1. Introduction

Designing and selecting air conditioning systems involves many factors to be considered and these factors differ depending on the type of application. The primary goal in designing air conditioning systems is to provide thermal comfort with good indoor air quality while ensuring low energy consumption [

1]. In a study published by the U.S. Department of Energy [

2], it is mentioned that the buildings sector accounts for about 76% of the overall electricity consumption in the U.S. From this, the major energy consumption in these buildings is for heating, ventilating, and air conditioning, which accounts for 35% of the total building energy [

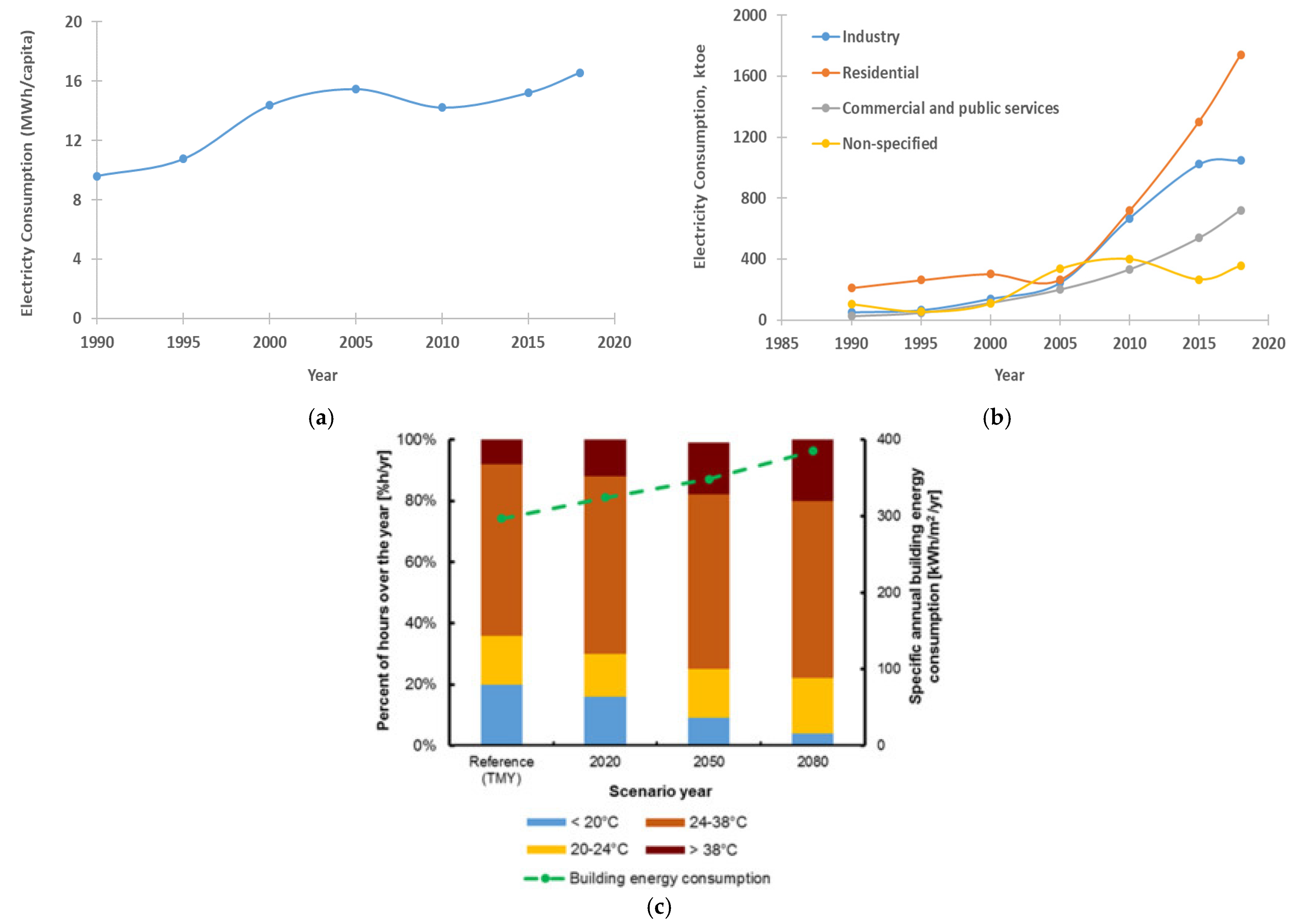

2]. In arid countries, such as those in the Gulf Cooperation Council (GCC), most of the energy in the building (commercial and residential) is used for cooling due to the extreme high temperature climate during summer, which typically lasts around 8 months. Typical temperatures in the summer are in the high 40 °Cs to low 50 °Cs. Besides this, in the last two decades, countries in the GCC such as Qatar are experiencing a large expansion of commercial and residential buildings due to an increase in population and economic activities. This increases the electrical energy consumption per capita are shown in

Figure 1 and reported in the literature [

3]. In Qatar, the air conditioning accounts for around 60–70% of Qatar’s total electricity demand [

4]. In view of the high demand for electricity for cooling, it is important to increase the efficiency of building systems and technologies in order to reduce the overall demand for energy [

2]. It is essential to select the most appropriate air conditioning system so that it can be used efficiently during its life cycle, keeping in mind that the energy sources are becoming scarcer around the world. One of the approaches that is worth considering is the usage of variable refrigerant flow systems (VRF) [

5].

The indoor units of the air conditioning system in Qatar consists of constant air volume (CAV) and variable air volume (VAV). In CAV, the machine supplies the same quantity of air to the conditioned area (single-zone application), whereas in VAV, the tenants can control the temperature inside the room by reducing or increasing the air volume accordingly (multi-zone application where there are constant changing loads). Both systems can be used in ducted units and in package units and both systems are used in commercial and residential buildings in Qatar. The current work in this paper is looking from the refrigerant side of the cooling system, thus comparing the constant refrigerant flow (CRF) unit against the variable refrigerant flow (VRF) unit.

The VRF system can be best explained by using

Figure 2. The system consists of multiple indoor units (IU), an outdoor unit (OU), and a variable speed controller. The electronic expansion valve (EEV) controls the mass flow rate in each of the indoor units. The electronic expansion valve (EEV) plays an important role in regulating the refrigerant flow rate through the heat exchanger of the indoor unit, while the inverter-driven variable speed compressors allow for a larger modulation capacity considering part load factors in the VRF systems. The VRF system allows each IU to be controlled independently and does not lose too much energy through ductwork like conventional systems [

5]. Such VRF systems have been used widely in Japan since the 1980s and in the U.S. since 2002 [

5]. An initial review on VRF systems was done by Aynur [

6], who looked at the VRF system from the experimental and modeling perspective. It was reported that the VRF system has a high initial cost compared to the common air conditioning systems; however, due to the energy saving potential, the estimated payback period of the VRF system compared to conventional chiller system in a generic commercial building could be about 1.5 years. In another study, Patel et al. [

7] reported that VRF could fetch energy savings between 10% and 40%. Regarding VRF system responsiveness, Herdendez [

8] reported that responsiveness and sensitivity are related to the quantity of indoor evaporators that are connected to the system. A lot of other works have been done with the VRF system in terms of the system architecture [

9,

10,

11], modeling and simulation [

12,

13,

14,

15,

16,

17,

18], and experimental work and field testing [

6,

19,

20,

21,

22,

23]. The work surrounding VRF system architecture has looked at performance improvement and integrated system design. It was found that one of the significant benefits of this system is its flexibility. Future work on VRF architecture needs to focus on efficient ventilation methods. In the area of modeling and simulation, research areas are centered on steady state and transient models, as well as empirical and component-based modeling. It was found that there is a need for more user-friendly dynamic models that are easy to be implemented, focusing on empirical dynamic models as the way forward. There is also a need to standardize the different simulation tools being used. Most of the experimental testing using VRF was conducted in Asia and was focusing on the cooling mode. This is because of the hot and humid weather in most of these Asian countries where the studies were conducted. There is still room to evaluate physical performance of VRF in terms of system stability and defrosting.

Most of the reported work pertaining to VRF is done in Asia (Japan and China in particular), Europe, and the U.S. To the best of authors knowledge, not much work in terms of VRF systems has been conducted in arid regions such as the GCC countries. In such hot climates, a lot of energy is consumed from conventional air conditioning systems and the usage of the latest technology is important to reduce the energy demand for cooling [

24,

25,

26]. In view of this, and as an initial step in this direction, the objective of this study is to prove the economic feasibility of the VRF system over the conventional system in cooling mode only, especially for the countries with hot climates such as Qatar. The cooling process is very crucial for such countries while the heating demand is negligible. The paper is organized as follows: In

Section 2, the current case is discussed in detail. The building characteristics are listed and the conventional CRF system using traditional ducted units is explained. Then, the VRF technology is explained, and a VRF system is modeled to the existing office building while the same indoor units’ capacities are kept, so that the results remain accurate while comparing the energy consumption of the condensers between both systems. In

Section 3, the discussion and the results are provided. In the final section, the conclusive remarks are stated.

2. Materials and Methods

For the purpose of conducting a comprehensive life cycle cost analysis based on CRF and VRF, an existing building in Qatar was selected. The name of the building is Al Muftah Plaza located in the city of Doha (

Figure 3). This building has two basements, a ground floor and five floors above ground. The total built up area is 18,102 m

2 while the rentable area is 10,715 m

2. The ground floor consists of two car showrooms covering an area of 1475 m

2, while the upper floors consist of four offices each with an area of 1802 m

2. The height of the ground floor is 3.5 m from the finished floor level to the false ceiling level and 1.1 m from the false ceiling level to the upper slab level. In the five upper floors, the height is 3.2 m between the two slabs, out of which 0.5 m is between the false ceiling and the upper slab. The two basements provide a parking space for 125 cars without any cooling services except for the elevator lobbies, which are served by independent split units. The most widely used air conditioning system in commercial and residential buildings (below 10 floors) in Qatar is the traditional ducted unit system, which connects one outdoor unit to one indoor ducted unit.

The operating principal of this air conditioning system is very simple, as shown in

Figure 4. To cool the air inside a room, the compressor sucks low-temperature and low-pressure refrigerant gas, and with the help of a heat exchanger and a fan, it discharges high-temperature and high-pressure gas into the surrounding outdoor area and becomes high-pressure refrigerant liquid after transferring the latent heat. Then, a throttling element, usually an expansion valve, changes the high-pressure refrigerant liquid into low-temperature and low-pressure liquid and goes into the indoor heat exchanger. The internal fan helps the liquid evaporates and transforms into low-temperature and low-pressure refrigerant gas. The cycle continues to operate as long as there is a cooling demand. In this traditional system, there is a constant flow of refrigerant. It is an “on” and “off” mechanism so that when the compressor is performing its job, the entire refrigerant quantity is used in the process, whether the load is big or small, as long as there is a temperature difference and a need for cooling.

The VRF system allows us to connect multiple indoor units to a single outdoor unit or multiple ones if needed. The indoor units can vary between split, cassette, ducted, and other type of equipment [

6]. In general, there are two piping configurations in a VRF system: the two-way and the three-way configuration. For this case study model, the cooling mode using only the two-way piping was studied, because the other configuration is generally used when there is a need for cooling and heating at the same time (

Figure 5).

In the model used here, a VRF system for each office is considered. It comprises outdoor units depending on the total cooling capacity needed and indoor units as per the office layout. The total cooling system of one system cannot exceed 50 tons of refrigeration (TR) as per the manufacturer’s catalog. Two dedicated systems for all the common areas, such as corridors and elevator lobbies, were designed. Ducted indoor units were selected equal to CRF in order to focus the analysis on comparing the CRF and VRF outdoor units particularly in terms of energy savings, and generally in terms of life cycle cost analysis. In the following sections and after conducting a detailed heat load analysis, all the VRF system components were selected in detail. In this study, the ASHRAE Transfer Function Method (TFM) [

27,

28] was used for the calculation of the cooling load by using the well-known Hourly Analysis Program (HAP 4.9) [

29,

30,

31] by Carrier (Carrier, Palm Beach Gardens, FL, USA), a company that provides solutions for air conditioning. The TFM method is a derivative of the Heat Balance Method and can predict the hourly cooling load of Al Muftah Plaza building. The heat transfer coefficients used in our study are listed in

Table 1. For the cooling load estimation, it was assumed that the ‘design day’ is when there is relatively high humidity, little or no haze, and all internal loads are at their peak, which corresponds to the month of July. The HAP software utilizes the following input data before running the simulation: (1) climate data surrounding the building of interest; (2) information on the building material, such as that shown in

Table 1; (3) the orientation of the building; (4) interior heat gain characteristics; (5) data on the HVAC system; (6) electricity tariff and energy source.