Abstract

The adoption of Industrial Symbiosis (IS) practices within urban areas is gaining interest due to the environmental impacts entailed by the development of cities. However, there is still a lack of knowledge about how the relationships between industrial and urban areas can be modelled. In this context, this research aimed at posing a conceptual model to understand and represent Urban-Industrial Systems (UIS). To this end, a set of worldwide previous UIS experiences were overviewed to identify the agents, dynamics, and collaboration opportunities that characterize them. The multi-perspective analysis of these cases indicated that UIS are complex systems, which means that they are autonomous, self-organized, responsive, nonlinear, and willing to consolidate their resilience. As such, Agent-Based Models (ABM) were suggested to be the most suitable approach for their representation.

1. Introduction

Today, around 50% of the world’s population lives in cities. This figure is expected to rise up to 70% by 2050 [1]. To face this rapid growth, cities must be planned to harmonize the three pillars of sustainable development, namely economy, environment, and society [2]. The explosion of industrial activity and population over the last two centuries have caused serious environmental degradation [3], putting current societies in a situation in which production processes must be reformulated to be efficient in the use of energy and natural resources. An industrial transformation towards sustainability is of great opportunity for a step change. Digital technologies in flexible manufacturing [4] and in-depth comprehension of the transformation patterns for decision making in resource dependent cities [5] can support this evolution.

Industrial Ecology (IE) and Urban Metabolism (UM) are two concepts closely related to this situation. IE is an interdisciplinary research area aimed at mimicking natural ecosystems in the production of goods and services, thereby trying to close energy and resource cycles [6]. UM concerns the exchange of resource flows and information between urban settlements and their surroundings [7]. As a bridge between both terms, the concept of Urban-Industrial Symbiosis (UISym) emerged to try to close the cycles between industrial and urban areas by promoting resource and energy exchange to each other [8]. The main obstacle behind this interaction is the need for strong investment to implement these symbiotic networks.

Some investigations have been developed throughout the years to address different aspects related to Urban-Industrial Systems (UIS). Both Sun et al. [9] and Dong et al. [10] focused on determining the ecological benefits derived from the implementation of an UIS in Liuzhou (China), obtaining important reductions in resource mining and waste disposal. Sun et al. [11], Bian et al. [12], and Shah et al. [13] extended the scope of these types of studies by introducing the concept of eco-efficiency, thus exploring the economic impacts and geographic feasibility of implementing an UIS in the cities of Shen-yang and Guiyang (China) and Ulsan (Korea). Other investigations have recently applied more specific tools or methods to design UIS. Fan et al. [14] developed a Pinch Analysis approach for waste integration, and Yong et al. [15] developed an approach for energy integration in UISym sites. The results obtained from each demonstration case study revealed the potential of the extension of the Pinch method for the engineering design of UIS.

The trend of UIS-related research reveals that most studies provide methodological contributions to account for the environmental benefits derived from the analysis of individual case studies while discussing the factors that hinder the implementation of symbiotic practices [16]. In this context, this research analyses the behavioural patterns observed in the main international UIS experiences, whereby the main agents, dynamics, and collaboration types involved in the interrelation between urban and industrial areas are brought together. A methodology based on research on design has been conducted to assess the main international UIS experiences that are in operation nowadays [17]. To this end, Section 2 of this article includes an overview of the symbiotic networks of seven selected real UISym case studies, and Section 3 contains the identification and description of the main features resulting from a multi-perspective analysis of these systems. Then, in Section 4, the fundamentals of a new conceptual model based on the insights obtained from the analysis are raised. Finally, Section 5 contains the main findings of the study, highlighting both their implications for this research field and future lines of action to address the limitations of this study.

2. Overview of Real Urban-Industrial Symbiosis Case Studies

The methodological approach used in this work is based on research on design [17]. With the aim of developing a UIS conceptual model, several worldwide UIS case studies were included in the research for this analysis. These case studies needed to have been successfully created, implemented, and operated. There were seven UIS case studies that met this condition and that were selected to analyse the development and implementation of synergies between industrial and urban areas, focusing on the challenges found for the materialization of this interaction. A total of three of these cases were in Europe (Forth Valley, Kalundborg, and Norrköping), one was in North America (Londonderry), and three were in Asia (Suzhou, Kawasaki, and Liuzhou). Other experiences such as Devens (U.S.), Ginebra (Switzerland), or Salaise-Sablons (France) were not considered due to their early stage of operation and/or limited data availability. First, a characterization of the case studies was conducted in terms of the symbiotic exchanges that occurred in each experience. Table 1 summarizes the main characteristics of the case studies that were overviewed, including their location, starting year, and operation scheme (do-nor(s), flow(s), and recipient(s)). The donor is the agent involved in the symbiotic exchange that supplies any waste flow, secondary outputs, or financial capital. The recipient is the agent involved in the symbiotic exchange that receives any waste flow, secondary outputs, or financial capital. Every exchange connection is denoted by the flow(s) supplied from the donor to the recipient(s). As it can be observed for each case, any agent (e.g., the Suzhou case, WWTP, incineration plant, cogeneration plant) can perform a dual role as a donor or a recipient indistinctly.

Table 1.

Characteristics of the main worldwide experiences on the development of Urban-Industrial Systems (UIS).

The industrial park of Suhzou was selected by the Chinese government to promote clean and renewable energy. There are two main groups of synergies in this park: the symbiosis among wastewater treatment, sludge, and cogeneration plants and the exchanges involving heating, cooling, and electric energy. Recovered water is mainly used for cooling in cogeneration plants. However, treating large volumes of water involves great amounts of sludge, which are generally disposed in landfills due to the absence of standards in this sense. To palliate this, a drying sludge plant was built next to a Wastewater Treatment Plant (WWTP) and a cogeneration plant in 2011. The processing of wet sludge and its subsequent use as fuel for generating electricity through cogeneration saves 12,000 tCO2eq/year. The ash stemming from the incineration of sludge is used to produce construction materials. During the drying process, 90,000 t/year of condensate are also sent to cogeneration, which serves to save 1 M RMB/year in terms of water and heating costs. The steam generated during cogeneration goes through cooling towers to produce water for the Moon Bay district. Hence, 3390 t CO2eq, 8000 t CO2, 70 t SO2, and 70 t NOx per year can be saved as well as 50,000,000 RMB/year. associated with maintenance works.

Forth Valley couples Edinburgh and the petrochemical complex of Grangemouth, which is the greatest industrial area in Scotland. Moreover, Forth Valley includes four large electric plants, a cement plant, two oil companies, and two paper factories. Its synergies include the reuse of shells for roads and inert waste for aggregates and soil as well as the recycling of home appliances. Other synergies related to wastewater, heating, sludge treatment, and energy are also being investigated. The drying of sludge results in pellets, which can provide fuel to supply 30,000 households. Power plants recover and reuse about 500,000 t/year of fly ash and solid ash, resulting in GBP 988,000 in savings in 2004. The cement plant in the park uses 3 M of waste tires and 20,000 t of recycled liquid fuel produced by other companies, which enables the saving of more than 40,000 t of fossil fuels and the reduction nitrogen oxide emissions. A power plant was established to burn 110,000 t/year of bird faeces, generating 81 GWh/year of electricity to supply 20,000 households. The remaining ash stemming from the process was used as high-quality fertilizer.

The Kawasaki case study emerged because of the interest of the Japanese government to form eco-cities. To this end, it funded five facilities related to reuse paper and valorise plastics as inputs for use in both blast furnaces and in the manufacturing of ammonia and concrete moulds. A typical example of by-product exchange in Kawasaki is the use of slags from the production of steel as raw materials in the manufacturing of cement. These steelworks are fed with iron and non-ferrous materials from an appliance recycling facility, whilst cement plants are recycling the sludge from urban wastewater to replace clay as well as wood, plastic, tires, and oil wastes to substitute carbon. Kawasaki has the first paper recycling plant to achieve zero emissions. The city government manages and supervises the collection of Municipal Solid Waste (MSW) and Industrial Water (IW). Non-recyclable MSW are transferred to incineration plants, the ash of which is either reused by cement plants or disposed in a landfill. Besides the incinerators, the government also controls five collection centres and one transportation centre for MSW.

Londonderry is using eco-industrial development to deal with the negative effects of rapid growth. The inhabitants of the city have mobilized to preserve its agricultural heritage and to promote adequate environmental and cultural development. A recycling company approached a creamery to acquire its plastic waste and rinse them using grey water. This was the first step in the Londonderry eco-industrial park project, in which every member would be audited in terms of energy efficiency, water conservation, product management, materials usage, etc. A private investor owned the land and financed the development of the park. A 720 MW combined cycle power plant was installed in this park and was built underground. Soil extracted during its construction was used to develop the regional Manchester airport. In addition, the plant is cooled with 15,140 m3/day of treated wastewater that is pumped from the WWTP in Manchester. However, the inclusion of companies in using the steam and residual heat from the power plant did not come to fruition, resulting in the power plant going to receivership in 2004.

Kalundborg arose from the premise of conserving natural reserves and improving the economy. Since 1960, it has been an important industrial centre for the country due to its large scale eco-industrial park configuration. In 1961, the power plant of the city decided to replace the use of groundwater with surface water from a lake, prompting a shift in the awareness of resource valuation. The system is formed by five main components: a power plant (600 employees and a carbon-based capacity of 1500 MW), a refinery (250 employees and a capacity of 3.2 Mt/year.), a gypsum board company (160 employees and an annual production of 14 M m2), an international pharmacy company (1400 employees and annual sales of $2000 M), and the municipality of Kalundborg, which provides heating to 20,000 inhabitants and supplies houses and companies with water. The relationships among these agents resembles a food chain, including actions such as supplying houses, greenhouses, and aquaculture farms with heat obtained from generators and by reusing biological sludge for use as fertilizers or calcium sulphate and fuel gas to manufacture gypsum boards.

Liuzhou is a Chinese city whose economy is headed by the steel and automotive industry. The situation in this city is complex, involving different companies with a variety of economic, environmental, and social interests. This fact hindered the spontaneous creation of a symbiotic network. For these reasons, the government boosted the testing of Liuzhou as a laboratory to assess the potential benefits of IS. A steel company performs as a central node in the symbiotic system, such that it is surrounded by other industries with a high potential for material and energy exchange, such as power plants, cement plants, chemicals plants, etc. There are nine types of materials, energy sources, and wastes that can be exchanged, including blast furnace slags, treated slags, metallurgical gas, waste heat, desulfurization by-products, steel, plastics, tires, and ash. As a result, this UIS can save more than 2.4 M t of materials and 0.9 M t CO2eq of energy through exchanges, while reducing solid waste by 3.4 M t and CO2 emissions by 2.3 M t.

Norrköping is characterized by strong renewable energy developments and close cooperation among industrial companies that create self-organized clusters. This municipality was a pioneer in installing and operating an urban heating system. Today, it feeds a cogeneration plant with MSW (25,000 t/year.), which provides urban heat and industrial steam water. A refinery produces distillery slops that become either forage to be used in agriculture or substrate for a biogas plant. The development of this network has been aided by the commitment of the municipality with the environment, the creation of an urban heating system, the development of a cogeneration plant, and the biogas demand by the transport sector. There are future plans for promoting new synergies in Norrköping, such as a sawmill, which would be used to produce wood pellets.

3. Multi-Perspective Analysis of Urban-Industrial Systems

After the characterization of the UIS case studies described in Section 2, a further investigation was done to compare the behavioural patterns of the experiences. A systematic multi-perspective analysis was realized to identify and describe the main features of these systems. This section accounts for the main results, which are summarized in Table 2.

Table 2.

Characteristics of the agents involved in Urban-Industrial Systems (UIS).

3.1. Types of Urban-Industrial Systems

The main aspect defining the existing types of UIS is the nature of their investor. Private investors fund and facilitate contact among companies to obtain economic benefits. Instead, public investors are national or local governments that use funds or taxes to promote cooperation among companies to bring together the economic, social, and environmental benefits. In both cases, the figure playing the role of the investor can take part in the management of the exchange networks. In the case of public investment, the process can take place with or without the support of a facilitator, who is an intermediary assuming the promotion and management of the network.

According to the case studies in Table 1, public investment (governments as donors) was the approach taken in Suzhou, Forth Valley, Kawasaki, Kalundborg, Liuzhou, and Norrköping, whilst Londonderry was the only city financed through private investment (private investor as a donor). Regardless of the source, it is always necessary to have external funding to boost and maintain UIS. Otherwise, the arrangement of cases such as these is very complicated and is unlikely to happen spontaneously. Investors are usually motivated by environmental needs, such as the valorisation of urban waste generated in municipalities (e.g., Norrköping) or the increasing concern of industrial pollution (e.g., Suzhou).

3.2. Agents in Urban-Industrial Systems

Regardless of the type of UIS, there are common agents in these systems, as demonstrated in Table 2. First is the industry, whose main aim is to transform raw materials into products. SMEs have a similar purpose but work with lower business volumes and mainly perform as waste recipients. The municipality is home to a population, generating Municipal Solid Waste (MSW) and wastewater. Rural areas relate to zones devoted to agriculture and livestock, whilst power plants deal with the production of electric energy.

There are three other agents focused on valorising either materials, water, or energy. The former seeks to provide new uses for wastes, whilst water valorisation concerns treatment plants aimed at purifying wastewater from the industry and the municipality, such that it can be reused without damaging the environment. Finally, energy valorisation stands for both the incineration of MSW and the drying of sludge. Incineration causes a volume reduction in waste, which is transformed into ash that can be used in industry as additives. Thermal energy can also be obtained throughout this process. As for sludge drying, it consists of dehydrating the wet sludge stemming from WWTP and converting it into pellets to be used as fuel by other agents.

3.3. Dynamics in Urban-Industrial Systems

The mechanisms to create and successfully operate the UIS analysed in the worldwide experiences took a long-term approach. Overall, the operation of UIS can be divided into initial, intermediate, and advanced stages of development. The initial stage, led by either a public or private investor, serves to encourage the required participants to form a basic exchange network in contact with each other. During the intermediate stage, the symbiotic network grows through the addition of more partakers. In the advanced stage, the system is managed by either public or private investors to maximize its benefits.

The agents become involved in the system at different stages. The components participating in the system from the beginning of the process are only municipality and industry. They are both at the core of UIS not only for conceptual reasons, but also because of the amount of waste they generate, which can be reused by other agents that enter the system in the intermediate stage, such as SMEs, power plants, and rural areas. The latter join the system to strengthen the symbiotic network and obtain benefits from it. Although they are not as essential as those parties who are involved in the initial stage, their role is crucial in terms of association and cooperation.

The agents related to resource valorisation are created complementarily to the existing symbiosis network in the advanced stage to improve it and minimize the amount of waste. They work as intermediaries among agents that could not cooperate otherwise, resulting in new options for the reuse of waste. Despite the differences between the intermediate and advanced stages, this breakdown is not always put into practice. For instance, these steps emerged at the same time in the third case study that was overviewed (Kawasaki) since there was an interest in rapidly densifying the network and closing material loops.

3.4. Collaboration in Urban-Industrial Systems

The most common means of collaboration observed in the main worldwide experiences (Table 1) concern the exchange of materials, water, and energy. This does not have to always be this way; other cases lacking heavy industry might be more active in sharing infrastructure and/or services [34].

The collaboration identified in the case studies can be grouped as to the type of flows exchanged between the donors and recipients summarized in Table 1. These flows were organized and allocated to each type of agent as input and output flows, as presented in Table 2. There are four distinct main categories: materials (MSW—plastic waste, organic waste, scrap, glass; industrial waste—plastics, scrap, ash, slags, fuel, fertilizers, wet sludge), water (urban wastewater, industrial wastewater, treated water, water for cooling purposes), energy (thermal energy), and economy (money, investment, funding, tax reduction, control of service management, benefits from exchanges).

Contacts among the parties involved usually stem from meetings among representatives of the industries promoted by the investor, in which the potential benefits of collaboration are shown. In this sense, computer tools are used to facilitate cooperation, such as synergy databases, where companies can search for potential exchanges. It is also common to form councils involving representatives of both the industry and the municipality to take charge of the development and management of the symbiotic network. As a summary of all the aspects covered in this section, Table 2 shows the agents involved in UIS as well as their role, aims, flows (inputs and outputs), and type.

4. Proposal of a New Conceptual Model

The genesis of the case studies summarized in Figure 1 demonstrates similar characteristics with Planned Eco-Industrial Parks (PEIPs), which seek compatible activities with potential to cause symbiotic networks with the financial support of an external agent [35]. This coincides with the role played by the investors, who promote and coordinate the creation of these experiences. However, this situation would appear to change with the increasing autonomy of park agents, and they start searching for their own benefits with time, to the extent that they end up resembling the dynamics of Self-Organizing Symbiosis (SOS) [36] rather than those of PEIPs.

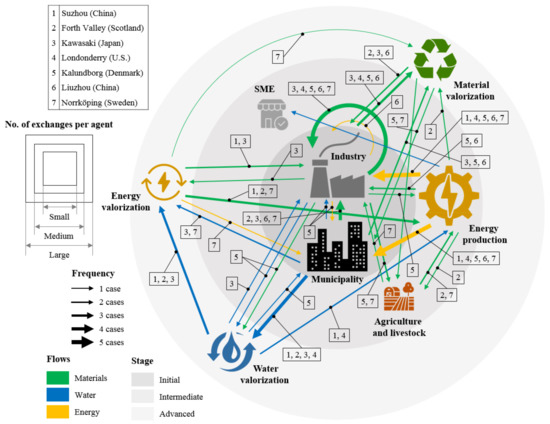

Figure 1.

Graphical summary of the type, size, and time of the relationships among the agents involved in the main worldwide Urban-Industrial Systems (UIS).

This unsteady condition highlights the need for elaborating a model for their systemic conceptualization. To this end, the analysis of the behavioural patterns in the main UIS experiences reported worldwide was first, as listed in Figure 1. The dynamics observed in these case studies enabled their subsequent examination as complex systems. Then, a list of indicators was proposed to measure the eco-efficiency of the agents involved in the UIS. The last step consisted of the selection of a modelling method according to the characteristics of UIS as complex systems.

This course of action is in line with the conclusions drawn from recent studies in the field of UIS to emphasize the development of this kind of approach as a key line of research to develop in the future. For instance, Lu et al. [37] pointed out that the lifecycle of a perspective UIS, which is closely related to the evolutionary behaviour of these complex systems with time, must be considered. Moreover, Fan et al. [14] underlined to the importance of implicating all of the agents and flows involved in UIS. In the same vein, Bian et al. [12] referred to the creation of comprehensive systemic models to account for the interactions among UIS sectors while proposing an eco-efficiency indicator approach to account for the effects and contributions in UIS.

4.1. Behavioral Patterns in Urban-Industrial Systems

Figure 1 provides a graphical scheme of the agents identified in Table 2 and their relationships to each other, based on the case studies summarized in Table 1. These agents are represented using different sizes (small, medium, large) depending on the number of exchanges in which they participate, while highlighting the stage of development when they entered the system. Industry, energy production, and municipality agents are depicted as the largest in terms of exchanges, whereas SME, energy valorisation, and agriculture agents are the smallest. Material and water valorisation agents participated in a number of exchanges in between and therefore are represented by as being of medium-sized. The scheme also indicates the frequency with which each flow (materials, water, and energy) is exchanged, specifying its correspondence to the case studies under analysis (e.g., the energy production agent exchanges energy with industry and municipality in five case studies). The inspection of Figure 1 reveals that most of the interactions take place in the last stage. This is due to the ad hoc purpose of the material, energy, and water valorisation agents entering the system in this step since they are aimed at complementing the symbiotic network and increasing the number of relationships in order to reduce waste and close loops.

Most of the cases that were overviewed (2, 5, 6, and 7), where both industry and municipality participate from the initial stage through flow exchanges, are governed by a similar pattern in their dynamics. Their initial stage is deeply rooted due to both the exchange of different waste flows between industry and municipality and the support of public investors. Companies devoted to the production of electric energy are essential in the intermediate stage since they can contribute to increasing the efficiency of the system, either directly (interacting with industry and/or municipality) or indirectly (through other agents, such as in the case of agriculture and livestock in Case 2). Finally, the agents in charge of the valorisation of materials are indispensable in the advanced stage to absorb waste and, therefore, to densify the network. The other agents involved in this stage depend on the priority flows to be reused, resulting in energy and water valorisation plants such as incinerators (e.g., case 7, Norrköping) and WWTP (e.g., case 5, Kalundborg).

As for Case 3, the rush of the public investors to transform Kawasaki into an eco-city provoked a leap in the Urban-Industrial System, whereby the intermediate stage was omitted. Instead, valorisation agents, which usually belong to the advanced stage, were straightforwardly incorporated to intensify the exchange network. This experience further highlights the great importance of these components in consolidating UIS; however, the haste in strengthening the network might lead to some agents, such as power plants, whose role may eventually yield better results in terms of efficiency, being disregarded.

Cases 1 and 4 were not initially conceived as UIS experiences. In the case of Suzhou, public investment was targeted at improving energy efficiency. In the end, this original goal resulted in an ecological urban-industrial development. Instead, Londonderry started with the aim of creating an eco-industrial park through material exchanges in the industry. The municipality adhered to the network in the subsequent steps and did not conduct direct exchanges with the industry. These cases could be defined as late UIS since the incorporation of the municipality takes place after the initial stage and because the exchanges with the industry are indirect.

4.2. Urban-Industrial Systems as Complex Systems

A system can be defined as a set of interactive elements [38]. Complex systems have a structure formed by the following characteristics: (1) autonomous, (2) self-organized, (3) responsive, (4) not governed by linear patterns, and (5) willing to consolidate their resilience [39]. Autonomy is especially relevant for agents in low hierarchical levels because they are responsible for boosting the symbiotic networks. Table 1 highlights how industry plays a different role from the remaining players, setting relationships with a variety of agents, including the link between the refinery industry with the municipality (Kalundborg), the bio-industry with rural areas based on agriculture and livestock (Norrköping), or even between itself as the steelworks and cement plant pair (Kawasaki).

Self-organization stems from the agents within the system that do not require any external support. Thus, every agent belonging to the UIS increases the number and intensity of its relationships with the remaining components in the system [40,41]. In this sense, investors are important in promoting the existence of these cooperation actions. As for their reaction capacity, the basic components of UIS (people, companies, etc.) respond differently to changes in their environment. In the first case study that was overviewed (Shuzou), the network emerged in response to the taxes and fees created by the government due to the high pollution produced in the municipality, which resulted because the bad practices of heavy industries were favoured in the area. Instead, the situation in Norrköping was very different since the goal was to improve the energy efficiency of the system. The agents involved in this case used the support of the government to intensify and promote new cooperative relationships to each other.

Cooperation among companies is boosted by the existence of confidence and previous agreements; however, these aspects do not follow linear patterns, which results in the generation of unpredictable conduct in the system. In turn, this involves additional complexity for the development of interactions [42,43]. The investigation of the case studies compiled in this work suggests that some of the experiences were initiated in a similar manner. However, different networks emerged later on, and the benefits achieved by these networks differed from each other. In addition, many complex systems are also adaptive. The behaviour of the basic components in adaptive systems can evolve with time, providing a certain reaction capacity against changes in the environment through learning mechanisms.

This factor results in the last characteristic of complex systems, which concerns their resilience. UIS are capable of both dealing with technological and social challenges as well as admitting new agents and eliminating exchange flows [44]. An example of resilience in UIS is the collaboration among the agents, which enhances the robustness, adaptability, and flexibility of the system. In the case of Kawasaki, the Japanese government considered this feature and promoted the creation of ad hoc agents to ensure the resilience of the system with time. Based on the examination of all of these characteristics, it can be concluded that UIS are complex and adaptive systems.

4.3. List of Eco-Efficiency Indicators

The concept of eco-efficiency, which arises from the consideration of environmental impacts throughout the lifecycle of products and the willingness to reduce them them, can be useful to value changes in UIS. It seeks to produce more and pollute less [45]. Given the differences in the data quality among economic, environmental, and social parameters established by international organizations to monitor sustainable development as well as the complexity in adapting them to the specifics of UIS, it is difficult to produce consistent aggregations to evaluate the performance of the whole system.

Instead, the World Business Council for Sustainable Development (WBCSD) proposes a series of indicators that can be used to measure the eco-efficiency of a system [46]. Table 3 includes some of these indicators, which were grouped as follows: applicable to the industry and municipality, applicable to the whole UIS, and exclusive for the industry and municipality. The first group is valid for the two main agents in the system (industry and municipality) and can be used to obtain valuable information about the changes produced in any of them thanks to a symbiosis process. They account for energy consumption, the conversion of urban and industrial wastes into by-products, the amount of greenhouse gas emissions produced, and the reduction of waste taxes.

Table 3.

List of indicators to measure the eco-efficiency of Urban-Industrial Systems (UIS) [46].

The second group, which concerns all of the agents in the UIS, has a predominantly environmental nature. Energy consumption includes electricity, fossil fuels, biomass, wood, solar and wind power, etc. Water represents all of the freshwater provided by the public network or that is obtained from surface or groundwater sources as well as water used for cooling purposes. The third indicator measures the amount of acid gas or steam emitted into the air as a result of fossil combustion and reactive processes.

The last group considers exclusive indicators for the industry and municipality. The first subgroup accounts for quantitative indicators related to industrial goods, products and services, and substances destined for disposal. In addition, it addresses economic aspects concerning sales, discounts, and income. The subgroup associated with the municipality includes the wealth generated per resident inhabitant, the monitoring of diseases derived from pollution, and the increase in population. In the end, the joint consideration of the indicators in the three groups represents resource flows (materials, water, and energy) and social, environmental, and economic aspects whose management is expected to improve due to the proposed urban-industrial model.

4.4. Selection of Modelling Method

The selection of a modelling method needs to be consistent with the characteristics of the system to be represented [47]. In particular, the creation of a mathematical model to describe UIS is very difficult due to, among other things, the uncertainty, emergence, or adaptability of these complex systems [48]. In this sense, there are some analytical methods used to represent complex systems. A brief description of the most relevant ones and a valuation of their suitability to be applied for modelling UIS can be summarized as follows [49]:

- Statistical models and Bayesian networks serve to model different phenomena through a set of variables and dependence relationships among them. However, they cannot easily represent feedback as it is conducted in UIS;

- Systems dynamics are widely used for modelling complex systems in engineering, economics and business, project and environmental management, etc. Their adaptive capacity is limited, which contrasts with the evolutionary nature of UIS agents;

- Evolutionary models can represent learning and adaptation characteristics; however, they are not adequate to model the heterogeneity and autonomy that define UIS;

- Cellular automata can be defined as a dynamical system formed by a set of simple and homogeneous elements whose aggregation enables modelling complex behaviors. As such, it is unsuitable to model the variety of components in UIS;

- Agent-based models (ABM) enable the simulation of the actions and interactions of autonomous individuals as well as their effects on the system from the micro to macro levels. ABM agents act according to their own interests and can learn and adapt to changes.

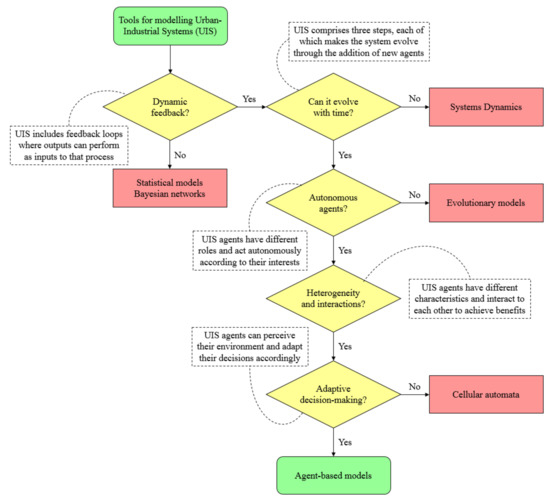

Figure 2 summarizes the workflow for selecting the most suitable tool for modelling UIS. As introduced above, the specifics of UIS suggest that ABM is the best option. The first reason supporting this is based on the existence of complex nonlinear discrete interactions among the agents. This means that the actions of an agent can be altered by others, such that their description through traditional methods (e.g., statistical approaches) might be difficult. There is a variety of exchange flows in UIS (Figure 1); however, this does not mean that an agent can only exchange one flow type. For example, the incinerator in the third case study (Kawasaki) only generates ash, whilst this same facility exchanges both material and thermal energy flows in Norrköping.

Figure 2.

Flowchart for the selection of the most suitable tool for modelling Urban-Industrial Systems (UIS). Adapted from Heckbert et al. [49].

There are not only different types of agents in UIS, but some of the same kind exhibit different attributes. Traditional modelling approaches represent agents with average characteristics, which is far from the real situation in UIS. Table 2 compiles the ten types of agents involved in UIS. The case of industry is especially enlightening in this sense because it encompasses a variety of different types (cement, chemical, pharmacy, etc.) and has very different relationships to the remaining agents, regardless of their specific field of activity.

The topology of the interactions among the agents in the system is heterogeneous and complex. This is especially relevant for social processes, which involve learning and adaptation. ABM enables realistic topological modelling, which is required to explain the aggregated behaviour of the system. The high number of potential interactions among agents and the variety of flow types that can be exchanged in UIS hinder their modelling.

Finally, UIS have a complex and stochastic behaviour that changes with time, which precludes its forecast in advance. Hence, it cannot be approached using equations or transition rates. This circumstance is clearly represented in the adaptive capacity of the Norrköping case study. In this situation, the government invested in improving a power plant to enable feeding it with biofuel; however, the situation evolved to a greater exploitation of the system with the passage of time, including MSW and densifying the network by promoting different flow exchanges.

5. Conclusions

In accordance with the aims initially set in this research, a conceptual model to understand and represent Urban-Industrial Systems (UIS) has been presented. To this end, the patterns of different worldwide urban-industrial symbiotic networks were observed. Such patterns served to outline a model capable of accounting for all of the characteristics of UIS as complex systems, including their stages, dynamics, participating agents, and exchange flows. The analysis also emphasized the importance of public and private investment to boost the creation and development of UIS.

The examination of existing UIS enabled the identification of the main agents and flows involved in symbiotic networks as well as their importance. The comprehension of these dynamics led the posing of an analytical model to represent UIS reliably and systematically, giving insight into the relationships among the agents within the system as they join the network throughout its different stages. The proposed model is intended to improve the eco-efficiency of UIS through the consideration of a series of indicators that represent the technical, social, environmental, and economic characteristics of the agents involved.

The trends and characteristics observed in the analysis as well as the conceptualization of UIS modelling are important contributions for encouraging the development of new experiences focused on the creation of UIS. The inferences extracted from the investigation of existing cases provide useful information for potential investors, emphasizing both the profile of the agents required to form a symbiotic network and the time in which each of them should enter the system. Although a preliminary conceptual model has been inferred, its robustness would benefit from widening this systematic research on more successful cases. The representation of UIS through the application of the proposed model is the main line of research that needs to be developed in the future in order to continue building a road map to maximize the benefits of promoting symbiotic interactions between urban and industrial areas in terms of sustainable development. Companies, policy makers, and interested stakeholders could explore the patterns and the effects that their strategies and policies could have on the hopefully successful reconfiguration and implementation of a new urban-industrial model that is able to use waste and secondary outputs as resources. A smart digitalization of industry and cities can become key in supporting and accelerating this transformation towards sustainability.

Funding

This research was funded by the Spanish Ministry of Science, Innovation and Universities, grant number DPI2017-88127-R (AEI/FEDER, UE).

Data Availability Statement

Not applicable.

Conflicts of Interest

The author declares no conflict of interest. The funders had no role in the design of the study; in the collection, analyses, or interpretation of data; in the writing of the manuscript, or in the decision to publish the results.

References

- Uras, M.; Cossu, R.; Ferrara, E.; Liotta, A.; Atzori, L. PmA: A real-world system for people mobility monitoring and analysis based on Wi-Fi probes. J. Clean. Prod. 2020, 270, 122084. [Google Scholar] [CrossRef]

- Rodrigues, M.; Franco, M. Measuring the urban sustainable development in cities through a composite index: The case of Portugal. Sustain. Dev. 2020, 28, 507–520. [Google Scholar] [CrossRef]

- Saudi, M.H.M.; Sinaga, O.; Roespinoedji, D.; Jabarullah, N.H. Industrial, commercial, and agricultural energy consumption and economic growth leading to environmental degradation. Ekoloji 2019, 28, 299–310. [Google Scholar]

- Margherita, E.G.; Braccini, A.M. Industry 4.0 technologies in flexible manufacturing for sustainable organizational value: Reflections from a multiple case study of Italian manufacturers. Inf. Syst. Front. 2020, 1–22. [Google Scholar] [CrossRef]

- Mao, W.; Wang, W.; Sun, H.; Yao, P.; Wang, X.; Luo, D. Urban industrial transformation patterns under natural resource dependence: A rule mining technique. Energy Policy 2021, 156, 112383. [Google Scholar] [CrossRef]

- Gibbs, D.; Deutz, P.; Proctor, A. Industrial ecology and eco-industrial development: A potential paradigm for local and regional development? Reg. Stud. 2005, 39, 171–183. [Google Scholar] [CrossRef]

- Dijst, M.; Worrell, E.; Böcker, L.; Brunner, P.; Davoudi, S.; Geertman, S.; Harmsen, R.; Helbich, M.; Holtslag, A.A.M.; Kwan, M.P.; et al. Exploring urban metabolism—Towards an interdisciplinary perspective. Resour. Conserv. Recycl. 2018, 132, 190–203. [Google Scholar] [CrossRef]

- Van Berkel, R.; Fujita, T.; Hashimoto, S.; Geng, Y. Industrial and urban symbiosis in Japan: Analysis of the eco-town program 1997–2006. J. Environ. Manag. 2009, 90, 1544–1556. [Google Scholar] [CrossRef] [PubMed]

- Sun, L.; Li, H.; Dong, L.; Fang, K.; Ren, J.; Geng, Y.; Fujii, M.; Zhang, W.; Zhang, N.; Liu, Z. Eco-benefits assessment on urban industrial symbiosis based on material flows analysis and energy evaluation approach: A case of Liuzhou city, China. Resour. Conserv. Recycl. 2017, 119, 78–88. [Google Scholar] [CrossRef] [Green Version]

- Dong, L.; Liang, H.; Zhang, L.; Liu, Z.; Gao, Z.; Hu, M. Highlighting regional eco-industrial development: Life cycle benefits of an urban industrial symbiosis and implications in China. Ecol. Modell. 2017, 361, 164–176. [Google Scholar] [CrossRef]

- Sun, L.; Fujii, M.; Li, Z.; Dong, H.; Geng, Y.; Liu, Z.; Fujita, T.; Yu, X.; Zhang, Y. Energy-saving and carbon emission reduction effect of urban-industrial symbiosis implementation with feasibility analysis in the city. Technol. Forecast. Soc. Chang. 2020, 151, 119853. [Google Scholar] [CrossRef]

- Bian, Y.; Dong, L.; Liu, Z.; Zhang, L. A sectoral eco-efficiency analysis on urban-industrial symbiosis. Sustainability 2020, 12, 3650. [Google Scholar] [CrossRef]

- Shah, I.H.; Dong, L.; Park, H.S. Tracking urban sustainability transition: An eco-efficiency analysis on eco-industrial development in Ulsan, Korea. J. Clean. Prod. 2020, 262, 121286. [Google Scholar] [CrossRef]

- Fan, Y.V.; Varbanov, P.S.; Klemeš, J.J.; Romanenko, S.V. Urban and industrial symbiosis for circular economy: Total EcoSite Integration. J. Environ. Manag. 2021, 279, 111829. [Google Scholar] [CrossRef]

- Yong, W.N.; Liew, P.Y.; Woon, K.S.; Wan Alwi, S.R.; Klemeš, J.J. A pinch-based multi-energy targeting framework for combined chilling heating power microgrid of urban-industrial symbiosis. Renew. Sust. Energ. Rev. 2021, 150, 111482. [Google Scholar] [CrossRef]

- Fraccascia, L. Industrial symbiosis and urban areas: A systematic literature review and future research directions. Procedia Environ. Sci. Eng. Manag. 2018, 5, 73–83. [Google Scholar]

- Van den Brink, A.; Bruns, D.; Tobi, H.; Bell, S. The Relationship between Research and Design. Research in Landscape Architecture: Methods and Methodology, 1st ed.; Routledge: London, UK, 2016. [Google Scholar] [CrossRef] [Green Version]

- Wen, Z.; Meng, X. Quantitative assessment of industrial symbiosis for the promotion of circular economy: A case study of the printed circuit boards industry in China’s Suzhou New District. J. Clean. Prod. 2015, 90, 211–219. [Google Scholar] [CrossRef]

- Yu, C.; Dijkema, G.P.J.; De Jong, M.; Shi, H. From an eco-industrial park towards an eco-city: A case study in Suzhou, China. J. Clean. Prod. 2015, 102, 264–274. [Google Scholar] [CrossRef]

- Berkel, R.; Bossilkov, A.; Corder, G. Regional Synergies for Sustainable Resource Processing: A Status Report; Technical Report; Centre for Sustainable Resource Processing: London, UK, 2005. [Google Scholar]

- Golev, A.; Corder, G.D. Developing a classification system for regional resource synergies. Miner. Eng. 2012, 29, 58–64. [Google Scholar] [CrossRef]

- Harris, S. Drivers and Barriers to Industrial Ecology in the UK. Ph.D. Thesis, The University of Edinburgh, Edinburgh, UK, 2004. [Google Scholar]

- Harris, S.; Berkel, R.; Kurup, B. Fostering Industrial Symbiosis for Regional Sustainable Development Outcomes. In Proceedings of the Corporate Responsibility Research Conference (CRRC), Belfast, UK, 7–9 September 2008; pp. 1–21. [Google Scholar]

- Geng, Y.; Tsuyoshi, F.; Chen, X. Evaluation of innovative municipal solid waste management through urban symbiosis: A case study of Kawasaki. J. Clean. Prod. 2010, 18, 993–1000. [Google Scholar] [CrossRef]

- Ohnishi, S.; Dong, H.; Geng, Y.; Fujii, M.; Fujita, T. A comprehensive evaluation on industrial & urban symbiosis by combining MFA, carbon footprint and energy methods—Case of Kawasaki, Japan. Ecol. Indic. 2017, 73, 315–324. [Google Scholar] [CrossRef]

- Chertow, M.R. Industrial symbiosis: Literature and taxonomy. Annu. Rev. Energy Environ. 2000, 25, 313–337. [Google Scholar] [CrossRef] [Green Version]

- Deutz, P.; Gibbs, D. Eco-industrial development and economic development: Industrial ecology or place promotion? Bus. Strategy Environ. 2004, 13, 347–362. [Google Scholar] [CrossRef]

- Van Berkel, R. Regional resource synergies for sustainable development in heavy industrial areas: An overview of opportunities and experiences. Perth WA Aust. 2006, 135, 139. [Google Scholar]

- Cervantes Torre-Marín, G.; Granados, R.S.; Herrera, G.R.; Martínez, F.R. Ecología industrial y desarrollo sustentable. Ingeniería 2009, 13, 63–70. [Google Scholar]

- Ehrenfeld, J.; Gertler, N. Industrial ecology in practice: The evolution of interdependence at Kalundborg. J. Ind. Ecol. 1997, 1, 67–79. [Google Scholar] [CrossRef]

- Dong, L.; Zhang, H.; Fujita, T.; Ohnishi, S.; Li, H.; Fujii, M.; Dong, H. Environmental and economic gains of industrial symbiosis for Chinese iron/steel industry: Kawasaki’s experience and practice in Liuzhou and Jinan. J. Clean. Prod. 2013, 59, 226–238. [Google Scholar] [CrossRef]

- Hatefipour, S.; Baas, L.; Eklund, M. The Händelö Area in Norrköping, Sweden Does It Fit for Industrial Symbiosis Development? In World Renewable Energy Congress; Linköping University Electronic Press: Linköping, Sweden, 2011; p. 8. [Google Scholar]

- Rehn, S. Influencing Industrial Symbiosis Development: A Case Study of Händelö and Northern Harbour Industrial Areas. Master’s Thesis, Linköping University, Linköping, Sweden, 2013. [Google Scholar]

- Neves, A.; Godina, R.; GAzevedo, S.; Pimentel, C.; COMatias, J. The potential of industrial symbiosis: Case analysis and main drivers and barriers to its implementation. Sustainability 2019, 11, 7095. [Google Scholar] [CrossRef] [Green Version]

- Albino, V.; Fraccascia, L.; Giannoccaro, I. Exploring the role of contracts to support the emergence of self-organized industrial symbiosis networks: An agent-based simulation study. J. Clean. Prod. 2016, 112, 4353–4366. [Google Scholar] [CrossRef]

- Tao, Y.; Evans, S.; Wen, Z.; Ma, M. The influence of policy on industrial symbiosis from the Firm’s perspective: A framework. J. Clean. Prod. 2019, 213, 1172–1187. [Google Scholar] [CrossRef]

- Lu, C.; Wang, S.; Wang, K.; Gao, Y.; Zhang, R. Uncovering the benefits of integrating industrial symbiosis and urban symbiosis targeting a resource-dependent city: A case study of Yongcheng, China. J. Clean. Prod. 2020, 255, 120210. [Google Scholar] [CrossRef]

- Von Bertalanffy, L. General System Theory: Foundations, Development, Applications, 1st ed.; George Braziller: New York, NY, USA, 1969. [Google Scholar]

- Holland, J.H. Studying complex adaptive systems. J. Syst. Sci. Complex. 2006, 19, 1–8. [Google Scholar] [CrossRef]

- Allen, P.M. Cities and Regions as Self-Organizing Systems Models of Complexity; Taylor & Francis: London, UK, 1997. [Google Scholar]

- Boons, F. Self-organization and sustainability: The emergence of a regional industrial ecology. Emerg. Complex. Organ. 2008, 10, 41. [Google Scholar]

- Boccara, N. Modeling Complex Systems; Springer: Berlin/Heidelberg, Germany, 2004. [Google Scholar]

- Jato-Espino, D.; Ruiz-Puente, C. Bringing facilitated industrial symbiosis and game theory together to strengthen waste exchange in industrial parks. Sci. Total Environ. 2021, 771, 145400. [Google Scholar] [CrossRef] [PubMed]

- Walker, B.; Holling, C.; Carpenter, S.; Kinzig, A. Resilience, Adaptability and Transformability in Social–Ecological Systems. Retrieved 2 June 2021. Ecol. Soc. 2004, 9. Available online: http://www.jstor.org/stable/26267673 (accessed on 18 August 2021). [CrossRef]

- Koskela, M.; Vehmas, J. Defining eco-efficiency: A case study on the Finnish forest industry. Bus. Strateg. Environ. 2012, 21, 546–566. [Google Scholar] [CrossRef]

- Verfaillie, H.A.; Bidwell, R. Measuring eco-efficiency: A guide to reporting company performance. Ginebra 2000, 3, 16–21. [Google Scholar]

- Romero, E.; Ruiz, M.C. Proposal of an agent-based analytical model to convert industrial areas in industrial eco-systems. Sci. Total Environ. 2014, 468–469, 394–405. [Google Scholar] [CrossRef]

- Romero, E.; Ruiz, M.C. Framework for applying a complex adaptive system approach to model the operation of eco-industrial parks. J. Ind. Ecol. 2013, 17, 731–741. [Google Scholar] [CrossRef]

- Heckbert, S.; Baynes, T.; Reeson, A. Agent-based modeling in ecological economics. Ann. N. Y. Acad. Sci. 2010, 1185, 39–53. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the author. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).