Assessment of Potential Barriers to the Implementation of an Innovative AB-FB Energy Storage System under a Sustainable Perspective

Abstract

:1. Introduction

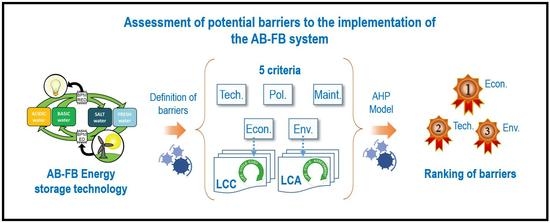

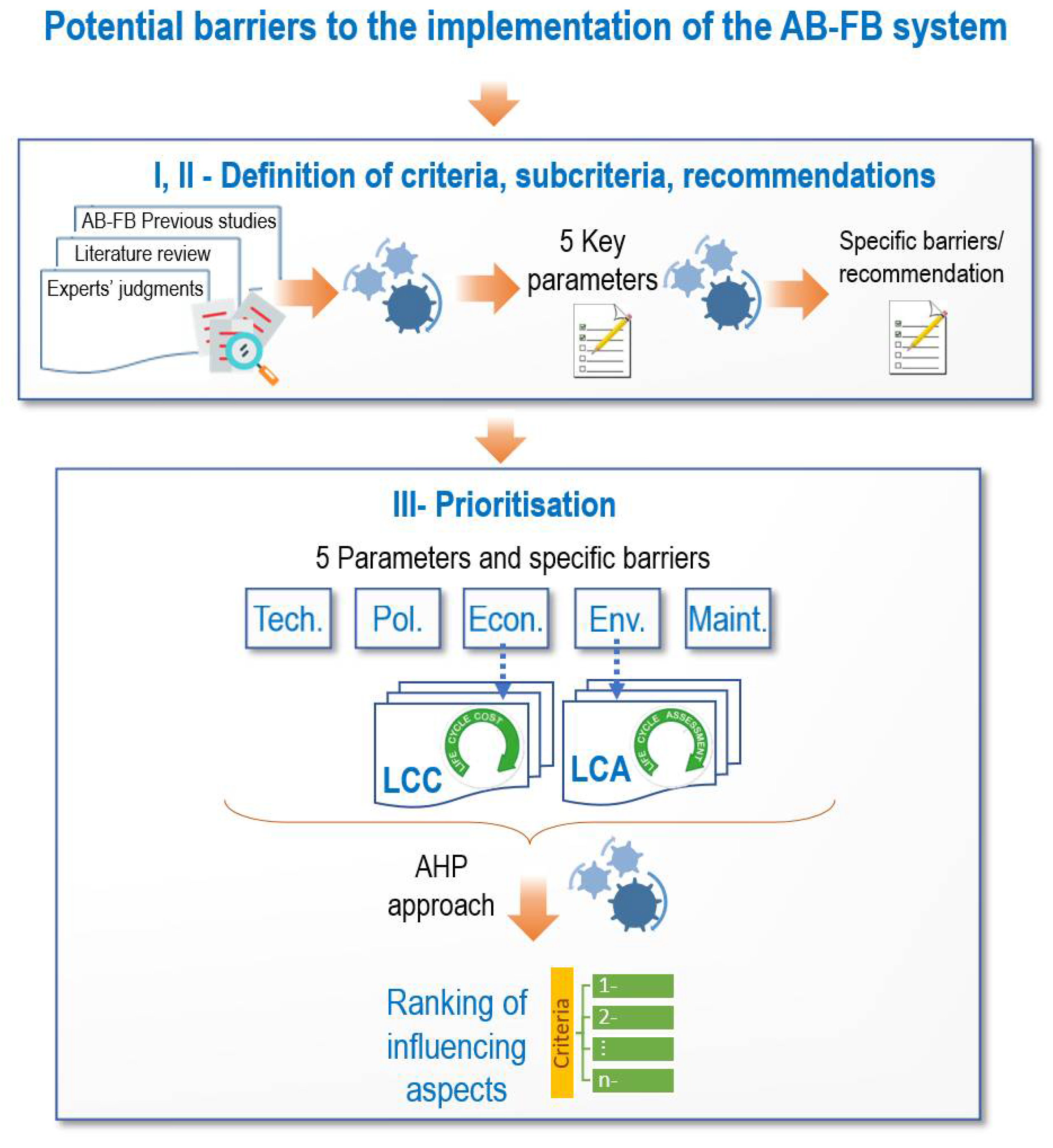

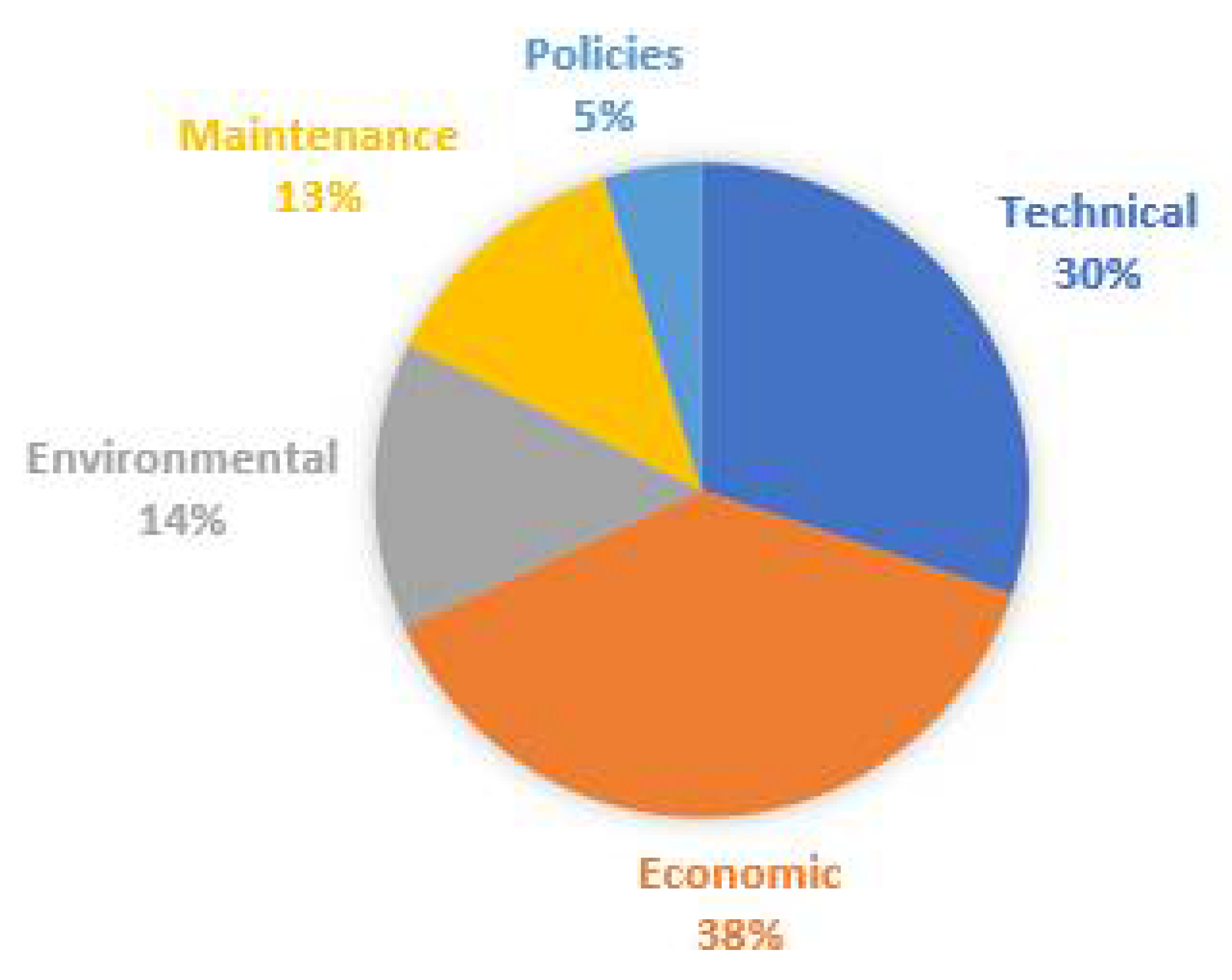

2. Materials and Methods

- (i)

- To identify specific barriers corresponding to each of the five key influencing parameters (called criteria, according to the AHP model): technical, economic, environmental, policy and maintenance aspects.

- (ii)

- To define specific recommendations to overcome the detected specific barriers (called sub-criteria, according to the AHP model).

- (iii)

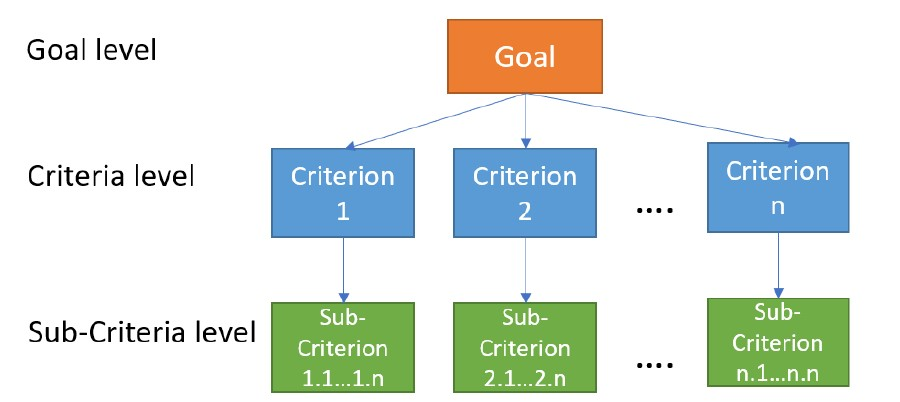

- To quantify the influence of the five parameters (criteria) and their specific barriers (sub-criteria) using the AHP method.

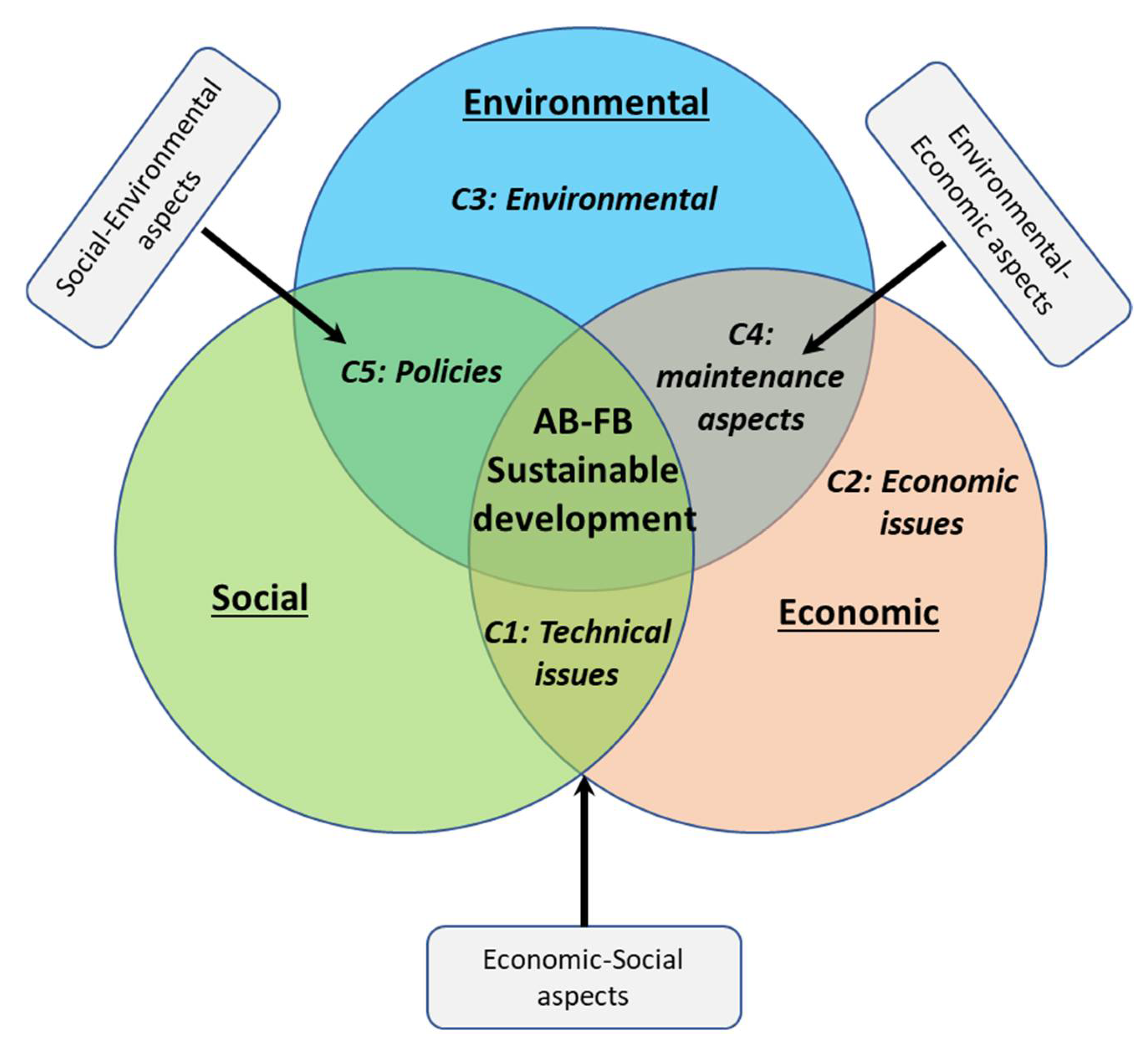

2.1. Definition of the Key Influencing Parameters and Related Specific Barriers under a Sustainability Perspective

2.2. Prioritisation of Barriers

3. Results and Discussions

3.1. Barrier Categories and Recommendations

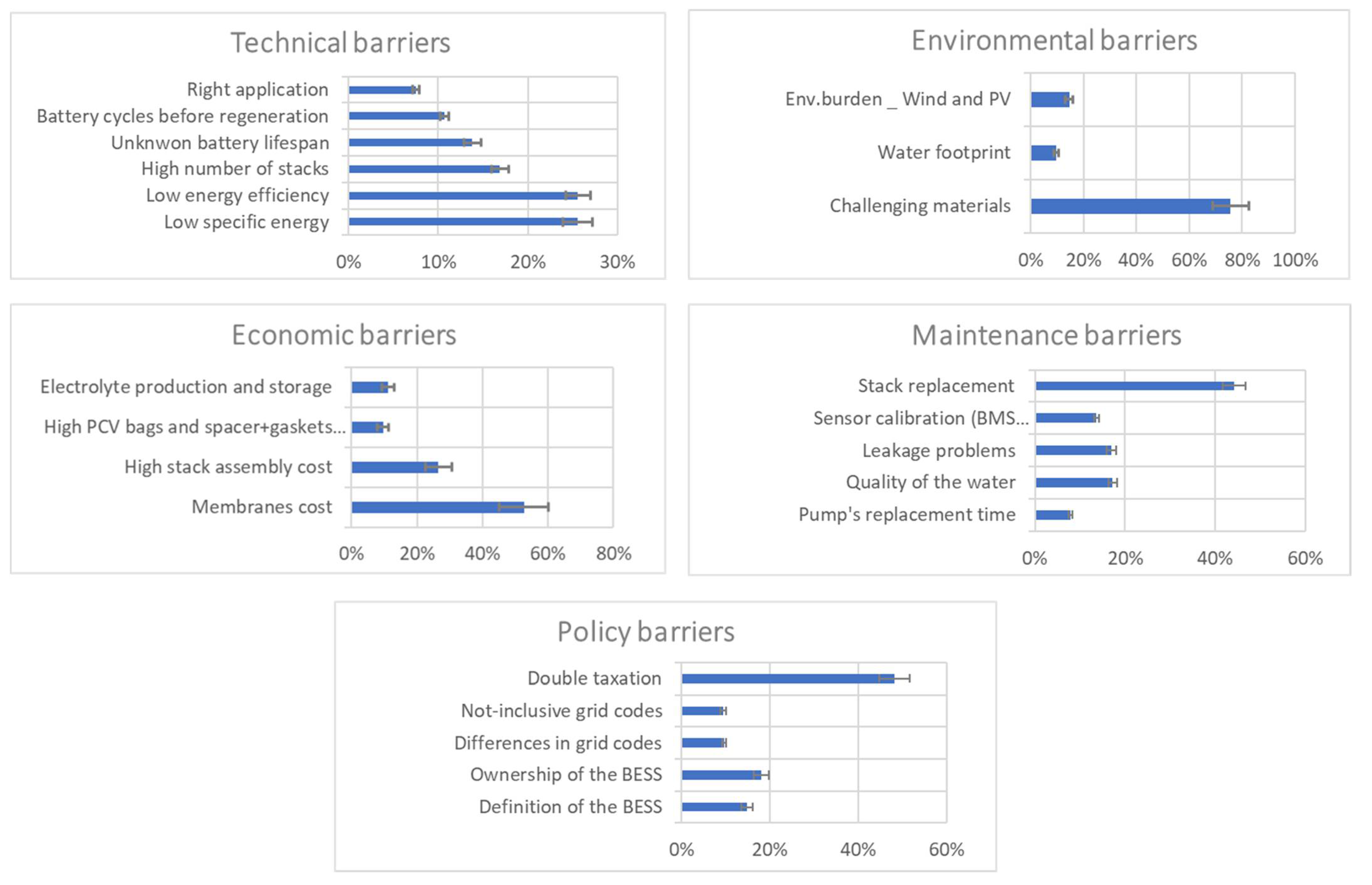

3.1.1. Technical

- Low specific energy of the new system:

- Low energy efficiency and corresponding energy losses

- Need for a high number of stacks due to low battery reversible voltage

- Lack of information regarding the battery system lifespan and component replacement time

- Low number of battery cycles before regeneration of the electrolyte solutions

- Finding the right application according to the location of the battery

3.1.2. Economic

- Membrane cost dominates the stack cost

- High expenditure on stack assembly

- High investment cost of PVC bags, spacers, and gaskets

- Large facilities needed for storing BAoBaB electrolyte

3.1.3. Environmental

- Challenging materials

- High-water footprint

- Environmental burden from wind and PV installations

3.1.4. Maintenance

- Pump replacement

- Quality of the water

- Leakage problems in the system

- BMS maintenance

- Stack replacement every 10 years

3.1.5. Policies

- Definition of BESS

- Ownership of the BESS

- Differences in grid codes

- Not-inclusive grid codes

- Double taxation

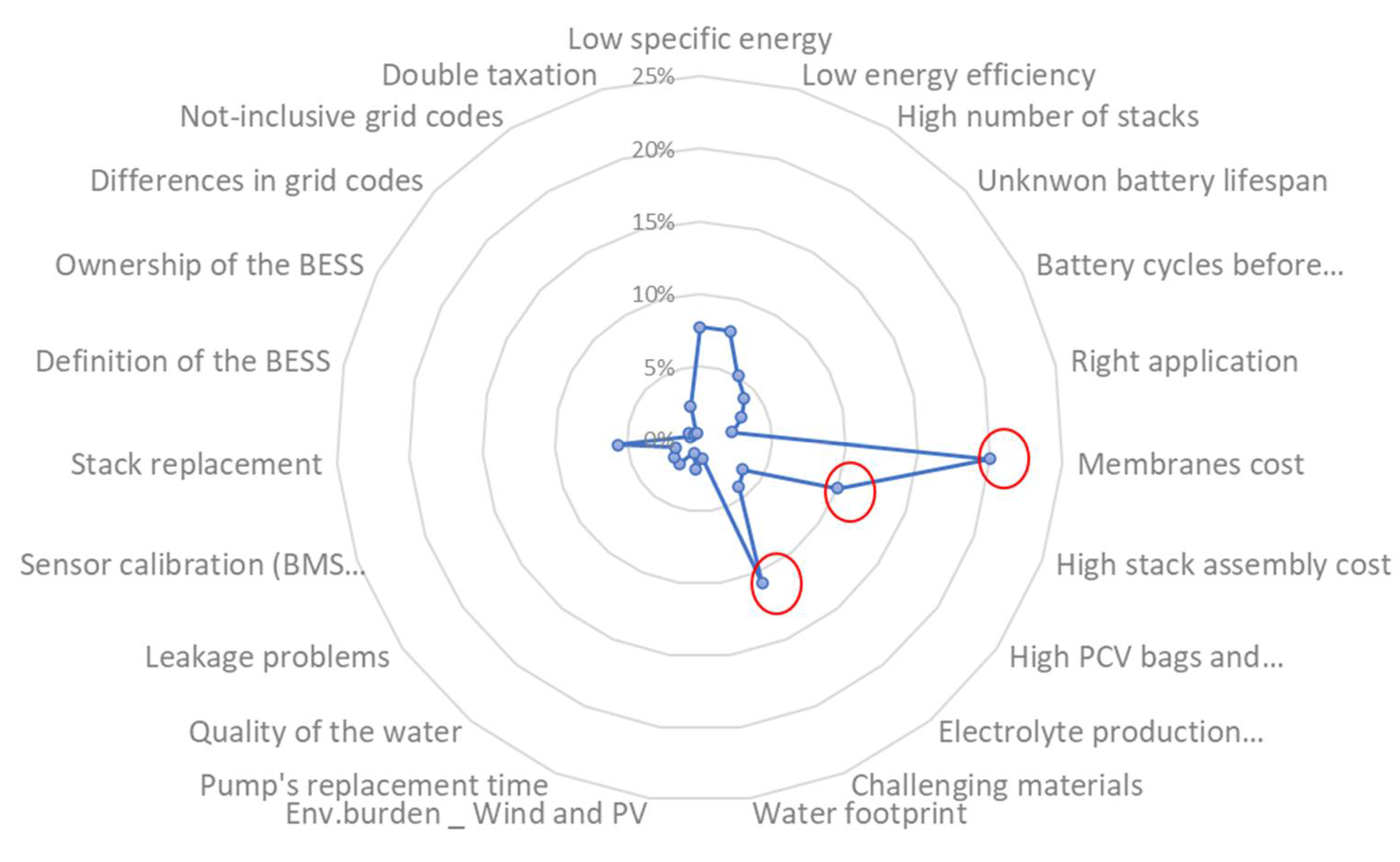

3.2. Assessment of Barriers’ Influence

4. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Díaz-Ramírez, M.C.; Ferreira, V.J.; García-Armingol, T.; López-Sabirón, A.M.; Ferreira, G. Environmental Assessment of Electrochemical Energy Storage Device Manufacturing to Identify Drivers for Attaining Goals of Sustainable Materials 4.0. Sustainability 2020, 12, 342. [Google Scholar] [CrossRef] [Green Version]

- Sánchez-Díez, E.; Ventosa, E.; Guarnieri, M.; Trovò, A.; Flox, C.; Marcilla, R.; Soavi, F.; Mazur, P.; Aranzabe, E.; Ferret, R. Redox flow batteries: Status and perspective towards sustainable stationary energy storage. J. Power Sources 2021, 481, 228804. [Google Scholar] [CrossRef]

- Pusceddu, E.; Zakeri, B.; Castagneto Gissey, G. Synergies between energy arbitrage and fast frequency response for battery energy storage systems. Appl. Energy 2021, 283, 116274. [Google Scholar] [CrossRef]

- Keck, F.; Lenzen, M.; Vassallo, A.; Li, M. The impact of battery energy storage for renewable energy power grids in Australia. Energy 2019, 173, 647–657. [Google Scholar] [CrossRef]

- Kebede, A.A.; Coosemans, T.; Messagie, M.; Jemal, T.; Behabtu, H.A.; Van Mierlo, J.; Berecibar, M. Techno-economic analysis of lithium-ion and lead-acid batteries in stationary energy storage application. J. Energy Storage 2021, 40, 102748. [Google Scholar] [CrossRef]

- Mao, J.; Jafari, M.; Botterud, A. Planning low-carbon distributed power systems: Evaluating the role of energy storage. Energy 2022, 238, 121668. [Google Scholar] [CrossRef]

- He, G.; Ciez, R.; Moutis, P.; Kar, S.; Whitacre, J.F. The economic end of life of electrochemical energy storage. Appl. Energy 2020, 273, 115151. [Google Scholar] [CrossRef]

- Huang, C.; Xu, T. Electrodialysis with Bipolar Membranes for Sustainable Development. Environ. Sci. Technol. 2006, 40, 5233–5243. [Google Scholar] [CrossRef] [PubMed]

- van Egmond, W.J.; Saakes, M.; Noor, I.; Porada, S.; Buisman, C.J.N.; Hamelers, H.V.M. Performance of an environmentally benign acid base flow battery at high energy density. Int. J. Energy Res. 2018, 42, 1524–1535. [Google Scholar] [CrossRef] [Green Version]

- Pärnamäe, R.; Gurreri, L.; Post, J.; Johannes Van Egmond, W.; Culcasi, A.; Saakes, M.; Cen, J.; Goosen, E.; Tamburini, A.; Vermaas, D.A.; et al. The Acid-Base Flow Battery: Sustainable Energy Storage via Reversible Water Dissociation with Bipolar Membranes. Membranes 2020, 10, 409. [Google Scholar] [CrossRef] [PubMed]

- Culcasi, A.; Gurreri, L.; Zaffora, A.; Cosenza, A.; Tamburini, A.; Micale, G. On the modelling of an Acid/Base Flow Battery: An innovative electrical energy storage device based on pH and salinity gradients. Appl. Energy 2020, 277, 115576. [Google Scholar] [CrossRef]

- Díaz-Ramírez, M.C.; Blecua-de-Pedro, M.; Arnal, A.J.; Post, J. Acid/Base Flow Battery Environmental and Economic Performance based on Its Potential Service to Renewables Support (Manuscript Submitted for Publication). 2021; Unpublished work. [Google Scholar]

- European Commission. Critical Raw Materials Resilience: Charting a Path towards Greater Security and Sustainability; European Commission: Brussels, Belgium, 2020. [Google Scholar]

- Gouveia, J.; Mendes, A.; Monteiro, R.; Mata, T.M.; Caetano, N.S.; Martins, A.A. Life cycle assessment of a vanadium flow battery. Energy Rep. 2020, 6, 95–101. [Google Scholar] [CrossRef]

- Díaz-Ramírez, M.C.; Ferreira, V.J.; García-Armingol, T.; López-Sabirón, A.M.; Ferreira, G. Battery Manufacturing Resource Assessment to Minimise Component Production Environmental Impacts. Sustainability 2020, 12, 6840. [Google Scholar] [CrossRef]

- Mardani, A.; Zavadskas, E.K.; Khalifah, Z.; Zakuan, N.; Jusoh, A.; Nor, K.M.; Khoshnoudi, M. A review of multi-criteria decision-making applications to solve energy management problems: Two decades from 1995 to 2015. Renew. Sustain. Energy Rev. 2017, 71, 216–256. [Google Scholar] [CrossRef]

- Ribeiro, F.; Ferreira, P.; Araújo, M. Evaluating future scenarios for the power generation sector using a Multi-Criteria Decision Analysis (MCDA) tool: The Portuguese case. Energy 2013, 52, 126–136. [Google Scholar] [CrossRef] [Green Version]

- Kurbatova, A.; Ahmed Abu-Qdais, H. Using Multi-Criteria Decision Analysis to Select Waste to Energy Technology for a Mega City: The Case of Moscow. Sustainability 2020, 12, 9828. [Google Scholar] [CrossRef]

- Klein, S.J.W. Multi-Criteria Decision Analysis of Concentrated Solar Power with Thermal Energy Storage and Dry Cooling. Environ. Sci. Technol. 2013, 47, 13925–13933. [Google Scholar] [CrossRef]

- Özkan, B.; Kaya, İ.; Cebeci, U.; Başlıgil, H. A Hybrid Multicriteria Decision Making Methodology Based on Type-2 Fuzzy Sets For Selection Among Energy Storage Alternatives. Int. J. Comput. Intell. Syst. 2015, 8, 914–927. [Google Scholar] [CrossRef] [Green Version]

- Algarin, C.A.R.; Llanos, A.P.; Castro, A.O. An Analytic Hierarchy Process Based Approach for Evaluating Renewable Energy Sources. Int. J. Energy Econ. Policy 2017, 7, 38–47. [Google Scholar]

- Culcasi, A.; Gurreri, L.; Micale, G.; Tamburini, A. Bipolar membrane reverse electrodialysis for the sustainable recovery of energy from pH gradients of industrial wastewater: Performance prediction by a validated process model. J. Environ. Manage. 2021, 287, 112319. [Google Scholar] [CrossRef]

- Xia, J.; Eigenberger, G.; Strathmann, H.; Nieken, U. Acid-Base Flow Battery, Based on Reverse Electrodialysis with Bi-Polar Membranes: Stack Experiments. Processes 2020, 8, 99. [Google Scholar] [CrossRef] [Green Version]

- Lim, A.; Lee, J.S.; Lee, S.; Lee, S.Y.; Kim, H.; Yoo, S.J.; Jang, J.H.; Sung, Y.-E.; Park, H.S. Polymer electrolyte membrane unitized regenerative fuel cells: Operational considerations for achieving high round trip efficiency at low catalyst loading. Appl. Catal. B Environ. 2021, 297, 120458. [Google Scholar] [CrossRef]

- Ubertini, S.; Facci, A.L.; Andreassi, L. Hybrid Hydrogen and Mechanical Distributed Energy Storage. Energies 2017, 10, 35. [Google Scholar] [CrossRef] [Green Version]

- Weber, S.; Peters, J.F.; Baumann, M.; Weil, M. Life Cycle Assessment of a Vanadium Redox Flow Battery. Environ. Sci. Technol. 2018, 52, 10864–10873. [Google Scholar] [CrossRef] [PubMed]

- Zaffora, A.; Culcasi, A.; Gurreri, L.; Cosenza, A.; Tamburini, A.; Santamaria, M.; Micale, G. Energy Harvesting by Waste Acid/Base Neutralization via Bipolar Membrane Reverse Electrodialysis. Energies 2020, 13, 5510. [Google Scholar] [CrossRef]

- Tanaka, Y. 17—Bipolar Membrane Electrodialysis. In Ion Exchange Membranes, 2nd ed.; Tanaka, Y., Ed.; Elsevier: Amsterdam, the Netherlands, 2015; pp. 369–392. ISBN 978-0-444-63319-4. [Google Scholar]

- Strathmann, H. (Ed.) Membrane Science and Technology Series. In Ion-Exchange Membrane Separation Processes; Membrane Science and Technology; Elsevier: Amsterdam, The Netherlands, 2004; Volume 9, p. ii. [Google Scholar]

- Kim, J.; Suharto, Y.; Daim, T.U. Evaluation of Electrical Energy Storage (EES) technologies for renewable energy: A case from the US Pacific Northwest. J. Energy Storage 2017, 11, 25–54. [Google Scholar] [CrossRef]

- Escalante Soberanis, M.A.; Mithrush, T.; Bassam, A.; Mérida, W. A sensitivity analysis to determine technical and economic feasibility of energy storage systems implementation: A flow battery case study. Renew. Energy 2018, 115, 547–557. [Google Scholar] [CrossRef]

- Kapila, S.; Oni, A.O.; Kumar, A. The development of techno-economic models for large-scale energy storage systems. Energy 2017, 140, 656–672. [Google Scholar] [CrossRef]

- Smallbone, A.; Jülch, V.; Wardle, R.; Roskilly, A.P. Levelised Cost of Storage for Pumped Heat Energy Storage in comparison with other energy storage technologies. Energy Convers. Manag. 2017, 152, 221–228. [Google Scholar] [CrossRef]

- Huang, Y.; Chen, H.S.; Zhang, X.J.; Keatley, P.; Huang, M.J.; Vorushylo, I.; Wang, Y.D.; Hewitt, N.J. Techno-economic Modelling of Large Scale Compressed Air Energy Storage Systems. Energy Procedia 2017, 105, 4034–4039. [Google Scholar] [CrossRef]

- Bhatnagar, D.; Currier, A.; Hernandez, J.; Ma, O.; Kirby, B. Market and Policy Barriers to Energy Storage Deployment A Study for the Energy Storage Systems Program; Sandia National Lab.: Albuquerque, NM, USA, 2013. [Google Scholar]

- Schrøder Pedersen, A. Joint EASE/EERA Recommendations for a European Energy Storage Technology Development Roadmap towards 2030-Final; European Association for Storage of Energy (EASE): Brussels, Belgium, 2013. [Google Scholar]

| Punctuation | Punctuation Definition |

|---|---|

| 1 | Equal importance of the row criterion over the column criterion |

| 2 | Between equal and weak importance of the row criterion over the column criterion |

| 3 | Weak importance of the row criterion over the column criterion |

| 4 | Between weak and strong importance of the row criterion over the column criterion |

| 5 | Strong importance of the row criterion over the column criterion |

| 6 | Between strong and demonstrated importance of the row criterion over the column criterion |

| 7 | Demonstrated importance of the row criterion over the column criterion |

| 8 | Between demonstrated and absolute importance of the row criterion over the column criterion |

| 9 | Absolute importance of the row criterion over the column criterion |

| Parameters | Specific Barriers |

|---|---|

| C1: Technical | Low specific energy |

| Low energy efficiency | |

| High number of stacks | |

| Unknown battery system lifespan | |

| Low number of battery cycles before regeneration | |

| Right application | |

| C2: Economic | Membrane cost |

| High stack assembly cost | |

| High PVC bag and spacer + gasket costs | |

| Electrolyte production and storage | |

| C3: Environmental | Challenging materials |

| Water footprint | |

| Environmental burden from wind and PV installations | |

| C4: Maintenance | Pump replacement time |

| Quality of the water | |

| Leakage problems | |

| Sensor calibration (BMS maintenance) | |

| Stack replacement (10 years) | |

| C5: Policies | Definition of BESS (Battery Energy Storage Systems) |

| Ownership of the BESS | |

| Differences in grid codes | |

| Non-inclusive grid codes | |

| Double taxation |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blecua-de-Pedro, M.; Díaz-Ramírez, M.C. Assessment of Potential Barriers to the Implementation of an Innovative AB-FB Energy Storage System under a Sustainable Perspective. Sustainability 2021, 13, 11042. https://doi.org/10.3390/su131911042

Blecua-de-Pedro M, Díaz-Ramírez MC. Assessment of Potential Barriers to the Implementation of an Innovative AB-FB Energy Storage System under a Sustainable Perspective. Sustainability. 2021; 13(19):11042. https://doi.org/10.3390/su131911042

Chicago/Turabian StyleBlecua-de-Pedro, María, and Maryori C. Díaz-Ramírez. 2021. "Assessment of Potential Barriers to the Implementation of an Innovative AB-FB Energy Storage System under a Sustainable Perspective" Sustainability 13, no. 19: 11042. https://doi.org/10.3390/su131911042

APA StyleBlecua-de-Pedro, M., & Díaz-Ramírez, M. C. (2021). Assessment of Potential Barriers to the Implementation of an Innovative AB-FB Energy Storage System under a Sustainable Perspective. Sustainability, 13(19), 11042. https://doi.org/10.3390/su131911042