Influence of Plant Leaf Moisture Content on Retention of Electrostatic-Induced Droplets

Abstract

:1. Introduction

2. Materials and Methods

2.1. Crop Materials

2.2. Experimental Setup

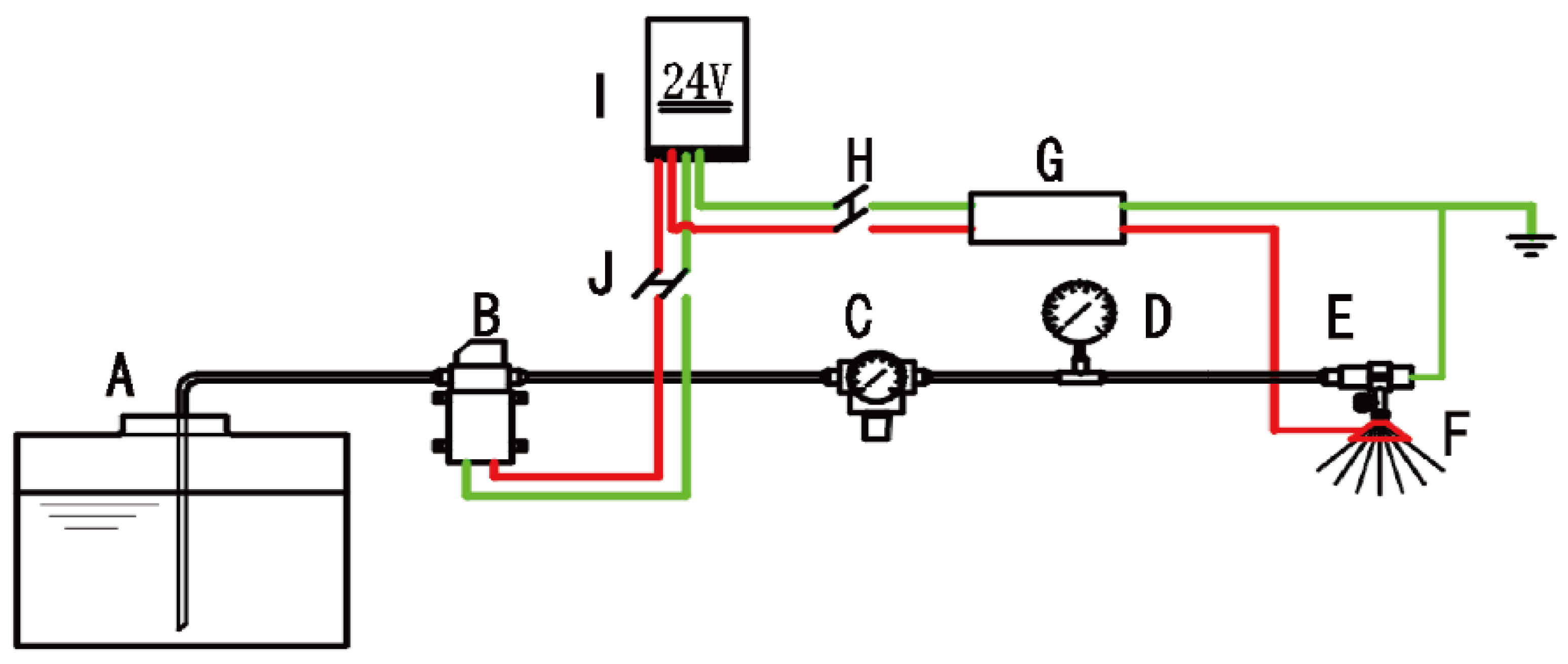

2.2.1. Electrostatic Spraying System

2.2.2. Droplet Retention Measuring Device

2.3. Leaf Characterization

2.3.1. Capacitance

2.3.2. Moisture Content

2.4. Spray Retention on per Unit Leaf Area

2.4.1. Spray Retention Acquisition

2.4.2. Leaf Area

3. Results

3.1. Calibration between Moisture Content and Capacitance Value

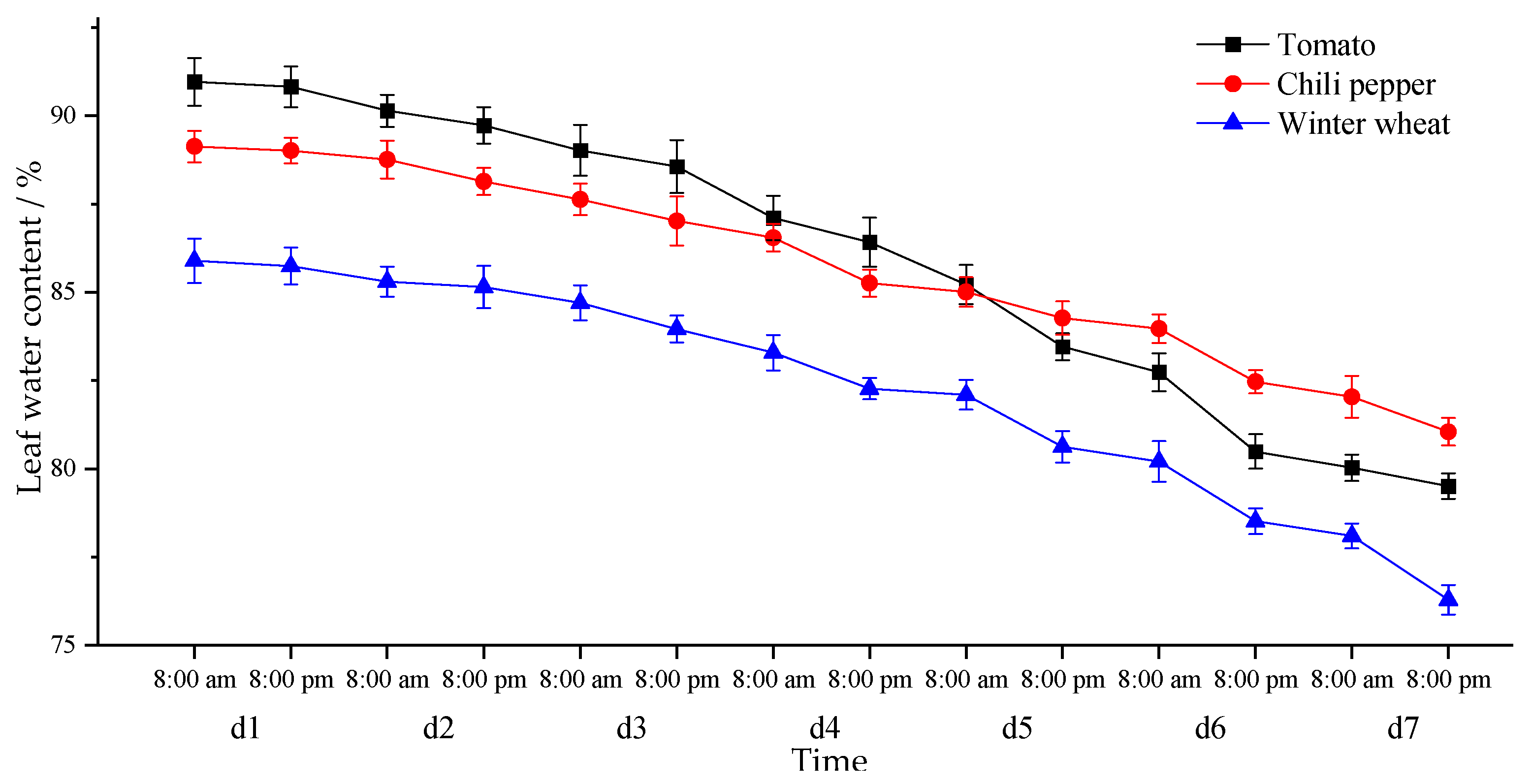

3.1.1. Variation in Water Content

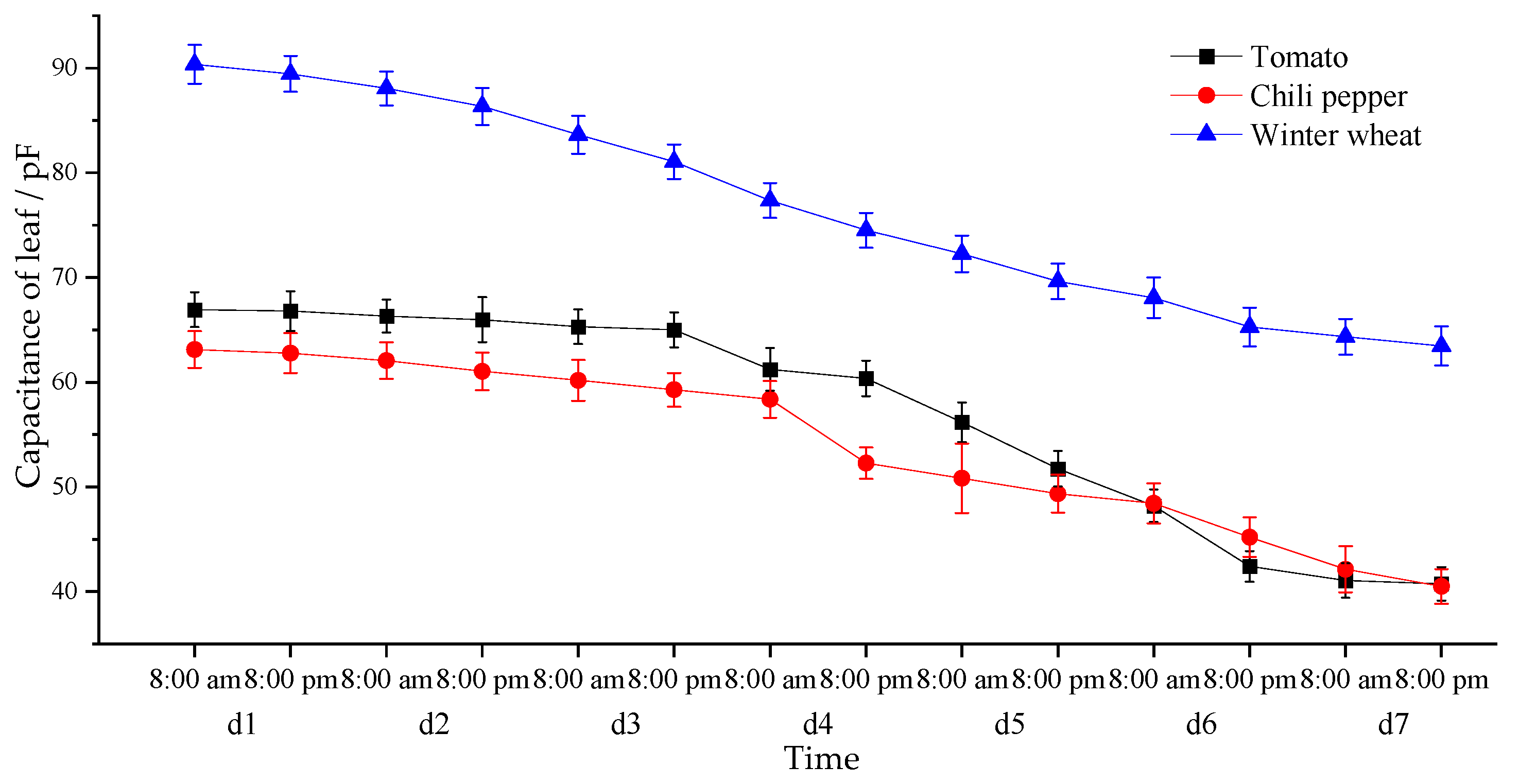

3.1.2. Capacitance Values

3.1.3. Regression Analysis of Capacitance and Water Content

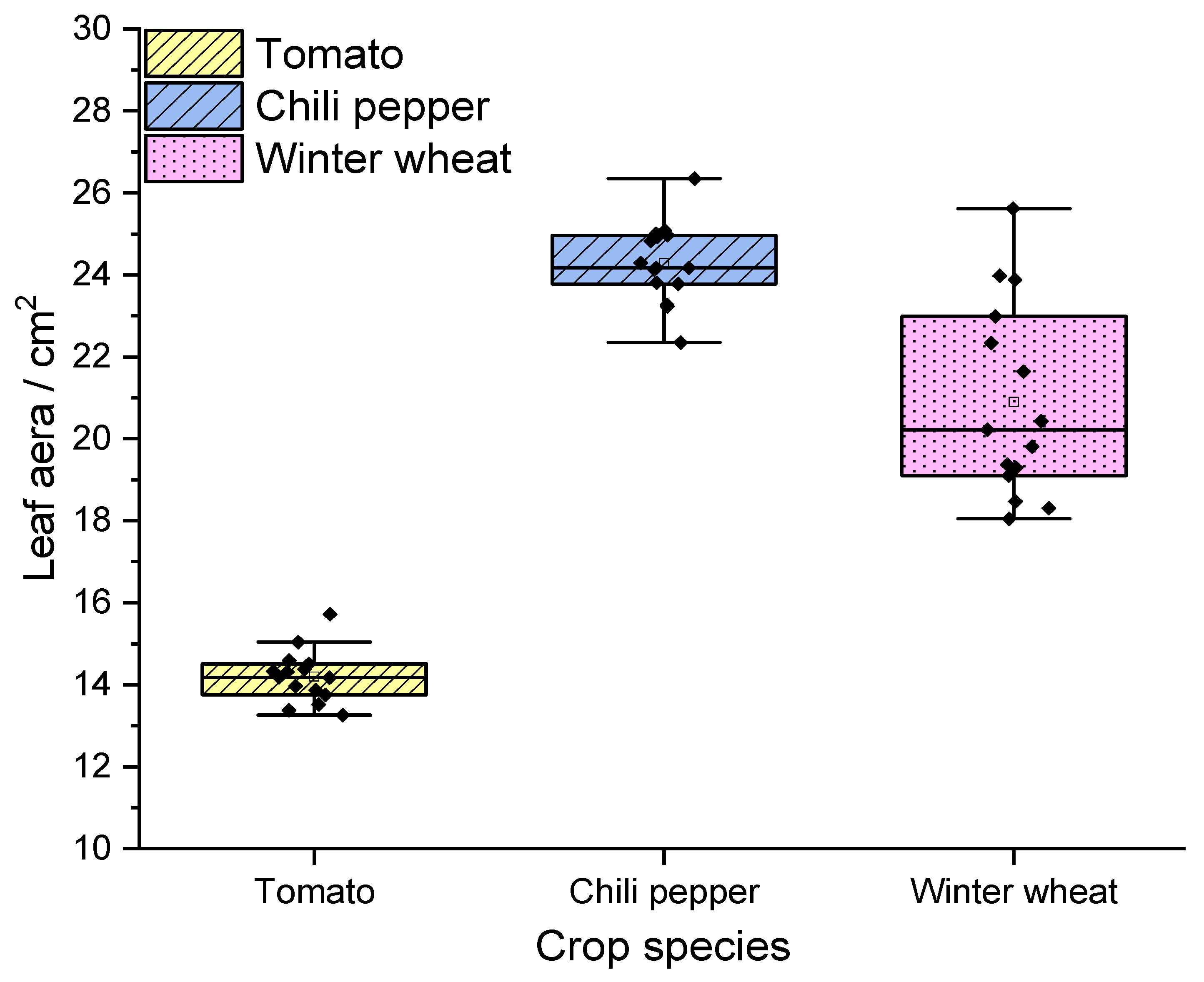

3.2. Leaf Area of Crops

3.3. Effect of Water Content on Droplet Retention

3.3.1. Effect of Water Content on Droplet Retention in Electrostatic and Non-Electrostatic Sprays

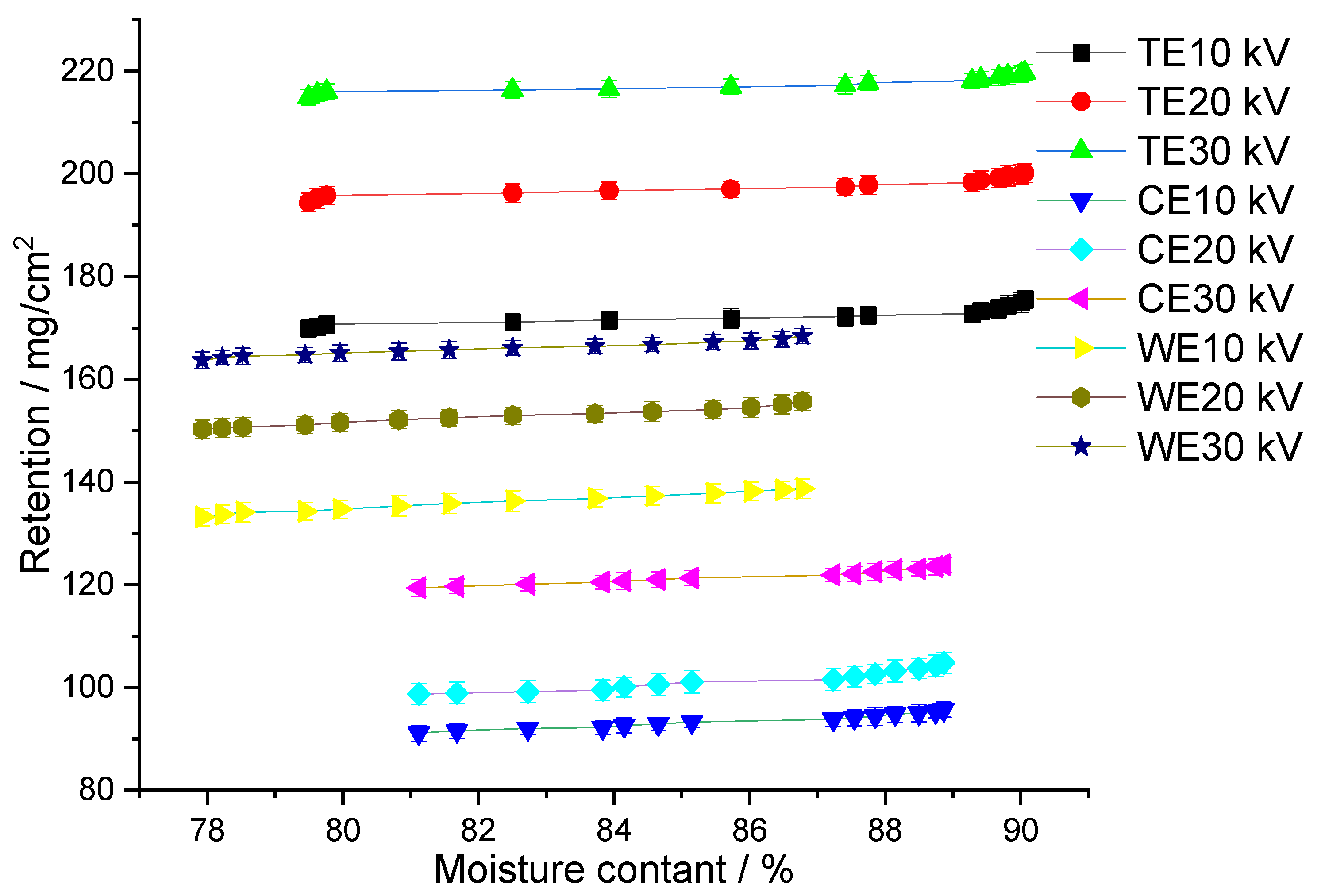

3.3.2. Effect of Water Content on Droplet Retention at Different Electrostatic Spray Voltages

4. Discussion

4.1. Leaf Water Content and Leaf Capacitance

4.2. Electrostatic Droplet Holding Capacity

5. Conclusions

- (1)

- A linear function between water content and leaf capacitance was established for three crops—tomato, pepper, and winter wheat—and the water content of crop leaves were obtained without loss.

- (2)

- From the perspective of crop leaf surface retention, electrostatic spraying technology proved itself to be superior to non-electrostatic spraying technology. The retention capacity of electrostatic spraying increased with an increase in leaf water content, and the retention capacity of non-electrostatic spraying conditions decreased with an increase in water content.

- (3)

- Increasing the electrostatic spraying voltage had a significant effect on the retention capacity of leaves. Within a certain voltage range (0~30 kV), increasing the electrostatic spraying voltage improved the retention of droplets on the leaves of the different crops.

Supplementary Materials

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Inculet, I.I.; Castle, G.S.P.; Menzies, D.R.; Frank, R. Deposition studies with a novel form of electrostatic crop sprayer. J. Electrost. 1981, 10, 65–72. [Google Scholar] [CrossRef]

- Maski, D.; Durairaj, D. Effects of charging voltage, application speed, target height, and orientation upon charged spray deposition on leaf abaxial and adaxial surfaces. Crop. Prot. 2010, 29, 134–141. [Google Scholar] [CrossRef]

- Law, S.E.; Steven, C.C. Depositional Characteristics of Charged and Uncharged Droplets Applied by an Orchard Air Carrier Sprayer. Trans. ASAE 1988, 31, 984–989. [Google Scholar]

- Latheef, M.A.; Carlton, J.B. Aerial electrostatic-charged sprays for deposition and efficacy against sweet potato whitefly (Bemisia tabaci) on cotton. Pest Manag. Sci. 2009, 65, 744–752. [Google Scholar] [CrossRef] [PubMed]

- Jones, C.D.; Hopkinson, P.R. Electrical theory and measurements on an experimental charged crop-spraying system. Pestic. Sci. 1979, 10, 91–103. [Google Scholar] [CrossRef]

- Zhou, L. Research progress and application status of electrostatic pesticide spray technology. Trans. Chin. Soc. Agric. Eng. 2018, 34, 1–11. [Google Scholar]

- Law, S.E. Agricultural electrostatic spray application: A review of significant research and development during the 20th century. J. Electrost. 2001, 51–52, 25–42. [Google Scholar] [CrossRef]

- Patel, M.K.; Sharma, T.; Nayak, M.K.; Ghanshyam, C. Computational modeling and experimental evaluation of the effects of electrode geometry and deposition target on electrostatic spraying processes. Int. J. Comput. Appl. 2015, 124, 10–15. [Google Scholar]

- Patel, M.K.; Praveen, B.; Sahoo, H.K.; Patel, B.; Kumar, A.; Singh, M.; Nayak, M.; Rajan, P. An advance air-induced air-assisted electrostatic nozzle with enhanced performance. Comput. Electron. Agric. 2017, 135, 280–288. [Google Scholar] [CrossRef]

- Patel, M.K.; Ghanshyam, C.; Kapur, P. Characterization of electrode material for electrostatic spray charging: Theoretical and engineering practices. J. Electrost. 2013, 71, 55–60. [Google Scholar] [CrossRef]

- Pascuzzi, S.; Cerruto, E.; Manetto, G. Foliar spray deposition in a “tendone” vineyard as affected by airflow rate, volume rate and vegetative development. Crop. Prot. 2017, 91, 34–48. [Google Scholar] [CrossRef]

- Appah, S.; Jia, W.; Ou, M.; Wang, P.; Gong, C. Investigation of Optimum Applied Voltage, Liquid Flow Pressure, and Spraying Height for Pesticide Application by Induction Charging. Appl. Eng. Agric. 2019, 35, 795–804. [Google Scholar] [CrossRef]

- Gen, M.; Ikawa, S.; Sagawa, S.; Lenggoro, W. Simultaneous Deposition of Submicron Aerosols onto Both Surfaces of a Plate Substrate by Electrostatic Forces. e-J. Surf. Sci. Nanotechnol. 2014, 12, 238–241. [Google Scholar] [CrossRef] [Green Version]

- Guo, J.; Tailor, M.; Bamber, T.; Chamberlain, M.; Justham, L.; Jackson, M. Investigation of relationship between interfacial electro adhesive force and surface texture. J. Phys. D Appl. Phys. 2015, 49, 035303. [Google Scholar] [CrossRef] [Green Version]

- Zhao, S.; Castle, G.; Adamiak, K. Factors affecting deposition in electrostatic pesticide spraying. J. Electrost. 2008, 66, 594–601. [Google Scholar] [CrossRef]

- Pan, Z.; Lie, D.; Qiang, L.; Shaolan, H.; Shilai, Y.; Yande, L.; Yu, Y.; Pan, H. Effects of citrus tree-shape and spraying height of small unmanned aerial vehicle on droplet distribution. Int. J. Agric. Biol. Eng. 2016, 9, 45–52. [Google Scholar]

- Maghsoudi, H.; Minaei, S. A review of applicable methodologies for variable-rate spraying of orchards based on canopy characteristics. J. Crop. Prot. 2014, 3, 531–542. [Google Scholar]

- Li, X.; He, X. Effect of different spray factors on charged droplet deposit using response surface methodology. High Volt. Eng. 2007, 33, 32–36. [Google Scholar]

- Mizukami, Y.; Sawai, Y.; Yamaguchi, Y. Moisture Content Measurement of Tea Leaves by Electrical Impedance and Capacitance. Biosyst. Eng. 2006, 93, 293–299. [Google Scholar] [CrossRef]

- Afzal, A.M.I.N.; Mousavi, S.F. Estimation of moisture in maize leaf by measuring leaf dielectric constant. Int. J. Agricul. Biol. 2008, 10, 66–68. [Google Scholar]

- Afzal, A.M.I.N.; Mousavi, S.F. Estimation of leaf moisture content by measuring the capacitance. J. Agric. Sci. Technol. 2010, 12, 339–346. [Google Scholar]

- Grimnes, S.; Martinsen, O.G. Bioimpedance and Bioelectricity Basics; Academic Press: London, UK, 2011. [Google Scholar]

- Chuah, H.T.; Kam, S.W.; Chye, Y.H. Microwave dielectric properties of rubber and oil palm leaf samples: Measurement and modelling. Int. J. Remote Sens. 1997, 18, 2623–2639. [Google Scholar] [CrossRef]

- Kocakusak, A.; Colak, B.; Helhel, S. Frequency dependent complex dielectric permittivity of rubber and magnolia leaves and leaf water content relation. J. Microw. Power Electromagn. Energy 2016, 50, 294–307. [Google Scholar] [CrossRef]

- Blackman, C.J.; Brodribb, T.J.; Brodribb, T. Two measures of leaf capacitance: Insights into the water transport pathway and hydraulic conductance in leaves. Funct. Plant Biol. 2011, 38, 118–126. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Afzal, A.; Duiker, S.W.; Watson, J.E.; Luthe, D. Leaf Thickness and Electrical Capacitance as Measures of Plant Water Status. Trans. ASABE 2017, 60, 1063–1074. [Google Scholar] [CrossRef]

- Rascio, A.; Rinaldi, M.; De Santis, G.; Pecchioni, N.; Palazzo, G.; Palazzo, N. Measurement of leaf lamina moisture with a low-cost electrical humidity sensor: Case study on a wheat water-mutant. BMC Plant. Biol. 2019, 19, 1–8. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Massinon, M.; Lebeau, F. Experimental method for the assessment of agricultural spray retention based on high-speed imaging of drop impact on a synthetic superhydrophobic surface. Biosyst. Eng. 2012, 112, 56–64. [Google Scholar] [CrossRef]

- Allagui, A.; Bahrouni, H.; M’Sadak, Y. Deposition of Pesticide to the Soil and Plant Retention During Crop Spraying: The Art State. J. Agric. Sci. 2018, 10, 104. [Google Scholar] [CrossRef]

- De Oliveira, R.B.; Precipito LM, B.; Gandolfo, M.A.; de Oliveira, J.V.; Lucio, F.R. Effect of droplet size and leaf surface on retention of 2,4-D formulations. Crop. Prot. 2019, 119, 97–101. [Google Scholar] [CrossRef]

- Gaskin, R.; Steele, K.; Forster, W. Characterising plant surfaces for spray adhesion and retention. N. Z. Plant. Prot. 2005, 58, 179–183. [Google Scholar] [CrossRef]

- Yamazaki, K. Nutrient Solution Culture; Pak-kyo Co.: Tokyo, Japan, 1982; p. 41. [Google Scholar]

- Zhang, M.I.N.; Willison, J.H.M. Electrical Impedance Analysis in Plant Tissues: Impedance Measurement in Leaves. J. Exp. Bot. 1993, 44, 1369–1375. [Google Scholar] [CrossRef]

- Wei, Y.; Wu, F.; Xu, J.; Sha, J.; Zhao, Z.; He, Y.; Li, X. Visual detection of the moisture content of tea leaves with hyperspectral imaging technology. J. Food Eng. 2019, 248, 89–96. [Google Scholar] [CrossRef]

- Dorr, G.J.; Forster, W.A.; Mayo, L.C.; McCue, S.W.; Kempthorne, D.M.; Hanan, J.; Turner, I.; Belward, J.A.; Young, J.; Zabkiewicz, J.A. Spray retention on whole plants: Modelling, simulations and experiments. Crop. Prot. 2016, 88, 118–130. [Google Scholar] [CrossRef] [Green Version]

- Guo, W.C.; Wu, L.; Wei, Y.S. Influence of water loss on physiological and electrical properties of plants. J. Northwest A & F Univ. (Nat. Sci. Ed.) 2007, 35, 185–191. [Google Scholar]

- Ruichi, P. Plant Physiology; Higher Education Press (HEP): Beijing, China, 2008. [Google Scholar]

- Luan, Z.; Liu, X. Relationship between Wheat Leaf Capacitance and Water Content under Water Stress. Acta Bot. Boreal.-Occident. Sin. 2007, 27, 2323–2327. [Google Scholar]

- Liao, J.; Guo, H.; Shao, Y. Modeling of microwave dielectric properties of rice growth stages in Zhaoqing test site of southern China. Int. Geosci. Remote Sens. Symp. 2002, 5, 2620–2622. [Google Scholar]

| Device | Type | Parameters | Value |

|---|---|---|---|

| High voltage electrostatic generator | KEF00-JD10060 | Voltage (kV) | 10, 20, 30 |

| Pesticide tank | — | Volume (L) | 40 |

| Diaphragm pump | PLD-1205 | Rated pressure (MPa) | 0.3 |

| Flow (L/min) | 1.4 | ||

| Pressure gauge | Y-100 | Measuring range (MPa) | 0~0.6 |

| Pressure regulator | CCM5NJ | Regulations range | 10~100% |

| Fan nozzle | Lechler ST110-02 | Spray angle (°) | 110 |

| Pressure (MPa) | 0.2~1.5 | ||

| Flow rate (L/min) | 0.78 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Ma, J.; Liu, K.; Chen, C.; Ahmad, F.; Qiu, B. Influence of Plant Leaf Moisture Content on Retention of Electrostatic-Induced Droplets. Sustainability 2021, 13, 11685. https://doi.org/10.3390/su132111685

Ma J, Liu K, Chen C, Ahmad F, Qiu B. Influence of Plant Leaf Moisture Content on Retention of Electrostatic-Induced Droplets. Sustainability. 2021; 13(21):11685. https://doi.org/10.3390/su132111685

Chicago/Turabian StyleMa, Jing, Kuan Liu, Chenggong Chen, Fiaz Ahmad, and Baijing Qiu. 2021. "Influence of Plant Leaf Moisture Content on Retention of Electrostatic-Induced Droplets" Sustainability 13, no. 21: 11685. https://doi.org/10.3390/su132111685

APA StyleMa, J., Liu, K., Chen, C., Ahmad, F., & Qiu, B. (2021). Influence of Plant Leaf Moisture Content on Retention of Electrostatic-Induced Droplets. Sustainability, 13(21), 11685. https://doi.org/10.3390/su132111685