Water Quality Monitoring and Management of Building Water Tank Using Industrial Internet of Things

Abstract

:1. Introduction

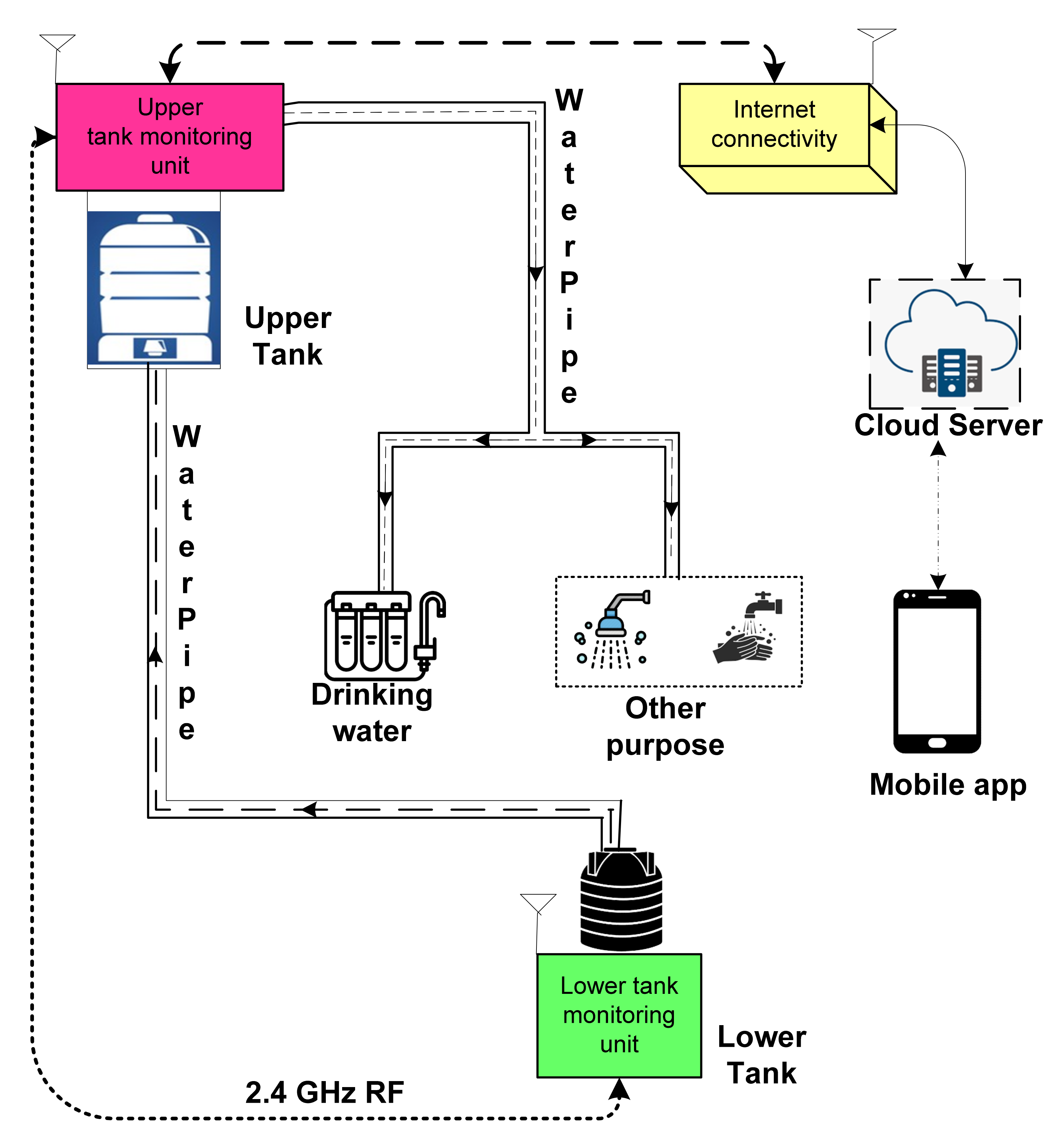

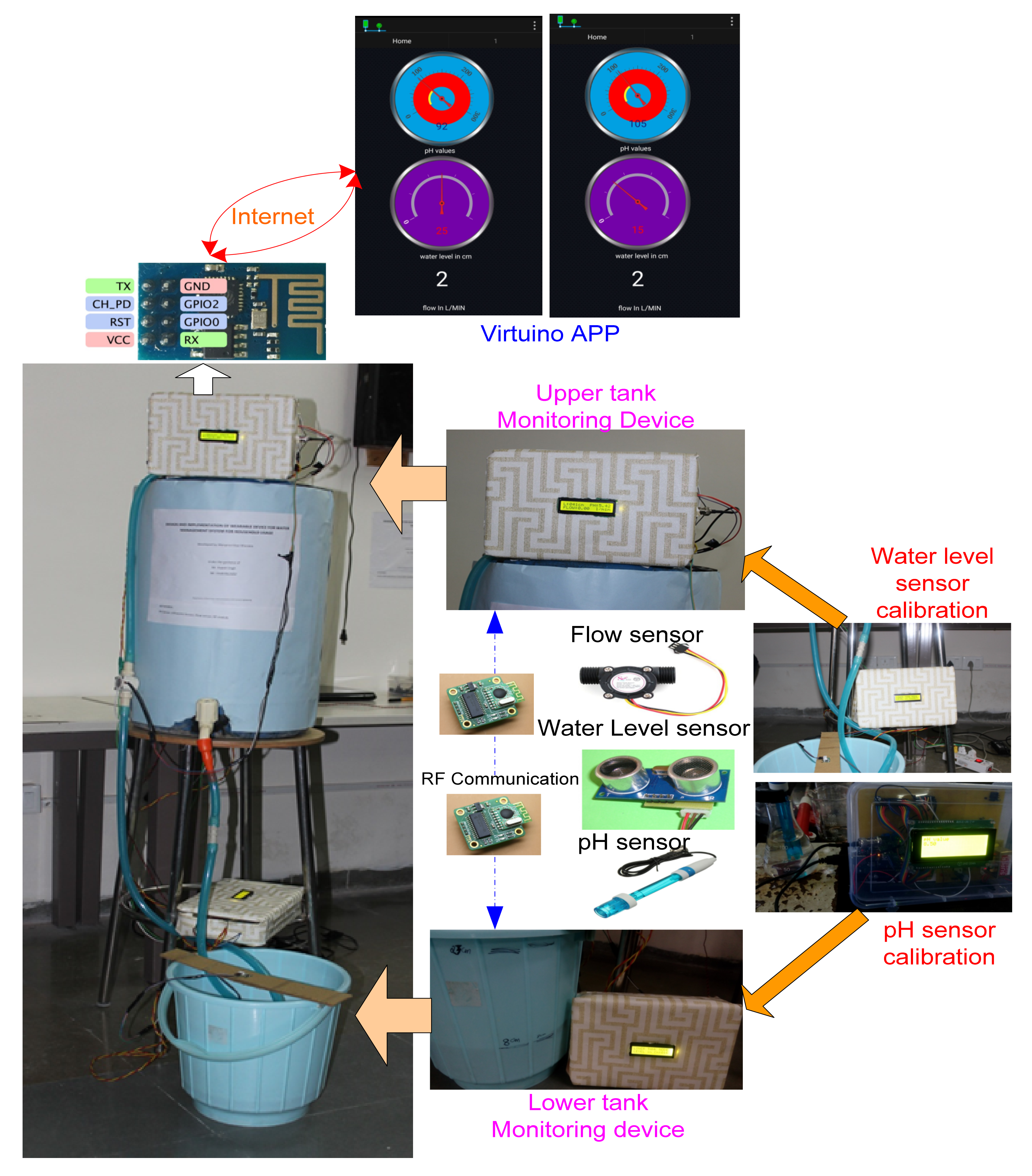

- An IoT-enabled architecture is proposed and implemented for monitoring the level and quality of water in the domestic water tank with customized build hardware.

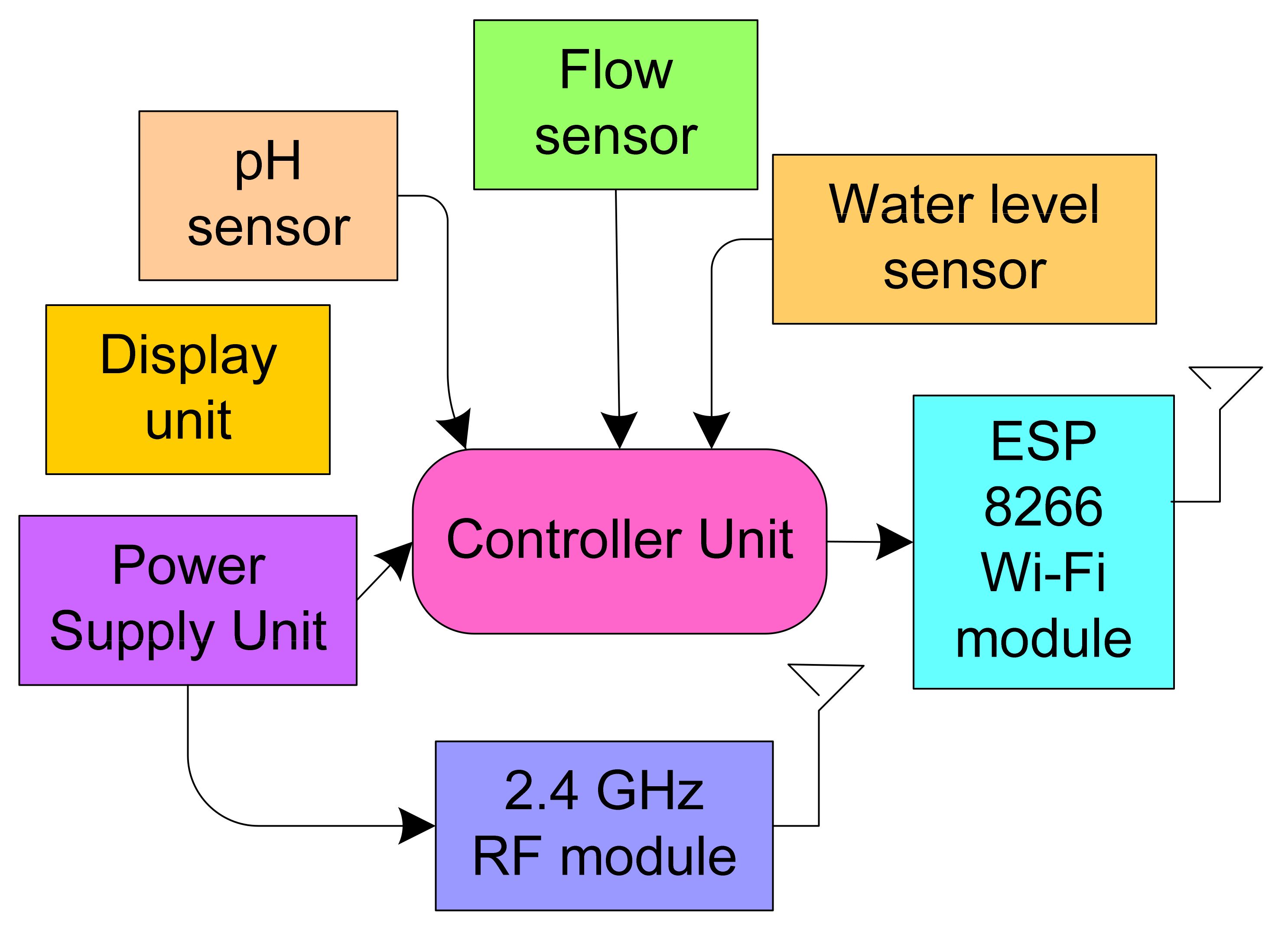

- The customized hardware of the upper tank monitoring unit is built on a 2.4 GHz RF module to communicate with lower tank monitoring and an ESP 8266 Wi-Fi module for enabling to visualize and monitoring the status of the water tank through the internet.

- Proteus simulation environment is utilized for designing the schematic of the customized hardware.

- The calibration of the pH sensor and ultrasonic value is conducted for presetting the actual value in the hardware prototype for obtaining the error-free value during real-time implementation.

- Cloud server enabled Virtuino app is employed for visualizing and monitoring the status of the domestic water tank.

2. Review of Literature

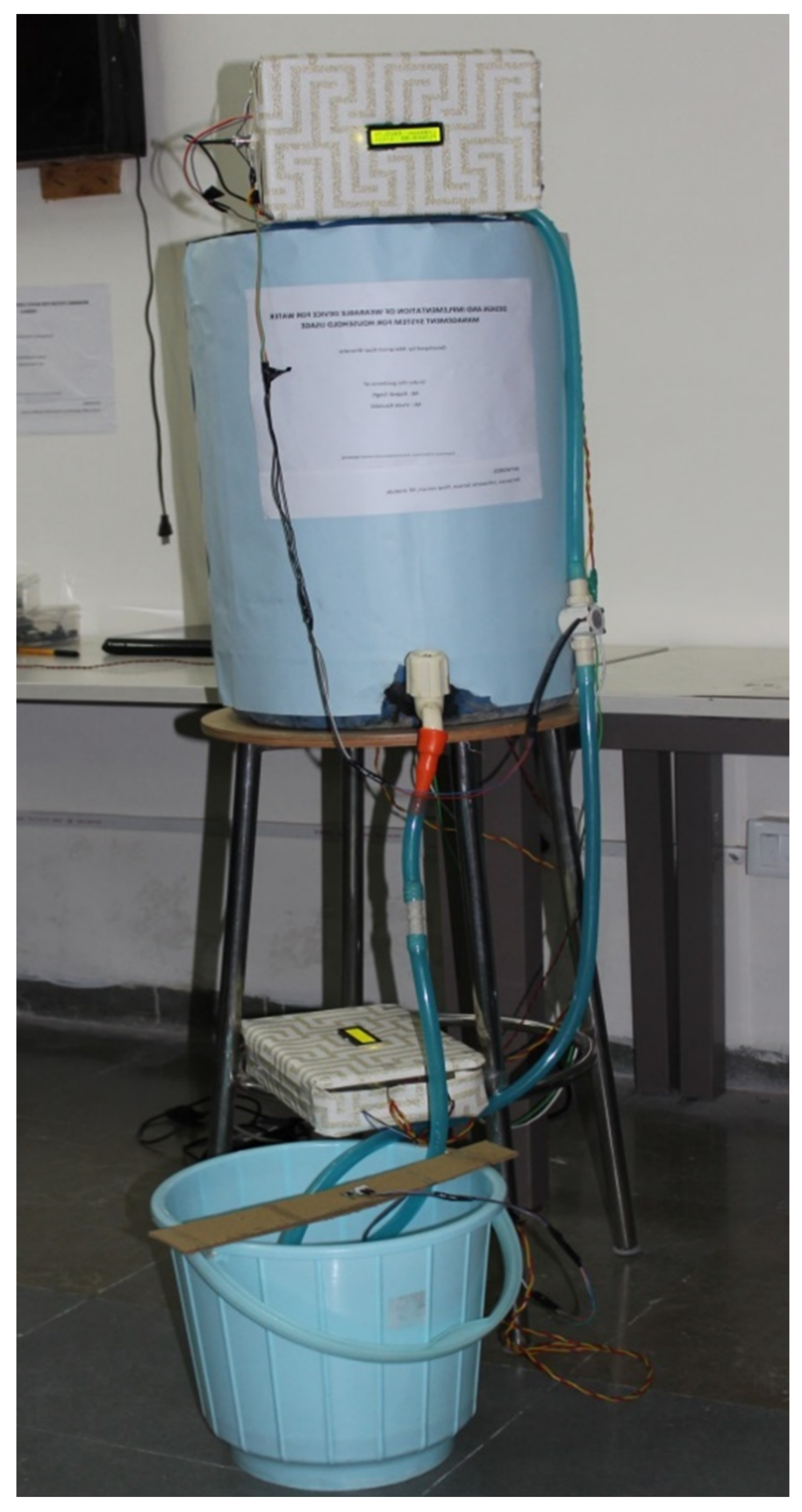

3. Proposed Architecture

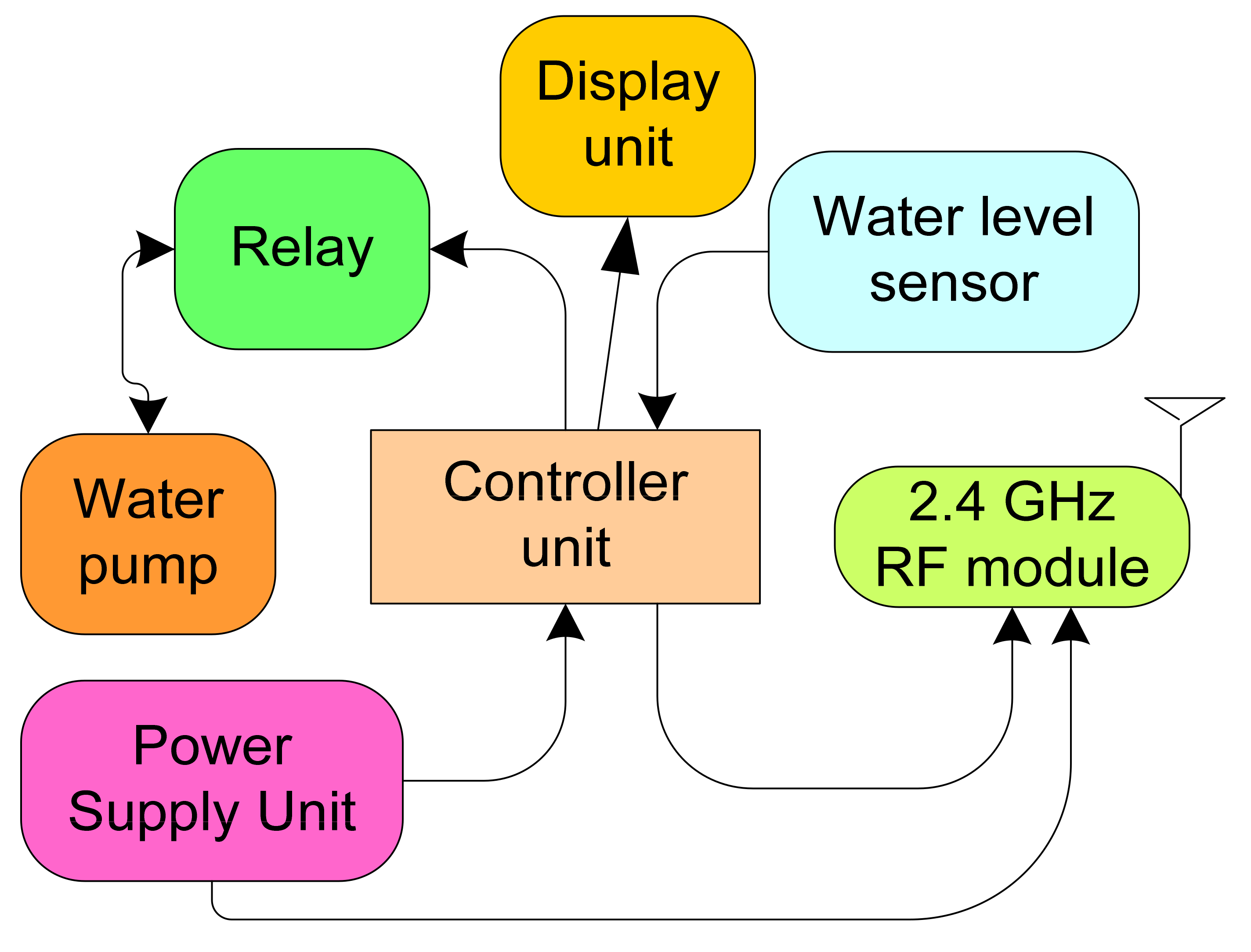

4. Hardware Description

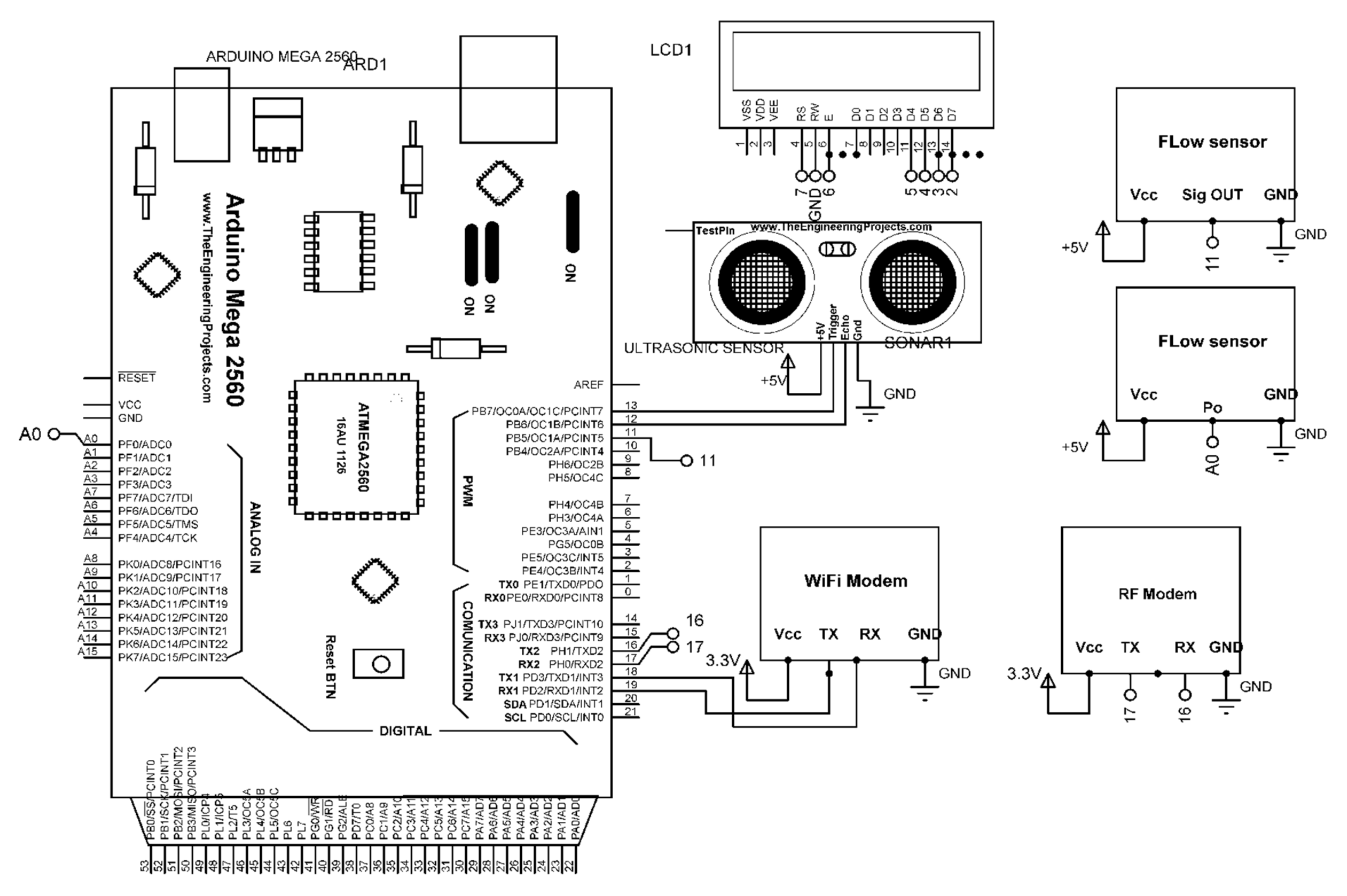

4.1. Circuit Schematic of the System

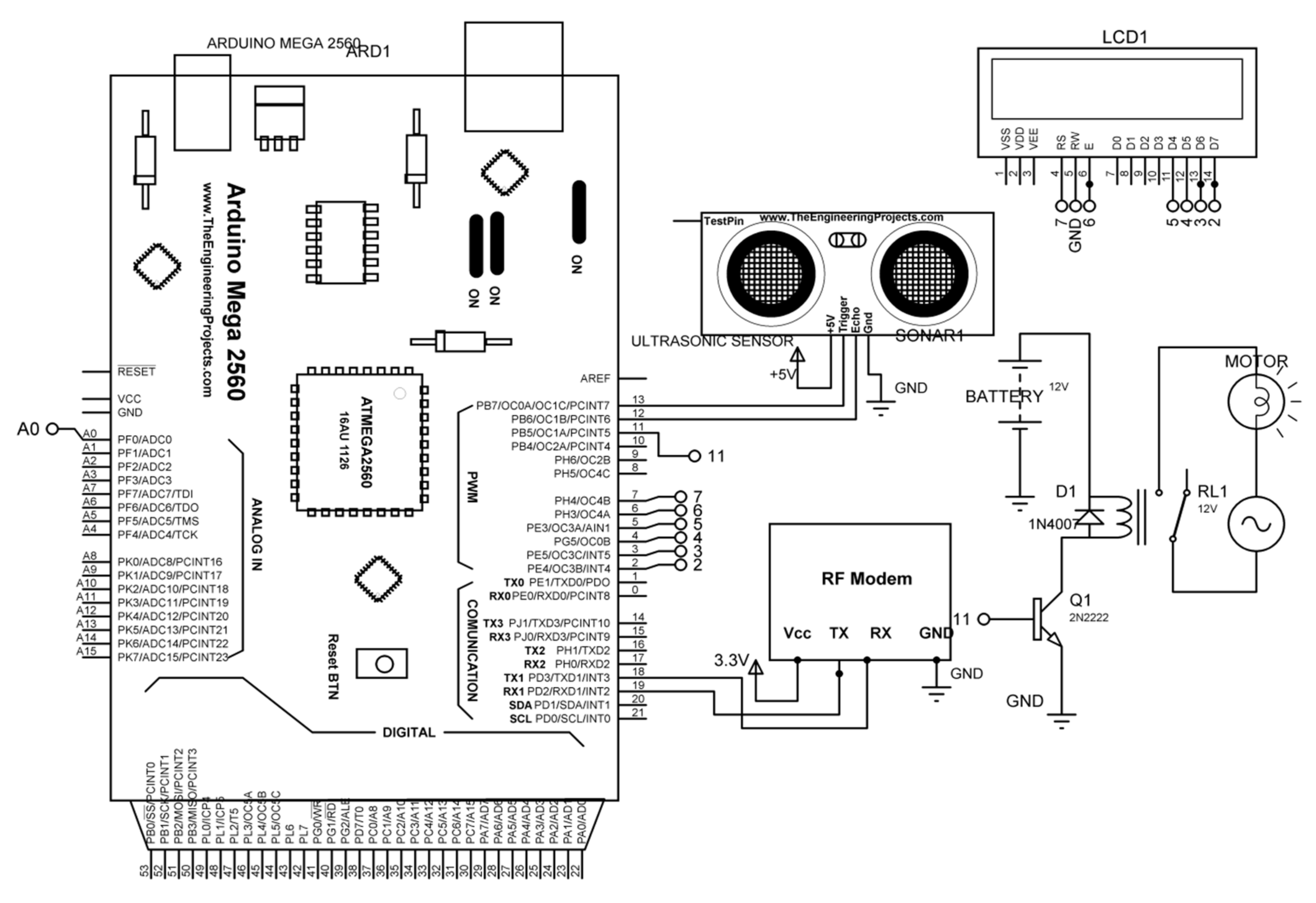

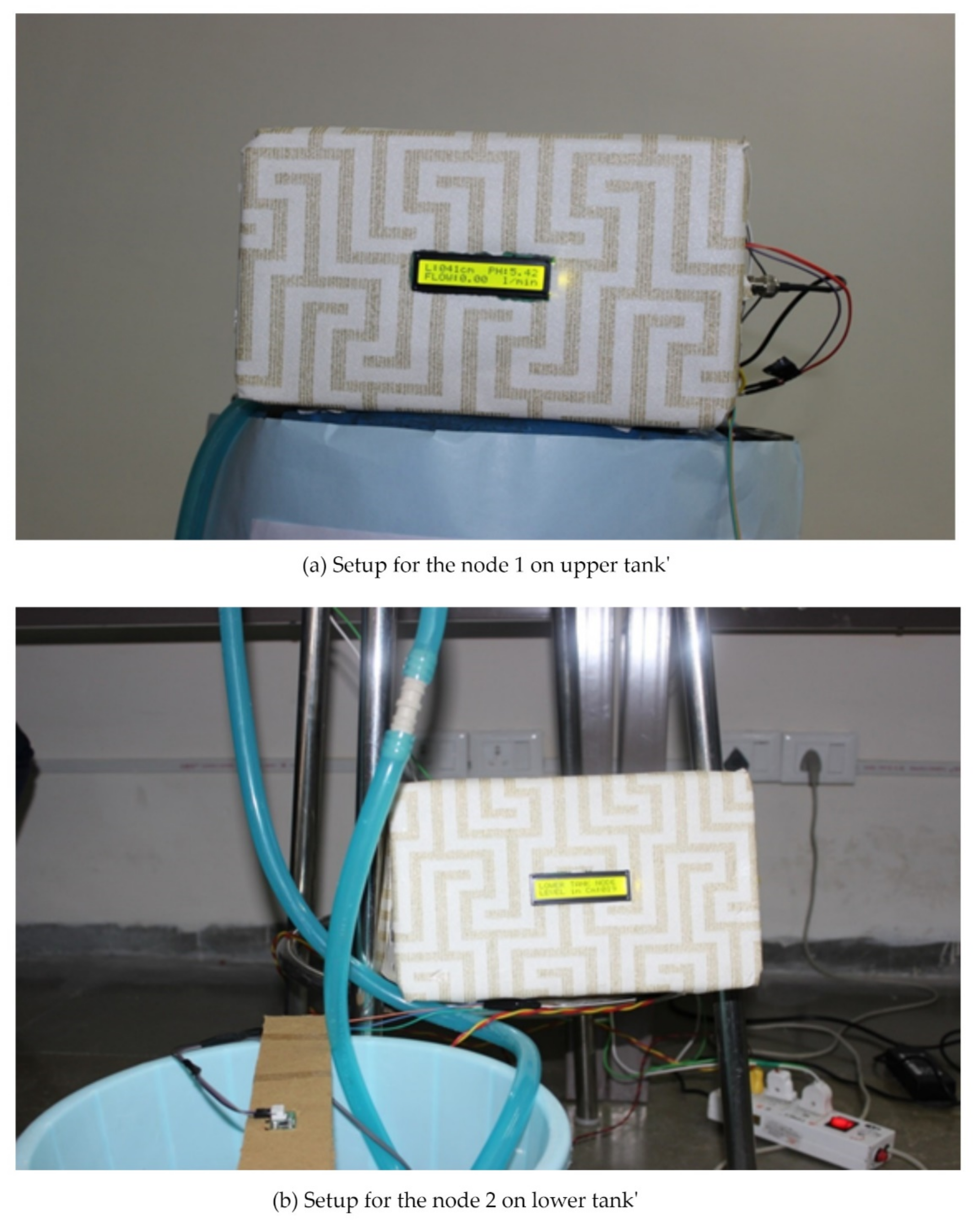

4.1.1. Node 1 Transmitter Unit

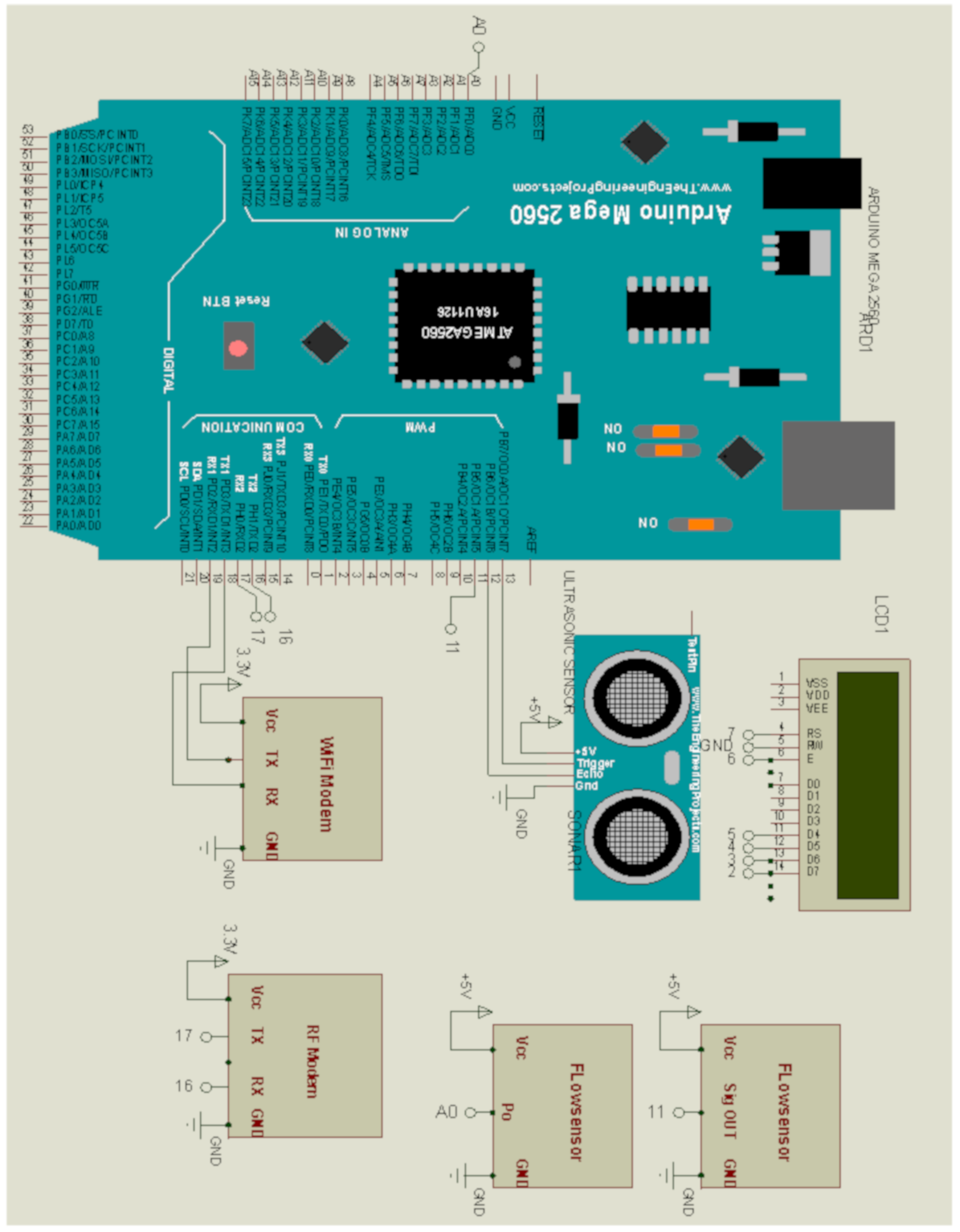

4.1.2. Node 2 Transmitter Unit

4.2. Description of Hardware Components

4.2.1. Arduino Mega 2560

4.2.2. Ultrasonic Sensor (HC-SR04)

4.2.3. pH Sensor

4.2.4. Flow Sensor

4.2.5. ESP 8266 Wi-Fi Modem

4.2.6. RF Module

5. Working and Simulation

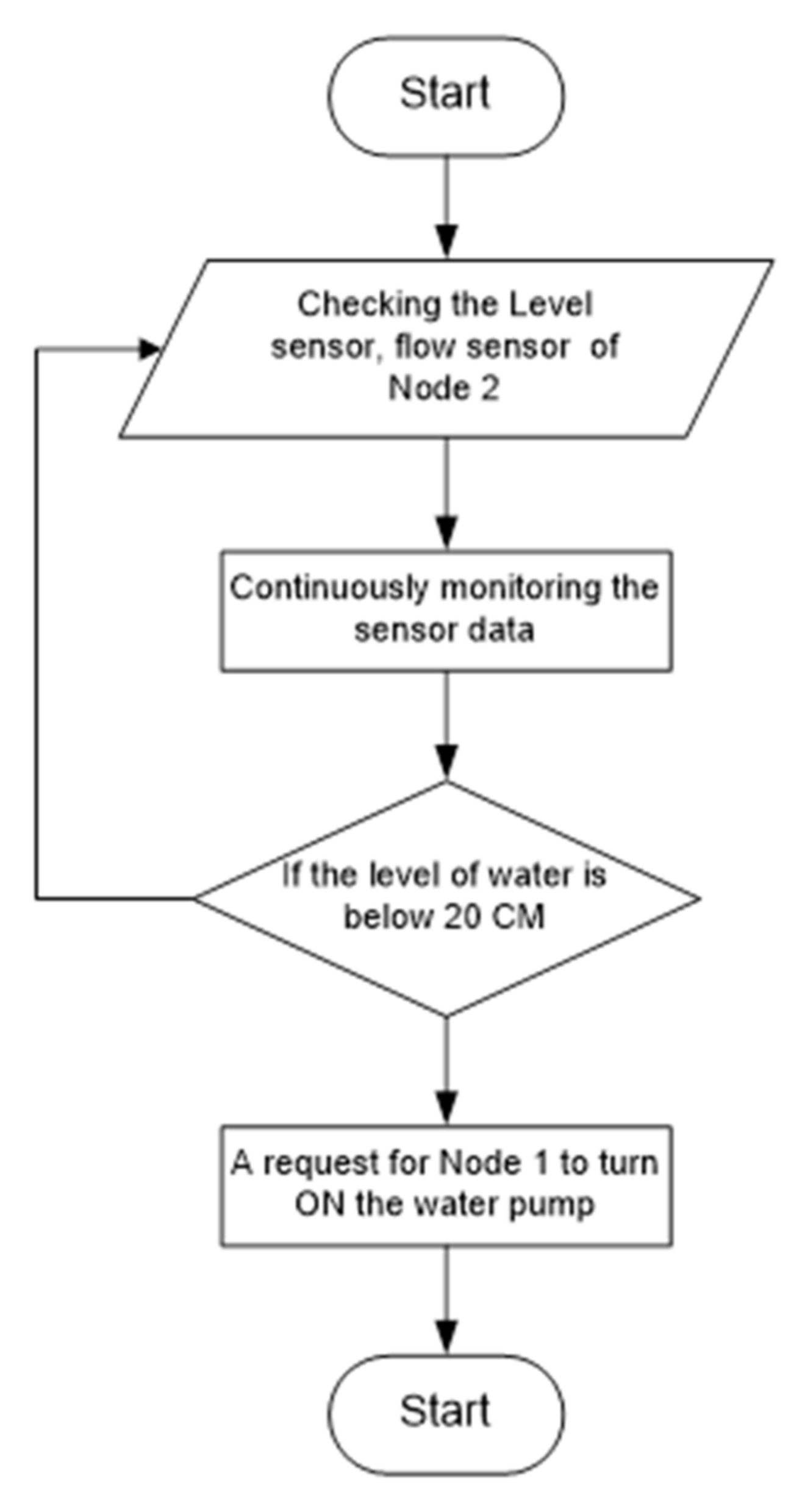

5.1. Working Diagram

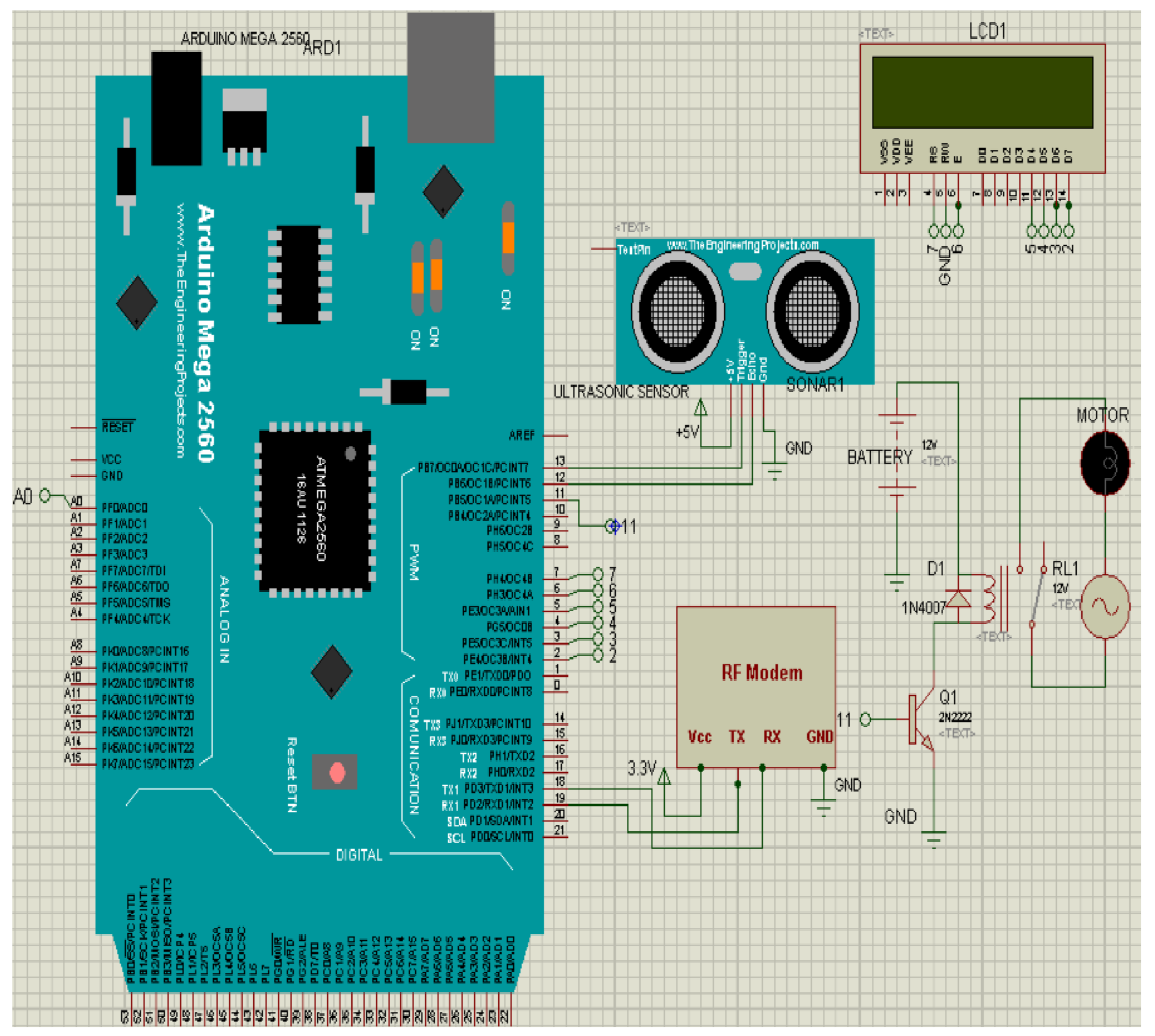

5.2. Proteus Simulation

6. Experimental Results

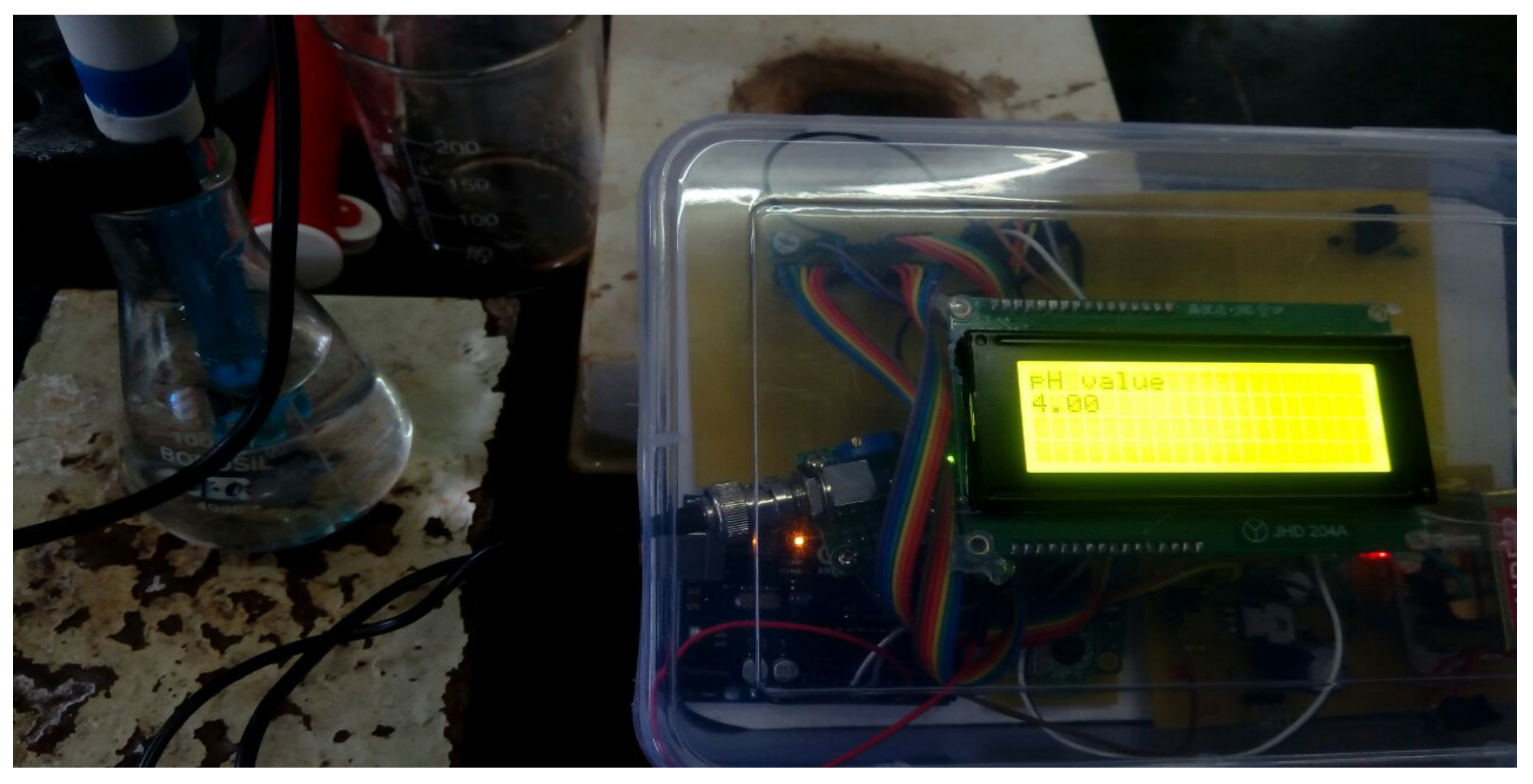

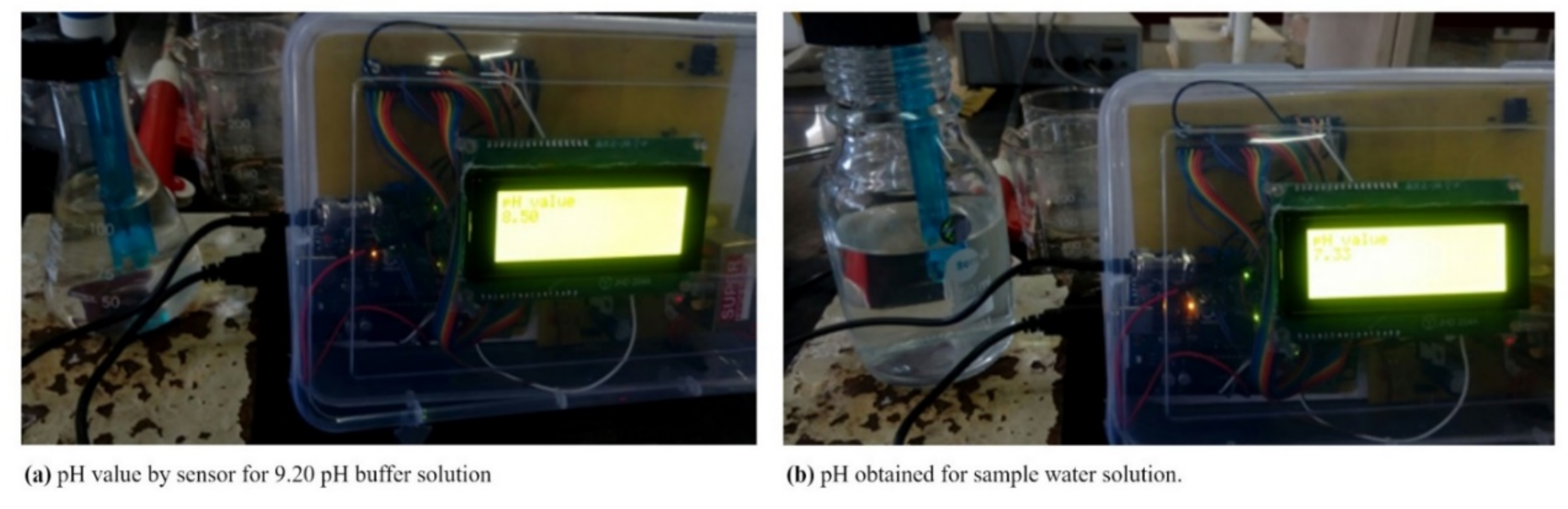

6.1. Calibration of Sensors

6.1.1. Ultrasonic Sensor HC-SR04

6.1.2. pH Sensor

6.2. Virtuino App for Logging and Visualizing Sensor Values

7. Conclusions

8. Future Scope and Challenges

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

Abbreviations

| IoT | Internet of Things |

| RF | Radio frequency |

| Wi-Fi | Wireless fidelity |

| IP | Internet protocol |

| GSM | Global system for mobile communication |

| GPRS | Global packet for radio service |

| WSN | Wireless sensor network |

| GPS | Global positioning system |

| DO | Dissolved oxygen |

| GUI | Graphical user interface |

| UHF | Ultra high frequency |

| RS | Register select |

| RW | Read/write |

| VCC | Voltage at common collector |

| VEE | Voltage at common emitter |

| LCD | Liquid crystal display |

| D4-D7 | Data pins |

| E | Enable pin |

| UART | Universal asynchronous receiver/transmitter |

| ICSP | In-circuit serial programming (ICSP) |

| PWM | Pulse wave modulation |

| USB | Universal serial bus |

| SOC | System on chip |

| LED | Liquid emitting diode |

| cm | Centimeter |

| GND | Common ground |

| RX | Receiver |

| TX | Transmitter |

| ADC | Analog to digital converter |

| INT | Interrupt pin |

References

- Water Resources Management Overview. Available online: https://www.worldbank.org/en/topic/waterresourcesmanagement (accessed on 11 June 2021).

- FAO (Food and Agriculture Organization of the United Nations). The State of the World’s Land and Water Resources: Managing Systems at Risk; Food and Agriculture Organization of the United Nations: Rome, Italy, 2011. [Google Scholar]

- Food and Agriculture Organization of the United Nations. Agriculture: Cause and Victim of Water Pollution, but Change is Possible. Available online: http://www.fao.org/land-water/news-archive/news-detail/en/c/1032702/ (accessed on 11 June 2021).

- Johari, A.; Abd Wahab, M.H.; Latif, N.S.A.; Ayob, M.E.; Ayob, M.I.; Ayob, M.A.; Mohd, M.N.H. Tank water level monitoring system using GSM network. Int. J. Comput. Sci. Inf. Technol. 2011, 2, 1114–1115. [Google Scholar]

- Shankari, M.; Jyothi, M.E.; Naveen, I.; Herle, H. Wireless automatic water level control using radio frequency communication”. Int. J. Adv. Res. Electr. Electron. Instrum. Eng. 2013, 2, 1320–1324. [Google Scholar]

- Jin, N.; Ma, R.; Lv, Y.; Lou, X.; Wei, Q. A Novel Design of Water Environment Monitoring System Based on WSN. In Proceedings of the 2010 International Conference On Computer Design and Applications, San Jose, CA, USA, 7–11 November 2010; Volume 2, pp. 2–593. [Google Scholar]

- Jatmiko, S.; Mutiara, A.B.; Indriati, M. Prototype of water level detection system with wireless. J. Theor. Appl. Inf. Technol. 2012, 37, 52–59. [Google Scholar]

- Xu, Y.; Liu, F. Application of Wireless Sensor Network in Water Quality Monitoring. In Proceedings of the 22017 IEEE International Conference on Computational Science and Engineering (CSE) and IEEE International Conference on Embedded and Ubiquitous Computing (EUC), Guangzhou, China, 21–24 July 2017; Volume 2, pp. 368–371. [Google Scholar]

- Singh, R.; Gehlot, A.; Thakur, A.K.; Swain, M.; Akram, S.V. Wireless Sensor Network with Power Management System for Water Level Regulation in Paddy Fields. Int. J. Innov. Technol. Explor. Eng. (IJITEE) 2020, 9, 1243–1246. [Google Scholar]

- Haron, N.S.; Mahamad, M.K.B.; Aziz, I.A.; Mehat, M. A system architecture for water quality monitoring system using wired sensors. In Proceedings of the 2008 International Symposium on Information Technology, Kuala Lumpur, Malaysia, 26–28 August 2008; Volume 4, pp. 1–7. [Google Scholar]

- Jian, C.; Suxiang, Q.; Hongsheng, H.; Gongbiao, Y. Wireless Monitoring and Assessment System of Water Quality Based on GPRS. In Proceedings of the 8th International Conference on Electronic Measurement and Instruments, Xi’an, China, 16–18 August 2007; pp. 2–124. [Google Scholar]

- Postolache, O.; Girão, P.S.; Pereira, J.; Ramos, H. Self-Organizing Maps Application in a Remote Water Quality Monitoring System. IEEE Trans. Instrum. Meas. 2005, 54, 322–329. [Google Scholar] [CrossRef]

- Olatinwo, S.O.; Joubert, T. Enabling Communication Networks for Water Quality Monitoring Applications: A Survey. IEEE Access 2019, 7, 100332–100362. [Google Scholar] [CrossRef]

- Malik, P.K.; Sharma, R.; Singh, R.; Gehlot, A.; Satapathy, S.C.; Alnumay, W.S.; Pelusi, D.; Ghosh, U.; Nayak, J. Industrial Internet of Things and its Applications in Industry 4.0: State of The Art. Comput. Commun. 2021, 166, 125–139. [Google Scholar] [CrossRef]

- Nord, J.H.; Koohang, A.; Paliszkiewicz, J. The Internet of Things: Review and theoretical framework. Expert Syst. Appl. 2019, 133, 97–108. [Google Scholar] [CrossRef]

- Gutiérrez, J.; Villa-Medina, J.F.; Nieto-Garibay, A.; Porta-Gándara, M.Á. Automated irrigation system using a wireless sensor network and GPRS module. IEEE Trans. Instrum. Meas. 2013, 63, 166–176. [Google Scholar] [CrossRef]

- Zia, H.; Harris, N.R.; Merrett, G.; Rivers, M.; Coles, N. The impact of agricultural activities on water quality: A case for collaborative catchment-scale management using integrated wireless sensor networks. Comput. Electron. Agric. 2013, 96, 126–138. [Google Scholar] [CrossRef] [Green Version]

- Rasin, Z.; Hamzah, H.; Aras, M.S.M. Application and Evaluation of High Power Zigbee Based Wireless Sensor Network in Water Irrigation Control Monitoring System. In Proceedings of the 2009 IEEE Symposium on Industrial Electronics & Applications, Kuala Lumpur, Malaysia, 4–6 October 2009; Volume 2, pp. 548–551. [Google Scholar]

- Jiang, P.; Xia, H.; He, Z.; Wang, Z. Design of a Water Environment Monitoring System Based on Wireless Sensor Networks. Sensors 2009, 9, 6411–6434. [Google Scholar] [CrossRef] [Green Version]

- Zhou, Y.; Yang, X.; Wang, L.; Ying, Y. A Wireless Design of Low-Cost Irrigation System Using ZigBee Technology. In Proceedings of the 2009 International Conference on Networks Security, Wireless Communications and Trusted Computing; Institute of Electrical and Electronics Engineers (IEEE), Wuhan, China, 25–26 April 2009; Volume 1, pp. 572–575. [Google Scholar]

- Nasser, N.; Ali, A.; Karim, L.; Belhaouari, S.B.; Ali, A. An efficient Wireless Sensor Network-based water quality monitoring system. In Proceedings of the 2013 ACS International Conference on Computer Systems and Applications (AICCSA), Ifrane, Morocco, 27–30 May 2013; pp. 1–4. [Google Scholar]

- Gehlot, A.; Singh, R.; Thakur, A.K.; Pandey, R. Design and Development of Wireless Fan Regulator using ZigBee Concept. Int. J. 2020, 9. [Google Scholar] [CrossRef]

- O’Flynn, B.; Martinez-Catala, R.; Harte, S.; O’Mathuna, C.; Cleary, J.; Slater, C.; Regan, F.; Diamond, D.; Murphy, H. SmartCoast: A Wireless Sensor Network for Water Quality Monitoring. In Proceedings of the 32nd IEEE Conference on Local Computer Networks (LCN 2007), Dublin, Ireland, 15–18 October 2007; pp. 815–816. [Google Scholar]

- Tripathy, A.K.; Das, T.K.; Chowdhary, C.L. Monitoring Quality of Tap Water in Cities Using IoT. In Emerging Technologies for Agriculture and Environment; Springer: Singapore, 2020; pp. 107–113. [Google Scholar]

- Rajalashmi, K.; Yugathian, N.; Monisha, S.; Jeevitha, N. IoT based water quality management system. Mater. Today Proc. 2021, 45, 512–515. [Google Scholar] [CrossRef]

- Akram, S.V.; Singh, R.; Al Zain, M.A.; Gehlot, A.; Rashid, M.; Faragallah, O.S.; El-Shafai, W.; Prashar, D. Performance Analysis of IoT and Long-Range Radio-Based Sensor Node and Gateway Architecture for Solid Waste Management. Sensors 2021, 21, 2774. [Google Scholar] [CrossRef] [PubMed]

- Swain, M.; Zimon, D.; Singh, R.; Hashmi, M.F.; Rashid, M.; Hakak, S. LoRa-LBO: An Experimental Analysis of LoRa Link Budget Optimization in Custom Build IoT Test Bed for Agriculture 4. Agronomy 2021, 11, 820. [Google Scholar] [CrossRef]

- Kinar, N.J.; Brinkmann, M. Development of a sensor and measurement platform for water quality observations: Design, sensor integration, 3D printing, and open-source hardware. Res. Sq. 2021. [Google Scholar] [CrossRef]

- Lasrado, R.; Melroy, F.; Anil, M.; Prinson, V. Automation of Water Management System Using Labview. J. Mech. Eng. Autom. 2015, 5, 88–93. [Google Scholar]

- Kulkarni, S.; Raikar, V.D.; Rahul, B.K.; Rakshitha, L.V.; Sharanya, K.; Jha, V. Intelligent Water Level Monitoring System Using IoT. In Proceedings of the 2020 IEEE International Symposium on Sustainable Energy, Signal Processing and Cyber Security (iSSSC), Gunupur Odisha, India, 16–17 December 2020; pp. 1–5. [Google Scholar]

- Masoumi, S.; Haghkhah, M.; Mehrabani, D.; Ghasempour, H.R.; Esmaeelnejad, Z.; Ghafari, N.; Saeedzadeh, A.; Moradi, F.; Rezaeianzadeh, A. Quality of drinking water of household filter systems in Shiraz, Southern Iran. Middle-East J. Sci. Res. 2013, 17, 270–274. [Google Scholar]

- Cao, H.; Guo, Z.; Wang, S.; Cheng, H.; Zhan, C. Intelligent Wide-Area Water Quality Monitoring and Analysis System Exploiting Unmanned Surface Vehicles and Ensemble Learning. Water 2020, 12, 681. [Google Scholar] [CrossRef]

- Eichhorn, M.; Ament, C.; Jacobi, M.; Pfuetzenreuter, T.; Karimanzira, D.; Bley, K.; Boer, M.; Wehde, H. Modular AUV System with Integrated Real-Time Water Quality Analysis. Sensors 2018, 18, 1837. [Google Scholar] [CrossRef] [Green Version]

- Hong, W.J.; Shamsuddin, N.; Abas, E.; Apong, R.A.; Masri, Z.; Suhaimi, H.; Gödeke, S.H.; Noh, M.N.A. Water Quality Monitoring with Arduino Based Sensors. Environments 2021, 8, 6. [Google Scholar] [CrossRef]

- Olatinwo, S.O.; Joubert, T.-H. Optimizing the Energy and Throughput of a Water-Quality Monitoring System. Sensors 2018, 18, 1198. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Arduino Mega 2560 Pinout. Available online: https://www.electroschematics.com/arduino-mega-2560-pinout/ (accessed on 11 June 2021).

- Voltage, S.; Current, S.; Format, O.D. Ultrasonic Distance Sensor-Serial Out [1166]: Sunrom Electron-ics/Technologies. Available online: https://www.sunrom.com/get/984800/ (accessed on 20 June 2021).

- Liquid PH Value Detection Detect Sensor Module Monitoring Control for Arduino-Scion Electronics. Available online: https://scionelectronics.com/product/liquid-ph-value-detection-detect-sensor-module-monitoring-control-for-arduino/ (accessed on 11 June 2021).

- New Arrival PH Electrode Probe BNC Connector for Aquarium PH Controller Meter Sensor gib Best Promotion: Industrial & Scientific. Available online: https://www.amazon.com/Electrode-Connector-Aquarium-Controller-Promotion/dp/B07KDQVY6X (accessed on 11 June 2021).

- SeeedStudio Water Flow Sensor (1/2)-RobotShop. Available online: https://www.robotshop.com/en/seeedstudio-water-flow-sensor.html (accessed on 11 June 2021).

- ESP8266 Introduction|FabAcademy-Tutorials. Available online: http://fabacademy.org/2019/docs/FabAcademy-Tutorials/week15_networking_and_communications/esp8266.html (accessed on 11 June 2021).

- RF Serial Data Link UART, 2.4 Ghz [1418]: Sunrom Electronics. 2007, Volume 3, pp. 154–196. Available online: https://www.sunrom.com/get/349000 (accessed on 20 June 2021).

| Reference | Findings | Conclusion |

|---|---|---|

| [5] | Radio Frequency (RF), Global System for Mobile Communications (GSM), Graphical User Interface (GUI), Ultra High Frequency (UHF), General Packet Radio Service (GPRS) | Wireless Automatic Water Level Control using Radio Frequency Communication. |

| [7] | Water level detection system with wireless | The ping sensor is used as a distance sensor for detecting water levels by measuring the distance between the sensor and water surfaces. |

| [18] | Water level monitoring using pH sensors and FSR | Water Monitoring System Using Wireless Sensor Network |

| [19] | Level control using fuzzy logic | Water management system with remote access having intelligence. |

| [29] | Automation of Water Management System Using LabVIEW | Water Management, LabVIEW, Automation |

| [30] | Water level; water pump; water conductivity monitoring using microcontroller and GSM modem | Automated Water Level Management System |

| [31] | Water filter system bacterial contamination drinking water | Determine the microbiological quality of drinking water from building water filter systems |

| [32] | The ensemble learning method is recommended to examine water quality, which requires a scientific basis for wide-area water quality testing | The results of the experiments show and validate that the proposed system can meet water quality monitoring criteria and improve overall working efficiency. |

| [33] | Technical implementation and practical utilization for real-time acquisition of water quality indicators on fish farms of a mini-converted sensor system integrated with an autonomous underwater vehicle | Autonomous underwater vehicle (AUV) and the principle of the sensor system |

| [34] | Examining the feasibility of employing for water quality monitoring with Arduino. | The testing at different locations should generate much-needed additional data and accuracies for the assessment and validation of the river health system. |

| [35] | The new algorithms have improved the system performance by 36% and the fairness index by 13% for two-sensor systems. | The recommended WIPT system is energy-efficient and confirms sustainable communication. |

| Measuring Scale Reading (cm) | Ultrasonic Sensor Reading (cm) |

|---|---|

| 8 | 23 − 16 = 7 |

| 10 | 23 − 14 = 9 |

| 12 | 23 − 12 = 11 |

| 14 | 23 − 10 = 13 |

| 16 | 23 − 8 = 15 |

| Case ‘1’ | Case ‘2’ |

|---|---|

| pH Sensor value obtained for pH 9.20 buffer solution = 8.90 | pH Sensor value obtained for pH 9.20 buffer solution = 8.50 |

| Error value = 9.20 − 8.90 = 0.30 | Error value = 9.20 − 8.50 = 0.70 |

| pH value obtained for water = 8.07 | pH value obtained for water = 7.33 |

| Actual pH value = 8.07 + 0.30 = 8.37 | Actual pH value = 7.33 + 0.70 = 8.03 |

| Actual pH value = 8.37 | Actual pH value = 8.03 |

| Dashboard | pH Sensor | Water Level (cm) | Flow Rate (L/min) |

|---|---|---|---|

| Dashboard ‘1′ | 7 | 15 | 2 |

| Dashboard ‘2′ | 8 | 15 | 2 |

| Dashboard ‘3′ | 8 | 20 | 2 |

| Pin Configuration in Arduino Mega 2560 | Connection |

| Pin 16: Tx2 | Transmitter 2 for serial communications |

| Pin 17: Rx2 | Receiver 2 for serial communication |

| Pin 18: Tx1 | Transmitter1 for serial communication |

| Pin 19: Rx1 | Receiver 1 for serial communication |

| Pin 11: OC1A/PCINT5 | Digital pin 11 |

| Pin 12: PB6 (OC1B/PCINT6) | Digital pin 12 |

| Pin 13: PB7 OC0A/OC1C/PCINT7 | Digital pin 13 |

| PF0 (ADC0) | Analog pin 0 |

| Pin configuration in Wi-Fi modem | Connection |

| Vcc | Power supply for Wi-Fi (3.3 V) |

| Rx | Receiver pin connecting to RX1 pin of Arduino Uno |

| Tx | Transmitter pin connecting to TX1 pin of Arduino Uno |

| GND | Common ground |

| Pin configuration in RF modem | Connection |

| Vcc | Power supply for RF modem (3.3 V) |

| Rx | Receiver pin connecting to RX 2 pin, i.e., 16th pin of Arduino Uno |

| Tx | Transmitter pin connecting to TX 2 pin i.e., 17th pin of Arduino Uno |

| GND | Common ground |

| Pin configuration in Flow sensor | Connection |

| Vcc | Power supply for flow sensor (+5 V) |

| Po | Pulse output connect to A0 pin of Arduino Uno |

| Sig OUT | Signal connected to 11 pin of Arduino Uno |

| GND | Common ground |

| Pin configuration in Ultrasonic sensor | Connection |

| +5V | Power supply to sensor |

| Trigger | Trigger the ultrasonic sound pulses and it is connected to pin 13 of Arduino Uno |

| Echo | Pin produces a pulse when the reflected signal is received, and it is connected to pin 12 of Arduino Uno |

| GND | Common ground |

| Pin configuration in LCD | Connection |

| Pin 4: RS | Pin 7 of Arduino Uno |

| Pin 5: RW | Gnd to the Arduino Uno |

| Pin 6: E | Pin 6 of Arduino Uno |

| Pin 11: D 4 | Pin 5 of Arduino Uno |

| Pin 12: D 5 | Pin 4 of Arduino Uno |

| Pin 13: D 6 | Pin 3 of Arduino Uno |

| Pin 14: D 7 | Pin 2 of Arduino Uno |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Singh, R.; Baz, M.; Gehlot, A.; Rashid, M.; Khurana, M.; Akram, S.V.; Alshamrani, S.S.; AlGhamdi, A.S. Water Quality Monitoring and Management of Building Water Tank Using Industrial Internet of Things. Sustainability 2021, 13, 8452. https://doi.org/10.3390/su13158452

Singh R, Baz M, Gehlot A, Rashid M, Khurana M, Akram SV, Alshamrani SS, AlGhamdi AS. Water Quality Monitoring and Management of Building Water Tank Using Industrial Internet of Things. Sustainability. 2021; 13(15):8452. https://doi.org/10.3390/su13158452

Chicago/Turabian StyleSingh, Rajesh, Mohammed Baz, Anita Gehlot, Mamoon Rashid, Manpreet Khurana, Shaik Vaseem Akram, Sultan S. Alshamrani, and Ahmed Saeed AlGhamdi. 2021. "Water Quality Monitoring and Management of Building Water Tank Using Industrial Internet of Things" Sustainability 13, no. 15: 8452. https://doi.org/10.3390/su13158452

APA StyleSingh, R., Baz, M., Gehlot, A., Rashid, M., Khurana, M., Akram, S. V., Alshamrani, S. S., & AlGhamdi, A. S. (2021). Water Quality Monitoring and Management of Building Water Tank Using Industrial Internet of Things. Sustainability, 13(15), 8452. https://doi.org/10.3390/su13158452