The Influence of Cork and Manufacturing Parameters on the Properties of Cork–Rubber Composites for Vibration Isolation Applications

Abstract

1. Introduction

2. Materials and Methods

2.1. Preparation of Samples

2.2. Characterization of Samples

2.3. Statistical Analysis

2.4. Regression Models

3. Results and Discussion

3.1. Effect of Cork Granules

3.1.1. Addition of Cork Granules

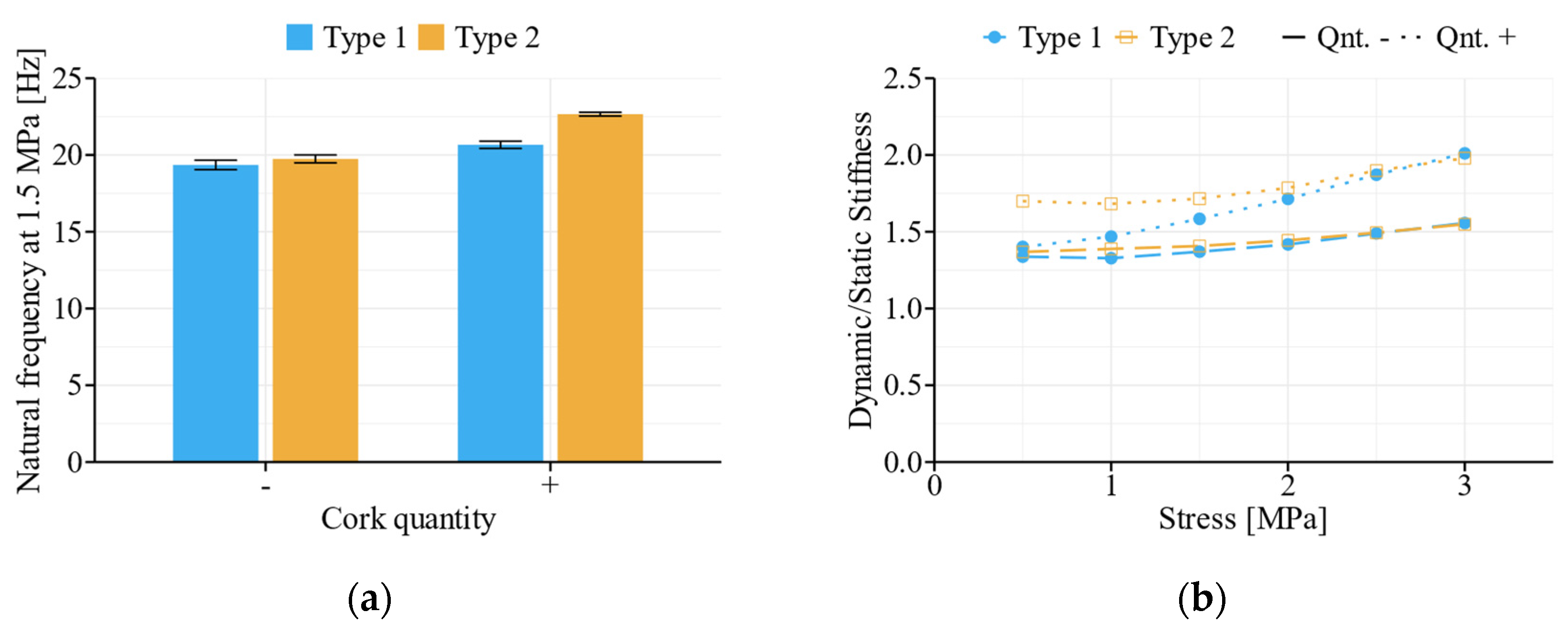

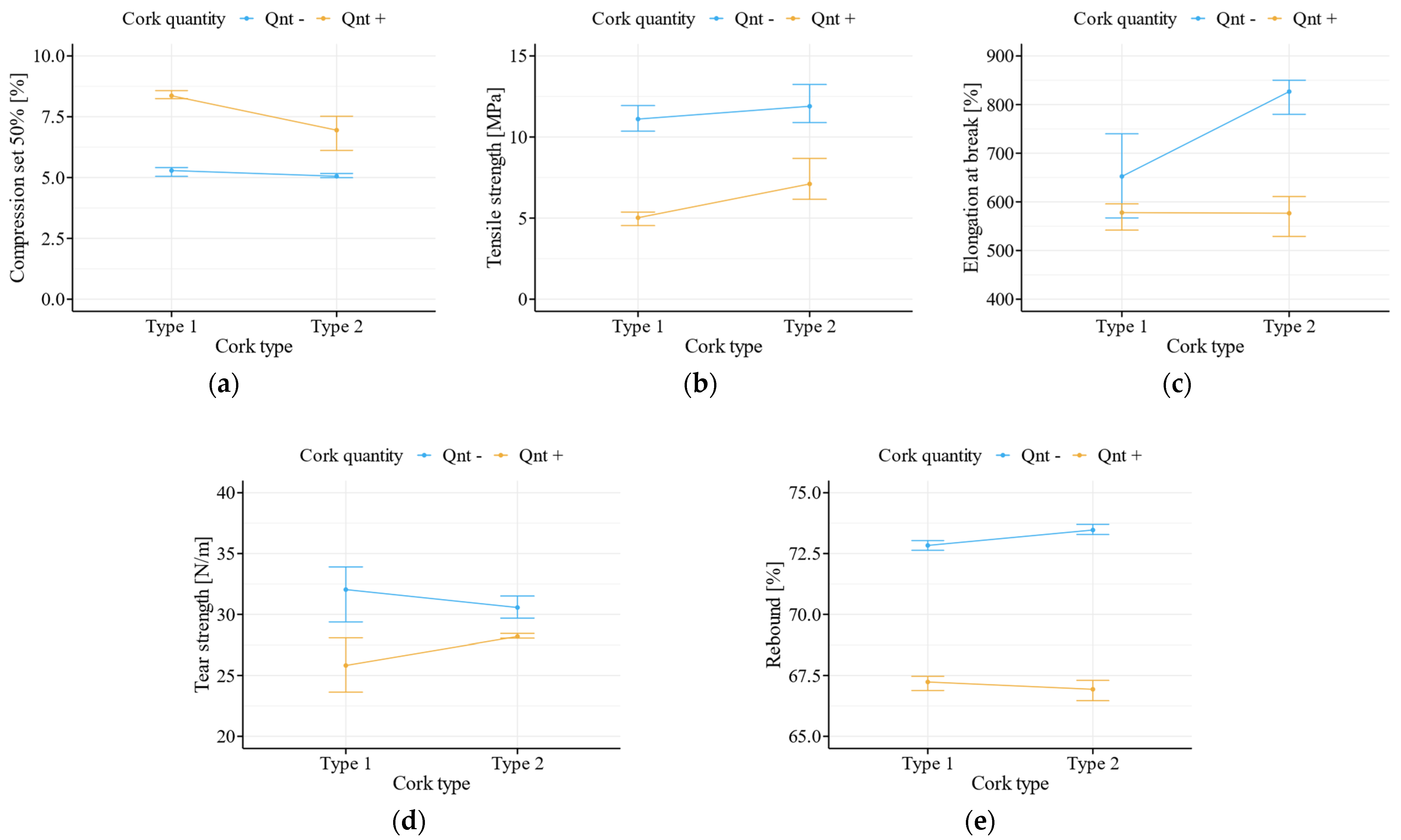

3.1.2. Granulometry and Quantity

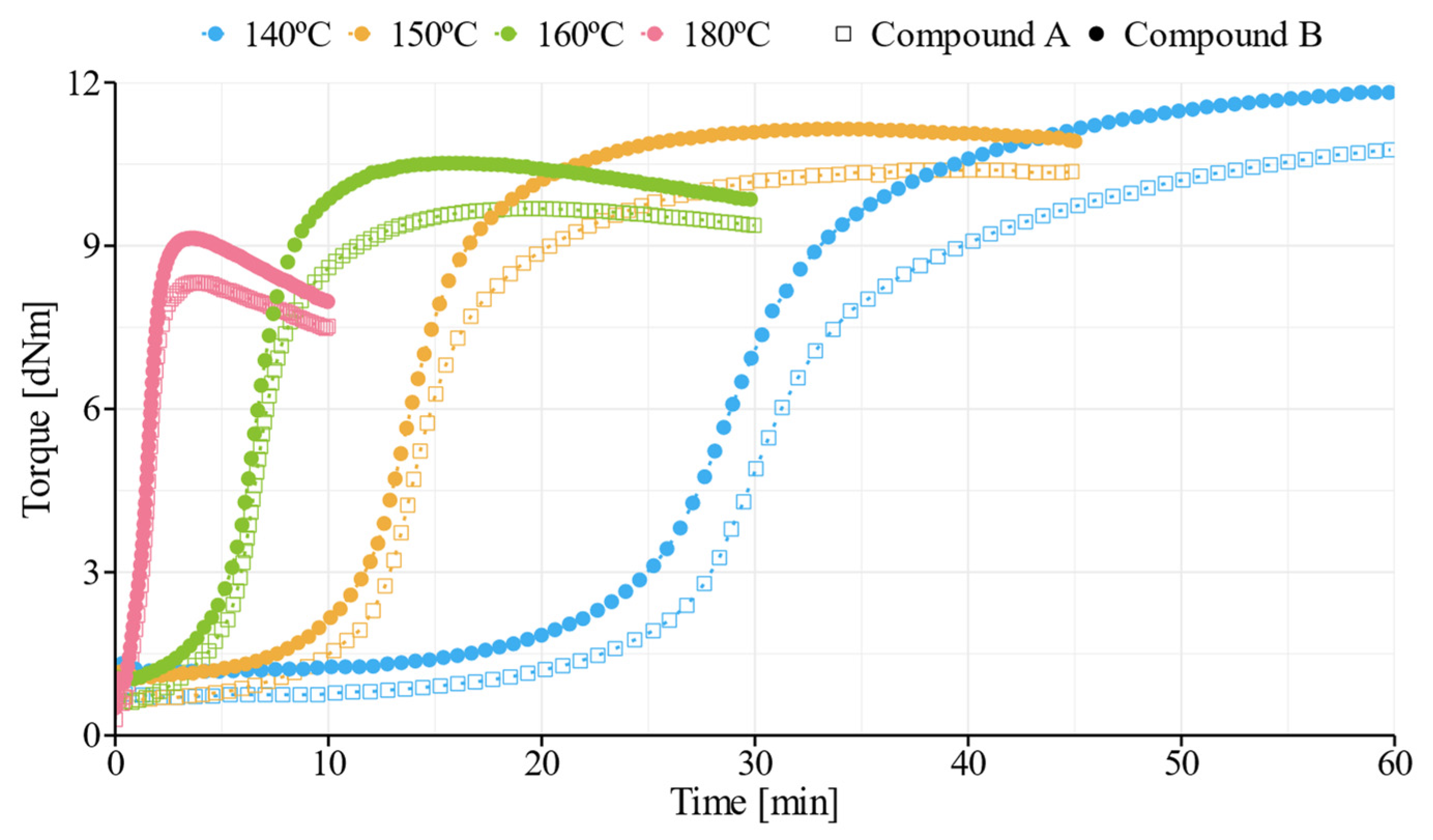

3.2. Effect of Vulcanization Parameters

3.2.1. Molding Pressure

3.2.2. Vulcanization Temperature

3.3. Application of Regression Models

4. Conclusions

Author Contributions

Funding

Conflicts of Interest

References

- Saheb, D.N.; Jog, J.P. Natural fiber polymer composites: A review. Adv. Polym. Technol. 1999, 18, 351–363. [Google Scholar] [CrossRef]

- Thakur, V.K.; Thakur, M.K.; Gupta, R. Review: Raw Natural Fiber–Based Polymer Composites. Int. J. Polym. Anal. Charact. 2014, 19, 256–271. [Google Scholar] [CrossRef]

- Ku, H.; Wang, H.; Pattarachaiyakoop, N.; Trada, M. A review on the tensile properties of natural fiber reinforced polymer composites. Compos. Part B: Eng. 2011, 42, 856–873. [Google Scholar] [CrossRef]

- Gil, L. Cortiça. In Ciência e Engenharia de Materiais de Construção; Gonçalves, M.C., Margarido, F., Eds.; INETI: Lisboa, Portugal, 2012; pp. 663–715. ISBN 978-989-8481-17-7. [Google Scholar]

- Mestre, A.; Vogtlander, J. Eco-efficient value creation of cork products: An LCA-based method for design intervention. J. Clean. Prod. 2013, 57, 101–114. [Google Scholar] [CrossRef]

- Gürgen, S.; Sofuoğlu, M.A. Smart polymer integrated cork composites for enhanced vibration damping properties. Compos. Struct. 2020, 258, 113200. [Google Scholar] [CrossRef]

- da Silva, V.M.C.; Sabino, M.A.; Fernandes, E.; Correlo, V.M.; Boesel, L.F.; Reis, R.L. Cork: Properties, capabilities and applications. Int. Mater. Rev. 2005, 50, 345–365. [Google Scholar] [CrossRef]

- Fernandes, E.M.; Pires, R.A.; Reis, R.L. Cork biomass biocomposites. In Lignocellulosic Fibre and Biomass-Based Composite Materials; Jawaid, M., Tahir, P.M., Saba, N., Eds.; Elsevier: Cambridge, UK, 2017; pp. 365–385. ISBN 978-0-08-10095p. [Google Scholar]

- Parra, C.; Sánchez, E.M.; Miñano, I.; Benito, F.; Hidalgo, P. Recycled Plastic and Cork Waste for Structural Lightweight Concrete Production. Sustainability 2019, 11, 1876. [Google Scholar] [CrossRef]

- Fernandes, F.; Jardin, R.; Pereira, A.; de Sousa, R.A. Comparing the mechanical performance of synthetic and natural cellular materials. Mater. Des. 2015, 82, 335–341. [Google Scholar] [CrossRef]

- Gil, L. Cork Composites: A Review. Materials 2009, 2, 776–789. [Google Scholar] [CrossRef]

- Knapic, S.; Oliveira, V.; Machado, J.S.; Pereira, H. Cork as a building material: A review. Holz Als Roh- Und Werkst. 2016, 74, 775–791. [Google Scholar] [CrossRef]

- Jones, D.I.G. Handbook of Viscoelastic Vibration Damping; John Wiley & Sons: Chichester, West Sussex, UK, 2001; ISBN 978-0-471-49248-1. [Google Scholar]

- Ismail, H.; Rozman, H.; Jaffri, R.; Ishak, Z. Oil palm wood flour reinforced epoxidized natural rubber composites: The effect of filler content and size. Eur. Polym. J. 1997, 33, 1627–1632. [Google Scholar] [CrossRef]

- Ismail, H.; Jaffri, R. Physico-mechanical properties of oil palm wood flour filled natural rubber composites. Polym. Test. 1999, 18, 381–388. [Google Scholar] [CrossRef]

- Ismail, H.; Edyham, M.; Wirjosentono, B. Bamboo fibre filled natural rubber composites: The effects of filler loading and bonding agent. Polym. Test. 2002, 21, 139–144. [Google Scholar] [CrossRef]

- Jacob, M.; Thomas, S.; Varughese, K.T. Mechanical properties of sisal/oil palm hybrid fiber reinforced natural rubber composites. Compos. Sci. Technol. 2004, 64, 955–965. [Google Scholar] [CrossRef]

- Martins, M.A.; Mattoso, L.H.C. Short sisal fiber-reinforced tire rubber composites: Dynamic and mechanical properties. J. Appl. Polym. Sci. 2003, 91, 670–677. [Google Scholar] [CrossRef]

- Geethamma, V.; Kalaprasad, G.; Groeninckx, G.; Thomas, S. Dynamic mechanical behavior of short coir fiber reinforced natural rubber composites. Compos. Part A: Appl. Sci. Manuf. 2005, 36, 1499–1506. [Google Scholar] [CrossRef]

- Shao, D.; Xu, M.; Cai, L.; Shi, S.Q. Fabrication of Wood-Rubber Composites Using Rubber Compound as a Bonding Agent Instead of Adhesives. Materials 2016, 9, 469. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, W.Z.W.; Baharum, A.; Ahmad, I.; Abdullah, I.; Zakaria, N.E. Effects of Fiber Size and Fiber Content on Mechanical and Physical Properties of Mengkuang Reinforced Thermoplastic Natural Rubber Composites. BioResources 2018, 13, 2945–2959. [Google Scholar] [CrossRef]

- Masłowski, M.; Miedzianowska, J.; Strzelec, K. Natural Rubber Composites Filled with Crop Residues as an Alternative to Vulcanizates with Common Fillers. Polymers 2019, 11, 972. [Google Scholar] [CrossRef] [PubMed]

- Masłowski, M.; Miedzianowska, J.; Strzelec, K. The potential application of cereal straw as a bio-filler for elastomer composites. Polym. Bull. 2019, 77, 2021–2038. [Google Scholar] [CrossRef]

- Deuri, A.S.; Bhownick, A.K.; John, B.; Ram, T.S. Effect of moulding pressure, cooling rate and curing temperature on the properties of rocket insulator compound. J. Mater. Sci. Lett. 1987, 6, 1117–1122. [Google Scholar] [CrossRef]

- Shao, D.; Xu, M.; Cai, L.; Shi, S.Q. Fabrication of Wood Fiber-rubber Composites with Reclaimed Rubber. BioResources 2018, 13, 3300–3314. [Google Scholar] [CrossRef]

- Sergi, C.; Tirillò, J.; Sarasini, F.; Pozuelo, E.B.; Saez, S.S.; Burgstaller, C. The Potential of Agglomerated Cork for Sandwich Structures: A Systematic Investigation of Physical, Thermal, and Mechanical Properties. Polymers 2019, 11, 2118. [Google Scholar] [CrossRef] [PubMed]

- Buil, R.M.; Angulo, D.R.; Ivens, J. Analysis of the capability of cork and cork agglomerates to absorb multiple compressive quasi-static loading cycles. Holz Als Roh- Und Werkst. 2021, 1–14. [Google Scholar] [CrossRef]

- Buil, R.M.; Angulo, D.R.; Ivens, J.; Blasco, J.O.A. Experimental study of natural cork and cork agglomerates as a substitute for expanded polystyrene foams under compressive loads. Wood Sci. Technol. 2021, 55, 419–443. [Google Scholar] [CrossRef]

- Kumar, S.S.; Milwich, M.; Deopura, B.; Plank, H. Finite element analysis of Carbon composite sandwich material with agglomerated Cork core. Procedia Eng. 2011, 10, 478–483. [Google Scholar] [CrossRef][Green Version]

- Gürgen, S.; Fernandes, F.A.O.; de Sousa, R.J.A.; Kuşhan, M.C. Development of Eco-friendly Shock-absorbing Cork Composites Enhanced by a Non-Newtonian Fluid. Appl. Compos. Mater. 2021, 28, 165–179. [Google Scholar] [CrossRef]

- Brites, F.; Malça, C.; Gaspar, F.; Horta, J.; Franco, M.; Biscaia, S.; Mateus, A. Cork Plastic Composite Optimization for 3D Printing Applications. Procedia Manuf. 2017, 12, 156–165. [Google Scholar] [CrossRef]

- Gama, N.; Ferreira, A.; Timmons, A.B. 3D printed cork/polyurethane composite foams. Mater. Des. 2019, 179, 107905. [Google Scholar] [CrossRef]

- Daver, F.; Lee, K.P.M.; Brandt, M.; Shanks, R. Cork–PLA composite filaments for fused deposition modelling. Compos. Sci. Technol. 2018, 168, 230–237. [Google Scholar] [CrossRef]

- da Silva, S.M.; Antunes, T.; Costa, M.E.; Oliveira, J.M. Cork-like filaments for Additive Manufacturing. Addit. Manuf. 2020, 34, 101229. [Google Scholar] [CrossRef]

- Policarpo, H.; Neves, M.M.; Diogo, A.C.; Maia, N.M.M. A note on the estimation of cork composite elasto-dynamic properties and their frequency dependence. In Proceedings of the ICEDyn 2013—International Conference on Structural Engineering Dynamics, Sesimbra, Portugal, 17–19 June 2013. [Google Scholar]

- Gul, J.; Saleemi, A.R.; Mirza, S.; Feroze, N.; Mansha, M. Thermal and mechanical characteristics of cork filled insulation for aerospace applications. Plast. Rubber Compos. 2010, 39, 28–32. [Google Scholar] [CrossRef]

- Gul, J.; Mirza, S. Effect of Cork Loading on Mechanical and Thermal Properties of Silica-Ethylene-Propylene-Diene Monomer Composite. Key Eng. Mater. 2012, 510-511, 277–283. [Google Scholar] [CrossRef]

- DIN 53504 Testing of rubber—Determination of Tensile Strength at Break, Tensile Stress at Yield, Elongation at Break and Stress Values in A Tensile Test; Deutsches Institut fur Normung E.V. (DIN): Berlin, Germany, 2017.

- ASTM D624-00 Standard Test Method for Tear Strength of Conventional Vulcanized Rubber and Thermoplastic Elastomers; ASTM International: West Conshohocken, PA, USA, 2020.

- ASTM D1054-02 Standard Test Method for Rubber Property—Resilience Using a Goodyear-Healey Rebound Pendulum (Withdrawn 2010); ASTM International: West Conshohocken, PA, USA, 2007.

- ASTM D2240-00 Standard Test Method for Rubber Property—Durometer Hardness; ASTM International: West Conshohocken, PA, USA, 2002.

- ISO 1856 Flexible Cellular Polymeric Materials—Determination of Compression Set; ISO: Geneva, Switzerland, 2018.

- DIN 53513 Determination of The Viscoelastic Properties of elastomers on Exposure to Forced Vibration at Non-Resonant Frequencies; Deutsches Institut fur Normung E.V. (DIN): Berlin, Germany, 1990.

- Wilcox, R.R. Introduction to Robust Estimation and Hypothesis Testing, 3rd ed.; Elsevier: Burlington, MA, USA, 2012; ISBN 9780123869838. [Google Scholar]

- Field, A.; Miles, J.; Field, Z. Discovering Statistics Using R; SAGE Publications: London, UK, 2012; ISBN 9781446200452. [Google Scholar]

- Montgomery, D.C.; Peck, E.A.; Vining, G.G. Introduction to Linear Regression Analysis, 5th ed.; John Wiley & Sons, Inc: Hoboken, NJ, USA, 2012; ISBN 978-0-470-54281-1. [Google Scholar]

- Fox, J.; Weisberg, S. Robust Regression in R. In An R Companion to Applied Regression; SAGE Publications: Thousand Oaks, CA, USA, 2018; ISBN 9781544336473. [Google Scholar]

- Gent, A.N. Engineering with Rubber; Gent, A.N., Ed.; Carl Hanser Verlag: München, Germany, 2012; ISBN 978-3-446-42764-8. [Google Scholar]

- Zhou, Y.; Fan, M.; Chen, L.; Zhuang, J. Lignocellulosic fibre mediated rubber composites: An overview. Compos. Part B: Eng. 2015, 76, 180–191. [Google Scholar] [CrossRef]

- Salim, Z.A.S.A.; Hassan, A.; Ismail, H. A Review on Hybrid Fillers in Rubber Composites. Polym. Technol. Eng. 2017, 57, 523–539. [Google Scholar] [CrossRef]

- Zanchet, A.; Dotta, A.L.B.; De Sousa, F.D.B. Relationship among Vulcanization, Mechanical Properties and Morphology of Blends Containing Recycled EPDM. Recycling 2017, 2, 16. [Google Scholar] [CrossRef]

- Akbay, I.K.; Güngör, A.; Özdemir, T. Optimization of the vulcanization parameters for ethylene–propylene–diene termonomer (EPDM)/ground waste tyre composite using response surface methodology. Polym. Bull. 2017, 74, 5095–5109. [Google Scholar] [CrossRef]

- Kurian, T.; George, K.E.; Francis, D.J. Effect of vulcanization temperature on the cure characteristics and vulcanizate properties of natural rubber and styrene-butadiene rubber. Die Angew. Makromol. Chem. 1988, 162, 123–134. [Google Scholar] [CrossRef]

- Zhang, H.; Li, Y.; Shou, J.-Q.; Zhang, Z.-Y.; Zhao, G.-Z.; Liu, Y.-Q. Effect of curing temperature on properties of semi-efficient vulcanized natural rubber. J. Elastomers Plast. 2015, 48, 331–339. [Google Scholar] [CrossRef]

- Ma, S.; Zhu, S.; Liu, M.; Zhong, B.; Chen, Y.; Luo, Y.; Liu, F.; Jia, Z.; Jia, D. A high-performance, thermal and electrical conductive elastomer composite based on Ti3C2 MXene. Compos. Part A: Appl. Sci. Manuf. 2021, 145, 106292. [Google Scholar] [CrossRef]

| Compound | A | B | C | D | E | F |

|---|---|---|---|---|---|---|

| Cork granulometry | − | Type 1 | Type 1 | Type 1 | Type 2 | Type 2 |

| Cork quantity (phr 1) | 0 | x | x/2 | 2x | x/2 | 2x |

| Hardness Shore A | Stress at 10% Strain (MPa) | Nat. freq. at 1.5MPa (Hz) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Median | Mean | Std. dev. | Median | Mean | Std. dev. | Median | Mean | Std. dev. | |

| Compound A | 52 | 52.1 | 0.652 | 1.336 | 1.322 | 0.052 | 20.86 | 20.89 | 0.096 |

| Compound B | 57 | 56.3 (+8.1%) | 0.975 | 1.536 | 1.520 (+15%) | 0.041 | 20.43 | 20.50 (−1.8%) | 0.191 |

| Properties | Significant Factors 1 | Test Statistic | Percentage Contribution 3 |

|---|---|---|---|

| Hardness | A | F(1,16) = 150.59, p-value < 0.001 | 47.25% |

| B | F(1,16) = 150.59, p-value < 0.001 | 47.25% | |

| Stress at 10% strain | AB | F(1,16) = 17.32, p-value < 0.001 | 11.50% |

| Natural frequency at 1.5 MPa | AB | F(1,16) = 55.79, p-value < 0.001 | 9.54% |

| Compression set 50% 2 | A | Q = 12.95, p-value = 0.017 | 8.92% 4 |

| B | Q = 117.56, p-value < 0.001 | 81.00% 4 | |

| Tensile strength | A | F(1,8) = 5.95, p-value = 0.041 | 5.93% |

| B | F(1,8) = 85.08, p-value < 0.001 | 84.88% | |

| Elongation at break | AB | F(1,8) = 7.78, p-value = 0.024 | 15.61% |

| Tear strength 2 | B | Q = 16.17, p-value = 0.005 | 58.62% 4 |

| Rebound | AB | F(1,20) = 7.40, p-value = 0.013 | 0.58% |

| Hardness Shore A | Stress at 10% Strain (MPa) | Nat. freq. at 1.5 MPa (Hz) | |||||||

|---|---|---|---|---|---|---|---|---|---|

| Median | Mean | Std. dev. | Median | Mean | Std. dev. | Median | Mean | Std. dev. | |

| Low (5 MPa) | 57 | 57.3 | 0.447 | 0.91 | 0.91 | 0.024 | 21.0 | 21.0 | 0.203 |

| High (20 MPa) | 56.5 | 56.3 | 0.274 | 1.00 | 1.00 | 0.012 | 20.6 | 20.6 | 0.209 |

| Properties | Compound A | Compound B |

|---|---|---|

| Hardness | H (3) = 17.72, p-value < 0.001 1 | F (3,16) = 87.98, p-value < 0.001 |

| Stress (10% strain) | F (3,7.4) = 246.72, p-value < 0.001 2 | F (3,16) = 395.50, p-value < 0.001 |

| Natural frequency | F (3,16) = 367.37, p-value < 0.001 | F (3,16) = 86.31, p-value < 0.001 |

| Term | Coefficients | 95% CI | t | p-Value |

|---|---|---|---|---|

| Intercept (β0) | 13.260 | [13.005; 13.515] | 109.430 | <0.001 |

| Cork quantity (β1) | 0.040 | [0.018; 0.062] | 3.799 | 0.001 |

| Term | Coefficients | Percentage Contribution 1 | |

|---|---|---|---|

| OLS | Huber M-Estimator | ||

| Intercept (β0) | 1.497 | 1.489 | − |

| (β1) | 0.179 | 0.188 | 87.73% |

| (β2) | −0.049 | −0.048 | 0.55% |

| (β3) | 0.067 | 0.065 | 0.97% |

| (β4) | 0.002 | 0.002 | 4.74% |

| (β5) | 0.006 | 0.005 | 0.73% |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Lopes, H.; Silva, S.P.; Carvalho, J.P.; Machado, J. The Influence of Cork and Manufacturing Parameters on the Properties of Cork–Rubber Composites for Vibration Isolation Applications. Sustainability 2021, 13, 11240. https://doi.org/10.3390/su132011240

Lopes H, Silva SP, Carvalho JP, Machado J. The Influence of Cork and Manufacturing Parameters on the Properties of Cork–Rubber Composites for Vibration Isolation Applications. Sustainability. 2021; 13(20):11240. https://doi.org/10.3390/su132011240

Chicago/Turabian StyleLopes, Helena, Susana P. Silva, João Paulo Carvalho, and José Machado. 2021. "The Influence of Cork and Manufacturing Parameters on the Properties of Cork–Rubber Composites for Vibration Isolation Applications" Sustainability 13, no. 20: 11240. https://doi.org/10.3390/su132011240

APA StyleLopes, H., Silva, S. P., Carvalho, J. P., & Machado, J. (2021). The Influence of Cork and Manufacturing Parameters on the Properties of Cork–Rubber Composites for Vibration Isolation Applications. Sustainability, 13(20), 11240. https://doi.org/10.3390/su132011240