Abstract

According to recent literature in the field of sustainability, the circular economy (CE) appears to be a thriving opportunity for creating new businesses, although less attention has been paid to the form in which its principles fit into a comprehensive framework that enables companies to design it in a practical way. This paper presents the methodology that has been adopted to pave the way to a coherent reference framework for circular business model innovation and its outstanding design and implementation, taking into consideration the entire value and supply chain. A unique analysis of recent innovations in circular economy models is provided herein, together with an exhaustive analysis of those elements that enable or hinder their implementation. The main interactions among all those critical elements influencing how organisations innovate and operate cooperatively within a CE ecosystem are also evaluated. In addition, a study of five industrial cases in the pulp and paper industry allowed searching for industrial insights and empirical evidence of the relevance of those elements, including observation, document analysis, and interviews. Lastly, the main outcomes of this research are illustrated using the CE reference framework designed when applied to the aforementioned industrial cases, and relevant insights into future improvements are also provided.

1. Introduction

The circular economy concept has evolved since the late 1960s to focus on practical applications in modern economic systems and industrial processes [1]. The expansion of this field is attributed to the increasing number of significant research reports and prestigious schools of thought, such as the performance economy, cradle-to-cradle, cleaner production, closed-loop economy, industrial ecology, and sustainability. One of the main areas of research in the circular economy research field concerns the transition from linear (“take, make, use, and waste”) to circular economy models, which appears to be an essential solution to avoid the increasing use of finite resources and the growing amount of waste. Moreover, the advantages that such a transition could offer companies when looking to sustain a competitive advantage is becoming more and more relevant in terms of business model innovation. To replace existing business models or even to seize new ones would guarantee such a transition for these companies, which could even take advantage of “the impending technology revolution to create 0.9 trillion EUR more than in the current linear development path” [2].

Many scholars and practitioners in the sustainability research field have noted that the circular economy has emerged as a consequence of companies going beyond placing sustainability at the core of their company’s business strategy [3,4]. In addition, the focus has turned towards the development of business cases for sustainability [5,6,7], searching for the positive impact of embedded sustainability efforts on business performance. Several conceptualising frameworks have been designed and made available to assist companies in creating effective and sustainable circular models. However, the form in which their principles fit the creation of new circular business models for companies is still incomplete. Thus, although several case studies representing successful circular business actions or models can be found, these models have limited transferability. As such, a comprehensive framework that assists companies with the practical design of new circular business models seems not to have been developed to date [8].

In line with the above, some scholars in the business model innovation literature have designed well-known conceptual frameworks for creating circular business models (e.g., [8,9,10,11]) and, as Lewandowski (2016) asserted, existing conceptual frameworks are often based on the ReSOLVE model, developed by the Ellen MacArthur Foundation [8]. Although researchers and practitioners have taken various routes in their attempts to describe and propose an approach to circular business model innovation, the transition towards circularity requires deep modifications that go beyond eco-design, green design, or business model innovation. A systemic approach that takes into account the different parts of the ecosystem (i.e., internal and external) that constitute the CEM, as well as their interactions, is still lacking in the field. As a result of this research, the development of a comprehensive and industry-applied reference framework, its supporting constituents for the creation, and the effective operability of a circular economy model were sought.

This paper presents a review and analysis of recent developments in reference frameworks, methods, or guidelines published by researchers and practitioners in the circular economy research field. It also investigates the set of critical elements that influence the success of circular economy models, initially from a theoretical perspective, following an exhaustive literature review, and secondly, using an empirical approach based on the characterisation of five industrial circular case studies. On the basis of this analysis, a reference framework to assist companies in their circular business model innovation strategies in an industrial resource recovery scenario is established. However, this approach can easily be adapted to other CE strategies since it provides a structure that supports firms (or systems) in producing innovative and value-added solutions from a collaborative perspective and considering the entire value chain.

The structure of the paper follows the sequence of research, which begins with a description of the research approach in Section 2. The literature review process is described in Section 3, including a brief background of existing strategies in the circular economy field, as well as current frameworks for circular business model innovation and a comprehensive literature review undertaken to identify those elements that enable or hinder the design, implementation, and success of a circular economy model. The role of each critical element in the complex circular economy model or interlinked system is analysed and described in Section 4. The results of a qualitative study based on the use of system dynamics modelling techniques, which allows discovering the main interactions, are explained in detail. Section 5 provides the results and analysis of five industrial case studies undertaken to search for empirical evidence of the critical elements constituting the reference model and their building blocks in an industrial resource recovery scenario. An overall analysis of the research that has been conducted to move towards a holistic reference framework for practical implementation of circular economy models is provided in Section 6, followed by discussion Section 7 and relevant conclusions drawn from the research presented in Section 8.

2. Research Approach

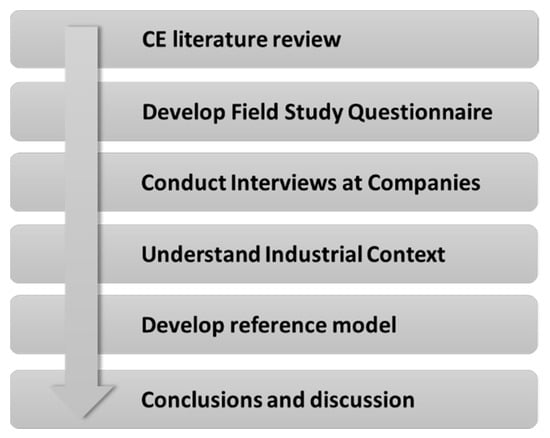

This study endeavoured to analyse previous reference frameworks developed to assist companies in the design and implementation of circular economy models, to understand the variety of their components, and to identify recent research trends in the circular economy field. These approaches were classified in order to provide an overview of the research area and to identify research gaps that allow discovering challenging improvements in the field. Figure 1 depicts the research approach utilised in this study.

Figure 1.

Research approach scheme.

The research activities were structured to address the key challenges described below. To determine the critical elements, sufficiently representative of the whole system) by either enabling success in the transition towards a circular economy or constraining the operational and/or strategic processes of a circular economy model, two steps were carried out. First, derived from circular economy literature, a thorough search (including both large databases of peer-reviewed literature, such as Scopus or Science Direct, and relevant consultancy reports in the field) was performed to understand the global spectrum of circular economy strategies and identify successful case studies. Secondly, with the focus on business model innovation, a comprehensive literature review was conducted on the basis of three main theoretical perspectives: existing schemes for the design of circular economy models (CEM), circular business innovation (CBMI), and business models for sustainability (BMfS). These activities provided a wide variety of theoretical evidence regarding those critical elements meriting further consideration as key processes, activities, skills, or strategic goals for the reference framework. Additionally, with the aim of discovering the role of each critical element in the complex system that a circular economy model embodies, a systemic approach that provided a sound awareness of the interactions of the critical elements identified in the previous stage was followed.

The second research challenge involved obtaining a preliminary characterisation of the five industrial cases considered in this study. The entire value chain in each industrial symbiosis scenario was considered to identify those critical elements that might have a relevant influence on the success of the circular economy models. A structured field study questionnaire was developed and used to guide the explorative study of five circular case studies aimed at searching for evidence during implementation of the CEM. The participants in those case studies, which were the five demo cases of the paperChain project from different sectors (construction, transport infrastructure, chemical, and mining), collaborated by way of interviews and workshops, thus providing information that allowed developing a global understanding of the context. The purpose of these activities was to understand the enablers and roadblocks encountered when creating and implementing a circular economy model in resource recovery or industrial symbiosis scenarios. This interaction with industry is an essential part of the action research methodology that was employed, wherein researchers apply a collaborative approach with companies and plan to play an active role in the implementation of theory and analyse the impact of their research.

An analysis of the results from these activities helped obtain a clearer understanding of circular economy models that could be operationalised and, as a result, allowed the framing of the main building blocks for the reference framework.

3. The Foundation of Innovation in Circular Economy Models

The notion of circular economy embraces several concepts, such as the performance economy, cradle-to-cradle, or industrial ecology. The main idea behind the circular economy is to shift from a “take, make, use, and waste” linear model to closed materials loops in which waste becomes a resource. Although the term circular economy first appeared in 1996 in the European Union with a Federal German waste law designed to promote the recycling and protection of natural resources, the Ellen MacArthur Foundation has brought the concept of circular economy to a new level by considering that a circular economy is inspired by living systems from 2010. According to the Foundation, there is no waste in a truly circular economy model, only new resources for the members of the system. Four main principles emerge when copying living systems: waste is equal to food, build resilience through diversity, use energy from renewable resources, and think in systems. These principles were translated into six business actions, which make up the ReSOLVE framework: regenerate, share, optimise, loop, virtualise, and exchange [2].

Different business models have been used to implement circular economy principles. Thus, Lewandowski attempted to review the different models and proposed categorising them according to the ReSOLVE framework [8]. For example, under the “regenerate” business action, he presented five business models, namely, energy recovery, circular supplies, efficient buildings, sustainable product locations, and chemical leasing. Another categorisation was provided by Accenture after analysing “more than 120 case studies of companies that are generating resource productivity improvements in an innovative way” [12]. In that categorisation, the different CEMs were organised into five types of business models:

- Circular supplies: in these business models, supplies and raw materials are fully renewable, recycled, or made from biodegradable resource inputs;

- Resource recovery: these models aim to close resource loops to protect the value of embedded components and materials;

- Product-life extension: these models aim to extend the use of products by repairing, upgrading, or remanufacturing them or some of their components;

- Sharing platforms: to increase the rate of utilisation of a product, platforms are used to promote collaboration among product users;

- Product as a service: instead of the conventional buy-and-own approach, products are leased or can be used according to a pay-for-use arrangement by one or many customers.

It is worth noting that a common definition of a “circular economy model” in the paperChain project was established to appropriately address the configuration and definition of the objectives, concepts, components, and characteristics that the reference framework should encompass:

“A circular economy model in the paperChain project will be a new organisation of partners (businesses, governments, researchers, citizens) working together into a system to create new ways of preserving natural resources (extending product lifetimes) or turning waste into a resource (recycling), requiring new changes in the value chain and involving innovative business models. The new models may lead to new norms and practices, new modes of consumer behaviours and changes at policy levels.”[1]

Having illustrated a generic view of the concept, dimensions, and taxonomy concerning circular economy, this section aims to show existing research addressing the challenge of identifying common patterns in circular economy models. In this sense, those elements considered critical and incorporated as components of the reference framework in the literature are selected after performing a comprehensive literature review.

A critical element is defined as “sufficiently representative within the whole system by either enabling success in the transition towards a circular economy or constraining the operational and/or strategic processes of a circular economy model” [13]. Researchers and practitioners have tended to take different journeys once they realise the potential benefit that could be achieved in terms of business innovation when the circular economy is prioritised at the strategic sustainability level. As such, current pathways were explored and grouped into the following three categories:

- Methods expanding the theory of business innovation towards circular business innovation [8,9,14,15,16,17,18];

- Research studies that study all principles and mechanisms related to circular economy models [8,9,19];

- Procedures related to the creation of business cases for sustainability [4,5,20,21].

The literature findings were grouped according to the aforementioned aspects and are summarised in Table S1 (Supplementary Information A), identifying those elements that are critical for the success of a circular economy model.

4. Systemic Approach

In order to discover the role of each critical element in a complex interlinked circular economy model or system, their interactions were evaluated following a systemic approach. Such a role is related to how their interactions with other elements of the CE model/system enable or hinder their development and performance. The benefits that the system thinking perspective could provide to a qualitative analysis of the main relationships between the critical elements are shown using system dynamics [22,23].

A qualitative analysis by creating a system dynamics (hereafter SD) causal diagram that allows their interactions to be evaluated was developed. Detailed information of this causal diagram and its components are included in Supplementary Information B. This analysis allowed discovering the leverage points, that is, those elements that promote and sustain the circular economy model. By application of SD, managers are able to develop a shared understanding of complex situations and test the effect of specific business policies [24].

SD models could help decision makers (in this case, circular economy management) to structure a problem, review several intervention options, and assess their impact on the results. Furthermore, they allow different agents to debate about several dimensions of the same problem. Some examples claiming that a circular economy model should be considered as a complex problem/system and that it could be evaluated from a systemic perspective can be found in the literature [25,26,27]. From a global perspective, the EEA (European Environment Agency) highlights that, for the time being, there are several unknowns with regard to the practical implications of the circular economy transition that need to be clarified to help policymakers, investors, businesses, consumers, and civil society to find the most promising transition pathways [28], p. 5. The EEA acknowledges that “better insight is needed into various aspects of system dynamics, such as production structures and functions, consumption dynamics, finance and fiscal mechanisms, and triggers and pathways for technological and social innovations” [28].

In line with this argument, publications in the sustainability literature have provided various examples attempting to conceptualise a systemic analysis of circular economy models. For example, in their study, Schaltegger et al. (2012) placed the business case drivers as “intermediating variables which link the corporate sustainability strategy with the ‘architectural’ business model level of a firm” [5], p. 102. According to Abdelkafi and Täuscher (2016), system thinking is a promising approach for studying business models for sustainability [26]. Their attempt to develop a conceptual model for BMfS finally demonstrated how value creation capacity, value to the customers, value to the natural environment, and captured value can reinforce each other [26]. Grounded in the perspective of considering sustainable development as a dynamic process (from an ecosystem perspective), Hjorth and Bagheri (2006) showed the causal loop diagrams for human needs and economic, environmental, and life services structures and showed how the sustainability dynamic process actively adapts the system to changes [25], p. 90.

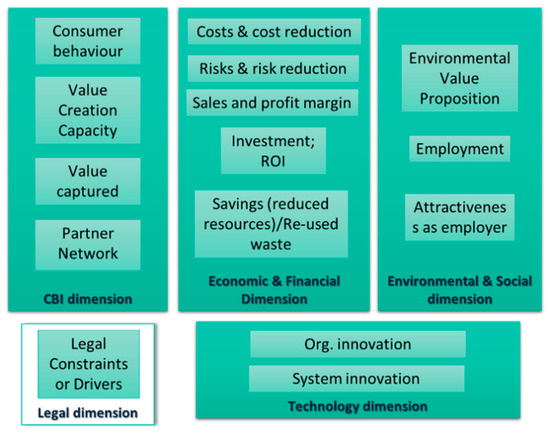

Figure 2 shows those groups of components that will be further explored by way of a qualitative analysis of their interactions:

Figure 2.

Conceptual model explored using system dynamics.

- The interactions among the variables (which could be the critical elements) described above determine the dynamic behaviour: how the firm/system combines investments in new technology and value creation in line with the sustainability goals within the CE perspective. This SD analysis helped to better understand how the new technological capabilities interact with the elements of circular business innovation at different stages of the process.

As a result of our systemic analysis, some specific challenges were discovered that were further checked with the industry and are described in the form of managerial recommendations, as follows:

- Top-management commitment, from each of the firms participating in the system: the prior awareness and resulting commitment from decision makers will support the initiatives of organisational innovation, as well as system innovation.

- Creation of a well-defined partner network in favour of organisational innovation and market share growth: the circular economy model process involves engaging a wide range of stakeholders. Several roles of stakeholders should be considered along the path from conception to implementation (e.g., government, citizens, customers, and suppliers) and, thus, a well-structured process for supporting the firm/system in stakeholder selection from the beginning of the process. Moreover, the influence of value creation capacity over such a partner network should be monitored.

- The performance of the circular business model should be measured by way of appropriate KPIs, which will be specific for each context: from a socioeconomic perspective (e.g., employment generated, volume of reused waste), a financial perspective (e.g., cost reduction, ROI of the total investment), and a business innovation perspective (e.g., value creation capacity, (waste) supplier power).

- Although some relevant aspects were excluded from the model, due to their relevance to the CEM, they are considered in the reference framework. First, the organisational readiness, which is embodied in individuals, in the structures, and in the routines and the cultural values of organisations, must be previously evaluated to guarantee good progress of model implementation. Second, the strategic alignment of the CEM to the organisation’s strategic goals is required from the very beginning of the process. Lastly, the CBI model should be aligned to the market, customer, and environment perspectives.

The relationships among capabilities, processes, culture, and strategy, on the one hand, and several mechanisms for their adaptation and integration in the global system, on the other, should allow the firm/system to generate initiatives for organisational innovation and system innovation.

5. Five CEMs in the Industry

After gathering relevant insights from previous steps, the next objective focused on understanding industrial needs and ensuring an industrial-driven approach to the research by providing relevant qualitative data for analysis. More specifically, the industry participated in various discussions via virtual web-based and face-to-face meetings at several European locations. This interaction was intended to result in a complete characterisation of the five demo cases including their global value chain, critical elements, and the business model at the ecosystem level.

On the basis of the understanding gained from the literature review, a structured questionnaire was developed to capture best industrial practices with regard to the design and implementation of the five CEMs. It was used to guide the industrial field study via virtual and face-to-face interviews with managers and engineers. Having distributed the questionnaire among the engineering companies and technology developers involved in the five demo cases, valuable insights regarding the setup of each CEM were collected. Furthermore, the data gathering process was completed with two additional information sources:

- Data concerning technical, legal, and environmental dimensions from the information available in an internal report that addresses the “quality assurance procedures for the circular models”, which provides a quality control and assurance plan (QC/QA) for the use of recycled products from the pulp and paper industry in the industrial target applications of the paperChain project.

- Complementary information was received from partners during a working session that was held in 2017 in which all partners were grouped by circular case to discuss organisational, financial, economic, and business-innovation elements. If those topics were linked to sensitive data coming from all stakeholders in the value chain, they were requested (1) to describe the barriers or drivers for each dimension qualitatively, (2) to provide practical feedback from their own experience in previous/ongoing projects, and (3) to identify those tools, methods, or capabilities that would support the transition to CEM.

The entire value chain in each resource recovery scenario was explored in depth to identify those critical elements that would/could have a relevant influence on the success of the circular economy models (CEMs) that they embody. It should be noted that, in some cases, the critical elements affect the system as a whole rather than the stakeholders concerned individually. More detailed information of the five CEMs is included in Supplementary Information C.

5.1. Set of Critical Elements Derived from Industry

All the critical elements derived by matching the inputs from interviews, the literature review, and the systemic analysis were categorised and listed, as shown in Table 1.

Table 1.

Set of critical elements identified in the industrial study [13].

5.2. Industry-Based Insights

The identification and subsequent selection of the main key components that need to be incorporated into a comprehensive reference framework is a laborious activity. Thanks to some validation sessions with industry, an initial framework format was critically discussed and suggestions for improvement were added.

The first aspect evaluated regarded identifying the optimal circular economy model and its business strategies according to the sustainability strategies of the company. In terms of principles, recent literature studies provide some aspects of industrial symbiosis [2,29,30,31] that can be adapted to resource recovery models, and participants agree on the following ones in order to precisely define the CEM’s goals:

- Circular principles are not fully understood by many executives and, in some industrial sectors that are more resistant to innovations (e.g., road and highway construction), there is limited initial awareness of the positive impact of the CEM;

- Commitment to sustainable development: the organisational strategy, goals, and performance measures must motivate managers to develop and participate in the synergy projects, thus contributing to the company and regional development;

- Information: the detailed qualitative and quantitative data on waste streams and local industries’ material/water/energy requirements provide the starting point for the development of (regional) resource synergies;

- Cooperation and trust between key players, sharing of information, and network development are critical factors for new circular economy models;

- Uncertainty of technical feasibility: a lack of technical knowledge within the industries may be an additional barrier to any new project;

- Uncertainties of environmental legislation and difficulties with obtaining approval for waste reuse projects from the regulatory authorities;

- Socioeconomic benefits to multiple stakeholders: increased revenue, reducing the overall operating costs and risks, diversifying and/or achieving long-term resource security, reduced waste management costs, diminished environmental impact with lower demand for virgin resources and energy, etc.;

- Benefits from reducing the overall operating costs and risks and from achieving long-term resource security (e.g., collaborative agreement for reducing costs across the networks).

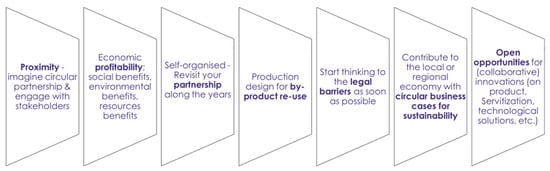

As for the strategic goals, according to the first collection of best practices identified and collected by way of the qualitative analysis of industrial cases, Figure 3 provides managers with a good starting point to define the strategic goals.

Figure 3.

Recommendations from the analysis of BBPP in resource recovery models.

Secondly, the definition of the sustainable business model which will effectively provide value to stakeholders, society, and the environment was analysed taking into consideration the support that managers will require ensuring that all the stakeholders in the value chain effectively provide the key competencies throughout the whole processes. Therefore, the six dimensions previously mentioned were explored, and, according to the industry-based insights, inspiring challenges about their implications emerged. The innovation management process may be adapted according to a circular business model innovation (CBMI) perspective; proactive strategic management and regular creation of business cases for sustainability are expected, and the value proposition should guarantee an increase in customer loyalty. Moreover, new market opportunities for SMEs involved in the new value chain of the CEM should be explored to attract them to the partnership. Most companies agreed on the relevance of the technology dimension and its elements. In this regard, new processes or complementary activities are necessary (e.g., must meet required new quality standards, investment planning process adapted to CEM for resource recovery, specific requirements in terms of supply chain management such as geographical barriers or the need for a specific technology, waste transportation will undoubtedly increase the costs of the final product), the diversity and quality of wastes require specific attention due to them influencing the properties of the new product, the requirements in terms of technology development or equipment investments should be anticipated, and specialised skills and/or adapted machinery will be required to develop the new circular product. As far as the economic and finance dimension is concerned, the economic benefits of the circular economy are widely recognised and transferred [28]. Given such positive benefits, the creation of a circular economy model will offer the firms relevant economic advantages, although relevant barriers that constrain the organisational impulse to initiate such economic models mentioned by the academy exist (e.g., [32]). In this sense, all companies interviewed agreed upon the fact that a broad definition of effective KPIs from an economic and financial perspective (e.g., cost reduction (related to energy savings, to the reduction of material flows or cleaner production, improved sales and profit margin, increase in company profits, improved reputation and brand value), as well as additional financing alternatives (economic incentives or disincentives for companies to engage in environmentally sustainable development, political regulation of their environmental practices and financial performance, economic recycling incentives, shifting taxes from labour to natural resources and pollution, internalisation of environmental costs, finance mechanisms supporting circular economy models, sustainable public procurement), are essential conditions. The environmental dimension plays an essential role in any reference framework devoted to promoting circular economy strategies since it points out the positive environmental effects. In the context of this study, this concerns the net reduction in environmental pressure from waste disposal and the production of virgin materials [28]. Most companies agreed on the need for implementing an accurate and complete risk-management process and LCA analysis. They also highlighted that a best-practice document could be developed by the waste manager for the logistics and construction companies. With regard to the social dimension, it can be seen as the institutional perspective of the CEM, which “conceives the enterprise as a social system embedded in a social context of expectations, values, and norms and constrained by a broader set of stakeholders than primary market actors, including public authorities, professions, interest groups, and the media” [28]. The companies interviewed revealed the following societal challenges: processes such as recruiting, selection, and training and development programmes have to be modified on the basis of new values coming from the circular economy culture; intensive communication efforts will be required to disseminate the positive impact resulting from the innovative solution and gain acceptance from target stakeholders (society, employees, government) for the cultural transition towards CE. As for the legal dimension, the companies interviewed kept it in view as one of the main roadblocks to overcome when designing circular business models concerning the unawareness of the legal environment to embrace the new concepts and/or new processes derived from the CEM. They found long delays in receiving the corresponding environmental licences or approvals due to the lack of harmonisation in end-of-waste (EoW) and by-product use standards at the European level, as well as the required legal status over the utilisation of waste as a new raw material. These delays put strong pressure on the company and threaten the viability of the model [33].

Dealing with all the standards or patterns accounting for social, environmental, and business impacts in the circular economy field, it should be noted that positive feedback loops have to be built in order to ensure fruitful interactions among the needs and the evaluations coming from citizens or customers and the strategy and policies designed by the top layers of society (public authorities and scientific, technological, and industrial stakeholders) [34]. Several examples, such as comprehensive approaches of governments that support CE transitions (at a European level), new specific tax systems (e.g., taxing non-renewable resources or circular products), product passports, economic incentives to facilitate CE transitions, and public–private procurement, emerged from consultation with industry.

Monitoring aspects were also evaluated due to the important role they play in evaluating the transition towards the circular business model. The lack of a measurement system and the lack of a monitoring tool specific to CEMs were the barriers indicated most often by the companies interviewed, with both being relevant for any transition or change management. Both common linear KPIs and circular KPIs, i.e., those indicators that can measure the advancement of circularity within each circular business model, thereby preserving the economic interest of all stakeholders, should be identified and monitored.

The third element analysed was focused on establishing (and defining) the necessary key competencies (internal and external) to allow the cohesion of operational and business perspectives in a circular economy model. As far as functional aspects are concerned, the activities and processes (base functions/operations) required to operationalise the CEM should be identified within this dimension, and the execution of time-sequenced flows of operations related to the different phases of the model should be defined. Some relevant processes were envisioned as a result of the interviews, although new elements could arise while implementing the CEM. Concerning this element, the relevance of the transition perspective should be noted [32]. This perspective is focused on the institutional and strategic context for firms’ (and other organizations’) engagement in radical, systemic, and sustainable technological innovation and transition of industries or sectors. According to Christensen et al. (2017), the interplay between a diversity of actors and institutions can enable or inhibit sustainable technological innovation. Hence, the core of its perspective is incorporated into the third element, i.e., the system’s features go beyond the enterprise features.

6. Progressing towards a Reference Framework for the Circular Economy

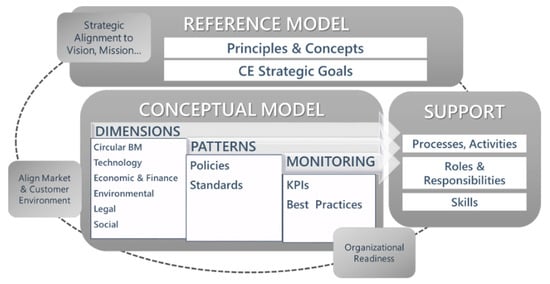

Given the set of critical elements identified previously (matching theoretical review and industrial-based exploration), a reference model for circular economy model creation in a resource recovery-based scenario was developed following an integral approach (Figure 4).

Figure 4.

General overview of the reference model’s components (Reprinted with permission from ref. [13], Copyright 2017, Owner’s Name: Amaia Sopelana).

This reference framework assists companies and managers to create, implement, and monitor the circular economy models in an industrial symbiosis scenario: “The reference model for creating and implementing a circular economy model of industrial symbiosis stands for a structure that supports firms (or systems) in producing innovative and value-added solutions (waste valorisation-based products) under a collaborative perspective. It encloses a collection of various elements that provide orientation, guidance, support, and a basis for communication. These elements can be used to model, plan, operate, and control corresponding innovation projects on a CE basis.” [13]

In order to provide a collaborative reference tool to facilitate all stakeholders’ efforts towards commonly agreed objectives, the main building blocks of the reference framework were deployed by summarising and formalising all relevant components and their interactions.

- The Reference Model: This includes the “CE principles” and “CE strategic goals” regarding the characterisation of the resource recovery scenario. It allows the strategic goals of CEMs to be defined and guarantees their alignment with companies’ sustainability vision. The companies’ awareness of the principles of circular economy and its most beneficial impacts that would benefit the initial stage should be strengthened from the initial stages of the CEM building.

- The Conceptual Model: This represents the interaction of the firm/system with the market and customer environment, as well as with the external agents of the CEM. This model encompasses the dimensions, patterns, and monitoring components essential to fulfil the stated objectives as follows:

- ○

- “Dimensions” starting with circular business innovation dealing with those elements that allow companies to generate business cases for sustainability and encourage the sustainability orientation of innovative capabilities; technology deals with elements associated with overcoming technical barriers, technological innovation, eco-innovation, technological path dependency, etc.; economic and finance relates its elements with assuring economic viability for the whole value chain through, among other elements, external financing incentives; the social dimension represents the interaction between the CEM and society, focusing on both the potential impact of the CEM on society and the constraining and facilitating factors to the CEM that come from society; the legal dimension involves the set of compulsory laws and norms for companies operating in a resource recovery circular economy model which mostly depend on the sector and the country context.

- ○

- “Patterns” that influence (positive or negatively) the viability of the model with regards to standards or policies (regional or European) and refer to all documentation of practical knowledge that is relevant to the problem(s) that the CEM is facing. In practice, although many patterns are available in the general industry domain, companies should customise and extend them to make them relevant to the circular model. They cover both the policy interventions related to the materials and sectors affected and the need to influence policy decision makers at local, regional, or European level.

- ○

- “Monitoring” enables the progress of the performance of the model to be monitored.

- The Support Scheme: This focuses on forming the operational structure of the constituting elements of a CEM, namely, the processes, activities, participants (and their roles), and skills or capabilities (including dynamic capabilities). These elements constitute the organisational readiness level. The final, yet no less important, pillar focuses on the support scheme that provides the appropriate configuration of processes, roles and responsibilities, and skills or capabilities that will contribute to operationalising the circular economy model built upon organisational readiness.

7. Discussion

This research study aimed to conceptualise the main supporting constituents that facilitate the transition from linear to circular economy models in the context of waste valorisation from the pulp and paper industry and its application as a secondary raw material in five different sectors. All research fields evaluated delivered a complete theoretical framework but failed to provide hands-on guidance for the creation, implementation, and management of a CEM when a resource recovery strategy was tracked.

This study started by exploring the critical components from the whole value chain collaboration, connecting, and integrating the fields of CE principles, organisational strategic goals on sustainability, all significant dimensions, and the operational structure. In combination with a qualitative system dynamics exploration, the interactions among some of the CEM’s critical elements could limit or benefit how the company/system combines investments in new technology and value creation in line with business cases for sustainability; therefore, they should be taken into consideration during operationalisation of the CEM. This exploration showed the connection of two strategic levels—the organisational and the system level—in which all stakeholders involved in the resource recovery model are represented (i.e., companies, the partner network, the environment, the decision maker, and the customer). Furthermore, this points to how the sustainability strategy of the company/system can result in changes in their circular business model and how the business model feeds back to the environmental value proposition, socioeconomic performance, and customer behaviour.

The five circular industrial cases examined provided relevant insights that were fed into the CE theoretical framework in terms of designing, launching, and implementing their CEMs, thereby leveraging the circular economy principles. When investigating those case studies, it became clear that the systemic changes a CEM entails require an ecosystem perspective to guarantee its successful implementation. Although the concept of CE is very appealing to businesses, policymakers, and technology developers, the discourse about the transition towards a circular economy is yet to be translated into real-world impact.

Most case studies coincide in the importance of getting robust cooperation from the initial stages. As such, the starting point should be to define the strategic economic, environmental, and society-driven goals of the ecosystem. This should be aligned, on the one hand, with a contribution to the circular transition and, on the other, to the companies’ strategy and business ambitions. The cooperation and the trust among key players are of vital importance in this endeavour, mainly because the sharing of information and network development (local or regional) are crucial factors for new CEMs. The chemical case study showed a strong partnership between partners founded not only on historical and geographical grounds but also on trustful negotiations, while the case study in Portugal illustrated that the industry–academia combination can boost new business opportunities for SMEs (concrete and asphalt manufactures). When setting up a CEM, dialogue with key stakeholders at an early stage of the project (through focus groups or visits) is crucial. Given that most of the companies involved in the partners network aspire to different aims (e.g., gain competitiveness or market share growth), a well-structured process for supporting the firm/system in stakeholder selection from the beginning of the process is essential. The case study on producing hydraulic road binders for soil stabilisation services (Spain) shows the influence of value creation capacity in such a partner network.

A further dimension to those usually considered by the current strategic frameworks was proposed: the circular business innovation dimension. In this regard, and in addition to the innovation process, capacities, and CE awareness required, partners from the five case studies also agreed on the relevance of tools that assist managers in defining all the elements that can help them move towards the circular business model that the CEM requires. This would undoubtedly help to raise awareness of its positive impacts in some industrial sectors that are more reluctant to use valorised waste as a secondary raw material.

The five case studies herein exhibited similar noteworthy challenges with regard to the technology dimension, with the need to implement new processes to meet the required quality standards for both waste and new secondary materials, as well as favourable waste transport conditions (distance) that could inhibit scaling up of the CEMs, being of particular interest. On a demo site scale, technological developments showed remarkable performance. For example, the mining case study reported a relevant impact at a local level, although innovative technologies for mining waste remediation will always be contingent upon the particular mine. This points to the importance of tailoring the CEM to the local conditions and the need for the CEM to demonstrate technological reliability to gain traction in the mining industry.

All economic and financial critical elements were considered to be very critical. Indeed, all members of the CEMs, ranging from PPI to end-users, agreed upon the fact that the existence of a viable business model (revenues overcoming costs) should guarantee an economically advantageous solution compared to classic or linear ones. More precisely, positive economic effects should arise from the availability of cheaper materials derived from waste, including avoiding the costs of waste disposal and capturing the residual economic value of existing material streams [28]. The case study in Portugal pointed to the existence of subsidies from the local/regional government as one of the key financial drivers, while the case study that developed the new composite for slope stabilisation (in Slovenia) highlighted that the existence/availability of Green Public Procurement focusing on the end-user sectors may favour customer acceptance of circular products. This dimension, together with the environmental and social categories, also requires a monitoring scheme tailored to the measurement of the CEM’s performance, including context-specific KPIs, such as job creation, the volume of waste reused, tons of landfill avoided per year, reduction in CO2 emissions, cost reduction, ROI of the total investment, or waste supplier power.

As far as patterns and legal dimensions are concerned, the outcomes from case studies revealed that regulatory and standards criteria can either boost or inhibit the successful implementation of CEMs. Thus, in some regions where CEMs were implemented, stringent regulations concerning the declassification of waste (and legal approval as a by-product) markedly delay commercialisation of the circular product, while, in others, the regulatory framework encourages waste reduction and promotes the development of new circular products by the setting up innovative public–private partnership models. Therefore, exploring the regulatory context and context patterns from the earliest stages appears to be a relevant prerequisite to avoid delays that impede the viability and reliability of the CEM.

Overall, a significant challenge can be observed across the main elements of the reference framework, i.e., that hands-on development of the reference framework for resource recovery CEMs should possess a twofold aim: to develop both a conceptual and a practical approach at the same time.

8. Conclusions

This research showed how the combination of a theoretical perspective with industry-based exploration can contribute to accompany the firms in the practical conception and implementation of CEMs. From an exhaustive analysis of the critical elements influencing CEM development, not only do the technical factors arise as relevant (structural and operational factors), but nontechnical factors may also significantly impact both the creation and the implementation, such as customer awareness and trustful negotiations among the partners of the eco-system. In terms of implementation, there are still many barriers that a systemic perspective could tackle; therefore, industrial system strategies should be delineated and aligned with institutional and societal interests to successfully prosper in CE.

The empirical insights contributed to better outline a comprehensive reference framework that allows companies to better understand those critical elements and their interactions, as well as to forecast their role in a resource recovery scenario. Its three main building blocks were conceptualised to address the key challenges of developing circular products in competition with linear ones while operating cooperatively. Firstly, to optimally define the CE ecosystem and its business strategies, top-management commitment from all participants should be guaranteed since relevant changes in companies’ practices, cultural values, policies, etc. will be required. Moreover, the partner network may be conceptualised in favour of organisational innovation and market share growth, and the influence of value creation capacity over such a partner network should be periodically monitored and revised. Secondly, to effectively provide value to stakeholders, society, and the environment, the performance of the circular business model should be measured through the selection of the appropriate KPIs that will be specific for every dimension. This study also showed that achieving an effective operationalisation of the CEMs profoundly depends on the legal and regulatory environment which can hinder all companies’ efforts. An efficient CEM implementation will require new business models operating with specific support through new policies, environmental legislation, and financing instruments. The cooperation among regional, national, and European policy and regulation entities should be boosted to foster waste valorisation and the use of SRM in a CE transition. Lastly, to facilitate the cohesion of operational and business perspectives in a circular economy model, establishment (and defining) of the necessary key competencies (internal and external) would be required.

In addition to its contribution to knowledge in the fields of business model innovation and corporate sustainability by delivering a theoretical framework with practical applications, this reference framework can be fed into a practical guidance scheme for companies. The conceptual approach was covered and explained in this paper; however, going forward from the conceptual recommendations, a complete management guide to assist companies through the whole life cycle of the CEM appears essential. However, since it is very descriptive, further development of a methodological guidance is required for setting up, designing, implementing, and managing circular economy models, as the unfolding of its processes would shed more light on how its building blocks and their interactions occur. In this sense, a preliminary phased approach guide for CE implementation management can be defined that will be further tested in the five circular cases.

Supplementary Materials

The following are available online at https://www.mdpi.com/article/10.3390/su131810285/s1. Supplementary Information A, Table S1. Main findings in the circular economy literature; Supplementary Information B. The system dynamics causal diagram; Supplementary Information C. Detailed information of the industrial circular cases.

Author Contributions

Conceptualisation, A.S. and C.A.; methodology, A.S.; validation, A.B., K.F., H.P., C.M., and G.W.; investigation, A.S., C.A., J.R., and A.O.; writing—original draft preparation, A.S. and C.A.; writing—review and editing, A.S.; visualisation, A.C.; supervision, A.B. All authors have read and agreed to the published version of the manuscript.

Funding

This research was funded by European Union, grant number 730305, a collaborative research project entitled “New market niches for the pulp and paper industry waste based on circular economy approaches (paperChain)” from the European Union’s Horizon 2020 research and innovation programme.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

The authors wish to acknowledge the European Commission for its support in the collaborative European research project paperChain, as well as the other partners in the consortium (https://www.paperchain.eu). The authors specially thank the participants in the interviews and the workshops for their industrial-based contribution, belonging to The Navigator Company, Spral, Megavia, Vipap, Saica, Sz-Infrastruktu, Domsjö Fabriker (DOMJSO), Sekab, Nouryon, and Boliden Mineral.

Conflicts of Interest

The authors declare no conflict of interest. The founding sponsors had no role in the design of the study; in data collection, analysis, or interpretation; in the writing of the manuscript; or on the decision to publish the results.

References

- Auriault, C.; Aze, F.; Sopelana, A.; Fifer, K.; Ferreira, V.; Cepria, J. Comprehensive Analysis of the Existing and Emerging Approaches of Circular Economy Models in Pulp and Paper Industry; paperChain project. 2017. Available online: https://ec.europa.eu/research/participants/documents/downloadPublic?documentIds=080166e5b510caf8&appId=PPGMS (accessed on 14 September 2017).

- Schulze, G. Growth Within: A Circular Economy Vision for a Competitive Europe. Ellen MacArthur Foundation and the McKinsey Center for Business and Environment, Cowes, UK. 2016. Available online: https://www.vci.de/ergaenzende-downloads/2016-11-28-assessment-prof-guenther-schulze-of-report-growth-within-a-circular-economy-vision-for-a-competitive-europe.pdf (accessed on 11 January 2020).

- Rauter, R.; Jonker, J.; Baumgartner, R.J. Going one’s own way: Drivers in developing business models for sustainability. J. Clean. Prod. 2017, 140, 144–154. [Google Scholar] [CrossRef]

- Witjes, S.; Lozano, R. Towards a more Circular Economy: Proposing a framework linking sustainable public procurement and sustainable business models. Resour. Conserv. Recycl. 2016, 112, 37–44. [Google Scholar] [CrossRef] [Green Version]

- Schaltegger, S.; Lüdeke-Freund, F.; Hansen, E.G. Business cases for sustainability: The role of business model innovation for corporate sustainability. Int. J. Innov. Sustain. Dev. 2012, 6, 95–119. [Google Scholar] [CrossRef]

- Bocken, N.; Miller, K.; Evans, S. Assessing the environmental impact of new Circular business models. In Proceedings of the Conference “New Business Models”—Exploring a Changing View on Organizing Value Creation, Toulouse, France, 16–17 June 2016. [Google Scholar]

- Bohnsack, R.; Pinkse, J.; Kolk, A. Business models for sustainable technologies: Exploring business model evolution in the case of electric vehicles. Res. Policy 2014. [Google Scholar] [CrossRef] [Green Version]

- Lewandowski, M. Designing the business models for circular economy-towards the conceptual framework. Sustainability 2016, 8, 43. [Google Scholar] [CrossRef] [Green Version]

- Antikainen, M.; Valkokari, K. A Framework for Sustainable Circular Business Model Innovation. Technol. Innov. Manag. Rev. 2016, 6, 5–12. [Google Scholar] [CrossRef]

- Mentink, B. Circular Business Model Innovation: A Process Framework and a Tool for Business Model Innovation in a Circular Economy; Delft University of Technology: Delft, The Netherlands, 2014. [Google Scholar]

- Talukder, M.H. Circular Business Model Innovation—A Process Framework and a Tool towards More Circular Economy. Available online: https://repository.tudelft.nl/islandora/object/uuid:c2554c91-8aaf-4fdd-91b7-4ca08e8ea621?collection=education (accessed on 8 May 2014).

- Accenture Strategy. Circular Advantage: Innovative Business Models and Technologies to Create Value in a World without Limits to Growth. 2014. Available online: https://www.accenture.com/t20150523T053139__w__/us-en/_acnmedia/Accenture/Conversion-Assets/DotCom/Documents/Global/PDF/Strategy_6/Accenture-Circular-Advantage-Innovative-Business-Models-Technologies-Value-Growth.pdf (accessed on 22 May 2015).

- Sopelana, A.; Auriault, C.; Aze, F.; Fifer, K.; Mauko, A.; Basal, A.; Cepria, J.J. Reference Framework for the Circular Economy Models; Paperchain Project. 2017. Available online: https://ec.europa.eu/research/participants/documents/downloadPublic?documentIds=080166e5b73c2307&appId=PPGMS (accessed on 16 December 2017).

- Amit, R.; Zott, C. Creating Value through Business Model Innovation. MIT Sloan Manag. Rev. 2012, 53, 41. [Google Scholar]

- Johnson, M.W.; Suskewicz, J. How to Jump-Start the Clean-Tech Economy. Harv. Bus. Rev. 2009, 87, 52. [Google Scholar]

- Wells, P.; Seitz, M. Business models and closed-loop supply chains: A typology. Supply Chain Manag. Int. J. 2005, 10, 249–251. [Google Scholar] [CrossRef]

- Nußholz, J. Circular Business Models: Defining a Concept and Framing an Emerging Research Field. Sustainability 2017, 9, 1810. [Google Scholar] [CrossRef] [Green Version]

- Poutiainen, P.S. Designing out waste: An exploratory study of circular business models. Master’s Thesis, Aalto University, Espoo, Finland, 2015. [Google Scholar]

- Moreno, M.; De los Rios, C.; Rowe, Z.; Charnley, F. A Conceptual Framework for Circular Design. Sustainability 2016, 8, 937. [Google Scholar] [CrossRef] [Green Version]

- Stubbs, W.; Cocklin, C. Conceptualizing a “Sustainability Business Model”. Organ. Environ. 2008, 21, 103–127. [Google Scholar] [CrossRef]

- Florin, N.; Madden, B.; Sharpe, S.; Benn, S.; Agarwal, R.; Perey, R.; Giurco, D. Shifting Business Models for a Circular Economy: Metals Management for Multi-Product-Use Cycles; UTS: Sydney, Australia, 2015; ISBN 978-1-4863-0582-7. [Google Scholar]

- Sterman, J.D. Business Dynamics: Systems Thinking and Modeling for a Complex World; Irwin/McGr.: Boston, MA, USA, 2000; ISBN 0072311355. [Google Scholar]

- Harrison, J.R.; Lin, Z.; Carroll, G.R.; Carley, K.M. Simulation modeling in organizational and management research. Acad. Manag. Rev. 2007, 32, 1229–1245. [Google Scholar] [CrossRef] [Green Version]

- Kunc, M.; Morecroft, J.D.W. System Dynamics Modelling for Strategic Development. In Supporting Strategy: Frameworks, Methods and Models; Dyson, R., O’Brien, F., Eds.; Wiley & Sons: New York, NY, USA, 2007; pp. 157–189. [Google Scholar]

- Hjorth, P.; Bagheri, A. Navigating towards sustainable development: A system dynamics approach. Futures 2006, 38, 74–92. [Google Scholar] [CrossRef]

- Abdelkafi, N.; Täuscher, K. Business Models for Sustainability from a System Dynamics Perspective. Organ. Environ. 2016, 29, 74–96. [Google Scholar] [CrossRef]

- Haack, J. The Business Model for Sustainability from a System Dynamics Perspective by; Lund University: Lund, Sweden, 2017. [Google Scholar]

- European Environment Agency (EEA). Circular Economy in Europe—Developing the Knowledge Base; European Environment Agency (EEA): København, Denmark, 2016; ISBN 9789292137199.

- Pheifer, A.A.G. Barriers & Enablers to Circular Business Models; ValueC: Le Brielle, The Netherlands, 2017. [Google Scholar]

- Golev, A.; Corder, G.D.; Giurco, D.P. Barriers to Industrial Symbiosis: Insights from the Use of a Maturity Grid. J. Ind. Ecol. 2015, 19, 141–153. [Google Scholar] [CrossRef]

- Velenturf, A.P.M.; Jensen, P.D. Promoting Industrial Symbiosis: Using the Concept of Proximity to Explore Social Network Development. J. Ind. Ecol. 2016, 20, 700–709. [Google Scholar] [CrossRef] [Green Version]

- Christensen, J.F.; Truffer, B.; Hekkert, M. Enterprise Strategies for Sustainable Development—Towards an Integrative Research Foundation. 2017, pp. 1–80. Available online: http://www.eis-all.dk/-/media/Sites/EIS_Energy_Innovation_Systems/english/about%20eis/Publications/Radarpaper-Sust-inno-JFC-Final.ashx?la=da (accessed on 19 March 2016).

- Mouazan, E. Understanding circular business models: Drivers, obstacles and conditions towards a successful transition. 2016. [Google Scholar]

- Futuring Project. FUTURING_D1.3: Description of the Building Blocks and Pillar Actions Methodology. Futuring Project. 2017. Available online: https://ec.europa.eu/research/participants/documents/downloadPublic?documentIds=080166e5b0a8f309&appId=PPGMS (accessed on 28 February 2017).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).