Abstract

Integration of the lean and resilience paradigms has attracted increasing attention among scientists and practitioners. In an interconnected world, the need to be resilient involves increased readiness to deal with risks from both outside and inside an enterprise, and to be lean involves maximizing value while minimizing waste. The combination of these requirements has been the catalyst for a move towards lean–resilience operations. To better understand this trend, which seeks to help firms retain a competitive position and survive disruptions, this paper provides a systematic literature review of 53 articles identified through the C-I-M-O (context-intervention-mechanism-outcome) framework and examines them using descriptive and content analysis. The results trace the growth of lean–resilience research from its infancy to its current advanced state. This paper also identifies for the first time the lack of structured research on the number and categories of implemented practices and their associated benefits. To address this deficiency, a concept map is developed to provide guidance on the topic, identify gaps and inconsistencies in the literature, understand the state of development and suggest future research directions. The results are used to identify four dominant streams: application, compatibility, integration, and impact assessment in the context of the supply chain, conceptual development and operational research of various organizational and industry sectors. Further topics for investigation are recommended in the form of research questions. The proposed concept map is intended to assist researchers and practitioners to develop knowledge about the integration of lean and resilience paradigms in new contexts and formulate more effective deployment strategies.

1. Introduction

In an interconnected world, enterprises and supply chains are continuously challenged by risks, uncertainties and market vulnerabilities [1,2]. The frequency of disruption is high, leading to a wide range of consequences, including human and financial losses. Disruption can take various forms, from the operational level to the strategic, including delays, quality obstacles in the production process, accidents or equipment failure, as well as pandemics and natural hazards [3,4,5]. In this increasingly competitive era, with unpredictable events, fierce competition and high levels of market instability, organizations must invest resources to survive and sustain themselves. Consequently, organizations are seeking more reliable strategies for risk management of their supply chain to consistently and efficiently manage internal and external disruptions [6]. According to Ivanov and Dolgui [7], the prerequisite to effectively managing risk is to adopt a resilience paradigm in supply chain processes. Resilience can be considered as a proactive capability of any operating system to contend with minor or major disruptions [8]. Resilience combines two essential components: the ability to reduce the destruction triggered by a particular risk and the capability to return to an acceptable level of performance under the effect of such risk [9,10]. The contemporary worldwide market has forced manufacturing organizations to pursue excellence in operational processes and enhance their performance to lower their costs and provide higher quality products in shorter lead times. Many scholars have investigated the role of resilience paradigms in supply chain. For example, Namdar et al. [11] scrutinized the use of sourcing strategies to accomplish supply chain resilience under disruptions. Borekci et al. [12] investigated the resilience of triadic buyer–supplier–supplier relations. Recently, Ivanov and Dolgui [13] measured the resilience of organization under COVID-19 disruption in the supply network.

The “lean” paradigm has been used by manufacturing organizations to reduce costs and achieve a competitive advantage in the marketplace [14]. The lean paradigm focuses on reducing waste [15] to increase value-adding, fulfil customer needs and maintain profitability [16]. Implementing lean principles has led to sustainable benefits for companies [17], including an improved operational performance by reducing lead times and inventory and improved quality and productivity [18,19]. Lean thinking contributes to sustainability in multiple ways [20,21]. For example, Henao et al. [22] investigated the literature around the integration of lean and sustainability performance, concluding that two are tightly interconnected across three themes—environmental, social and economic—and share similar goals and synergies. Despite this, lean principles lack the capability to respond to higher levels of volatility in the marketplace. To manage these challenges, companies must now consider both the lean and resilience paradigms together to achieve operational excellence. With the rapid development of knowledge in this complex area, there is a growing need to understand its context, framing and conditions. In response, this paper proposes a systematic literature review to analyze and understand the relationship between lean and resilience paradigms. It also investigates discrepancies and gaps in the literature and identifies new research directions required to address them. The study systematically collects and examines the current contributions on lean, relevant to its application to, and association with the resilience paradigm. Two research questions were adopted for this study:

- What themes have been researched previously on the lean paradigm and its application to, and linkages with resilience?

- What are the research gaps and prospective research directions for the lean–resilience theme?

2. Materials and Methods

This research aims to identify and examine the current state of research on the links between the resilience and lean paradigms and then classify this work to uncover potential gaps and discrepancies, along with directions for further research. A literature review is a valid approach to providing an understanding of a field and its development. It is useful for identifying areas where research is required, helping to structure knowledge of a field and develop theory and conceptual content [23], while providing a new contribution to the context where extensive research already exists [24]. The literature review in the present paper follows a clear, explicit, reproducible and systematic process which leads to reliable findings that provide the basis for drawing rigorous conclusions [25]. A systematic literature review is a method that adopts an accurate, transparent and well-defined approach of a sequence of stages to obtain reliable results [26]. The two research questions posed in the previous section can be answered using a systematic review of the existing literature.

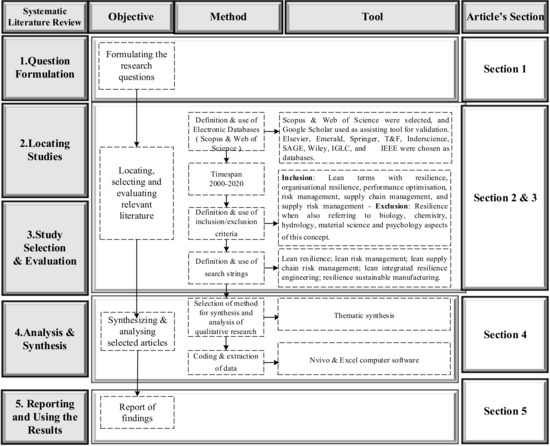

A systematic literature review has the following five sequential phases, proposed by Denyer and Tranfield [27]: (1) articulating questions, (2) positioning studies, (3) defining categories and selection criteria for study selection and assessments, (4) scrutinizing and synthesis and (5) reporting and utilizing the findings. This process is at the core of a structured and effective literature review. As Saunders et al. [28] contend, to address the transparency issue in a systematic literature review, the review must explain in detail how its processes were carried out, especially the literature selection, and decisions made about the use of particular search terms and databases. Figure 1 describes the stages of the systematic literature review undertaken in this paper, and the tools and methods utilized to assist every stage, together with the section of the paper where these are delivered.

Figure 1.

Summary of the systematic literature review stages and processes adapted from Garza-Reyes [29].

2.1. Selection of Databases, Search Criteria and Timing

Academic publications are accessible by way of various database engines, including Web of Science, Scopus and Google Scholar. Opinions about these databases vary, with Falagas et al. [30] arguing that Scopus is preferred, while Wang and Waltman [31] contend that the classification of journals on Web of Science is better. This paper uses both the Web of Science and Scopus databases, and Google Scholar is also used as a support tool. Other publisher databases were searched for this study including Elsevier (sciencedirect.com), Springer (springerlink.com), MDPI (mdpi.com), Emerald (emeraldinsight.com), Taylor & Francis (T&F) (tandfonline.com), Wiley (onlinelibrary.wiley.com), Inderscience (inderscience.com), SAGE (sagepub.com), Institute of Electrical and Electronics Engineers (IEEE) (ieeexplore.ieee.org) and the International Group for Lean Construction (IGLC) (iglc.net).

The search period was from 2000 to 2020, which also includes “in press” research that would later be published in 2021. The reason for selecting 2000 as the starting point was that the debate on integrating lean and resilience can be traced to this period. In the engineering domain, resilience can be traced back to the 2000s when Hollnagel et al. [32] defined engineering resilience as the inherent ability of a system to adapt its functionality in the presence of a disturbance and unpredicted changes. There is also limited evidence that resilience and lean have been examined in the scholarly literature as complementary paradigms since the early 2000s [33].

The search criteria used for identifying the studies followed the C-I-M-O (context-intervention-mechanism-outcome) framework to establish the exclusion/inclusion criteria of the search strings [34]. These strings were (lean resilience), (lean risk management), (lean supply chain risk management), (lean supply chain resilience) and (lean resilience-sustainability). This procedure was assisted by including the defined search criteria and eliminating articles that did not have both terms or a relationship among them. This selection and systematic approach ensured the completeness of the procedure. Manual checks were conducted to prevent consideration of duplicate articles within the search strings by reviewing abstracts. Importantly, those articles that did not clearly focus on resilience and lean (e.g., by discussing “lean resilience” within the context of material science, chemistry, and biology) were eliminated. Consequently, lean–resilience related papers, such as Wears et al. [35], Johnson et al. [36] and Bombelli [37], were not included in the review.

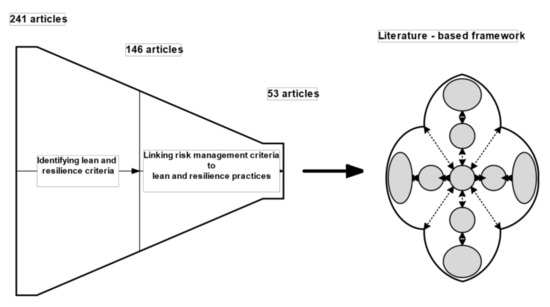

Research findings encompassed peer-reviewed papers in English, published in academic journals and the proceedings of international conferences only, as Saunders et al. [28] argued these resources are the most reliable for literature reviews. In the next step, an in-depth analysis was carried out of how lean and resilience can contribute to risk management. The content analysis technique proposed by White and Marsh [38] was used to conduct a data reduction process, as shown in Figure 2.

Figure 2.

A literature-based framework.

By applying the preferred reporting items for systematic reviews and meta-analysis (PRISMA) process of Moher et al. [39], this study initially identified 241 documents through database searching of combined lean and resilience context. Following application of exclusion criteria, 146 were considered for general analysis. Finally, 53 articles were identified as relevant for detailed analysis to answer the first research question by applying the inclusion criteria.

Based on the criteria explained in this section, a final sample of 53 papers referring to lean and resilience was identified and uploaded to NVivo software. Following the extraction of the eligible records, a qualitative literature synthesis was undertaken using NVivo to establish a more holistic conceptual framework to understand lean and resilience interconnections. NVivo was endorsed by Thomas and Harden [40] as highly efficient software for coding data from full articles. NVivo was used to conduct a thematic synthesis, enhance the outcomes on lean–resilience and deliver an abstracted theoretical factor structure.

2.2. Analysis and Synthesis

To synthesize qualitative research, a large number of methods, including qualitative meta-analysis, meta-ethnography, thematic analysis/synthesis and qualitative comparative analysis can be considered [38,40,41]. Thematic synthesis was used for this paper as it is recommended for analyzing the outcomes from the systematic review of the literature, due to its efficiency in classifying significant recurring themes and structured methods of dealing with data within each theme [41].

The analysis procedure in this paper followed Garza-Reyes [29], and the selected articles were initially classified into three main sub-categories (see Table 1). As resilience and lean paradigms must be synchronized for their implementation, the processes were categorized into supply chain domain or operation/process, based on their micro or macro level, as suggested by Slack et al. [42], to identify commonalities. These classifications created second and third sub-categories, while the first sub-category included those items that considered resilience and lean from a conceptual perspective. The number of articles classified by sub-category is shown in Table 1. This initial categorization provided the foundation for coding and specific analysis of the 53 articles, as well as their classification in a sub-category. Features pertinent to lean–resilience were discovered in this way, and new classifications were developed based on these categories and coding, ultimately leading to a concept map in Figure 9. The results of the thematic synthesis are shown in Section 3, separated into a descriptive section (Section 3.1) and a concept map (Section 4.1).

Table 1.

Initial thematic categorization of articles in the literature review.

3. Results

3.1. Descriptive Analysis of Results

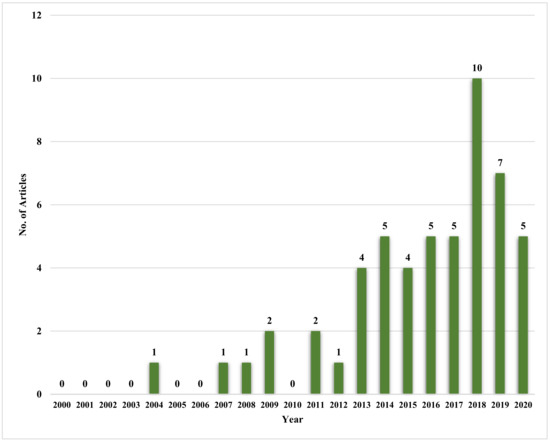

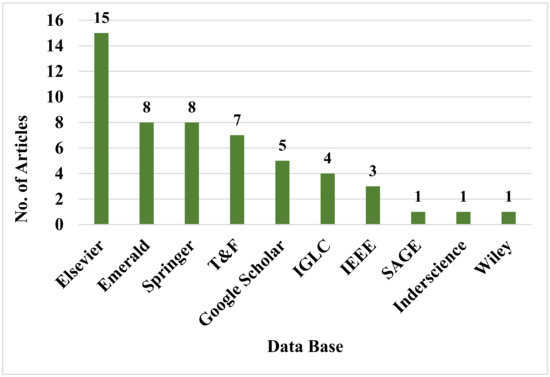

Based on the selection criteria, 53 articles related to lean and resilience (and associated topics such as supply chain, risk management and performance optimization) were identified. The next section presents the number of articles published by year (Figure 3), database (Figure 4, cross-referenced to the database in Table 4), research methods used (Figure 5), application area (Figure 6), country of origin (Figure 7) and keyword analysis of articles (Figure 8).

Figure 3.

Number of publications studied per year.

Figure 4.

Distribution of articles by database.

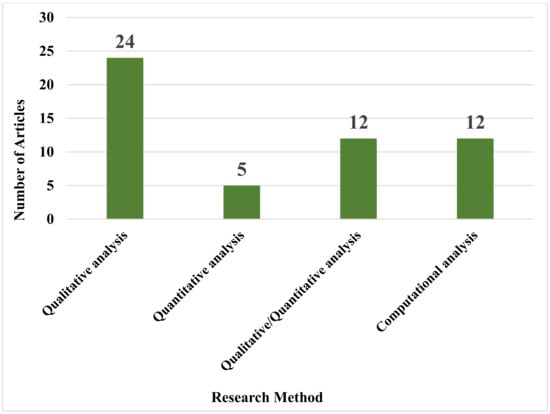

Figure 5.

Research methods applied in the articles.

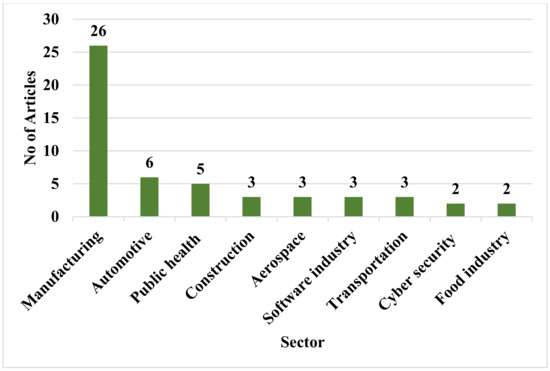

Figure 6.

Number of articles by sector.

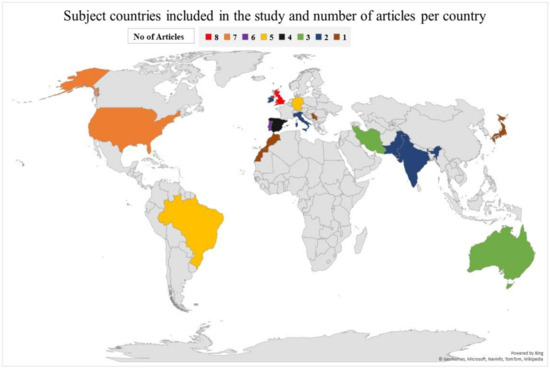

Figure 7.

Articles by geographic origin.

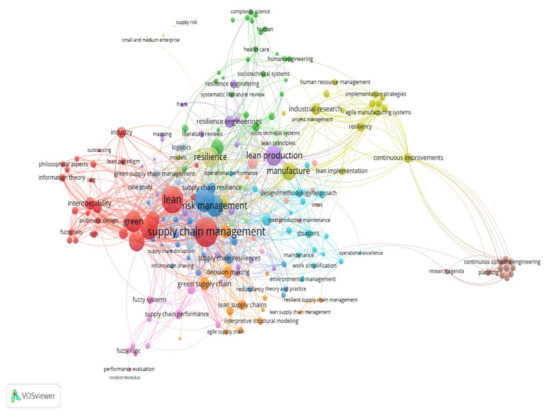

Figure 8.

Keyword analysis of articles.

3.1.1. Sources and Number of Articles per Year and per Journal or/Conference

Figure 3 shows the number of articles on the lean–resilience theme has increased since 2011. Over 90% (46) of the 53 articles from 2000 to 2020 have been released since 2011, indicating the lean–resilience topic is an emerging research field. As more organizations seek to improve their resilience against disruptions [43,44], the number of lean–resilience articles is likely to increase. Reviewing past research shows that over 70% of articles were in journals, likely due to the higher status of journals over conferences in most cases.

Table 2 presents the distribution of the articles by journal. Three journals each have 10% (4) of the articles: International Journal of Production Research, Journal of Manufacturing Technology Management and Journal of Cleaner Production, respectively. The lean–resilience subject is also published in a broad range of specialized journals including Production Planning and Control, which is specialized in the management of operations, Sustainable Production and Consumption, specialized in environmental topics and Total Quality Management and Business Excellence, which is concentrated on Quality Management issues and is also appropriate for journals with a more general thematic such as International Journal of Production Economics.

Table 2.

Distribution of articles by journal.

Webster and Watson [24] acknowledged the importance of high-quality conference proceedings as valuable scientific sources for conducting the systematic literature review. For this reason, Table 3 presents lean–resilience related conference articles published by the International Group for Lean Construction in its annual conference, with nearly 10% of the identified articles, followed by IEEE (5%).

Table 3.

Distribution of articles by conference.

Figure 4 shows the publishers’ databases where the majority of articles were identified. In addition, Das [45], Grijalva [46], Fitzgerald and Stol [47], Maslaric et al. [48] and Carvalho and Machado [49] were not in any of these databases and were found through Google Scholar.

3.1.2. Research Methods Applied in the Articles

Figure 5 presents the research methods used in the 53 articles. Almost 45% of all articles used a qualitative method (a subjective viewpoint, not based on quantifiable data), while quantitative analysis (the presentation of a mathematical and statistical approach to comprehension and prediction) was only used in 10% (5) of the articles. About 23% (12) used a mixed method (a combination of both the qualitative and quantitative approaches), and about 23% used computational analysis (the use of computer techniques to mine data). With only five articles using quantitative analysis, it suggests there is a need for further quantitative research to determine the ultimate impact of combining the lean and resilience paradigms.

3.1.3. Sectoral and Geographical Analysis

This section describes the findings by sectoral classification (Figure 6). According to Ruiz-Benítez et al. [50], further research is required to contribute supplementary insights into the impact of the implementation of resilience and lean paradigms on the performance of organizations in different industrial sectors beyond manufacturing. About half of the articles (49%) focused on the manufacturing area, followed by articles focused on public health [33,51], the food industry [6,45] and cyber security [43,52]. Research has also been conducted on transportation [48], construction [53,54], automotive [55] and aerospace [56] sectors highlighting the demand for further research on these sectors due to significance of both paradigms. In the identified literature, the service sector was not studied, suggesting a gap in findings.

Mapping the literature on lean–resilience paradigms by countries under investigation provides essential information about the most productive geographical areas. Figure 7 shows the articles classified by 16 countries of origin: Australia, Brazil, Germany, India, Iran, Ireland, Italy, Japan, Morocco, Pakistan, Portugal, Serbia, Singapore, Spain, United Kingdom and the United States. Remarkably, over 50% of authors publishing in this domain were from Europe (including the UK), demonstrating an extensively high level of interest in executing lean–resilience paradigms in Europe. Articles from the United Kingdom are at the forefront of lean and resilience paradigms, not only from a theoretical viewpoint, but also in terms of the industrial context where the proposed frameworks and methods are applied [43,57,58]. After the United Kingdom (8), a significant number of articles are from the United States, Portugal and Germany. These countries have similar developmental and economic goals, as well as comparable social orientations. This trend might stem from the need to mitigate the disruption caused by overdependence and interconnected supply chains in these countries.

3.1.4. Bibliometric Analysis of Findings

Bibliometric analysis uses multiple approaches including identifying co-occurrence, keyword mapping, author analysis, citation analysis and countries for their impacts on the context of the systematic literature review [59]. This methodology is famous for generating a wide-ranging review of a theme, defining its boundaries and offering unbiased agendas for future research [60].

The present study conducted a co-occurrence analysis of keywords, to determine the central research clusters associated with lean and resilience. Figure 8 provides insights into these results. The scientometric map of the top keywords offers a network visualization of dominant themes. The circle’s size of keywords denotes the occurrence weight of each theme. Thus, the bigger the circle associated with each keyword, the higher the importance in the scientometric network. Following the extraction of eligible records, a scientometric analysis using VOS-viewer was performed to establish a more holistic mental map of keywords. This figure shows that supply chain management is the dominant cluster associated with the selected keywords, followed by risk management, lean production, green supply chain management, agile manufacturing systems and supply chain performance. The keyword co-occurrence map facilitates the identification of the interrelation between these clusters. Moreover, this mapping helps researchers to find leading and frequent keyword clusters, paving the way to fill in any gaps in future studies [60,61].

4. Discussion

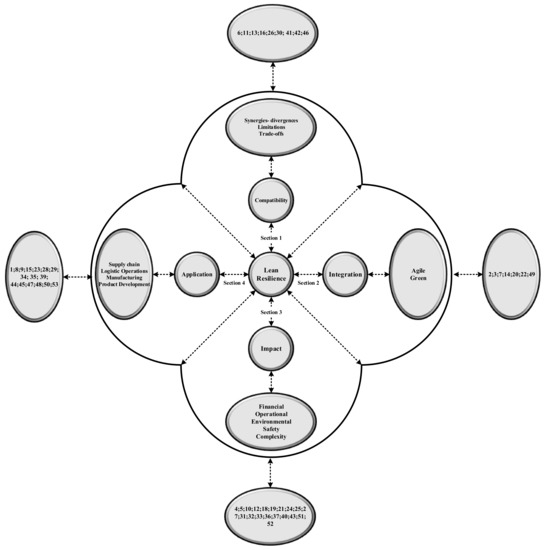

The present paper raises two research questions. The first asks about trends linking lean and resilience paradigms. To answer this question, we used diverse content analysis and bibliometric techniques to distinguish the critical domain in the research context. This section discusses the contribution of the lean–resilience paradigms in different contexts to answer the second question. As a result of this section, a concept map is proposed demonstrating four diverse research streams, including integration of resilience and lean with other paradigms, application of combined paradigms, compatibility with each other and their impacts on performance indicators.

4.1. Concept Map for Lean Resilience

As described in Section 2.2, the articles were initially categorized according to either the micro level (operation/process) or macro level (supply chain) in which the lean–resilience topic was discussed (see Table 1). This process facilitated the analysis and identification of similarities and differences. While all the articles involved in the review encapsulated the topic of lean–resilience, the thematic analysis and preceding classification revealed that several had overlapping objectives (Table 1). Thus, an inductive classification process was conducted to visualize, coordinate and shape the discussions and findings through the design of a conceptual map. The articles were also ascribed to each of the developed conceptual map’s research streams based on their thematic focus. Concise visualization was used to present the number of articles issued per category and sub-category. As a result, the concept map presents those fields where lean–resilience research has been conducted and those where it has been neglected.

Figure 9 displays the conceptual map for this research, with lean–resilience located at the core, surrounded by four research themes: application, integration, compatibility and impact. The themes were characterized according to the thematic focus of the articles. All of the articles, based on the thematic analysis, fell within one of these four themes. This classification not only covers the operation/process level but also facilitates deploying lean and resilience paradigms within organizations through their supply chain [62]. These four themes were subdivided into four subcategories to demonstrate with more precision and detail, the lean–resilience topics of the articles. The numbers assigned to each category and sub-category cross-reference to the articles in Table 4. For instance, Ivanov and Dolgui [7] is the sixth in Table 4 and connected to the “compatibility” category, indicating that the Ivanov and Dolgui article covers all the ascribed thematic. The four streams and their sub-categories are reviewed in Section 4.1.1, Section 4.1.2, Section 4.1.3 and Section 4.1.4.

Figure 9.

Concept map of the integration of lean–resilience literature review.

Table 4.

Core set of articles included in the literature review.

4.1.1. Compatibility between Lean and Resilience

The dual needs to be lean, that is, to maximize value while minimizing waste, and to be resilient, which is to be aware of risks and be prepared to overcome them efficiently, are essential for organizations to improve their operational performance [68]. This awareness has inspired researchers to investigate the potential incorporation of lean and resilience paradigms, which are conventionally implemented separately and with diverse objectives, by examining their synergies and differences. Figure 9 identifies the articles that have explored the compatibility of resilience and lean. It shows there is a broad range of domains including manufacturing [66], logistics [3], supply chain [80] and operations [90]. On the other hand, the potential impact of the lean–resilience compatibility on different organizational features—such as complexity [4], safety [53], finances [84], variability [54], sustainability [81], flexibility [43] and operational [62]—has also been considered.

In general, there is no consensus among scholars on the interrelationships between lean and resilience paradigms [72]. Carvalho et al. [91], for example, argued that the synergies between these paradigms are associated with increasing integration level and information frequency, as well as reduced production and lead time. However, other supply chain attributes, such as inventory level, replenishment frequency and capacity surplus are influenced in opposite directions and generate divergences. Nevertheless, despite the lack of agreement, authors such as Lotfi and Saghiri [72], Birkie [79] and Purvis et al. [6] recommend that resilience and lean are concurrent and thus can efficiently work simultaneously. In addition, Ruiz-Benítez et al. [50] indicate that sequential interdependencies between resilience and lean should be investigated to assist each other, if their procedures are executed either separately or concurrently. These discrepancies uncovered in the literature indicate that further study is essential to delve into different attributes related to the integration of lean and resilience, as discussed in Section 4.1.2.

4.1.2. Integration of Lean and Resilience Paradigms

Figure 9 presents four distinct themes of the conceptual map. While synergies and divergences are explored in the integration section (see Table 5), a few scholars have also discussed lean–resilience integration through the application of different methods to integrate them. According to Azevedo et al. [78], concentrating on these approaches is crucial to take advantage of the resilience and lean synergies accessible when they are applied simultaneously. Likewise, Azadeh et al. [62] recommend that it is necessary to incorporate lean and resilience paradigms to achieve successful transitions in organizational efficiency. Figure 9 illustrates the articles in the recent lean–resilience literature aiming to incorporate these concepts. Some of the identified integrating approaches were developed to be enabled at an operation/process level in the manufacturing industry [58,75], while others have focused on supply chains [64,71]. Regardless of these, there appears to be a limited number of models or approaches that amalgamate resilience and lean thinking principles [4,72]. This indicates that to examine various features such as applicability, effectiveness, challenges and practical implications of these paradigms, further research is necessary. A prospective research path for diverse research streams related to the integrated lean and resilience is highlighted in Section 4.1.5.

Table 5.

Overview of synergies and divergencies between lean and resilience.

The successful implementation of lean and resilience practices in supply chains can contribute to achieving a higher level of competitiveness and increased profit margins, through reducing cost and external risks [55]. A few researchers, however, suggest that not only will the integration of lean and resilience assist supply chains and operations to become more productive, streamlined and sustainable, but this will also work for paradigms such as green and agile [57,78]. Consequently, authors such as Ramirez-Peña et al [63], Rachid [73], and Carvalho and Machado [49] have examined the amalgamation of the lean, agile, resilient and green (LARG) paradigms. These four have an identical overall objective: to meet customer needs at the lowest possible cost to all members in the supply chain. However, the main difference between them is the process. The lean supply chain pursues waste minimization; the resilient supply chain priorities responding efficiently to disturbances; the agile supply chain is centered on rapid response to market changes and the green supply chain strives to minimize environmental impacts [91]. A few studies proposed the implementation of lean practices in disaster risk management [92,93], which could provide a new path for further research in the integration of resilience and lean in post-disaster recovery projects. This review also suggests that further studies are required on the impact of the integration of these paradigms on reconstruction projects.

This research theme within lean and resilience reveals that academics need to consider the impact of integrating these paradigms (see Section 4.1.3) to assess their multi-dimensional effects on performance indicators and scrutinize their synergies and divergencies (see Table 5). Thus, performance improvement arising from the adoption of lean and resilience concepts, as well as integrating with other paradigms associated with improving the sustainability and agility of supply chains and operations, needs further research. This provides opportunities for a new study path concerning the amalgamation of lean and resilience with other performance improvement paradigms (see Section 4.1.4).

4.1.3. Impact of Lean and Resilience Paradigms

Performance measurement and metrics are essential to identify the consequences of implementing these paradigms on supply chain and organizational performance [62,91]. Selecting suitable supply chain performance measures is, however, challenging, predominantly due to the complexity of such systems [101]. Measuring supply chain performance becomes even more difficult when different practices are applied, and their need to be evaluated. However, operational and economic performance measures to evaluate supply chain performance are recommended in several studies [102,103]. For example, Ruiz-Benítez et al. [50] studied operational and economic performance measures to examine the relationship between lean and resilient supply chain practices and their impact on supply chain performance. Their findings revealed that lean supply chain practices act as drivers for resilient supply chain practices, since implementing lean practices in isolation could lead to a more vulnerable supply chain. Likewise, Maslaric et al. [48] investigated the trade-off between achieving a lean strategy and resilience in the supply chain. Their findings recommend using supply chain risk management practices to achieve an appropriate balance between lean and resilience.

A few studies examined the impact of lean and resilience paradigms on organizational performance. For instance, Hills [43] scrutinized building strategic resilience through lean scenario-driven exercises. Hills’ findings indicate the significant impact of continuous improvement through effective training and learning on organizational performance. Organizational performance is a multidimensional condition that requires further research to scrutinize the impact of lean and resilience paradigms on its various dimensions of performance. Figure 9 shows the articles which, to a certain extent, have examined such impacts. Exploring the practical implication of these impacts is an opportunity for further research (see Section 4.1.4).

4.1.4. Application of Lean and Resilience Paradigms

Figure 9 illustrates the application of lean and resilience paradigms in various industry sectors and organizational functions. Similarly, as revealed in Table 1 in the initial thematic classification of lean–resilience (see Section 2.2), over 50% of the articles were categorized based on their research focus on specific organizational functions in the supply chain and operations/process domains. As reviewed in Section 3.1.3, this indicates the significant and ongoing research emphasis given to the supply chain context [6,8,81]. While logistic operations are an indispensable component of the supply chain [104], the articles focused on them were categorized to reveal the resilience and lean research emphasis with more detail. Moreover, this implies that lean and resilience research focused on the logistic activity of supply chains is still very limited [3]. Therefore, future research on lean and resilience might focus on particular major supply chain activities such as procurement, transportation, warehousing and logistics [5].

Manufacturing has received significant attention from lean and resilience researchers, with 49% (26) of the selected articles having this theme (see Figure 6). The manufacturing sector, more than other sectors, has been forced to make their operations efficient and their supply chain more robust [70]. Traditionally, the manufacturing sector has been a pioneer of innovation and a significant contributor to research and working practices. Many lean manufacturing principles have later been adopted across other industries. The literature review also found a similar trend where the manufacturing sector has taken the research lead, followed by slow development into other industries such as cybersecurity [52], transportation [48], construction [54] and food production [45].

Lean construction is one of the major practices arising from the lean paradigm, which attracted significant attention from both academics and practitioners due to its reputation as being responsible for success in construction projects [105]. The application of integrated resilience and lean paradigms in the construction industry could benefit the construction sector. A lack of research in this context is a critical issue that highlights an emerging need. Meanwhile, a few studies have proposed implementing lean practices in disaster risk management as a complementary tool for rebuilding better [92,93]. Thus, a further potential field for implementation of lean–resilience paradigms might be recovery projects. In particular, humanitarian supply chain management is one of the leading disaster management areas with significant potential for executing lean–resilience paradigms, due to its critical need in disaster relief operations [106]. Although previous research has introduced the importance of the agile principle as a suitable paradigm for disaster relief [107,108], the execution of integrated lean–resilience paradigms remains unclear. Enhancing evacuation response to natural hazards [109], optimizing location finding for relief supply chain in the aftermath of disasters [110], post-disaster inventory management [111] and disaster relief planning [112] are only few potential research areas for the execution of lean–resilience paradigms.

The identified research themes were assessed in several articles [5,62,70,78], but further research is necessary.

4.1.5. Future Research Paths

In the previous sections, four research themes associated with resilience and lean were identified and reviewed. Of these themes, a few have been developed by researchers, while others have been largely ignored and need more research. Figure 9 shows the number of articles in each category.

While this study set out to develop a deeper understanding of the lean and resilience relationship and its evolution, the research results in Section 3.1.1, Section 3.1.2, Section 3.1.3, Section 3.1.4, Section 4, Section 4.1, Section 4.1.1, Section 4.1.2, Section 4.1.3 and Section 4.1.4 have identified possible paths for further studies. These alternative paths are discussed in this section satisfying the second objective of this study and paving the way for future development of lean–resilience. Agee [113] argued that developing effective research questions can give shape and direction to future study while simultaneously preventing scholars from following unnecessary paths. Therefore, precise and explicit research questions based on the discussions and analyses presented in the prior sections were recommended to identify possible pathways for future researchers to follow. Table 6 shows the research questions that can help future researchers follow the new paths presented in Section 4.1.1, Section 4.1.2, Section 4.1.3 and Section 4.1.4.

Table 6.

Research questions to guide further research.

5. Conclusions

In this study, we conducted a systematic review of the literature about the integration of lean and resilience paradigms. Through this review, 53 articles published between 2000 and December 2020 were identified using C-I-M-O framework. The systematic literature review method was deliberately chosen to review a large sample size of articles and improve the reliability of our findings. This method was used to answer two research questions.

The first question asks, what themes have been researched previously on the lean paradigm and its application to and linkages with resilience? The answer to this question, which is developed through diverse content and bibliometric analysis in Section 3 and Section 4, is four research themes associated with resilience and lean. These themes address the combination of resilience and lean paradigms in four ways: their application in organizational functions and industries, compatibility with each other, integration with other paradigms and impact on various organizational features such as performance.

The second question asks, what are the research gaps and prospective research directions for the lean–resilience theme? The answer to this question, which is developed in Section 4.1.5. (Future research paths) is presented through a series of research questions that can help the future researcher to identify possible pathways for future studies.

A general claim found in the research is that the resilience paradigm is imperative for organizations, and it must be aligned with their general priorities of profitability and productivity, particularly for manufacturing, operations management and logistics. Conversely, whereas lean practices aim to minimize all potential wastes in the process, resilient practices seek to minimize the impact of any unexpected event and crisis on the organization and process to bring them back to their initial state before the disturbance took place. Diverse characteristics of the resilience and lean concepts have been examined, and the different deployment of these practices has been proposed as a potential procedure for obtaining alignment. However, the development of this area is still in the early stages, with most of the studies published in the last ten years. This systematic review provides guidance on the topic for scholars and contributes to transparent paths for further studies, particularly for implementing the integrated lean–resilience concept in manufacturing, supply chain, logistics, construction, disaster management and many more disciplines.

While the present research has identified multiple knowledge gaps and future directions, they are not prioritized in any way; all are significant. Despite this, examining an integrated approach for organizational functions and practical advancement in industries would appear to be critical. Defining potential research areas can encourage academics to study specific issues, leading to a better understanding of the dynamics of integrated initiatives. In addition, to disseminate the practical implications of lean–resilience paradigms, this research seeks to provide industry practitioners with a general overview of lean and resilience to develop new knowledge about these paradigms and their practices, and to develop more effective approaches to their implementation.

Finally, while this review has been conducted in accordance with best practice methods, there are two practical limitations. First, the data were collected from different peer-reviewed academic journals and conferences, which excluded the content of master or doctoral theses, unreleased articles, and books. The second limitation was the collection of all papers from English-language journals. Consequently, the systematic review did not encompass journals in other languages.

Author Contributions

Conceptualization, M.H.R. and M.M.; methodology, M.H.R. and M.M.; analysis, M.H.R.; writing—original draft preparation, M.H.R. and M.M.; writing—review and editing, M.H.R., M.M. and M.J.O.; supervision, M.M. and M.J.O. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Data Availability Statement

Data are available from the corresponding author upon written request and subject to review.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Bosher, L. Built-in Resilience through Disaster Risk Reduction: Operational Issues. Build. Res. Inf. 2013, 42, 240–254. [Google Scholar] [CrossRef] [Green Version]

- Bryce, C.; Ring, P.; Ashby, S.; Wardman, J.K. Resilience in the Face of Uncertainty: Early Lessons from the COVID-19 Pandemic. J. Risk Res. 2020, 23, 880–887. [Google Scholar] [CrossRef]

- Zavitsas, K.; Zis, T.; Bell, M.G. The Impact of Flexible Environmental Policy on Maritime Supply Chain Resilience. Transp. Policy 2018, 72, 116–128. [Google Scholar] [CrossRef] [Green Version]

- Soliman, M.; Saurin, T.; Anzanello, M.J. The Impacts of Lean Production on the Complexity of Socio-technical Systems. Int. J. Prod. Econ. 2018, 197, 342–357. [Google Scholar] [CrossRef]

- Ivanov, D. Viable Supply Chain Model: Integrating Agility, Resilience and Sustainability Perspectives—Lessons from and Thinking beyond the COVID-19 Pandemic. Ann. Oper. Res. 2020, 2020, 1–21. [Google Scholar] [CrossRef]

- Purvis, L.; Spall, S.; Naim, M.; Spiegler, V. Developing a Resilient Supply Chain Strategy during ‘Boom’ and ‘Bust’. Prod. Plan. Control 2016, 27, 579–590. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. Low-Certainty-Need (LCN) Supply Chains: A New Perspective in Managing Disruption Risks and Resilience. Int. J. Prod. Res. 2019, 57, 5119–5136. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, W.; Rashdi, M.Z. Understanding the Influence of Lean and Agile Strategies on Creating Firms’ Supply Chain Risk Management Capabilities. Compet. Rev. 2020. [Google Scholar] [CrossRef]

- Dalziell, E.P.; McManus, S.T. Resilience, Vulnerability, and Adaptive Capacity: Implications for System Performance. 2004. Available online: https://ir.canterbury.ac.nz/handle/10092/2809 (accessed on 12 September 2020).

- Wedawatta, G.; Ingirige, B.; Amaratunga, D. Building up Resilienc e of Construction Sector Smes and their Supply Chains to Extreme Weather Events. Int. J. Strat. Prop. Manag. 2010, 14, 362–375. [Google Scholar] [CrossRef] [Green Version]

- Namdar, J.; Li, X.; Sawhney, R.; Pradhan, N. Supply Chain Resilience for Single and Multiple Sourcing in the Presence of Disruption Risks. Int. J. Prod. Res. 2018, 56, 2339–2360. [Google Scholar] [CrossRef] [Green Version]

- Yilmaz Borekci, D.; Rofcanin, Y.; Gürbüz, H. Organisational Resilience and Relational Dynamics in Triadic Networks: A Multiple Case Analysis. Int. J. Prod. Res. 2015, 53, 6839–6867. [Google Scholar] [CrossRef]

- Ivanov, D.; Dolgui, A. Viability of Intertwined Supply Networks: Extending the Supply Chain Resilience Angles towards Survivability. A Position Paper Motivated by COVID-19 Outbreak. Int. J. Prod. Res. 2020, 58, 2904–2915. [Google Scholar] [CrossRef] [Green Version]

- Shah, R.; Ward, P.T. Defining and Developing Measures of Lean Production. J. Oper. Manag. 2007, 25, 785–805. [Google Scholar] [CrossRef]

- Aziz, R.F.; Hafez, S.M. Applying Lean Thinking in Construction and Performance Improvement. Alex. Eng. J. 2013, 52, 679–695. [Google Scholar] [CrossRef] [Green Version]

- Womack, J.P.; Jones, D.T.; Roos, D. The Machine That Changed the World: The Story of Lean Production—Toyota’s Secret Weapon in the Global Car Wars That Is Now Revolutionizing World Industry; Simon and Schuster: New York, NY, USA, 2007. [Google Scholar]

- Ogunbiyi, O.; Goulding, J.S.; Oladapo, A. An Empirical Study of the Impact of Lean Construction Techniques on Sustainable Construction in the UK. Constr. Innov. 2014, 14. [Google Scholar] [CrossRef]

- Issa, U.H. Implementation of Lean Construction Techniques for Minimizing the Risks Effect on Project Construction Time. Alex. Eng. J. 2013, 52, 697–704. [Google Scholar] [CrossRef] [Green Version]

- Babalola, O.; Ibem, E.O.; Ezema, I.C. Implementation of Lean Practices in the Construction Industry: A Systematic Review. Build. Environ. 2019, 148, 34–43. [Google Scholar] [CrossRef]

- Järvenpää, E.; Lanz, M. Lean Manufacturing and Sustainable Development. Responsib. Consum. Prod. 2020, 423–432. [Google Scholar] [CrossRef]

- Abualfaraa, W.; Salonitis, K.; Al-Ashaab, A.; Ala’raj, M. Lean-Green Manufacturing Practices and their Link with Sustainability: A Critical Review. Sustainability. 2020, 12, 981. [Google Scholar] [CrossRef] [Green Version]

- Henao, R.; Sarache, W.; Gómez, I. Lean Manufacturing and Sustainable Performance: Trends and Future Challenges. J. Clean. Prod. 2019, 208, 99–116. [Google Scholar] [CrossRef]

- Seuring, S.; Müller, M. From a Literature Review to a Conceptual Framework for Sustainable Supply Chain Management. J. Clean. Prod. 2008, 16, 1699–1710. [Google Scholar] [CrossRef]

- Webster, J.; Watson, R.T. Analyzing the Past to Prepare for the Future: Writing a Literature Review. MIS Q. 2002, 26, xiii. [Google Scholar]

- Fink, A. Conducting Research Literature Reviews: From the Internet to Paper; Sage Publications: Thousand Oaks, CA, USA, 2019. [Google Scholar]

- Dresch, A.; Lacerda, D.P.; Antunes, J.A.V. Design Science Research: A Method for Science and Technology Advancement, 2015th ed.; Springer: Berlin, Germany, 2015. [Google Scholar]

- Tranfield, D.; Denyer, D.; Smart, P. Towards a Methodology for Developing Evidence-Informed Management Knowledge by Means of Systematic Review. Br. J. Manag. 2003, 14, 207–222. [Google Scholar] [CrossRef]

- Saunders, M.; Lewis, P.; Thornhill, A. Research Methods for Business Students; Pearson Education: London, UK, 2009. [Google Scholar]

- Garza-Reyes, J.A. Lean and Green—A Systematic Review of the State of the Art Literature. J. Clean. Prod. 2015, 102, 18–29. [Google Scholar] [CrossRef] [Green Version]

- Falagas, M.E.; Pitsouni, E.I.; Malietzis, G.; Pappas, G. Comparison of PubMed, Scopus, Web of Science, and Google Scholar: Strengths and Weaknesses. FASEB J. 2007, 22, 338–342. [Google Scholar] [CrossRef]

- Wang, Q.; Waltman, L. Large-Scale Analysis of the Accuracy of the Journal Classification Systems of Web of Science and Scopus. J. Inf. 2016, 10, 347–364. [Google Scholar] [CrossRef] [Green Version]

- Hollnagel, E.; Woods, D.D.; Leveson, N. Resilience Engineering: Concepts and Precepts; Ashgate Publishing, Ltd.: Farnham, UK, 2006. [Google Scholar]

- Shoaf, C.; Genaidy, A.; Karwowski, W.; Huang, S.H. Improving Performance and Quality of Working Life: A Model for Organizational Health Assessment in Emerging Enterprises. Hum. Factors Ergon. Manuf. 2003, 14, 81–95. [Google Scholar] [CrossRef]

- Rousseau, D.M. The Oxford Handbook of Evidence-Based Management; Oxford University Press: Oxford, UK, 2012. [Google Scholar]

- Wears, R.L.; Hollnagel, E.; Braithwaite, J. Resilient Health Care, Volume 2: The Resilience of Everyday Clinical Work; Ashgate Publishing, Ltd.: Hampshire, UK, 2015. [Google Scholar]

- Johnson, M.A.; Simmons, W.M.; Sullivan, P. Lean Technical Communication: Toward Sustainable Program Innovation; Routledge: Oxford, UK, 2017. [Google Scholar]

- Bombelli, A. Integrators’ Global Networks: A Topology Analysis with Insights into the Effect of the COVID-19 Pan-demic. J. Trans. Geogr. 2020, 87, 102815. [Google Scholar] [CrossRef] [PubMed]

- White, M.D.; Marsh, E. Content Analysis: A Flexible Methodology. Libr. Trends 2006, 55, 22–45. [Google Scholar] [CrossRef] [Green Version]

- Moher, D.; Liberati, A.; Tetzlaff, J.; Altman, D.G.; Prisma Group. Preferred Reporting Items for Systematic Reviews and Meta-Analyses: The PRISMA Statement. PLoS Med. 2009, 6, e1000097. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Thomas, J.; Harden, A. Methods for the Thematic Synthesis of Qualitative Research in Systematic Reviews. BMC Med. Res. Methodol. 2008, 8, 45. [Google Scholar] [CrossRef] [Green Version]

- Booth, A.; Sutton, A.; Papaioannou, D. Systematic Approaches to a Successful Literature Review, 1st ed.; Sage Publications Ltd.: London, UK, 2016; pp. 245–267. [Google Scholar]

- Slack, N.; Chambers, S.; Johnston, R. Operations Management; Pearson Education: London, UK, 2010. [Google Scholar]

- Hills, M. Assuring Organisational Resilience with Lean Scenario-Driven Exercises. Int. J. Emerg. Serv. 2015, 4, 37–49. [Google Scholar] [CrossRef]

- De Sanctis, I.; Meré, O.J.; Ciarapica, F.E. Resilience for Lean Organisational Network. Int. J. Prod. Res. 2018, 56, 6917–6936. [Google Scholar] [CrossRef]

- Das, K. Integrating Lean, Green, and Resilience Criteria in a Sustainable Food Supply Chain Planning Model. Int. J. Math. Eng. Manag. Sci. 2019, 4, 259–275. [Google Scholar] [CrossRef]

- Grijalva, P.; Eseonu, C. A tool to assess continuous improvement culture: Adapting SERVQUAL scale to measure employee satisfaction, and identify factors of success. In Proceedings of the International Annual Conference of the American Society for Engineering Management, Charlotte, NC, USA, 26–29 October 2016; pp. 1–10. [Google Scholar]

- Fitzgerald, B.; Stol, K.-J. Continuous Software Engineering and Beyond: Trends and Challenges. In Proceedings of the 1st International Workshop on Real World Domain Specific Languages, Barcelona, Spain, 12 March 2016; pp. 1–9. [Google Scholar]

- Maslaric, M.; Backalic, T.; Nikolicic, S.; Mircetic, D. Assessing the Trade-Off between Lean and Resilience through Supply Chain Risk Management. Int. J. Ind. Eng. Manag. 2013, 4, 229–236. [Google Scholar]

- Carvalho, H.; Cruz-Machado, V. Lean, Agile, Resilient and Green Supply Chain: A Review. In Proceedings of the 3rd International Conference on Management Science and Engineering Management, Bangkok, Thailand, 2–4 November 2009; pp. 66–76. [Google Scholar]

- Ruiz-Benítez, R.; López, C.; Real, J.C. The Lean and Resilient Management of the Supply Chain and its Impact on Performance. Int. J. Prod. Econ. 2018, 203, 190–202. [Google Scholar] [CrossRef]

- Rosso, C.B.; Saurin, T.A. The Joint Use of Resilience Engineering and Lean Production for Work System Design: A Study in Healthcare. Appl. Ergon. 2018, 71, 45–56. [Google Scholar] [CrossRef]

- Dynes, S.; Johnson, M.E.; Andrijcic, E.; Horowitz, B. Economic Costs of Firm-Level Information Infrastructure Failures. Int. J. Logist. Manag. 2007, 18, 420–442. [Google Scholar] [CrossRef] [Green Version]

- Schafer, D.; Abdelhamid, T.S.; Mitropoulos, P.; Howell, G.A. Resilience engineering: A new paradigm for safety in lean construction systems. In Proceedings of the 16th Annual Conference of the International Group for Lean Construction, Manchester, UK, 16–18 July 2008; pp. 16–18. [Google Scholar]

- Saurin, T.A.; Sanches, R.C. Lean construction and resilience engineering: Complementary perspectives of variability. In Proceedings of the 22nd Annual Conference of the International Group for Lean Construction, Oslo, Norway, 25–27 June 2014; pp. 61–71. [Google Scholar]

- Govindan, K.; Azevedo, S.G.; Carvalho, H.; Machado, V. Lean, Green and Resilient Practices Influence on Supply Chain Performance: Interpretive Structural Modeling Approach. Int. J. Environ. Sci. Technol. 2015, 12, 15–34. [Google Scholar] [CrossRef] [Green Version]

- Benítez, R.R.; López, C.; Real, J.C. Environmental Benefits of Lean, Green and Resilient Supply Chain Management: The Case of the Aerospace Sector. J. Clean. Prod. 2017, 167, 850–862. [Google Scholar] [CrossRef]

- Bhattacharya, A.; Cheffi, W.; Dey, P.K.; Thomas, A.; Byard, P.; Francis, M. Profiling the Resiliency and Sustainability of UK Manufacturing Companies. J. Manuf. Technol. Manag. 2016, 27. [Google Scholar] [CrossRef]

- Puchkova, A.; Srinivasan, R.; McFarlane, D.; Thorne, A. Towards Lean and Resilient Production; Elsevier: Amsterdam, The Netherlands, 2015. [Google Scholar]

- Khanra, S.; Dhir, A.; Mäntymäki, M. Big Data Analytics and Enterprises: A Bibliometric Synthesis of the Literature. Enterp. Inform. Syst. 2020, 14, 737–768. [Google Scholar] [CrossRef]

- Emrouznejad, A.; Marra, M. The State of the Art Development of AHP (1979–2017): A Literature Review with a Social Network Analysis. Int. J. Prod. Res. 2017, 55, 6653–6675. [Google Scholar] [CrossRef] [Green Version]

- Kazemi, N.; Modak, N.; Govindan, K. A Review of Reverse Logistics and Closed Loop Supply Chain Management Studies Published in IJPR: A Bibliometric and Content Analysis. Int. J. Prod. Res. 2019, 57, 4937–4960. [Google Scholar] [CrossRef] [Green Version]

- Azadeh, A.; Yazdanparast, R.; Zadeh, S.A. Performance Optimization of Integrated Resilience Engineering and Lean Production Principles. Expert Syst. Appl. 2017, 84, 155–170. [Google Scholar] [CrossRef] [Green Version]

- Ramirez-Peña, M.; Sotano, A.J.S.; Pérez-Fernandez, V.; Abad, F.J.; Batista, M. Achieving a Sustainable Shipbuilding Supply Chain under I4.0 Perspective. J. Clean. Prod. 2020, 244, 118789. [Google Scholar] [CrossRef]

- López, C.; Ruiz-Benítez, R. Multilayer Analysis of Supply Chain Strategies’ Impact on Sustainability. J. Purch. Supply Manag. 2020, 26, 100535. [Google Scholar] [CrossRef]

- Caldera, H.; Desha, C.; Dawes, L. Evaluating the Enablers and Barriers for Successful Implementation of Sustainable Business Practice in ‘Lean’ SMEs. J. Clean. Prod. 2019, 218, 575–590. [Google Scholar] [CrossRef]

- Tan, W.J.; Zhang, A.N.; Cai, W. A Graph-Based Model to Measure Structural Redundancy for Supply Chain Resilience. Int. J. Prod. Res. 2019, 57, 6385–6404. [Google Scholar] [CrossRef]

- Nunes-Vaz, R.; Arbon, P.; Steenkamp, M. Imperatives for Health Sector Decision-Support Modelling. Int. J. Disaster Risk Reduct. 2019, 38, 101234. [Google Scholar] [CrossRef]

- Lotfi, M. Which Practices are Lean, Agile and Resilient? Literature Review and Practitioners’ Perspective. Int. J. Adv. Oper. Manag. 2019, 11, 142–170. [Google Scholar]

- Paul, S.K.; Asian, S.; Goh, M.; Torabi, S.A. Managing Sudden Transportation Disruptions in Supply Chains under Delivery Delay and Quantity Loss. Ann. Oper. Res. 2019, 273, 783–814. [Google Scholar] [CrossRef] [Green Version]

- Ahmed, W.; Huma, S. Impact of Lean and Agile Strategies on Supply Chain Risk Management. Total. Qual. Manag. Bus. Excel. 2021, 32, 33–56. [Google Scholar] [CrossRef]

- Rajesh, R. On Sustainability, Resilience, and the Sustainable–Resilient Supply Networks. Sustain. Prod. Consum. 2018, 15, 74–88. [Google Scholar] [CrossRef]

- Lotfi, M.; Saghiri, S. Disentangling Resilience, Agility and Leanness. J. Manuf. Technol. Manag. 2018, 29, 168–197. [Google Scholar] [CrossRef] [Green Version]

- Rachid, B. Supply Chain Improvement in LARG (Lean, Agile, Resilient, Green) Context: A Risk Management Approach. In Proceedings of the 2017 6th IEEE International Conference on Advanced Logistics and Transport (ICALT), Bali, Indonesia, 24–27 July 2017; pp. 212–220. [Google Scholar]

- Villalba-Diez, J.; de Sanctis, I.; Ordieres-Meré, J.; Ciarapica, F.E. Lean Structural Network Resilience; Springer: Berlin, Germany, 2017. [Google Scholar]

- Zarrin, M.; Azadeh, A. Simulation Optimization of Lean Production Strategy by Considering Resilience Engineering in a Production System with Maintenance Policies. Simulation 2016, 93, 49–68. [Google Scholar] [CrossRef]

- Fitzgerald, B.; Stol, K.-J. Continuous Software Engineering: A Roadmap and Agenda. J. Syst. Softw. 2017, 123, 176–189. [Google Scholar] [CrossRef]

- Peñaloza, G.A.; Formoso, C.T.; Saurin, T.A. Safety Performance Measurement Systems Based on Resilience Engineering: A Literature Review. In Proceedings of the 25th Annual Conference of the International Group for Lean Construction (IGLC), Heraklion, Greece, 9–12 July 2017; pp. 903–910. [Google Scholar]

- Azevedo, S.G.; Carvalho, H.; Cruz-Machado, V. LARG Index A Benchmarking Tool for Improving the Leanness, Agility, Resilience and Greenness of the Automotive Supply Chain. Benchmark. Int. J. 2016, 23, 1472–1499. [Google Scholar] [CrossRef]

- Birkie, S.E. Operational Resilience and Lean: In Search of Synergies and Trade-Offs. J. Manuf. Technol. Manag. 2016, 27, 185–207. [Google Scholar] [CrossRef]

- Gao, L. Collaborative Forecasting, Inventory Hedging and Contract Coordination in Dynamic Supply Risk Management. Eur. J. Oper. Res. 2015, 245, 133–145. [Google Scholar] [CrossRef]

- Govindan, K.; Azevedo, S.G.; Carvalho, H.; Cruz-Machado, V. Impact of Supply Chain Management Practices on Sustainability. J. Clean. Prod. 2014, 85, 212–225. [Google Scholar] [CrossRef]

- Carvalho, H.; Azevedo, S. Trade-Offs among Lean, Agile, Resilient and Green Paradigms in Supply Chain Management: A Case Study Approach; Springer: Berlin/Heidelberg, Germany, 2014; pp. 953–968. [Google Scholar]

- Rolo, A.; Pires, A.R.; Saraiva, M. Supply Chain as a Collaborative Virtual Network Based on LARG Strategy; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Resurreccion, J.Z.; Santos, J.R. Uncertainty Modeling of Hurricane-Based Disruptions to Interdependent Economic and Infrastructure Systems. Nat. Hazards 2013, 69, 1497–1518. [Google Scholar] [CrossRef]

- Saurin, T.A.; Rooke, J.; Koskela, L.; Kemmer, S. Guidelines for the Management of Complex Socio-Technical Systems: An Exploratory Study of a Refurbishment Project. In Proceedings of the 21th Annual Conference of the International Group for Lean, Fortaleza, Brazil, 29 July–2 August 2013. [Google Scholar]

- Thomas, A.; Francis, M.; John, E.; Davies, A. Identifying the Characteristics for Achieving Sustainable Manufacturing Companies. J. Manuf. Technol. Manag. 2012, 23, 426–440. [Google Scholar] [CrossRef]

- Birkie, S.E.; Trucco, P.; Kaulio, M. State-of-the-Art Review on Operational Resilience: Concept, Scope and Gaps. In Lecture Notes in Control and Information Sciences; Springer: Berlin/Heidelberg, Germany, 2013; pp. 273–280. [Google Scholar]

- Li, H.-H.J.K.; Tan, K.H.; Hida, A. Sustaining Growth in Electronic Manufacturing Sector: Lessons from Japanese Mid-Size EMS Providers. Int. J. Prod. Res. 2011, 49, 5415–5430. [Google Scholar] [CrossRef]

- Soni, U.; Jain, V. Minimizing the Vulnerabilities of Supply Chain: A new Framework for Enhancing the Resilience. In Proceedings of the 2011 IEEE International Conference on Industrial Engineering and Engineering Management, Changchun, China, 3–5 September 2011; pp. 933–939. [Google Scholar]

- Benefield, R. Agile Deployment: Lean Service Management and Deployment Strategies for the SaaS Enterprise. In Proceedings of the 2009 42nd Hawaii International Conference on System Sciences, Washington, DC, USA, 5–8 January 2009; pp. 1–5. [Google Scholar]

- Carvalho, H.; Duarte, S.; Machado, V. Lean, Agile, Resilient and Green: Divergencies and Synergies. Int. J. Lean Six Sigma 2011, 2, 151–179. [Google Scholar] [CrossRef]

- Mojtahedi, S.M.H.; Oo, B.L. Possibility of Applying Lean in Post-Disaster Reconstruction: An Evaluation Study. In Proceedings of the 20th Annual Conference of the International Group for Lean Construction (IGLC 20), San Diego, CA, USA, 18–20 July 2012. [Google Scholar]

- Demirkesen, S. Investigating the Synergy between Lean Construction Practices and Post Disaster Management Processes. Chall. J. Struct. Mech. 2020, 6, 23. [Google Scholar] [CrossRef]

- Womack, J.P.; Jones, D.T. Lean Thinking—Banish Waste and Create Wealth in your Corporation. J. Oper. Res. Soc. 1997, 48, 1148. [Google Scholar] [CrossRef]

- Koskela, L. Application of the New Production Philosophy to Construction; Technical Report, No. 72; CIFE: Nice, France; Stanford University: Stanford, CA, USA, 1992; p. 81. [Google Scholar]

- Koskela, L.J. Moving on-beyond Lean Thinking. Lean Constr. J. 2004, 1, 24–37. [Google Scholar]

- Ballard, G. Cycle time reduction in home building. In Proceedings of the 9th Annual Conference of the International Group for Lean Construction, Kent Ridge, Singapore, 6–8 August 2001; pp. 6–8. [Google Scholar]

- Hines, P.; Holweg, M.; Rich, N. Learning to Evolve. Int. J. Oper. Prod. Manag. 2004, 24, 994–1011. [Google Scholar] [CrossRef] [Green Version]

- Bhamra, R.; Dani, S.; Burnard, K. Resilience: The Concept, a Literature Review and Future Directions. Int. J. Prod. Res. 2011, 49, 5375–5393. [Google Scholar] [CrossRef]

- Wehbe, F.; Al Hattab, M.; Hamzeh, F. Exploring Associations between Resilience and Construction Safety Performance in Safety Networks. Saf. Sci. 2016, 82, 338–351. [Google Scholar] [CrossRef]

- Beamon, B.M. Measuring Supply Chain Performance. Int. J. Oper. Prod. Manag. 1999, 19, 275–292. [Google Scholar] [CrossRef]

- Chavez, R.; Gimenez, C.; Fynes, B.; Wiengarten, F.; Yu, W. Internal Lean Practices and Operational Performance. Int. J. Oper. Prod. Manag. 2013, 33, 562–588. [Google Scholar] [CrossRef]

- Prajogo, D.; Oke, A.; Olhager, J. Supply Chain Processes. Int. J. Oper. Prod. Manag. 2016, 36, 220–238. [Google Scholar] [CrossRef]

- Rushton, A.; Croucher, P.; Baker, P. The Handbook of Logistics and Distribution Management: Understanding the Supply Chain; Kogan Page Publishers: London, UK, 2014. [Google Scholar]

- Koskela, L.; Howell, G.; Ballard, G.; Tommelein, I. The Foundations of Lean Construction. Design and Construction. Build. Value 2002, 291, 211–226. [Google Scholar]

- Dubey, R.; Gunasekaran, A. The Sustainable Humanitarian Supply Chain Design: Agility, Adaptability and Alignment. Int. J. Logist. Res. Appl. 2016, 19, 62–82. [Google Scholar] [CrossRef]

- Cozzolino, A.; Rossi, S.; Conforti, A. Agile and Lean Principles in the Humanitarian Supply Chain: The Case of the United Nations World Food Programme. J. Humani. Logist. Supply Chain Manag. 2012, 2. [Google Scholar] [CrossRef]

- Oloruntoba, R.; Gray, R. Humanitarian Aid: An Agile Supply Chain? Supply Chain Manag. Int. J. 2006, 11. [Google Scholar] [CrossRef] [Green Version]

- Yazdani, M.; Mojtahedi, M.; Loosemore, M. Enhancing Evacuation Response to Extreme Weather Disasters Using Public Transportation Systems: A Novel Simheuristic Approach. J. Comput. Des. Eng. 2020, 7, 195–210. [Google Scholar] [CrossRef]

- Khalili, S.M.; Babagolzadeh, M.; Yazdani, M.; Saberi, M.; Chang, E. A Bi-Objective Model for Relief Supply Location in Post-Disaster Management; Institute of Electrical and Electronics Engineers (IEEE): New Jersey, NJ, USA, 2016; pp. 428–434. [Google Scholar]

- Behl, A.; Dutta, P. Humanitarian Supply Chain Management: A Thematic Literature Review and Future Directions of Research. Ann. Oper. Res. 2019, 283, 1001–1044. [Google Scholar] [CrossRef]

- Upadhyay, A.; Mukhuty, S.; Kumari, S.; Garza-Reyes, J.A.; Shukla, V. A Review of Lean and Agile Management in Humani-Tarian Supply Chains: Analysing the Pre-Disaster and Post-Disaster Phases and Future Directions. Prod. Plan. Control 2020, 1–14. [Google Scholar] [CrossRef]

- Agee, J. Developing Qualitative Research Questions: A Reflective Process. Int. J. Qual. Stud. Educ. 2009, 22, 431–447. [Google Scholar] [CrossRef] [Green Version]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).