Recent Trends in Sustainable Inventory Models: A Literature Review

Abstract

1. Introduction

2. Materials and Methods

- Papers selection phase:

- Comprehensive material research. This process entails finding keywords, creating search strings, and choosing the academic databases for data collection.

- Selection criteria. This step entails the determination of inclusion and exclusion criteria to identify relevant papers to be in-depth reviewed.

- Descriptive and content analysis of the selected documents:

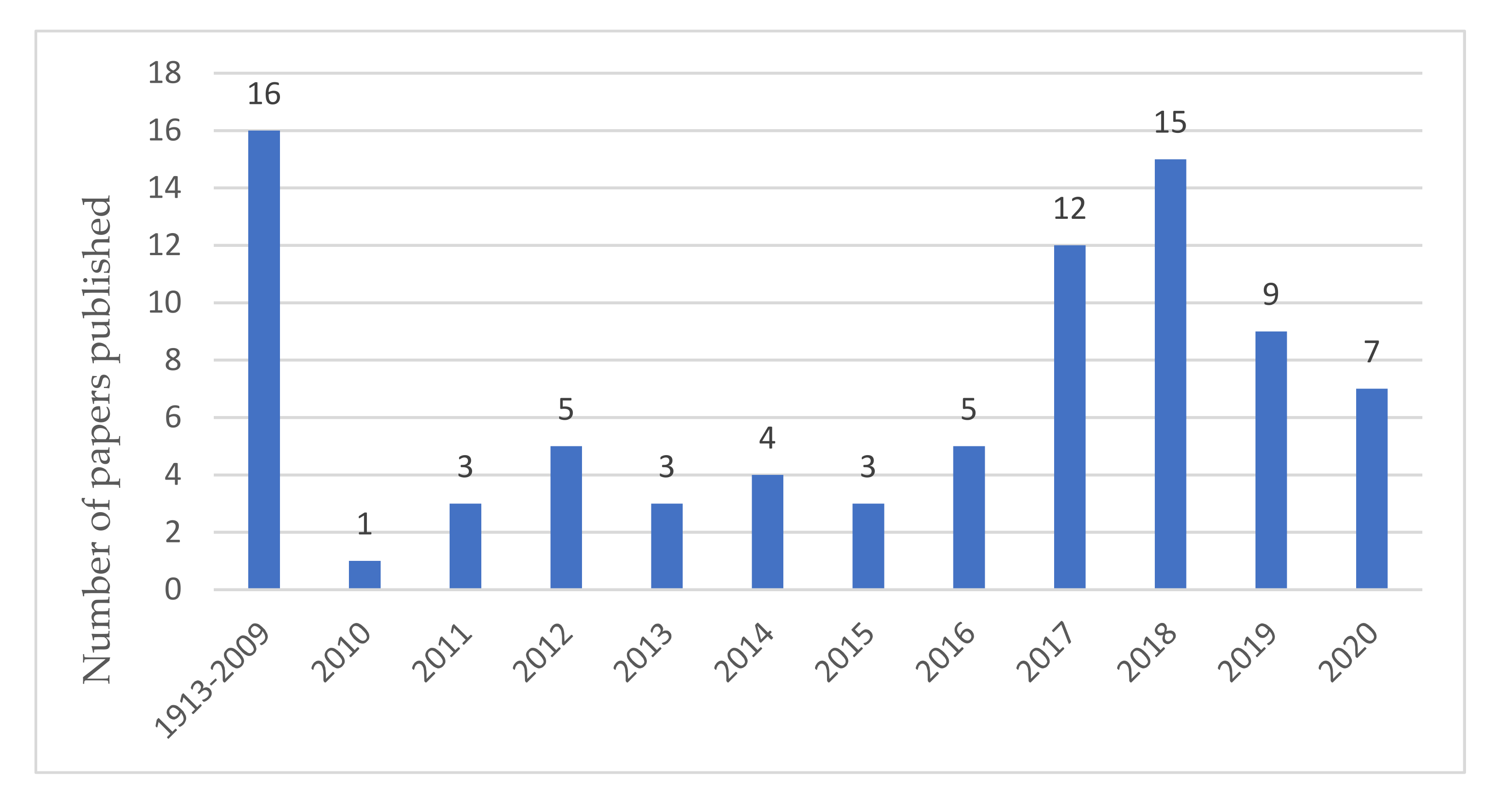

- Descriptive analysis. To have an overall mapping of the chosen articles, the papers are analyzed according to different perspectives (i.e., distribution of papers based on the year of publication, distribution of papers among journals, distribution of papers based on methods).

- Content analysis. The full text of the selected papers is thoroughly analyzed to identify the literature’s strengths and weaknesses, research gaps, and relevant research issues to be further investigated.

3. Data Collection

3.1. Phase of Material Search

- Only papers published in peer-reviewed journals were selected.

- Articles from subject areas that were not related to the issue under investigation were excluded.

3.2. Paper Selection Process

4. Descriptive Analysis

4.1. Distribution of Papers Based on the Publication Year

4.2. Distribution of Papers among Journals

4.3. Distribution of Papers based on Methods

5. Content Analysis

6. Discussion of the Results and Research Agenda

7. Conclusions and Implications

7.1. Contribution to Theory

7.2. Contribution to Managerial Practice and Policymakers

7.3. Limitations of the Study

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Appendix A

| Authors | Publication Year/Journal Name | Research Objective |

|---|---|---|

| Ambec et al. | 2008/Academy of Management Perspectives | Does It Pay to be Green? A Systematic Overview |

| Andriolo et al. | 2015/International Journal of Production Economics | Haulage sharing approach to achieve sustainability in material purchasing: New method and numerical applications |

| Andriolo et al. | 2016/International Journal of Production Research | A new bi-objective approach for including ergonomic principles into EOQ model |

| Asghar et al. | 2019/Energies | Optimize production lot size, production rate and readability parameters |

| Bai et al. | 2019/Environmental Science and Technology | Further Improvement of Air Quality in China Needs Clear Ammonia Mitigation Target |

| Battini et al. | 2014/International Journal of Production Economics | A sustainable EOQ model: Theoretical formulation and applications |

| Bazan et al. | 2017/International Journal of Production Economics | Carbon emissions and energy effects on a two-level manufacturer-retailer closed-loop supply chain model with remanufacturing subject to different coordination mechanisms |

| Benjaafar et al. | 2012/IEEE transactions on automation science and engineering | Carbon footprint and the management of supply chains: Insights from simple models |

| Biuki et al. | 2020/Journal of cleaner production | By using GA and PSO to find the optimal solution to the problem |

| Bonney et al. | 2011/International Journal of Production Economics | Environmentally responsible inventory models: Non-classical models for a non-classical era |

| Bouchery et al. | 2012/European Journal of Operational Research | Including sustainability criteria into inventory models |

| Bozorgi et al. | 2014/International Journal of Production Economics | A new inventory model for cold items that considers costs and emissions |

| Centobelli et al. | 2017/Transport and Environment | Environmental sustainability in the service industry of transportation and logistics service providers: Systematic literature review and research directions |

| Cerchione et al. | 2016/International Journal of Production Economics | A systematic review of Supply Chain knowledge management research: State of the art and research opportunities |

| Chen et al. | 2013/Operations Research Letters | The carbon-constrained EOQ |

| Choi et al. | 2019/Sustainability | Approaching PTR (pollution base regulation) and BCR (Baseline credit regulation) to analyze stochastic optimization of the problem |

| Daryanto et al. | 2018/Journal of Advanced Management Science | Carbon emissions from the EPQ model was minimized in order to create a cleaner manufacturing environment |

| Daryanto et al. | 2019/International Journal of Industrial Engineering and Engineering Management | To minimize carbon emission cost, total operation, and production quantity |

| Datta et al. | 2017/Advances in Operations Research | Effect of Green Technology Investment on a Production-Inventory System with Carbon Tax |

| Digiesi et al. | 2013/Management and Production Engineering Review | Supply lead time uncertainty in a sustainable order quantity inventory model |

| Digiesi et al. | 2014/IMA Journal of Management Mathematics | A sustainable EOQ model for repairable spare parts under uncertain demand |

| Digiesi et al. | 2016/In New Models for Sustainable Logistics | Sustainable Inventory Management |

| Elkington et al. | 1998/Environmental Quality Management | Partnerships from cannibals with forks: The triple bottom line of 21st-century business |

| Gaston et al. | 2019/Environmental Science and Technology | Prioritization Approaches for Substances of Emerging Concern in Groundwater: A Critical Review |

| Gautam et al. | 2018/Uncertain Supply Chain Management, | The model is ideally tailored to real-time inventory situations because it decreases the total expense of the device |

| Gautam et al. | 2019/Journal of cleaner production | To maximize the total profit with management of defectives and reducing carbon emission |

| Hariga et al. | 2017/Journal of Cleaner Production | Integrated economic and environmental models for a multi-stage cold supply chain under carbon tax regulation |

| Harris et al. | 1913/Production Engineer | Development of the EOQ model |

| Hassini et al. | 2012/International Journal of Production Economics | A literature review and a case study of sustainable supply chains with a focus on metrics |

| Hovelaque et al. | 2015/International Journal of Production Economics | The carbon-constrained EOQ model with carbon emission dependent demand |

| Hua et al. | 2016/International Journal of Simulation Modelling | Carbon-constrained perishable inventory management with freshness-dependent demand |

| Jasch et al. | 2003/Journal of Cleaner production | The use of Environmental Management Accounting (EMA) for identifying environmental costs |

| Jena et al. | 2018/Journal of the Operational Research Society | Managing channel profit and total surplus in a closed-loop supply chain network |

| Jokar et al. | 2020/Journal of the Operational Research Society | Simultaneous coordination of order quantity and corporate social responsibility in a two-Echelon supply chain: A combined contract approach |

| Kamna et al. | 2020/International Journal of System Assurance Engineering and Management | To maximize the overall inventory turnover by conjointly optimize selling price as well as production rate and time |

| Karmakar et al. | 2017/Journal of cleaner production | A pollution-sensitive dense fuzzy economic production quantity model with cycle time dependent production rate |

| Kazemi et al. | 2018/International Journal of Systems Science | Incorporation of carbon pollution prices into the buyer’s strategy in order to reduce lot sizes and achieve minimal costs |

| Khan et al. | 2016/International Journal of Production Economics | Information sharing in a sustainable supply chain |

| Kumar et al. | 2021/Journal of Environmental Planning and Management | Static and dynamic regression models are used to gauge the impact of environmental management practices on firm profitability |

| Law et al. | 2010/Asia Pacific Management Review, | Factors affecting sustainability development: High-tech manufacturing firms in Taiwan |

| Lee | 2019/Journal of the Operational Research Society | Investment optimal lot size and carbon emission reduction in model with cap-and-price regulation policy |

| Lee et al. | 2017/Sustainability | Sustainable EOQ under lead-time uncertainty and multi-modal transport |

| Lin et al. | 2018/Journal of Applied Science and Engineering | Integrate economic and environmental viewpoints into the conventional inventory structure to integrate the sustainability concept |

| Marklund et al. | 2017/Sustainable supply chains | Green inventory management |

| Mishra et al. | 2021/Journal of Cleaner Production | Development of a carbon cap and tax-regulated sustainable inventory management for a buyer utilizing a linear and non-linear price-dependent demand |

| Mishra et al. | 2019/Energies | Affected total profit and all decision variable due to impact of key parameters such as demand, production, and reduction of set-up cost, ordering cost, loss factor, and carbon emission |

| Mishra et al. | 2020/Journal of cleaner production | This model gives better justifiable profit with highest cycle time, lowest value of fractional length period, as well as lower green technology investment cost |

| Modak et al. | 2021/Journal of the Operational Research Society | Mathematical models are proposed for expected profit maximization under a carbon emissions tax |

| Mukhopadhyay et al. | 2014/Systems Science & Control Engineering | Economic production quantity models for imperfect items with pollution costs |

| Plambeck et al. | 2012/Energy Economics | Reducing greenhouse gas emissions through operations and supply chain management |

| Poplawska et al. | 2017/Journal of the Operational Research Society | From vicious to virtuous circles: Problem structuring for quantified decision making in operationalization of corporate social responsibility |

| Rădulescu et al. | 2009/European Journal of Operational Research | Sustainable production technologies which take into account environmental constraints |

| Reinmuth et al. | 2017/Environmental Science and Technology | Air Pollution and Climate Change Effects on Allergies in the Anthropocene: Abundance, Interaction, and Modification of Allergens and Adjuvants |

| Reyes et al. | 2018/International Journal of Environmental Sustainability | Corporate social initiatives of top oil players in the Philippines |

| Robinson et al. | 2019/Environmental Management | Integration of social and ecological sciences for natural resource decision making: Challenges and opportunities |

| Saadany et al. | 2011/Management Research Review | Environmental performance measures for supply chains |

| Sarkar et al. | 2017/Journal of Industrial & Management Optimization | An integrated inventory model with variable transportation cost, two-stage inspection, and defective items |

| Sarkar et al. | 2018/Applied Sciences | Minimize overall cost of production, carbon footprint reduction, and electricity cost |

| Sarkar et al. | 2019/International Journal of Production Economics | Control carbon footprint and optimum cash-flow within a smart production system such as manufacturing, distribution, consumption, and remanufacturing |

| Shen et al. | 2019/Sustainability | For buyer and vendor to find maximum profit and optimal production, delivery, ordering |

| Shu et al. | 2017/Journal of cleaner production | Manufacturers’/remanufacturers’ inventory control strategies with cap-and-trade regulation |

| Soleymanfar et al. | 2015/Journal of Industrial and Systems Engineering | Economic manufacturing model under partial backordering and sustainability considerations |

| Suprayoga et al. | 2020/Journal of Environmental Planning and Management | Identifying barriers to implementing a sustainability assessment tool for road project planning: an institutional perspective from practitioners in Indonesia |

| Taleizadeh et al. | 2018/Journal of cleaner production | To assess the optimal value of the decision element, various scarcity conditions such as missed revenue, full backordering, and partly backordering were used |

| Tang et al. | 2020/Mathematical problems in engineering | The results indicate that a carbon tax policy can improve social welfare and the sustainability of transportation and inventory but could hinder corporate profits |

| Tao et al. | 2010/Annual Kent State International Symposium on Green Supply Chains | A green cost based economic production/order quantity model |

| Tenggren et al. | 2020/Journal of Environmental Planning and Management | Climate risk in a globalized world: Empirical findings from supply chains in the Swedish manufacturing sector |

| Tiwari et al. | 2018/Journal of Cleaner Production | Due effect of carbon emission cost reducing the delivery frequency and increasing the delivery quantity to minimize both the total inventory and carbon emission costs |

| Tiwari, et al. | 2018/Journal of Cleaner Production | Sustainable inventory management with deteriorating and imperfect quality items considering carbon emission |

| Toptal et al. | 2014/International Journal of Production Research | Joint decisions on inventory replenishment and emission reduction investment under different emission regulations |

| Wangsa et al. | 2017/International Journal of Industrial Engineering Computations | Greenhouse gas penalty and incentive policies for a joint economic lot size model with industrial and transport emissions |

| Wangsa et al. | 2018/Energies | The parameters like price of electricity and elasticity coefficient, production cost, scaling factor, and rate of power supply affect optimal decision variable and total profit |

| Wangsa et al. | 2020/Journal of cleaner production | Find minimum total cost to optimize the decision variables such as order quantity, total emission, safety time, lead time, and number of shipments |

| Waxin et al. | 2019/Environmental Management | Drivers and challenges for implementing ISO 14001 environmental management systems in an emerging Gulf Arab country |

| Weaver, et al. | 2019/Environmental Management | A Framework for Climate Change-Related Research to Inform Environmental Protection |

| Wilting et al. | 2017/Environmental Science and Technology | Quantifying Biodiversity Losses Due to Human Consumption: A Global-Scale Footprint Analysis |

| Wu et al. | 2018/International Conference on Management Science and Engineering Management | To assess the relationship between the ideal quality product’s predicted rate and the right output lot |

| Xiao et al. | 2016/International Journal of Environmental Sustainability | Public design and household participation in recycling for sustainability: A case study in Hong Kong |

| Yassine | 2018/Annals of Operations Research | Reducing environmental and social impacts to optimize lot size and total production cost |

| Yıldızbaşı et al. | 2021/Environment, Development and Sustainability | Development of a Multi-Criteria Decision-Making (MCDM) method to identify the situation in terms of the social sustainability of the automotive industry companies in Turkey |

| Zadjafa et al. | 2018/Journal of cleaner production | A sustainable inventory model by considering environmental ergonomics and environmental pollution, case study: Pulp and paper mills |

| Zadjafar & Gholamian | 2018/Journal of cleaner production | Optimized the cost function along with reduction of gases and water pollutants |

| Zavanella et al. | 2019/Journal of Business Economics | Energy cost directly impact in total cost and its environmental linkage |

References

- Zorrilla-Muñoz, V.; Petz, M.; Agulló-Tomás, M.S. GARCH model to estimate the impact of agricultural greenhouse gas emissions per sociodemographic factors and CAP in Spain. Environ. Dev. Sustain. 2021, 23, 4675–4697. [Google Scholar] [CrossRef]

- Law, K.M.Y. Factors affecting sustainability development: High-tech manufacturing firms in Taiwan. Asia Pac. Manag. Rev. 2010, 15, 619–633. [Google Scholar]

- Zadjafar, M.A.; Gholamian, M.R. A sustainable inventory model by considering environmental ergonomics and environmental pollution, case study: Pulp and paper mills. J. Clean. Prod. 2018, 199, 444–458. [Google Scholar] [CrossRef]

- Turki, S.; Didukh, S.; Sauvey, C.; Rezg, N. Optimization and Analysis of a Manufacturing–Remanufacturing–Transport–Warehousing System within a Closed-Loop Supply Chain. Sustainability 2017, 9, 561. [Google Scholar] [CrossRef]

- Turki, S.; Rezg, N. Impact of the Transport Activities within a Closed-loop Supply Chain: Study of the Lost Profit Risk. In Proceedings of the IEEE 6th International Conference on Industrial Engineering and Applications, Tokyo, Japan, 26–29 April 2019. [Google Scholar]

- Tenggren, S.; Olsson, O.; Vulturius, G.; Carlsen, H.; Benzie, M. Climate risk in a globalized world: Empirical findings from supply chains in the Swedish manufacturing sector. J. Environ. Plan. Manag. 2020, 63, 1266–1282. [Google Scholar] [CrossRef]

- Reyes, J.C. Corporate social initiatives of top oil players in the Philippines. Int. J. Environ. Sustain. 2018, 14, 13–23. [Google Scholar] [CrossRef]

- Modak, N.M.; Kelle, P. Using social work donation as a tool of corporate social responsibility in a closed-loop supply chain considering carbon emissions tax and demand uncertainty. J. Oper. Res. Soc. 2021, 72, 61–77. [Google Scholar] [CrossRef]

- Turki, S.; Sahraoui, S.; Sauvey, C.; Sauer, N. Optimal Manufacturing-Reconditioning Decisions in a Reverse Logistic System under Periodic Mandatory Carbon Regulation. Appl. Sci. 2020, 10, 3534. [Google Scholar] [CrossRef]

- Tighazoui, A.; Turki, S.; Sauvey, C.; Sauer, N. Optimal design of a manufacturing-remanufacturing-transport system within a reverse logistics chain. Int. J. Adv. Manuf. Technol. 2018, 101, 1773–1791. [Google Scholar] [CrossRef]

- Chen, L.; Blanc-Betes, E.; Hudiburg, T.W.; Hellerstein, D.; Wallander, S.; Delucia, E.H.; Khanna, M. Assessing the Returns to Land and Greenhouse Gas Savings from Producing Energy Crops on Conservation Reserve Program Land. Environ. Sci. Technol. 2021, 55, 1301–1309. [Google Scholar] [CrossRef]

- Turki, S.; Sauvey, C.; Rezg, N. Modelling and optimization of a manufacturing/remanufacturing system with storage facility under carbon cap and trade policy. J. Clean. Prod. 2018, 193, 441–458. [Google Scholar] [CrossRef]

- Mishra, U.; Wu, J.-Z.; Sarkar, B. Optimum sustainable inventory management with backorder and deterioration under controllable carbon emissions. J. Clean. Prod. 2021, 279, 123699. [Google Scholar] [CrossRef]

- Weaver, C.P.; Miller, C.A. A Framework for Climate Change-Related Research to Inform Environmental Protection. Environ. Manag. 2019, 64, 245–257. [Google Scholar] [CrossRef]

- Bai, Z.; Winiwarter, W.; Klimont, Z.; Velthof, G.; Misselbrook, T.; Zhao, Z.; Jin, X.; Oenema, O.; Hu, C.; Ma, L. Further Improvement of Air Quality in China Needs Clear Ammonia Mitigation Target. Environ. Sci. Technol. 2019, 53, 10542–10544. [Google Scholar] [CrossRef] [PubMed]

- Reinmuth-Selzle, K.; Kampf, C.J.; Lucas, K.; Lang-Yona, N.; Fröhlich-Nowoisky, J.; Shiraiwa, M.; Lakey, P.S.J.; Lai, S.; Liu, F.; Kunert, A.T.; et al. Air Pollution and Climate Change Effects on Allergies in the Anthropocene: Abundance, Interaction, and Modification of Allergens and Adjuvants. Environ. Sci. Technol. 2017, 51, 4119–4141. [Google Scholar] [CrossRef] [PubMed]

- Wilting, H.C.; Schipper, A.M.; Bakkenes, M.; Meijer, J.R.; Huijbregts, M.A.J. Quantifying Biodiversity Losses Due to Human Consumption: A Global-Scale Footprint Analysis. Environ. Sci. Technol. 2017, 51, 3298–3306. [Google Scholar] [CrossRef]

- Kumar, S.; Dua, P. Environmental management practices and financial performance: Evidence from large listed Indian enterprises. J. Environ. Plan. Manag. 2021, 1–27. [Google Scholar] [CrossRef]

- Tiwari, S.; Daryanto, Y.; Wee, H.M. Sustainable inventory management with deteriorating and imperfect quality items considering carbon emission. J. Clean. Prod. 2018, 192, 281–292. [Google Scholar] [CrossRef]

- Xiao, J.X.; Siu, K.W.M. Public design and household participation in recycling for sustainability: A case study in Hong Kong. Int. J. Environ. Sustain. 2016, 12, 27–40. [Google Scholar]

- Jena, S.K.; Ghadge, A.; Sarmah, S.P. Managing channel profit and total surplus in a closed-loop supply chain network. J. Oper. Res. Soc. 2018, 69, 1345–1356. [Google Scholar] [CrossRef]

- Waxin, M.-F.; Knuteson, S.L.; Bartholomew, A. Drivers and challenges for implementing ISO 14001 environmental management systems in an emerging Gulf Arab country. Environ. Manag. 2019, 63, 495–506. [Google Scholar] [CrossRef]

- Harris, F. How many parts to make at once. Prod. Eng. 1913, 10, 135–136. [Google Scholar] [CrossRef]

- Suprayoga, G.B.; Witte, P.; Spit, T. Identifying barriers to implementing a sustainability assessment tool for road project planning: An institutional perspective from practitioners in Indonesia. J. Environ. Plan. Manag. 2020, 63, 2380–2401. [Google Scholar] [CrossRef]

- Robinson, K.F.; Fuller, A.K.; Stedman, R.C.; Siemer, W.F.; Decker, D.J. Integration of social and ecological sciences for natural resource decision making: Challenges and opportunities. Environ. Manag. 2019, 63, 565–573. [Google Scholar] [CrossRef]

- Poplawska, J.; Labib, A.; Reed, D.M. From vicious to virtuous circles: Problem structuring for quantified decision making in operationalization of corporate social responsibility. J. Oper. Res. Soc. 2017, 68, 291–307. [Google Scholar] [CrossRef][Green Version]

- Elkington, J. Partnerships from cannibals with forks: The triple bottom line of 21st-century business. Environ. Qual. Manag. 1998, 8, 37–51. [Google Scholar] [CrossRef]

- Yıldızbaşı, A.; Öztürk, C.; Efendioğlu, D.; Bulkan, S. Assessing the social sustainable supply chain indicators using an integrated fuzzy multi-criteria decision-making method: A case study of Turkey. Environ. Dev. Sustain. 2021, 23, 4285–4320. [Google Scholar] [CrossRef]

- Raza, F.; Alshameri, B.; Jamil, S.M. Assessment of triple bottom line of sustainability for geotechnical projects. Environ. Dev. Sustain. 2021, 23, 4521–4558. [Google Scholar] [CrossRef]

- Jokar, A.; Hosseini-Motlagh, S.-M. Simultaneous coordination of order quantity and corporate social responsibility in a two-Echelon supply chain: A combined contract approach. J. Oper. Res. Soc. 2020, 71, 69–84. [Google Scholar] [CrossRef]

- Bonney, M.; Jaber, M.Y. Environmentally responsible inventory models: Non-classical models for a non-classical era. Int. J. Prod. Econ. 2011, 133, 43–53. [Google Scholar] [CrossRef]

- Jasch, C. The use of Environmental Management Accounting (EMA) for identifying environmental costs. J. Clean. Prod. 2003, 11, 667–676. [Google Scholar] [CrossRef]

- El Saadany, A.M.A.; Jaber, M.Y.; Bonney, M. Environmental performance measures for supply chains. Manag. Res. Rev. 2011, 34, 1202–1221. [Google Scholar] [CrossRef]

- Battini, D.; Persona, A.; Sgarbossa, F. A sustainable EOQ model: Theoretical formulation and applications. Int. J. Prod. Econ. 2014, 149, 145–153. [Google Scholar] [CrossRef]

- Bozorgi, A.; Pazour, J.; Nazzal, D. A new inventory model for cold items that considers costs and emissions. Int. J. Prod. Econ. 2014, 155, 114–125. [Google Scholar] [CrossRef]

- Centobelli, P.; Cerchione, R.; Esposito, E. Environmental sustainability in the service industry of transportation and logistics service providers: Systematic literature review and research directions. Transp. Res. Part D Transp. Environ. 2017, 53, 454–470. [Google Scholar] [CrossRef]

- Cerchione, R.; Esposito, E. A systematic review of Supply Chain knowledge management research: State of the art and research opportunities. Int. J. Prod. Econ. 2016, 192, 276–292. [Google Scholar] [CrossRef]

- Bazan, E.; Jaber, M.Y.; Zanoni, S. Carbon emissions and energy effects on a two-level manufacturer-retailer closed-loop supply chain model with remanufacturing subject to different coordination mechanisms. Int. J. Prod. Econ. 2017, 183, 394–408. [Google Scholar] [CrossRef]

- Hassini, E.; Surti, C.; Searcy, C. A literature review and a case study of sustainable supply chains with a focus on metrics. Int. J. Prod. Econ. 2012, 140, 69–82. [Google Scholar] [CrossRef]

- Gaston, L.; Lapworth, D.J.; Stuart, M.; Arnscheidt, J. Prioritization Approaches for Substances of Emerging Concern in Groundwater: A Critical Review. Environ. Sci. Technol. 2019, 53, 6107–6122. [Google Scholar] [CrossRef]

- Mittal, A.; Krejci, C.C.; Craven, T.J. Logistics Best Practices for Regional Food Systems: A Review. Sustainability 2018, 10, 168. [Google Scholar] [CrossRef]

- Mukhopadhyay, A.; Goswami, A. Economic production quantity models for imperfect items with pollution costs. Syst. Sci. Control Eng. Open Access J. 2014, 2, 368–378. [Google Scholar] [CrossRef]

- Ambec, S.; Lanoie, P. Does It Pay to be Green? A Systematic Overview. Acad. Manag. Perspect. 2008, 22, 45–62. [Google Scholar]

- Rădulescu, M.; Rădulescu, S.; Rădulescu, C.Z. Sustainable production technologies which take into account environmental constraints. Eur. J. Oper. Res. 2009, 193, 730–740. [Google Scholar] [CrossRef]

- Benjaafar, S.; Li, Y.; Daskin, M. Carbon footprint and the management of supply chains: Insights from simple models. IEEE Trans. Autom. Sci. Eng. 2012, 10, 99–116. [Google Scholar] [CrossRef]

- Plambeck, E.L. Reducing greenhouse gas emissions through operations and supply chain management. Energy Econ. 2012, 34, S64–S74. [Google Scholar] [CrossRef]

- Bouchery, Y.; Ghaffari, A.; Jemai, Z.; Dallery, Y. Including sustainability criteria into inventory models. Eur. J. Oper. Res. 2012, 222, 229–240. [Google Scholar] [CrossRef]

- Tao, Z.; Guiffrida, A.L.; Troutt, M.D. A green cost based economic production/order quantity model. In Proceedings of the 1st Annual Kent State International Symposium on Green Supply Chains, Canton, OH, USA; 2010; pp. 210–223. [Google Scholar]

- Chen, X.; Benjaafar, S.; Elomri, A. The carbon-constrained EOQ. Oper. Res. Lett. 2013, 41, 172–179. [Google Scholar] [CrossRef]

- Andriolo, A.; Battini, D.; Gamberi, M.; Sgarbossa, F.; Persona, A. 1913–2013: The EOQ theory and next steps towards sustainability. IFAC Proc. Vol. 2013, 46, 1708–1713. [Google Scholar] [CrossRef]

- Digiesi, S.; Mossa, G.; Mummolo, G. Supply lead time uncertainty in a sustainable order quantity inventory model. Manag. Prod. Eng. Rev. 2013, 4, 15–27. [Google Scholar] [CrossRef]

- Digiesi, S.; Mossa, G.; Rubino, S. A sustainable EOQ model for repairable spare parts under uncertain demand. IMA J. Manag. Math. 2014, 26, 185–203. [Google Scholar] [CrossRef]

- Toptal, A.; Özlü, H.; Konur, D. Joint decisions on inventory replenishment and emission reduction investment under different emission regulations. Int. J. Prod. Res. 2014, 52, 243–269. [Google Scholar] [CrossRef]

- Hovelaque, V.; Bironneau, L. The carbon-constrained EOQ model with carbon emission dependent demand. Int. J. Prod. Econ. 2015, 164, 285–291. [Google Scholar] [CrossRef]

- Andriolo, A.; Battini, D.; Persona, A.; Sgarbossa, F. Haulage sharing approach to achieve sustainability in material purchasing: New method and numerical applications. Int. J. Prod. Econ. 2015, 164, 308–318. [Google Scholar] [CrossRef]

- Soleymanfar, V.R.; Taleizadeh, A.A.; Pourmohammad Zia, N. Economic manufacturing model under partial backordering and sustainability considerations. J. Ind. Syst. Eng. 2015, 8, 86–96. [Google Scholar]

- Hua, G.W.; Cheng, T.C.E.; Zhang, Y.; Zhang, J.L.; Wang, S.Y. Carbon-constrained perishable inventory management with freshness-dependent demand. Int. J. Simul. Model. 2016, 15, 542–552. [Google Scholar] [CrossRef]

- Andriolo, A.; Battini, D.; Persona, A.; Sgarbossa, F. A new bi-objective approach for including ergonomic principles into EOQ model. Int. J. Prod. Res. 2016, 54, 2610–2627. [Google Scholar] [CrossRef]

- Khan, M.; Hussain, M.; Saber, H.M. Information sharing in a sustainable supply chain. Int. J. Prod. Econ. 2016, 181, 208–214. [Google Scholar] [CrossRef]

- Darom, N.A.M.; Hishamuddin, H. Integration of economic and environmental aspects in sustainable supply chain management: A review. In Proceedings of the 6th International Conference on Industrial Engineering and Operations Management, Kuala Lumpur, Malaysia, 8–10 March 2016. [Google Scholar]

- Digiesi, S.; Mascolo, G.; Mossa, G.; Mummolo, G. Sustainable Inventory Management. In New Models for Sustainable Logistics; Springer: Berlin/Heidelberg, Germany, 2016; pp. 21–42. [Google Scholar]

- Karmakar, S.; De, S.K.; Goswami, A. A pollution sensitive dense fuzzy economic production quantity model with cycle time dependent production rate. J. Clean. Prod. 2017, 154, 139–150. [Google Scholar] [CrossRef]

- Lee, S.K.; Yoo, S.; Cheong, T. Sustainable EOQ under lead-time uncertainty and multi-modal transport. Sustainability 2017, 9, 476. [Google Scholar] [CrossRef]

- Marklund, J.; Berling, P. Green inventory management. In Sustainable Supply Chains; Springer: Berlin/Heidelberg, Germany, 2017; pp. 189–218. [Google Scholar]

- Datta, T.K. Effect of Green Technology Investment on a Production-Inventory System with Carbon Tax. Adv. Oper. Res. 2017, 2017, 1–12. [Google Scholar] [CrossRef]

- Shu, T.; Wu, Q.; Chen, S.; Wang, S.; Lai, K.K.; Yang, H. Manufacturers’/remanufacturers’ inventory control strategies with cap-and-trade regulation. J. Clean. Prod. 2017, 159, 11–25. [Google Scholar] [CrossRef]

- Hariga, M.; As’ad, R.; Shamayleh, A. Integrated economic and environmental models for a multi stage cold supply chain under carbon tax regulation. J. Clean. Prod. 2017, 166, 1357–1371. [Google Scholar] [CrossRef]

- Sarkar, B.; Shaw, B.K.; Kim, T.; Sarkar, M.; Shin, D. An integrated inventory model with variable transportation cost, two-stage inspection, and defective items. J. Ind. Manag. Optim. 2017, 13, 1975. [Google Scholar] [CrossRef]

- Wangsa, I. Greenhouse gas penalty and incentive policies for a joint economic lot size model with industrial and transport emissions. Int. J. Ind. Eng. Comput. 2017, 8, 453–480. [Google Scholar]

- Bouchery, Y.; Ghaffari, A.; Jemai, Z.; Tan, T. Impact of coordination on costs and carbon emissions for a two-echelon serial economic order quantity problem. Eur. J. Oper. Res. 2017, 260, 520–533. [Google Scholar] [CrossRef]

- Uthayakumar, R.; Sekar, T. A Multiple production setups inventory model for imperfect items considering salvage value and reducing environmental pollution. Oper. Res. Appl. Int. J. 2017, 4. [Google Scholar] [CrossRef]

- Kazemi, N.; Abdul-Rashid, S.H.; Ghazilla, R.A.R.; Shekarian, E.; Zanoni, S. Economic order quantity models for items with imperfect quality and emission considerations. Int. J. Syst. Sci. Oper. Logist. 2018, 5, 99–115. [Google Scholar] [CrossRef]

- Taleizadeh, A.A.; Soleymanfar, V.R.; Govindan, K. Sustainable economic production quantity models for inventory systems with shortage. J. Clean. Prod. 2018, 174, 1011–1020. [Google Scholar] [CrossRef]

- Daryanto, Y.; Wee, H.M. Sustainable Economic Production Quantity Models: An Approach toward a Cleaner Production. J. Adv. Manag. Sci. 2018, 6, 206–212. [Google Scholar] [CrossRef]

- Sarkar, B.; Omair, M.; Choi, S.B. A multi-objective optimization of energy, economic, and carbon emission in a production model under sustainable supply chain management. Appl. Sci. 2018, 8, 1744. [Google Scholar] [CrossRef]

- Wu, P.; Huang, Y.; Shao, J. Optimal Production Lots Model for Items with Random Quality and Emission Constraint. In Proceedings of the International Conference on Management Science and Engineering Management, Melbourne, VIC, Australia, 1–4 August 2018; Springer: Berlin/Heidelberg, Germany, 2018; pp. 1529–1537. [Google Scholar]

- Gautam, P.; Khanna, A. An imperfect production inventory model with setup cost reduction and carbon emission for an integrated supply chain. Uncertain Supply Chain Manag. 2018, 6, 271–286. [Google Scholar] [CrossRef]

- Lin, H.J. Investing in Transportation Emission Cost Reduction on Environmentally Sustainable EOQ Models with Partial Backordering. J. Appl. Sci. Eng. 2018, 21, 291–303. [Google Scholar]

- Yassine, N. A sustainable economic production model: Effects of quality and emissions tax from transportation. Ann. Oper. Res. 2018, 290, 1–22. [Google Scholar] [CrossRef]

- Wangsa, I.D.; Yang, T.M.; Wee, H.M. The Effect of Price-Dependent Demand on the Sustainable Electrical Energy Supply Chain. Energies 2018, 11, 1645. [Google Scholar] [CrossRef]

- Daryanto, Y.; Wee, H.M. Low Carbon Economic Production Quantity Model for Imperfect Quality Deteriorating Items. Int. J. Ind. Eng. Eng. Manag. 2019, 7, 234. [Google Scholar] [CrossRef]

- Lee, J.Y. Investing in carbon emissions reduction in the EOQ model. J. Oper. Res. Soc. 2019, 71, 1–12. [Google Scholar] [CrossRef]

- Gautam, P.; Kishore, A.; Khanna, A.; Jaggi, C.K. Strategic defect management for a sustainable green supply chain. J. Clean. Prod. 2019, 233, 226–241. [Google Scholar] [CrossRef]

- Shen, Y.; Shen, K.; Yang, C. A Production Inventory Model for Deteriorating Items with Collaborative Preservation Technology Investment Under Carbon Tax. Sustainability 2019, 11, 5027. [Google Scholar] [CrossRef]

- Asghar, I.; Sarkar, B.; Kim, S.J. Economic Analysis of an Integrated Production–Inventory System under Stochastic Production Capacity and Energy Consumption. Energies 2019, 12, 3179. [Google Scholar] [CrossRef]

- Sarkar, B.; Guchhait, R.; Sarkar, M.; Cárdenas-Barrón, L.E. How does an industry manage the optimum cash flow within a smart production system with the carbon footprint and carbon emission under logistics framework? Int. J. Prod. Econ. 2019, 213, 243–257. [Google Scholar] [CrossRef]

- Zavanella, L.E.; Marchi, B.; Zanoni, S.; Ferretti, I. Energy considerations for the economic production quantity and the joint economic lot sizing. J. Bus. Econ. 2019, 89, 1–21. [Google Scholar] [CrossRef]

- Choi, S.; Park, K.; Shim, S.O. The Optimal Emission Decisions of Sustainable Production with Innovative Baseline Credit Regulations. Sustainability 2019, 11, 1. [Google Scholar] [CrossRef]

- Mishra, U.; Wu, J.Z.; Chiu, A.S.F. Effects of Carbon-Emission and Setup Cost Reduction in a Sustainable Electrical Energy Supply Chain Inventory System. Energies 2019, 12, 1226. [Google Scholar] [CrossRef]

- Kamna, K.M.; Gautam, P.; Jaggi, C.K. Sustainable inventory policy for an imperfect production system with energy usage and volume agility. Int. J. Syst. Assur. Eng. Manag. 2020, 12, 1–9. [Google Scholar] [CrossRef]

- Wangsa, I.D.; Tiwari, S.; Wee, H.M.; Reong, S. A sustainable vendor-buyer inventory system considering transportation, loading and unloading activities. J. Clean. Prod. 2020, 271, 122120. [Google Scholar] [CrossRef]

- Mishra, U.; Wu, J.Z.; Sarkar, B. A sustainable production-inventory model for a controllable carbon emissions rate under shortages. J. Clean. Prod. 2020, 256, 120268. [Google Scholar] [CrossRef]

- Biuki, M.; Kazemi, A.; Alinezhad, A. An integrated location-routing-inventory model for sustainable design of a perishable products supply chain network. J. Clean. Prod. 2020, 260, 120842. [Google Scholar] [CrossRef]

- Tang, Z.; Liu, X.; Wang, Y. Integrated Optimization of Sustainable Transportation and Inventory with Multiplayer Dynamic Game under Carbon Tax Policy. Math. Probl. Eng. 2020, 2020, 1–16. [Google Scholar] [CrossRef]

| Keywords Used | (“Inventory Models”) and (“Environmental” or “Sustainability” or “Carbon Footprint” or “Carbon Cap-and-Trade Policies” or “CO2 Pollution” or “Greenhouse Gas Emission”) |

|---|---|

| Scopus database | 132 papers |

| Web of Science database | 60 papers |

| Total papers retrieved in the two databases excluding duplications | 165 papers |

| List | Description | Number of Papers |

|---|---|---|

| A | Papers whose abstracts focus on sustainable inventory management | 140 |

| B | Papers whose abstracts do not focus on sustainable inventory management | 25 |

| Authors | Publication Year/Journal Name | GHG Emission and Their Cost | Models/Objective | Result and Finding |

|---|---|---|---|---|

| Kazemi et al. [72] | 2018/International Journal of Systems Science | Carbon Emission cost from inventory holding and obsolescence disposal. | EOQ/Four defective quality models with carbon emission costs were produced. | Incorporation of carbon pollution prices into the buyer’s strategy in order to reduce lot sizes and achieve minimal costs. |

| Tiwari et al. [19] | 2018/Journal of Cleaner Production | Carbon emission cost from transporting, warehousing, and deteriorating item. | Single vendor single buyer IM/With carbon emissions in mind, a standard for imperfect, decaying objects was developed. | Due effect of carbon emission cost reducing the delivery frequency and increasing the delivery quantity to minimize both the total inventory and carbon emission costs. |

| Taleizadeh et al. [73] | 2018/Journal of cleaner production | Environmental concern from production. | S-EPQ/by considering different shortage situation developed four SEPQ models. | To assess the optimal value of the decision element, various scarcity conditions such as missed revenue, full backordering, and partly backordering were used. |

| Daryanto et al. [74] | 2018/Journal of Advanced Management Science | Carbon emission cost from production, warehousing, and waste disposal. | S-EPQ/They designed their models with carbon pollution costs factored into the overall cost function to approach cleaner production. | Carbon emissions from the EPQ model was minimized in order to create a cleaner manufacturing environment. |

| Sarkar et al. [75] | 2018/Applied Sciences | Carbon emission cost and source of energy cost from electricity, solar energy, diesel fuel, and gasoline. | EPQ/Generated a multi-objective manufacturing model that takes into account long-term supply chain management. | Minimize overall cost of production, carbon footprint reduction, and electricity cost. |

| Wu et al. [76] | 2018/International Conference on Management Science and Engineering Management | Carbon emission cost. | EPQ/Provide the right production lot models for products with perfect and faulty product quality, as well as pollution restrictions. | To assess the relationship between the ideal quality product’s predicted rate and the right output lot. |

| Gautam et al. [77] | 2018/Uncertain Supply Chain Management, | Carbon emission cost from transportation. | EPQ/In order to minimize costs, an incomplete production was created that took into account transportation pollution. | The model is ideally tailored to real-time inventory situations because it decreases the total expense of the device. |

| Lin et al. [78] | 2018/Journal of Applied Science and Engineering | Carbon emission cost from holding inventory, transporting, and disposing. | S-EOQ/Incorporate sustainability concept in the traditional inventory system by integrating economic and environmental perspectives. | Integrate economic and environmental viewpoints into the conventional inventory structure to integrate the sustainability concept. |

| Zadjafar & Gholamian [3] | 2018/Journal of cleaner production | Emission of Sulfur dioxide, Nitrogen oxide gases, was BOD, COD from wastewater. (Biochemical oxygen demand (BOD) and chemical oxygen demand (COD)) | GEOQ/Considering simultaneously effects of environmental and social factor developed a sustainable model. | Optimized the cost function along with reduction of gases and water pollutants. |

| Yassine [79] | 2018/Annals of Operations Research | Transport emission cost and tax. | SEPQ/Along with emission tax from transportation and effects of different quality of raw materials they developed production model. | Reducing environmental and social impacts to optimize lot size and total production cost. |

| Wangsa et al. [80] | 2018/Energies | Consumption of electrical energy cost from holding, transmission, distribution, and power generation. | SESCE/Considering four type of customer price dependent demand such as increasing linearly, quadratically, and multiplicatively and decrease multiplicatively developed their model. | Parameters like price of electricity and elasticity coefficient, production cost, scaling factor and rate of power supply affect optimal decision variable and total profit. |

| Daryanto et al. [81] | 2019/International Journal of Industrial Engineering and Engineering Management | Carbon emission cost from electric consumption during production and inventory storage and waste disposing. | CEPQ/Deteriorating imperfect quality items model developed with considering environmental concept and carbon tax regulation. | To minimize carbon emission cost, total operation, and production quantity. |

| Lee [82] | 2019/Journal of the Operational Research Society | Carbon emission due to replenishment and production. | EOQ/With cap and price regulation policy developed classical EOQ model. | Investment optimal lot size and carbon emission reduction in model with cap-and-price regulation policy. |

| Gautam et al. [83] | 2019/Journal of cleaner production | Carbon emission cost are due to transportation and waste disposal). | Vendor-buyer inventory Model/considering carbon emissions and strategies of defect management developed a model. | To maximize the total profit with management of defectives and reducing carbon emission. |

| Shen et al. [84] | 2019/Sustainability | Carbon emission cost due to inventory producing, purchasing, holding. | EPQ/Under carbon tax policy and preservation technology formulated a model for deteriorating items. | For buyer and vendor to find maximum profit and optimal production, delivery, ordering. |

| Asghar et al. [85] | 2019/Energies | Energy consumption cost due to manufacturing, producing, repairing, storing. | EPQ/stochastic production and inventory system under variable energy consumption costs. | Optimize production lot size, production rate, and readability parameters. |

| Sarkar et al. [86] | 2019/International Journal of Production Economics | Carbon footprint cost for setup and labor and carbon emission cost per quantity. | EPQ/Under advance logistics management formulated a model with carbon emission and footprint. | Control carbon footprint and optimum cash-flow within a smart production system such as manufacturing, distribution, consumption, and remanufacturing. |

| Zavanella et al. [87] | 2019/Journal of Business Economics | Energy cost. | EPQ & JELS/Based on both economic and environmental concern extending the economic production quantity and joint economic lot size models. | Energy cost directly impact in total cost and its environmental linkage. |

| Choi et al. [88] | 2019/Sustainability | Emission cost due to production. | Stochastic model/By using cap and trade regulation designed two inventory optimization models. | Approaching PTR (pollution base regulation) and BCR (Baseline credit regulation) to analyze stochastic optimization problem. |

| Mishra et al. [89] | 2019/Energies | Carbon emission cost of energy holding of transmission, power generation. | SEESCIM/Effect of carbon emission they formulated an inventory model with linear price dependent demand under set up cost. | Affected total profit and all decision variable due to impact of key parameters such as demand, production, and reduction of set-up cost, ordering cost, loss factor, and carbon emission. |

| Kamna et al. [90] | 2020/International Journal of System Assurance Engineering and Management | Carbon emission cost and energy cost. | SPIM/Effect of carbon emission during production, storage of good as well as energy consumption discussion in this model. | To maximize the overall inventory turnover by conjointly optimize selling price as well as production rate and time. |

| Wangsa et al. [91] | 2020/Journal of cleaner production | Carbon emission cost. | IIM/Considering environmental and economic issue, developed an integrated inventory model. | Find minimum total cost to optimize the decision variables such as order quantity, total emission, safety time, lead time, and number of shipments. |

| Mishra et al. [92] | 2020/Journal of cleaner production | Carbon tax and cap. | SEPQ/Under carbon tax and cap policy developed three SEPQ Model with and without shortage. | This model gives better justifiable profit with highest cycle time, lowest value of fractional length period, as well as lower green technology investment cost. |

| Biuki et al. [93] | 2020/Journal of cleaner production | Sustainable level growth. | ILRIM/Developed a multi objective mixed integer programming model based on the sustainability issue. | By using GA and PSO to find the optimal solution of the problem. |

| Tang et al. [94] | 2020/Mathematical problems in engineering | Carbon Tax. | IOSIM/Under the carbon tax policy to optimize the sustainable transportation and inventory. | The results indicate that a carbon tax policy can improve social welfare and the sustainability of transportation and inventory but could hinder corporate profits. |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Pattnaik, S.; Nayak, M.M.; Abbate, S.; Centobelli, P. Recent Trends in Sustainable Inventory Models: A Literature Review. Sustainability 2021, 13, 11756. https://doi.org/10.3390/su132111756

Pattnaik S, Nayak MM, Abbate S, Centobelli P. Recent Trends in Sustainable Inventory Models: A Literature Review. Sustainability. 2021; 13(21):11756. https://doi.org/10.3390/su132111756

Chicago/Turabian StylePattnaik, Suchitra, Mitali Madhusmita Nayak, Stefano Abbate, and Piera Centobelli. 2021. "Recent Trends in Sustainable Inventory Models: A Literature Review" Sustainability 13, no. 21: 11756. https://doi.org/10.3390/su132111756

APA StylePattnaik, S., Nayak, M. M., Abbate, S., & Centobelli, P. (2021). Recent Trends in Sustainable Inventory Models: A Literature Review. Sustainability, 13(21), 11756. https://doi.org/10.3390/su132111756