Abstract

This study uses 31 provinces and municipalities from China’s textile industry as a research sample and divides the region into four geographical areas: eastern, central, western, and northeastern. It quantified smart servitization in the textile industry using input–output data and applied the fuzzy set qualitative comparison analysis to identify potential pathways for promoting smart servitization in the textile industry. The study’s findings indicate that there are significant geographical differences in the level of smart servitization in the textile industry across China. Moreover, the transformation and development of the textile industry require the co-operation of numerous factors, and the Chinese textile industry’s transformation paths can be summarized as “high-input” path, “technology—aggregation” path, “open” path, and “economic-agglomeration” path.

1. Introduction

The textile industry and its products are one of the strategic industries for many countries and are significant contributors to the international economy [1]. In the case of China, the world’s largest producer of textiles and the number one exporter of apparel, up to 2019, China exported USD 27.34 billion worth of technical textiles, up 2.1% year-on-year, especially to the emerging markets along the “Belt and Road”; China’s exports of technical textiles to the “Belt and Road” in 2019 to countries along the “Belt and Road” reached USD 10.85 billion in 2019, up 7.1% year-on-year, far exceeding other industries. It is clear that there is indeed an important link between the textile industry and economic development. However, in recent years, with the challenges and changes brought by globalization, the textile industry is facing tariff barriers, inadequate infrastructure [1], environmental pollution and other problems, increasing competitive pressure, and a more complex internal and external development environment [2], which forces the textile industry to seek new ways of development.

The advent of a new wave of disruptive technological innovation has impacted the manufacturing industry as consumer demand for mass customization and increased levels of sustainability have changed the landscape of manufacturing, forcing traditional manufacturing to transform. How to carry out the transformation? With the deep integration of information technology and manufacturing industry, countries are using new generation information technology to strengthen the transformation and upgrading of the manufacturing industry, such as Germany ‘Industry 4.0’ [3], Japan ‘Smart Manufacturing’, ‘Made in China 2025’ [4], and other industrial strategies. On the one hand, advanced manufacturing enterprises are actively using the Internet of Things, big data, artificial intelligence, and other information technology means to innovate the production model of manufacturing industry in production research and development, marketing, management and other aspects, and comprehensively improve product design, manufacturing and management [5]. On the other hand, manufacturing companies began to add service elements to their products to enhance product value through manufacturing servitization [6]. It can be seen that it is the key to the development of traditional manufacturing industry to improve the overall smart and service level through the good integration of manufacturing industry and information technology. This is also true for the textile industry, information technology in the textile industry, design, production, marketing, logistics, and other aspects of in-depth application will promote the production model to flexibility, smart, fine change from traditional production and manufacturing to service-oriented manufacturing [3]. Evidently, the deep integration of the textile industry with information technology and the internet provides a broad space for industrial transformation and development. At the same time, in the process of transforming the textile industry, it will be affected by many factors, so the research on the transformation of the textile industry into smart servitization has an important impact on the future development of the industry.

Based on the above background, this paper discusses the smart servitization transformation path of the textile industry in 31 Chinese provinces and cities and mainly explores the following issues. First, what is the degree of smart servitization transformation of the textile industry in 31 Chinese provinces and cities, and what are the similarities and differences among them? Secondly, what factors influence the transformation of the textile industry into smart servitization? What are the links between these factors, and what are the impact mechanisms of the transformation? Finally, what is the unique Chinese path for the smart servitization transformation of the textile industry?

2. Literature Review

2.1. Smart Servitization Transformation

The integration and development of artificial intelligence, big data, Internet of Things, cloud computing, 5G, and other new generation of intelligent technologies and products have given rise to the emergence of smart and connected products and smart services. Services created by tying new smart technologies to smart connected products can be called smart services, such as cloud computing services, data analytics services, Internet of Things (IoT) services, etc. Early studies have used the term “electronic service” or “digital service” to refer to the phenomenon of smart services. In 2005, Allmendinger and Lombreglia pointed out that “the value of smart services goes beyond the upgrades and maintenance bundled with products,” highlighting the importance of manufacturing to add value to customers and companies through smart services [7]. Since then, the term “smart services” has been adopted and rapidly adopted by the academic community [8]. In 2015, Bustinza introduced the concept of smart servitization in their review of smart connected products, where they considered smart servitization as the delivery of technology-enabled services that rely on digital components embedded in physical products [9]. In turn, scholars have turned their attention to studying the integration development path of traditional manufacturing service smarts. Frank and Mendes et al. explore the convergence of servitization and Industry 4.0 in the digital transformation of manufacturing firms to produce a new business model that focuses on process-customer orientation. This closed-loop system can double the value structure of manufacturing firms, where manufacturers have upgraded their level of smart servitization from the digital level to the Industry 4.0 level [10]. To create, deliver, and capture the value of a wide range of services enabled by digital intelligence technologies and industrial firms, Kamalaldin et al. argue that smart servitization transforms processes, capabilities, and products within industrial firms and their associated ecosystems [11]. In a study on platform-based servitization and business model alignment for manufacturers, Tian et al. defined smart servitization as a higher level of servitization than digital services, involving a deeper shift to connected, intelligent, and autonomous product service systems [12]. From a macro perspective, smart servitization can be seen as a service system that includes program interactivity, technological innovation, and continuity [13]. Interpreted from a micro perspective, research at this stage focuses on understanding smart servitization as a solution strategy capable of providing a dynamic, digital, or even personalized high level of service to companies, collecting the product itself and digital value-added services [14]. It can be seen that the connotation of smart service manufacturing can be interpreted from two aspects, data-based smart manufacturing, and value-added service manufacturing.

2.1.1. Smart Manufacturing

Kang et al. consider smart manufacturing as a new industrial transformation [15]. Machado et al. point out that the integration of manufacturing operations systems with Information and Communication Technology (ICT), especially the Internet of Things (IoT), results in an integrated Cyber-Physical System (CPS) that can help companies achieve higher production performance while meeting the requirements of green production and sustainable development in a smart manufacturing environment [16]. These concepts include Industry 4.0 [17], Fourth Industrial Evolution [18], Industrial Internet of Things [19], and Smart Factory [20]. At present, domestic and international research on smart manufacturing mainly focuses on technology and engineering and industrial policy research. Based on the deep integration of manufacturing technology and communication information technology, Kang et al. argue that the smart manufacturing system is a highly flexible production method that integrates perception, analysis, decision making, and execution [15]. From an industrial policy perspective, Li believes that smart manufacturing is a national strategy that aims to support the transformation and upgrading of manufacturing industries and enhance global competitiveness [4]. As mentioned in the social background of this paper, countries such as Germany, the United States, and Japan have established relevant research and technology transfer programs with smart manufacturing as the main focus area, which indicates that manufacturing intelligence has become an important topic for global policy researchers.

2.1.2. Service-Based Manufacturing

The marketing literature points out that with the rise of the service economy and the continued deepening of product servitization, the linear value chain thinking of the traditional Goods Dominant Logic and the separation of goods and services theory are becoming increasingly difficult to explain the phenomenon of value creation in the new economic form [21]. For this reason, Vargo and Lusch propose the new idea of Service-Dominant Logic as an alternative to dominant commodity logic [22]. Vargo and Lusch refined the theory of service-dominant logic in 2008, proposing that operational resources represented by knowledge and skills are the core elements of corporate competition [23]. In 2010 and 2011, they further clarified the critical role of value co-creation of customers and other stakeholders [24], and developed the theory of service ecosystems [25].

In the industrial field, more and more manufacturing industries are adding value to their products by providing services; this phenomenon is called “Servitization” [26,27]. The servitization of manufacturing emphasizes the transition of businesses from focusing solely on product manufacturing to concentrating on services. Such services are not directly consumed, but rather used to establish a service guarantee for the manufacturing industry, with progressively specialized intellectual capital elements and human capital elements serving as key inputs, demonstrating the output of human and intellectual capital services.

With the development of information technology, marketing scholars are beginning to focus on the impact of technology on servitization [28], with the emergence of digital servitization and smart servitization research themes [29,30]. Digital servitization research points to the increasingly important role of digital technologies (e.g., ICT) in creating and delivering new product services [31]. On the other hand, smart servitization research emphasizes the role of smart technologies (e.g., Internet of Things, big data, artificial intelligence, etc.) in the autonomous coordination and optimization of product-service innovation processes [32]. As a result, digital and smart technologies are increasingly driving the servitization of manufacturing.

Based on the above conclusions, the smart servitization of the manufacturing industry studied in this paper refers to an advanced transformation and upgrading mode of the manufacturing industry under the Internet economic environment of “cloud computing, Internet of things and big data” and the increasing role of consumers in each link of the industrial chain, value chain, and innovation chain. It has three characteristics: the first one is the characteristics of supply and demand, no longer production-oriented but demand-oriented; the second one is the characteristics of manufacturing input factors, human capital and intellectual capital account for an increasing proportion; the third one is the closer connection between industries, manufacturing industries are no longer alone, but integrated with the information technology industry and service industry, and the barriers between industries are gradually weakened to achieve overall value-added.

2.2. Drivers of Industry Transformation

Regarding the factors that promote industrial transformation and upgrading, scholars have chosen different perspectives to conduct experiments using different methods over the years, and the conclusions have not reached unity. Mijiyawa et al. analyzed the drivers of manufacturing development in Africa using the system-GMM technique, examining economic factors, such as GDP and exchange rates, government efficiency, and market size, demonstrating that increasing competitiveness, expanding the size of the domestic market, combating corruption, and improving government efficiency are all necessary components of manufacturing development [33]. Dou examines the influence of three dimensions of factors on the advanced manufacturing industry, namely technology, economy, and environment. They believe that technological innovation should promote the development of synergistic integration between manufacturing and other industries. Economic growth should be used to address overcapacity [34]. Taking manufacturing and agriculture as examples, scholars such as Kaňovská point out that the drivers of smart servitization transformation are mainly related to competitive advantage [35]. Synthesizing the scholars’ studies, this paper gathers the drivers of industrial transformation in four dimensions: technological orientation, economic orientation, resource orientation, and strategic openness orientation.

In terms of technology, Lee et al. reported that the traditional manufacturing industry should focus on design and innovation to ensure the development of manufacturing enterprises [36]. Lee H et al. found that innovative technology affects the manufacturing industry’s productivity, and the development of the manufacturing industry can be ensured through the improvement of innovative technology [37]. Grant and Yeo used clustering and decision tree induction, combined with the TOE framework, to analyze the significant impact of technology on the performance of manufacturing and service industries, demonstrating the importance of investment in technology in the process of industrial transformation [38]. Ghobakhloo discusses 11 factors that facilitate digital transformation in manufacturing companies; the study identifies external support for digitalization as the first step in ensuring successful digital transformation in the medium and operational technology readiness as the most challenging determinant of success to achieve [39].

On the economic side, Cantore explored the impact of structural transformation and employment size on the development of industrialization from both perspectives [40]. Similarly, Charles explored the relationship between manufacturing transformation and upgrading and employment rate [41].

In terms of resources, the agglomeration effect created by human capital and industrial agglomeration is a powerful catalyst for industrial transformation and upgrading. Zheng reported that industrial agglomeration has a positive impact on the improvement of industrial energy efficiency [42]. Wei studied different intensive industries in different regions and found that high levels of agglomeration do not always promote total factor productivity growth, but moderate levels of agglomeration help promote economic development [43]. A country or region’s human capital will be effectively accumulated, and its technology level will be effectively improved, according to industrialization experience in the United States, Japan, Europe, and other developed countries [44]. Narayanan and Suresh confirmed from the data of the Malaysian manufacturing industry that enhancing investment in human skills and attracting talent pool is an effective way to achieve industrial upgrading [45]. From a micro perspective, human resources also have an important role to play for corporate teams [46,47].

In terms of strategic openness, scholars such as Bigsten and Fafchamps have argued that exports have a significant impact on the performance of African manufacturing firms [48,49], and Goran Buturac has confirmed that export growth indirectly contributes to the performance of manufacturing industries [50].

Reviewing the existing literature, research on smart servitization has focused on aspects such as technology engineering and industrial policy research, emphasizing the wide application of emerging digital technologies at the enterprise and industry levels on the one hand, and examining the financial performance brought by smart servitization on the other hand, but these studies are more inclined to be a national industrial strategy [4,15], especially in the context of Industry 4.0, while the servitization realization paths are less empirically studied. Similar to the main theme of this paper, Tian conducted a questionnaire study on Chinese textile enterprises and pointed out that the transformation path of Chinese textile enterprises into smart servitization has gone through three stages: service, digitalization, and intelligence [12]. However, this study is at the micro-enterprise level, with limited participation and no geographical characteristics, and still cannot answer the question of the transformation path of the Chinese textile industry. As can be seen, there is a relative lack of existing research on the paths of smart servitization. In the research related to the transformation and upgrading of manufacturing industry, scholars mainly focus on a single aspect such as technological innovation, economic level, resource factors, and institutional factors from the macro level [33,36,42,48]. However, not many studies have been conducted on how to fully utilize these advantages for industrial upgrading and development. Therefore, this paper uses provincial areas as the research unit to explore the influencing factors and paths of smart servitization transformation of the textile industry in 31 Chinese provinces to promote the progress of the textile industry from the macro level of economic development. At the same time, this study will also focus on the synergy among the factors to determine the path of smart servitization transformation of the textile industry.

3. Research Design

3.1. Methodology

On the basis of the previous analysis, the research in this paper focuses on the exploration of the transformation path of China’s textile industry into a smart servitization for different factor conditions. Additionally, this paper tries to explore the contribution of the linkage of the influencing factors to achieve a high level of smart servitization transformation of the textile industry. Therefore, this paper selects fuzzy set qualitative comparison analysis (FsQCA) as the research method to study the transformation path. This method was chosen because (1) FsQCA is suitable for small and medium sample studies. (2) FsQCA allows for component analysis among variables. Compared with traditional multiple regression, structural equation, factor analysis, and other methods of causal inference based on the correlation of independent variables, the QCA qualitative comparative analysis method focuses more on the conditional grouping of interactions between variables [51], which in turn can compensate for the shortage of causal monotony in quantitative research. (3) FsQCA can provide multiple paths to achieve a certain identical result. It can make causal inference with multiple concurrent and different paths, and better reveal the complex aggregate relationship between multiple variables [52].

3.2. Variable Measurements

3.2.1. Result Variables

The outcome variable of this paper is the level of smart servitization transformation of the textile industry. For the quantitative method of industrial transformation, Fai uses the patent coefficient method to measure the positive and negative technology integration coefficients of two industries, and then calculates the correlation coefficients between them to measure the level of transformation development between industries [53]; however, the statistical caliber of patent data in some countries or regions is rarely divided according to industries, so it will produce certain limitations in practical operation. So far, few scholars have measured the level of industrial smart servitization; however, with the public disclosure of world input–output data and Chinese input–output data, scholars have tried to quantify the degree of industrial integration using input–output data. The input–output approach is one of the most commonly used methods to analyze the economic impact of a specific area, usually a country or region [54], and it facilitates the analysis of particular economic structures and inter-industry linkages due to its ability to analyze inter-industry relationships throughout the industry structure [55]. In 2019, Yang used input–output data tables to measure the level of servitization of manufacturing industries in China’s Yangtze River Economic Zone [56]. She reflected the degree of transformation of manufacturing industries into productive services by relying on the input and output profiles among industries, and distinguished input coefficients from output coefficients to determine the direction of industrial transformation, an approach that provides implications for our study. On this basis, the level of smart servitization in the textile industry can be seen as the extent to which the textile industry is linked to smart industries and services, and this linkage can be reflected by the input–output situation between industries. If the textile industry has a larger number of inputs and outputs to smart industries and services, it means that there are more links between these industries and that the textile industry is integrated with smart industries and services, thus representing a higher level of smart servitization. In a comprehensive view, the input–output method is relatively more appropriate for measuring smart servitization of the textile industry in this paper. Drawing on the application of the input–output method in industrial development [55,57,58], this paper uses it to systematically measure the development characteristics of the two-way integration of the textile industry with the smart industries and the service industries. Moreover, it provides a quantitative basis for the later development of an empirical study related to the factors influencing the smart servitization of the textile industry.

Specifically, this paper first carries out the measurement of a single integration degree that defines the use of smart industries and services by the textile industry as positive integration, and the proportion of intermediate inputs from smart industries and service industries in the textile industry’s production process was first measured, referring to the research methods of Park [59] and Liu et al. [60]—see Equation (1). Then, the absorption of smart industries and service industries into the textile industry is regarded as reverse integration, and the ratio of intermediate inputs from the textile industry to smart industries and service industries in the total output of the textile industry is used to measure the degree of reverse integration of smart industries and service industries with the textile industry, based on Yang’s calculation [56], as in Equation (2). Z denotes forward fusion, and F denotes reverse fusion. Again, to facilitate the subsequent study, Yang calculated the forward and reverse fusion degrees to form an integrated fusion degree [56]; it is measured based on the above data and expressed as G, as in Equation (3). Among them, according to the business content, smart industries include communication equipment and computer manufacturing, other electronic equipment manufacturing, information transmission computer services and software industry, scientific research and development, and six other digital intelligent industries; services include catering, accommodation, finance, insurance, video and television program production, publishing services, legal and accounting activities, management consulting activities, and 12 other producer services and consumer services. Considering the comprehensive integration degree, if G > 1, the industrial integration is mainly reflected in the driving effect of smart industries and service industries on the textile industry. Conversely, it shows that the “reverse drive” of the textile industry to the smart industry and the service industry, that is, the smart industry and the service industry are more dependent on the investment in the manufacturing industry.

3.2.2. Condition Variables

By combing through the literature section, the conditional variables in this paper are gathered in the dimensions of technological innovation, economic development, resource factors, and open strategy. For the variables of technological innovation, this paper draws on Shen Lei’s practice of using R&D expenditure data to reflect technological innovation [61], and here the R&D expenditure data of Chinese provinces are mainly selected. Since economic development variables, with only GDP as a measure of economic development, are too one-sided, drawing on the ideas of Mijiyawa and Cantore [33,40], this paper focuses on the process and results of economic development to determine the quality of economic development and considers economic development efficiency, structural optimization, and development stability from the perspective of the GDP and employment rate of each province in China to consider the economic growth and economic stability. For the measurement of resource factors, the two variables of industrial agglomeration and human agglomeration are mainly measured by the number of enterprise units and the average number of employees in the industry [62]; for the open strategy, the two variables of foreign direct investment and import and export volume are mainly considered [50]. Please refer to Table 1 for a list of specific variables.

Table 1.

Variables list.

3.3. Sample and Date Source

This paper selects 31 provinces and municipalities of China’s textile industry as the research sample and divides the region into the eastern region, the central region, the western region, and the northeastern region by geographical location and analyzes the distribution pattern of China’s textile industry’s intelligent service level in the regional location through the different geographical locations in which the provinces are located.

The data involved in this paper are mainly derived from the 2002–2017 China Regional Input–Output Tables (this data is released every five years, and the latest version is currently the 2017 version), the China Science and Technology Statistical Yearbook, the China Labor Statistical Yearbook, and the statistical yearbooks of Chinese provinces and cities.

4. The Level of Smart Servitization of the Textile Industry in China by Region

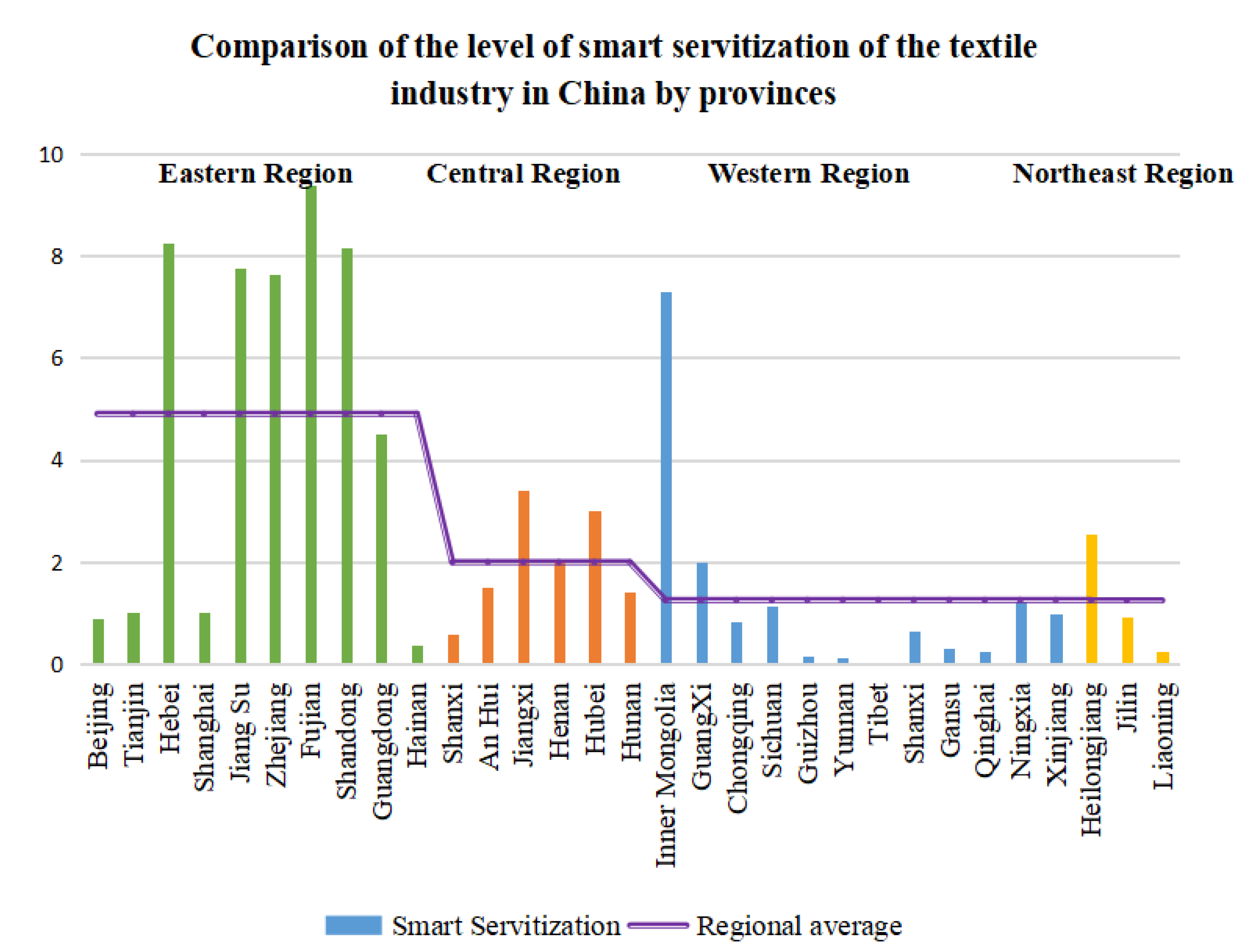

Through the formula to measure the level of smart servitization of the textile industry in each region of China, the development of smart servitization of the textile industry in each province and city is shown in Figure 1.

Figure 1.

Textile industry smart servitization level statistics.

It is evident that there are incredibly uneven geographical differences in the transformation development of the textile industry in various provinces and cities in China. The eastern region has obvious advantages in the level of intelligent service in the textile industry compared with other regions, among which Fujian, Shandong, Hebei, Jiangsu, and Zhejiang are the most significant. These provinces and cities should summarize the advantages of their development and strive to promote the transformation of the textile industry nationwide. Central region textile industry transformation in the national midstream status, of which Jiangxi and Hubei provinces play a role that cannot be ignored; the western region and the northeast region of the textile industry transformation development level is lower, especially Tibet, Yunnan, Guizhou, and other regions, its textile industry intelligent service level at the end of the country. Still, in the western region and the northeast region, there are also provinces and cities with high industrial transformation, such as Inner Mongolia, Heilongjiang, and other places. These regions should play their industrial advantages, radiation to the surrounding provinces and cities, to play a leading role.

As illustrated in Figure 1, the level of smart servitization of China’s textile industry varies by province. The eastern region outperforms the other regions, while the western and northeastern regions lag behind, indicating regional differences in the development of smart servitization of the textile industry. So, what happened? The economic, technical, human, and other factors vary by province. Therefore, this study focuses on how to use the different influencing factors in each province to promote the smart servitization transformation of the textile industry.

5. Analysis of the Transformation Path of Smart Servitization in China’s Textile Industry

5.1. Necessary Condition Analysis

Before analyzing the combination of conditions, we should consider the possibility that individual variables are necessary conditions for the outcome variable, and the level of consistency of variables can be used to determine whether a variable is an essential condition. Based on the existing theories, we can consider this single variable as necessary for the outcome variable when the consistency value is greater than or equal to 0.9 [70]. Using G and LowG as the outcome variables, respectively, the consistency was analyzed using FsQCA software to obtain the scores of individual variables on the consistency of the outcome variables, as shown in the table. As illustrated in Table 2, the highest consistency value (0.786254) is observed for high industrial agglomeration when the outcome variable is a high smart servitization index. For high economic stability (0.801942) when the outcome variable is a low smart servitization index, however, these values are insufficient to consider this condition as a necessary condition for industrial smart servitization transformation, as none of the variables have a consistency score greater than or equal to 0.9, indicating that none of the variables are a necessary condition.

Table 2.

Necessary condition analysis.

5.2. Conditional Configuration Analysis

With G and LowG as the outcome, respectively, based on the results of the truth table—which was processed by the FsQCA3.0 software for standard analysis—we chose the intermediate solutions that not only include the core conditions but also cover the edge conditions as the main interpretation results. The results of the condition grouping are shown in Table 3 and Table 4.

Table 3.

Conditional configuration analysis (Outcome = G).

Table 4.

Conditional configuration analysis (Outcome = LowG).

According to the results in Table 3, in this sample of cases, there are six groupings that achieve high intelligent service transformation of the textile industry, and the consistency of the overall solution is 0.87, which means that in all cases of intelligent service transformation of the textile industry in each region that satisfy these six types of condition groupings, there exist 87% of the transformations that show a high level of performance. The coverage of the solution is 0.69, the significance of which can be interpreted as the above-mentioned six types of conditional groupings can explain about 69% of the cases of high-level intelligent service transformation. The consistency of the solutions and the coverage of the solutions are both higher than the critical values, implying that the empirical analysis is valid. Through these conditional groupings, this paper will further elaborate the differentiated adaptation relationships among technology, economy, resources, and open strategy in promoting smart service transformation in the textile industry.

- Configuration a1: Technological Innovation * Economic growth * Industrial Agglomeration * Import and Export volume * Foreign Direct Investment

It means that regardless of the regional economic stability and human aspect, the smart servitization transformation of the textile industry will show a high level of performance in the case of high technological innovation, high economic growth, high industrial aggregation, high import and export volume, and high foreign investment, and the typical representative cases of this path are Shanghai, Tianjin, Guangdong, and Fujian These regions have a better level of economic development and a stronger degree of openness, which is very important for the introduction of technology and talents to the industry, and the industry has more resources, so it is more likely to realize the transformation and upgrading of the industry.

- 2.

- Configuration a2: Technological Innovation * Industrial Agglomeration * Human Resources * Import and Export volume * Foreign Direct Investment

It means that no matter what kind of economic development the region is in, the transformation of the textile industry will also show higher quality under the high level of technology, resources, and open policy. The representative cases of this configuration are Zhejiang and Jiangsu, which have the largest and most complete home textile characteristic towns in China, and the textile industry is also the characteristic industry of their city development, with more textile industrial bases. Both situations a1 and a2 are high-input type, which requires the sample cases to have high technology level and industry aggregation and high degree of openness, so we will make this path “high-input” path.

- 3.

- Configuration a3: Technological Innovation* ~Economic Stability * Industrial Agglomeration * ~Human Resources * ~Import and Export volume

It indicates that regardless of economic growth and foreign investment, high levels of technological innovation and high levels of industrial aggregation can contribute to the transformation of the textile industry into a smart servitization, even when economic stability, human resource aggregation, and import and export volumes are at low levels, a path that emphasizes the important contribution of the role of technology and the aggregation effect of the industry to the transformation of the textile industry. Typical representatives of this grouping are Hubei and Shandong, whose governments support the development of the textile industry and have issued relevant policies to accelerate industrial aggregation and investment in technology research and development, promoting the formation of a number of textile and apparel brands with high market impact and international competitiveness, such as Handu Yi She, Huafeng, Zorme, Wuhan Hongren Clothing, Wuhan Catman Clothing, etc. As can be seen, for the transformation of the textile industry intelligent services, technological innovation and industrial agglomeration played a greater role in promoting, so we will call this path “technology—aggregation” path. This approach is more suitable for the central provinces of China to choose.

- 4.

- Configuration a4: Technological Innovation *~Economic Stability * ~Industrial Agglomeration * ~Human Resources* Import and Export volume

Regardless of economic growth and foreign investment, as long as technological innovation and import and export volume are at a high level, even if the economic stability, industrial aggregation, and human resources are not sufficient, these do not affect the transformation of the textile industry to a high level of smart servitization development. This histogram emphasizes the important influence of foreign markets on China’s textile industry, especially in regions where resource factors are not sufficient, developing overseas markets, increasing openness, and providing technology introduction are the keys to successful transformation of the textile industry. The representative provinces and cities of this situation are Sichuan and Hebei.

- 5.

- Configuration a5: ~Technological Innovation * ~Economic growth * Economic Stability * ~Industrial Agglomeration* Import and Export volume * ~Foreign Direct Investment

Regardless of the situation of human aspect, a high level of economic stability and import and export volume can make up for the lack of technology, economic growth, and industrial agglomeration, so that the textile industry to achieve a high level of transformation. This path is represented by Guangxi Province. Comprehensive configuration a4 and a5, we can find that the import and export situation of this factor played a non-negligible effect, so this transformation path will be called the “open” path. This path is more suitable for China’s western region to learn from.

- 6.

- Configuration a6: ~Technological Innovation * Economic growth * Economic Stability * Industrial Agglomeration * ~Import and Export volume * ~Foreign Direct Investment

Regardless of the human situation, high-quality economic development and high industrial agglomeration can make up for the lack of technological innovation and openness, and eventually take the textile industry to a high level of smart servitization development. This path is represented by Jiangxi Province. In this path, the economic development factor is an important driving force, while the increase in industrial agglomeration also makes the industrial chain more complete, so we call this model the “economic-agglomeration” path.

In order to explore the factors influencing the transformation of the textile industry into a smart service industry in a more comprehensive and detailed manner, this paper analyzes the possible scenarios leading to a lower index of smart servitization in Table 4, as well.

Comprehensive configuration b1 (~Technological Innovation * Economic growth * ~Industrial Agglomeration * ~Human Resources * ~Import and Export volume * ~Foreign Direct Investment) and configuration b2 (~Technological Innovation* Economic Stability * ~Industrial Agglomeration * ~Human Resources* ~Import and Export volume * ~Foreign Direct Investment), the meaning is that when technological innovation, industrial agglomeration, human resource agglomeration, and openness are all at low levels, high economic development does not enable the textile industry to develop at a high level, which means that the transformation of the industry will still not have a better effect if it only relies on high level of economic development and lacks the support of technology, resources, and policies, indicating that the benign development of the industry cannot rely on the contribution of a single factor alone, but requires the joint action between multiple factors.

Configuration b3 (~Technological Innovation * Economic growth * ~Economic Stability * Industrial Agglomeration* Human Resources * ~Import and Export volume * ~Foreign Direct Investment) represents when there is the rapid economic growth and high level of industrial aggregation, human resources, and other factors, but there is a lack of technological innovation and openness to support the transformation of the textile industry’s intelligent services so it still cannot be in a high quality state. This configuration also reverses to confirm the correctness of configuration a4, and emphasizes the important role of technology and openness to the outside world.

Configuration b4 (Technological Innovation * Economic growth * ~Economic Stability * ~Industrial Agglomeration * ~Human Resources) implies that regardless of the degree of openness, when the sample cases are at a high level of technological innovation and economic growth, yet lack the support of economic stability, industrial agglomeration, and human resources, the transformation still cannot perform at a high level. The reverse of this path highlights the contribution of resources to the transformation of the textile industry, and the development of China’s textile industry can learn from such relevant policies as increasing industrial agglomeration and strengthening talent training.

6. Conclusions

Based on the relevant theories of the input–output method, this paper analyzes the development level of smart servitization of the textile industry in each region of China and uses the research method of FsQCA to gather the factors of technology, economy, resources, and openness to explore how each factor works co-operatively to promote the transformation of the textile industry and summarizes the unique paths of smart servitization transformation of the textile industry in China according to the mechanism of each configuration.

The research results prove that, first of all, there are obvious geographical differences in the development level of smart servitization in China’s textile industry, with a step-down from the eastern region to the western region, and the upgrading level of the textile industry in the northeastern region is the most backward. Second, through qualitative comparative analysis, we obtain six ways to promote the transformation of the textile industry into a smart servitization. All these results confirm that the transformation and development of the textile industry require mutual co-operation among the factors, and the correlation between the factors will have a positive impact on the transformation of the textile industry into a smart servitization. Finally, this study summarizes four transformation paths of the textile industry for regions with different development conditions, including the “high-input” path, “technology—aggregation” path, “open” path, “economic-agglomeration” path.

The research in this paper provides suggestions for the transformation and upgrading of the textile industry from a macro development perspective. Despite the fact that the measurement method of industrial smart servitization is yet to be improved and the limitations of this paper’s research, the interaction between the textile industry and other related industries is indeed an issue of concern in terms of the trend of industrial integration.

Author Contributions

Conceptualization, methodology, software, validation, formal analysis, investigation, C.S. and M.A.; resources, L.S. and C.S.; writing—original draft preparation, C.S.; writing—review and editing, M.A.; visualization, L.S. and M.A.; supervision, L.S.; project administration, L.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Data can be provided on demand.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Truett, L.J.; Truett, D.B. A ray of hope? Another look at the Italian textile industry. Empir. Econ. 2014, 46, 525–542. [Google Scholar] [CrossRef]

- Truett, L.J.; Truett, D.B. Globalization challenges for the Mexican textile industry. Int. Rev. Econ. Financ. 2010, 19, 733–741. [Google Scholar] [CrossRef]

- Fromhold-Eisebith, M.; Marschall, P.; Peters, R.; Thomes, P. Torn between digitized future and context dependent past–how implementing ‘Industry 4.0’ production technologies could transform the German textile industry. Technol. Forecast. Soc. Chang. 2021, 166, 120620. [Google Scholar] [CrossRef]

- Li, L. China’s manufacturing locus in 2025: With a comparison of “Made-in-China 2025” and “Industry 4.0”. Technol. Forecast. Soc. Chang. 2018, 135, 66–74. [Google Scholar] [CrossRef]

- Arnold, J.M.; Javorcik, B.; Lipscomb, M.; Mattoo, A. Services reform and manufacturing performance: Evidence from India. Econ. J. 2016, 126, 1–39. [Google Scholar] [CrossRef]

- Thangavelu, S.M.; Wang, W.; Oum, S. Servicification in global value chains: Comparative analysis of selected Asian countries with OECD. World Econ. 2018, 41, 3045–3070. [Google Scholar] [CrossRef]

- Allmendinger, G.; Lombreglia, R. Four strategies for the age of smart services. Harv. Bus. Rev. 2005, 83, 131. [Google Scholar] [PubMed]

- Alt, R.; Demirkan, H.; Ehmke, J.F.; Moen, A.; Winter, A. Smart services: The move to customer orientation. Electron. Mark. 2019, 29, 1–6. [Google Scholar] [CrossRef]

- Bustinza-Sánchez, O.F.; Parry, G.; Vendrell-Herrero, F.; Myrthianos, V. Link channels or how to enhance upstream-downstream relations in servitized contexts. Dyna 2015, 90, 588–589. [Google Scholar] [CrossRef][Green Version]

- Frank, A.G.; Mendes, G.H.S.; Ayala, N.F.; Ghezzi, A. Servitization and Industry 4.0 convergence in the digital transformation of product firms: A business model innovation perspective. Technol. Forecast. Soc. Chang. 2019, 141, 341–351. [Google Scholar] [CrossRef]

- Kamalaldin, A.; Linde, L.; Sjödin, D.; Parida, V. Transforming provider-customer relationships in digital servitization: A relational view on digitalization. Ind. Mark. Manag. 2020, 89, 306–325. [Google Scholar] [CrossRef]

- Tian, J.M.; Coreynen, W.; Matthyssens, P.; Shen, L. Platform-based servitization and business model adaptation by established manufacturers. Technovation 2021. [Google Scholar] [CrossRef]

- Beverungen, D.; Matzner, M.; Janiesch, C. Information systems for smart services. Inf. Syst. E-Bus. Manag. 2017, 15, 781–787. [Google Scholar] [CrossRef]

- Dreyer, S.; Olivotti, D.; Lebek, B.; Breitner, M.H. Focusing the customer through smart services: A literature review. Electron. Mark. 2019, 29, 55–78. [Google Scholar] [CrossRef]

- Kang, H.S.; Lee, J.Y.; Choi, S.; Kim, H.; Park, J.H.; Son, J.Y.; Kim, B.H.; Noh, S. Do smart manufacturing: Past research, present findings, and future directions. Int. J. Precis. Eng. Manuf.-Green Technol. 2016, 3, 111–128. [Google Scholar] [CrossRef]

- Machado, C.G.; Winroth, M.P.; Ribeiro da Silva, E.H.D. Sustainable manufacturing in Industry 4.0: An emerging research agenda. Int. J. Prod. Res. 2020, 58, 1462–1484. [Google Scholar] [CrossRef]

- Lasi, H.; Fettke, P.; Kemper, H.G.; Feld, T.; Hoffmann, M. Industry 4. Bus. Inf. Syst. Eng. 2014, 6, 239–242. [Google Scholar] [CrossRef]

- Li, G.; Hou, Y.; Wu, A. Fourth Industrial Revolution: Technological drivers, impacts and coping methods. Chin. Geogr. Sci. 2017, 27, 626–637. [Google Scholar] [CrossRef]

- Boyes, H.; Hallaq, B.; Cunningham, J.; Watson, T. The industrial internet of things (IIoT): An analysis framework. Comput. Ind. 2017, 101, 1–12. [Google Scholar] [CrossRef]

- Wang, S.; Wan, J.; Li, D.; Zhang, C. Implementing smart factory of industrie 4.0: An outlook. Int. J. Distrib. Sens. Netw. 2016, 12, 3159805. [Google Scholar] [CrossRef]

- Prahalad, C.K. The blinders of dominant logic. Long Range Plan. 2004, 37, 171–179. [Google Scholar] [CrossRef]

- Vargo, S.L.; Lusch, R.F. Evolving to a new dominant logic for marketing. J. Mark. 2004, 68, 1–17. [Google Scholar] [CrossRef]

- Vargo, S.L.; Lusch, R.F. Service-dominant logic: Continuing the evolution. J. Acad. Mark. Sci. 2008, 36, 1–10. [Google Scholar] [CrossRef]

- Vargo, S.L.; Lusch, R.F. From repeat patronage to value co-creation in service ecosystems: A transcending conceptualization of relationship. J. Bus. Mark. Manag. 2010, 4, 169–179. [Google Scholar] [CrossRef]

- Vargo, S.L.; Lusch, R.F. It’s all B2B...and beyond: Toward a systems perspective of the market. Ind. Mark. Manag. 2011, 40, 181–187. [Google Scholar] [CrossRef]

- Baines, T.S.; Lightfoot, H.W.; Benedettini, O.; Kay, J.M. The servitization of manufacturing: A review of literature and reflection on future challenges. J. Manuf. Technol. Manag. 2009, 20, 547–567. [Google Scholar] [CrossRef]

- Rada, S.V.J. Servitization of business: Adding value by adding services. Eur. Manag. J. 1988, 6, 314–324. [Google Scholar] [CrossRef]

- Nambisan, S. Information technology and product/service innovation: A brief assessment and some suggestions for future research. J. Assoc. Inf. Syst. 2013, 14, 215–226. [Google Scholar] [CrossRef]

- Luz Martín-Peña, M.; Díaz-Garrido, E.; Sánchez-López, J.M. The digitalization and servitization of manufacturing: A review on digital business models. Strateg. Chang. 2018, 27, 91–99. [Google Scholar] [CrossRef]

- Porter, M.E.; Heppelmann, J.E. How smart, connected products are transforming companies. Harv. Bus. Rev. 2015, 93, 96–112. [Google Scholar]

- Raddats, C.; Kowalkowski, C.; Benedettini, O.; Burton, J.; Gebauer, H. Servitization: A contemporary thematic review of four major research streams. Ind. Mark. Manag. 2019, 83, 207–223. [Google Scholar] [CrossRef]

- Stief, P.; Dantan, J.Y.; Etienne, A.; Siadat, A. A new methodology to analyze the functional and physical architecture of existing products for an assembly oriented product family identification. Procedia CIRP 2018, 70, 47–52. [Google Scholar] [CrossRef]

- Mijiyawa, A.G. Drivers of structural transformation: The case of the manufacturing sector in Africa. World Dev. 2017, 99, 141–159. [Google Scholar] [CrossRef]

- Dou, Z.; Sun, Y.; Wang, T.; Wan, H.; Fan, S. Exploring regional advanced manufacturing and its driving factors: A case study of the Guangdong–Hong Kong–Macao Greater Bay Area. Int. J. Environ. Res. Public Health 2021, 18, 5800. [Google Scholar] [CrossRef] [PubMed]

- Kaňovská, L.; Tomášková, E. Drivers for smart servitization in manufacturing companies. AGRIS On-Line Pap. Econ. Inform. 2018, 10, 57–68. [Google Scholar] [CrossRef]

- Lee, Z.Y.; Chu, M.T.; Chen, S.S.; Tsai, C.H. Identifying comprehensive key criteria of sustainable development for traditional manufacturing in Taiwan. Sustainability 2018, 10, 3275. [Google Scholar] [CrossRef]

- Lee, H.S.; Choi, Y. Environmental performance evaluation of the Korean manufacturing industry based on sequential DEA. Sustainability 2019, 11, 874. [Google Scholar] [CrossRef]

- Grant, D.; Yeo, B. A global perspective on tech investment, financing, and ICT on manufacturing and service industry performance. Int. J. Inf. Manag. 2018, 43, 130–145. [Google Scholar] [CrossRef]

- Ghobakhloo, M.; Iranmanesh, M. Digital transformation success under Industry 4.0: A strategic guideline for manufacturing SMEs. J. Manuf. Technol. Manag. 2021, 32. [Google Scholar] [CrossRef]

- Cantore, N.; Clara, M.; Lavopa, A.; Soare, C. Manufacturing as an engine of growth: Which is the best fuel? Struct. Chang. Econ. Dyn. 2017, 42, 56–66. [Google Scholar] [CrossRef]

- Charles, K.K.; Hurst, E.; Schwartz, M. The transformation of manufacturing and the decline in US employment comment. NBER Macroecon. Annu. 2019, 33, 373–379. [Google Scholar] [CrossRef]

- Zheng, Q.; Lin, B. Impact of industrial agglomeration on energy efficiency in China’s paper industry. J. Clean. Prod. 2018, 184, 1072–1080. [Google Scholar] [CrossRef]

- Wei, W.; Zhang, W.L.; Wen, J.; Wang, J.S. TFP growth in Chinese cities: The role of factor-intensity and industrial agglomeration. Econ. Model. 2020, 91, 534–549. [Google Scholar] [CrossRef]

- Romer, P. Endogenous technological growth. J. Political Econ. 1990, 98, S71–S102. [Google Scholar] [CrossRef]

- Narayanan, S.; Lai, Y.W. Immigrant labor and industrial upgrading in Malaysia. Asian Pacific Migr. J. 2014, 23, 273–297. [Google Scholar] [CrossRef]

- Lei, S.; Qin, C.; Ali, M.; Freeman, S.; Zheng, S.-J. The impact of authentic leadership on individual and team creativity: A multilevel perspective. Leadersh. Org. Dev. J. 2021, 42, 644–662. [Google Scholar] [CrossRef]

- Doronin, D.; Shen, L.; Ali, M. Parallel mediating effect of knowledge sharing quality on team innovativeness. Technol. Anal. Strateg. Manag. 2020, 32, 1449–1461. [Google Scholar] [CrossRef]

- Bigsten, A.; Collier, P.; Dercon, S.; Fafchamps, M.; Gauthier, B.; Gunning, J.W.; Oduro, A.; Oostendorp, R.; Pattillo, C.; Söderbom, M.; et al. Do African manufacturing firms learn from exporting? J. Dev. Stud. 2004, 40, 115–141. [Google Scholar] [CrossRef]

- Fafchamps, M.; El Hamine, S.; Zeufack, A. Learning to export: Evidence from Moroccan manufacturing. J. Afr. Econ. 2008, 17, 305–355. [Google Scholar] [CrossRef]

- Buturac, G.; Mikulić, D.; Palić, P. Sources of export growth and development of manufacturing industry: Empirical evidence from Croatia. Econ. Res. Istraz. 2019, 32, 101–127. [Google Scholar] [CrossRef]

- Thomann, E.; Maggetti, M. Designing research with qualitative comparative analysis (QCA): Approaches, challenges, and tools. Sociol. Methods Res. 2020, 49, 356–386. [Google Scholar] [CrossRef]

- Fiss, P.C. Building better causal theories: A fuzzy set approach to typologies in organization research. Acad. Manag. J. 2011, 54, 393–420. [Google Scholar] [CrossRef]

- Fai, F.; Von Tunzelmann, N. Industry-specific competencies and converging technological systems: Evidence from patents. Struct. Change Econ. Dyn. 2001, 12, 141–170. [Google Scholar] [CrossRef]

- Van Wyk, L.; Saayman, M.; Rossouw, R.; Saayman, A. Regional economic impacts of events: A comparison of methods. S. Afr. J. Econ. Manag. Sci. 2015, 18, 155–176. [Google Scholar] [CrossRef]

- Kim, Y.-J.; Lee, S.-G.; Trimi, S. Industrial linkage and spillover effects of the logistics service industry: An input–output analysis. Serv. Bus. 2021, 15, 231–252. [Google Scholar] [CrossRef]

- Yang, L. Research on the Measurement and Characteristics of Manufacturing Service Level in the Yangtze River Economic Belt. Contemp. Financ. Econ. 2019, 6. [Google Scholar] [CrossRef]

- Tohmo, T. The economic impact of tourism in Central Finland: A regional input–output study. Tour. Rev. 2018, 73, 521–547. [Google Scholar] [CrossRef]

- Zuhdi, U. The dynamics of indonesian creative industry sectors: An analysis using input–output approach. J. Knowl. Econ. 2015, 6, 1177–1190. [Google Scholar] [CrossRef]

- Park, S.H. Intersectoral relationships between manufacturing and services: New evidence from selected pacific basin countries. ASEAN Econ. Bull. 1994, 10, 245–263. [Google Scholar] [CrossRef]

- Liu, B.; WANG, N. Input servitization of manufacturing and dual margins of firms’ export—An empirical study based on the data of chinese micro-enterprise. China Ind. Econ. 2016, 9, 59–74. [Google Scholar] [CrossRef]

- Shen, L.; Sun, C.; Ali, M. Role of Servitization, Digitalization, and Innovation Performance in Manufacturing Enterprises. Sustainability 2021, 13, 9878. [Google Scholar] [CrossRef]

- Coll-Martínez, E.; Moreno-Monroy, A.I.; Arauzo-Carod, J.M. Agglomeration of creative industries: An intra-metropolitan analysis for barcelona. Pap. Reg. Sci. 2019, 98, 409–431. [Google Scholar] [CrossRef]

- State Statistical Bureau of China. China Regional Input-Output Table; China Statistical Press: Beijing, China, 2002. [Google Scholar]

- State Statistical Bureau of China. China Regional Input-Output Table; China Statistical Press: Beijing, China, 2007. [Google Scholar]

- State Statistical Bureau of China. China Regional Input-Output Table; China Statistical Press: Beijing, China, 2012. [Google Scholar]

- State Statistical Bureau of China. China Regional Input-Output Table; China Statistical Press: Beijing, China, 2017. [Google Scholar]

- Ministry of Science and Technology; National Bureau of Statistics. China Statistical Yearbook on Science and Technology; China Statistical Press: Beijing, China, 2002–2017. [Google Scholar]

- State Statistical Bureau of China. China Statistical Yearbook; China Statistical Press: Beijing, China, 2002–2017. [Google Scholar]

- State Statistical Bureau of China. China Labour Statistical Yearbook; China Statistical Press: Beijing, China, 2002–2017. [Google Scholar]

- Douglas, E.J.; Shepherd, D.A.; Prentice, C. Using fuzzy-set qualitative comparative analysis for a finer-grained understanding of entrepreneurship. J. Bus. Ventur. 2020, 35, 105970. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).