Waste Cooking Oil as a Sustainable Bio Modifier for Asphalt Modification: A Review

Abstract

:1. Introduction

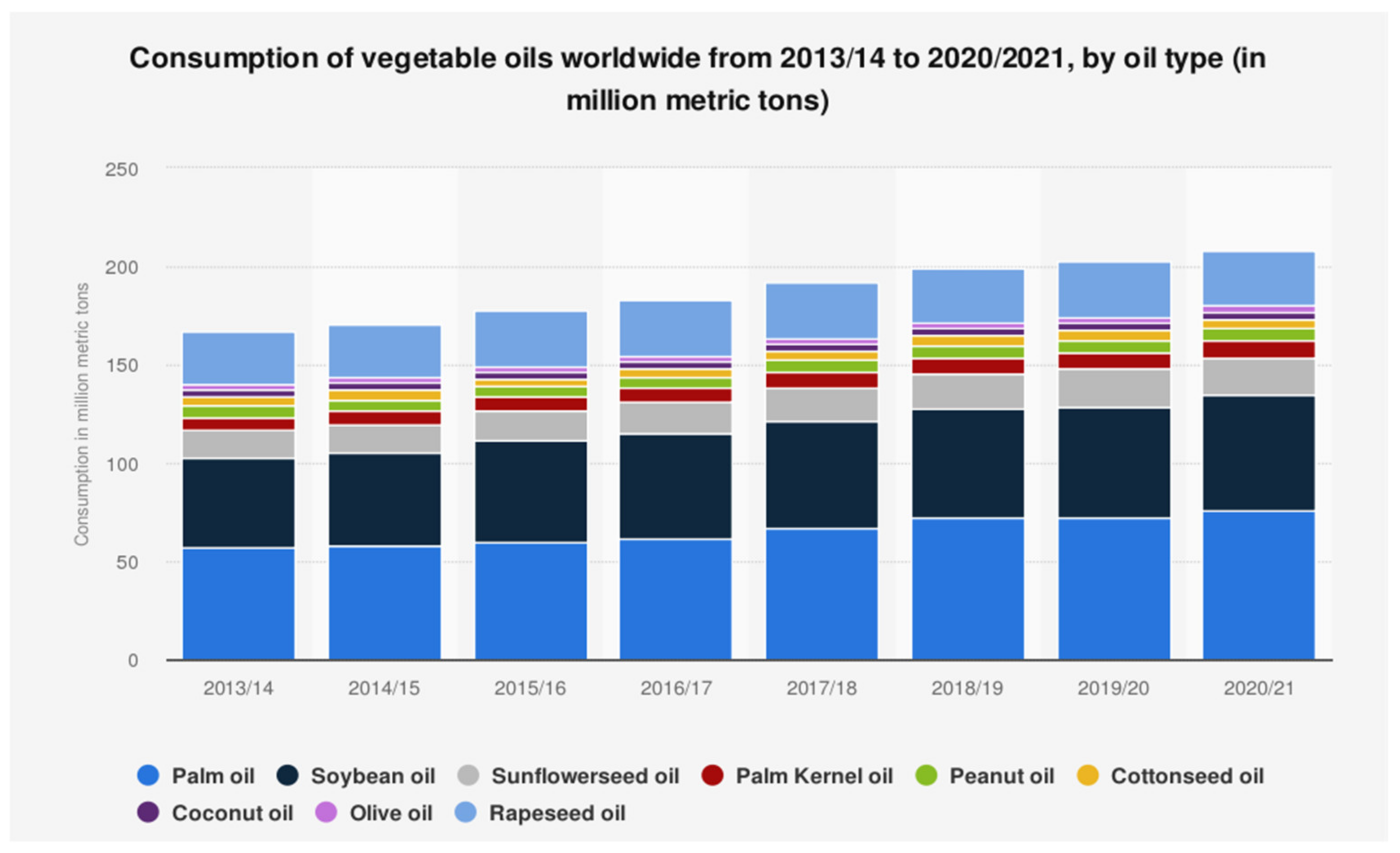

2. Production of Waste Cooking Oil

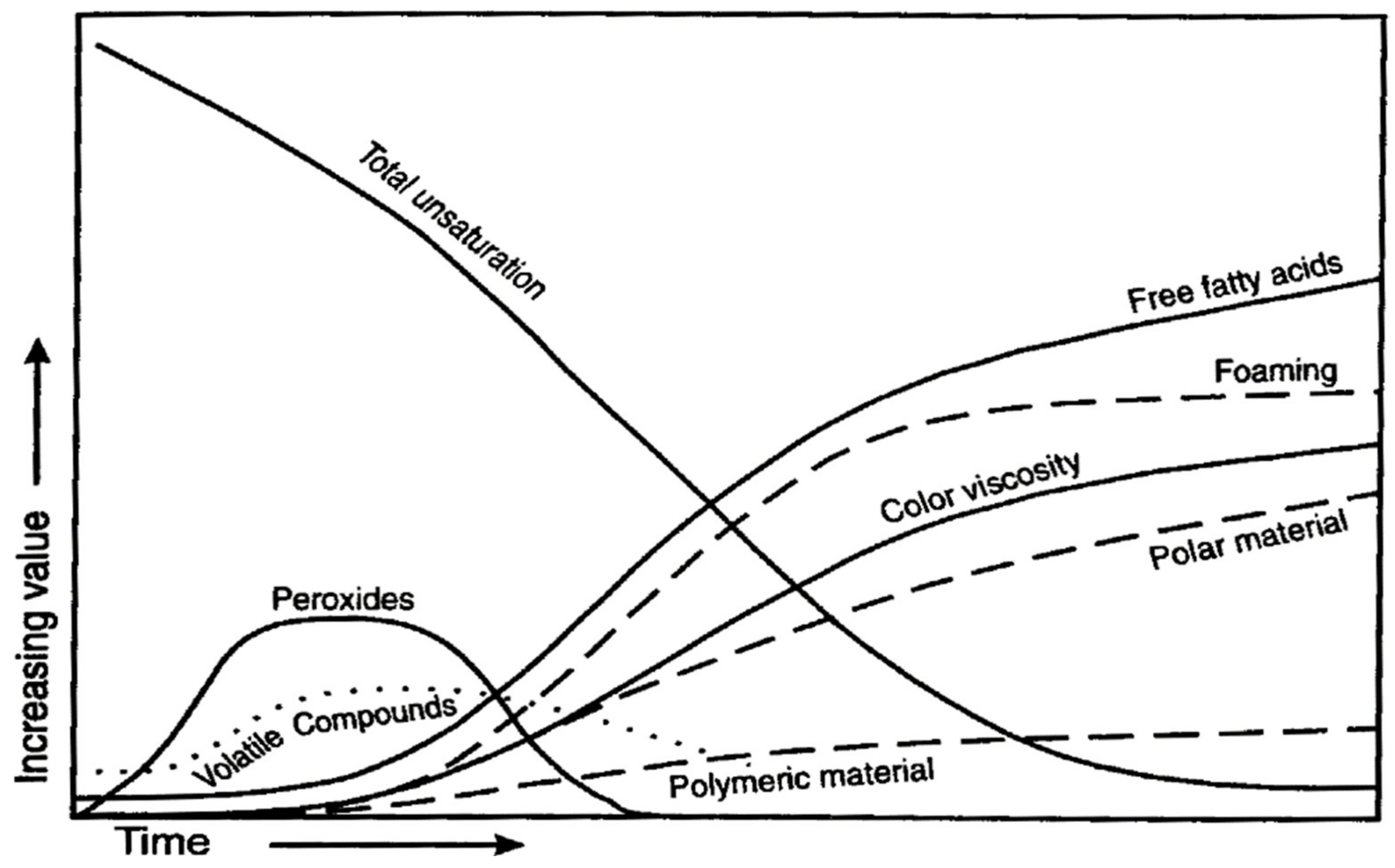

3. Physical and Chemical Properties of Waste Cooking Oil

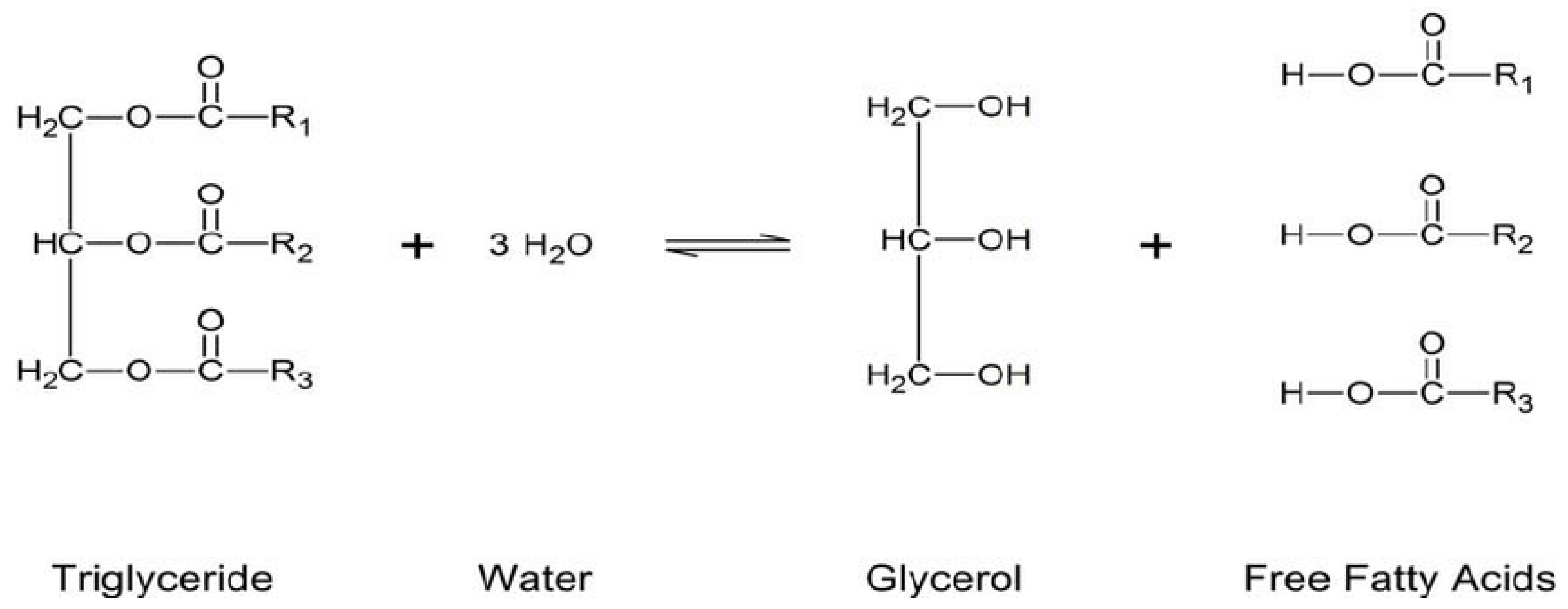

4. Free Fatty Acid in Waste Cooking Oil

5. Effect of Acid Value and Water Content on Asphalt Binder Performance

6. Available Technologies to Minimize FFA from Waste Cooking Oil

6.1. Technologies for Treating Waste Cooking Oil Physically

6.1.1. Filtration and Centrifugation

6.1.2. Distillation

6.1.3. Membrane Separation

6.2. Technologies for Treating Waste Cooking Oil Chemically

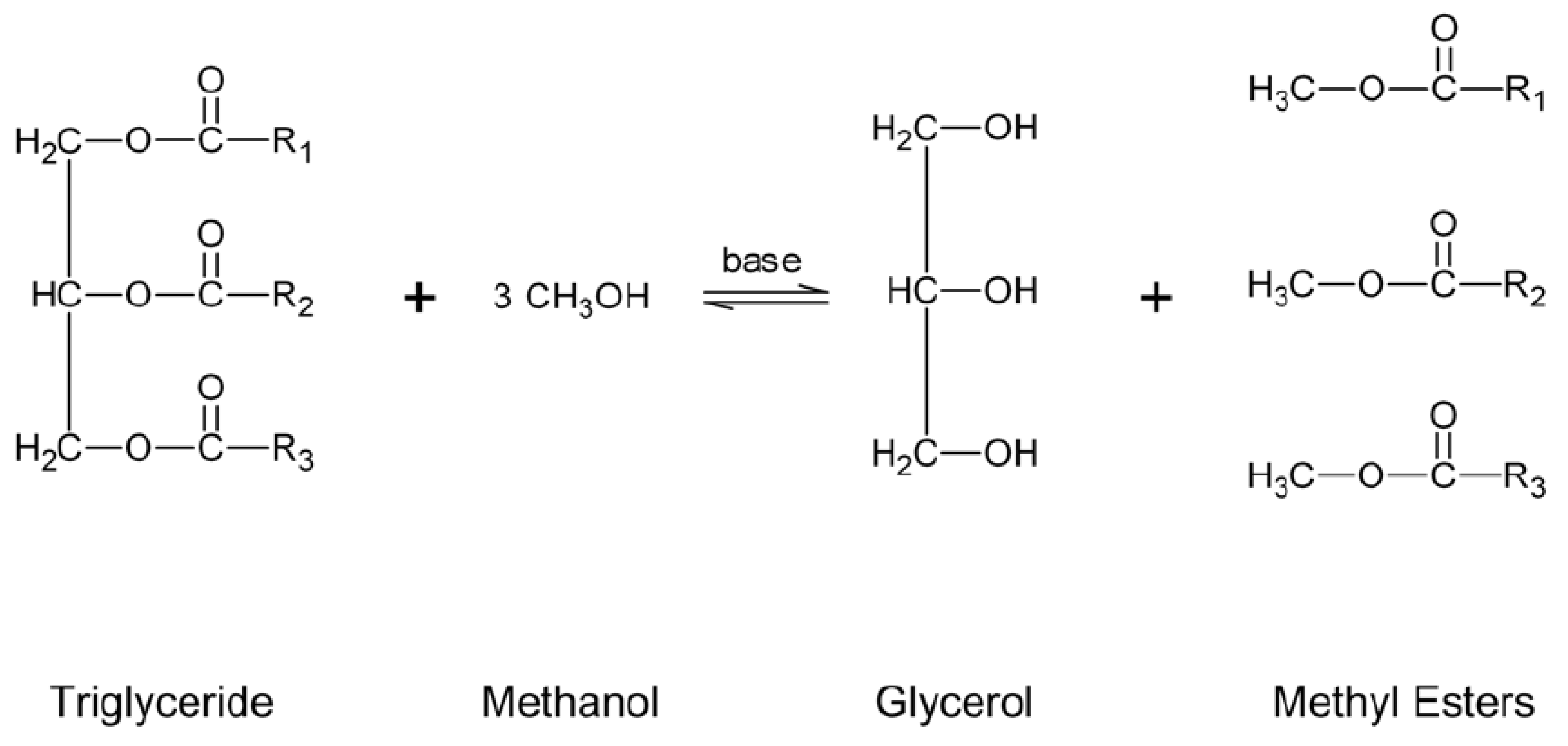

6.2.1. Base-Catalyzed Transesterification

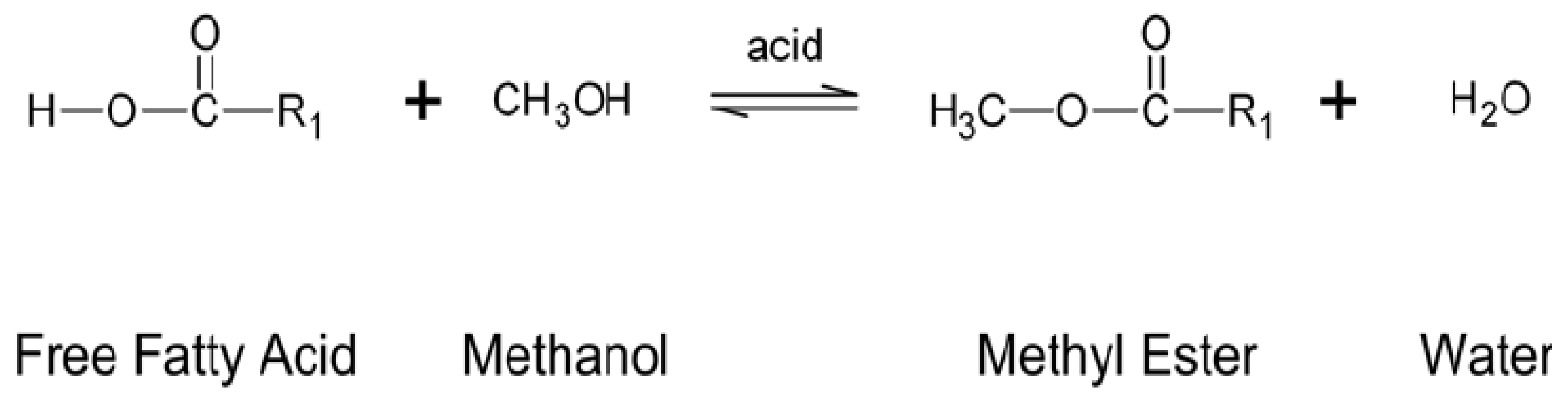

6.2.2. Acid-Catalyzed Esterification

6.2.3. Microwave Irradiation Transesterification

7. Available Technologies to Minimize Water Content from Waste Cooking Oil

8. Application of Waste Cooking Oil as a Bio-Asphalt Binder in Pavement Industry

9. Effect of Untreated and Chemically Treated Waste Cooking Oil on Conventional Properties of Asphalt Binder

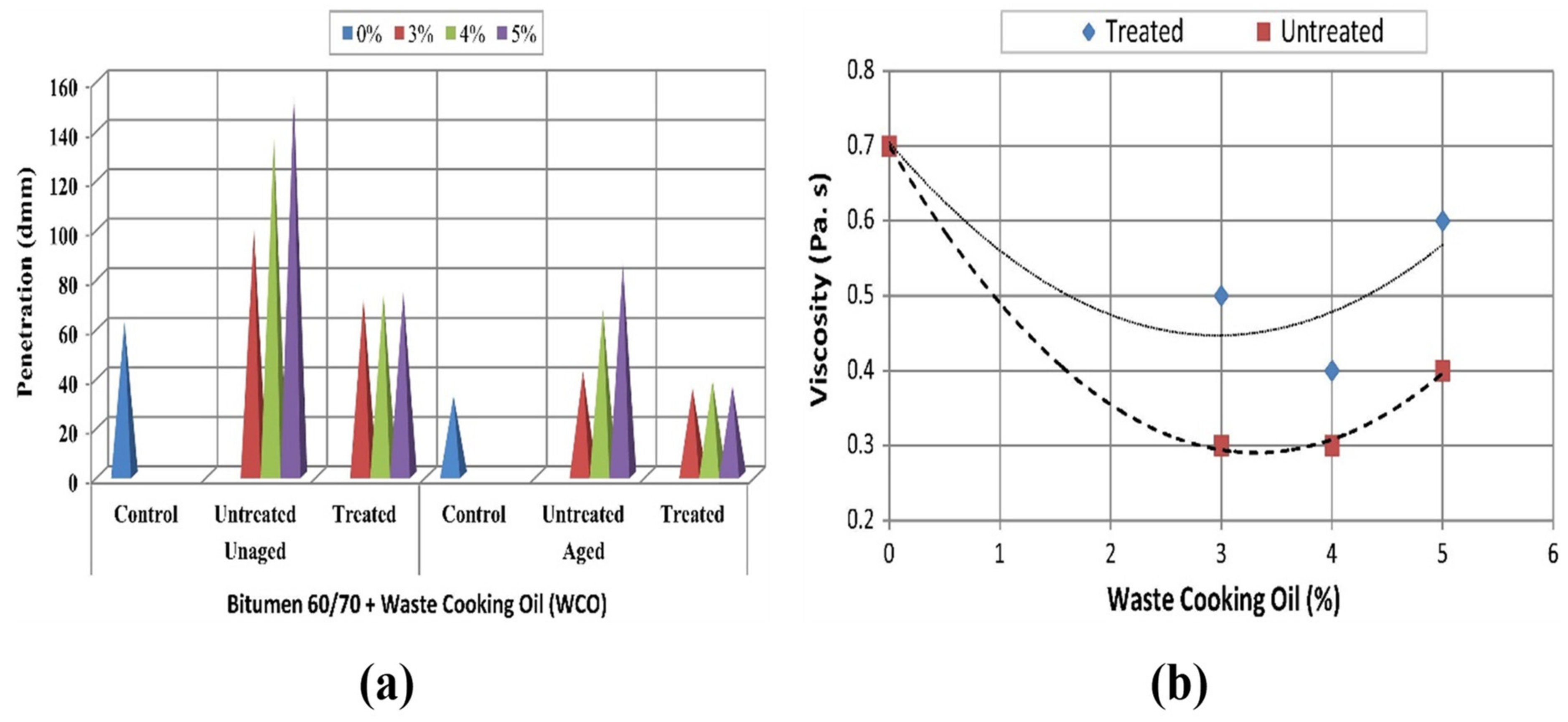

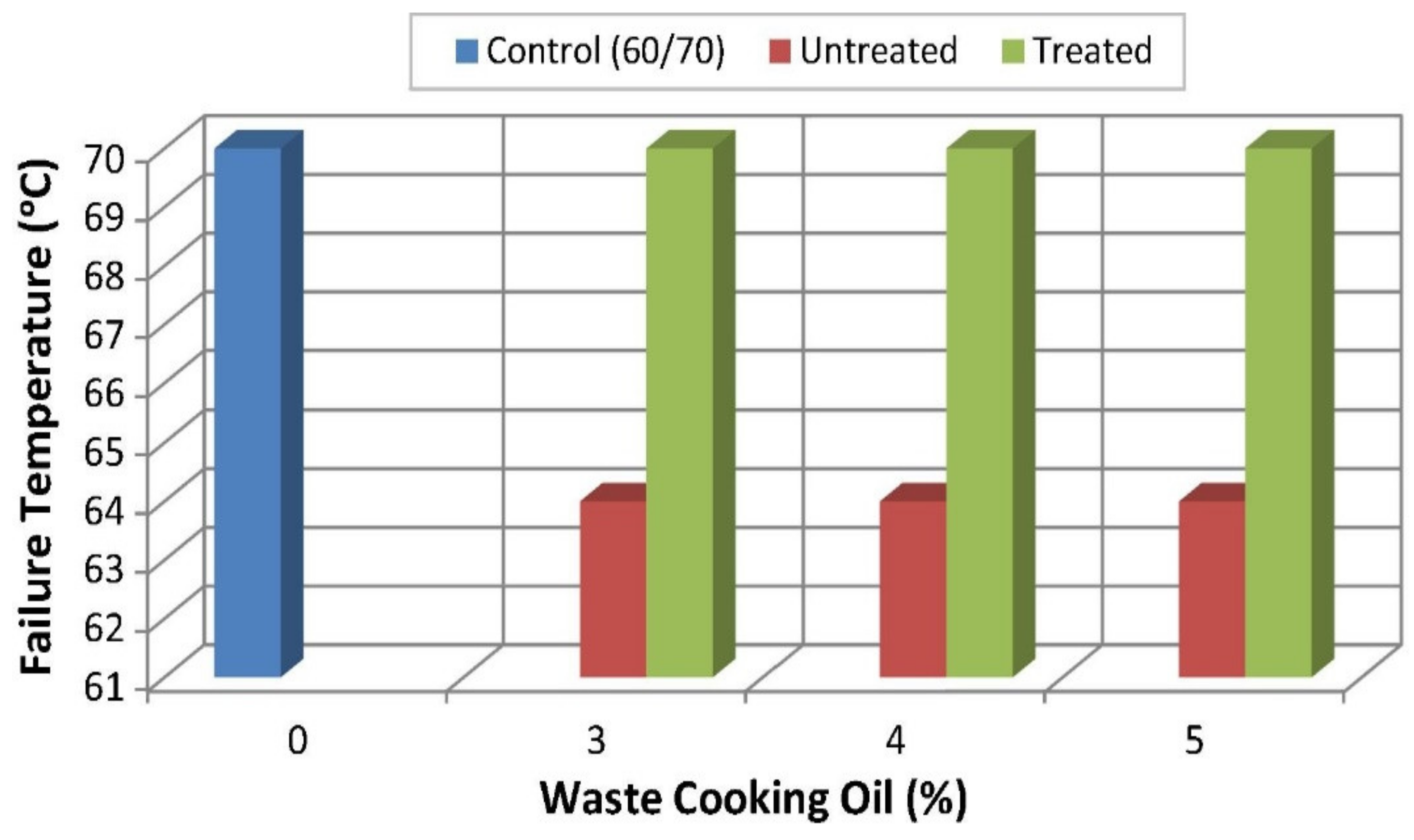

10. Effect of Untreated and Chemically Treated Waste Cooking Oil on Rheological Properties of Asphalt Binder

11. Effect of Waste Cooking Oil with Additional Additives on Conventional Properties of Asphalt Binder

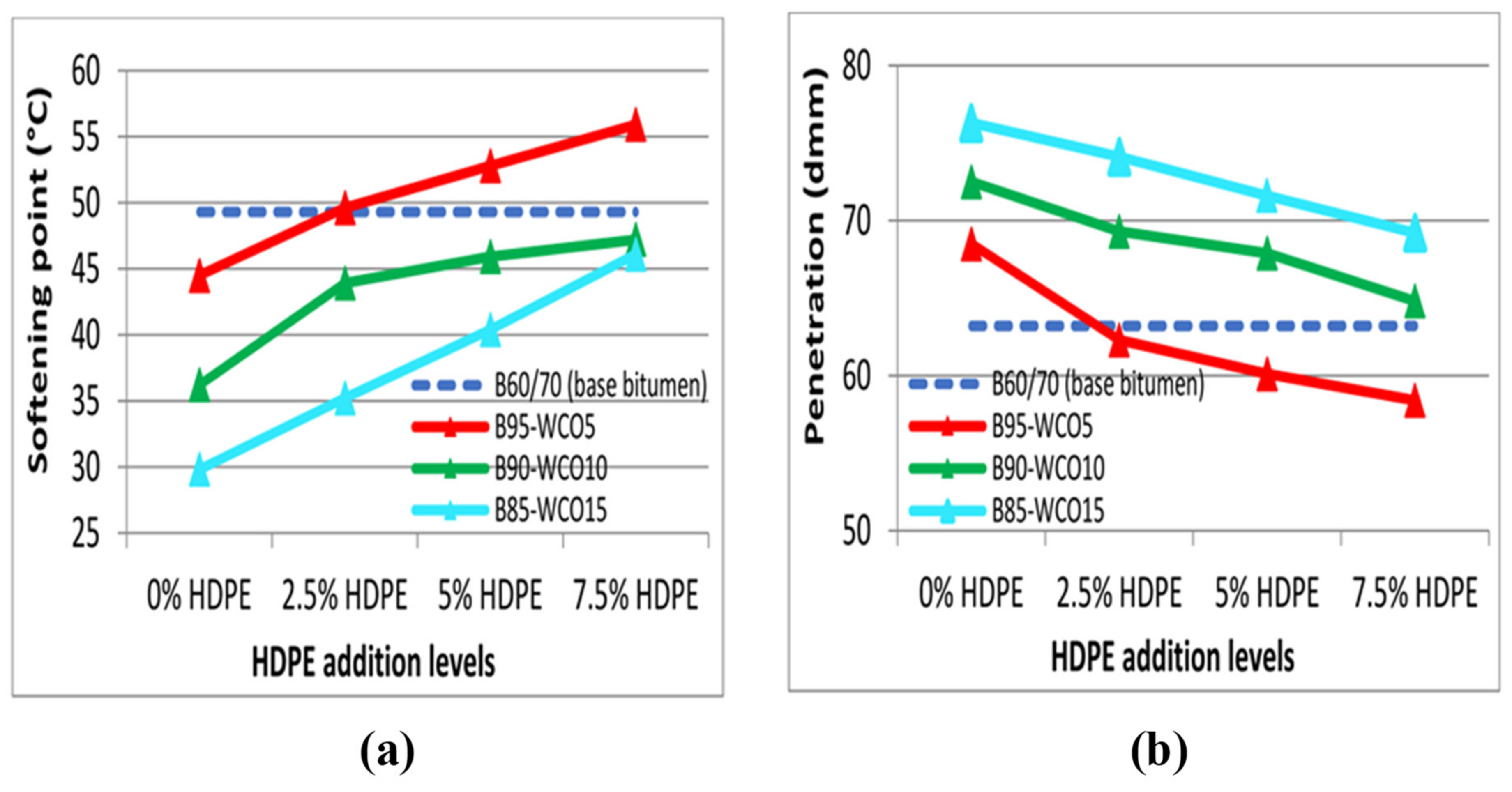

12. Effect of Waste Cooking Oil with Additional Additives on Rheological Properties of Asphalt Binder

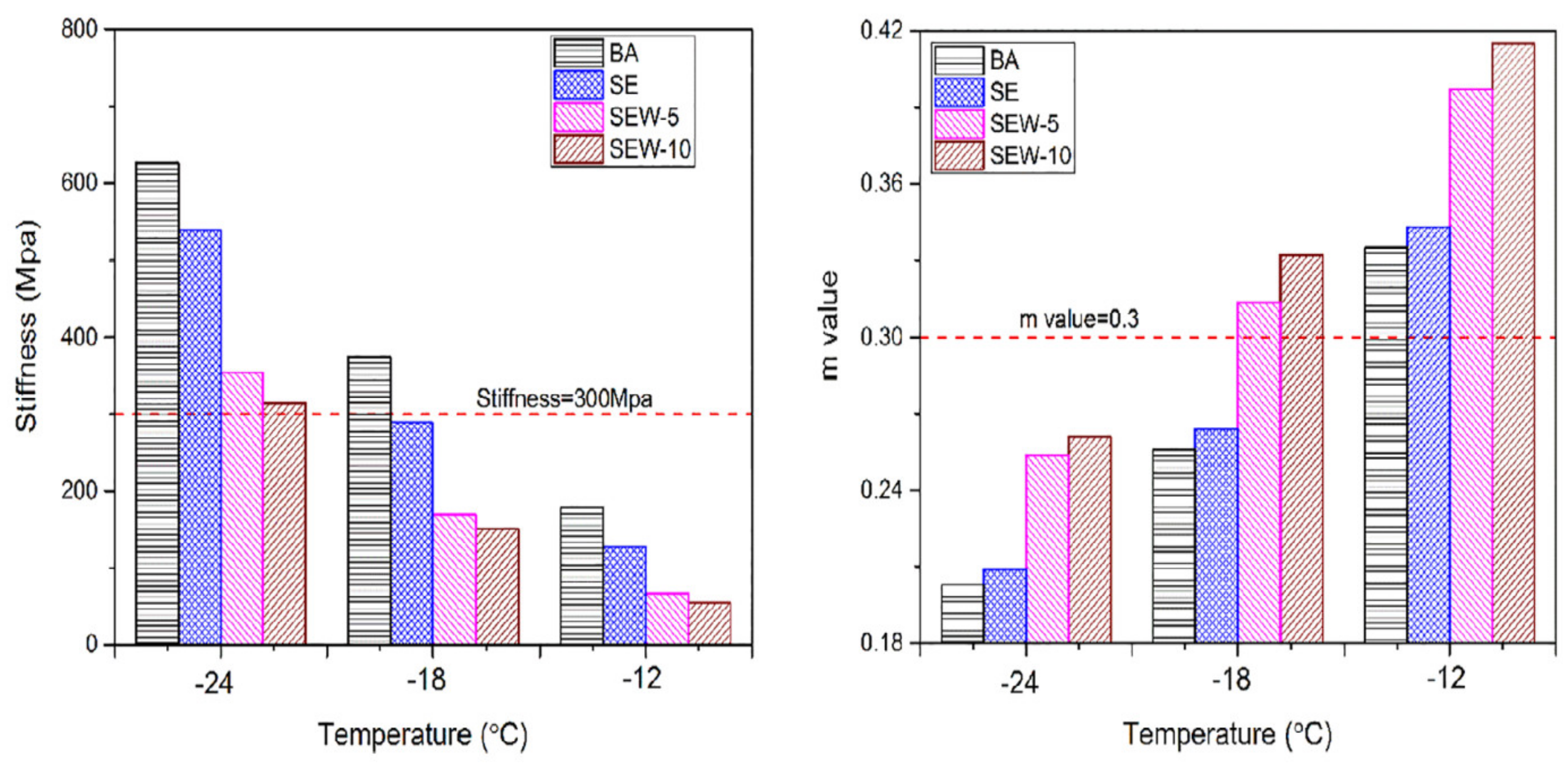

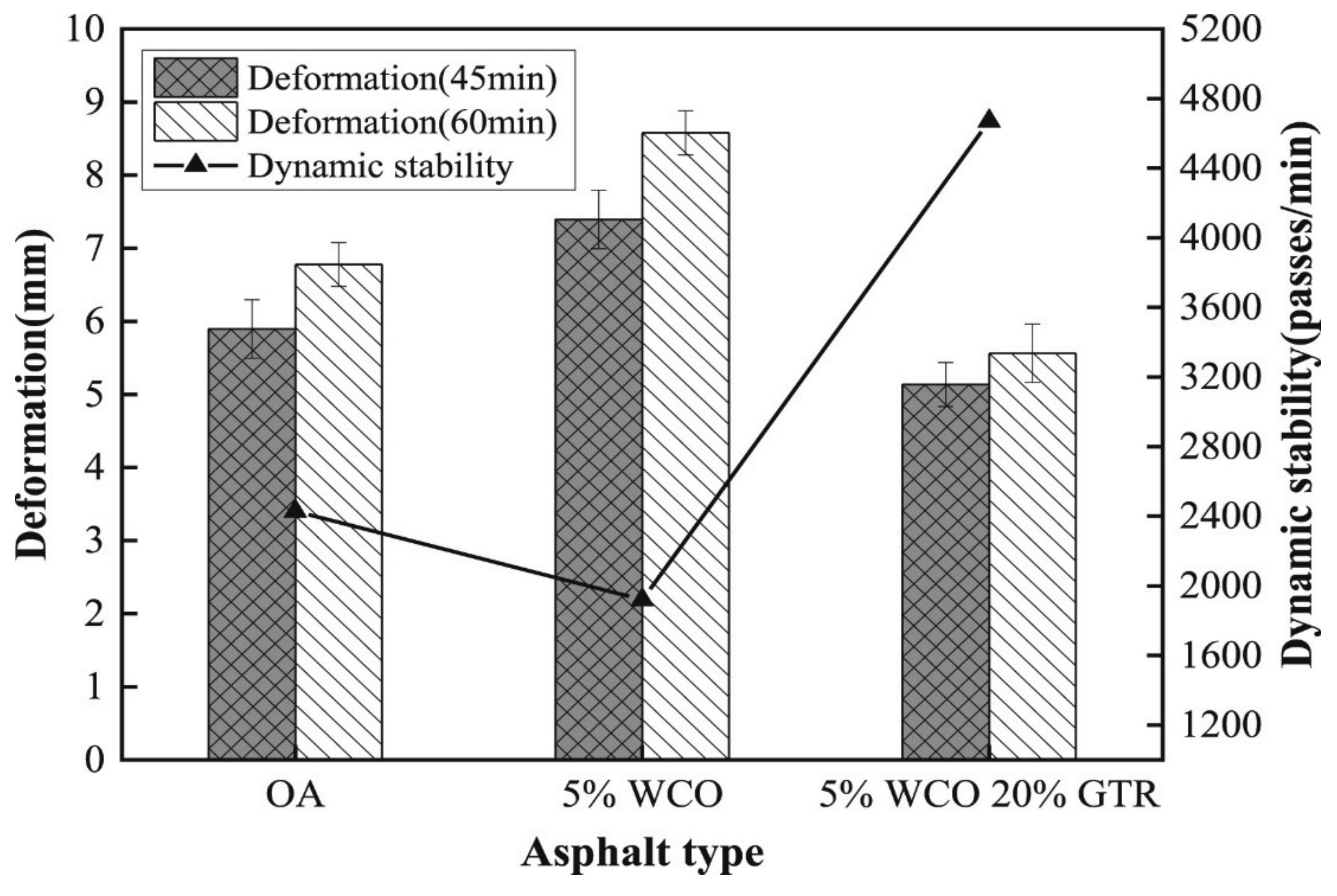

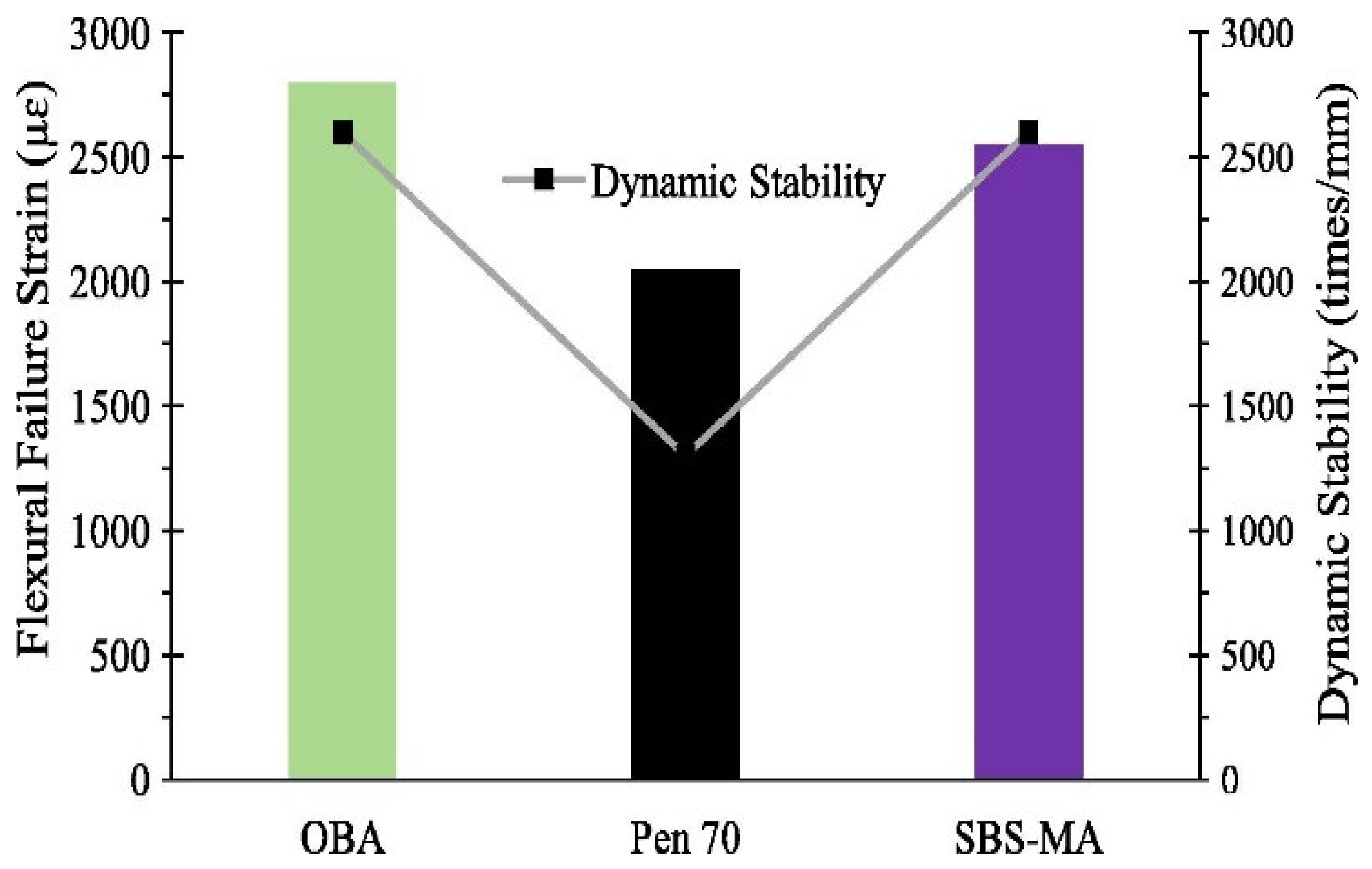

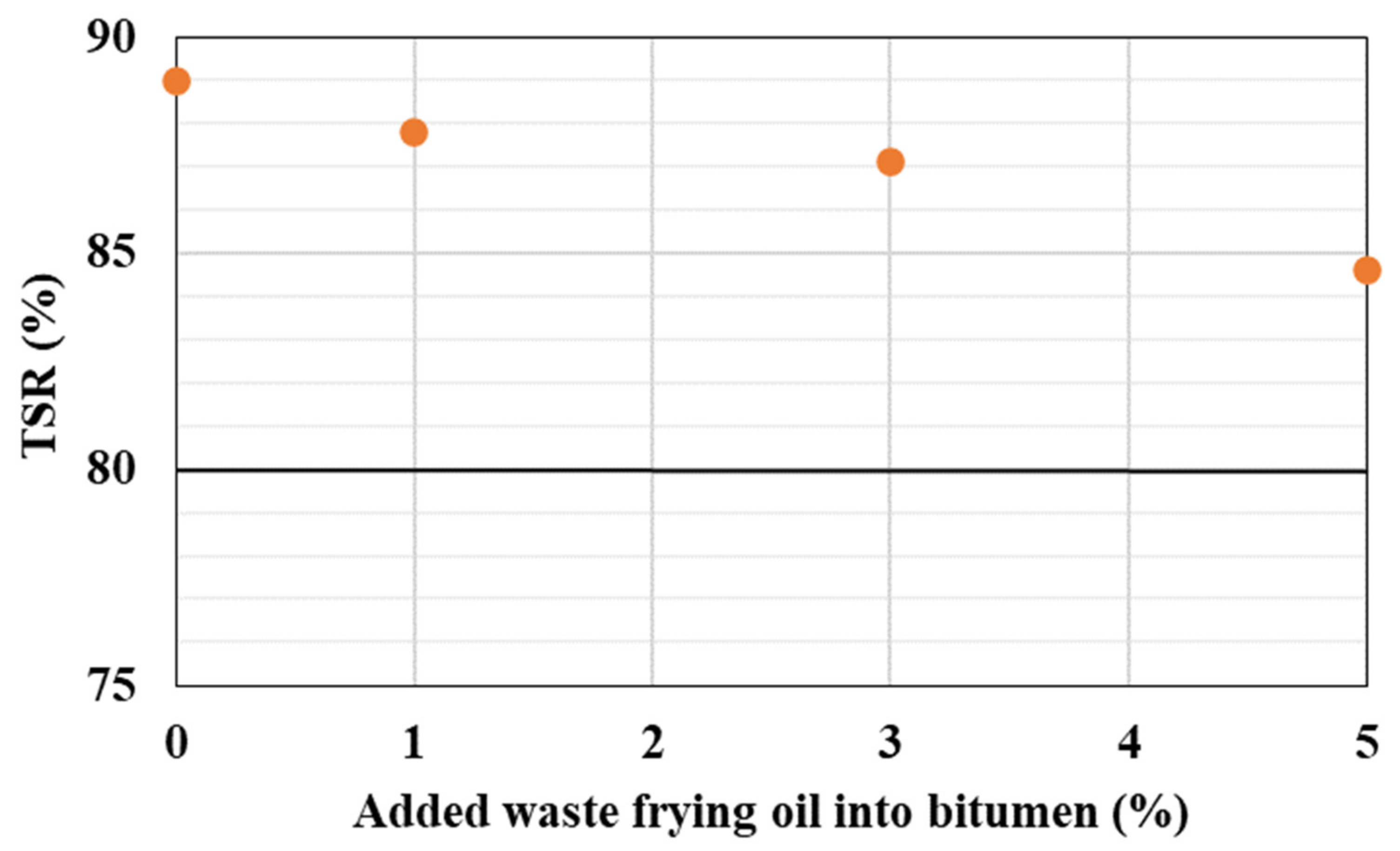

13. The Impact of Waste Cooking Oil on the Performance of Asphalt Mixtures

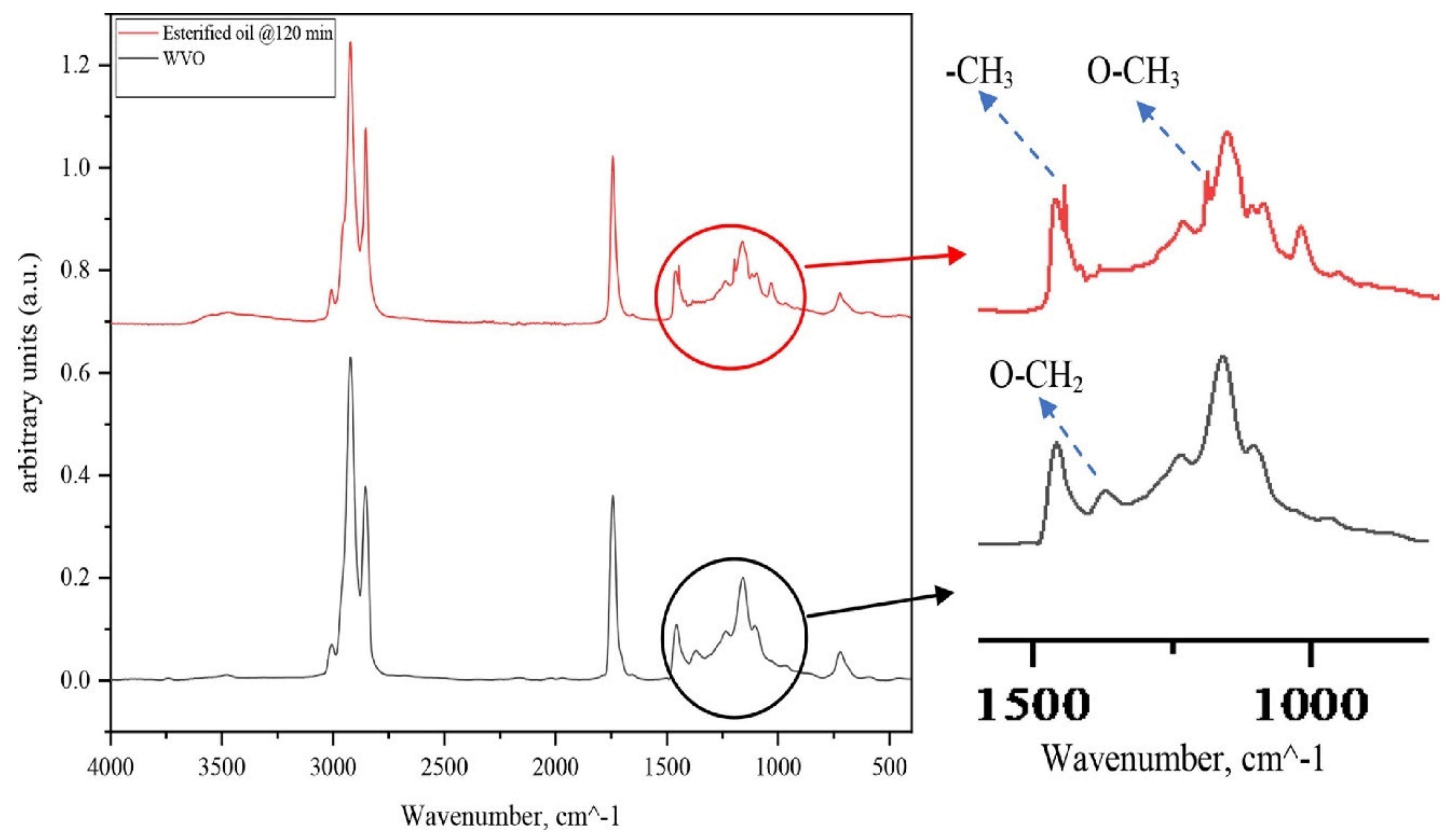

14. Fourier Transform Infrared Spectroscopy of WCO Modified Asphalt Binders

15. Conclusions and Recommendations

- The acid value, water content, and overall quality of WCO have a major impact on the efficiency of the modification process. The limited available technologies have been utilized to minimize the effect of FFA and water content on asphalt properties.

- The concentration and quality of the WCO have a major impact on the properties of filtered WCO-modified asphalt binder. As the incremental dose of WCO introduces additional lighter oil components, the physical, rheological, and mixture performance are greatly influenced. However, at lower temperature, addition of WCO enhance the binder flexibility, thus leading to improved thermal and fatigue resistance.

- Few additives, such as GTR, NC, waste plastic, and POFA, have been added in WCO-modified binder to analyze their effect. Improved physical properties with the mixed trend of rutting and fatigue parameters were observed based on types and concentrations of additive along with WCO %.

- The oxidative study using FTIR revealed that untreated WCO has undesired components, such as C=O stretch, responsible for the poor rutting performance of WCO-modified asphalt binder. The treated WCO-based binder contains an increased peak of C–H bond and C=C aromatic bond, with a negligible amount of unwanted chemicals, such as C=O stretch.

- The simply filtered WCO does not work well on mixture performance at high temperatures, whereas treated WCO-modified or additive/WCO-modified asphalt mixture favors improved resistance to permanent deformation.

- All the WCO-modified asphalt fulfilled the TSR requirement. However, in few studies, adding additives in WCO-modified mixture showed comparatively less TSR value than WCO-modified mixture.

- Available technologies can be utilized for the physical and chemical treatment of WCO prior to incorporating it into the asphalt binder.

- The physical and chemical interaction of WCO with asphalt binder should be investigated further.

- The analysis of the bond between WCO and different modifiers should be defined at a micro-level, as the focus on this area of study needs to be in-depth.

- Further in-depth evaluation of the performance of asphalt mixture with different modifiers and gradations is required to fully analyze the behaviors of mixtures.

- More studies should be conducted to evaluate the mixing variables for proper blending of WCO with asphalt binder, also in conjunction with other additional additives.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Fini, E.H.; Al-Qadi, I.; You, Z.; Zada, B.; Mills-Beale, J. Partial replacement of asphalt binder with bio-binder: Characterisation and modification. Int. J. Pavement Eng. 2012, 13, 515–522. [Google Scholar] [CrossRef]

- Ansari, A.H.; Jakarni, F.M.; Muniandy, R.; Hassim, S.; Elahi, Z. Natural rubber as a renewable and sustainable bio-modifier for pavement applications: A review. J. Clean. Prod. 2021, 289, 125727. [Google Scholar] [CrossRef]

- Zhang, X.; Zhang, K.; Wu, C.; Liu, K.; Jiang, K. Preparation of bio-oil and its application in asphalt modification and rejuvenation: A review of the properties, practical application and life cycle assessment. Constr. Build. Mater. 2020, 262, 120528. [Google Scholar] [CrossRef]

- Wang, H.; Ma, Z.; Chen, X.; Hasan, M.R.M. Preparation process of bio-oil and bio-asphalt, their performance, and the application of bio-asphalt: A comprehensive review. J. Traffic Transp. Eng. 2020, 7, 137–151. [Google Scholar] [CrossRef]

- Aziz, M.A.; Rahman, T.; Hainin, M.R.; Abu Bakar, W.A.W. An overview on alternative binders for flexible pavement. Constr. Build. Mater. 2015, 84, 315–319. [Google Scholar] [CrossRef]

- Yang, X.; You, Z.; Dai, Q. Performance evaluation of asphalt binder modified by bio-oil generated from waste wood resources. Int. J. Pavement Res. Technol. 2013, 6, 431–439. [Google Scholar] [CrossRef]

- Yang, X. The Laboratory Evaluation of Bio Oil Derived from Waste Resources as Extender for Asphalt Binder. Ph.D. Dissertation, Michigan Technological University, Houghton, MI, USA, 2013. [Google Scholar]

- Mohammad, L.N.; Elseifi, M.A.; Cooper, S.B.; Challa, H.; Naidoo, P. Laboratory Evaluation of Asphalt Mixtures that Contain Biobinder Technologies. Transp. Res. Rec. J. Transp. Res. Board 2013, 2371, 58–65. [Google Scholar] [CrossRef]

- Fini, E.H.; Kalberer, E.W.; Shahbazi, A.; Basti, M.; You, Z.; Ozer, H.; Aurangzeb, Q. Chemical Characterization of Biobinder from Swine Manure: Sustainable Modifier for Asphalt Binder. J. Mater. Civ. Eng. 2011, 23, 1506–1513. [Google Scholar] [CrossRef]

- Sun, D.; Sun, G.; Du, Y.; Zhu, X.; Lu, T.; Pang, Q.; Shi, S.; Dai, Z. Evaluation of optimized bio-asphalt containing high content waste cooking oil residues. Fuel 2017, 202, 529–540. [Google Scholar] [CrossRef]

- Rogers, J.; Brammer, J. Estimation of the production cost of fast pyrolysis bio-oil. Biomass-Bioenergy 2012, 36, 208–217. [Google Scholar] [CrossRef]

- Ramadhansyah, P.J.; Masri, K.A.; Azahar, W.N.A.W.; Mashros, N.; Norhidayah, A.H.; Warid, M.N.M.; Satar, M.K.I.M.; Yaacob, H. Waste Cooking Oil as Bio Asphalt Binder: A Critical Review. IOP Conf. Ser. Mater. Sci. Eng. 2020, 712, 012040. [Google Scholar] [CrossRef] [Green Version]

- Wen, H.; Bhusal, S.; Wen, B. Laboratory Evaluation of Waste Cooking Oil-Based Bioasphalt as an Alternative Binder for Hot Mix Asphalt. J. Mater. Civ. Eng. 2013, 25, 1432–1437. [Google Scholar] [CrossRef]

- Al-Sabaeei, A.M.; Napiah, M.B.; Sutanto, M.H.; Alaloul, W.S.; Usman, A. A systematic review of bio-asphalt for flexible pavement applications: Coherent taxonomy, motivations, challenges and future directions. J. Clean. Prod. 2020, 249, 119357. [Google Scholar] [CrossRef]

- Mannu, A.; Garroni, S.; Porras, J.I.; Mele, A. Available Technologies and Materials for Waste Cooking Oil Recycling. Processes 2020, 8, 366. [Google Scholar] [CrossRef] [Green Version]

- De Feo, G.; Di Domenico, A.; Ferrara, C.; Abate, S.; Osseo, L.S. Evolution of Waste Cooking Oil Collection in an Area with Long-Standing Waste Management Problems. Sustainability 2020, 12, 8578. [Google Scholar] [CrossRef]

- Teixeira, M.R.; Nogueira, R.; Nunes, L.M. Quantitative assessment of the valorisation of used cooking oils in 23 countries. Waste Manag. 2018, 78, 611–620. [Google Scholar] [CrossRef]

- Zhao, Y.; Wang, C.; Zhang, L.; Chang, Y.; Hao, Y. Converting waste cooking oil to biodiesel in China: Environmental impacts and economic feasibility. Renew. Sustain. Energy Rev. 2021, 140, 110661. [Google Scholar] [CrossRef]

- Zahoor, M.; Nizamuddin, S.; Madapusi, S.; Giustozzi, F. Sustainable asphalt rejuvenation using waste cooking oil: A comprehensive review. J. Clean. Prod. 2021, 278, 123304. [Google Scholar] [CrossRef]

- Ramos, T.R.P.; Gomes, M.; Barbosa-Povoa, A. Planning waste cooking oil collection systems. Waste Manag. 2013, 33, 1691–1703. [Google Scholar] [CrossRef]

- Li, L.; Xin, C.; Guan, M.; Guo, M. Using Molecular Dynamics Simulation to Analyze the Feasibility of Using Waste Cooking Oil as an Alternative Rejuvenator for Aged Asphalt. Sustainability 2021, 13, 4373. [Google Scholar] [CrossRef]

- Tsai, W.-T. Mandatory Recycling of Waste Cooking Oil from Residential and Commercial Sectors in Taiwan. Resources 2019, 8, 38. [Google Scholar] [CrossRef] [Green Version]

- Azahar, W.N.A.W.; Bujang, M.; Jaya, R.P.; Hainin, M.R.; Ngadi, N.; Abdullah, M.M.A.B. Performance of Waste Cooking Oil in Asphalt Binder Modification. Key Eng. Mater. 2016, 700, 216–226. [Google Scholar] [CrossRef]

- Asli, H.; Ahmadinia, E.; Zargar, M.; Karim, M.R. Investigation on physical properties of waste cooking oil—Rejuvenated bitumen binder. Constr. Build. Mater. 2012, 37, 398–405. [Google Scholar] [CrossRef]

- Azahar, W.N.A.W.; Jaya, R.P.; Hainin, M.R.; Bujang, M.; Ngadi, N. Chemical modification of waste cooking oil to improve the physical and rheological properties of asphalt binder. Constr. Build. Mater. 2016, 126, 218–226. [Google Scholar] [CrossRef]

- Ben Zair, M.; Jakarni, F.; Muniandy, R.; Hassim, S. A Brief Review: Application of Recycled Polyethylene Terephthalate in Asphalt Pavement Reinforcement. Sustainability 2021, 13, 1303. [Google Scholar] [CrossRef]

- Ansari, A.H.; Jakarni, F.M.; Muniandy, R.; Hassim, S. A review on the application of natural rubber as asphalt modifier. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1075, 012031. [Google Scholar] [CrossRef]

- Rodrigues, C.; Capitão, S.; Picado-Santos, L.; Almeida, A. Full Recycling of Asphalt Concrete with Waste Cooking Oil as Rejuvenator and LDPE from Urban Waste as Binder Modifier. Sustainability 2020, 12, 8222. [Google Scholar] [CrossRef]

- Niu, D.; Xie, X.; Zhang, Z.; Niu, Y.; Yang, Z. Influence of binary waste mixtures on road performance of asphalt and asphalt mixture. J. Clean. Prod. 2021, 298, 126842. [Google Scholar] [CrossRef]

- Khan, J.; Hussain, A.; Haq, F.; Ahmad, K.; Mushtaq, K. Performance Evaluation of Modified Bitumen with Replaced Percentage of Waste Cooking Oil & Tire Rubber with Bagasse Ash as Modifier. Civ. Eng. J. 2019, 5, 587. [Google Scholar] [CrossRef] [Green Version]

- Adesina, P.A.; Dahunsi, B.I. Blended waste utilization in road construction: Physical characteristics of bitumen modified with waste cooking oil and high-density polyethylene. Int. J. Pavement Res. Technol. 2021, 14, 98–104. [Google Scholar] [CrossRef]

- Jamil, F.; Al-Muhtaseb, A.; Myint, M.T.Z.; Al-Hinai, M.; Al-Haj, L.; Baawain, M.; Al-Abri, M.; Kumar, G.; Atabani, A. Biodiesel production by valorizing waste Phoenix dactylifera L. Kernel oil in the presence of synthesized heterogeneous metallic oxide catalyst (Mn@MgO-ZrO 2). Energy Convers. Manag. 2018, 155, 128–137. [Google Scholar] [CrossRef]

- Safari, A.; Salamat, R.; Baik, O.-D. A review on heat and mass transfer coefficients during deep-fat frying: Determination methods and influencing factors. J. Food Eng. 2018, 230, 114–123. [Google Scholar] [CrossRef]

- Koh, E.; Surh, J. Food types and frying frequency affect the lipid oxidation of deep frying oil for the preparation of school meals in Korea. Food Chem. 2015, 174, 467–472. [Google Scholar] [CrossRef] [PubMed]

- Cárdenas, J.; Orjuela, A.; Sánchez, D.L.; Narváez, P.C.; Katryniok, B.; Clark, J. Pre-treatment of used cooking oils for the production of green chemicals: A review. J. Clean. Prod. 2021, 289, 125129. [Google Scholar] [CrossRef]

- Daud, M.S.M.; Ngadiman, N.I.; Suliman, M.S. The awareness of recycling the used of cooking oil. J. Crit. Rev. 2020, 7, 30–32. [Google Scholar] [CrossRef]

- Choe, E.; Min, D.B. Chemistry of Deep-Fat Frying Oils. J. Food Sci. 2007, 72, R77–R86. [Google Scholar] [CrossRef]

- Tomasevic, A.; Siler-Marinkovic, S. Methanolysis of used frying oil. Fuel Process. Technol. 2003, 81, 1–6. [Google Scholar] [CrossRef]

- Wen, Z.; Yu, X.; Tu, S.-T.; Yan, J.; Dahlquist, E. Biodiesel production from waste cooking oil catalyzed by TiO2–MgO mixed oxides. Bioresour. Technol. 2010, 101, 9570–9576. [Google Scholar] [CrossRef]

- Demirbas, A. Biodiesel from waste cooking oil via base-catalytic and supercritical methanol transesterification. Energy Convers. Manag. 2009, 50, 923–927. [Google Scholar] [CrossRef]

- Phan, A.N.; Phan, T.M. Biodiesel production from waste cooking oils. Fuel 2008, 87, 3490–3496. [Google Scholar] [CrossRef]

- Ivanov Jordanov, D.; Stoyanov Petkov, P.; Kirov Dimitrov, Y.; Kunev Ivanov, S. Methanol transesterification of different vegetable oils. Pet. Coal 2007, 2, 21–23. [Google Scholar]

- Shahidi, F. Quality characteristics of edible oils. Adv. Exp. Med. Biol. 2004, 542, 239–249. [Google Scholar] [CrossRef]

- Naz, S.; Siddiqi, R.; Sheikh, H.; Sayeed, S.A. Deterioration of olive, corn and soybean oils due to air, light, heat and deep-frying. Food Res. Int. 2005, 38, 127–134. [Google Scholar] [CrossRef]

- Zhang, Q.; Saleh, A.S.; Chen, J.; Shen, Q. Chemical alterations taken place during deep-fat frying based on certain reaction products: A review. Chem. Phys. Lipids 2012, 165, 662–681. [Google Scholar] [CrossRef]

- Ahmed, R.B.; Hossain, K. Waste cooking oil as an asphalt rejuvenator: A state-of-the-art review. Constr. Build. Mater. 2020, 230, 116985. [Google Scholar] [CrossRef]

- Azahar, W.N.A.W.; Jaya, R.P.; Hainin, M.R.; Bujang, M.; Ngadi, N. Mechanical performance of asphaltic concrete incorporating untreated and treated waste cooking oil. Constr. Build. Mater. 2017, 150, 653–663. [Google Scholar] [CrossRef]

- Zhang, D.; Chen, M.; Wu, S.; Liu, J.; Amirkhanian, S. Analysis of the Relationships between Waste Cooking Oil Qualities and Rejuvenated Asphalt Properties. Materials 2017, 10, 508. [Google Scholar] [CrossRef]

- Zargar, M.; Ahmadinia, E.; Asli, H.; Karim, M.R. Investigation of the possibility of using waste cooking oil as a rejuvenating agent for aged bitumen. J. Hazard. Mater. 2012, 233–234, 254–258. [Google Scholar] [CrossRef]

- Oldham, D.; Rajib, A.; Dandamudi, K.P.R.; Liu, Y.; Deng, S.; Fini, E.H. Transesterification of Waste Cooking Oil to Produce A Sustainable Rejuvenator for Aged Asphalt. Resour. Conserv. Recycl. 2021, 168, 105297. [Google Scholar] [CrossRef]

- Lam, M.K.; Lee, K.T.; Mohamed, A.R. Homogeneous, heterogeneous and enzymatic catalysis for transesterification of high free fatty acid oil (waste cooking oil) to biodiesel: A review. Biotechnol. Adv. 2010, 28, 500–518. [Google Scholar] [CrossRef]

- Cvengroš, J.; Cvengrošová, Z. Used frying oils and fats and their utilization in the production of methyl esters of higher fatty acids. Biomass-Bioenergy 2004, 27, 173–181. [Google Scholar] [CrossRef]

- Yuan, X.; Liu, J.; Zeng, G.; Shi, J.; Tong, J.; Huang, G. Optimization of conversion of waste rapeseed oil with high FFA to biodiesel using response surface methodology. Renew. Energy 2008, 33, 1678–1684. [Google Scholar] [CrossRef]

- Ladhe, A.R.; Krishna Kumar, N.S. Application of Membrane Technology in Vegetable Oil Processing, 1st ed.; Elsevier Ltd.: Amsterdam, The Netherlands, 2010; ISBN 9781856176323. Available online: https://www.researchgate.net/publication/286013694_Application_of_Membrane_Technology_in_Vegetable_Oil_Processing (accessed on 14 October 2021).

- Vaisali, C.; Charanyaa, S.; Belur, P.; Regupathi, I. Refining of edible oils: A critical appraisal of current and potential technologies. Int. J. Food Sci. Technol. 2014, 50, 13–23. [Google Scholar] [CrossRef]

- Koris, A.; Vatai, G. Dry degumming of vegetable oils by membrane filtration. Desalination 2002, 148, 149–153. [Google Scholar] [CrossRef]

- Yang, Z.; Peng, H.; Wang, W.; Liu, T. Crystallization behavior of poly(ε-caprolactone)/layered double hydroxide nanocomposites. J. Appl. Polym. Sci. 2010, 116, 2658–2667. [Google Scholar] [CrossRef]

- Clark, J.G.; Mountain, S.; Us, T.N. Filtration and Filtration Method for Cooking Ol Used in Frying Process. U.S. Patent US20070289927A1, 20 December 2007. [Google Scholar]

- Ma, F.; Hanna, M.A. Biodiesel production: A review. Bioresour. Technol. 1999, 70, 1–15. [Google Scholar] [CrossRef]

- Enweremadu, C.; Mbarawa, M. Technical aspects of production and analysis of biodiesel from used cooking oil—A review. Renew. Sustain. Energy Rev. 2009, 13, 2205–2224. [Google Scholar] [CrossRef]

- Atapour, M.; Kariminia, H.-R. Characterization and transesterification of Iranian bitter almond oil for biodiesel production. Appl. Energy 2011, 88, 2377–2381. [Google Scholar] [CrossRef]

- Babcock, R.E.; Clausen, E.C.; Popp, M.P.; Schulte, W.B. Yield Characteristics of Biodiesel Produced from Chicken Fat-Tall Oil Blended Feedstocks. 2008. Available online: https://trid.trb.org/view/850767 (accessed on 14 October 2021).

- Talebian-Kiakalaieh, A.; Amin, N.A.S.; Mazaheri, H. A review on novel processes of biodiesel production from waste cooking oil. Appl. Energy 2013, 104, 683–710. [Google Scholar] [CrossRef]

- Jeromin, L.; Peukert, E.; Wollmann, G. Process for the Pre-Esterification of Free Fatty Acds in Fats and Ols. U.S. Patent US4698186A, 6 October 1987. [Google Scholar]

- Zhang, Y.; Dubé, M.; McLean, D.; Kates, M. Biodiesel production from waste cooking oil: 1. Process design and technological assessment. Bioresour. Technol. 2003, 89, 1–16. [Google Scholar] [CrossRef]

- Sahoo, P.; Das, L.; Babu, M.; Naik, S.N. Biodiesel development from high acid value polanga seed oil and performance evaluation in a CI engine. Fuel 2007, 86, 448–454. [Google Scholar] [CrossRef]

- Crabbe, E.; Nolasco-Hipolito, C.; Kobayashi, G.; Sonomoto, K.; Ishizaki, A. Biodiesel production from crude palm oil and evaluation of butanol extraction and fuel properties. Process. Biochem. 2001, 37, 65–71. [Google Scholar] [CrossRef]

- Baldwin, D.; Barr, V.; Briggs, A.; Havill, J.; Maxwell, B.; Walker, H.M. Variables Affecting the Yields of Fatty Esters from Transesterified Vegetable Oils 1. J. Am. Oil Chem. Soc. 1984, 61, 677–678. [Google Scholar] [CrossRef]

- Wang, Y.; Ou, S.; Liu, P.; Xue, F.; Tang, S. Comparison of two different processes to synthesize biodiesel by waste cooking oil. J. Mol. Catal. A Chem. 2006, 252, 107–112. [Google Scholar] [CrossRef]

- Zhang, H.; Ding, J.; Zhao, Z. Microwave assisted esterification of acidified oil from waste cooking oil by CERP/PES catalytic membrane for biodiesel production. Bioresour. Technol. 2012, 123, 72–77. [Google Scholar] [CrossRef]

- Lertsathapornsuk, V.; Pairintra, R.; Aryusuk, K.; Krisnangkura, K. Microwave assisted in continuous biodiesel production from waste frying palm oil and its performance in a 100 kW diesel generator. Fuel Process. Technol. 2008, 89, 1330–1336. [Google Scholar] [CrossRef]

- Supraja, K.V.; Behera, B.; Paramasivan, B. Optimization of process variables on two-step microwave-assisted transesterification of waste cooking oil. Environ. Sci. Pollut. Res. 2020, 27, 27244–27255. [Google Scholar] [CrossRef]

- Refaat, A.A.; El Sheltawy, S.T.; Sadek, K.U. Optimum reaction time, performance and exhaust emissions of biodiesel produced by microwave irradiation. Int. J. Environ. Sci. Technol. 2008, 5, 315–322. [Google Scholar] [CrossRef] [Green Version]

- Palanisamy, K.; Idlan, M.K.; Saifudin, N. Preliminary evaluation of the effectiveness of moisture removal and energy usage in pretreatment module of waste cooking oil for biodiesel production. IOP Conf. Ser. Earth Environ. Sci. 2013, 16, 12053. [Google Scholar] [CrossRef] [Green Version]

- Dias, J.M.; Alvim-Ferraz, M.C.; Almeida, M.F. Comparison of the performance of different homogeneous alkali catalysts during transesterification of waste and virgin oils and evaluation of biodiesel quality. Fuel 2008, 87, 3572–3578. [Google Scholar] [CrossRef]

- Felizardo, P.; Correia, M.J.N.; Raposo, I.; Mendes, J.F.; Berkemeier, R.; Bordado, J. Production of biodiesel from waste frying oils. Waste Manag. 2006, 26, 487–494. [Google Scholar] [CrossRef]

- Issariyakul, T.; Kulkarni, M.G.; Dalai, A.K.; Bakhshi, N.N. Production of biodiesel from waste fryer grease using mixed methanol/ethanol system. Fuel Process. Technol. 2007, 88, 429–436. [Google Scholar] [CrossRef]

- Su, N.; Xiao, F.; Wang, J.; Cong, L.; Amirkhanian, S. Productions and applications of bio-asphalts—A review. Constr. Build. Mater. 2018, 183, 578–591. [Google Scholar] [CrossRef]

- Su, J.-F.; Qiu, J.; Schlangen, E.; Wang, Y.-Y. Investigation the possibility of a new approach of using microcapsules containing waste cooking oil: In situ rejuvenation for aged bitumen. Constr. Build. Mater. 2015, 74, 83–92. [Google Scholar] [CrossRef]

- Wang, H.N.; Gao, J.F.; You, Z.P.; Tian, Y.Y. Advances in bio-binder application on road pavement. Wuhan Ligong Daxue Xuebao/J. Wuhan Univ. Technol. 2014, 36, 55–60. [Google Scholar] [CrossRef]

- Luo, W.; Zhang, Y.; Cong, P. Investigation on physical and high temperature rheology properties of asphalt binder adding waste oil and polymers. Constr. Build. Mater. 2017, 144, 13–24. [Google Scholar] [CrossRef]

- Somé, S.C.; Pavoine, A.; Chailleux, E. Evaluation of the potential use of waste sunflower and rapeseed oils-modified natural bitumen as binders for asphalt pavement design. Int. J. Pavement Res. Technol. 2016, 9, 368–375. [Google Scholar] [CrossRef]

- Al-Omari, A.A.; Khedaywi, T.S.; Khasawneh, M.A. Laboratory characterization of asphalt binders modified with waste vegetable oil using SuperPave specifications. Int. J. Pavement Res. Technol. 2018, 11, 68–76. [Google Scholar] [CrossRef]

- Wang, C.; Xue, L.; Xie, W.; You, Z.; Yang, X. Laboratory investigation on chemical and rheological properties of bio-asphalt binders incorporating waste cooking oil. Constr. Build. Mater. 2018, 167, 348–358. [Google Scholar] [CrossRef]

- Eriskin, E.; Karahancer, S.; Terzi, S.; Saltan, M. Waste frying oil modified bitumen usage for sustainable hot mix asphalt pavement. Arch. Civ. Mech. Eng. 2017, 17, 863–870. [Google Scholar] [CrossRef]

- Rasman, M.; Hassan, N.A.; Hainin, M.R.; Jaya, R.P.; Haryati, Y.; Shukry, N.A.M.; Abdullah, M.E.; Kamaruddin, N.H.M. Engineering properties of bitumen modified with bio-oil. MATEC Web Conf. 2018, 250, 02003. [Google Scholar] [CrossRef]

- Çavdar, E.; Kumandaş, A.; Oruç, Ş. Effect of waste cooking oil use in the modification of sbs modified asphalt binder. In Proceedings of the 3rd International Conference on Advanced Engineering Technologies, Bayburt, Turkey, 19–21 September 2019. [Google Scholar]

- Maharaj, R.; Ramjattan-Harry, V.; Mohamed, N. Rutting and Fatigue Cracking Resistance of Waste Cooking Oil Modified Trinidad Asphaltic Materials. Sci. World J. 2015, 2015, 1–7. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Bilema, M.; Aman, M.Y.; Hassan, N.A.; Abdullah, N.F.A. Investigation on rheology and physical properties of asphalt binder blended with waste cooking oil. IOP Conf. Ser. Mater. Sci. Eng. 2019, 527, 012045. [Google Scholar] [CrossRef]

- Nordiana, M.; Aifa, W.A.W.N.; Hainin, M.R.; Naqiuddin, M.W.M.; Norhidayah, A.H.; Haryati, Y.; Juraidah, A.; Ramadhansyah, P.J. Rutting resistance of untreated and treated waste cooking oil in bitumen after aging condition. IOP Conf. Ser. Earth Environ. Sci. 2019, 244, 012041. [Google Scholar] [CrossRef]

- Joni, H.H.; Al-Rubaee, R.H.A.; Al-Zerkani, M.A. Characteristics of asphalt binder modified with waste vegetable oil and waste plastics. IOP Conf. Ser. Mater. Sci. Eng. 2020, 737, 012126. [Google Scholar] [CrossRef]

- Rahman, T.; Hainin, M.R.; Abu Bakar, W.A.W. Use of waste cooking oil, tire rubber powder and palm oil fuel ash in partial replacement of bitumen. Constr. Build. Mater. 2017, 150, 95–104. [Google Scholar] [CrossRef]

- Saboo, N.; Sukhija, M.; Singh, G. Effect of Nanoclay on Physical and Rheological Properties of Waste Cooking Oil–Modified Asphalt Binder. J. Mater. Civ. Eng. 2021, 33, 04020490. [Google Scholar] [CrossRef]

- Liu, S.; Zhou, S.; Peng, A.; Li, W. Investigation of physiochemical and rheological properties of waste cooking oil/SBS/EVA composite modified petroleum asphalt. J. Appl. Polym. Sci. 2019, 137, 1–13. [Google Scholar] [CrossRef]

- Dahunsi, B.I.; Adesina, P.A. Properties of Bitumen Modified with Waste Cooking Oil and High Density Polythylene for Applications in Flexible Pavement. In Proceedings of the 1st International Conference on Construction Materials for Sustainable Future, Zadar, Croatia, 19–21 April 2017. [Google Scholar]

- Mahrez, A.; Karim, M.R.; Ibrahim, M.R.; Katman, H.Y. Prospects of using waste cooking oil as rejuvenating agent in bituminous binder. Proc. East. Asia Soc. Transp. Stud. 2009, 7, 1751–1766. [Google Scholar]

- Sun, Z.; Yi, J.; Huang, Y.; Feng, D.; Guo, C. Properties of asphalt binder modified by bio-oil derived from waste cooking oil. Constr. Build. Mater. 2016, 102, 496–504. [Google Scholar] [CrossRef]

- Cao, W.; Wang, Y.; Wang, C. Fatigue characterization of bio-modified asphalt binders under various laboratory aging conditions. Constr. Build. Mater. 2019, 208, 686–696. [Google Scholar] [CrossRef]

- Gong, M.; Yang, J.; Zhang, J.; Zhu, H.; Tong, T. Physical–chemical properties of aged asphalt rejuvenated by bio-oil derived from biodiesel residue. Constr. Build. Mater. 2016, 105, 35–45. [Google Scholar] [CrossRef]

- Zhu, H.; Xu, G.; Gong, M.; Yang, J. Recycling long-term-aged asphalts using bio-binder/plasticizer-based rejuvenator. Constr. Build. Mater. 2017, 147, 117–129. [Google Scholar] [CrossRef]

- Hong, W.; Mo, L.; Pan, C.; Riara, M.; Wei, M.; Zhang, J. Investigation of rejuvenation and modification of aged asphalt binders by using aromatic oil-SBS polymer blend. Constr. Build. Mater. 2020, 231, 117154. [Google Scholar] [CrossRef]

- Nassar, I.M.; Abdel-Monem, R.M.; Sayed, M.A.; Ragab, A.A. Eco-friendly green alternative binder for asphalt from waste oil and waste polymer. Polym. Bull. 2020, 1–23. [Google Scholar] [CrossRef]

- Jia, X.; Huang, B.; Bowers, B.F.; Zhao, S. Infrared spectra and rheological properties of asphalt cement containing waste engine oil residues. Constr. Build. Mater. 2014, 50, 683–691. [Google Scholar] [CrossRef]

- Zahoor, M.; Nizamuddin, S.; Madapusi, S.; Giustozzi, F. Recycling asphalt using waste bio-oil: A review of the production processes, properties and future perspectives. Process. Saf. Environ. Prot. 2021, 147, 1135–1159. [Google Scholar] [CrossRef]

- Guarin, A.; Khan, A.; Butt, A.A.; Birgisson, B.; Kringos, N. An extensive laboratory investigation of the use of bio-oil modified bitumen in road construction. Constr. Build. Mater. 2016, 106, 133–139. [Google Scholar] [CrossRef]

- Zaumanis, M.; Mallick, R.B.; Poulikakos, L.; Frank, R. Influence of six rejuvenators on the performance properties of Reclaimed Asphalt Pavement (RAP) binder and 100% recycled asphalt mixtures. Constr. Build. Mater. 2014, 71, 538–550. [Google Scholar] [CrossRef]

- Fini, E.H.; Samieadel, A.; Rajib, A. Moisture Damage and Its Relation to Surface Adsorption/Desorption of Rejuvenators. Ind. Eng. Chem. Res. 2020, 59, 13414–13419. [Google Scholar] [CrossRef]

- Hung, A.M.; Pahlavan, F.; Shakiba, S.; Chang, S.L.Y.; Louie, S.M.; Fini, E.H. Preventing Assembly and Crystallization of Alkane Acids at the Silica–Bitumen Interface To Enhance Interfacial Resistance to Moisture Damage. Ind. Eng. Chem. Res. 2019, 58, 21542–21552. [Google Scholar] [CrossRef]

- Chen, M.; Leng, B.; Wu, S.; Sang, Y. Physical, chemical and rheological properties of waste edible vegetable oil rejuvenated asphalt binders. Constr. Build. Mater. 2014, 66, 286–298. [Google Scholar] [CrossRef]

- Azahar, W.N.A.W.; Bujang, M.; Jaya, R.P.; Hainin, M.R.; Ngadi, N.; Mohamad, M. Chemical Identification of Waste Cooking Oil as Additive in Bitumen. Key Eng. Mater. 2016, 700, 207–215. [Google Scholar] [CrossRef]

| Reference | Viscosity @ 40 °C (m2/s) | Density (g/cm3) | Water Content (%) |

|---|---|---|---|

| [39] | 4.2 × 10−6 | 0.91 | 1.9 |

| [40] | 36.4 × 10−6 | 0.924 | 0.42 |

| [38] | 144.5 × 10−6–179.9 × 10−6 | 0.932–0.936 | – |

| [41] | 30.5 × 10−6–31.77 × 10−6 | 0.920 | – |

| [42] | 64.1 × 10−6 | 0.933 | – |

| [12] | 4.9 × 10−6 | 0.9013 | 0.140 |

| Chemical Reaction | Reason of Reaction | Variation in Chemical Composition |

|---|---|---|

| Hydrolysis | Water, steam, oxygen | Production of di.mono-acylglycerols, glycerol, and free fatty acids |

| Oxidation | Surrounding air or oxygen | Production of CO, CO2, and dimeric compounds |

| Polymerization | Heating oil at high-temperature range 260–340 °C | Formation of dimers including oligomers that increase the molecular weight of oil |

| Formulation of Fatty Acids | Type of Free Fatty Acid | Possible % in Waste Cooking Oil (WCO) | Type of Saturation |

|---|---|---|---|

| C18:1 (Cis 9) | Oleic Acid | 43.67 | Unsaturated |

| C16:0 | Palmitic acid | 38.35 | Saturated |

| C18:2 (Cis) | Linoleic acid | 11.39 | Unsaturated |

| C18:0 | Stearic acid | 4.33 | Saturated |

| C14:0 | Myristic acid | 1.03 | Saturated |

| C18:3 alpha | ɣ- Linolenic acid | 0.37 | Unsaturated |

| C12:0 | Lauric acid | 0.34 | Saturated |

| C18:2 t | Linolenic acid | 0.29 | Unsaturated |

| C20:1 | Cis-11-Eicosenoic acid | 0.16 | Unsaturated |

| C21:0 | Heneicosanoic acid | 0.08 | Saturated |

| TOTAL | 100 |

| Reference | Temperature (°C) | Reduction in Water Content (%) | Reduction in FFA (%) |

|---|---|---|---|

| [53] | 220 | From 1.15% to 0.062% | From 29% to 2% |

| [52] | 200–280 | From 5% to 0.1% | Less than 0.5% |

| Author/Reference | Recommended FFA (%) |

|---|---|

| [59] | Less than 1 |

| [64] | Less than 0.5 |

| [65] | Less than 0.5 |

| [66] | Less than 2 |

| [67] | Less than 2 |

| [25] | Less than 1 |

| Operating Parameters | [75] | [76] | [77] |

|---|---|---|---|

| Solvent | Anhydrous sodium sulphate | Magnesium sulphate | Silica gel |

| Filtration type | Vacuum | Vacuum | Vacuum |

| Pre-moisture | – | – | 0.7% |

| Post-moisture | – | 0.07–0.13% | 0.2 ± 0.1% |

| Category of Application Content in the Binder | Content in the Binder | Current State |

|---|---|---|

| Modifier | <10% | The application mode is relatively mature |

| Extender/substitute | 25–75% | The application mode is common |

| Alternative | 100% | The application mode cannot be achieved due to the limitation of the performance of bio-asphalt |

| Reference | Shearing Time (min) | Shearing Speed (rpm) | Shearing Temperature (°C) |

|---|---|---|---|

| [81] | 50 | 4000 | 170 |

| [23] | 60 | 1000 | 160 |

| [82] | 30 | – | 190 |

| [83] | 5 | 1600 | 145 |

| [47] | 60 | 1000 | 160 |

| [84] | 30 | 4000 | 140 |

| [25] | 60 | 1000 | 160 |

| [85] | 60 | 4000 | 160 |

| [86] | 60 | 1000 | 163 |

| [87] | 120 | 2000 | 150 |

| Reference | Modifier | Content of WCO/Additives (wt.%) | Penetration (dmm) | Viscosity @ 135 °C (Pa.s) | Softening Point (°C) | Ductility (cm) | Rutting Resistance (Pa) | Fatigue Resistance (Pa) | Low Temperature Stiffness (Mpa) |

|---|---|---|---|---|---|---|---|---|---|

| [13] | Simply filtered WCO | 10, 30,60 | ↑ | ↓ | ↓ | – | ↓ | ↓ | ↑ |

| [82] | 17.9 | ↑ | – | ↓ | – | ↓ | – | ↑ | |

| [83] | 1,2,4,6,8 | ↑ | ↓ | ↓ | ↑ | ↓ | ↑ | ↑ | |

| [88] | 10 | – | – | – | ↓ | ↑ | – | ||

| [23] | 3,4,5 | ↑ | ↓ | ↓ | – | ↓ | – | – | |

| [85] | 1,3,5 | ↑ | ↓ | – | – | – | – | – | |

| [86] | 1,2,3 | ↑ | ↓ | ↓ | – | ↓ | – | – | |

| [89] | 2,4,6 | ↑ | ↓ | ↓ | – | ↓ | – | – | |

| [25] | Chemically treated WCO | ↓↑ | – | ||||||

| [90] | 3,4,5 | – | – | – | – | ↑ | – | – | |

| [81] | SBS/PE/WCO | 5.5,5 5,3 5 | ↓ | ↑ | ↑ | ↑ | ↑ | – | ↓ |

| [31] | HDPE/WCO | 2.5,5,7.5 5,10,15 | ↓ | – | ↑ | – | – | – | – |

| [29] | GTR/WCO | 10,15,20 2.5,5,7.5,10 | ↓ | ↑ | ↑ | ↑ | ↑ | ↓ | ↓ |

| [91] | LDPE+PVC/WCO | 1,3,5 1,2,3 | ↓ | ↑ | ↑ | ↑ | – | – | – |

| [92] | WCO/TR/POFA | 5 5,7.5,10 5,7.5,10 | ↑ | ↑ | ↓ | – | ↑ | ↑ | – |

| [93] | NC/WCO | 2,4,6 2.5,5,5 |  | ↓ | ↓ | – | ↑ |  | – |

| [87] | WCO in SBS-modified binder | 1,3,5,7,9 | ↑ | ↓ | ↓ |  | – | – | – |

| [94] | SBS/EVA/WCO | 3.5 5.5 5,10 | ↓ | ↑ | ↑ | ↑ | ↓ | ↑ | ↑ |

| [30] | WCO/TR/Bagasse | 5,10,15,20 5,8,12,15,18 7,7,7.5,8,10 | ↑ | ↑ | ↑ | – | ↑ | ↑ | ↑ |

| [95] | HDPE/WCO | 2.5,5,7.5 5 | ↓ | – | ↑ | – | – | – | – |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Elahi, Z.; Mohd Jakarni, F.; Muniandy, R.; Hassim, S.; Ab Razak, M.S.; Ansari, A.H.; Ben Zair, M.M. Waste Cooking Oil as a Sustainable Bio Modifier for Asphalt Modification: A Review. Sustainability 2021, 13, 11506. https://doi.org/10.3390/su132011506

Elahi Z, Mohd Jakarni F, Muniandy R, Hassim S, Ab Razak MS, Ansari AH, Ben Zair MM. Waste Cooking Oil as a Sustainable Bio Modifier for Asphalt Modification: A Review. Sustainability. 2021; 13(20):11506. https://doi.org/10.3390/su132011506

Chicago/Turabian StyleElahi, Zafreen, Fauzan Mohd Jakarni, Ratnasamy Muniandy, Salihudin Hassim, Mohd Shahrizal Ab Razak, Anwaar Hazoor Ansari, and Mohamed Meftah Ben Zair. 2021. "Waste Cooking Oil as a Sustainable Bio Modifier for Asphalt Modification: A Review" Sustainability 13, no. 20: 11506. https://doi.org/10.3390/su132011506

APA StyleElahi, Z., Mohd Jakarni, F., Muniandy, R., Hassim, S., Ab Razak, M. S., Ansari, A. H., & Ben Zair, M. M. (2021). Waste Cooking Oil as a Sustainable Bio Modifier for Asphalt Modification: A Review. Sustainability, 13(20), 11506. https://doi.org/10.3390/su132011506