Durability Behavior of Mortars Containing Perlite Tailings: Alkali–Silicate Reaction Viewpoint

Abstract

:1. Introduction

2. Materials and Methods

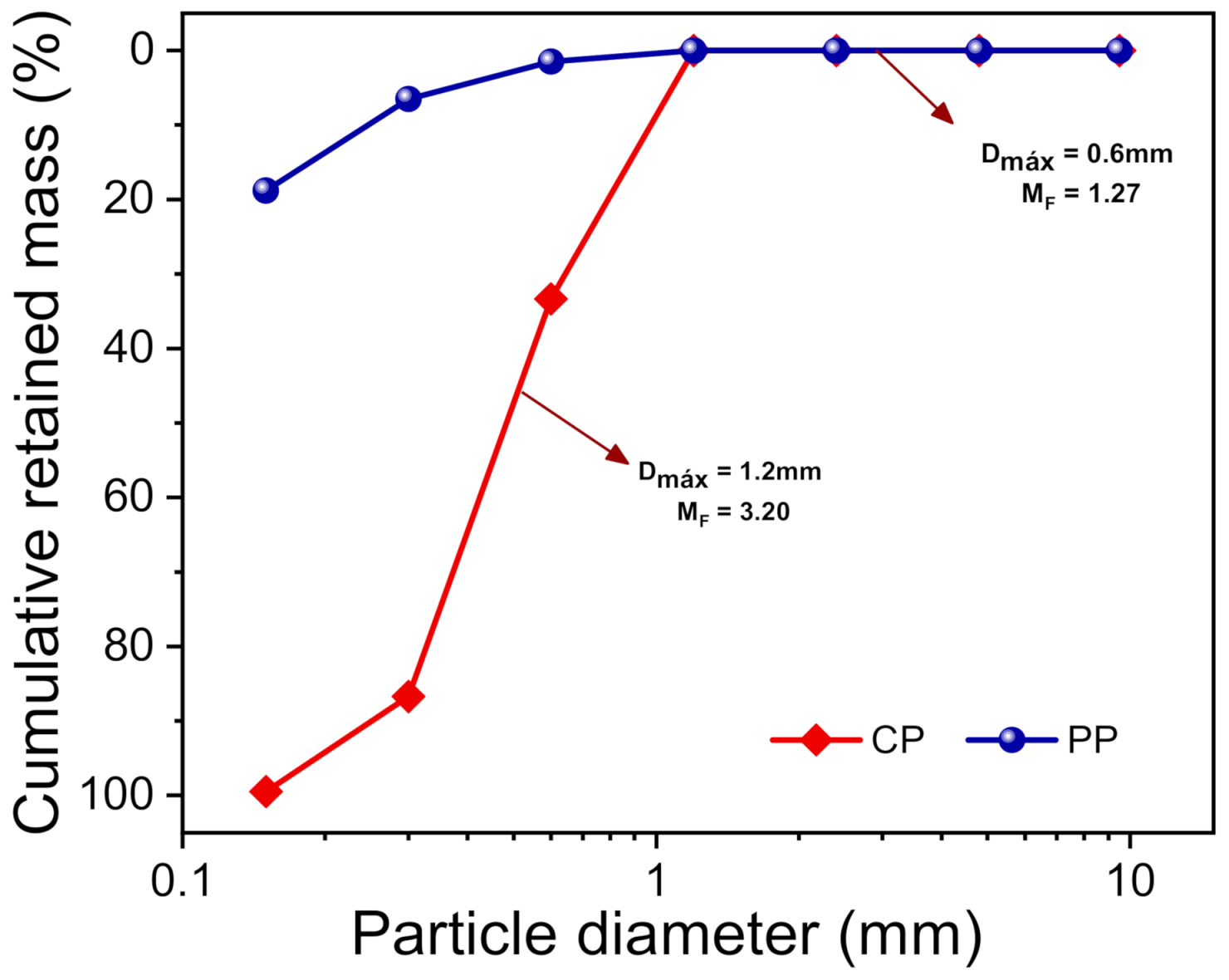

2.1. Materials

2.2. Methods

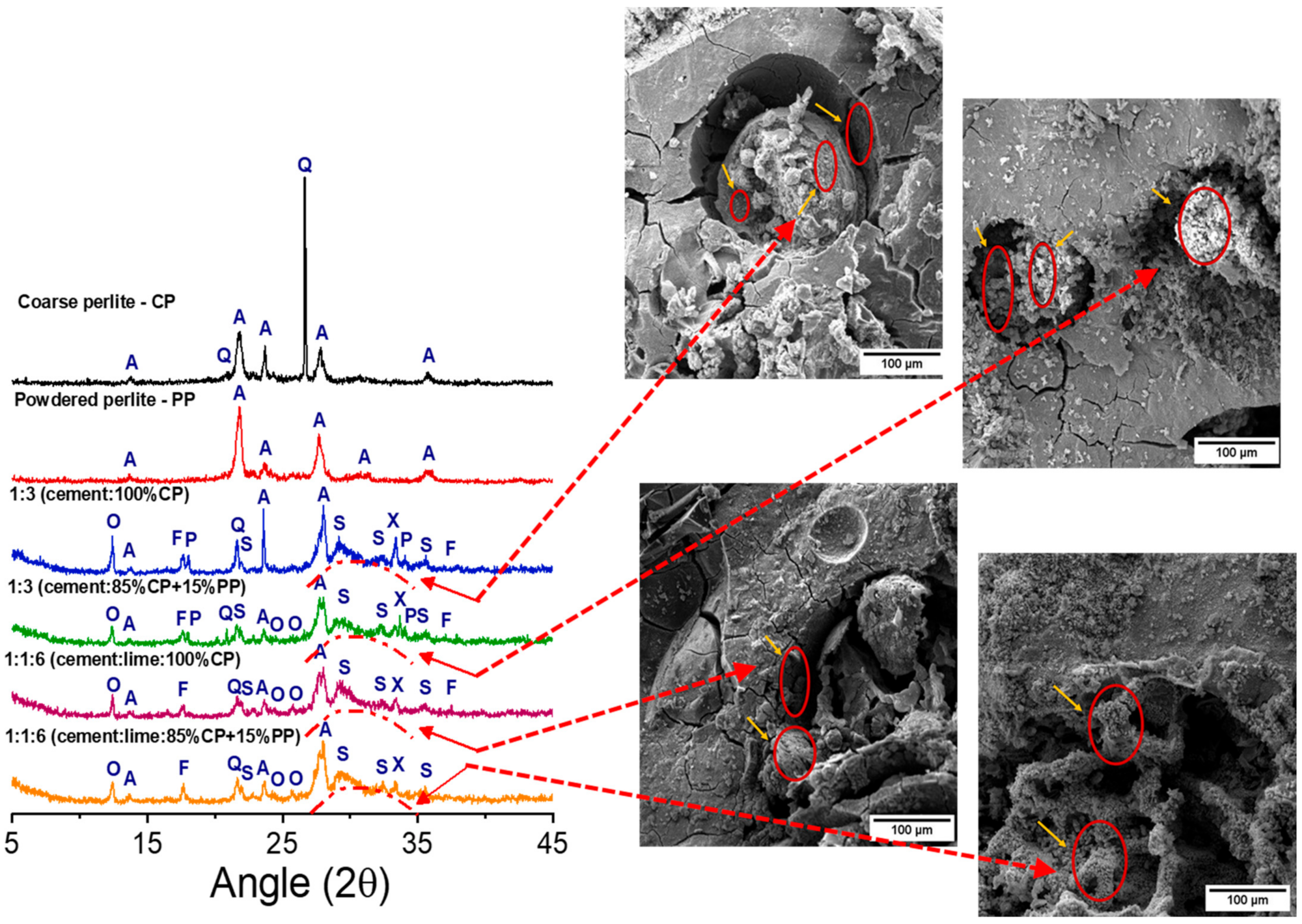

2.2.1. Chemical, Thermal, and Mineralogical Characterization

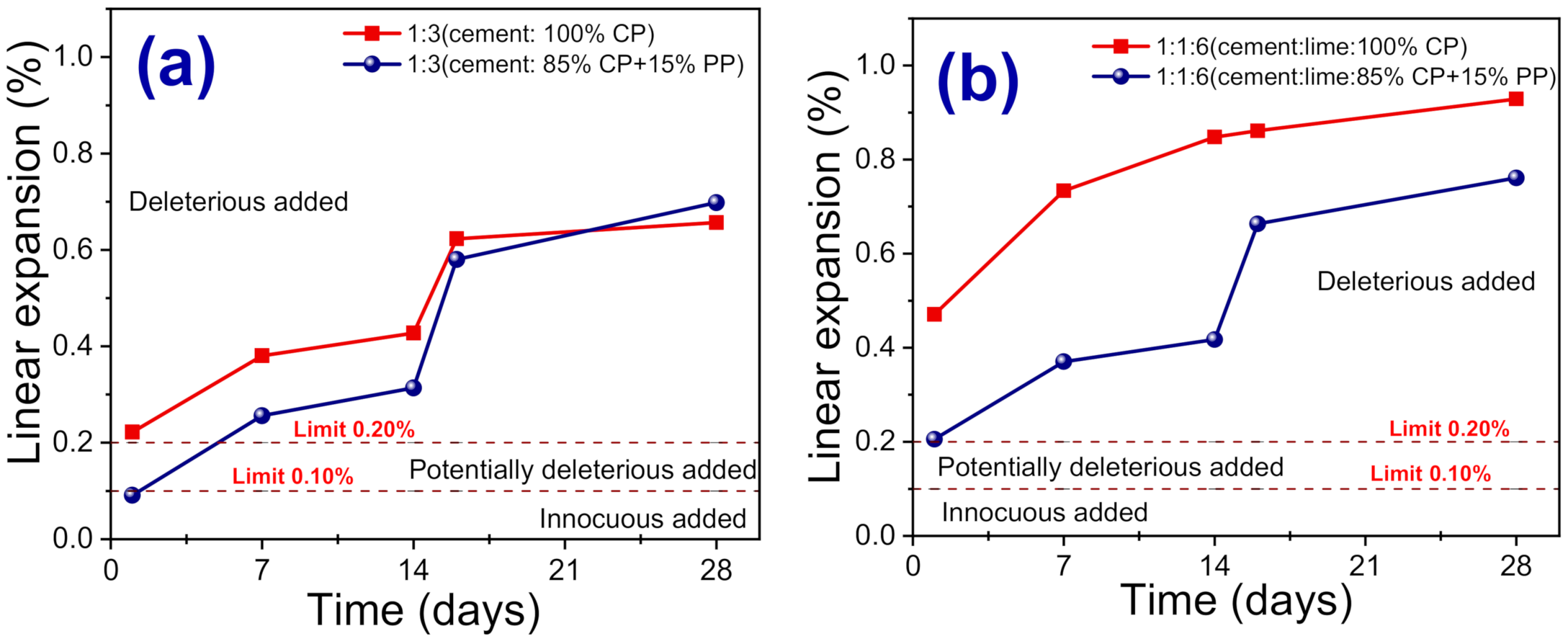

2.2.2. Resistance to Alkali–Aggregate Reaction

3. Results and Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Rashad, A.M. A synopsis about perlite as building material—A best practice guide for Civil Engineer. Constr. Build. Mater. 2016, 121, 338–353. [Google Scholar] [CrossRef]

- El Mir, A.; Nehme, S.G. Utilization of industrial waste perlite powder in self-compacting concrete. J. Clean. Prod. 2017, 156, 507–517. [Google Scholar] [CrossRef]

- Çelikten, S.; Işıkdağ, B. Properties of geopolymer mortars derived from ground calcined perlite and NaOH solution. Eur. J. Environ. Civ. Eng. 2021, 1–15. [Google Scholar] [CrossRef]

- Tie, T.S.; Mo, K.H.; Alengaram, U.J.; Kaliyavaradhan, S.K.; Ling, T.-C. Study on the use of lightweight expanded perlite and vermiculite aggregates in blended cement mortars. Eur. J. Environ. Civ. Eng. 2020, 1–20. [Google Scholar] [CrossRef]

- Alghadi, A.M.; Tirkes, S.; Tayfun, U. Mechanical, thermo-mechanical and morphological characterization of ABS based composites loaded with perlite mineral. Mater. Res. Express 2019, 7, 015301. [Google Scholar] [CrossRef]

- El Mir, A.; Nehme, S.G.; Assaad, J.J. Durability of self-consolidating concrete containing natural waste perlite powders. Heliyon 2020, 6, e03165. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Kotwica, Ł.; Pichór, W.; Kapeluszna, E.; Różycka, A. Utilization of waste expanded perlite as new effective supplementary cementitious material. J. Clean. Prod. 2017, 140, 1344–1352. [Google Scholar] [CrossRef]

- Kapeluszna, E.; Kotwica, Ł.; Malata, G.; Murzyn, P.; Nocuń-Wczelik, W. The effect of highly reactive pozzolanic material on the early hydration of alite–C3A–gypsum synthetic cement systems. Constr. Build. Mater. 2020, 251, 118879. [Google Scholar] [CrossRef]

- Almeida, E.; Carreiro, M.; Rodrigues, A.; Ferreira, H.; Santana, L.; Menezes, R.; Neves, G. A new eco-friendly mass formulation based on industrial mining residues for the manufacture of ceramic tiles. Ceram. Int. 2021, 47, 11340–11348. [Google Scholar] [CrossRef]

- De Figueirêdo, J.M.R.; Da Costa, F.P.; Fernandes, J.V.; Rodrigues, A.M.; Neves, G.D.A.; Menezes, R.R.; Santana, L.N.D.L. Development of scheelite tailings-based ceramic formulations with the potential to manufacture porcelain tiles, semi-stoneware and stoneware. Materials 2020, 13, 5122. [Google Scholar] [CrossRef] [PubMed]

- Fernandes, J.; Guedes, D.; Da Costa, F.; Rodrigues, A.; Neves, G.; Menezes, R.; Santana, L. Sustainable ceramic materials manufactured from ceramic formulations containing quartzite and scheelite tailings. Sustainability. 2020, 12, 9417. [Google Scholar] [CrossRef]

- Gao, H.; Liu, H.; Liao, L.; Mei, L.; Shuai, P.; Xi, Z.; Lv, G. A novel inorganic thermal insulation material utilizing perlite tailings. Energy Build. 2019, 190, 25–33. [Google Scholar] [CrossRef]

- Kayacı, K. The use of perlite as flux in the production of porcelain stoneware tiles. Bol. Soc. Esp. Ceram. Vidr. 2020, 59, 4–11. [Google Scholar] [CrossRef]

- Ramezanianpour, A.; Karein, S.M.M.; Vosoughi, P.; Pilvar, A.; Isapour, S.; Moodi, F. Effects of calcined perlite powder as a SCM on the strength and permeability of concrete. Constr. Build. Mater. 2014, 66, 222–228. [Google Scholar] [CrossRef]

- Polat, R.; Demirboğa, R.; Khushefati, W.H. Effects of nano and micro size of CaO and MgO, nano-clay and expanded perlite aggregate on the autogenous shrinkage of mortar. Constr. Build. Mater. 2015, 81, 268–275. [Google Scholar] [CrossRef]

- Oktay, H.; Yumrutaş, R.; Akpolat, A. Mechanical and thermophysical properties of lightweight aggregate concretes. Constr. Build. Mater. 2015, 96, 217–225. [Google Scholar] [CrossRef]

- Kramar, D.; Bindiganavile, V. Impact response of lightweight mortars containing expanded perlite. Cem. Concr. Compos. 2013, 37, 205–214. [Google Scholar] [CrossRef]

- Erdoğan, S.T.; Sağlık, A. Ünsal Early-age activation of cement pastes and mortars containing ground perlite as a pozzolan. Cem. Concr. Compos. 2013, 38, 29–39. [Google Scholar] [CrossRef]

- Guenanou, F.; Khelafi, H.; Aattache, A. Behavior of perlite-based mortars on physicochemical characteristics, mechanical and carbonation: Case of perlite of Hammam Boughrara. J. Build. Eng. 2019, 24, 100734. [Google Scholar] [CrossRef]

- Różycka, A.; Pichór, W. Effect of perlite waste addition on the properties of autoclaved aerated concrete. Constr. Build. Mater. 2016, 120, 65–71. [Google Scholar] [CrossRef]

- Angulo-Ramírez, D.E.; Mejía de Gutiérrez, R.; Medeiros, M. Alkali-activated Portland blast furnace slag cement mortars: Performance to alkali-aggregate reaction. Constr. Build. Mater. 2018, 179, 49–56. [Google Scholar] [CrossRef]

- Rutkauskas, A.; Nagrockienė, D.; Skripkiūnas, G.; Barkauskas, K. Determining reactivity level of granite aggregate for con-crete. Constr. Sci. 2017, 20, 33–37. [Google Scholar] [CrossRef] [Green Version]

- Ribeiro, D.V.; Silva, A.M.S.; Labrincha, J.A.; Morelli, M.R. Study of alkali-silica reactions associated with the use of red mud in plastering mortars. Cerâmica 2012, 58, 90–98. [Google Scholar] [CrossRef]

- Rashidian-Dezfouli, H.; Rangaraju, P.R. Study on the effect of selected parameters on the alkali-silica reaction of aggregate in ground glass fiber and fly ash-based geopolymer mortars. Constr. Build. Mater. 2021, 271, 121549. [Google Scholar] [CrossRef]

- Barros, S.V.A.; Marciano, J.E.A.; Ferreira, H.C.; Menezes, R.R.; Neves, G.A. Addition of quartzite residues on mortars: Analysis of the alkali aggregate reaction and the mechanical behaviour. Constr. Build. Mater. 2016, 118, 344–351. [Google Scholar] [CrossRef]

- Munhoz, G.S.; Dobrovolski, M.E.G.; Pereira, E.; Medeiros-Junior, R.A. Effect of improved autogenous mortar self-healing in the alkali-aggregate reaction. Cem. Concr. Compos. 2020, 117, 103905. [Google Scholar] [CrossRef]

- Neto, R.E.d.O.; Cartaxo, J.d.M.; Rodrigues, A.M.; Barros, S.V.A.; Costa, F.P.d.; Neves, G.d.A.; Menezes, R.R. New sustainable mortar compositions containing perlite residues. Clean Technol. Environ. Policy 2021. submitted. [Google Scholar]

- ASTM. ASTM C1437-20. Standard Test Method for Flow of Hydraulic Cement Mortar; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar] [CrossRef]

- da Costa, F.P.; Morais, C.R.D.S.; Pinto, H.C.; Rodrigues, A.M. Microstructure and physico-mechanical properties of Al2O3-doped sustainable glass-ceramic foams. Mater. Chem. Phys. 2020, 256, 123612. [Google Scholar] [CrossRef]

- da Costa, F.P.; Morais, C.R.D.S.; Rodrigues, A.M. Sustainable glass-ceramic foams manufactured from waste glass bottles and bentonite. Ceram. Int. 2020, 46, 17957–17961. [Google Scholar] [CrossRef]

- ASTM. ASTM C1260-21 Standard Test Method for Potential Alkaline Reactivity of Aggregates (Mortar-Bar Method); ASTM International: West Conshohocken, PA, USA, 2021. [Google Scholar] [CrossRef]

- ASTM. ASTM C39/C39M-21. Standard Test Method for Compressive Strength of Cylindrical Concrete Specimens; ASTM International: West Conshohocken, PA, USA, 2021. [Google Scholar] [CrossRef]

- Xue, L.; Zhang, Z.; Wang, H. Hydration mechanisms and durability of hybrid alkaline cements (HACs): A review. Constr. Build. Mater. 2021, 266, 121039. [Google Scholar] [CrossRef]

- Moreira, K.M.D.V.; Oliveira, P.V.G.; De Deus, Ê.P.; Cabral, A.E.B. Alkali-silica reaction: Understanding the phenomenon. J. Build. Pathol. Rehabil. 2021, 6, 1–10. [Google Scholar] [CrossRef]

- Tiecher, F.; Florindo, R.N.; Vieira, G.L.; Gomes, M.E.B.; Molin, D.C.C.D.; Lermen, R.T. Influence of the Quartz Deformation Structures for the Occurrence of the Alkali–Silica Reaction. Materials 2018, 11, 1692. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Romano, R.C.D.O.; Torres, D.D.R.; Pileggi, R.G. Impact of aggregate grading and air-entrainment on the properties of fresh and hardened mortars. Constr. Build. Mater. 2015, 82, 219–226. [Google Scholar] [CrossRef]

- Filho, J.H.; Gobbi, A.; Pereira, E.; Quarcioni, V.A.; De Medeiros, M.H.F. Atividade pozolânica de adições minerais para cimento Portland (Parte I): Índice de atividade pozolânica (IAP) com cal, difração de raios-X (DRX), termogravimetria (TG/DTG) e Chapelle modificado. Matéria 2017, 22. [Google Scholar] [CrossRef]

- Moulton, B.J.A.; Rodrigues, A.M.; Pizani, P.S.; Sampaio, D.; Zanotto, E.D. A Raman investigation of the structural evolution of supercooled liquid barium disilicate during crystallization. Int. J. Appl. Glas. Sci. 2018, 9, 510–517. [Google Scholar] [CrossRef]

- Moulton, B.J.A.; Rodrigues, A.M.; Sampaio, D.V.; Silva, L.D.; Cunha, T.R.; Zanotto, E.D.; Pizani, P.S. The origin of the unusual DSC peaks of supercooled barium disilicate liquid. Cryst. Eng. Comm. 2019, 21, 2768–2778. [Google Scholar] [CrossRef]

- Colville, J.; Abboud, B.E.; Atkinson, R.H.; Bailey, W.G.; Beavers, S.R.; Beiner, R.J.; Brown, R.H.; Bryant, A.D.; Callahan, K.D.; Catani, M.J.; et al. Specification for Masonry Structures (ACI 530.1-02/ASCE 6-02/TMS 602-02); Masonry Standards Joint Committee: Reston, VA, USA, 1995. [Google Scholar]

| Raw Material | Oxides (%) | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | MgO | Al2O3 | Fe2O3 | SO3 | K2O | TiO2 | Na2Oeq a | LOI b | C3A c | |

| Cement | 61.35 | 19.1 | 1.33 | 5.33 | 4.1 | 4.87 | 1.04 | 0.5 | 0.69 | 2.2 | 7.18 |

| Lime | 62.54 | 0.56 | 1.20 | 0.27 | 0.15 | --- | 0.25 | --- | --- | 35.0 | --- |

| Material | Oxides (%) | |||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| CaO | SiO2 | MgO | Al2O3 | Fe2O3 | SO3 | K2O | Na2O | a Na2Oeq | b LOI | |

| PP | 1.5 | 73.0 | 0.6 | 15.3 | 1.1 | 0.1 | 3.3 | 3.0 | 5.2 | 2.1 |

| CP | 1.2 | 71.8 | 0.6 | 15.4 | 0.9 | 0.1 | 3.2 | 3.5 | 5.6 | 3.3 |

| Trace | Compression Strength (MPa) | |||

|---|---|---|---|---|

| After Immersion in 1 N NaOH | Standard Deviation | After Immersion in Distilled Water | Standard Deviation | |

| 1:3 (cement:100% CP) | 9.69 | ±0.7 | 13.04 | ±1.52 |

| 1:3 (cement:85% CP + 15% PP) | 12.12 | ±1.1 | 17.07 | ±1.13 |

| 1:1:6 (cement:lime:100% CP) | 5.80 | ±0.30 | 5.70 | ±0.13 |

| 1:1:6 (cement:lime:85% CP +15% PP) | 8.32 | ±0.51 | 11.76 | ±1.34 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Neto, R.E.d.O.; Cartaxo, J.d.M.; Rodrigues, A.M.; Neves, G.d.A.; Menezes, R.R.; da Costa, F.P.; Barros, S.V.A. Durability Behavior of Mortars Containing Perlite Tailings: Alkali–Silicate Reaction Viewpoint. Sustainability 2021, 13, 9203. https://doi.org/10.3390/su13169203

Neto REdO, Cartaxo JdM, Rodrigues AM, Neves GdA, Menezes RR, da Costa FP, Barros SVA. Durability Behavior of Mortars Containing Perlite Tailings: Alkali–Silicate Reaction Viewpoint. Sustainability. 2021; 13(16):9203. https://doi.org/10.3390/su13169203

Chicago/Turabian StyleNeto, Roberto Evaristo de Oliveira, Juliana de Melo Cartaxo, Alisson Mendes Rodrigues, Gelmires de Araújo Neves, Romualdo Rodrigues Menezes, Fabiana Pereira da Costa, and Sâmea Valensca Alves Barros. 2021. "Durability Behavior of Mortars Containing Perlite Tailings: Alkali–Silicate Reaction Viewpoint" Sustainability 13, no. 16: 9203. https://doi.org/10.3390/su13169203

APA StyleNeto, R. E. d. O., Cartaxo, J. d. M., Rodrigues, A. M., Neves, G. d. A., Menezes, R. R., da Costa, F. P., & Barros, S. V. A. (2021). Durability Behavior of Mortars Containing Perlite Tailings: Alkali–Silicate Reaction Viewpoint. Sustainability, 13(16), 9203. https://doi.org/10.3390/su13169203