Adaptive Design of Formworks for Building Renovation Considering the Sustainability of Construction in BIM Environment—Case Study

Abstract

1. Introduction

2. Literature Review

2.1. Formwork and Designing in Adaptive Architecture

- Self-weight, reinforcement and concrete loading;

- the properties of fresh concrete affect the magnitude of the pressure acting on the formwork structure;

- Site loads (workers, technical equipment, etc.), including the static and dynamic effect of the laying, compaction and secondary transport of fresh concrete;

- Environmental aspects (snow and wind loads, wheatear conditions, and so on).

2.2. Building Information Modelling and Adaptive Design of Formwork

3. Materials and Methods

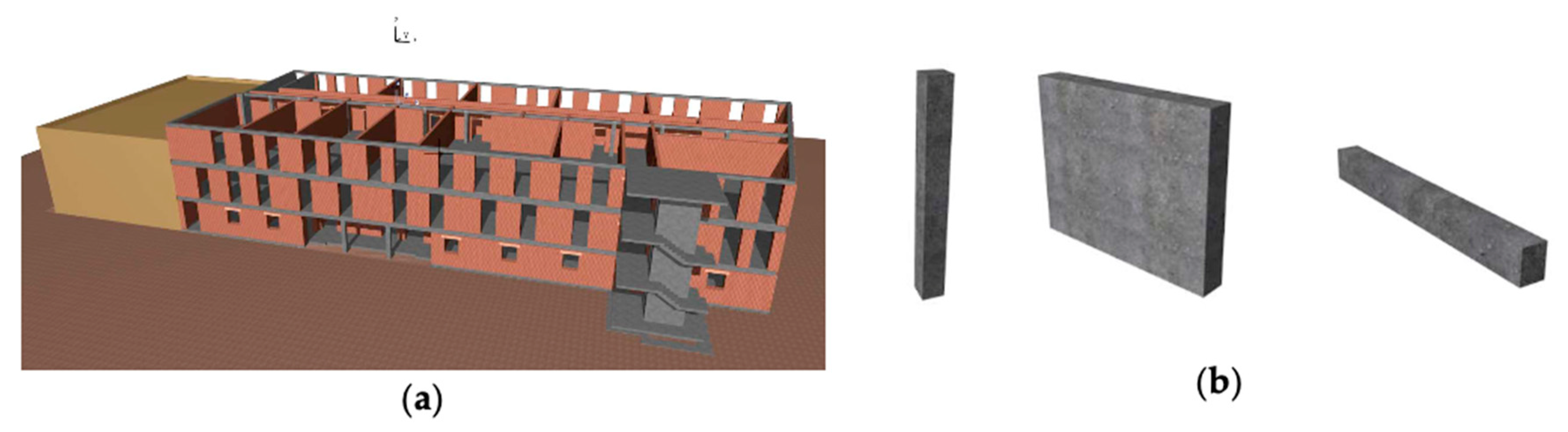

3.1. Research Material

3.1.1. Object of Case Study

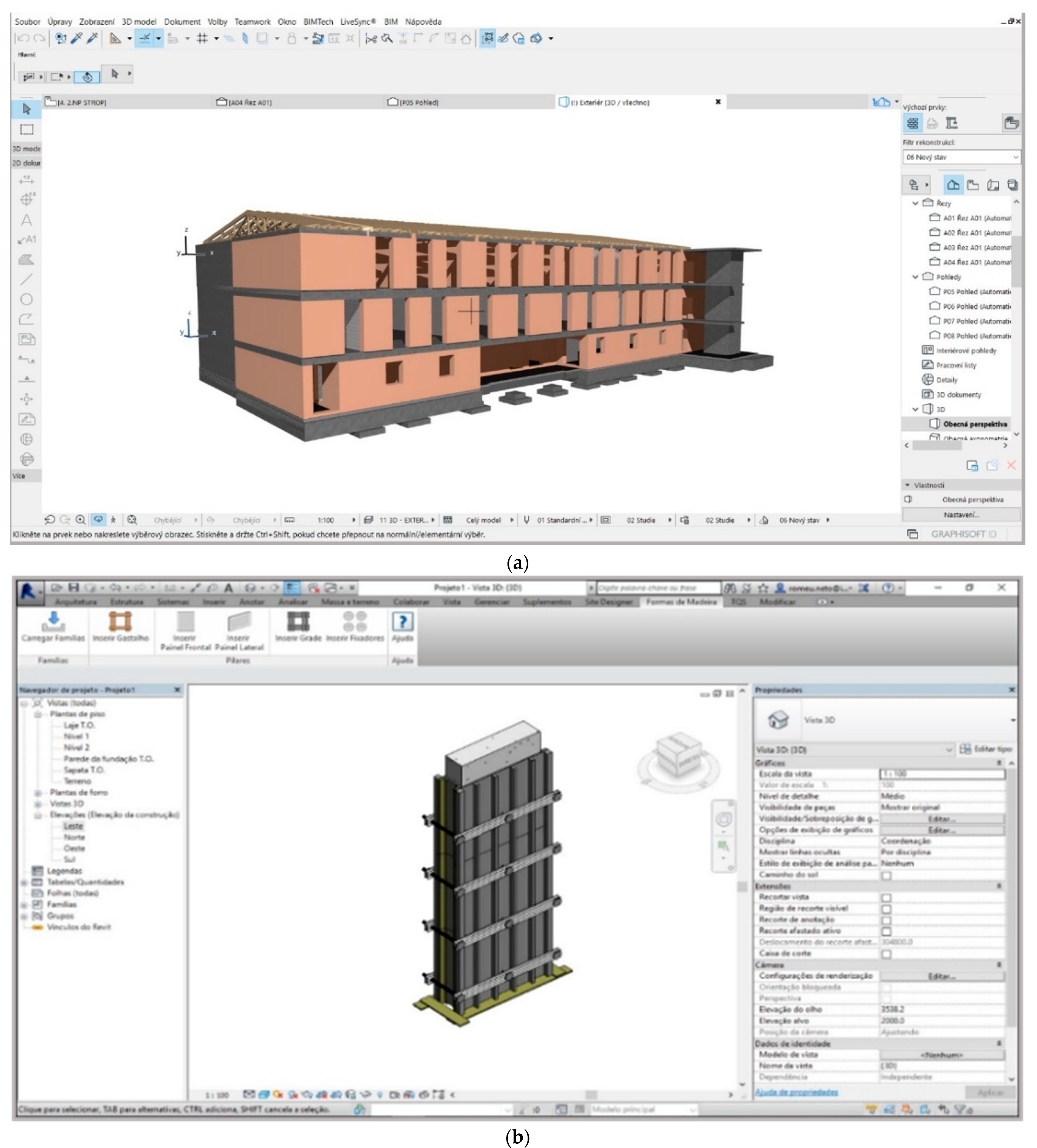

3.1.2. Software Tools for Adaptive Design of Formwork

- Building information modeling;

- Formwork design;

- Visualization of the information model.

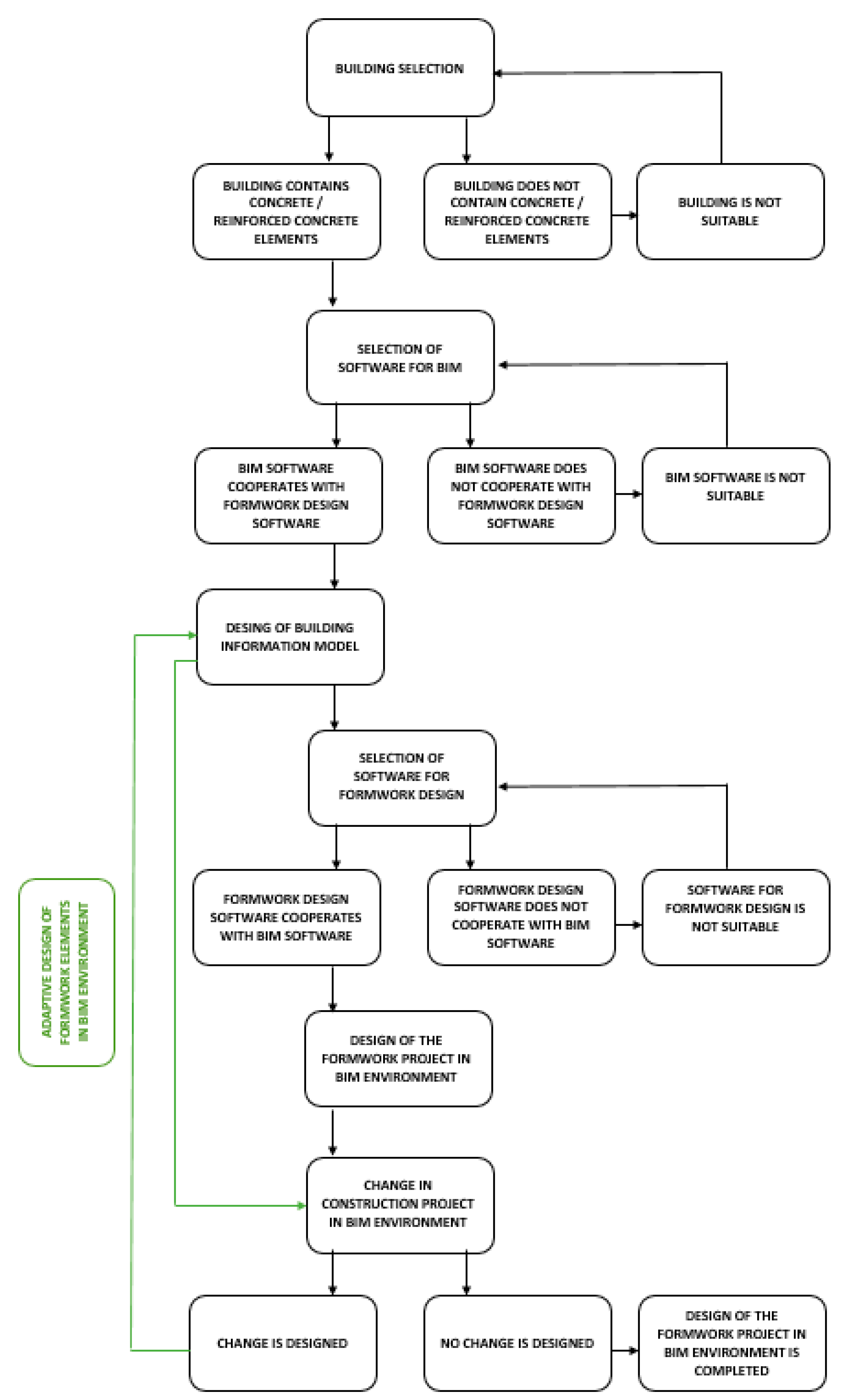

3.2. Research Methods

- Building selection;

- Selection of software for BIM;

- Selection of software for formwork design;

- Design of the formwork project in the BIM environment.

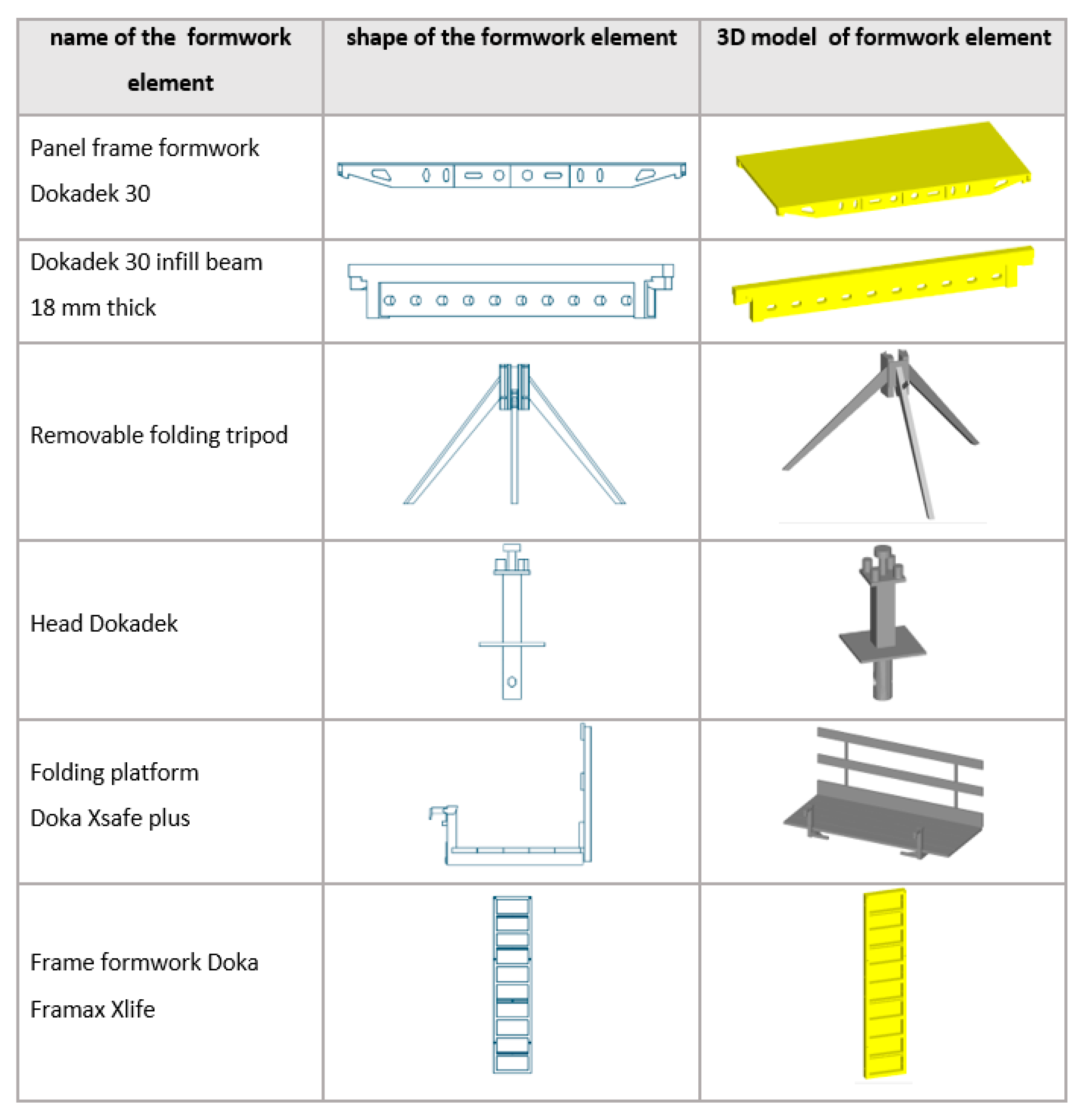

4. Results and Discussion

- Documents for the creation of the load-bearing construction 3D model (project documentation);

- Documents relating to the technological process for construction of the auxiliary structure—formwork (technological instructions, the technological standard by particularly provider of formwork elements);

- Data from the digital library of 3D elements of the formwork structure.

- Spatial collisions of construction elements and formwork elements;

- Inappropriate modeling of structural elements;

- Inappropriate installation of auxiliary structure systems in our case, such as formwork structures.

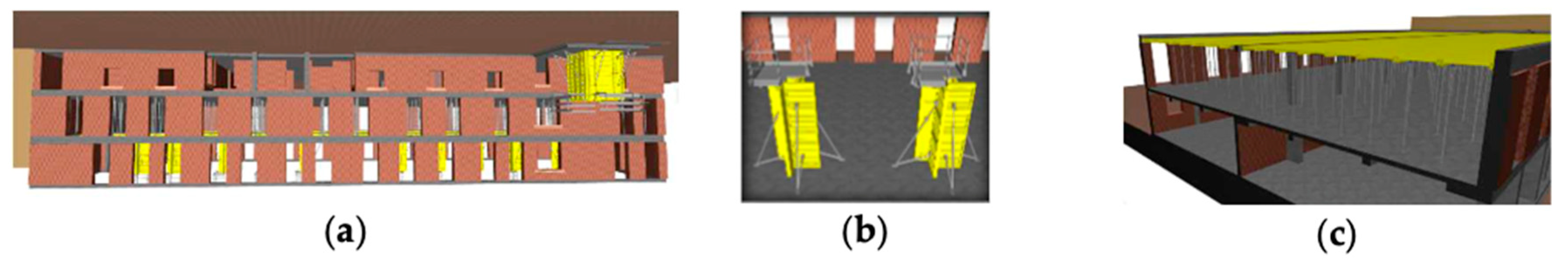

- Computer graphics 3D modeling software, e.g., ArchiCAD, Revit and others;

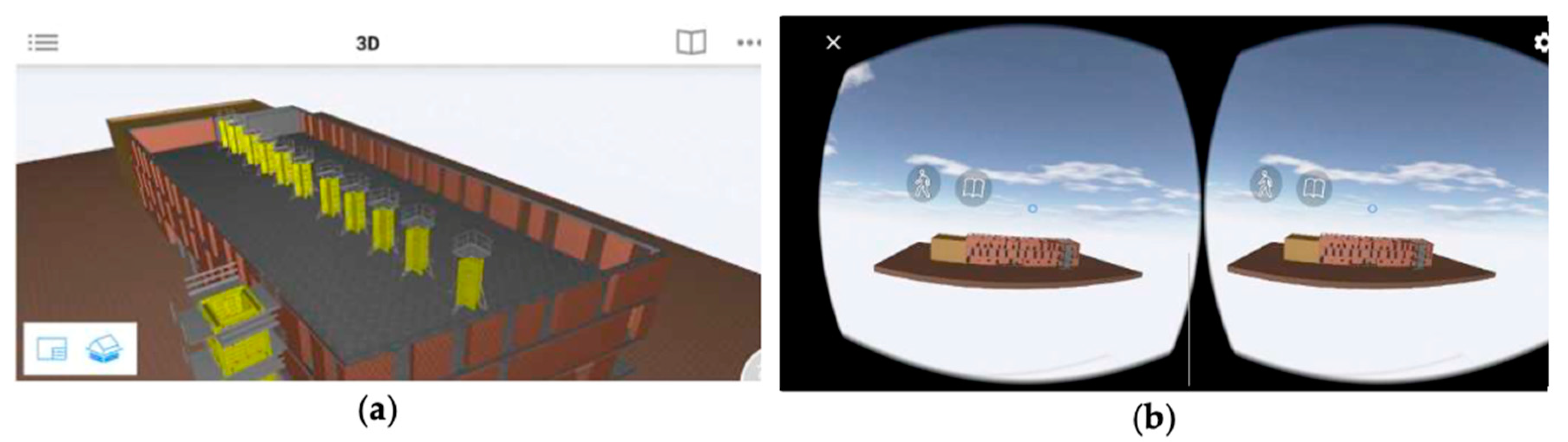

- BIMx application in the environment of a computer, tablet or smartphone;

- Virtual reality using the BIMx application (smartphone + glasses);

- Microsoft Hololens glasses that support mixed reality.

- Possibility of automatic collision detection;

- Connection of construction project stakeholder in the whole phase of the project;

- Possibility to analyze and solve errors already in the design project phase;

- Automated modeling, updating of 2D drawings from a 3D model;

- Possibility of presenting a 3D model using mixed, virtual and augmented reality;

- Increase the efficiency of the construction process (meeting schedule, costs and reducing failures).

- Price of graphic software;

- Investment in hardware equipment;

- Insufficient compatibility between individual software;

- A limited number of 3D models of formwork elements of accessible libraries;

- Higher level of skills with individual modeling software.

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Dolníková, E.; Katunský, D.; Darula, S. Assessment of overcast sky daylight conditions in the premises of engineering operations considering two types of skylights. Build. Environ. Int. J. Build. Sci. Appl. 2020, 180, 1–14. [Google Scholar]

- Dolníková, E.; Katunský, D.; Vertaľ, M.; Zozulák, M. Influence of Roof Windows Area Changes on the Classroom Indoor Climate in the Attic Space: A Case Study. Sustainability 2020, 12, 5046. [Google Scholar] [CrossRef]

- Vranay, F.; Pirsel, L.; Kacik, R.; Vranayová, Z. Adaption of HVAC systems to reduce the spread of COVID-19 in Buildings. Sustainability 2020, 12, 9992. [Google Scholar] [CrossRef]

- Longo, F.; Cascardi, A.; Lassandro, P.; Aiello, M.A. A new Fabric Reinforced Geopolymer Mortar (FRGM) with mechanical and energy benefits. Fibers 2020, 8, 49. [Google Scholar] [CrossRef]

- Longo, F.; Cascardi, A.; Lassandro, P.; Sannino, A.; Aiello, M.A. Mechanical and thermal characterization of FRCM-matrices. In Proceedings of the Key Engineering Materials—6th International Conference on Mechanics of Masonry Structures Strengthened with Composite Materials, MuRiCo6, Bologna, Italy, 26–28 June 2019; Volume 817, pp. 189–194. [Google Scholar]

- Galić, M.; Venkrbec, V.; Chmelik, F.; Feine, I.; Pucko, Z.; Klansek, U. Survey af accomplishments in BIM implementation in Croatia The Czech Republic, Germany and Slovenia. Electron. J. Fac. Civ. Eng. 2017, 8. [Google Scholar] [CrossRef]

- Darula, S.; Kittler, R. A methodology for designing amnd calibrating an artificial sky to simulate ISO/CIE sky types with an artificial sun. J. Illum. Eng. Soc. N. Am. 2014, 11, 1–13. [Google Scholar]

- Pohoryles, D.A.; Maduta, C.; Bournas, D.A.; Kouris, L.A. Energy performance of existing residential buildings in Europe: A novel approach combining energy with seismic retrofitting. Energy Build. 2020, 223, 110024. [Google Scholar] [CrossRef]

- Pohoryles, D.A.; Maduta, C.; Bournas, D.A. A unified macro-modelling approach for masonry-infilled RC frames strengthened with composite materials. Eng. Struct. 2020, 223, 111161. [Google Scholar] [CrossRef]

- Gasparik, J.; Funtik, T.; Gasparik, M.; Alamro, B. Continuing increasing of quality management level in construction company using excellence model with software support. In Proceedings of the ISARC 2018—35th International Symposium on Automation and Robotics in Construction and International AEC/FM Hackathon: The Future of Building Things, Berlin, Germany, 20–25 July 2018; pp. 207–213. [Google Scholar]

- Waeak, S.; Ljevo, Ž.; Vukomanović, M. Understanding the key quality factors in constrction projects—A systematic literature review. Sustainability 2020, 12, 1–25. [Google Scholar]

- Bello, S.A.; Oyedele, L.O.; Akinde, O.O.; Bilah, M.B.; Davila Delgado, J.A.; Akanbi, L.A.; Ajayi, A.O.; Owolabi, H.A. Cloud computing in construction industry: Use cases, benefits and challenges. Autom. Constr. 2021, 122, 1–18. [Google Scholar] [CrossRef]

- Wen, Q.; Li, Z.; Peng, Y.; Guo, B. Assessing the Effectiveness of Building Information Modeling in Developing Green Buildings from a Lifecycle Perspective. Sustainability 2020, 12, 9988. [Google Scholar] [CrossRef]

- Hong, J.; Zhang, X.; Shen, G.Q.; Zhang, W.; Feng, Y. A multi-regional based hybrid method for assessing life cycle energy use of buildings: A case study. J. Clean. Prod. 2017, 148, 760–772. [Google Scholar] [CrossRef]

- D’Amico, A.; Bergonzoni, G.; Pini Edoardo Currà, A. BIM for Healthy Buildings: An Integrated Approach of Architectural Design Based on IAQ Prediction. Sustainability 2020, 12, 10417. [Google Scholar] [CrossRef]

- ASB—Technology of the Principle of Design and Installation of Formwork. Available online: https://www.asb.sk/stavebnictvo/zaklady-a-hruba-stavba/cement-beton/technologicke-zasady-navrhu-a-montaze-debnenia (accessed on 19 September 2020).

- Sona, M. The impact of buildability factors on formwork in residential building construction. Lect. Notes Civ. Eng. 2021, 99, 85–96. [Google Scholar]

- Araújo, C.S.; Siqueira, L.C.; Ferreira, E.A.M.; Costa, D.B. Conceptual Framework for Tracking Metallic Formworks on Construction Sites Using IoT, RFID and BIM Technologies. Lect. Notes Civ. Eng. 2021, 98, 865–878. [Google Scholar]

- Romanovskyi, R.; Sanabria Mejia, L.; Rezazadeh Azar, E. BIM-based decision support system for concrete formwork design. In Proceedings of the 36th International Symposium on Automation and Robotics in Construction, ISARC, Banff, AB, Canada, 21–24 May 2019; pp. 1129–1135. [Google Scholar]

- Mansuri, D.; Chakraborty, D.; Elzarka, H.; Deshpande, A.; Gronseth, T. Building information modeling enabled cascading formwork management tool. Autom. Constr. 2017, 83, 259–272. [Google Scholar] [CrossRef]

- Lacarte, L.M.D.; Fan, J. Modelling of a thermally activated building system (TABS) combined with free-hanging acoustic ceiling units using computational fluid dynamics (CFD). Build. Simul. 2018, 11, 315–324. [Google Scholar] [CrossRef]

- Friembichler, F.; Handler, S.; Kreč, K.; Kuster, H. Energy-Storage Concrete: Thermal Component Activation, 1st ed.; Bundesministerium für Verkehr, Innovation und Technologie: Wien, Austria, 2017; p. 121. [Google Scholar]

- Struková, Z. Technológia Stavebných Procesov—Hrubá Stavba; Stavebná Fakulta Technickej Univerzity v Košiciach: Košice, Slovakia, 2011; p. 142. [Google Scholar]

- Kim, M.-K.; Putra Thedja, J.P.; Wang, O. Automated dimensional quality assessment for formwork and rebar of reinforced concrete components using 3D point cloud data. Autom. Constr. 2020, 112, 1–14. [Google Scholar] [CrossRef]

- Majer, R.; Ellimgerová, H.; Gašparík, J. Methods for the calculation of the lost profit in construction contracts. Buildings 2020, 10, 74. [Google Scholar] [CrossRef]

- Malara, J.; Plebankiewicz, E.; Juszczyk, M. Formula for determining the construction workers productivity including environmental factors. Buildings 2019, 9, 240. [Google Scholar] [CrossRef]

- Radziszewska-Zielina, E. Assessment methods of partnering relations of Polish, Slovak and Ukrainian construction enterprises with the use of fuzzy logic. Arch. Civ. Eng. 2011, 1, 87–118. [Google Scholar] [CrossRef]

- Radziszewska-Zielina, E.; Szewczyk, M. Examples of actions that improve partnering cooperation among the participants of construction projects. IOP Conf. Ser. Mater. Sci. Eng. 2017, 25, 12–51. [Google Scholar] [CrossRef]

- Gajzler, M.; Zima, K. Evaluation of Planned Construction Projects Using Fuzzy Logic. Int. J. Civ. Eng. 2017, 15, 641–652. [Google Scholar] [CrossRef]

- Ko, C.H.; Wang, W.C.; Kuo, J.D. Improving formwork engineering using the Toyota Way. J. Eng. Proj. Prod. Manag. 2011, 1, 13–27. [Google Scholar] [CrossRef]

- Mohammadi, S.; Tavakolan, M.; Zahraie, B. Automated planning of building construction considering the amount of available floor formwork. In Proceedings of the Construction Research Congress: Old and New Construction Technologies Converge in Historic San Juan, San Juan, Puerto Rico, 31 May–2 June 2016; pp. 1–16. [Google Scholar]

- Chakraborty, D.; Elzarka, H.; Bhatnagar, R. Generation of accurate weather files using a hybrid machine learning methodology for design and analysis of sustainable and resilient buildings. Sustain. Cities Soc. 2016, 24, 33–41. [Google Scholar] [CrossRef]

- Gallego, E.; Fuentes, J.M.; Ramírez, A.; Ayuga, F. Computer simulation of complex-shaped formworks using three-dimensional numerical models. Autom. Constr. 2011, 20, 830–836. [Google Scholar] [CrossRef]

- Hyun, C.; Jin, C.; Shen, Z.; Kim, H. Automated optimization of formwork design through spatial analysis in building information modeling. Autom. Constr. 2018, 95, 193–205. [Google Scholar] [CrossRef]

- ASB—Formwork. Available online: https://www.asb.sk/stavebnictvo/zaklady-a-hruba-stavba/betonaz/debnenie (accessed on 24 September 2020).

- Bašková, R. Realizácia betonových konštrukcií. Turany Staveb. Trh 2008, 272. [Google Scholar] [CrossRef]

- Juríček, I. Technológia Stavieb—Hrubá Stavba; Eurostav: Bratislava, Slovakia, 2018; p. 302. [Google Scholar]

- Kolarić, S.; Vukomanovoć, M. Potential of BIM and ERP integration in contractor construction companies. In Proceedings of the 13th International Conference Organization, Technology and Management in Construction, Poreč, Croatia, 27–30 September 2017; pp. 669–673. [Google Scholar]

- Drozd, W.; Leśniak, A. Ecological wall systems as an element of sustainable development-cost issues. Sustainability 2018, 10, 2234. [Google Scholar] [CrossRef]

- Mihić, M.; Vukomanović, M.; Završki, I. Review of previous applications of innovative information technologies in construction health and safety. Organ. Technol. Manag. Constr. 2019, 11, 1952–1967. [Google Scholar] [CrossRef]

- Behún, M.; Gavurova, B.; Tkacova, A.; Kotaskova, A. The impact of the manufacturing industry on the economic cycle of European Union countries. J. Compet. 2018, 10, 23–39. [Google Scholar] [CrossRef]

- Knapčíková, L.; Balog, M.; Husar, J.; Szilagyi, E. Material recycling of some automobile plastics waste. Przem. Chem. 2018, 95, 1716–1720. [Google Scholar]

- Eastman, C.H.; Eastman, C.; Teicholz, P.; Sacks, R.; Liston, K. BIM Handbook. A Guide to Building Information Modeling for Oweners, Managers, Designers, Engineers, and Contractors; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2008; p. 658. [Google Scholar]

- Smith, P. BIM Implementation—Global Strategies. Procedia Eng. 2017, 85, 482–492. [Google Scholar] [CrossRef]

- BiBlus—The Birth of BIM and the Virtual Model According to Estman. Available online: http://biblus.accasoftware.com/en/the-birth-of-bim-eastman/ (accessed on 10 October 2020).

- Thomas, N. BIM Vs. CAD Files: What’s the Difference. Available online: https://blog.thomasnet.com/cad-vs-bim-files (accessed on 12 October 2020).

- Thenbs, L. BIM Vs. CAD Files: What’s the Difference. Available online: https://blog.areo.io/level-of-development/ (accessed on 13 October 2020).

- Rigiops, Bim and Construction Contractors. Available online: https://www.rigips.sk/files/kniznica/bim-brozura.pdf (accessed on 12 October 2020).

- Sacks, R.; Eastman, C.H.; Lee, G.; Teicholz, P. BIM Handbook: A Guide to Building Information Modeling for Owners, Designers, Engineering, Contractors, and Facility Managers, 3rd ed.; John Wiley & Sons, Inc.: Hoboken, NJ, USA, 2018; p. 658. [Google Scholar]

- Smith, P. BIM Implementation—Global Strategies. Procedia Eng. 2014, 85, 482–492. [Google Scholar] [CrossRef]

- Graphisoft—ArchiCAD. Available online: https://graphisoft.com/solutions/products/archicad (accessed on 15 October 2020).

- Centrum—ArchiCAD. Available online: http://www.cegra.cz/produkty/software/archicad/ (accessed on 15 October 2020).

- Peri—Planning PERI Formwork System in Autodesk Revit. Available online: https://www.peri.com/en/company/press/planning-peri-formwork-systems-in-autodesk-revit.html (accessed on 18 October 2020).

- Doka—DokaCAD 9 for AutoCAD. Available online: https://www.doka.com/sk/solutions/services/dfds/dfds-planning-software/DokaCAD-for-AutoCAD-software-formwork-plannin (accessed on 18 October 2020).

- Tekla—Concrete Formwork with Tekla. Available online: https://www.tekla.com/solutions/concrete-contractors/formwork/ (accessed on 18 October 2020).

- Virtual Reality—What Is Virtual Reality? Available online: https://virtualnarealita.eu/co-je-virtualna-realita/ (accessed on 20 October 2020).

- GooglePlay—BIMx—eXplorer. Available online: https://play.google.com/store/apps/details?id=com.graphisoft.bimx&hl=sk (accessed on 18 October 2020).

- Augmented Reality. Available online: http://www.priemyselneinzinierstvo.sk/?page_id=1579/ (accessed on 20 October 2020).

- Doka—Doka Augmented Reality. Available online: https://www.doka.com/sk/home/apps/augmented-and-virtual-reality-app (accessed on 18 October 2020).

- Ahmed, S.; Arocho, I. Analysis of cost comparison and effects of change orders during construction: Study of a mass timber and a concrete building project. J. Build. Eng. 2021, 33, 101856. [Google Scholar] [CrossRef]

- Yana, A.A.G.A.; Rusdhi, H.A.; Wibowo, M.A. Analysis of Factors Affecting Design Changes in Construction Project with Partial Least Square. Procedia Eng. 2015, 125, 40–45. [Google Scholar] [CrossRef]

- Spitz, N.; Coniglio, N.; El Mansor, M.; Montagne, A.; Mezghani, S. Quantitative and representative adherence assessment of coated and uncoated concrete-formwork. Surf. Coat. Tech. 2018, 352, 247–256. [Google Scholar] [CrossRef]

| Disposable | Multiple | ||

|---|---|---|---|

| Type: | Version: | Type: | Version: |

| Carpentry: | +lumber parts | Partial | +formwork parts |

| Removed: | +cardboard tubes | System: | +large area |

| Permanently built-in: | +concrete blocks | +small area | |

| +steel mesh | +spatial | ||

| +arm blocks | Special: | +climbing | |

| +steel pipes | +lifting | ||

| +tiles | +inflatable | ||

| +thermal insulation blocks | +sliding | ||

| +filigree boards | +mobile | ||

| +perforated steel sheet | +portable | ||

| +inserts to create hollows | +molds for prefabricated parts | ||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (http://creativecommons.org/licenses/by/4.0/).

Share and Cite

Mésároš, P.; Spišáková, M.; Mandičák, T.; Čabala, J.; Oravec, M.M. Adaptive Design of Formworks for Building Renovation Considering the Sustainability of Construction in BIM Environment—Case Study. Sustainability 2021, 13, 799. https://doi.org/10.3390/su13020799

Mésároš P, Spišáková M, Mandičák T, Čabala J, Oravec MM. Adaptive Design of Formworks for Building Renovation Considering the Sustainability of Construction in BIM Environment—Case Study. Sustainability. 2021; 13(2):799. https://doi.org/10.3390/su13020799

Chicago/Turabian StyleMésároš, Peter, Marcela Spišáková, Tomáš Mandičák, Jozef Čabala, and Milan M. Oravec. 2021. "Adaptive Design of Formworks for Building Renovation Considering the Sustainability of Construction in BIM Environment—Case Study" Sustainability 13, no. 2: 799. https://doi.org/10.3390/su13020799

APA StyleMésároš, P., Spišáková, M., Mandičák, T., Čabala, J., & Oravec, M. M. (2021). Adaptive Design of Formworks for Building Renovation Considering the Sustainability of Construction in BIM Environment—Case Study. Sustainability, 13(2), 799. https://doi.org/10.3390/su13020799