Innovative Strategy to Reduce Single-Use Plastics in Sustainable Horticulture by a Refund Strategy for Flowerpots

Abstract

:1. Introduction

- -

- Reduce—weight reduction;

- -

- Reuse—to increase lifespan;

- -

- Recycling;

- -

- Use of alternative materials;

- -

- Avoidance (of single-use plastic).

2. Materials and Methods

2.1. Primary Activity Data—Case Study

2.2. Pot Production, Polypropylene and Carbon Footprint Calculation

2.3. Delivery of Flowerpots

3. Results

3.1. The Concept—Climate Friendly Customer Relationship

3.2. Carbon Footprint of Flowerpot Supply

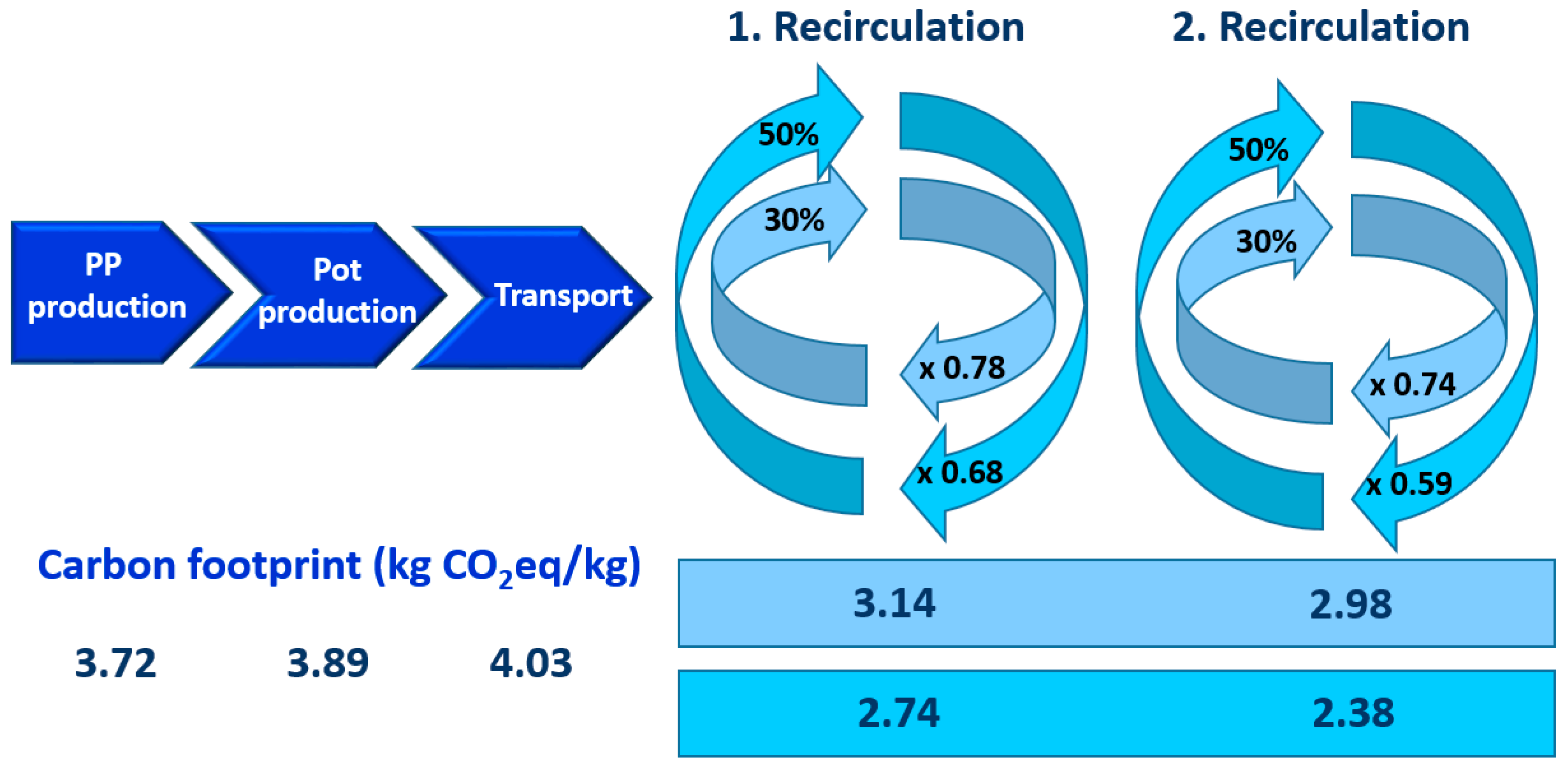

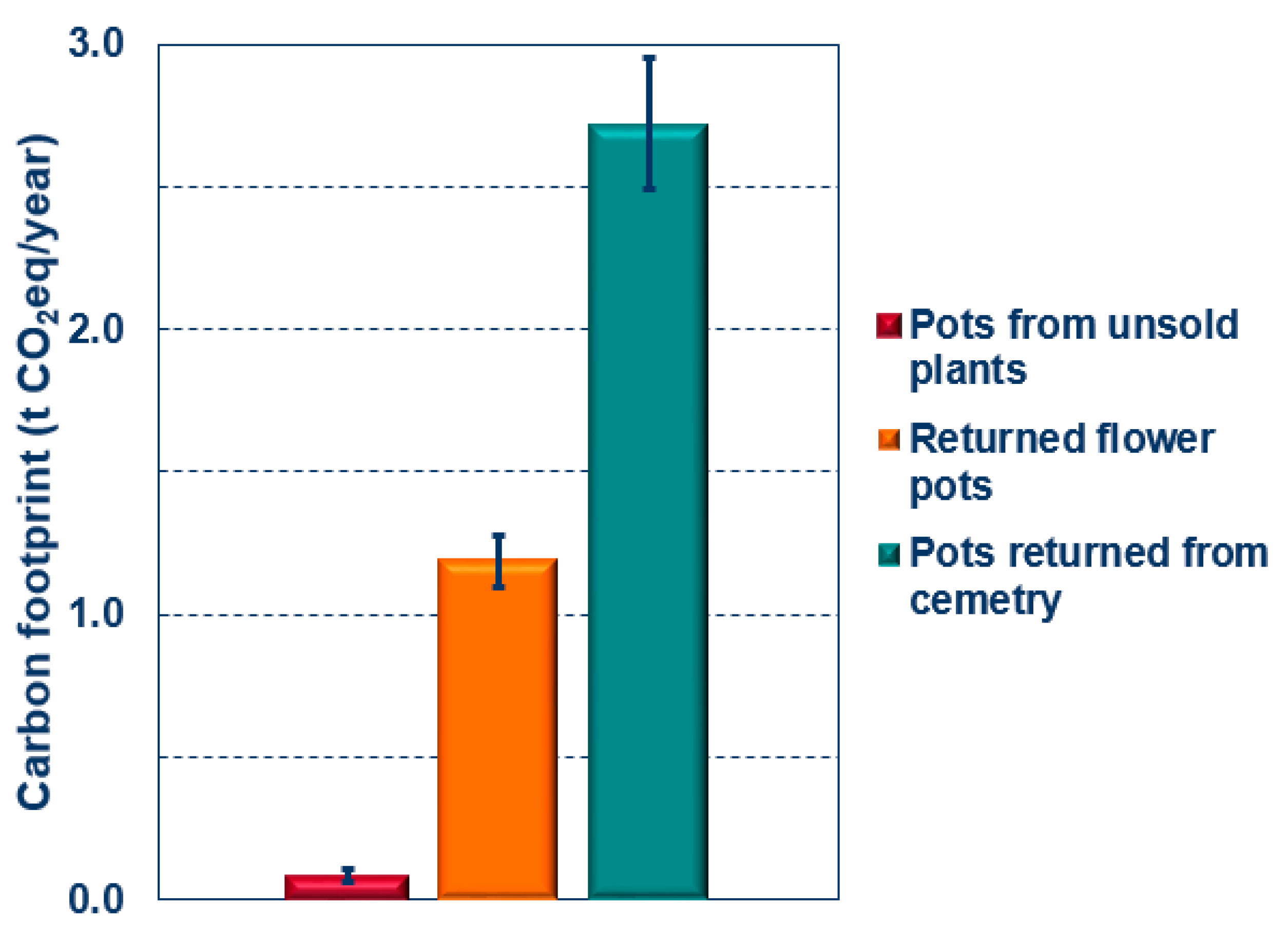

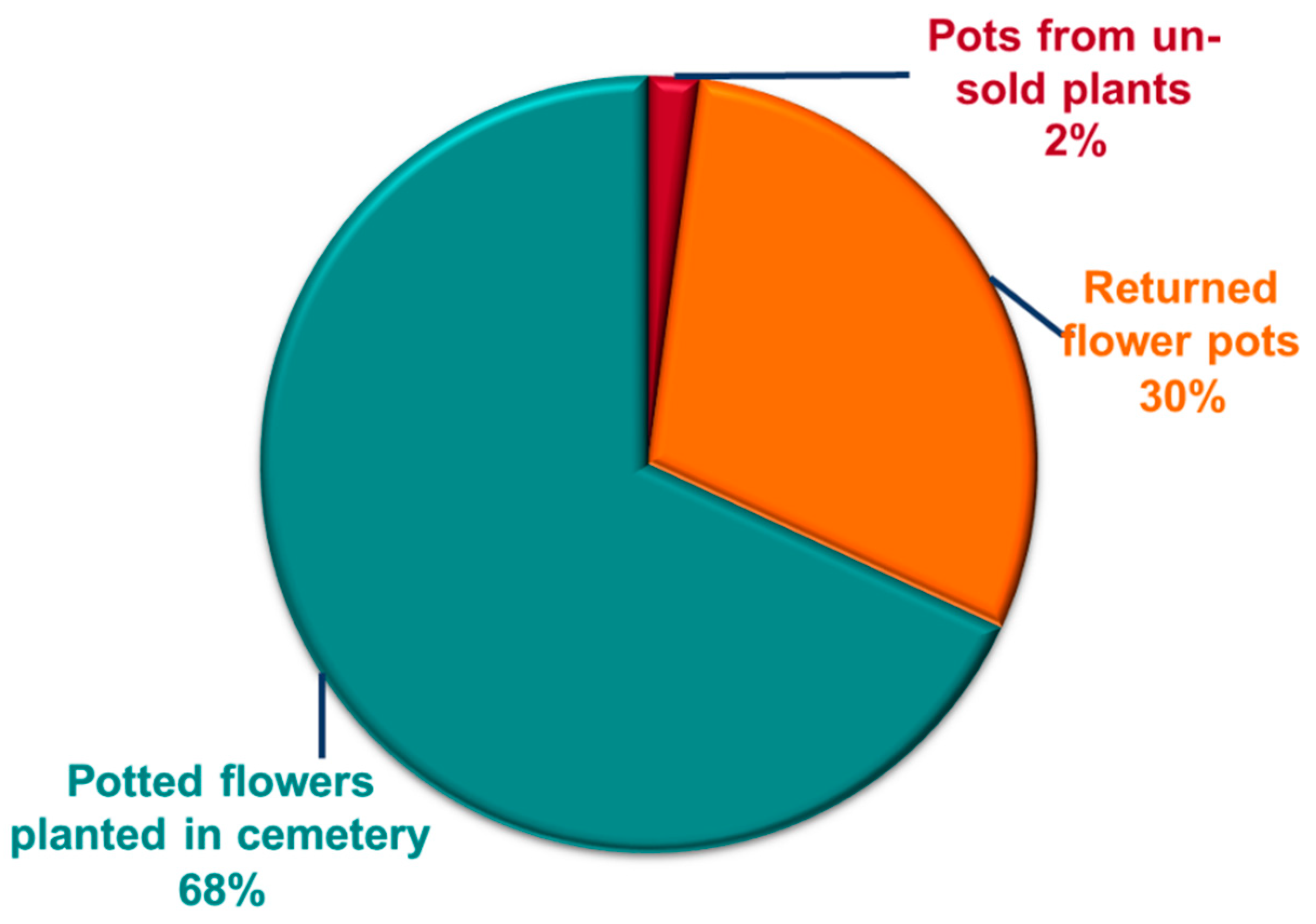

3.3. Carbon Footprint of Cycling Flowerpots in the Nursery

4. Discussion

5. Conclusions

6. Outlook, Scope and Upscaling

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- Gesses, L. Avoid Black Plastic Food Packaging. The Guardian 2 July 2019. Available online: https://www.theguardian.com/environment/2019/jul/02/use-compostable-plastic-and-the-16-other-essential-rules-of-effective-recycling%20 (accessed on 20 May 2021).

- Plastics Europe. Plastics—The Facts. Plastic Europe. Available online: https://www.plasticseurope.org/en/resources/publications/274-plastics-facts-2017 (accessed on 12 May 2021).

- A POTR Pots. A Greener Plant Pot. Available online: https://potrpots.com/pages/sustainablity (accessed on 10 April 2021).

- Zieck, W.; Desch Co., Nl. Re-Think Plastics; Lecture at GKL: Dernbach, Germany, 2019. [Google Scholar]

- Lebreton, L.; Andrady, A. Future scenarios of global plastic waste generation and disposal. Palgrave Commun. 2019, 5, 6. [Google Scholar] [CrossRef] [Green Version]

- Hess, P.; Kunz, A.; Blanke, M. Innovative strategies for the use of reflective foils for fruit colouration to reduce plastic use in orchards. Sustainability 2020, 13, 73. [Google Scholar] [CrossRef]

- Blanke, M. GKL-Congress on Plastics in Horticulture. Erwerbs Obstbau 2020, 489–497. [Google Scholar] [CrossRef]

- Schaefer, F.; Blanke, M. Farming and marketing affect carbon and water footprint—A case study using Hokkaido pumpkin. J. Clean. Prod. 2012, 28, 113–119. [Google Scholar] [CrossRef]

- Zheng, J.; Suh, S. Strategies to reduce the global carbon footprint of plastics. Nat. Clim. Chang. 2019. [Google Scholar] [CrossRef]

- Korol, J.; Hejna, A.; Burchart-Korol, D.; Wachowicz, J. Comparative analysis of carbon, ecological and water foot prints of polypropylene-based, composites filled with cotton, jute, and kenaf fibers. Materials 2020, 13, 3541. [Google Scholar] [CrossRef] [PubMed]

- BSI. PAS 2050-1: Assessment of Life Cycle Greenhouse Gas Emissions from Horticultural Products; British Standards Institute: London, UK, 2012; Available online: https://www.bsi-org.co.ac.uk (accessed on 22 May 2021).

- Schmied, M.; Knörr, W. Berechnung von Treibhausgasemissionen in Spedition und Logistik gemäß DIN EN16258, 2nd ed.; DSLV Deutscher Speditions- und Logistikverband e.V.: Berlin, Germany, 2013. [Google Scholar]

- TERRACYCLE 2021. Available online: https://www.terracycle.com/en-GB/collection-programs%20x (accessed on 20 July 2021).

- Umweltbundesamt. Die CO2 Bilanz des Bürgers. UBA 2007. Available online: https://www.umweltbundesamt.de/sites/default/files/medien/publikation/long/3327.pdf (accessed on 10 July 2021).

- Gierling, F.; Blanke, M. Carbon reduction strategies for regionally produced and consumed wine—From farm to fork. J. Environ. Manag. 2021, 15, 278. [Google Scholar] [CrossRef] [PubMed]

- AMI Markt Studie 2020. Warenstromanalyse 2018 Blumen, Zierpflanzen & Gehölze. Available online: https://www.bmel.de/SharedDocs/Downloads/DE/_Landwirtschaft/Pflanzenbau/warenstromanalyse-2018.pdf?__blob=publicationFile&v=13 (accessed on 25 June 2021).

| Type of Flowerpot (cm) | Weight [g] | Polypropylene [g CO2eq] | Truck Transport [g CO2eq] | Total [g CO2eq/Pot] |

|---|---|---|---|---|

| 9 | 6 | 20.6–24.6 | 0.8 | 21.4–25.4 |

| 12 | 13 | 44.5–53.3 | 1.7 | 46.2–55.1 |

| Year | Returned Pots | Pot Size [cm] | Returned Pots | Including Waste * |

|---|---|---|---|---|

| 2019 | 24,544 | 9 | 16,359 | 15,214 |

| 12 | 8185 | 7612 | ||

| 2020 | 39,979 | 9 | 26,636 | 24,771 |

| 12 | 13,333 | 12,400 |

| Year | Returned Pots | Pot Size [cm] | Pots * | GHG Savings [t CO2eq/Year] | Total [t CO2eq/Year] |

|---|---|---|---|---|---|

| 2019 | 24 544 | 9 | 15,214 | 0.33–0.39 | 0.68–0.81 |

| 12 | 7612 | 0.35–0.42 | |||

| 2020 | 39 979 | 9 | 24,771 | 0.53–0.60 | 1.10–1.28 |

| 12 | 12,400 | 0.57–0.68 |

| Portion Unsold Pots | Pot Size [cm] | Pot Number | GHG Savings [t CO2eq/Year] | Total [t CO2eq/Year] | |

|---|---|---|---|---|---|

| Pots from unsold plants | 5–10% | 9 | 30,000 | 0.035–0.069 | 0.06–0.11 |

| 5–10% | 12 | 10,000 | 0.025–0.050 | ||

| Planted in cemetery | 90,000 | 9 | 67,500 | 1.44–1.71 | 2.48–2.95 |

| pots | 12 | 22,500 | 1.04–1.24 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Blanke, M.M.; Golombek, S.D. Innovative Strategy to Reduce Single-Use Plastics in Sustainable Horticulture by a Refund Strategy for Flowerpots. Sustainability 2021, 13, 8532. https://doi.org/10.3390/su13158532

Blanke MM, Golombek SD. Innovative Strategy to Reduce Single-Use Plastics in Sustainable Horticulture by a Refund Strategy for Flowerpots. Sustainability. 2021; 13(15):8532. https://doi.org/10.3390/su13158532

Chicago/Turabian StyleBlanke, Michael M., and Sabine D. Golombek. 2021. "Innovative Strategy to Reduce Single-Use Plastics in Sustainable Horticulture by a Refund Strategy for Flowerpots" Sustainability 13, no. 15: 8532. https://doi.org/10.3390/su13158532

APA StyleBlanke, M. M., & Golombek, S. D. (2021). Innovative Strategy to Reduce Single-Use Plastics in Sustainable Horticulture by a Refund Strategy for Flowerpots. Sustainability, 13(15), 8532. https://doi.org/10.3390/su13158532