Sustainable Underground Iron Ore Mining in Ukraine with Backfilling Worked-Out Area

Abstract

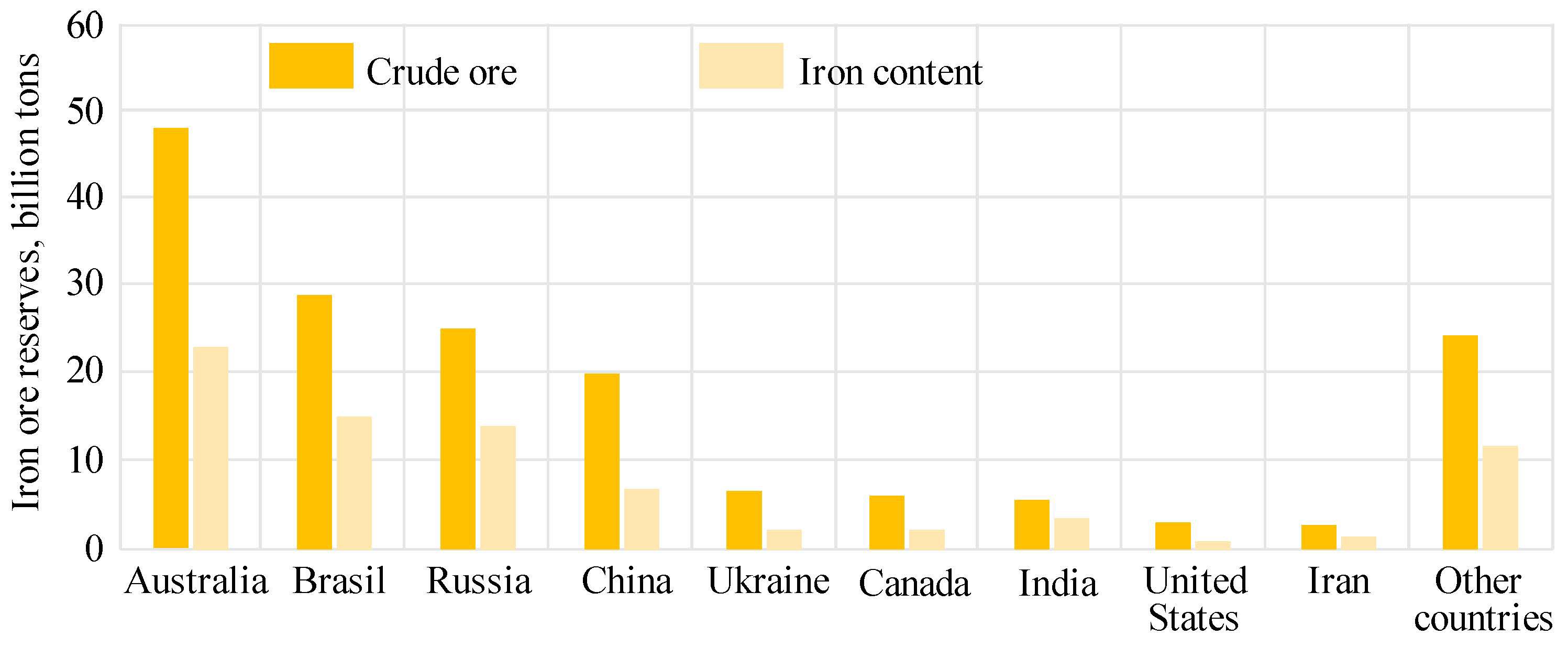

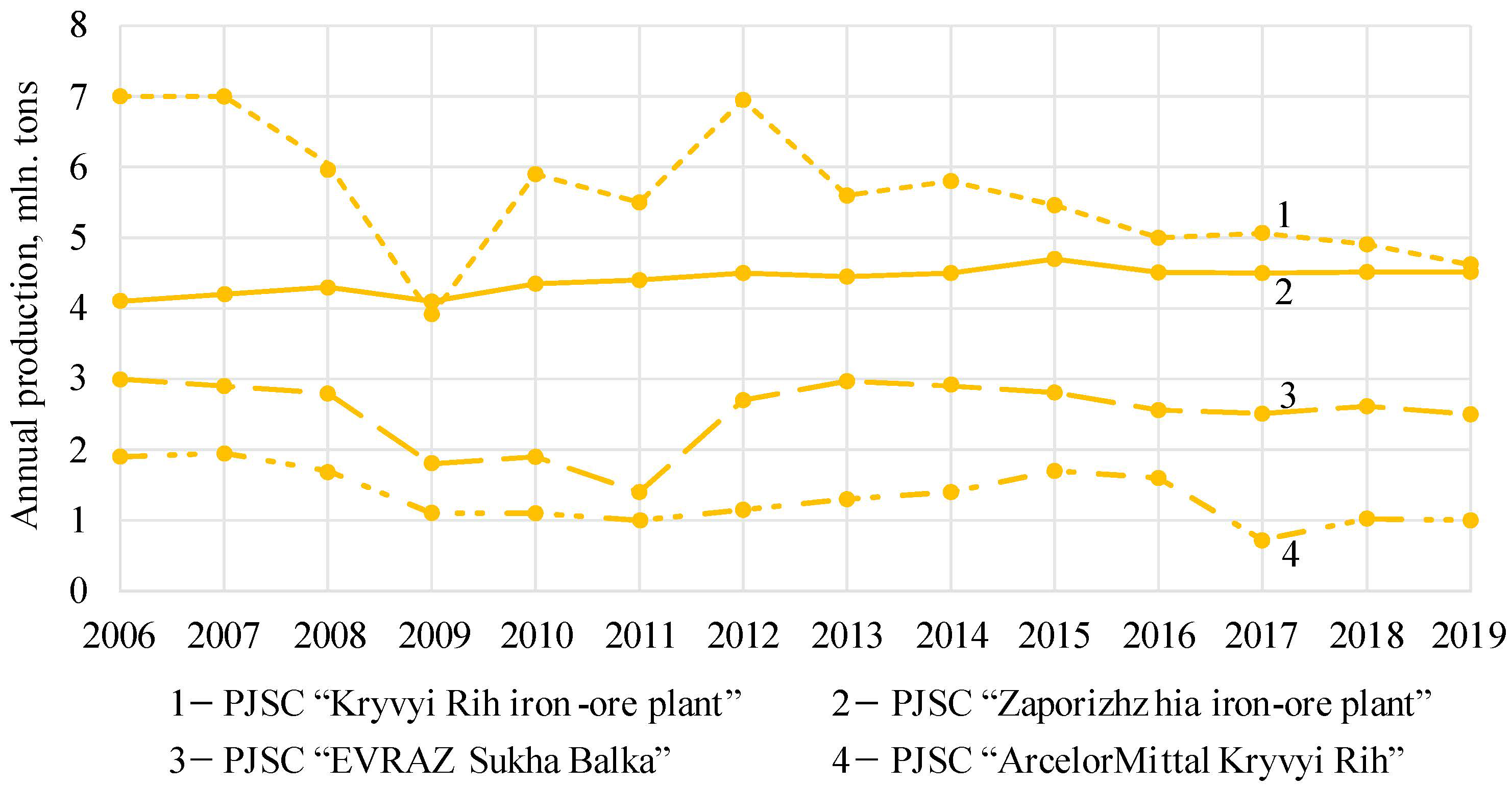

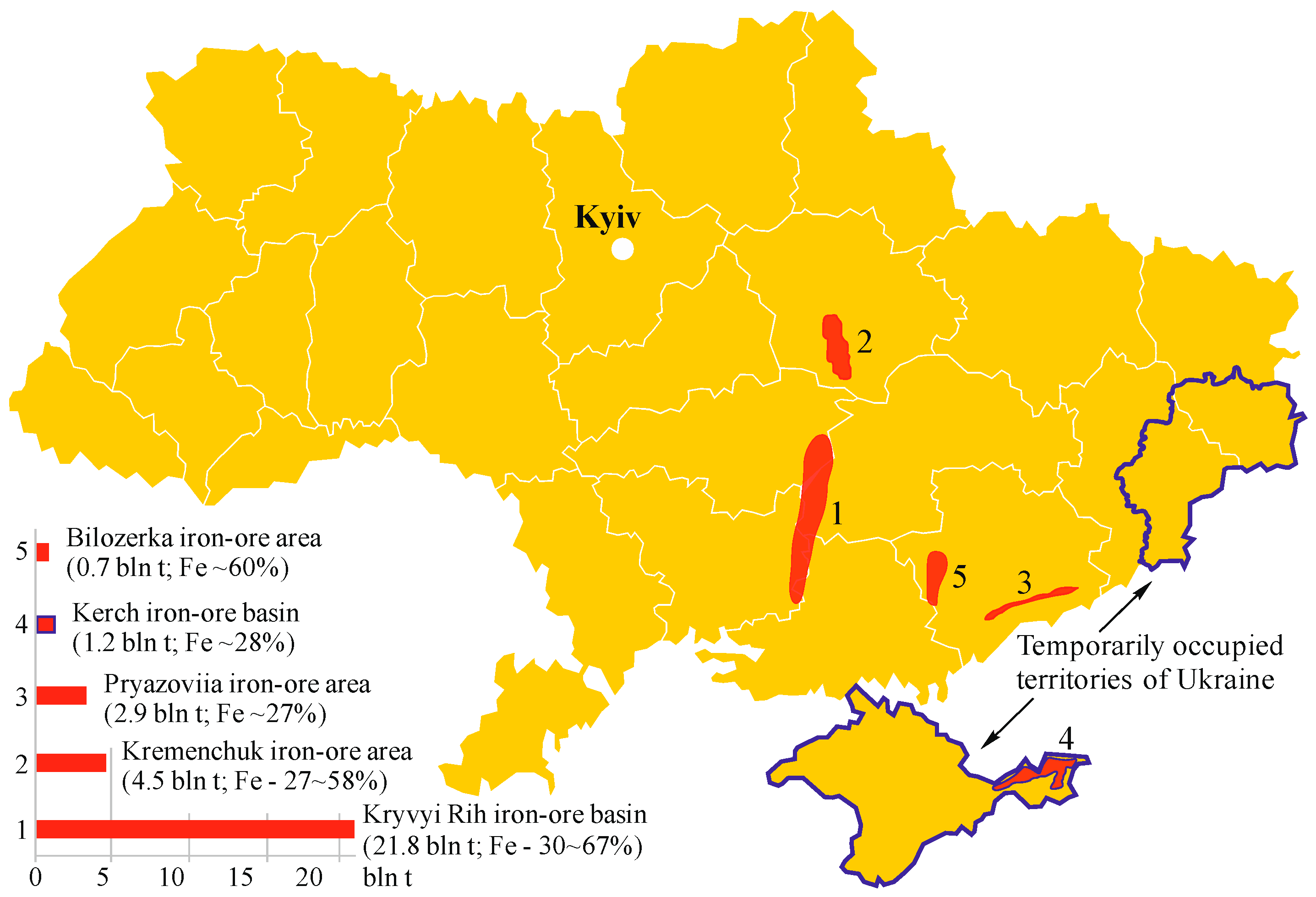

1. Introduction

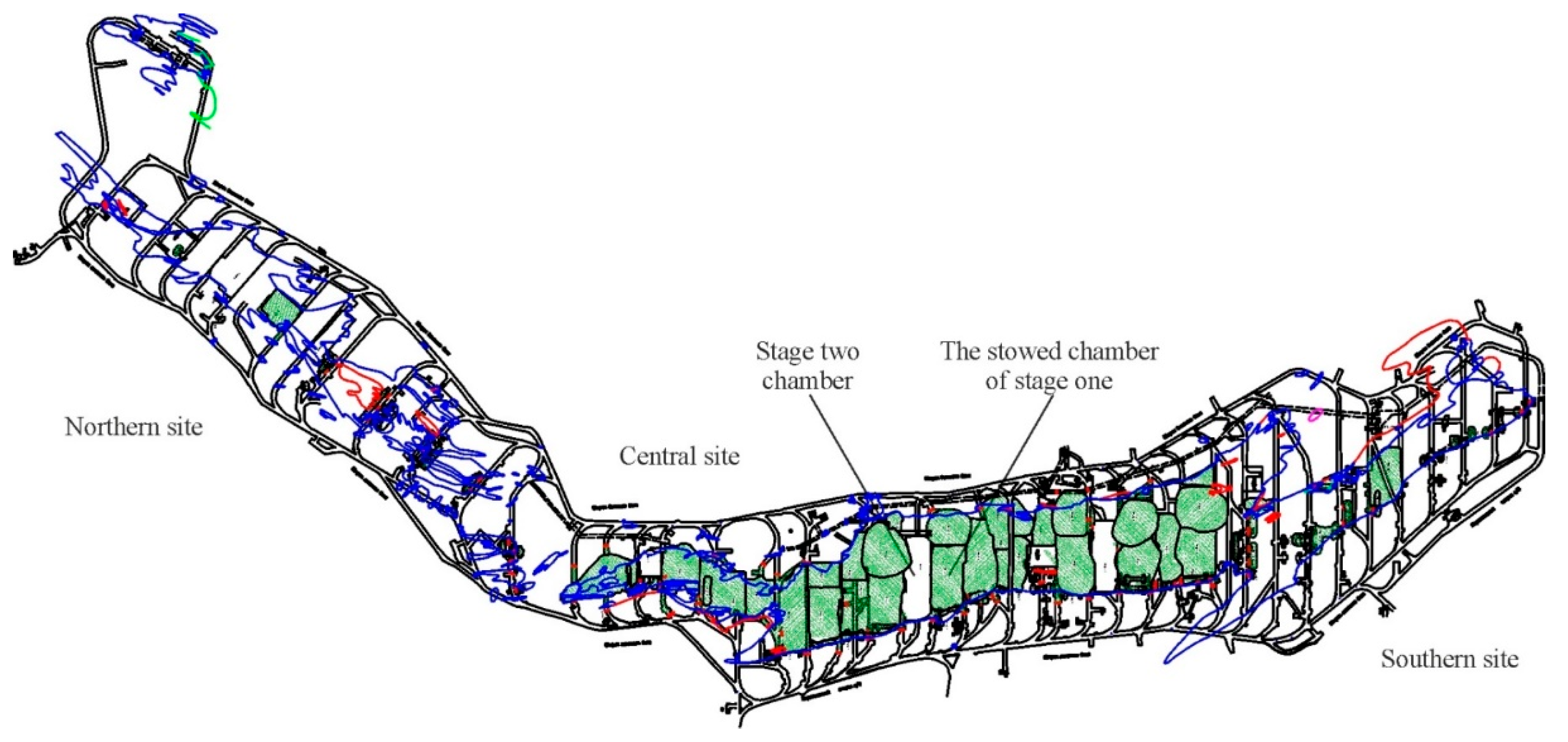

2. Progressive Mining System of Backfilling Technology in the Pivdenno-Bilozerske Field

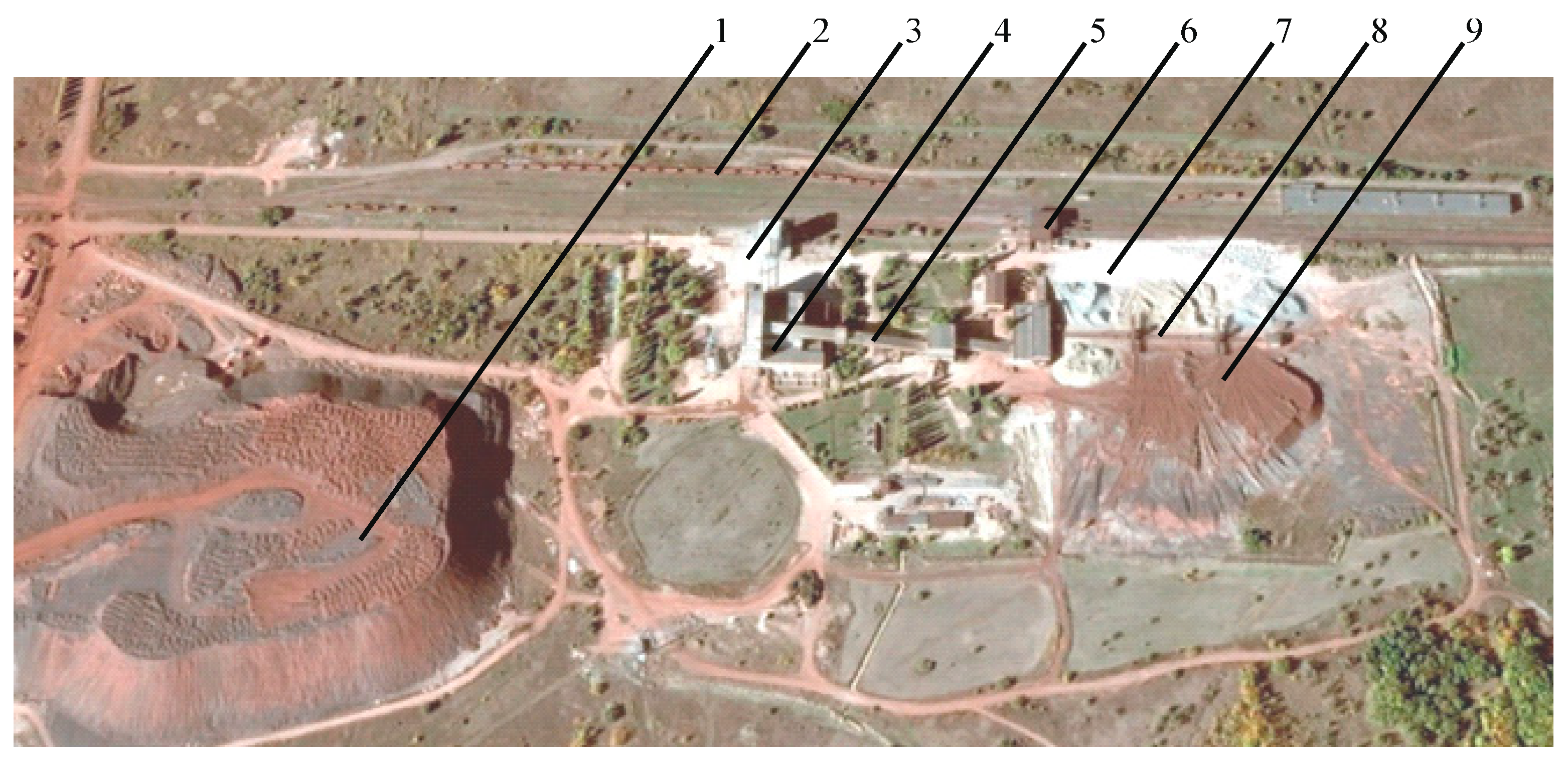

2.1. PJSC Zaporizhzhia Iron Ore Plant

2.2. Peculiarities of Geology, Hydrogeology, and Tectonics

2.3. Qualitative Characteristics of Iron Ores

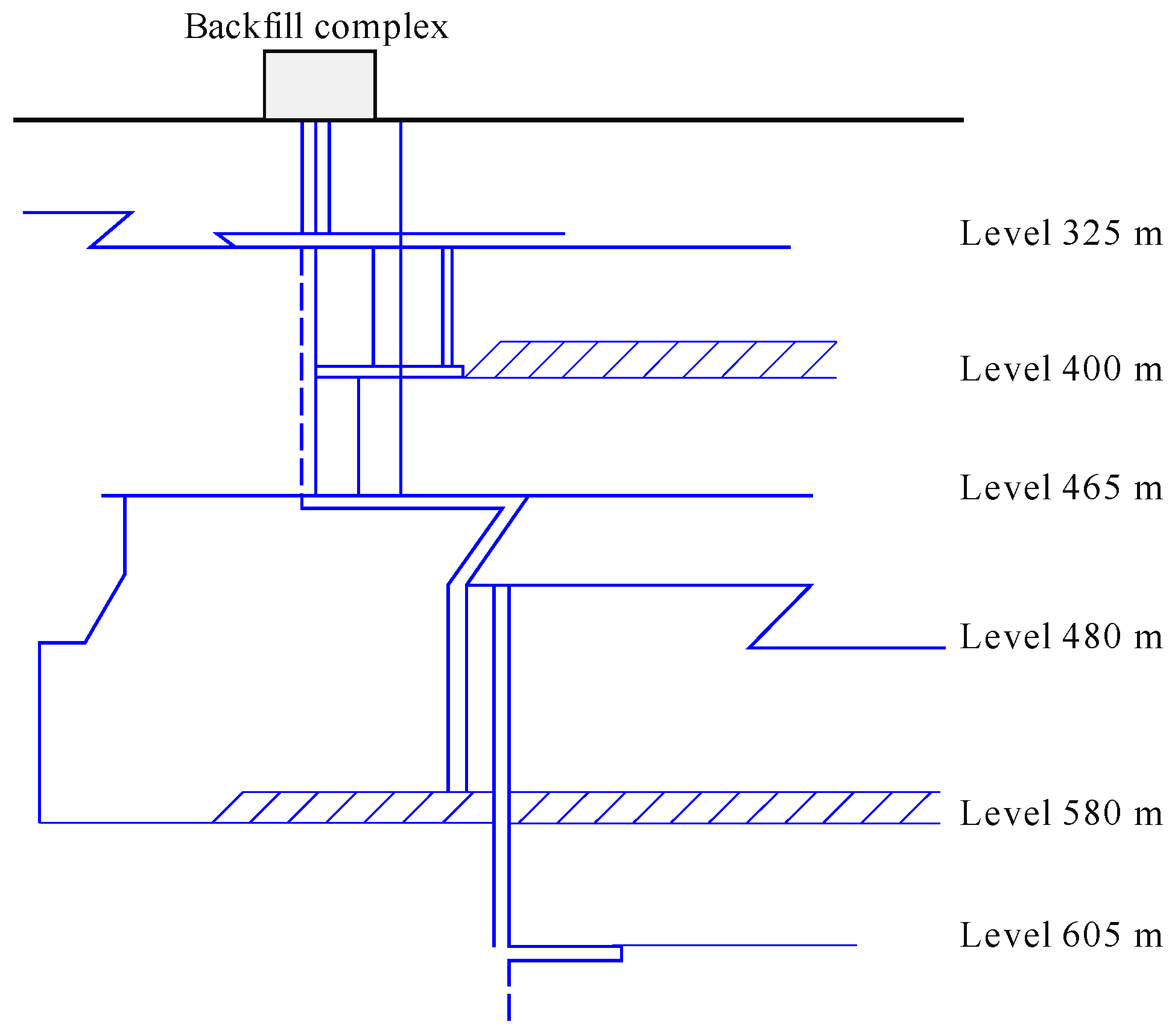

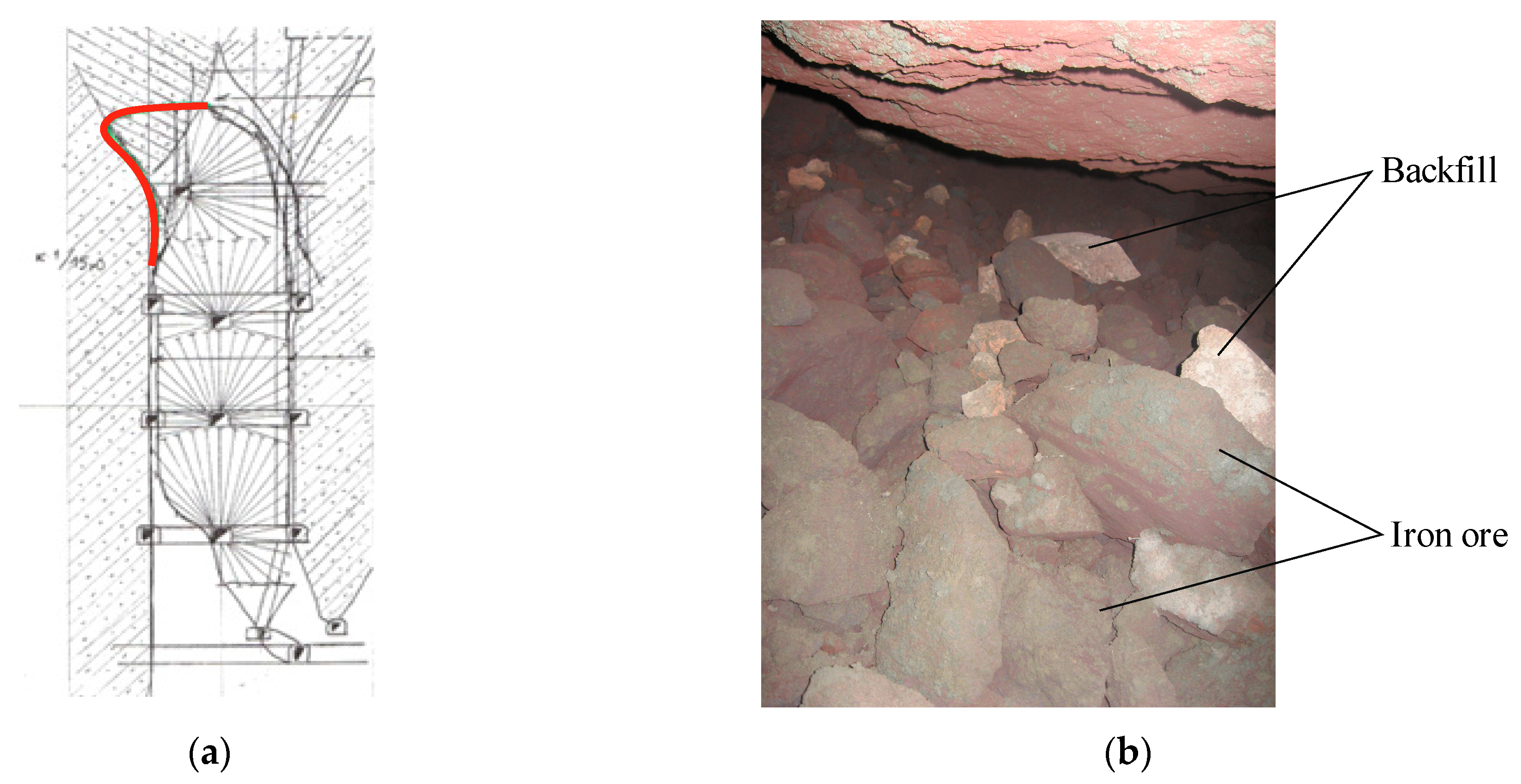

2.4. Ore Deposit Uncovering and Preparing and Method of Mining

2.5. Mining Schedule in Terms of Ore Body Area and Depth

3. Backfilling of the Mined-Out Area

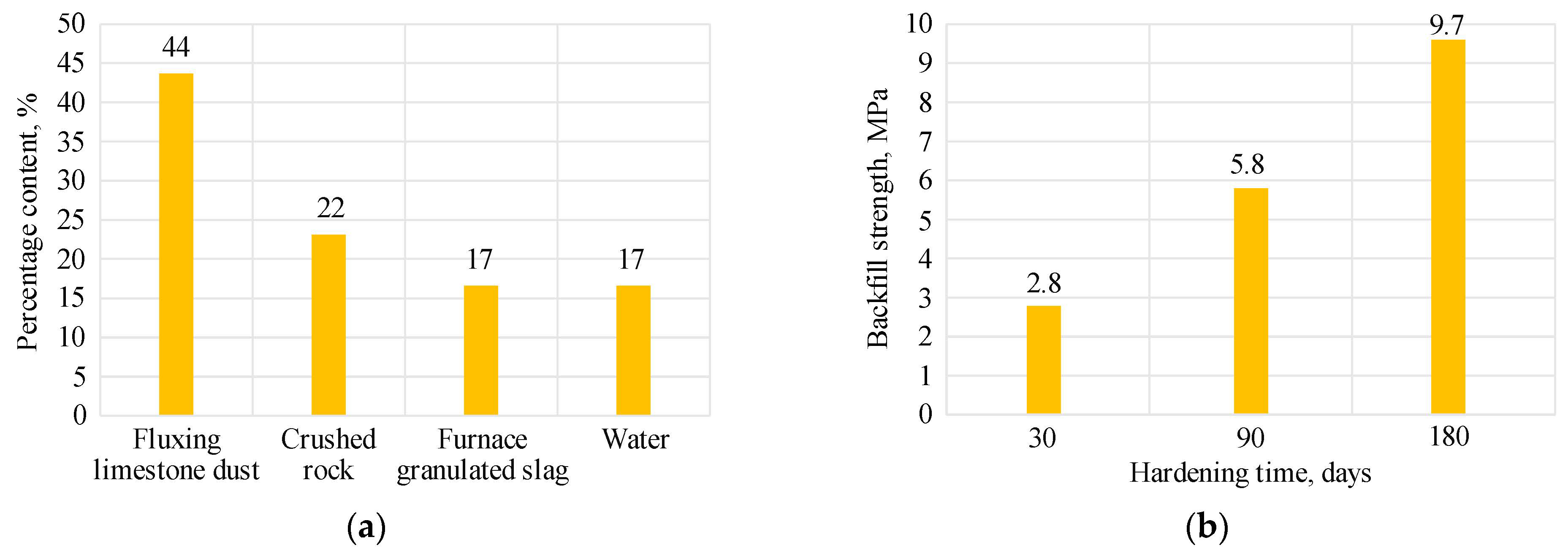

3.1. Preparation of Backfill Mixture and Its Composition

3.1.1. Type of Backfilling the Mined-Out Area Used

3.1.2. Variants of Backfill Mixtures Used in the Technological Cycle of Ore Mining

3.1.3. Achieved Modern Parameters of the Backfill Mixture

3.2. Transportation of Backfill Mixture

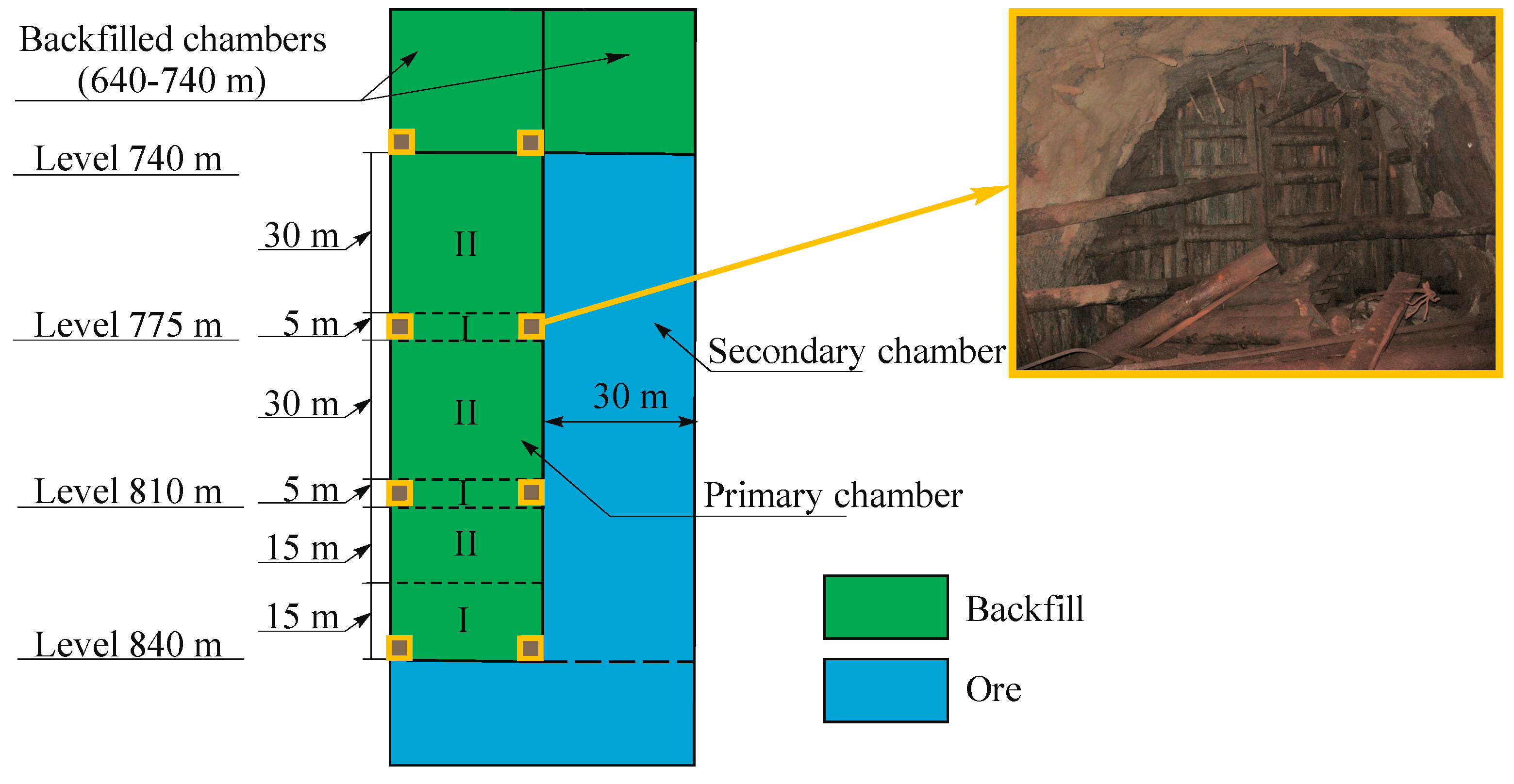

3.3. Backfill Mass Formation

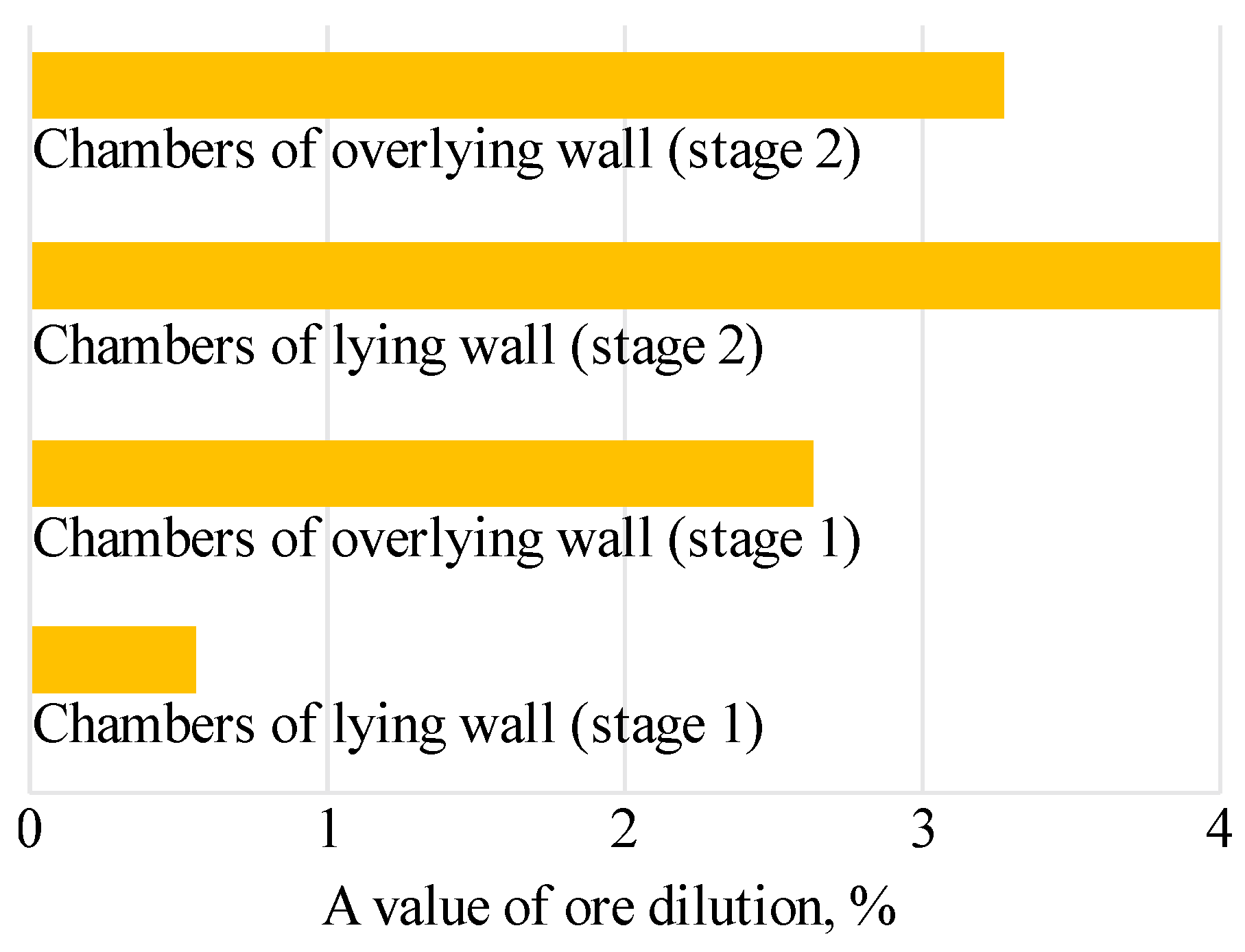

3.4. Backfill Mass Stability and Dilution Indices

4. Conclusions

- Exclude hollow mined-out areas of stopes and provide integrity and strength of backfilled areas and enclosing rocks while providing stability of the whole ore mass and safety of mine workings.

- Decrease vertical displacements of the mined-out ore mass and sedimentary stratum over the backfilled chambers, thereby decelerating the development of exfoliation of the whole rock mass and limiting the water inflow from aquifers to mine workings. Moreover, underground water reserves are preserved.

- Decrease both project and operational ore losses within interchamber pillars and floor pillars while reducing broken ore dilution in chambers and the possibility of rockfalls in the footwall and hanging wall of the deposit.

- Use dump rock as a component of a backfill mixture (up to 30%) without reducing the calculated strength of the hardening mixture and reduce the cost of imported fillers and backfill materials. Partial use of the dump rock makes it possible to gradually clear the waste dump for further reclamation of the land plot used as a mine site.

- Improve the tightness of the mine ventilation system, reduce internal air leakage, and provide a stable and economical airing of the mine.

- In the process of backfill mass erection, a heterogeneous mass occurs with clearly defined stratification, which significantly affects the stability of vertical outcrops of the backfill mass.

- Binding material consumption is high. When filling the chambers of the first stage, it is crushed (its content is 25% in the specific weight of the mixture).

- The dilution of the broken chamber reserves may achieve 5% when mining out the chambers in contact with the backfill mass.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- U.S. Geological Survey. Mineral Commodity Summaries; U.S. Geological Survey: North Pole, AK, USA, 2020. [CrossRef]

- Hellmer, S.; Ekstrand, J. The iron ore world market in the early twenty-first century—the impact of the increasing Chinese dominance. Miner. Econ. 2020, 25, 89–95. [Google Scholar] [CrossRef]

- State Fiscal Service of Ukraine. Available online: http://sfs.gov.ua (accessed on 9 November 2020).

- Haiko, H.; Saik, P.; Lozynskyi, V. The Philosophy of Mining: Historical Aspect and Future Prospect. Philos. Cosmol. 2019, 22, 76–90. [Google Scholar] [CrossRef] [PubMed]

- Ursul, A.; Ursul, T. Environmental Education for Sustainable Development. Future Human Image 2018, 9, 115–125. [Google Scholar] [CrossRef]

- Shatokha, V. The sustainability of the iron and steel industries in Ukraine: Challenges and opportunities. J. Sustain. Metall. 2015, 2, 106–115. [Google Scholar] [CrossRef]

- Fu, Z. The mechanism of imported iron ore price in China. Mod. Econ. 2018, 9, 1908–1931. [Google Scholar] [CrossRef][Green Version]

- Peregudov, V.V.; Gritsina, A.E.; Dragun, B.T. Current state and future development of iron-ore industry in Ukraine. Metall. Min. Ind. 2010, 2, 145–151. [Google Scholar]

- Khomenko, O.; Kononenko, M.; Myronova, I. Ecological and technological aspects of iron-ore underground mining. Min. Miner. Depos. 2017, 11, 59–67. [Google Scholar] [CrossRef]

- Dryzhenko, A.; Moldabayev, S.; Shustov, A.; Adamchuk, A.; Sarybayev, N. Open pit mining technology of steeply dipping mineral occurences by steeply inclined sublayers. In International Multidisciplinary Scientific GeoConference SGEM2017, Science and Technologies in Geology, Exploration and Mining; SEGM: Bulgaria, Balkans, 2017. [Google Scholar] [CrossRef]

- Pysmenniy, S.; Shvager, N.; Shepel, O.; Kovbyk, K.; Dolgikh, O. Development of resource-saving technology when mining ore bodies by blocks under rock pressure. E3S Web Conf. 2020, 166, 02006. [Google Scholar] [CrossRef]

- Stupnik, N.; Kalinichenko, V.; Pismennij, S.; Kalinichenko, E. Features of underlying levels opening at “ArsellorMittal Kryvyic Rih” underground mine. New Dev. Min. Eng. 2015, 39–44. [Google Scholar] [CrossRef]

- Petlovanyi, M.V.; Shustov, O.O.; Zubko, S.A.; Sherstiuk, I.A. The Natural Technogenic Massif Stability at Iron Ore Deposits Production. Submitted Research Work Nominated to be Awarded by the President of Ukraine in 2020. Available online: http://www.kdpu-nt.gov.ua/en/node/310510 (accessed on 8 January 2021).

- Russkikh, V.V.; Lapko, V.V.; Zubko, S.A. Development and adoption of new technical decisions for development of Yuzhno-Belozerskoye ore deposit under difficult mining and geological conditions. Nauk. Visnyk Natsionalnoho Hirnychoho Universytetu 2012, 5, 34–38. [Google Scholar]

- Khomenko, O.; Kononenko, M.; Petlyovanyy, M. Investigation of stress-strain state of rock massif around the secondary chambers. Progress. Technol. Coal Coalbed Methane Ores Min. 2014, 241–245. [Google Scholar] [CrossRef]

- Bondarenko, V.; Kovalevs’ka, I.; Ganushevych, K. Progressive Technologies of Coal, Coalbed Methane, and Ores Mining; CRC Press: Boca Raton, FL, USA; Taylor & Francis Group: London, UK, 2014; pp. 1–523. ISBN 978-0367576097. [Google Scholar] [CrossRef]

- Khorolskyi, A.; Hrinov, V.; Kaliushenko, O. Network models for searching for optimal economic and environmental strategies for field development. Procedia Environ. Sci. Eng. Manag. 2019, 6, 463–471. [Google Scholar]

- Azaryan, A.A.; Batareyev, O.S.; Karamanits, F.I.; Kolosov, V.O.; Morkun, V.S. Ways to Reduce Ore Losses and Dilution in Iron Ore Underground Mining in Kryvbass. Sci. Innov. 2018, 14, 17–24. [Google Scholar] [CrossRef]

- Kuz’menko, A.; Furman, A.; Usatyy, V. Improvement of mining methods with hardening stowing of iron-ore deposits on big depths. New Tech. Technol. Min. 2010, 131–136. [Google Scholar] [CrossRef]

- Petlovanyi, M. Influence of configuration chambers on the formation of stress in multi-modulus mass. Min. Miner. Depos. 2016, 10, 48–54. [Google Scholar] [CrossRef]

- Pang, H.; Chen, C.; Xia, K.; Deng, Y.; Zhang, C.; Sun, C. A methodology based on strain analysis for identifying potential discontinuous deformation zones in sublevel caving mines. Eng. Geol. 2020, 279, 105872. [Google Scholar] [CrossRef]

- Petlovanyi, M.; Malashkevych, D.; Sai, K.; Zubko, S. Research into balance of rocks and underground cavities formation in the coal mine flowsheet when mining thin seams. Min. Miner. Depos. 2020, 14, 66–81. [Google Scholar] [CrossRef]

- Villegas, T.; Nordlund, E.; Dahnér-Lindqvist, C. Hangingwall surface subsidence at the Kiirunavaara Mine, Sweden. Eng. Geol. 2011, 121, 18–27. [Google Scholar] [CrossRef]

- Lapshyn, O.Y.; Lapshyn, O.O.; Khudyk, M. The tragic consequences of the collapse of the earth’s surface within the mining allotment of Ordzhonikidze mine. E3S Web Conf. 2020, 166, 3003. [Google Scholar] [CrossRef]

- Zhao, X.; Zhu, Q. Analysis of the surface subsidence induced by sublevel caving based on GPS monitoring and numerical simulation. Nat. Hazards 2020, 103, 3063–3083. [Google Scholar] [CrossRef]

- Parmar, H.; Yarahmadi, B.A.; Najafi, M. Impact of ground surface subsidence due to underground mining on surface infrastructure: The case of the Anomaly No. 12 Sechahun, Iran. Environ. Earth Sci. 2019, 78, 409. [Google Scholar] [CrossRef]

- Xia, K.; Chen, C.; Lu, Z.; Yang, K.; Zheng, Y.; Pang, H.; Sun, C. Investigation of the ground movement due to underground mining at the Jinshandian Iron Mine in China. Environ. Earth Sci. 2019, 78, 715. [Google Scholar] [CrossRef]

- Liu, G.; Li, N.A.; Yang, X.; Guo, L. Required strength estimation of a cemented backfill with the front wall exposed and back wall pressured. Int. J. Min. Miner. Eng. 2018, 9, 1–20. [Google Scholar] [CrossRef]

- Li, X.; Wang, D.; Li, C.; Liu, Z. Numerical Simulation of Surface Subsidence and Backfill Material Movement Induced by Underground Mining. Adv. Civ. Eng. 2019, 1–17. [Google Scholar] [CrossRef]

- Mineralni resursy Ukrainy. Derzhavnyi Informatsiinyi Heolohichnyi Fond Ukrainy. Available online: http://minerals-ua.info/ (accessed on 24 April 2005).

- Iron-ore Deposits of Ukraine. 2018. Available online: https://www.photoukraine.com/russian/articles?id=171 (accessed on 22 November 2020).

- Mykhailov, V.; Hrinchenko, O. Geology, Mining Industry and Environmental Problems of Ukraine. In Proceedings of the 12th International Conference on Monitoring of Geological Processes and Ecological Condition of the Environment, Kiev, Ukraine, 13–16 November 2018. [Google Scholar] [CrossRef]

- Baklashov, I.A. Geomechanics. The basis of Geomechanics; MGTU: Moscow, Russia, 2004; pp. 1–208. [Google Scholar]

- SNiP II-94-80. Underground Mining Workings; Stroiizdat, Gosstroi: Moscow, Russia, 1982; pp. 1–31. [Google Scholar]

- Chistyakov, E.; Ruskih, V.; Zubko, S. Investigation of the geomechanical processes while mining thick ore deposits by room systems with backfill of worked-out area. Geomech. Process. Undergr. Min. 2012, 127–132. [Google Scholar] [CrossRef]

- Petlovanyi, M.; Lozynskyi, V.; Zubko, S.; Saik, P.; Sai, K. The influence of geology and ore deposit occurrence conditions on dilution indicators of extracted reserves. Rud. Geol. Naft. Zb. 2019, 34, 83–91. [Google Scholar] [CrossRef]

- Petlovanyi, M.; Lozynskyi, V.; Saik, P.; Sai, K. Predicting the producing well stability in the place of its curving at the under-ground coal seams gasification. E3S Web Conf. 2019, 123, 1019. [Google Scholar] [CrossRef]

- Oryngozhin, Y.S.; Yeremin, N.A.; Metaxa, G.P.; Alisheva, Z.N. Underground uranium borehole leaching. News Natl. Acad. Sci. Repub. Kazakhstan Ser. Geol. Tech. Sci. 2020, 4, 62–69. [Google Scholar] [CrossRef]

- Sai, K.; Malanchuk, Z.; Petlovanyi, M.; Saik, P.; Lozynskyi, V. Research of Thermodynamic Conditions for Gas Hydrates Formation from Methane in the Coal Mines. Solid State Phenom. 2019, 291, 155–172. [Google Scholar] [CrossRef]

- Xia, K.; Chen, C.; Zheng, Y.; Zhang, H.; Liu, X.; Deng, Y.; Yang, K. Engineering geology and ground collapse mechanism in the Chengchao iron-ore mine in China. Eng. Geol. 2019, 249, 129–147. [Google Scholar] [CrossRef]

- Russkikh, V.; Yavors’kyy, A.; Zubko, S.; Chistyakov, Y. Study of rock geomechanical processes while mining two-level interchamber pillars. Annu. Sci. Tech. Collect. Min. Miner. Depos. 2013, 149–152. [Google Scholar] [CrossRef]

- Khomenko, O.; Kononenko, M.; Petlovanyi, M. Analytical modeling of the backfill massif deformations around the chamber with mining depth increase. New Dev. Min. Eng. 2015, 265–269. [Google Scholar] [CrossRef]

- Kononenko, M.; Khomenko, O.; Savchenko, M.; Kovalenko, I. Method for calculation of drilling- and-blasting operations parameters for emulsion explosives. Min. Miner. Depos. 2019, 13, 22–30. [Google Scholar] [CrossRef]

- Emad, M.Z.; Vennes, I.; Mitri, H.; Kelly, C. Backfill practices for sublevel stoping system. Mine Plan. Equip. Sel. 2014, 391–402. [Google Scholar] [CrossRef]

- Zaporozhskiy Zhelezorudnyy Kombinat. Produktsiya. Available online: http://www.zgrk.com.ua/?page=about&t=product (accessed on 4 November 2020).

- Li, L. A new concept of backfill design—Application of wick drains in backfilled stopes. Int. J. Min. Sci. Technol. 2013, 23, 763–770. [Google Scholar] [CrossRef]

- Sivakugan, N.; Rankine, R.M.; Rankine, K.J.; Rankine, K.S. Geotechnical considerations in mine backfilling in Australia. J. Clean. Prod. 2006, 14, 1168–1175. [Google Scholar] [CrossRef]

- Koupouli, J.F.; Belem, T.; Rivard, P.; Effenguet, H. Direct shear tests on cemented paste backfill-rock wall and cemented paste backfill-backfill interfaces. J. Rock Mech. Geotech. Eng. 2016, 8, 472–479. [Google Scholar] [CrossRef]

- Basarir, H.; Bin, H.; Fourie, A.; Karrech, A.; Elchalakani, M. An adaptive neuro fuzzy inference system to model the uniaxial compressive strength of cemented hydraulic backfill. Min. Miner. Depos. 2018, 12, 1–12. [Google Scholar] [CrossRef]

- Wu, J.; Feng, M.; Ni, X.; Mao, X.; Chen, Z.; Han, G. Aggregate gradation effects on dilatancy behavior and acoustic characteristic of cemented rockfill. Ultrasonics 2019, 92, 79–92. [Google Scholar] [CrossRef]

- Petlovanyi, M.V.; Zubko, S.A.; Popovych, V.V.; Sai, K.S. Physicochemical mechanism of structure formation and strengthening in the backfill massif when filling underground cavities. (2020). Vopr. Khimii Khimicheskoi Technol. 2020, 6, 142–150. [Google Scholar] [CrossRef]

- Kuz’menko, O.; Petlyovanyy, M.; Stupnik, M. The influence of fine particles of binding materials on the strength properties of hardening backfill. Annu. Sci. Tech. Collect. Min. Miner. Depos. 2013, 45–48. [Google Scholar] [CrossRef]

- Petlovanyi, M.; Kuzmenko, O.; Lozynskyi, V.; Popovych, V.; Sai, K.; Saik, P. Review of man-made mineral formations accumulation and prospects of their developing in mining industrial regions in Ukraine. Min. Miner. Depos. 2019, 13, 24–38. [Google Scholar] [CrossRef]

- Filonenko, O. Sustainable development of Ukrainian iron and steel industry enterprises in regards to the bulk manufacturing waste recycling efficiency improvement. Min. Miner. Depos. 2018, 12, 115–122. [Google Scholar] [CrossRef]

- Kalybekov, T.; Rysbekov, K.; Sandibekov, M.; Bi, Y.L.; Toktarov, A. Substantiation of the intensified dump reclamation in the process of field development. Min. Miner. Depos. 2020, 14, 59–65. [Google Scholar] [CrossRef]

- Petlovanyi, M.; Mamaikin, O. Assessment of an expediency of binder material mechanical activation in cemented rockfill. ARPN J. Eng. Appl. Sci. 2019, 14, 3492–3503. [Google Scholar]

- Chistyakov, E.P.; Kulish, S.A.; Zubko, A.N.; Karapa, I.A.; Sakhno, A.V.; Kordis, Y.M.; Bednov, D.H. Tekhnologicheskaya Instrukciya Proizvodstva Zakladochnyh Rabot na Zaporozhskom Zhelezorudnom Kombinate; GP «NIGRI»: Krivoy Rog, Ukraine, 2010. [Google Scholar]

- Aubertin, M. Interaction between backfill and rock mass in narrow stopes. Soil Rock Am. 2003, 1, 1157–1164. [Google Scholar]

- Emad, M.Z.; Mitri, H.; Kelly, C. Effect of blast-induced vibrations on fill failure in vertical block mining with delayed backfill. Can. Geotech. J. 2014, 51, 975–983. [Google Scholar] [CrossRef]

- Forster, K.; Milne, D.; Pop, A. Mining and rock mass factors influencing hangingwall dilution. Rock Mech. Meet. Soc. Chall. Demands 2007, 1361–1366. [Google Scholar] [CrossRef]

- Urli, V.; Esmaieli, K. A stability-economic model for an open stope to prevent dilution using the ore-skin design. Int. J. Rock Mech. Min. Sci. 2016, 82, 71–82. [Google Scholar] [CrossRef]

- Malanchuk, Z.; Korniienko, V.; Malanchuk, Y.; Soroka, V.; Vasylchuk, O. Modeling the formation of high metal concentration zones in man-made deposits. Min. Miner. Depos. 2018, 2, 76–84. [Google Scholar] [CrossRef]

- Kuzmenko, O.; Petlyovanyy, M.; Heylo, A. Application of fine-grained binding materials in technology of hardening backfill construction. Progress. Technol. Coal Coalbed Methane Ores Min. 2014, 465–469. [Google Scholar] [CrossRef]

- Petlovanyi, M.V.; Ruskykh, V.V.; Zubko, S.A. Peculiarities of the underground mining of high-grade iron ores in anomalous geological conditions. J. Geol. Geogr. Geoecol. 2019, 28, 706–716. [Google Scholar] [CrossRef]

- Sheshpari, M. Failures in Backfilled Stopes and Barricades in Underground Mines. Electron. J. Geotech. Eng. 2015, 20, 191–212. [Google Scholar]

- Liu, Z.; Lan, M.; Xiao, S.; Guo, H. Damage failure of cemented backfill and its reasonable match with rock mass. Trans. Nonferr. Met. Soc. China 2015, 25, 954–959. [Google Scholar] [CrossRef]

- Emad, M.Z. Numerical modelling approach for mine backfill. Sādhanā 2017, 42, 1595–1604. [Google Scholar] [CrossRef]

- Kononenko, M.; Petlovanyi, M.; Zubko, S. Formation the stress fields in backfill massif around the chamber with mining depth increase. Min. Miner. Depos. 2015, 9, 207–215. [Google Scholar] [CrossRef]

- Yang, P.; Li, L.; Aubertin, M. Stress ratios in entire mine stopes with cohesionless backfill: A numerical study. Minerals 2017, 7, 201. [Google Scholar] [CrossRef]

- Piotr, M.; Łukasz, O.; Piotr, B. Modelling the Small Throw Fault Effect on the Stability of a Mining Roadway and Its Verification by In Situ Investigation. Energies 2017, 10, 2082. [Google Scholar] [CrossRef]

- Abdiev, A.; Mambetova, R.; Abdiev, A.; Abdiev, S. Studying a correlation between characteristics of rock and their conditions. Min. Miner. Depos. 2020, 14, 87–100. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Bazaluk, O.; Petlovanyi, M.; Lozynskyi, V.; Zubko, S.; Sai, K.; Saik, P. Sustainable Underground Iron Ore Mining in Ukraine with Backfilling Worked-Out Area. Sustainability 2021, 13, 834. https://doi.org/10.3390/su13020834

Bazaluk O, Petlovanyi M, Lozynskyi V, Zubko S, Sai K, Saik P. Sustainable Underground Iron Ore Mining in Ukraine with Backfilling Worked-Out Area. Sustainability. 2021; 13(2):834. https://doi.org/10.3390/su13020834

Chicago/Turabian StyleBazaluk, Oleg, Mykhailo Petlovanyi, Vasyl Lozynskyi, Serhii Zubko, Kateryna Sai, and Pavlo Saik. 2021. "Sustainable Underground Iron Ore Mining in Ukraine with Backfilling Worked-Out Area" Sustainability 13, no. 2: 834. https://doi.org/10.3390/su13020834

APA StyleBazaluk, O., Petlovanyi, M., Lozynskyi, V., Zubko, S., Sai, K., & Saik, P. (2021). Sustainable Underground Iron Ore Mining in Ukraine with Backfilling Worked-Out Area. Sustainability, 13(2), 834. https://doi.org/10.3390/su13020834