1. Introduction

Railways are considered the lifeline of the economy of any country that not only help in providing cheap and convenient transportation for the masses but are also the main source of transporting goods across the country. Thus, the smooth operation of a railway system is extremely important, which is only possible through preventive maintenance of the wheel and rail interface. However, with trains following tight schedules it becomes almost impossible to have offline maintenance of the tracks and locomotives, including the wheelset as it is the point of contact and the cause of significant wear and tear. The health of the wheelset is of prime importance for the safe journey of trains anywhere in the world. The geometry of the wheelset and its contact with the rail needs to be in conformity for smooth operation. Thus, maintaining the conical shape of the wheelset is extremely important for ensuring a smooth wheel–rail contact and proper rolling on the track. The reliable identification of wheelset conicity, its tendency is to roll like a cone, has been a difficult technical challenge for researchers. The vehicles natural guidance and steering ability is compromised if the conicity deviates from a certain level on the wheel tread. This leads to situations such as passenger discomfort due to excess vibration and noise, and even derailment if left unattended. Thus, to have first hand experience of the wheelset condition, a number of field visits were conducted as illustrated in

Figure 1.

Wheel–rail interface is a well established point of contact where certain forces are generated due to traction and braking. These forces, in addition to environmental and man-made contaminations, may cause permanent damage to a wheelset resulting in deformity and issues such as wheel flats and false flanges. The level of overall adhesion can also become very low under poor contact conditions causing wheel slip/slide. These concerns result in wear of the wheelset wherein it tends to lose its conical shape. Therefore, it is important to maintain a certain conicity level on the wheel tread for safe and smooth railway operation.

Railway condition monitoring has witnessed several contributions from researchers in the form of signal-based and model-based techniques [

1,

2,

3,

4]. However, most of these techniques are applied to monitor the condition of the railway suspension system or wheel–rail adhesion, and researchers are still on the quest to explore ways to monitor wheel conicity. Therefore, a significant gap in the research exists to explore ways to successfully identify conicity condition and calculate its value for safe and reliable railway transportation.

Pakistan is a developing country and lacks proper maintenance of its railway vehicles and rails. The motivation of this work is largely due to the history of train accidents in Pakistan due to improper maintenance of the railway wheelset. Over the years, many train accidents have occurred in Pakistan resulting in the loss of precious lives. According to a report [

5], most of the accidents resulted in derailment due to improper maintenance and collisions at unmanned railway crossings. The authors in [

6] investigated the frequency of train accidents in Pakistan in terms of casualties and injuries. The statistics in this research clearly highlight the urgent need to look for proactive maintenance strategies that could minimize train accidents. A survey of the literature has also shown that the research community is striving to resolve the issues related to wheelset health, and this paper is our quest in this regard.

This paper attempts to identify railway wheelset conicity using a model-based estimation approach. Conicity is a parameter based on lateral force behavior. Thus, only the lateral dynamic is considered in this study because previous studies have proved that the lateral dynamics are sufficient to detect changes [

3,

7,

8]. Significant disturbance is mostly caused in the lateral direction due to speed, so, in this novel approach, conicity is indirectly identified by measuring the lateral acceleration of a wheelset. However, the research community still needs to work out practical solutions to produce real time information of the condition of the railway wheelset conicity. This paper proposes the use of lateral acceleration residuals from the actual wheelset model, and the model that is estimated using Kalman filters, to indirectly identify the conicity value. The residuals contain significant information that can be exploited to gain information about the conicity condition and wheel tread health. The varying conicity values provide an insight into the condition of a wheelset in terms of it being healthy or worn out. The results not only provide useful information to the driver but also assist the maintenance staff in carrying out predictive maintenance well in time. This also minimizes the time required in taking trains offline due to their unexpected breakdown and disturbing train schedules.

The paper is organized in this way. Following the introduction in

Section 1, the conicity management is discussed in

Section 2, followed by wheelset dynamics and modeling, model-based estimation, and the estimation of lateral dynamics in

Section 3,

Section 4 and

Section 5, respectively.

Section 6 discusses the estimation of conicity levels and, finally, the results obtained from the fuzzy logic identification of conicity are given in

Section 7. The last section is the conclusion and discusses future work.

2. Conicity Management

Conicity is an important geometrical description of the wheel that provides proper steering capability to roll like a cone over the track. This characteristic of the wheel helps the railway wheelset to run on straight tracks and negotiate curved tracks. However, during the course of operation, and due to inconsistent wheel–rail contact and lack of maintenance, the conicity tends to change, which results in inconsistent performance of the railway vehicle losing its tendency to naturally guide the wheel on the rail. The conicity of the wheels is one of the contributing factors influencing the contact force; however, no significant work has been conducted, as of yet, to ascertain the relationship between the dynamic characteristics of the vehicle and the varying conicity of the wheel [

9]. A scaled wheelset model was developed to demonstrate the effect of conicity on the dynamic characteristics of the wheelset. However, the limitation of this work is that the experiment was conducted on straight running paths ignoring curved rail paths [

9]. It has been suggested in the literature that low values of conicities result in instabilities [

10]. Conicity is one of the structural parameters influencing the lateral stability of railway wheelsets with the numeric values of 0.05 and 0.2 for a new wheel tread and worn wheel tread, respectively [

11]. One of the factors influencing the critical or hunting speed of a solid axle wheelset is conicity, in addition to wheel–rail profile geometry, suspension stiffness, and wheel–rail creep forces [

12].

The authors of [

13] discussed the inefficiency of the current technologies to measure parameters such as contact stress, creep forces, and creepage in wheel–rail contact patch directly. This further emphasizes the significance of calculating the important characteristic of conicity related to wheel tread wear and opens up the discussion of calculating it indirectly using the lateral dynamics of the wheelset. However, a few studies [

14,

15] have demonstrated a dynamic analysis for a railway vehicle model with different wheel conicities and established the relationship between the two. However, the work ignored non- linear creep forces in their analysis. In [

12,

16,

17,

18], the researchers presented their idea about the problem of stability for rail vehicles at high speed under varying conicity and creep coefficients.

Some authors have used the Kalman filter and the least squares approach for estimating the nonlinear conicity function [

19]. They argue that the wheel and rail interaction is the main influence on the dynamic response of a rail vehicle and, thus, a suitable estimator can be used to estimate the wheel–rail profile estimation. An experimental study was carried out in [

9] on the effect of wheel conicity on the dynamic characteristic of the vehicle using a scaled wheelset model. Researchers in [

20] argue that conicity could help us compare conditions of the wheel–rail contact in different states based on design and maintenance.

In [

21], the authors claim that conicity cannot be acquired directly from a physical component; rather, it needs to be determined with relative physical measures. They argue that it is an indirect measure and a strong indicator of the dynamic instability of a wheelset. The authors have attempted to determine the equivalent conicity using a data driven approach based on differential equations that represent the wheelset dynamics. However, the drawback is that the algorithm works only for identical wheel profiles for both wheels. The authors of [

22] claim that, in China, no special standard is established as yet to evaluate the equivalent conicity. Therefore, further research should be carried out to establish the rolling continuity of wheel–rail contacts and outline grinding standards where wheel–rail wear occurs, so that proper maintenance of the wheel and rail can be realistically conducted.

Many researchers over the years have investigated methods for finding the conicity using different mechanisms. Some authors have driven the further development of an important indicator for the running stability of railway vehicles called equivalent conicity, which requires the analysis of wheel–rail profiles [

20,

23,

24].

Recent work by [

25] provides an insight into how rail irregularities can augment derailment risk and compromise ride comfort due to varying wheel conicities, nominal rolling radii, and the effect of suspension parameters. Wear of the wheelset is an inevitable phenomenon due to the failure in maintaining acceptable conicity and avoiding collision between the wheel flange and rail [

26,

27,

28,

29]. Another recent study discusses early detection of wheel damage resulting in lower maintenance costs [

30]. In this work, a wayside monitoring strategy is adopted for wheel flat detection using sensors with the emphasis on their optimal position of installation. Similar work for detecting wheel flats is proposed using a reflective optical position sensor where not only the position of the wheel flat is determined but also its quantification is realized [

31]. However, quantification of wheel flats is still a daunting challenge for the research community due to the limitations of the various measuring conditions. Another endeavor was carried out using an onboard measurement system for identifying wheel flange wear. This proposed an inductive displacement sensor and successfully located wheel wear due to false flanges [

32]. Authors in [

33] proposed an algorithm for an adaptive, multiscale, morphological filtering method for extracting the information about wheel defects, such as wheel flats, from the vehicle axle box vibration signal, which also accommodates track condition information. However, the axle box vibration signal is influenced by issues such as speed variations, track irregularity, and vibration of the vehicle itself. In this study, an effort has been made to identify the conicity of the wheelset numerically providing sufficient information regarding the health of the wheelset using a multiple model approach. A decision-making system based on fuzzy logic is used to identify the conicity from the normalized values of the lateral acceleration residuals.

3. Wheelset Dynamics and Modelling

The dynamic behavior of the wheelset is influenced by certain contact forces generated in the lateral and longitudinal directions. In the past few decades, a pressing demand for faster railway services, including both passenger and cargo, has exerted huge pressure on the railway network to act efficiently. However, the infrastructure has not improved, especially in developing countries and wheel–rail contact health remains a significant issue in the railway industry worldwide.

A dearth of knowledge and understanding about the issue is a significant reason why maintaining wheelset conicity poses a significant technical challenge and renders it difficult to take effective measures for its remedy. The first realistic model of the lateral dynamics of the wheelset was developed by Carter in 1916 [

34]. This discusses the natural tendency of the wheelset to oscillate laterally and the use of a solid axle and coned wheels. The first mathematical analysis of the kinematic oscillation was given by Klingel in 1883 [

8]. This proposed the very first mathematical relationship between the wheel radius, the lateral distance between the wheel–rail contact points, frequency, and wheelset conicity [

8,

34]. It showed that increasing the speed has a direct influence on the frequency of the kinematic oscillations. At that time, due to lack of research, nothing significant could be deduced about the dynamic behavior of railway vehicles, which was due to certain active forces coming into play at the wheel–rail interface.

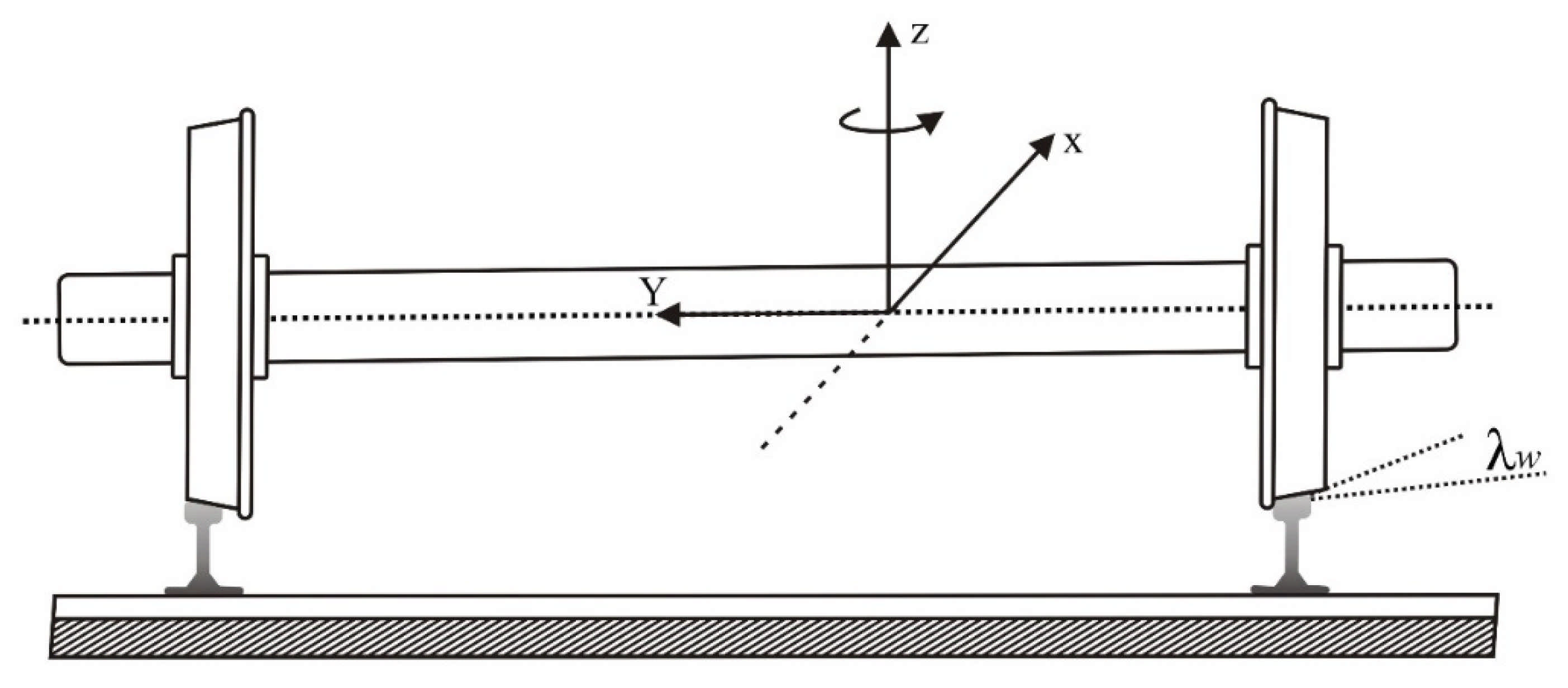

Wheelset modeling serves as a vital part of researching the problem under investigation; however, it is a very complex mechanical system and its dynamics depend upon various parameters. It also exhibits different degrees of freedom due to its movement in longitudinal, lateral, and upward directions. Thus, a thorough understanding of the dynamic behavior of the wheelset is necessary for developing a suitable system model. Attempts have been made to understand the dynamic behavior of the wheelset by various researchers [

9,

35]. In this work a single solid axle wheelset is considered with tread having conicity λ for both wheels. When the wheelset is slightly displaced laterally, the coned tread works as a natural feedback and adjusts itself on the centre position, as shown in

Figure 2.

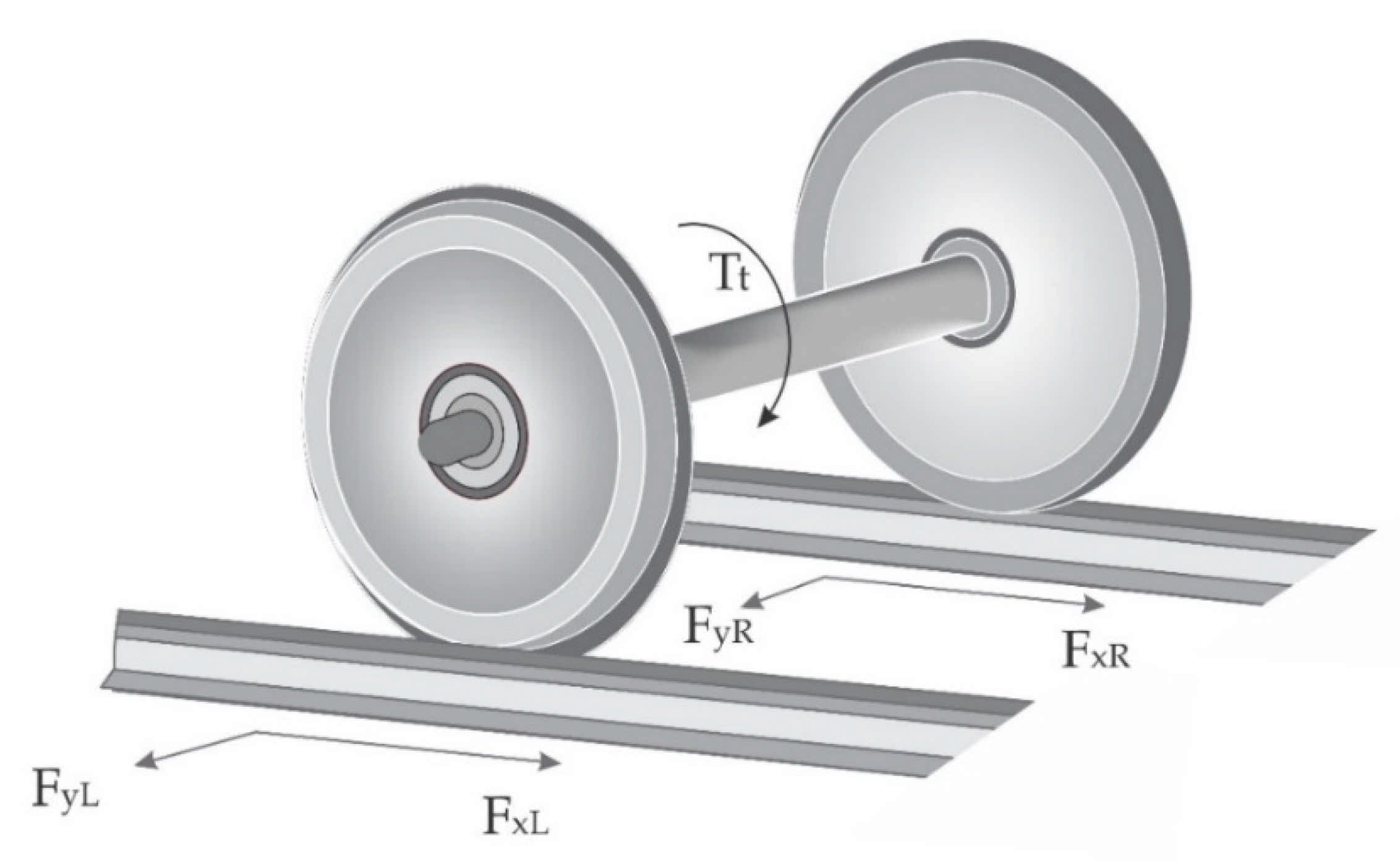

Wheel–rail contact patches are usually under the spotlight for researchers investigating faults pertaining to the wheel tread. The presence of creep forces at this point of the interface plays a key role in the dynamics of the wheelset in the lateral and longitudinal directions, as shown in

Figure 3. Creep forces have a significant impact on the dynamics of the wheelset as they exhibit their presence when the wheel deviates from pure rolling [

36]. The relevant equations of the motion of the wheelset for modeling include the longitudinal creep of the left and right wheels, the yaw movement, and the creep forces in the lateral direction and are given in Equations (1)–(4).

Yaw movement is also a cause of creep forces in opposite directions for the two wheels and is given by

Creep forces also have a direct effect on yaw and lateral dynamics and, thus, the total creep force in the lateral direction is given by

The description of the model parameters is given in

Table 1. These data are part of an ongoing research work and the current work is an extension of the work given in [

37]. The above equations are a simplified version of the actual wheelset model as only lateral and yaw dynamics are found to be sufficient to model the wheelset for finding the conicity under investigation. Further work has been carried out to linearize the creep forces considering the lateral and yaw dynamics to obtain the small signal model of the railway wheelset, as given in Equation (5) [

8].

To simulate wheelset dynamics, a random track input was generated in the presence of track irregularities. Thus, the track irregularities modeled as a transfer function representing actual frequencies generated upon wheel–rail contact are used, which serve as input to the model.

The wheelset was, thus, modeled in Simulink using the parameters in

Table 1. The next step was to test the wheelset model by analyzing a constrained solid axle wheelset, i.e., when yaw stiffness is applied. The lateral and yaw dynamics for different values of yaw stiffness were first evaluated operating at the same speed of 30 m/s and with conicity at 0.05. In

Figure 4, the yaw stiffness is

, i.e., a less stiff spring that results in an unstable response, whereas for a high stiffness spring value,

, the wheelset dynamics are stable, as shown in

Figure 5.

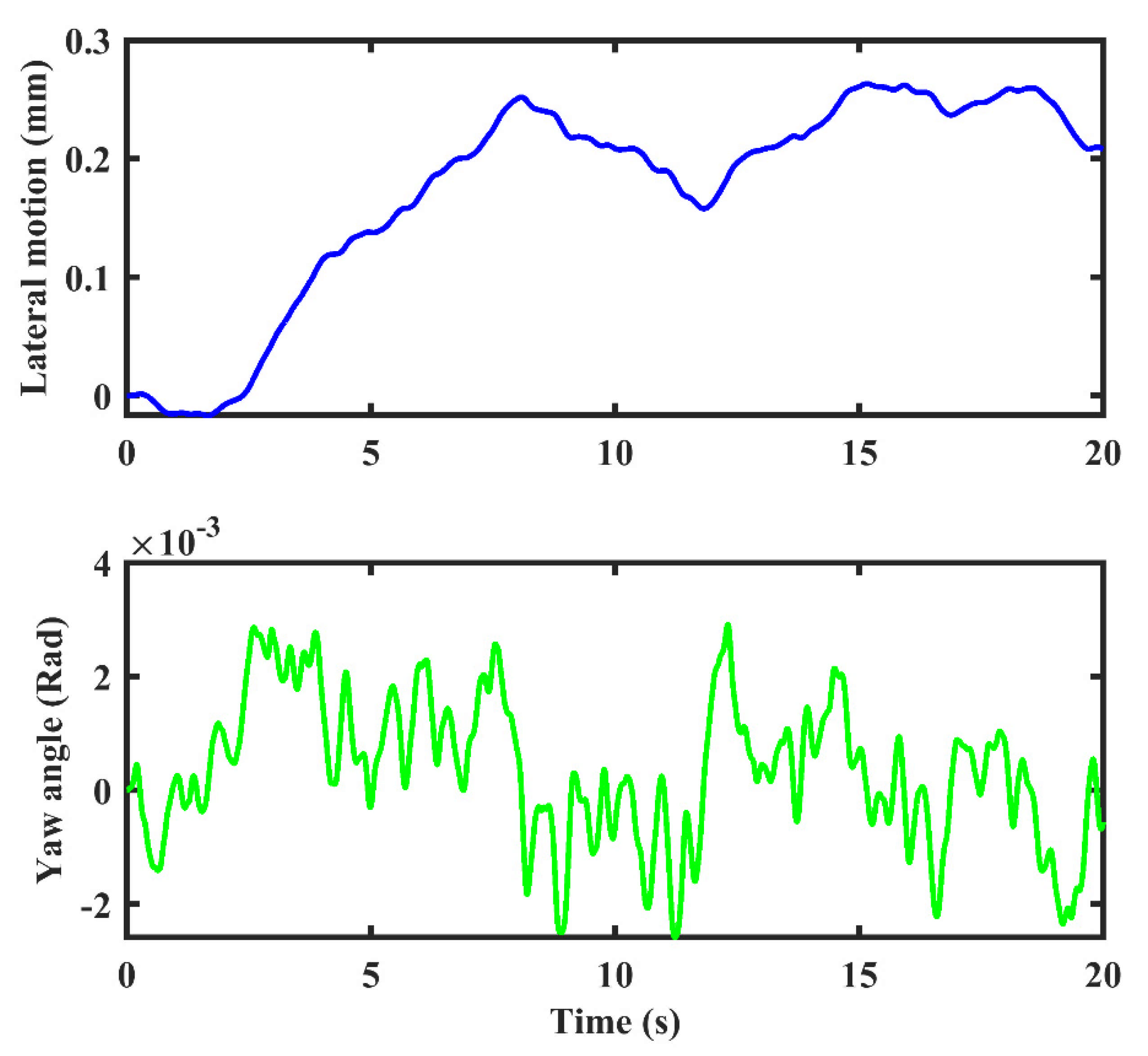

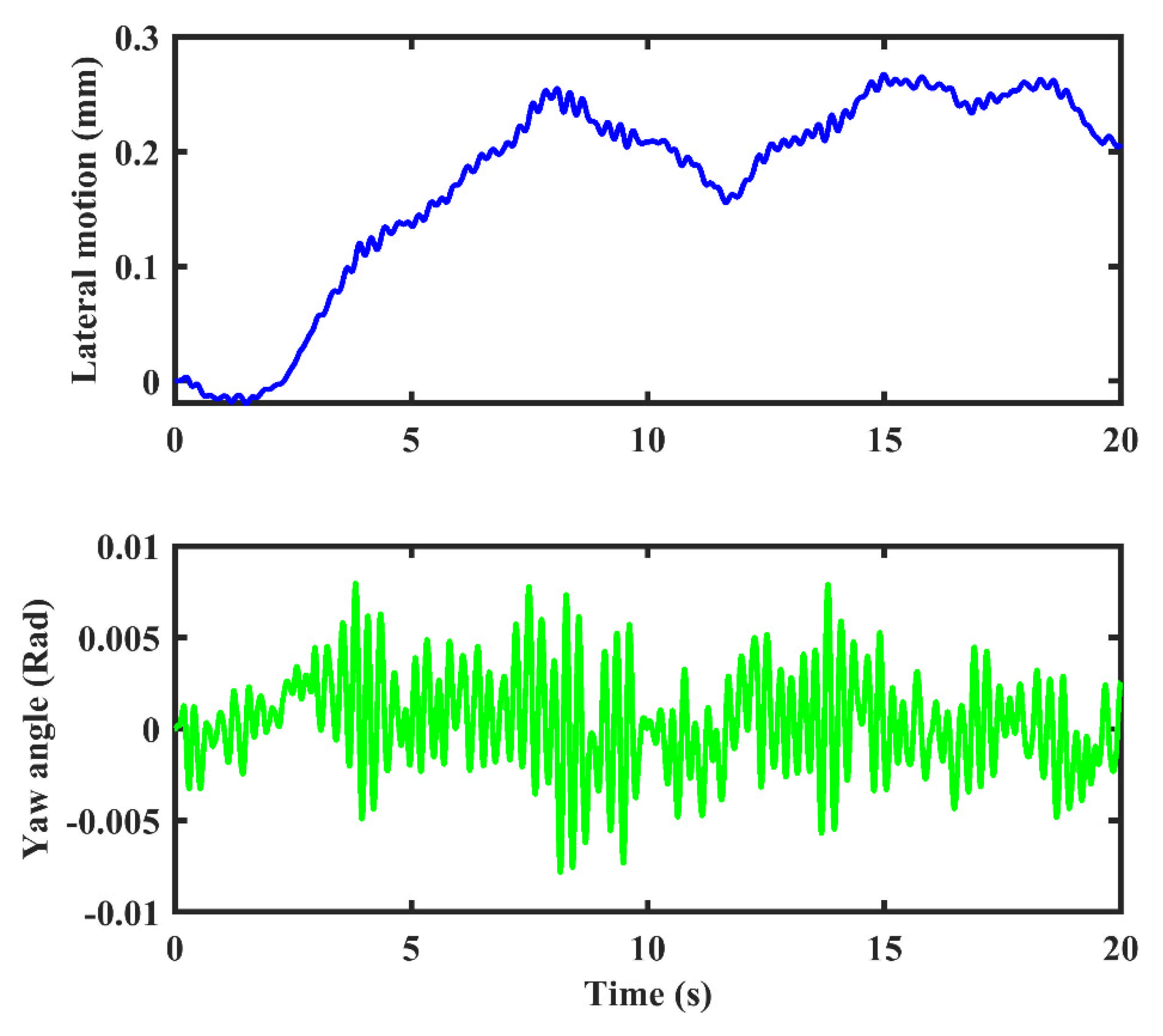

The wheelset model was further tested to validate the dependency of lateral dynamics on the conicity of the wheelset. First, the conicity was set at 0.25, with velocity at 30 m/s and yaw stiffness at

. The model was run and the results for lateral motion and yaw angle were produced, which show variations in the dynamics by increasing the value of conicity, as given in

Figure 6.

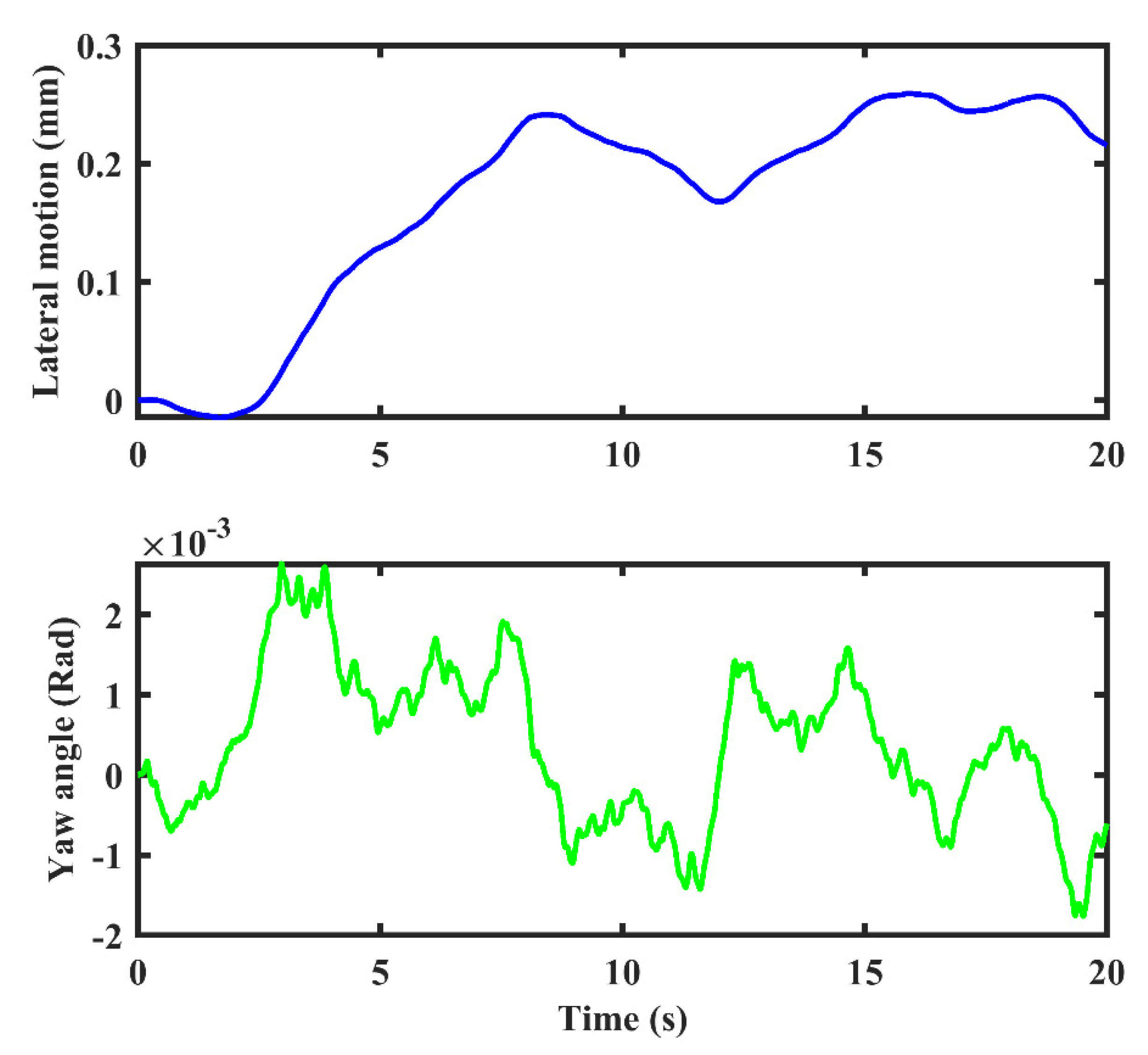

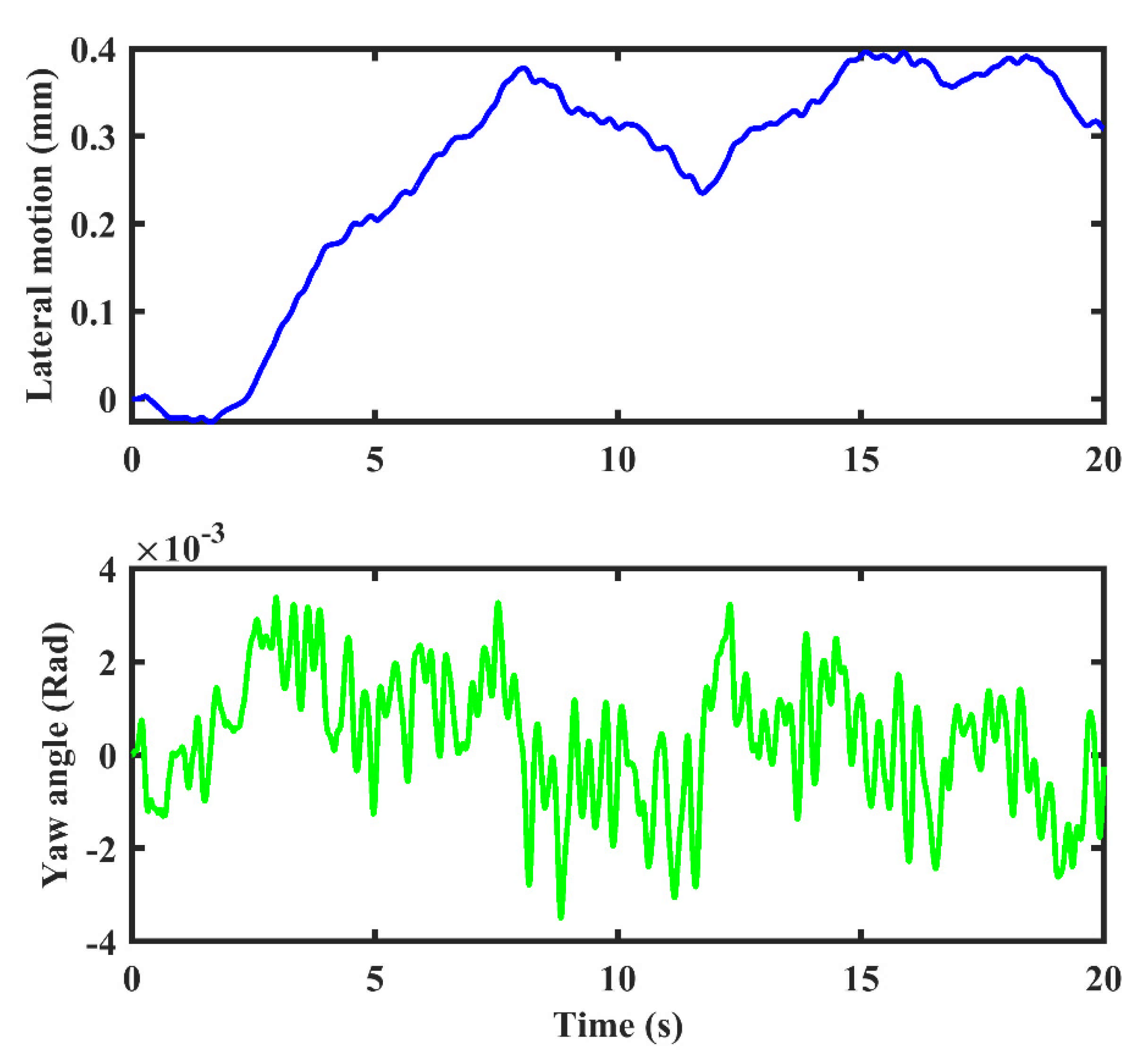

Furthermore, the wheelset model was examined by changing the velocity from 30 to 60 m/s, keeping the conicity at 0.05 and yaw stiffness

constant, as shown in

Figure 7. Here, it can be seen that both the lateral motion and yaw angle increased in magnitude, proving the satisfactory performance of the model.

4. Model-Based Estimation

Model-based estimation techniques find numerous applications in many advanced control systems including vehicles dynamics. The use of the Kalman filter has been rigorously researched and applied in applications involving stochastic noise for estimating state parameters. Due to its robustness and accuracy, it has been used in vehicle stability control and automation systems. It has also been used in railway vehicle systems for fault detection, driver assistance, and adhesion estimation. The Kalman filter has been used in condition monitoring applications in railways allowing maintenance to be scheduled, in order to avoid any possible failure before it happens [

38]. In railways, it determines the current condition of the vehicles in service to improve maintenance procedures [

39] and uses the mathematical model of the system along with an expert system and measured outputs to perform its diagnosis. The use of condition monitoring techniques to identify condition monitoring parameters and wheel–rail interface conditions, such as adhesion conditions, lateral dynamics including yaw rate, etc., have been proposed [

3,

18,

39]. Another model-based approach [

40] has estimated the creep forces in the wheel–rail contact area after obtaining data from inertial sensors mounted on the wheelset using Kalman–Bucy filters.

A model-based condition monitoring scheme for identifying adhesion level by measuring the dynamics response of the wheelset is given in [

3]. Authors in [

39] proposed condition monitoring techniques to estimate creep forces at the wheel–rail interface, which, in turn, could be helpful in identifying rolling contact fatigue, wheel tread wear, damages to wheel tread geometry, and adhesion level.

Authors in [

7] presented a technique to estimate the adhesion force coefficient based on the Kalman filter. Model-based condition monitoring applications using Kalman filtering, such as the linearized simulation model given by [

3], are used in low adhesion detection and wheel–rail profile estimation. The Kalman filter used to detect slip was given by [

41] using an indirect adhesion estimation method. A model-based, low adhesion condition detection system with onboard sensors was presented where the Kalman–Bucy filter estimates the states and provides information about adhesion levels after the postprocessing of data [

42].

A Kalman filter could be used to estimate the states when detecting faults in the suspension system. A multiple Kalman filter approach was used to detect and isolate faults with minimal detection error [

43]. Another attempt at detecting the onboard faults of railway vehicle suspension systems was carried out by estimating the states of vehicle suspension systems based on a Kalman filter [

44].

The Kalman filter has been extensively researched in the past due to its robustness in dealing with estimating the state of a process with limited access to useful measurements amidst noise from the process. Therefore, it has been used in this research work to estimate the lateral dynamics where the track induces noise. The filter basically constitutes a set of mathematical equations and estimates the states of the process. The Kalman filter is a well- established method used by researchers in situations where the signal of interest is surrounded by noise. Since track disturbances generated significant noise, thus, the wheelset dynamics were estimated using Kalman filter in a very efficient manner. Furthermore, the Kalman filters are fed the measured outputs comprising of the lateral dynamics, namely the lateral velocity and yaw rate along with sensor noise, to make the estimation closer to the real scenario.

Thus, the Kalman filter could be designed to estimate the states of the system using state space form; however, the track irregularities need to be made a part of the state space equation as it excites the lateral and yaw dynamics of the wheelset [

8,

45] as given in Equations (6) and (7). Parameter

is introduced in the modified state space model as a tunable parameter.

can be chosen arbitrarily to improve the estimation results. The best possible value of

was chosen after running the simulations at different values of

.

The model-based approach monitors the condition of the railway wheelset conicity by analyzing the variations in the dynamic response of the wheelset, which are sufficient enough to estimate the system states. Some knowledge of the system, along with track irregularities as an input to the system model, serves as the main excitation mechanism. These track irregularities are modeled as a transfer function representing actual frequencies generated when the wheelset comes in contact with the track. The measured output consisting of the yaw rate and velocity are fed to the estimator, which estimates the lateral acceleration for identifying the conicity.

5. Estimation of Lateral Dynamics

The main idea of this research is to indirectly calculate the conicity value by measuring the lateral acceleration. The lateral and yaw dynamics tend to suffice for undertaking study of the dynamics of the railway wheelset, thus, no torque input is required. The lateral track irregularities excite the yaw and lateral dynamics provided to estimators in a simplified design. However, track irregularities are not measurable and, therefore, cannot serve as input to Kalman filters. Instead, the yaw rate and lateral acceleration, along with sensor noise, are fed as input to a bank of filters operating at different conicity levels.

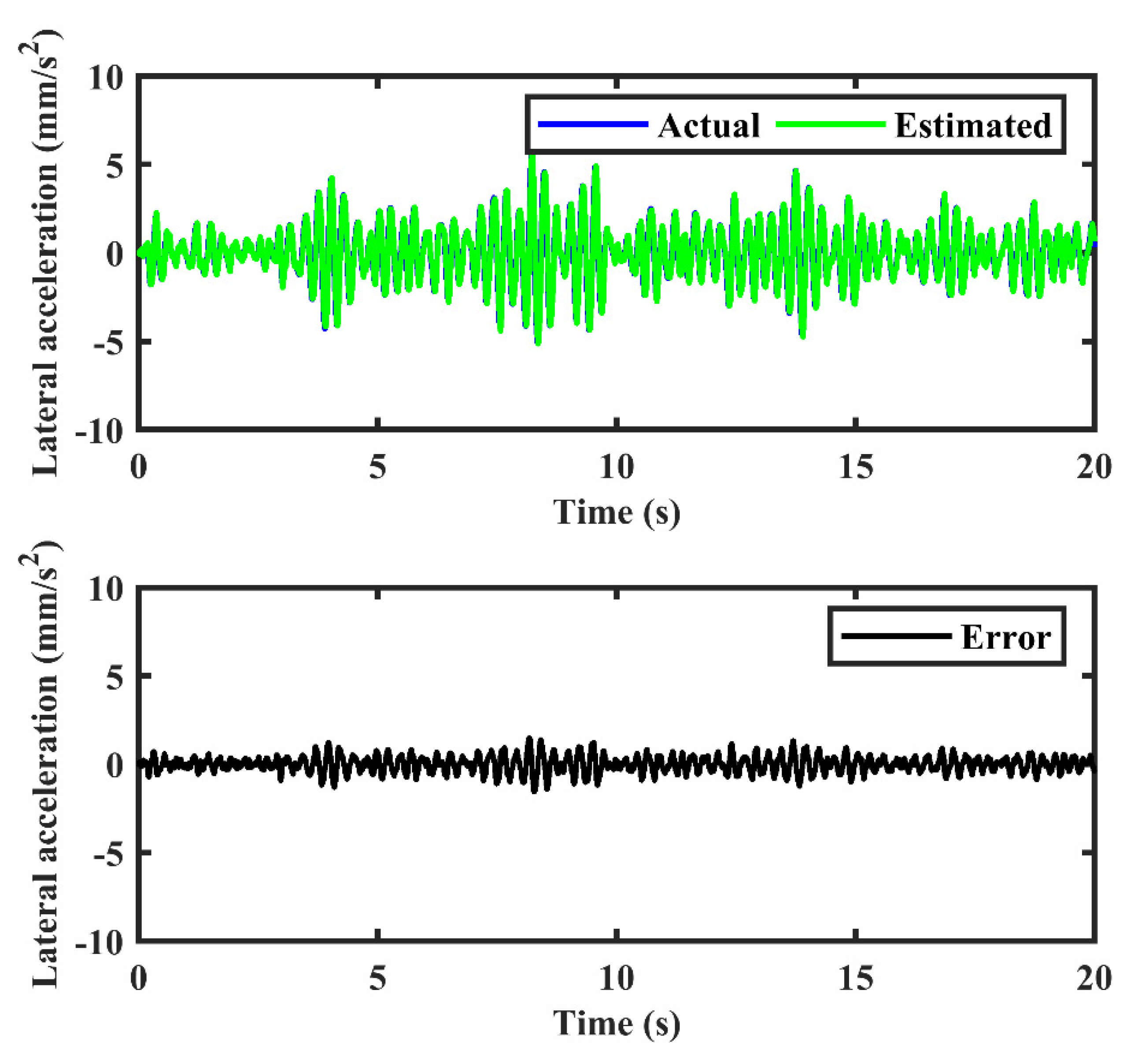

The estimation results prove that the Kalman filter can be useful in providing a reliable estimation of the wheelset states such as lateral acceleration. It can be seen that the estimated lateral acceleration closely matches the actual lateral acceleration with a minimum residual. Different lateral accelerations are produced for different conicity levels such as 0.05, 0.1, 0.2, and 0.25, and this shows a similar trend, as can be observed below where the actual and estimated lateral accelerations are produced for conicities 0.05 and 0.25, as given in

Figure 8 and

Figure 9, respectively. It can be observed that the error is usually less, which implies a good estimate of lateral acceleration by the Kalman filter. This is very significant because the rest of the hypothesis primarily depends on matched estimates for finding the actual conicity of wheelset.

It can be observed that the estimated lateral acceleration tends to match the actual lateral acceleration obtained from the wheelset model. For different conicity values, a similar trend is observed; thus, the estimator operating on a certain conicity produces a lateral acceleration that closely matches the actual lateral acceleration obtained from the system. In a real scenario, the actual lateral acceleration would be obtained from an accelerometer without knowing the conicity, whereas the estimator produces a closely matched value of lateral acceleration, thereby indirectly finding the conicity.

Since the attempt to measure conicity indirectly using lateral acceleration and a single Kalman filter estimation produces the lateral acceleration at a particular conicity level, it calls for a multiple Kalman filter approach to include other conicity levels. This concept is further explored for the estimation of wheelset conicity in the next section.

The problem under investigation has been thought upon extensively, and model- based techniques employing Kalman filter were found to be one of the techniques used extensively in literature to solve such problems. However, the use of a single estimator does not provide the required results because of the complexity of the dynamics of the wheelset and wheel–rail contact. Thus, a multiple model-based approach is used employing a number of Kalman filters tuned on a specific conicity. All of the filters are run in parallel, and the differences between the actual conicity from the system model and the filters are calculated and compared after they are normalized, providing a significant idea about the conicity condition.

6. Estimation of Conicity Levels

The multiple model-based estimation method was introduced by Magil [

46] where multiple dynamic models as estimators are employed in parallel. A bank of Kalman filters are used as estimators that exploit the error or residual between the sensor values collected from the wheelset and the values predicted by the estimator model, based on the Kalman filter [

47]. In railway vehicle research, multiple model-based estimation has been used, especially in fault detection [

48,

49,

50]. For instance, the authors of [

48] proposed a multiple model-based approach using onboard sensors to detect faults in the suspension.

Many past studies have shown that multiple model-based methods have been used in railway vehicle research, for instance, for the real time estimation of adhesion limits through an indirect method using creep forces [

51]. Seminal contributions have been made by authors in the literature for estimating rail–wheel contact conditions in real time by using a multiple model based on Kalman filtering and fuzzy logic [

52,

53]. Another related work, [

54], explored the dynamic properties of the railway wheelset and detected the wheel–rail contact condition indirectly using a multiple model approach. A multiple model-based estimation approach by the authors of [

45] identified the adhesion limit at the wheel–rail interface to help cope with the issue of wheel slip. Another multiple model method for traction and braking control by identifying the wheel–rail contact condition was proposed in [

55].

The multiple model approach continued to gain widespread acceptance by the end of the last decade where the authors of [

44] used a multiple model approach to detect the suspension failures of railway vehicles from onboard measurement data. The model focused on the lateral and yaw motions of the wheelsets and bogie, with sensors measuring the lateral acceleration and yaw rate.

The proposed idea identifies the conicity based on residual signals, which are the difference between the actual lateral dynamics obtained from the wheelset model and the estimated version from the estimators. Kalman filters are used in estimating the states of wheelset dynamics in different conicity conditions. All filters are run in parallel where each filter is tuned to operate on a specific conicity value. After obtaining the residual values, the signal is preprocessed using a moving average filter to smoothen the data, and then, normalized rms values of the residuals are taken so that residuals may be compared on a single scale.

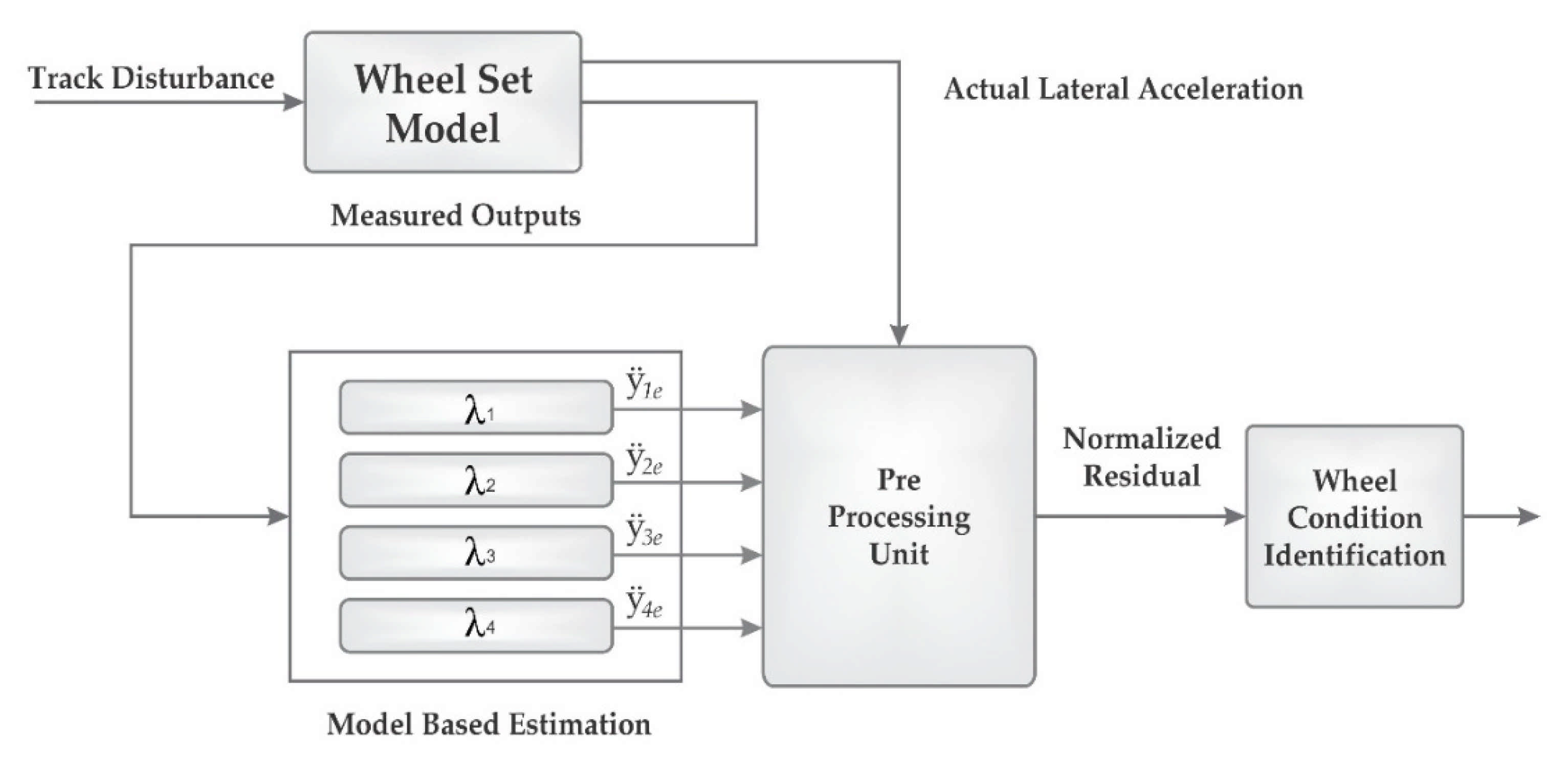

Figure 10 shows the proposed idea based on a multiple Kalman filter bank technique. Each filter, operating on a different conicity level, can be used to provide the estimation of lateral acceleration to match with the actual lateral acceleration.

The wheelset model is operated on a certain conicity level ranging from 0.01 to 0.25 and the lateral acceleration is acquired. The wheelset model output comprising of lateral and yaw dynamics, along with the sensor noise estimate, is fed to the estimators. The sensor noise is used to mimic the noise introduced by real sensors such as the accelerometer and gyroscope. After several attempts and observations, four Kalman filters were found to be satisfactory for estimating the lateral acceleration tuned at different conicity levels. The next step is to take the residuals of the actual and estimated lateral acceleration for all filters. The simulation is setup in a way where all filters run parallelly and for every filter the normalized rms values of the residuals are calculated using a moving time window. The output of all Kalman filters represents the estimated versions of the lateral acceleration on different conicities when the actual wheelset is operating on a certain conicity. Thus, a comparison of the estimation errors can lead to determining the range of conicity of the wheelset. The required number of Kalman filters is set up by carefully analyzing the variation of the normalized lateral acceleration residuals.

In this research, a case representing normal behavior as having a conicity under an acceptable range of approximately 0.1, and two other cases representing extreme conditions of wheel flats at a conicity of 0.05 and false flanges at a conicity of 0.25, are used.

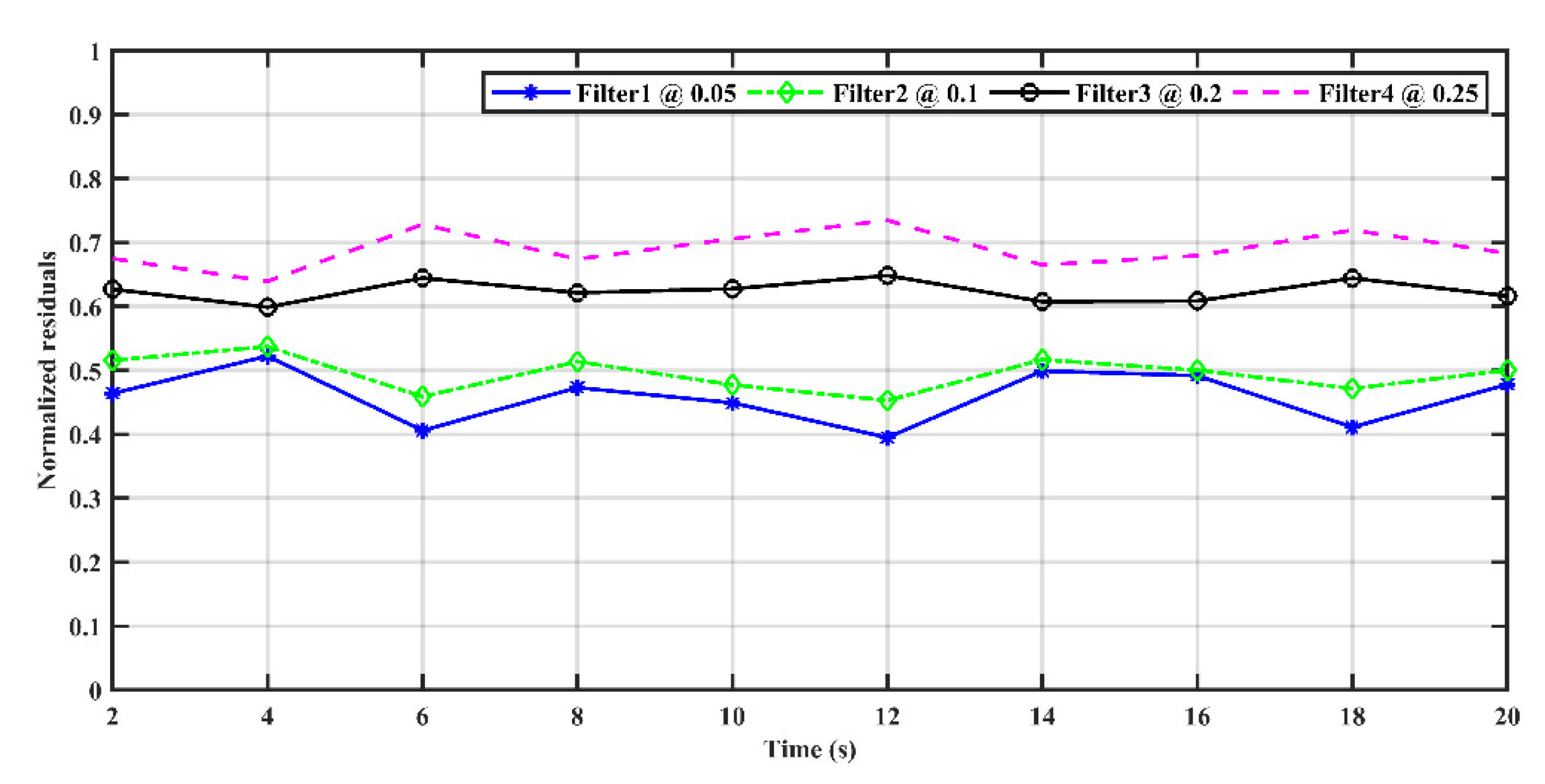

Figure 11 shows the case of wheel flats given by Case 1 where the actual wheelset was operating at a conicity of 0.05. Thus, it shows the least error for filter 1 and the maximum residual for filter 4. When the wheelset is operated in the normal condition referred to in Case 2, the normalized values of the residual are shown in

Figure 12. It can be seen that filter 2 operating on 0.1 matches with this case showing least error, however, filter 1 and filter 4 show a mismatch with relatively high residuals.

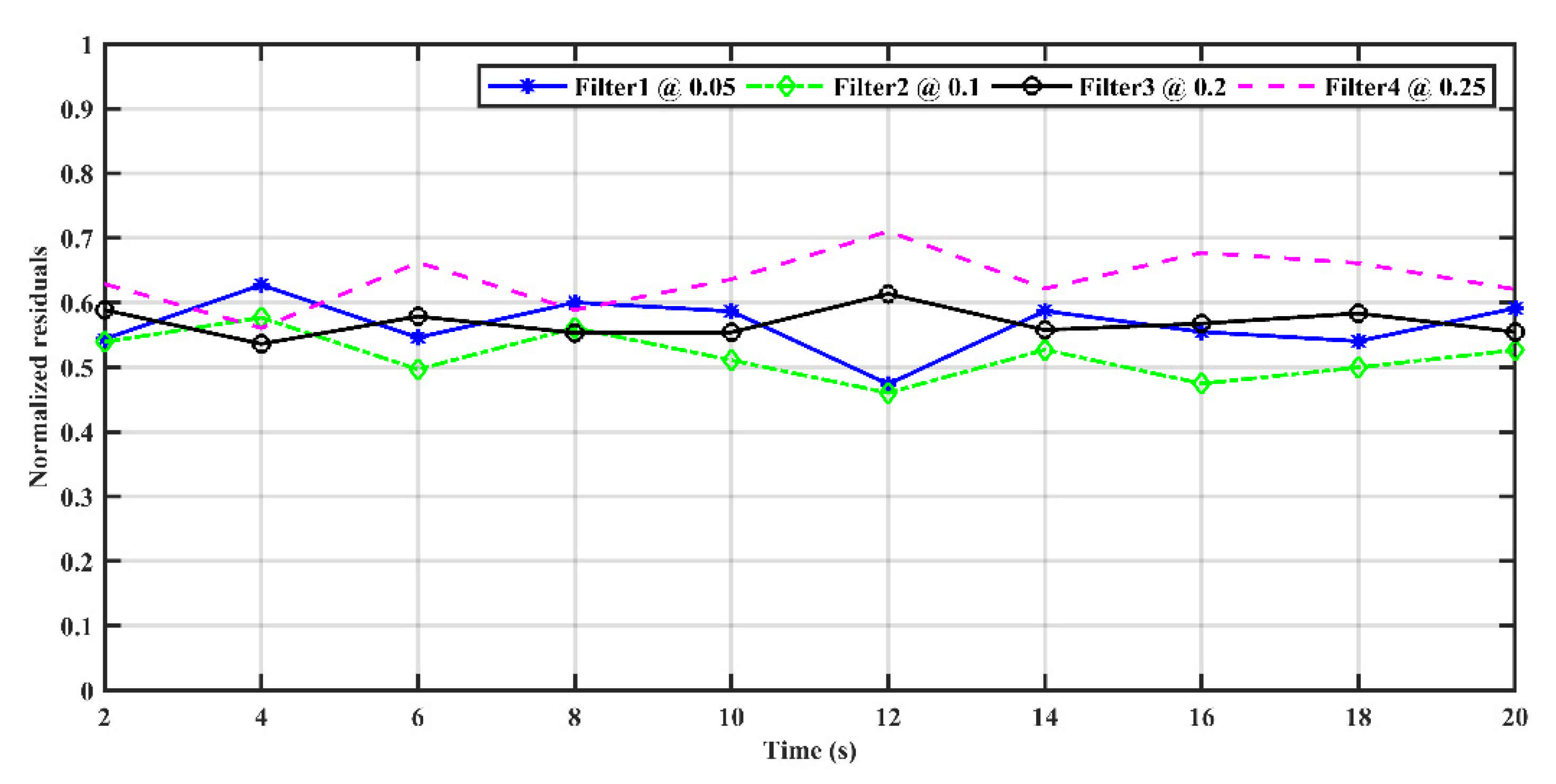

Figure 13 shows Case 3 representing the scenario of false flanges where the actual wheelset was operating at a conicity of 0.25 and, thus, gave the least residual for filter 4 and the maximum error for filter 1.

The actual lateral acceleration matches with the estimated lateral acceleration having least residual. However, the exact conicity can take on any value, whereas the filters are tuned on just a few values of conicity; increasing the number of Kalman filters would increase the system complexity making it unfeasible practically. Thus, in order to detect the exact conicity, a method could be used that combines the normalized residuals from all of the filters to gauge the possibility of which filter is tuned and closest to the actual conicity. The results show that the residual values provide a significant insight into the conicity values and, thus, the idea could be extended further to obtain a generic model predicting other possible conicity values.

7. Fuzzy Logic Identification

The use of fuzzy logic in conjunction with a multiple model-based estimator have been described in [

56,

57]. The different models in a multiple model-based system produce different sets of data; thus, a fuzzy logic system is used that works in the same way as a decision-making system by comparing the actual output with the results produced by various models and, then, accurately identifying the system parameter under investigation. The use of fuzzy logic also reduces the need for the use of lots of models to design the system, reducing the system’s complexity.

Fuzzy logic control has widely been used in many engineering applications, especially in vehicle dynamics control. It finds numerous applications in automotive engineering where control systems have been the vital parameter in the design of vehicles for better performance and safety [

58]. A fuzzy logic system is a handy tool for applications in the field of automotive engineering, vehicle control systems, driver assistance systems, ride comfort control, and forecasting situations where the information on hand is limited [

59].

The fuzzy logic identification system is used to analyze the data from the multiple model based on Kalman filters [

4,

52]. The normalized values of the residuals are used for the identification of the conicity level by producing numeric outputs associated with the models. Fuzzy logic finds numerous applications in industry [

58,

59] and the identification of conicity from the combination of residual values using fuzzy logic is suitable for such applications.

The proposed system model (shown in

Figure 10) intends to identify the conicity based on the difference between the systems model and its estimator design. All of the Kalman filters are operated parallelly and the normalized values of the residuals calculated, which in turn serves as input to the fuzzy logic system that processes the values to identify the conicity level. Depending upon the residuals, the input membership functions are divided into low, medium, and high regions, and when the residual of a filter is smaller, as compared to others, then it reflects the information about the conicity condition.

The residual of each filter is divided as low, moderate, and high to develop the input membership function. The residual values are then processed according to the fuzzy logic rules, which are developed by looking at the residuals given in cases 1 to 3. For example, in case 1 filter 1 is low, filter 2 is moderate, and filter 3 is high, thus the conicity is in the wheel flats region. Similar rules for other possible conicity levels of normal and false flanges are created.

The proposed system works on the principle of the difference between the wheelset model and the estimator model to identify the conicity. While the wheelset model operates on an exact conicity value producing lateral acceleration, the estimators, on the other hand, operate on carefully selected values of conicity in the range from 0.05 to 0.25 producing estimated versions of the lateral acceleration. After taking the individual residuals between each estimator and the model, the residuals are normalized in an attempt to prepare it for the next step. The fuzzy inference system then processes the normalized values of the residuals to identify the conicity level. The membership functions are divided into low, medium, and high, and when the residual of a filter is smaller as compared to the other residuals, then it reflects the information about the conicity condition.

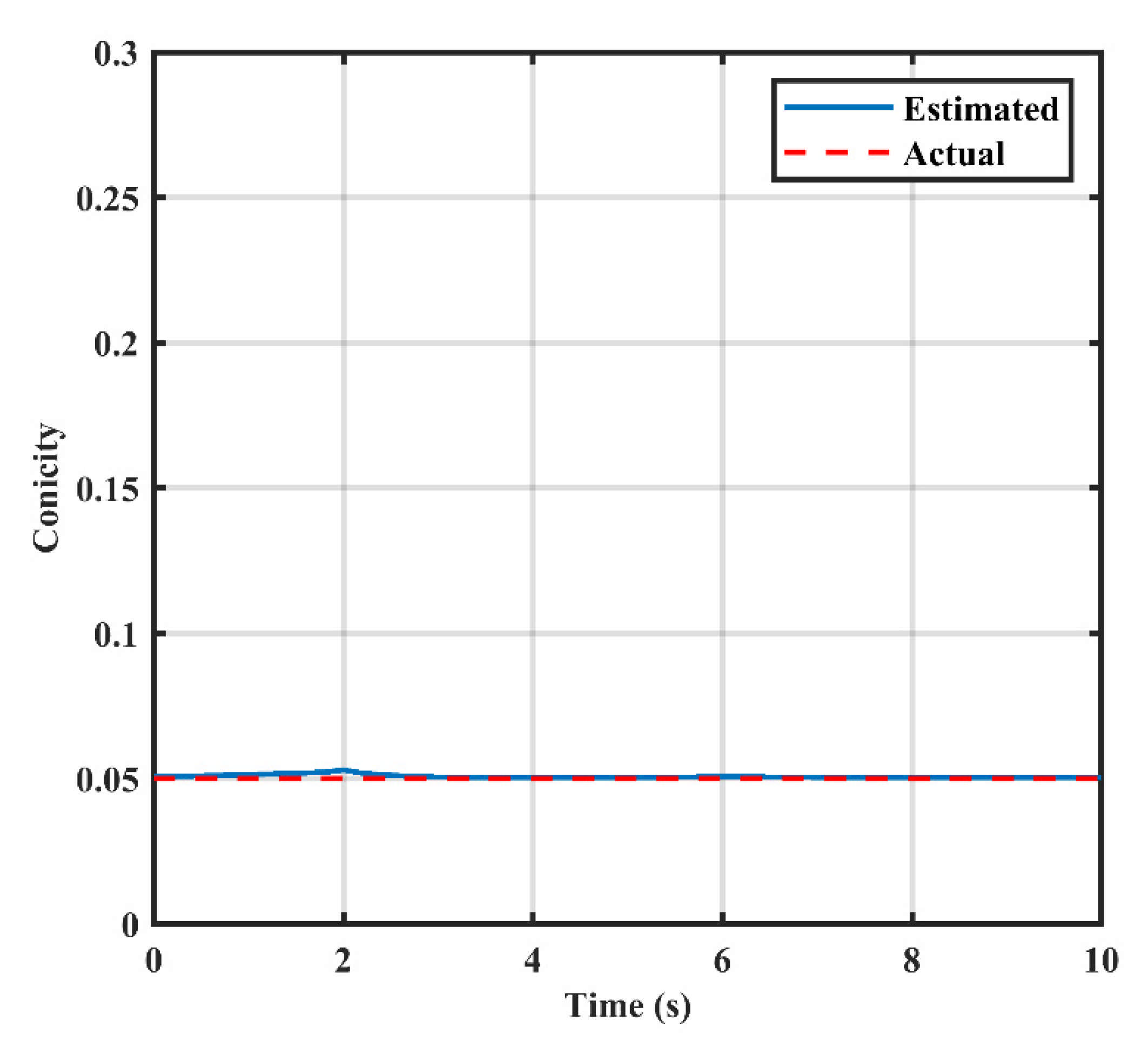

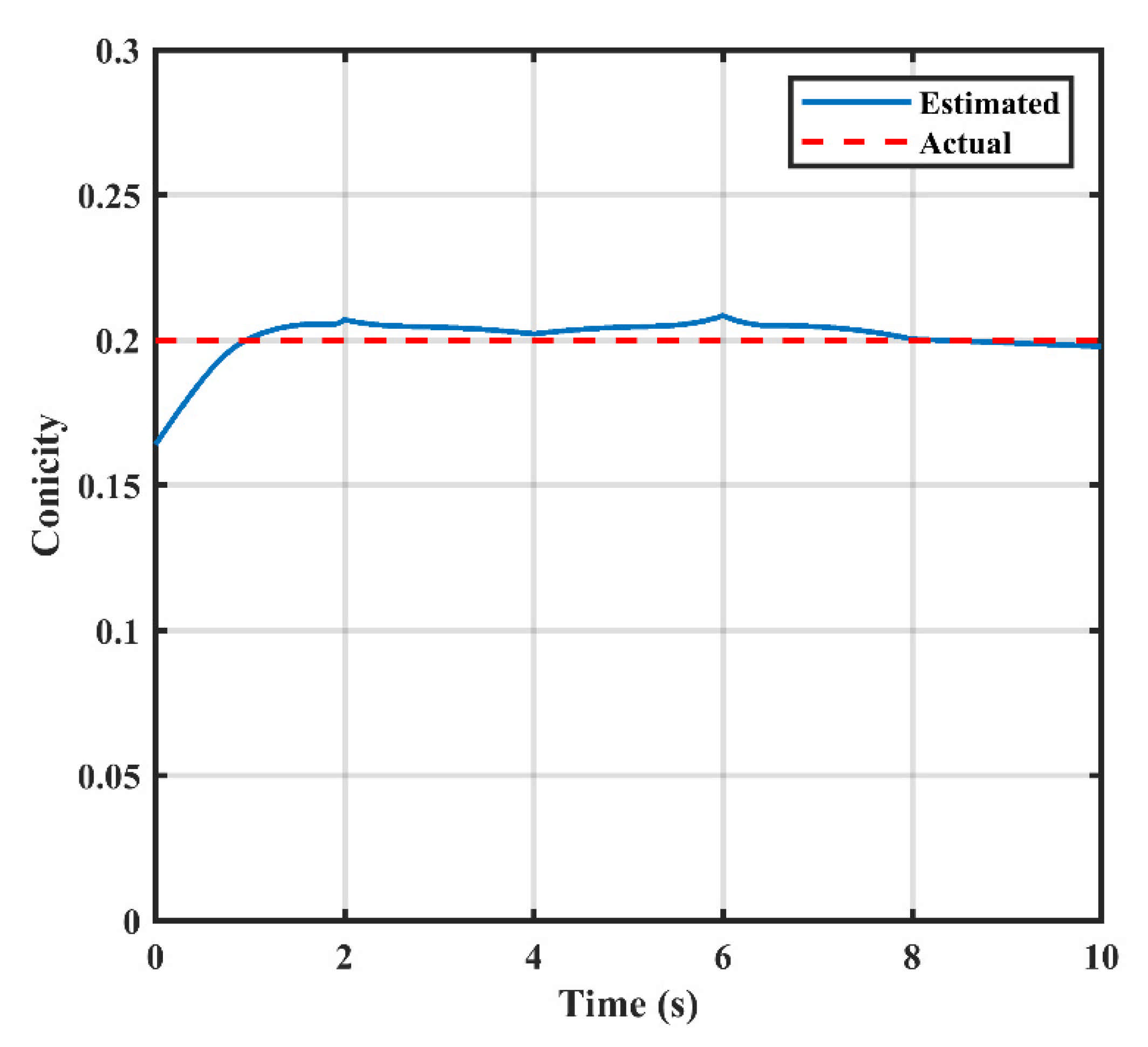

The normalized residuals were fed into the fuzzy logic controller in the Simulink platform and the result of the simulation when the wheelset was operated at a conicity of 0.05 is given in

Figure 14. The system takes roughly two seconds to stabilize and produce a stable result. The delay is due to the time needed in the simulation to reach a steady condition. The output of the fuzzy logic controller was then compared with the actual conicity and found to be nearly equal.

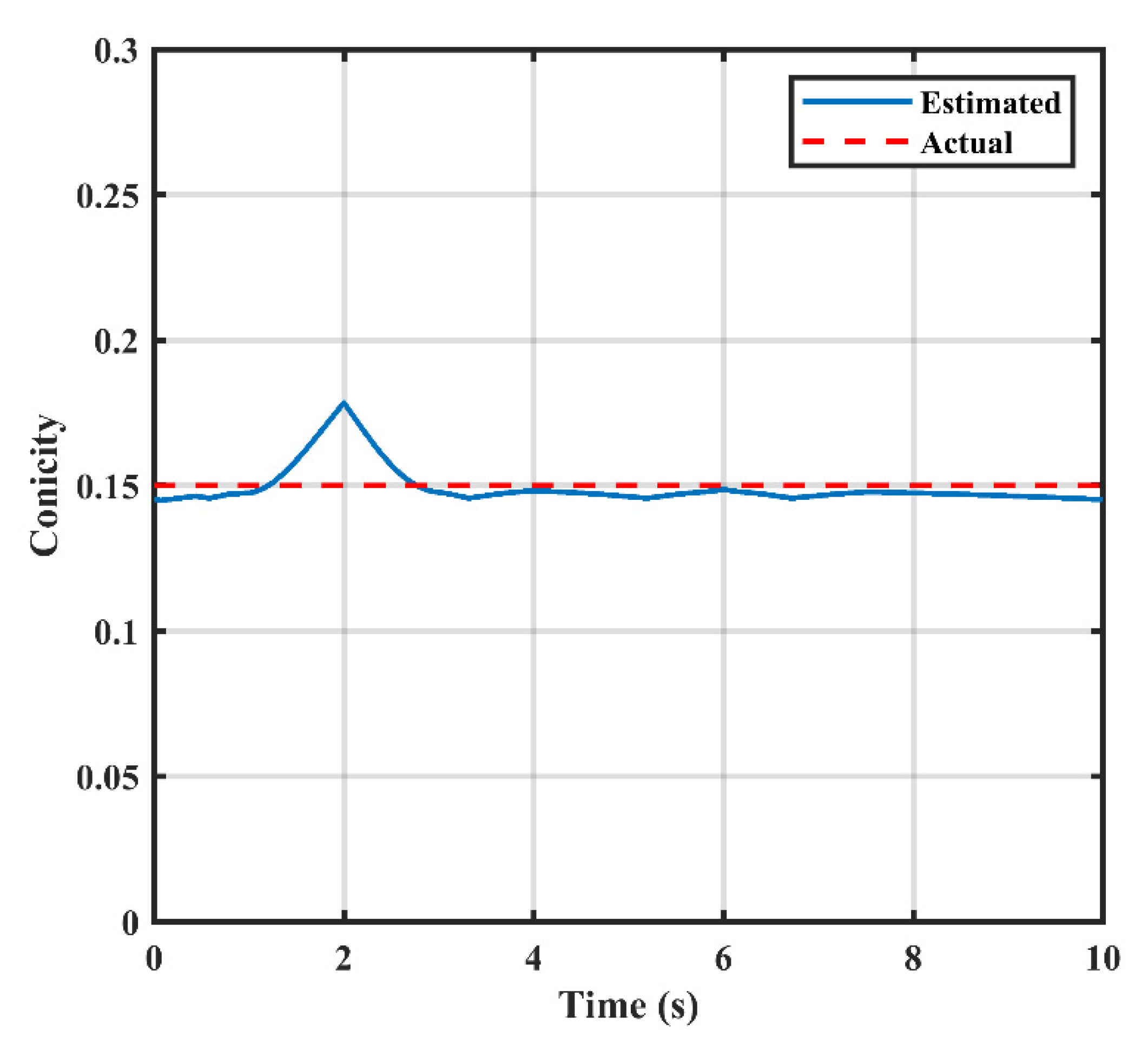

Figure 15 shows the results obtained by running the Simulink model when the wheelset was operating at a conicity of 0.15. Again, a steady output was produced after a delay of 2 s and, afterwards, the fuzzy logic system produced a value also in conformity with the actual value.

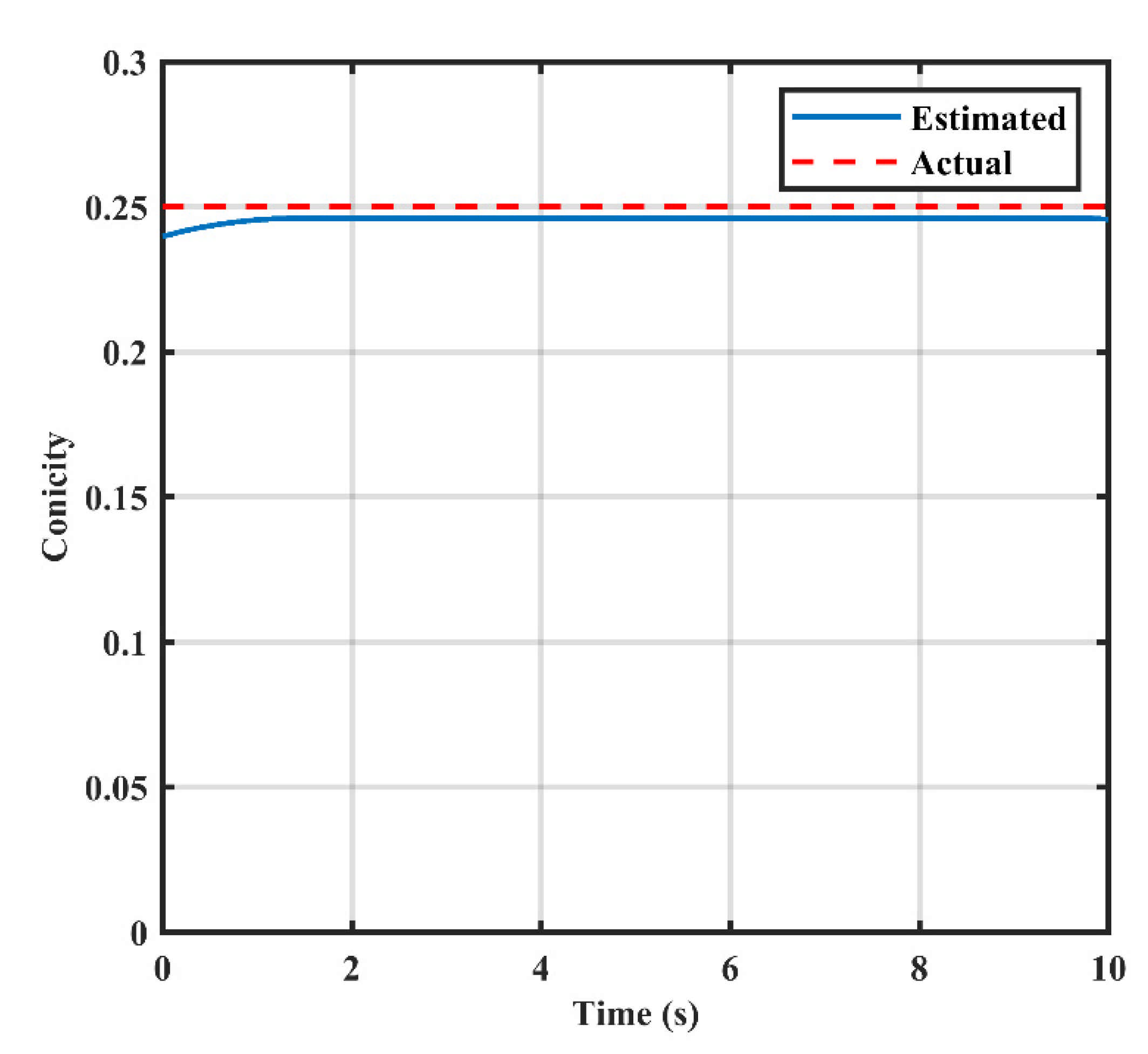

Simulation was further carried out by providing the actual conicity to the model and allowing the fuzzy identification system to identify the conicity from the residuals set as membership functions and the rules. The fuzzy logic system was tested for different values of conicity that not only included the values on which the filters were tuned but also for other values to test the robustness and feasibility of the proposed system.

Figure 16 explains one such case where the fuzzy system estimated the actual conicity of the wheelset at 0.2 even though none of the filters were tuned on this value. Here, the delay is around 1 s, after which the response becomes steady. The fuzzy system also successfully estimated another conicity value of 0.25 after stabilizing at 1 s, as shown in

Figure 17.

8. Conclusions and Future Work

Lack of an effective rolling stock maintenance methodology poses many challenges to railway operators in Pakistan. Extended downtimes due to unexpected failures and frequent railway incidents has not only resulted in huge financial losses but also human fatalities. In this paper, an attempt is made to address this issue to improve the reliability and safety of railway transport. The proposed multiple model-based technique provides a significant breakthrough in identifying the condition of the railway wheelset. It provides information about real time values of the railway wheelset conicity that would be useful for railway operators to perform timely maintenance and avoid any mishap.

The fuzzy system developed in this study has not only successfully identified the conicity conditions where the Kalman filters are tuned but also for other values too. This generic system thus helped to counter the requirement to increase the numbers of Kalman filters, which would have increased the complexity of the system, thereby, making it a more viable solution practically.

The problem of varying conicity of wheelset and its adverse effects on rail systems is a great challenge for the railway industry. In our view, the results emphasize the validity of our model and, thus, lay a significant foundation for a way ahead in the future. However, further work on experimental validation will be required before making it a reality. In this study, a single wheelset model is used to demonstrate the efficacy of the idea. Further work can be carried out by considering the complete bogie wheelset dynamics to mimic the actual railway vehicle dynamic behaviour for validation of the proposed detection method in a realistic situation. Future work could also focus on experimental research on a scaled version of the wheelset. Additionally, data from onsite sensors, such as accelerometers, installed on a wheelset imitating realistic conditions could be further explored to assess future development in this regard. The comparison of simulations and actual measurements could add more robustness to the model.

In addition to this, deep learning algorithms could be used as an identification method to identify actual conicity levels. Furthermore, a classifier could be developed to identify a conicity level by extracting features from the estimated lateral acceleration values. Accurate information about conicity will then allow the control system to put in place preventive maintenance for the safety of all.