guo, J.; Tang, B.; Huo, Q.; Liang, C.; Gen, M. Fuzzy programming of dual recycling channels of sustainable multi-objective waste electrical and electronic equipment (WEEE) based on triple bottom line (TBL) theory. Arab. J. Sci. Eng. 2021, 1–14. [Google Scholar] [CrossRef]

- He, K.; Sun, Z.; Hu, Y.; Zeng, X.; Yu, Z.; Cheng, H. Comparison of soil heavy metal pollution caused by e-waste recycling activities and traditional industrial operations. Environ. Sci. Pollut. Res. 2017, 24, 1299–1332. [Google Scholar] [CrossRef] [PubMed]

- Cao, J.X.; Zhang, Z.X.; Zhou, Y.G. A location-routing problem for biomass supply chains. Comput. Ind. Eng. 2021, 152, 107017. [Google Scholar] [CrossRef]

- Gamberini, R.; Gebennini, E.; Manzini, R.; Ziveri, A. On the integration of planning and environmental impact assessment for a WEEE transportation network—A case study. Resour. Conserv. Recycl. 2010, 54, 937–951. [Google Scholar] [CrossRef]

- Nowakowski, P. A proposal to improve e-waste collection efficiency in urban mining: Container loading and vehicle routing problems—A case study of Poland. Waste Manag. 2017, 145, 494–504. [Google Scholar] [CrossRef] [PubMed]

- Beneventti, G.D.; Bronfman, C.A.; Paredes-Belmar, G.; Marianov, V. A multi-product maximin hazmat routing-location problem with multiple origin-destination pairs. J. Clean. Prod. 2019, 240, 118193. [Google Scholar] [CrossRef]

- Sakti, S.; Yu, V.F.; Sopha, B.M. Heterogeneous fleet location routing problem for waste management: A case study of Yogyakarta, Indonesia. Int. J. Inf. Manag. Sci. 2019, 30, 1–16. [Google Scholar]

- Zhao, J.; Ke, G.Y. Incorporating inventory risks in location-routing models for explosive waste management. Int. J. Prod. Econ. 2017, 193, 123–136. [Google Scholar] [CrossRef]

- Dukkanci, O.; Kara, B.Y.; Bektas, T. The green location-routing problem. Comput. Oper. Res. 2019, 105, 187–202. [Google Scholar] [CrossRef]

- Zhou, L.; Wang, X.; Lin, N. Location-Routing problem with simultaneous home delivery and customer’s pickup for city distribution of online shopping purchases. Sustainability 2016, 8, 828. [Google Scholar] [CrossRef] [Green Version]

- Ng, A.; Agp, B.; Ob, A.; Mv, C. The multi-depot open location routing problem with a heterogeneous fixed fleet. Expert Syst. Appl. 2020, 165, 113846. [Google Scholar] [CrossRef]

- Vandani, B.; Mousavi, S. A robust approach to multiple vehicle location-routing problems with time windows for optimization of cross-docking under uncertainty. J. Intell. Fuzzy Syst. Appl. Eng. Technol. 2017, 32, 49–62. [Google Scholar]

- Kuroki, H.; Ishigaki, A.; Takashima, R. A location-routing problem with economic efficiency for recycling system. Procedia Manuf. 2020, 43, 215–222. [Google Scholar] [CrossRef]

- Pourhejazy, P.; Zhang, D.; Zhu, Q.; Wei, F.; Song, S. Integrated E-waste transportation using capacitated general routing problem with time-window. Transp. Res. Part Logist. Transp. Rev. 2021, 145, 102169. [Google Scholar] [CrossRef]

- Agnusdei, G.P.; Gnoni, M.G.; Tornese, F. Modelling and simulation tools for integrating forward and reverse logistics: A literature review. In Proceedings of the European Modeling & Simulation Symposium, Lisbon, Portugal, 18–20 September; pp. 317–326.

- Abid, S.; Radji, S.; Mhada, F.Z. Simulation techniques applied in reverse logistic: A review. In Proceedings of the 2019 International Colloquium on Logistics and Supply Chain Management (LOGISTIQUA), Paris, France, 12–14 June 2019; pp. 1–6. [Google Scholar]

- Surekha, P.; Sumathi, S. Solution to multi-depot vehicle routing problem using genetic algorithms. World Appl. Program. 2011, 1, 118–131. [Google Scholar]

- Yang, J.; Sun, H. Battery swap station location-routing problem with capacitated electric vehicles. Comput. Oper. Res. 2015, 55, 217–232. [Google Scholar] [CrossRef]

- Berglund, P.G.; Kwon, C. Robust facility location problem for hazardous waste transportation. Netw. Spat. Econ. 2014, 14, 91–116. [Google Scholar] [CrossRef]

- Ferdi, I.; Layeb, A. A grasp algorithm based new heuristic for the capacitated location routing problem. J. Exp. Theor. Artif. Intell. 2018, 30, 369–387. [Google Scholar] [CrossRef]

- Almouhanna, A.; Quintero-Araujo, C.L.; Panadero, J.; Juan, A.A.; Ouelhadj, D. The location routing problem using electric vehicles with constrained distance. Comput. Oper. Res. 2019, 115, 104864. [Google Scholar] [CrossRef]

- Schiffer, M.; Walther, G. The electric location routing problem with time windows and partial recharging. Eur. J. Oper. Res. 2017, 260, 995–1013. [Google Scholar] [CrossRef]

- Ponboon, S.; Qureshi, A.G.; Taniguchi, E. Branch-and-price algorithm for the location-routing problem with time windows. Transp. Res. Part Logist. Transp. Rev. 2016, 86, 1–19. [Google Scholar] [CrossRef]

- Pichka, K.; Bajgiran, A.H.; Petering, M.E.; Jang, J.; Yue, X. The two echelon open location routing problem: Mathematical model and hybrid heuristic. Comput. Ind. Eng. 2018, 121, 97–112. [Google Scholar] [CrossRef]

- Lopes, R.B.; Ferreira, C.; Santos, B.S. A simple and effective evolutionary algorithm for the capacitated location-routing problem. Comput. Oper. Res. 2016, 70, 155–162. [Google Scholar] [CrossRef]

- Kilic, H.S.; Cebeci, U.; Ayhan, M.B. Reverse logistics system design for the waste of WEEE in Turkey. Resour. Conserv. Recycl. 2015, 95, 120–132. [Google Scholar] [CrossRef]

- Zhang, S.; Chen, M.; Zhang, W. A novel location-routing problem in electric vehicle transportation with stochastic demands. J. Clean. Prod. 2019, 221, 567–581. [Google Scholar] [CrossRef]

- Gen, M.; Syarif, A. Hybrid genetic algorithm for multi-time period production/distribution planning. Comput. Ind. Eng. 2005, 48, 799–809. [Google Scholar] [CrossRef]

- Hu, H.; Li, X.; Zhang, Y.; Shang, C.; Zhang, S. Multi-objective location-routing model for hazardous material logistics with traffic restriction constraint in inter-city roads. Comput. Ind. Eng. 2018, 128, 861–876. [Google Scholar] [CrossRef]

- Cinar, D.; Gakis, K.; Pardalos, P.M. A 2-phase constructive algorithm for cumulative vehicle routing problems with limited duration. Comput. Ind. Eng. 2016, 56, 48–58. [Google Scholar] [CrossRef]

- Bektaş, T.; Laporte, G. The pollution-routing problem. Transp. Res. Part B Methodol. 2011, 45, 1232–1250. [Google Scholar] [CrossRef]

- Xie, H. Research on Strategic Choice and Development in A Car Rental Company; Tianjin University: Tianjin, China, 2016. [Google Scholar]

| References | Objective | Vehicle Fleet | Vehicle Capacity | Time Window | Solution Method |

|---|---|---|---|---|---|

| Cao et al. [7] | min FEC & TC | single | - | - | CPLEX,TS |

| Nowakowski [9] | min TC | single | ✓ | - | GLSA |

| Zhao et al. [12] | min TC, FEC & risk | single | ✓ | - | TOPSIS |

| Beneventtiet et al. [10] | max MWD; min THIP, FEC & TC | single | - | - | CPLEX |

| Dukkanci et al. [13] | min FEC, FC & C | single | - | ✓ | ILSA |

| Zhou et al. [14] | min FEC, TC & SDC | single | ✓ | ✓ | HESA |

| Ng et al. [15] | min TC | single | ✓ | - | MA |

| Vandani et al. [16] | min TC & IC | multi | ✓ | ✓ | MA |

| Kuroki et al. [17] | min RC & TC | single | - | - | SAA |

| Pourhejazy et al. [18] | max TP | single | ✓ | ✓ | TS |

| this study | min FC & RSVC | multi | ✓ | ✓ | CPLEX, GA, HA |

| Instances | CPLEX | GA | TSGL | |||||||

|---|---|---|---|---|---|---|---|---|---|---|

| [,] | ||||||||||

| 1 | [1,1] | 584.0 | 1.1 | 584.0 | 9.3 | 0.0 | 584.0 | 0.2 | 0.0 | |

| 2 | [1,1] | 259.5 | 1.1 | 259.5 | 9.7 | 0.0 | 267.0 | 0.3 | 2.9 | |

| 1 | [2,2] | 208.0 | 1.4 | 208.0 | 10.6 | 0.0 | 216.0 | 0.3 | 3.6 | |

| [5,2] | 2 | [2,2] | 208.0 | 1.4 | 208.0 | 10.6 | 0.0 | 216.0 | 0.3 | 3.6 |

| 1 | [1,1] | 259.5 | 1.1 | 259.5 | 9.7 | 0.0 | 267.0 | 0.3 | 2.9 | |

| 1 | [1,2] | 432.5 | 1.3 | 432.5 | 10.7 | 0.0 | 584.0 | 0.3 | 35.0 | |

| 2 | [1,2] | 259.5 | 1.3 | 259.5 | 10.3 | 0.0 | 267.0 | 0.3 | 2.9 | |

| no time windows, = 1 | 146.5 | 1.5 | 146.5 | 10.4 | 0.0 | 162.5 | 0.3 | 10.9 | ||

| Avg | 299.9 | 1.3 | 299.9 | 10.2 | 0.0 | 328.1 | 0.4 | 8.4 | ||

| 2 | [1,1,1] | 1159.5 | 3.4 | 1159.5 | 11.1 | 0.0 | 1166.5 | 0.4 | 0.6 | |

| 3 | [1,1,1] | 853.0 | 3.5 | 853.0 | 12.3 | 0.0 | 934.5 | 0.4 | 9.5 | |

| 2 | [2,2,2] | 437.5 | 5.3 | 437.5 | 14.0 | 0.0 | 443.5 | 0.4 | 1.4 | |

| [10,3] | 3 | [2,2,2] | 437.5 | 7.7 | 437.5 | 14.3 | 0.0 | 443.5 | 0.4 | 1.4 |

| 2 | [2,1,3] | 451.5 | 5.3 | 451.5 | 14.3 | 0.0 | 558.5 | 0.4 | 23.8 | |

| 3 | [2,1,3] | 451.5 | 5.3 | 451.5 | 14.3 | 0.0 | 558.5 | 0.4 | 23.8 | |

| no time windows, = 2 | 314.5 | 21.2 | 314.5 | 13.4 | 0.0 | 343.0 | 0.4 | 9.1 | ||

| Avg | 586.4 | 7.4 | 586.4 | 13.4 | 0.0 | 635.4 | 0.4 | 9.9 | ||

| 2 | [2,2,2,2,2] | 897.0 | 278.3 | 1064.5 | 17.9 | 18.7 | 1107.5 | 0.5 | 4.0 | |

| 3 | [2,2,2,2,2] | 378.0 | 26.1 | 398.0 | 19.4 | 5.3 | 581.5 | 0.4 | 46.1 | |

| 2 | [3,3,3,3,3] | 392.0 | 25.4 | 399.5 | 21.4 | 1.9 | 541.0 | 0.5 | 35.4 | |

| [15,5] | 3 | [3,3,3,3,3] | 375.5 | 37.7 | 379.5 | 23.0 | 1.0 | 579.5 | 0.5 | 52.7 |

| 2 | [2,3,2,3,1] | 506.5 | 38.7 | 522.0 | 20.0 | 3.1 | 585.5 | 0.5 | 12.2 | |

| 3 | [2,3,2,3,1] | 439.0 | 34.5 | 465.5 | 20.3 | 6.1 | 572.0 | 0.5 | 22.9 | |

| no time windows, = 2 | 756.0 | 832.4 | 792.0 | 17.5 | 4.8 | 820.0 | 0.5 | 3.5 | ||

| Avg | 498.0 | 73.5 | 538.2 | 20.3 | 6.0 | 661.2 | 0.5 | 28.9 | ||

| 2 | [2,2,2,2,2] | 1678.5 | 1516.9 | 1977.0 | 19.0 | 17.8 | 2220.5 | 0.7 | 12.3 | |

| 3 | [2,2,2,2,2] | 899.5 | 4639.3 | 1107.5 | 21.0 | 23.1 | 1148.5 | 0.7 | 3.7 | |

| 2 | [3,3,3,3,3] | - | - | 1024.5 | 23.3 | - | 1054.5 | 0.7 | 2.9 | |

| [20,5] | 3 | [3,3,3,3,3] | 476.0 | 734.5 | 507.5 | 26.5 | 6.6 | 724.5 | 0.6 | 42.8 |

| 2 | [2,3,2,3,2] | 930.0 | 1157.6 | 1102.5 | 18.5 | 40.1 | 1202.0 | 0.6 | 9.0 | |

| 3 | [2,3,2,3,2] | 511.0 | 354.7 | 538.0 | 23.8 | 5.3 | 743.0 | 0.7 | 38.1 | |

| no time windows, = 2 | - | - | 834.0 | 37.9 | - | 850.5 | 1.5 | 2.0 | ||

| Avg | 899.0 | 1680.6 | 1013.0 | 24.3 | 18.6 | 1134.8 | 0.8 | 15.8 | ||

| 3 | [2,2,2,2,2,2,2,2] | - | - | 1285.0 | 24.8 | - | 1356.5 | 1.2 | 5.6 | |

| 4 | [2,2,2,2,2,2,2,2] | 523.5 | 270.0 | 621.0 | 26.1 | 18.6 | 724.5 | 0.6 | 16.7 | |

| 3 | [2,2,2,2,2,2,2,2] | 524.0 | 841.7 | 579.5 | 30.5 | 10.6 | 744.5 | 1.1 | 28.4 | |

| [20,8] | 4 | [2,2,2,2,2,2,2,2] | 520.0 | 571.1 | 547.8 | 32.7 | 5.3 | 744.5 | 0.6 | 35.9 |

| 3 | [2,2,2,2,2,2,2,2] | 569.0 | 3169.2 | 602.0 | 27.5 | 5.8 | 776.5 | 0.6 | 29.0 | |

| 4 | [2,2,2,2,2,2,2,2] | 522.0 | 135.8 | 582.0 | 26.7 | 11.5 | 822.5 | 0.6 | 41.3 | |

| no time windows, = 2 | - | - | 543.2 | 28.9 | - | 682.0 | 0.7 | 25.6 | ||

| Avg | 531.7 | 997.6 | 680.1 | 28.2 | 10.4 | 835.9 | 0.8 | 26.1 | ||

| Instances | GA | TSGL | |||||

|---|---|---|---|---|---|---|---|

| [,] | |||||||

| 3 | [2,2,2,2,2,2,2,2] | 1616.0 | 34.8 | 1719.5 | 1.0 | 6.4 | |

| 4 | [2,2,2,2,2,2,2,2] | 1146.3 | 39.8 | 1193.5 | 1.1 | 4.1 | |

| 3 | [3,3,3,3,3,3,3,3] | 683.4 | 46.5 | 851.0 | 1.1 | 24.5 | |

| [25,8] | 4 | [3,3,3,3,3,3,3,3] | 708.0 | 48.8 | 847.0 | 1.1 | 19.6 |

| 3 | [3,2,2,3,2,2,2,3] | 891.6 | 30.8 | 944.0 | 0.7 | 5.9 | |

| 4 | [3,2,2,3,2,2,2,3] | 703.9 | 32.5 | 778.0 | 0.8 | 10.5 | |

| Avg | 958.2 | 38.9 | 1055.5 | 1.0 | 6.1 | ||

| 4 | [2,2,2,2,2,2,2,2,2,2] | 1786.2 | 32.5 | 1872.0 | 1.1 | 4.8 | |

| 5 | [2,2,2,2,2,2,2,2,2,2] | 1244.6 | 35.5 | 1462.5 | 0.9 | 17.5 | |

| 4 | [3,3,3,3,3,3,3,3,3,3] | 1018.8 | 42.6 | 1218.5 | 0.9 | 19.6 | |

| [35,10] | 5 | [3,3,3,3,3,3,3,3,3,3] | 902.6 | 45.2 | 1345.5 | 0.9 | 49.1 |

| 4 | [2,2,1,2,1,3,1,2,1,2] | 2504.2 | 30.4 | 2917.5 | 0.8 | 16.5 | |

| 5 | [2,2,1,2,1,3,1,2,1,2] | 1709.0 | 36.5 | 1986.5 | 0.8 | 16.2 | |

| Avg | 1527.6 | 37.1 | 1800.4 | 0.9 | 20.6 | ||

| 5 | [2,2,2,2,2,2,2,2,2,2,2,2] | 2618.6 | 58.9 | 2667.5 | 1.6 | 1.9 | |

| 6 | [2,2,2,2,2,2,2,2,2,2,2,2] | 1669.3 | 66.2 | 1709.5 | 1.6 | 2.4 | |

| 5 | [3,3,3,3,3,3,3,3,3,3,3,3] | 1204.6 | 82.1 | 1360.0 | 1.6 | 12.9 | |

| [45,12] | 6 | [3,3,3,3,3,3,3,3,3,3,3,3] | 1155.4 | 88.9 | 1383.0 | 1.6 | 19.7 |

| 5 | [2,3,4,2,3,2,2,2,2,3,2,3] | 1256.5 | 75.8 | 1310.5 | 1.6 | 4.3 | |

| 6 | [2,3,4,2,3,2,2,2,2,3,2,3] | 1305.5 | 77.8 | 1415.0 | 1.6 | 8.4 | |

| Avg | 1535.0 | 75.0 | 1640.9 | 1.6 | 7.1 | ||

| 6 | [2,2,2,2,2,2,2,2,2,2,2,2,2,2] | 2919.0 | 71.4 | 3013.0 | 1.8 | 3.2 | |

| 7 | [2,2,2,2,2,2,2,2,2,2,2,2,2,2] | 2118.4 | 77.2 | 2554.0 | 1.9 | 20.6 | |

| 6 | [3,3,3,3,3,3,3,3,3,3,3,3,3,3] | 1338.3 | 98.0 | 1474.0 | 1.8 | 10.1 | |

| [50,14] | 7 | [3,3,3,3,3,3,3,3,3,3,3,3,3,3] | 1188.4 | 103.5 | 1343.5 | 1.8 | 13.1 |

| 6 | [2,3,4,3,2,3,3,3,3,3,2,3,2,3] | 1377.8 | 96.2 | 1576.5 | 1.8 | 14.4 | |

| 7 | [2,3,4,3,2,3,3,3,3,3,2,3,2,3] | 1318.1 | 95.9 | 1369.0 | 1.8 | 3.9 | |

| Avg | 1710.0 | 90.4 | 1888.3 | 1.8 | 10.9 | ||

| 7 | [2,2,2,2,2,2,2,2,2,2,2,2,2,2,2,2] | 3227.2 | 56.2 | 3324.0 | 1.3 | 3.0 | |

| 8 | [2,2,2,2,2,2,2,2,2,2,2,2,2,2,2,2] | 2495.9 | 60.6 | 2514.5 | 1.3 | 0.7 | |

| 7 | [3,3,3,3,3,3,3,3,3,3,3,3,3,3,3,3] | 1708.6 | 78.2 | 1840.5 | 1.4 | 7.7 | |

| [55,16] | 8 | [3,3,3,3,3,3,3,3,3,3,3,3,3,3,3,3] | 1672.2 | 82.2 | 1815.0 | 1.5 | 8.5 |

| 7 | [2,3,2,2,3,3,1,2,1,2,3,2,2,3,3,2] | 1934.1 | 64.4 | 2054.0 | 1.5 | 6.2 | |

| 8 | [2,3,2,2,3,3,1,2,1,2,3,2,2,3,3,2] | 1716.4 | 69.5 | 1813.5 | 1.2 | 5.7 | |

| Avg | 2125.7 | 68.5 | 2226.9 | 1.4 | 5.3 | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zheng, F.; Sun, Z.; Liu, M. Location-Routing Optimization with Renting Social Vehicles in a Two-Stage E-Waste Recycling Network. Sustainability 2021, 13, 11879. https://doi.org/10.3390/su132111879

Zheng F, Sun Z, Liu M. Location-Routing Optimization with Renting Social Vehicles in a Two-Stage E-Waste Recycling Network. Sustainability. 2021; 13(21):11879. https://doi.org/10.3390/su132111879

Chicago/Turabian StyleZheng, Feifeng, Zhiyu Sun, and Ming Liu. 2021. "Location-Routing Optimization with Renting Social Vehicles in a Two-Stage E-Waste Recycling Network" Sustainability 13, no. 21: 11879. https://doi.org/10.3390/su132111879

APA StyleZheng, F., Sun, Z., & Liu, M. (2021). Location-Routing Optimization with Renting Social Vehicles in a Two-Stage E-Waste Recycling Network. Sustainability, 13(21), 11879. https://doi.org/10.3390/su132111879