Power Grid Integration and Use-Case Study of Acid-Base Flow Battery Technology

Abstract

1. Introduction

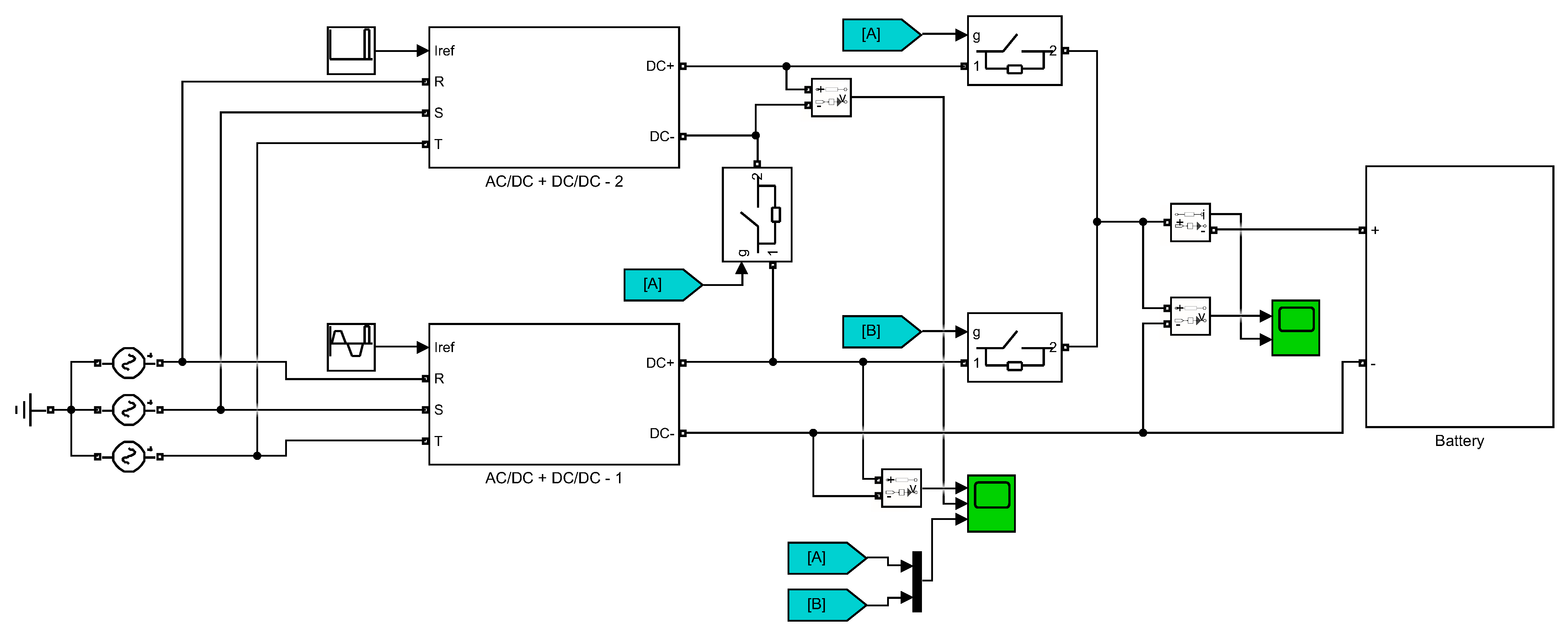

2. Competitive Use-Cases Applications for ABFB Technology

2.1. Comparing ABFB with Current ESS Solutions

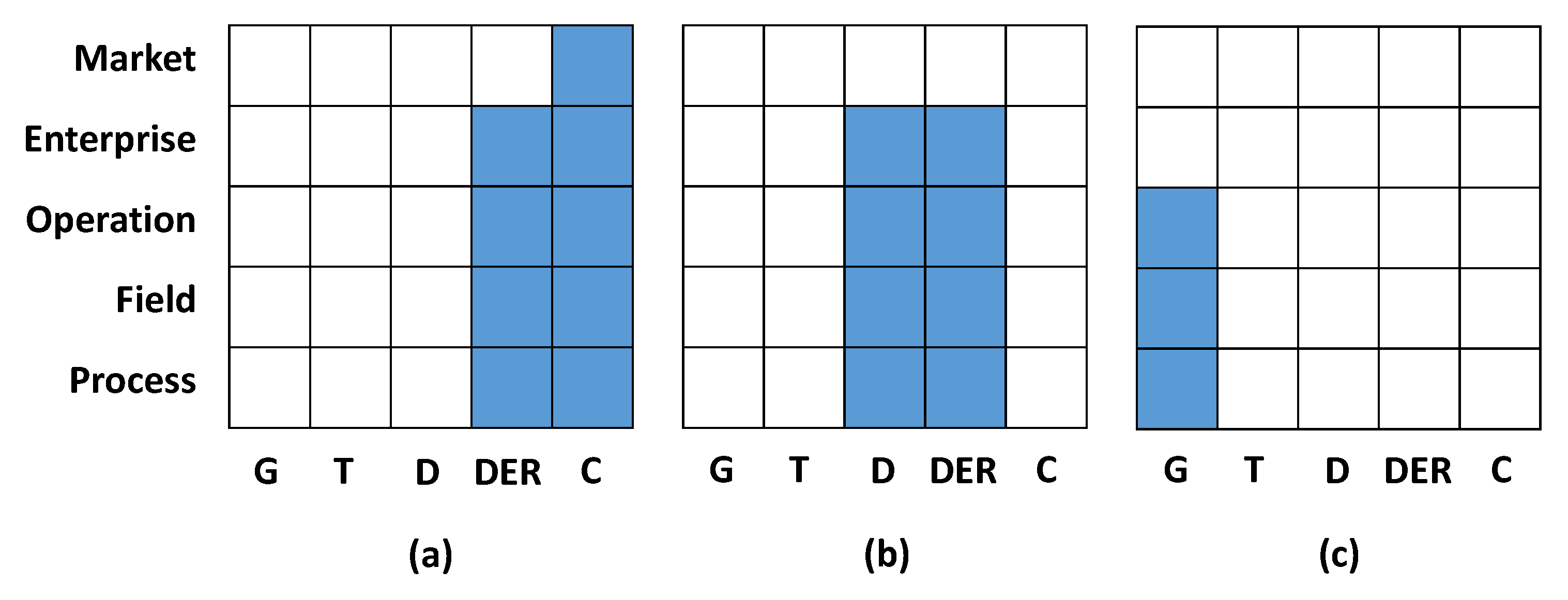

2.2. Smart-Grid Architecture Model

2.3. Use-Case 1: Light-Commercial Energy Storage

2.4. Use-Case 2: Low Voltage Network Congestion and Voltage Management

2.5. Use-Case 3: Bulk Storage to Support Generation

3. ABFB Power Grid Integration

3.1. Sizing of Current ESS Applications in Selected Use-Cases

3.1.1. Utility Scale

3.1.2. Residential Scale

3.2. Sizing Constrains of ABFB Technology

3.2.1. Specific Considerations Related to the Life Cycle of the Battery

3.2.2. Specific Requirements to Be Considered in the Power Converter Design

- The power converter should be as efficient as possible.

- The converter should be designed in such a way that mass production is possible to keep the price per kW as low as possible, so economic considerations are clearly also important.

- Scaling/multiplication of the solution should be possible. Not all battery systems will have an identical size and therefore it should be possible to change the size of the converter to match the battery size (in terms of kW/MW). In this regard, a modular approach could work, where for instance a standard 100 kW converter could be designed and multiplied in parallel according to customers demand. However, a scaling approach might also be appropriate, where the converter could be redesigned, or parts are expanded to meet demands. Regarding the scaling requirement, the attention should be also focused on the general scale-up of the technology. Large size solutions of hundreds of MW are currently only imagined to be possible in the future: to achieve that, first smaller systems need to be built. Therefore, smaller power converters are necessary. In general, this consideration implies that the sizing of the converters could be planned according to a two-axis approach: the timeline of development of the system (from a few kW up to hundreds of MW) and the scaling of systems according to the batteries built at a certain time (a scale factor of about 10 up/down).

- In normal charge and discharge mode, the voltage can vary between 0.4 and 1.6 V. However, the battery can undergo a “reset” sequence (“charge reset”) where all solutions are purified in situ so that the solutions are restored to factory settings, extending the lifetime of the battery significantly. The charge reset function requires a minimum voltage of 2 V per ABFB cell at charge current is necessary but preferably an even higher voltage is required, up to 6 V preferably; however, any voltage higher than 6 V adds little value to the functionality. If this leads to fundamental converter design issues making the converter too expensive, a trade-off need to take place between the quality of the reset sequence and the economic considerations mentioned earlier.

- The ABFB batteries used for the pilot have 56 cells which amounts to a total theoretical open-circuit voltage (OCV) of around 48 V at 100% state of charge (SOC). In the future, for much larger power requirements, it might be possible to switch to high voltage stacks (up to several hundreds of V). This of course will impact the power converter as well. Again, this should be considered when designing the “right converter at the right time”, as discussed above with the considerations about scaling requirements.

3.2.3. Limitations on the State of Charge of the Battery

3.2.4. Additional Limitation/Constraints on the Battery Currents

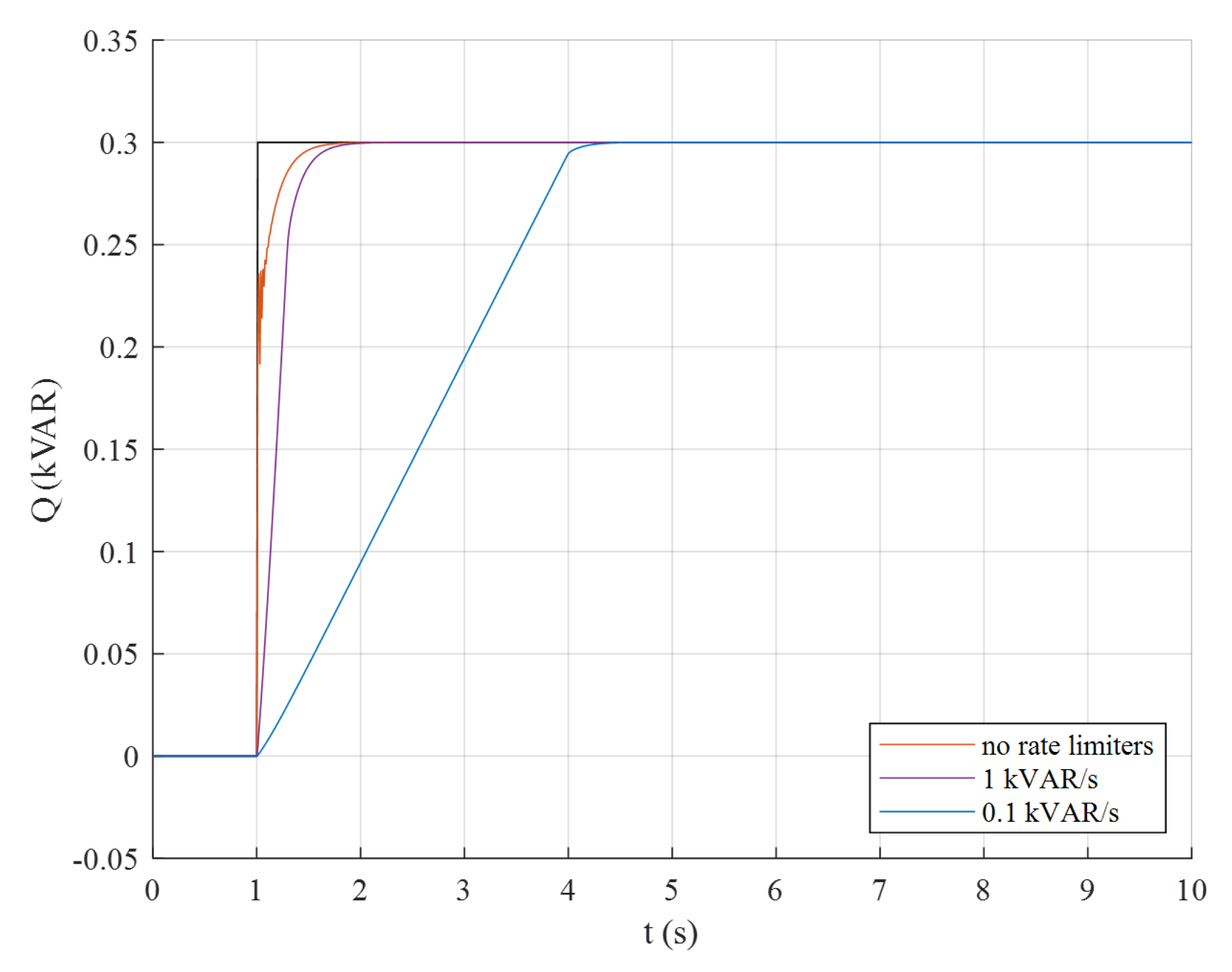

3.2.5. Sensitivity to the Rate of Change

3.3. Use-Cases Sizing Specifications

3.4. Power Converter Interface Configuration

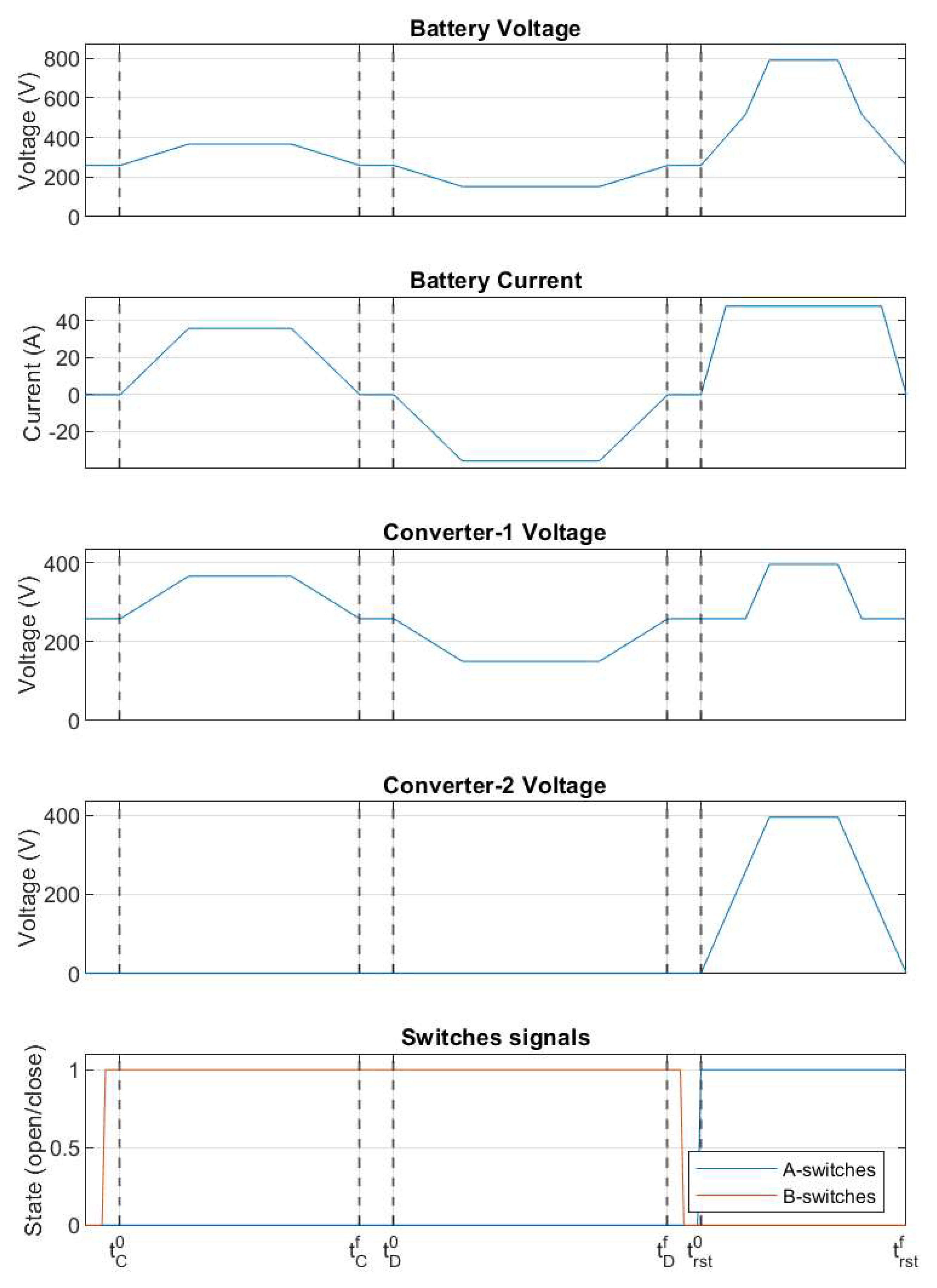

4. Operation of the Power Converter Interface for ABFB Technology

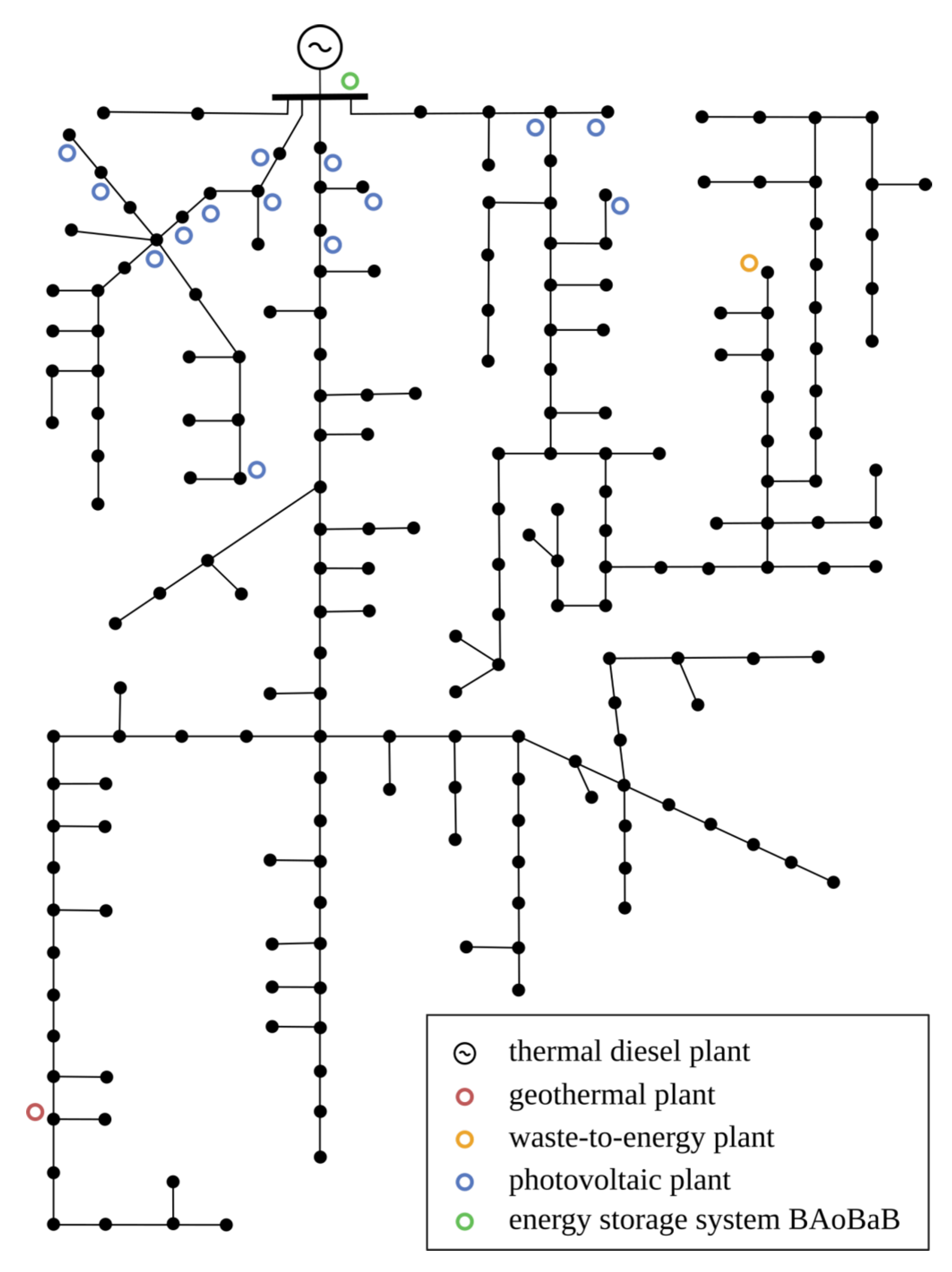

5. Application Example: Implementation in the Electrical Network of Pantelleria

5.1. Step on Power References

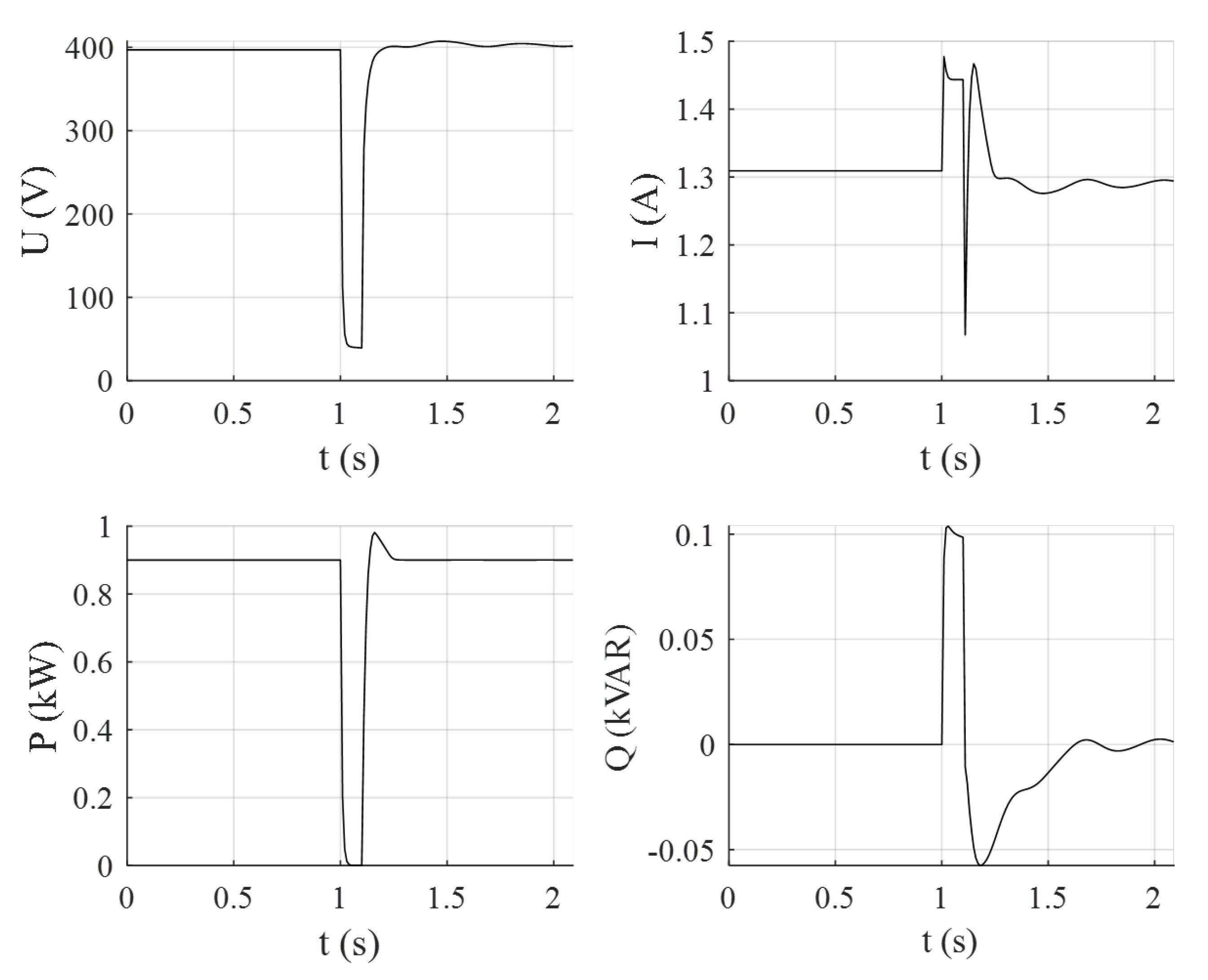

5.2. Terminal Short-Circuit

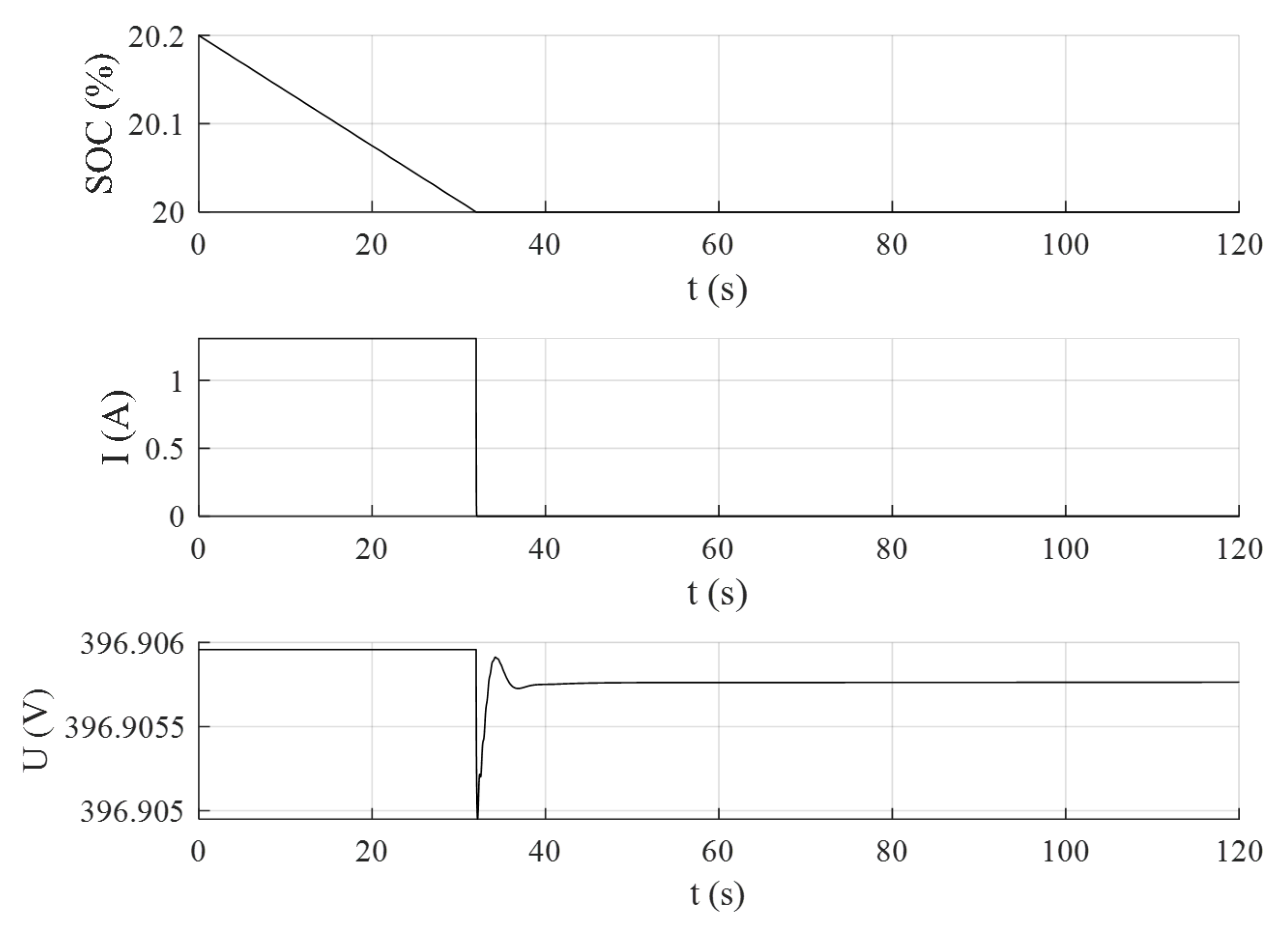

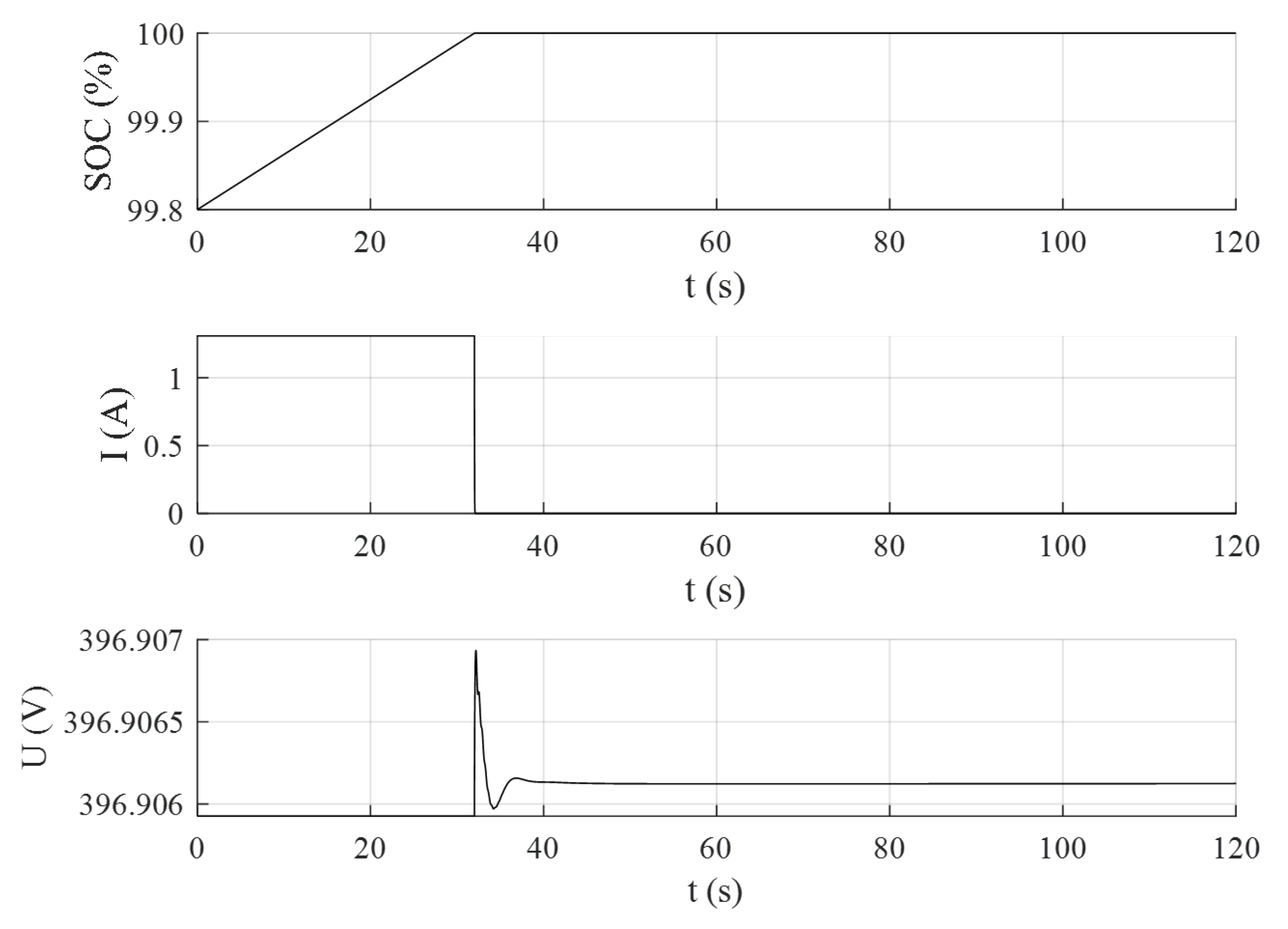

5.3. SOC limitations

6. Discussion

7. Conclusions

Author Contributions

Funding

Acknowledgments

Conflicts of Interest

References

- Bergen, M. Alphabet Wants to Fix Renewable Energy’s Storage Problem—With Salt; Bloomberg Quint: Mumbai, India, 2017. [Google Scholar]

- Cooper, J.J. Arizona Fire Highlights Challenges for Energy Storage; The Associated Press: New York, NY, USA, 2019. [Google Scholar]

- Frankel, T.C. Cobalt Mining for Lithium Ion Batteries Has a High Human Cost; The Washington Post: Washington, DC, USA, 2016. [Google Scholar]

- Pärnamäe, R.; Gurreri, L.; Post, J.; van Egmond, W.J.; Culcasi, A.; Saakes, M.; Cen, J.; Goosen, E.; Tamburini, A.; Vermaas, D.A.; et al. The Acid–Base Flow Battery: Sustainable Energy Storage via Reversible Water Dissociation with Bipolar Membranes. Membranes 2020, 10, 409. [Google Scholar] [CrossRef]

- Culcasi, A.; Gurreri, L.; Zaffora, A.; Cosenza, A.; Tamburini, A.; Micale, G. On the modelling of an Acid/Base Flow Battery: An innovative electrical energy storage device based on pH and salinity gradients. Appl. Energy 2020, 277, 115576. [Google Scholar] [CrossRef]

- Post, J.W.; Hamelers, H.V.M.; Buisman, C.J.N. Energy Recovery from Controlled Mixing Salt and Fresh Water with a Reverse Electrodialysis System. Environ. Sci. Technol. 2008, 42, 5785–5790. [Google Scholar] [CrossRef]

- Mei, Y.; Tang, C.Y. Recent developments and future perspectives of reverse electrodialysis technology: A review. Desalination 2018, 425, 156–174. [Google Scholar] [CrossRef]

- Al-Amshawee, S.; Yunus, M.Y.B.M.; Azoddein, A.A.M.; Hassell, D.G.; Dakhil, I.H.; Hasan, H.A. Electrodialysis desalination for water and wastewater: A review. Chem. Eng. J. 2020, 380, 122231. [Google Scholar] [CrossRef]

- Campione, A.; Gurreri, L.; Ciofalo, M.; Micale, G.; Tamburini, A.; Cipollina, A. Electrodialysis for water desalination: A critical assessment of recent developments on process fundamentals, models and applications. Desalination 2018, 434, 121–160. [Google Scholar] [CrossRef]

- Walther, J.F. Process for Production of Electrical Energy from the Neutralization of Acid and Base in a Bipolar Membrane Cell (U.S. Patent 4,311,771A); International Atomic Energy Agency (IAEA): Vienna, Austria, 1982. [Google Scholar]

- Pärnamäe, R.; Mareev, S.; Nikonenko, V.; Melnikov, S.; Sheldeshov, N.; Zabolotskii, V.; Hamelers, H.V.; Tedesco, M. Bipolar membranes: A review on principles, latest developments, and applications. J. Membr. Sci. 2021, 617, 118538. [Google Scholar] [CrossRef]

- Sáez, A.; Montiel, V.; Aldaz, A. An Acid-Base Electrochemical Flow Battery as energy storage system. Int. J. Hydrogen Energy 2016, 41, 17801–17806. [Google Scholar] [CrossRef]

- Emrén, A.T.; Holmström, V.J. Energy storage in a fuel cell with bipolar membranes burning acid and hydroxide. Energy 1983, 8, 277–282. [Google Scholar] [CrossRef]

- Pretz, J.; Staude, E. Reverse electrodialysis (RED) with bipolar membranes, an energy storage system. Berichte Bunsenges. Phys. Chem. 2010, 102, 676–685. [Google Scholar] [CrossRef]

- Zholkovskij, E.K.; Müller, M.C.; Staude, E. The storage battery with bipolar membranes. J. Membr. Sci. 1998, 141, 231–243. [Google Scholar] [CrossRef]

- Kim, J.H.; Lee, J.H.; Maurya, S.; Shin, S.H.; Lee, J.Y.; Chang, I.S.; Moon, S.H. Proof-of-concept experiments of an acid-base junction flow battery by reverse bipolar electrodialysis for an energy conversion system. Electrochem. Commun. 2016, 72, 157–161. [Google Scholar] [CrossRef]

- van Egmond, W.J.; Saakes, M.; Noor, I.; Porada, S.; Buisman, C.J.N.; Hamelers, H. Performance of an environmentally benign acid base flow battery at high energy density. Int. J. Energy Res. 2018, 42, 1524–1535. [Google Scholar] [CrossRef]

- Xia, J.; Eigenberger, G.; Strathmann, H.; Nieken, U. Acid-Base Flow Battery, Based on Reverse Electrodialysis with Bi-Polar Membranes: Stack Experiments. Processes 2020, 8, 99. [Google Scholar] [CrossRef]

- Veerman, J.; Post, J.W.; Saakes, M.; Metz, S.J.; Harmsen, G.J. Reducing power losses caused by ionic shortcut currents in reverse electrodialysis stacks by a validated model. J. Membr. Sci. 2008, 310, 418–430. [Google Scholar] [CrossRef]

- Tang, A.; McCann, J.; Bao, J.; Skyllas-Kazacos, M. Investigation of the effect of shunt current on battery efficiency and stack temperature in vanadium redox flow battery. J. Power Source 2013, 242, 349–356. [Google Scholar] [CrossRef]

- Culcasi, A.; Gurreri, L.; Zaffora, A.; Cosenza, A.; Tamburini, A.; Cipollina, A.; Micale, G. Ionic shortcut currents via manifolds in reverse electrodialysis stacks. Desalination 2020, 485, 114450. [Google Scholar] [CrossRef]

- Electric Power Research Institute. Quantifying the Value of Hydropower in the Electric Grid: Plant Cost Elements; Technical Report; Electric Power Research Institute: Washington, DC, USA, 2011. [Google Scholar]

- Das, C.K.; Bass, O.; Kothapalli, G.; Mahmoud, T.S.; Habibi, D. Overview of energy storage systems in distribution networks: Placement, sizing, operation, and power quality. Renew. Sustain. Energy Rev. 2018, 91, 1205–1230. [Google Scholar] [CrossRef]

- Sabihuddin, S.; Kiprakis, A.; Mueller, M. A Numerical and Graphical Review of Energy Storage Technologies. Energies 2014, 8, 172–216. [Google Scholar] [CrossRef]

- Few, S.; Schmidt, O.; Offer, G.J.; Brandon, N.; Nelson, J.; Gambhir, A. Prospective improvements in cost and cycle life of off-grid lithium-ion battery packs: An analysis informed by expert elicitations. Energy Policy 2018, 114, 578–590. [Google Scholar] [CrossRef]

- Stampatori, D.; Raimondi, P.P.; Noussan, M. Li-Ion Batteries: A Review of a Key Technology for Transport Decarbonization. Energies 2020, 13, 2638. [Google Scholar] [CrossRef]

- Horie, H. Future Lithium-ion Batteries. In Future Lithium-ion Batteries; Eftekhari, A., Ed.; Royal Society of Chemistry: London, UK, 2019; Chapter 7—Creatio; p. 367. [Google Scholar] [CrossRef]

- Mongird, K.; Fotedar, V.; Viswanathan, V.; Koritarov, V.; Balducci, P.; Hadjerioua, B.; Alam, J. Energy Storage Technology and Cost Characterization Report; Technical Report July; U.S. Department of Energy: Washington, DC, USA, 2019.

- Chen, J. Lithium-Ion Battery; Clean Energy Institute: Seattle, WA, USA, 2020. [Google Scholar]

- Belov, D.; Yang, M.H. Failure mechanism of Li-ion battery at overcharge conditions. J. Solid State Electrochem. 2008, 12, 885–894. [Google Scholar] [CrossRef]

- Doughty, D.; Roth, E.P. A general discussion of Li Ion battery safety. Electrochem. Soc. Interface 2012, 21, 37–44. [Google Scholar] [CrossRef]

- Normyle, A.; Pittock, J. A review of the impacts of pumped hydro energy storage construction on subalpine and alpine biodiversity: Lessons for the Snowy Mountains pumped hydro expansion project. Aust. Geogr. 2020, 51, 53–68. [Google Scholar] [CrossRef]

- Kobler, U.G.; Wüest, A.; Schmid, M. Effects of lake-reservoir pumped-storage operations on temperature and water quality. Sustainability 2018, 10, 1968. [Google Scholar] [CrossRef]

- Liu, W.; Ramirez, A. State of the art review of the environmental assessment and risks of underground geo-energy resources exploitation. Renew. Sustain. Energy Rev. 2017, 76, 628–644. [Google Scholar] [CrossRef]

- Deng, D. Li-ion batteries: Basics, progress, and challenges. Energy Sci. Eng. 2015, 3, 385–418. [Google Scholar] [CrossRef]

- Perry, M.L.; Saraidaridis, J.D.; Darling, R.M. Crossover mitigation strategies for redox-flow batteries. Curr. Opin. Electrochem. 2020, 21, 311–318. [Google Scholar] [CrossRef]

- Aneke, M.; Wang, M. Energy storage technologies and real life applications—A state of the art review. Appl. Energy 2016, 179, 350–377. [Google Scholar] [CrossRef]

- Scarabaggio, P.; Carli, R.; Cavone, G.; Dotoli, M. Smart control strategies for primary frequency regulation through electric vehicles: A battery degradation perspective. Energies 2020, 13, 4586. [Google Scholar] [CrossRef]

- Maheshwari, A.; Paterakis, N.G.; Santarelli, M.; Gibescu, M. Optimizing the operation of energy storage using a non-linear lithium-ion battery degradation model. Appl. Energy 2020, 261, 114360. [Google Scholar] [CrossRef]

- Toma, L.; Sanduleac, M.; Baltac, S.A.; Arrigo, F.; Mazza, A.; Bompard, E.; Musa, A.; Monti, A. On the virtual inertia provision by BESS in low inertia power systems. In Proceedings of the 2018 IEEE International Energy Conference, ENERGYCON 2018, Limassol, Cyprus, 3–7 June 2018; pp. 1–6. [Google Scholar] [CrossRef]

- Behabtu, H.A.; Messagie, M.; Coosemans, T.; Berecibar, M.; Fante, K.A.; Kebede, A.A.; Van Mierlo, J. A review of energy storage technologies’ application potentials in renewable energy sources grid integration. Sustainability 2020, 12, 10511. [Google Scholar] [CrossRef]

- Rohit, A.K.; Rangnekar, S. An overview of energy storage and its importance in Indian renewable energy sector: Part II—Energy storage applications, benefits and market potential. J. Energy Storage 2017, 13, 447–456. [Google Scholar] [CrossRef]

- Smart Grid Coordination Group. Smart Grids Methodology and New Applications; Technical Report; CEN-CENELEC-ETS: Brussels, Belgium, 2014. [Google Scholar]

- Uslar, M.; Delfs, C.; Gottschalk, M. The Use Case and Smart Grid Architecture Model Approach; Springer: Berlin, Germany, 2017; pp. 41–61. ISBN 978-3319492285. [Google Scholar]

- Santodomingo, R.; Uslar, M.; Göring, A.; Gottschalk, M.; Nordstrom, L.; Saleem, A.; Chenine, M. SGAM-based methodology to analyse Smart Grid solutions in DISCERN European research project. In Proceedings of the ENERGYCON 2014—IEEE International Energy Conference, Cavtat, Croatia, 13–16 May 2014; pp. 751–758. [Google Scholar] [CrossRef]

- Andrén, F.P.; Strasser, T.; Kastner, W. Applying the SGAM methodology for rapid prototyping of smart Grid applications. In Proceedings of the IECON 2016—42nd Annual Conference of the IEEE Industrial Electronics Society, Florence, Italy, 23–26 October 2016; pp. 3812–3818. [Google Scholar] [CrossRef]

- Wilker, S.; Meisel, M.; Sauter, T. Smart grid architecture model standardization and the applicability of domain language specific modeling tools. In Proceedings of the 2017 IEEE 26th International Symposium on Industrial Electronics (ISIE), Edinburgh, UK, 19–21 June 2017; pp. 152–157. [Google Scholar] [CrossRef]

- Liu, J.; Zhang, N.; Kang, C.; Kirschen, D.; Xia, Q. Cloud energy storage for residential and small commercial consumers: A business case study. Appl. Energy 2017, 188, 226–236. [Google Scholar] [CrossRef]

- Malhotra, A.; Battke, B.; Beuse, M.; Stephan, A.; Schmidt, T. Use cases for stationary battery technologies: A review of the literature and existing projects. Renew. Sustain. Energy Rev. 2016, 56, 705–721. [Google Scholar] [CrossRef]

- Ballestín-Fuertes, J.; Muñoz-Cruzado-alba, J.; Sanz-Osorio, J.F.; Laporta-Puyal, E. Role of wide bandgap materials in power electronics for smart grids applications. Electronics 2021, 10, 677. [Google Scholar] [CrossRef]

- Cochran, J.; Miller, M.; Zinaman, O.; Milligan, M.; Arent, D.; Palmintier, B.; O’Malley, M.; Mueller, S.; Lannoye, E.; Tuohy, A.; et al. Flexibility in 21st Century Power Systems; Technical Report; NREL: Golden, CO, USA, 2014. [CrossRef]

- Akrami, A.; Doostizadeh, M.; Aminifar, F. Power system flexibility: An overview of emergence to evolution. J. Mod. Power Syst. Clean Energy 2019, 7, 987–1007. [Google Scholar] [CrossRef]

- Sperstad, I.B.; Korpås, M. Energy storage scheduling in distribution systems considering wind and photovoltaic generation uncertainties. Energies 2019, 12, 1231. [Google Scholar] [CrossRef]

- Scarabaggio, P.; Grammatico, S.; Carli, R.; Dotoli, M. Distributed Demand Side Management with Stochastic Wind Power Forecasting. IEEE Trans. Control. Syst. Technol. 2021. [Google Scholar] [CrossRef]

- van Westering, W.; Hellendoorn, H. Low voltage power grid congestion reduction using a community battery: Design principles, control and experimental validation. Int. J. Electr. Power Energy Syst. 2020, 114, 105349. [Google Scholar] [CrossRef]

- Agbonaye, O.; Keatley, P.; Huang, Y.; Bani Mustafa, M.; Hewitt, N. Design, Valuation and Comparison of Demand Response Strategies for Congestion Management. Energies 2020, 13, 6085. [Google Scholar] [CrossRef]

- Pavić, I.; Luburić, Z.; Pandžić, H.; Capuder, T.; Andročec, I. Defining and evaluating use cases for battery energy storage investments: Case study in Croatia. Energies 2019, 12, 376. [Google Scholar] [CrossRef]

- Muñoz-Cruzado-Alba, J.; Rojas, C.A.; Kouro, S.; Díez, E.G. Power production losses study by frequency regulation in weak-grid-connected utility-scale photovoltaic plants. Energies 2016, 9, 317. [Google Scholar] [CrossRef]

- International Renewable Energy Agency. Utility-Scale Batteries Innovation Landscape Brief; IRENA: Abu Dhabi, United Arab Emirates, 2019. [Google Scholar]

- Torres, J.; Blanco, M.; Lafoz, M.; Navarro, G.; Nájera, J.; Santos-Herran, M. Dimensioning methodology of energy storage systems for power smoothing in a wave energy conversion plant considering efficiency maps and filtering control techniques. Energies 2020, 13, 3380. [Google Scholar] [CrossRef]

- Daud, M.Z.; Mohamed, A.; Hannan, M.A. A review of the integration of energy storage systems (ESS) for utility grid support. Prz. Elektrotechniczny 2012, 88, 185–191. [Google Scholar]

- Chang, L.; Zhang, W.; Xu, S.; Spence, K. Review on Distributed Energy Storage Systems for Utility Applications. CPSS Trans. Power Electron. Appl. 2017, 2, 267–276. [Google Scholar] [CrossRef]

- General Electric. GE Energy Storage Unit RSU-4000; Technical Report January; General Electric: Boston, MA, USA, 2020. [Google Scholar]

- Megapack|Tesla. Available online: https://www.tesla.com/megapack (accessed on 5 April 2021).

- Utility ESS—BYD USA. Available online: https://en.byd.com/energy/utility-ess/ (accessed on 5 April 2021).

- Vanadium Flow Battery Energy Storage|Invinity. Available online: https://invinity.com/solutions/vanadium-flow-batteries/ (accessed on 2 April 2021).

- Redox Flow Battery|Sumitomo Electric Industries. Available online: https://sumitomoelectric.com/products/redox (accessed on 7 April 2021).

- Energy, S.; Inverter, S. GE Energy Storage Reservoir Inverter Unit; Technical Report; General Electric: Boston, MA, USA, 2021. [Google Scholar]

- Lotspeich, C. A Comparative Assessment of Flow Battery Technologies. In Proceedings of the 2002 EESAT Conference, San Francisco, CA, USA, 15–17 April 2002; pp. 1–6. [Google Scholar]

- Bryans, D.; Amstutz, V.; Girault, H.H.; Berlouis, L.E. Characterisation of a 200 kw/400 kwh vanadium redox flow battery. Batteries 2018, 4, 54. [Google Scholar] [CrossRef]

- Tokuda, N.; Kanno, T.; Hara, T.; Shigematsu, T.; Tsutsui, Y.; Ikeuchi, A.; Itou, T.; Kumamoto, T. Development of a redox flow battery system. SEI Tech. Rev. 2000, 50, 88–94. [Google Scholar]

- Marra, F.; Yang, G.; Træholt, C.; Østergaard, J.; Larsen, E. A decentralized storage strategy for residential feeders with photovoltaics. IEEE Trans. Smart Grid 2014, 5, 974–981. [Google Scholar] [CrossRef]

- Solar Battery Storage: Including Tesla Powerwall, LG Chem, Powervault. Available online: https://nakedsolar.co.uk/storage/ (accessed on 2 April 2021).

- International Electrotechnical Commission. IEC 60038: IEC Standard Voltages; Technical Report; IEC: Geneva, Switzerland, 2002. [Google Scholar]

- Technology|BAoBaB. Available online: http://www.baobabproject.eu/technology (accessed on 26 June 2020).

| ESS | Power Range (MW) | Energy Density (Wh/L) | Power Density (W/L) | Round Trip eff. (%) | Response Time (ms-h) | Lifetime (year) | Daily Self-Discharge (%) | Tech. Maturity | CAPEX (EUR/kW) | CAPEX (EUR/kWh) | Environ. Impact |

|---|---|---|---|---|---|---|---|---|---|---|---|

| PHS | 10–5000 | 0.5–1.5 | 0.5–1.5 | 70–85 | min | 40–60 | ≃0.0 | Full dev. | 1–3 k | 5–100 | High/ Med. |

| FES | 0–0.25 | 20–80 | 1–2 k | 90–95 | s | 15 | 24–100 | Mature | 250–350 | 1–5 k | Very low |

| CAES | 5–500 | 3–6 | 0.5–2 | 70–90 | min | 20–40 | ≃0.0 | Proven | 400–800 | 2–120 | Med./ Low |

| Pb-A | 0–30 | 50–80 | 10–400 | 70–90 | 10 ms | 3–15 | 0.1–1.1 | Full dev. | 300–600 | 200–400 | High |

| Ni-Cd | 0–30 | 60–150 | 150–300 | 60–90 | 20 ms | 10–20 | 0.1–0.7 | Full dev. | 0.5–2 k | 0.8–2 k | High |

| Na-S | 0–3 | 150–250 | 150–230 | 80–90 | 1 ms | 10–15 | 20 | Proven | 1–3 k | 300–500 | High |

| NaNiCl2 | 0–3 | 150–180 | 220–300 | 85–90 | <s | 10–14 | 12–26 | Proven | 150–300 | 100–200 | Med./ Low |

| Li-ion | 0–100 | 200–500 | 0.5–2 k | 85–100 | 20 ms | 5–15 | 0.1–0.3 | Proven | 0.9–4 k | 0.6–3 k | Med./ Low |

| VRFB | 0.3–3 | 20–70 | 0.5–2 | 75–90 | s | 5–10 | small | Proven | 0.6–2 k | 0.2–1 k | Med./ Low |

| SCES | 0–0.3 | 2.5–15 | 0.5–5 k | 90–100 | 8 ms | 20 | 0.5–40 | Proven | 100–480 | 0.3–2 k | Very Low |

| SMES | 0.1–10 | 0.2–2.5 | 1–4 k | 95–100 | <100 ms | 20 | 1–15 | Proven | 200–490 | 1–10 k | Low |

| ABFB | 0.01–0.5 | 7 | 17 W/m2 (*) | 55.9 | s | 10 | small | Pilot | 1520 | 50 | Very Low |

| Zone | Representation |

|---|---|

| Process | Represents the transformation of energy (physical, spatial and chemical) and the physical equipment that is directly involved, such as PV panels, generators, transformers and cables. |

| Field | Incorporates the equipment that is required to collect, control, monitor or protect the process of the power system, such as sensors, controllers and smart devices. |

| Station | Denotes the aggregated level of the field zone, such as a local Supervisory Control and Data Acquisition (SCADA) system. |

| Operation | Provides power system control operations in the respective domain, e.g., an energy management system (EMS) in generation and transmission systems. |

| Enterprise | Includes commercial and organizational processes, services and infrastructures for enterprises, e.g., asset management, logistic, customer relation management, billing and procurement. |

| Market | Indicates potential market operations along the energy conversion chain, such as energy trading or ancillary services. |

| Scope and Objectives of Use-Case 1 | |

|---|---|

| Scope | There is a growing trend for installation of rooftop PV. Supplementary to this, installing an ESS allows the user to store excess energy generated from the PV panels for times of higher demand or lower generation, thus reducing their reliance on the grid and subsequently reducing their electricity bills. Further value can be provided to the user by promoting the localized trading of energy via a centralized ESS. |

| Objectives |

|

| Scope and Objectives of Use-Case 2 | |

|---|---|

| Scope | Strategic deployment of ESS at distribution level and close to locations with high load demand, such as residential areas, can reduce congestion at weak points in the network and adds flexibility to the grid. Network support functionality allows for increased penetration of renewables without compromising grid stability. |

| Objectives |

|

| Scope and Objectives of Use-Case 3 | |

|---|---|

| Scope | The intermittent nature of renewables is an obstacle to the provision of a reliable baseload to the grid. Furthermore, seasonal variations in generation means that excess energy is often wasted at one point of the year while generation falls short at another time of the year. A cheap, large-scale ESS solution can store energy during times of excess generation and provide a buffer during times where generation falls short of demand. |

| Objectives |

|

| Utility-Scale Storage System | Technology | Charge/ Discharge (kW) | Storage Capacity (kWh) |

|---|---|---|---|

| GE RSU-4000 [63] | Li-ion | 1300 | 4184 |

| Tesla Powerpack [64] | Li-ion | 1264.5 | 2529 |

| BYD Utility ESS [65] | Li-ion | 1000 | 1000 |

| Invinity VS3-022 [66] | VRFB | 78 | 220 |

| Sumimoto 250 kW-6 h [67] | VRFB | 250 | 1500 |

| Residential Battery Storage System | Charge/ Discharge (kW) | Storage Capacity (kWh) | Useable Capacity (kWh) |

|---|---|---|---|

| Tesla Powerwall | 5 | 13.5 | 13.5 |

| SolarEdge LG Chem RESU 10 | 5 | 9.8 | 9.3 |

| Puredrive Energy Storage 9.6 kWh | 3.6/4.2 | 9.6 | 8.8 |

| Powervault 3–12.3 kWh | 3.3/5.5 | 12.3 | 12.3 |

| Powervault 3–8.2 kWh | 3.3/5.5 | 8.2 | 8.2 |

| Sonnen 9.43–15 kWh | 3.3 | 15 | 13.5 |

| Sonnen 9.43–7.5 kWh | 3.3 | 7.5 | 6.75 |

| Alpha Smile 14.5 kWh | 3 | 14.5 | 13.92 |

| Solis/BYD 7 kWh | 3 | 7 | 5.6 |

| Puredrive Energy/Solis Hybrid 5 kWh | 3 | 4.8 | 4.4 |

| Moixa 4.8 kWh | 2.4 | 4.8 | 3.84 |

| Varta Pulse 6 | 2.3/2.5 | 6.5 | 5.9 |

| Solax Hybrid X1 Triplepower 6.3 kWh | 1.7 | 6.3 | 5.67 |

| ABFB Stack Parameters | |||

|---|---|---|---|

| Use-case | 1 | 2 | 3 |

| Number of ABFB cells in series | 240 | 240 | 310 |

| Number of ABFB stacks in parallel | 2 | 6 | 205 |

| Minimum operating voltage | 96 V | 96 V | 124 V |

| Maximum operating voltage | 384 V | 384 V | 496 V |

| RESET voltage | 792 V | 792 V | 1023 V |

| Charge current | 12 A | 36 A | 1230 A |

| Discharge current | −16 A | −48 A | −1640 A |

| Rated power | 12.7 kW | 38 kW | 1678 kW |

| Maximum output power | 4.6 kW | 13.8 kW | 610.1 kW |

| BAoBAB Prototype | ||

|---|---|---|

| Parameter | Value | Units |

| Rated power | 1 | kW |

| Minimum state of charge | 20 | % |

| Maximum state of charge | 100 | % |

| Maximum power rate limit | 1 | pu/s |

| Minimum power rate limit | −1 | pu/s |

| Control mode of active power | open-loop | - |

| Control mode of reactive power | close-loop | - |

| Active power control time constant | 0.01 | s |

| Reactive power control proportional gain | 1 | pu |

| Reactive power control integral gain | 10 | pu |

| Terminal voltage control proportional gain | 2 | pu |

| Terminal voltage control integral gain | 0 | pu |

| Converter time constant | 0.01 | s |

| Converter PLL bandwidth | 30 | rad/s |

| Pantelleria Power Grid | ||

| Power plant rated capacity | 20 | MW |

| Power plant inertia constant | 2 | s |

| Power plant frequency droop | 5 | % |

| Length range of medium voltage feeders | 4–14 | km |

| Resistance range of medium voltage feeders | 0.33–0.47 | Ω /km |

| Reactance range of medium voltage feeders | 0.23–0.31 | Ω /km |

| Capacitance range of medium voltage feeders | 0.1–0.24 | μF/km |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Muñoz-Cruzado-Alba, J.; Musca, R.; Ballestín-Fuertes, J.; Sanz-Osorio, J.F.; Rivas-Ascaso, D.M.; Jones, M.P.; Catania, A.; Goosen, E. Power Grid Integration and Use-Case Study of Acid-Base Flow Battery Technology. Sustainability 2021, 13, 6089. https://doi.org/10.3390/su13116089

Muñoz-Cruzado-Alba J, Musca R, Ballestín-Fuertes J, Sanz-Osorio JF, Rivas-Ascaso DM, Jones MP, Catania A, Goosen E. Power Grid Integration and Use-Case Study of Acid-Base Flow Battery Technology. Sustainability. 2021; 13(11):6089. https://doi.org/10.3390/su13116089

Chicago/Turabian StyleMuñoz-Cruzado-Alba, Jesús, Rossano Musca, Javier Ballestín-Fuertes, José F. Sanz-Osorio, David Miguel Rivas-Ascaso, Michael P. Jones, Angelo Catania, and Emil Goosen. 2021. "Power Grid Integration and Use-Case Study of Acid-Base Flow Battery Technology" Sustainability 13, no. 11: 6089. https://doi.org/10.3390/su13116089

APA StyleMuñoz-Cruzado-Alba, J., Musca, R., Ballestín-Fuertes, J., Sanz-Osorio, J. F., Rivas-Ascaso, D. M., Jones, M. P., Catania, A., & Goosen, E. (2021). Power Grid Integration and Use-Case Study of Acid-Base Flow Battery Technology. Sustainability, 13(11), 6089. https://doi.org/10.3390/su13116089