Recycled Asphalt Pavement Materials in Transport Pavement Infrastructure: Sustainability Analysis & Metrics

Abstract

:1. Introduction

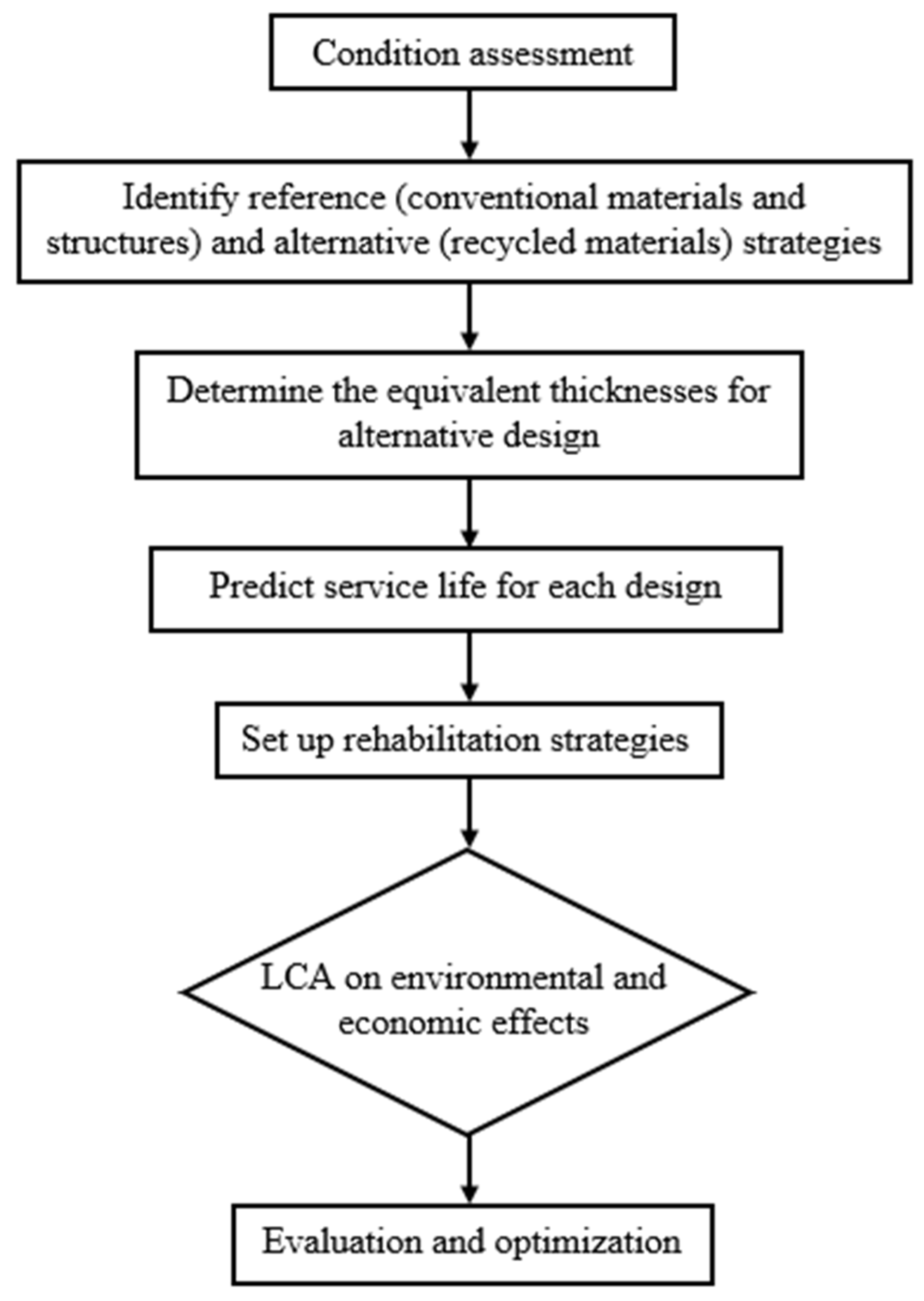

2. Methodology

2.1. Pavement Condition Assessment

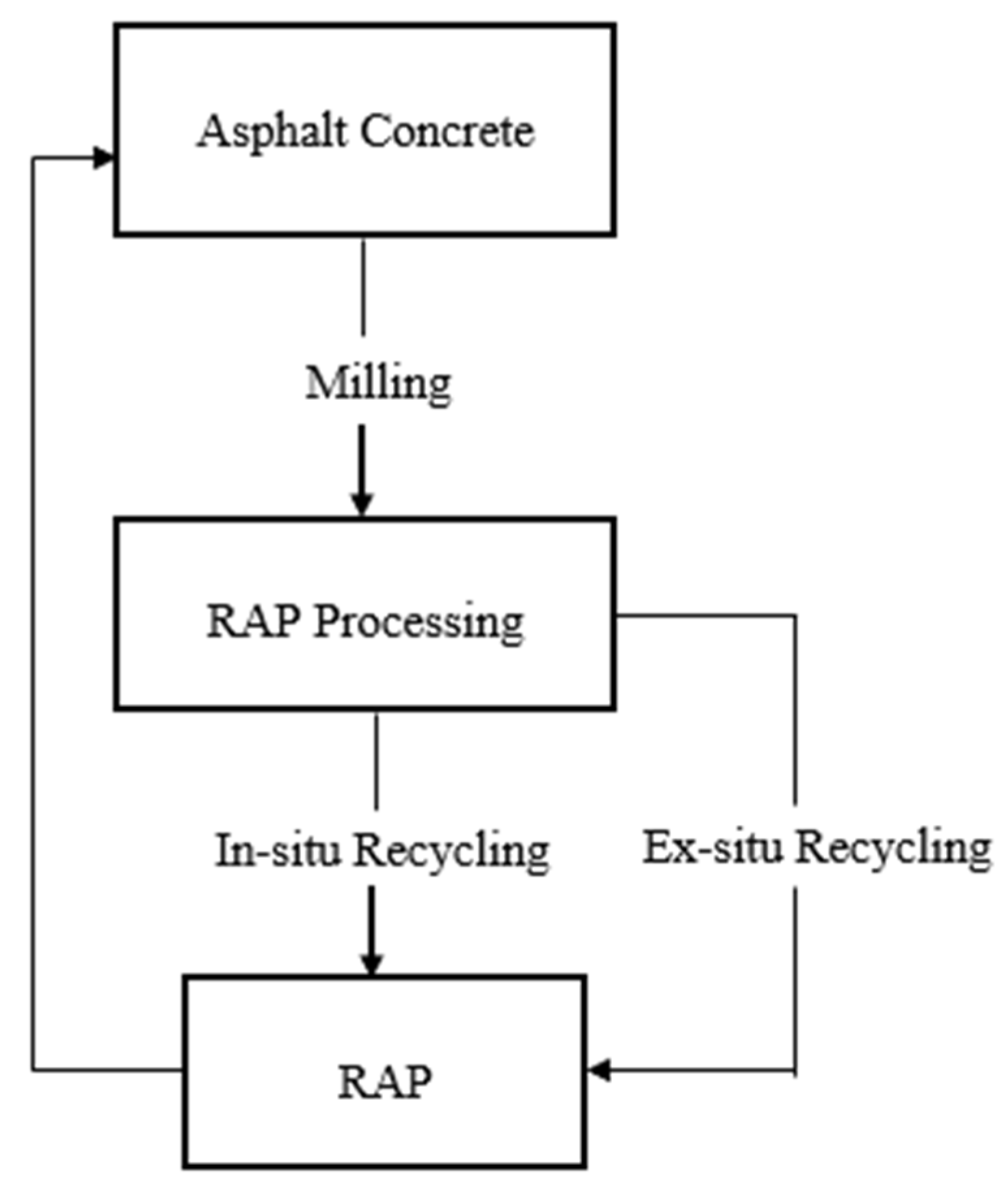

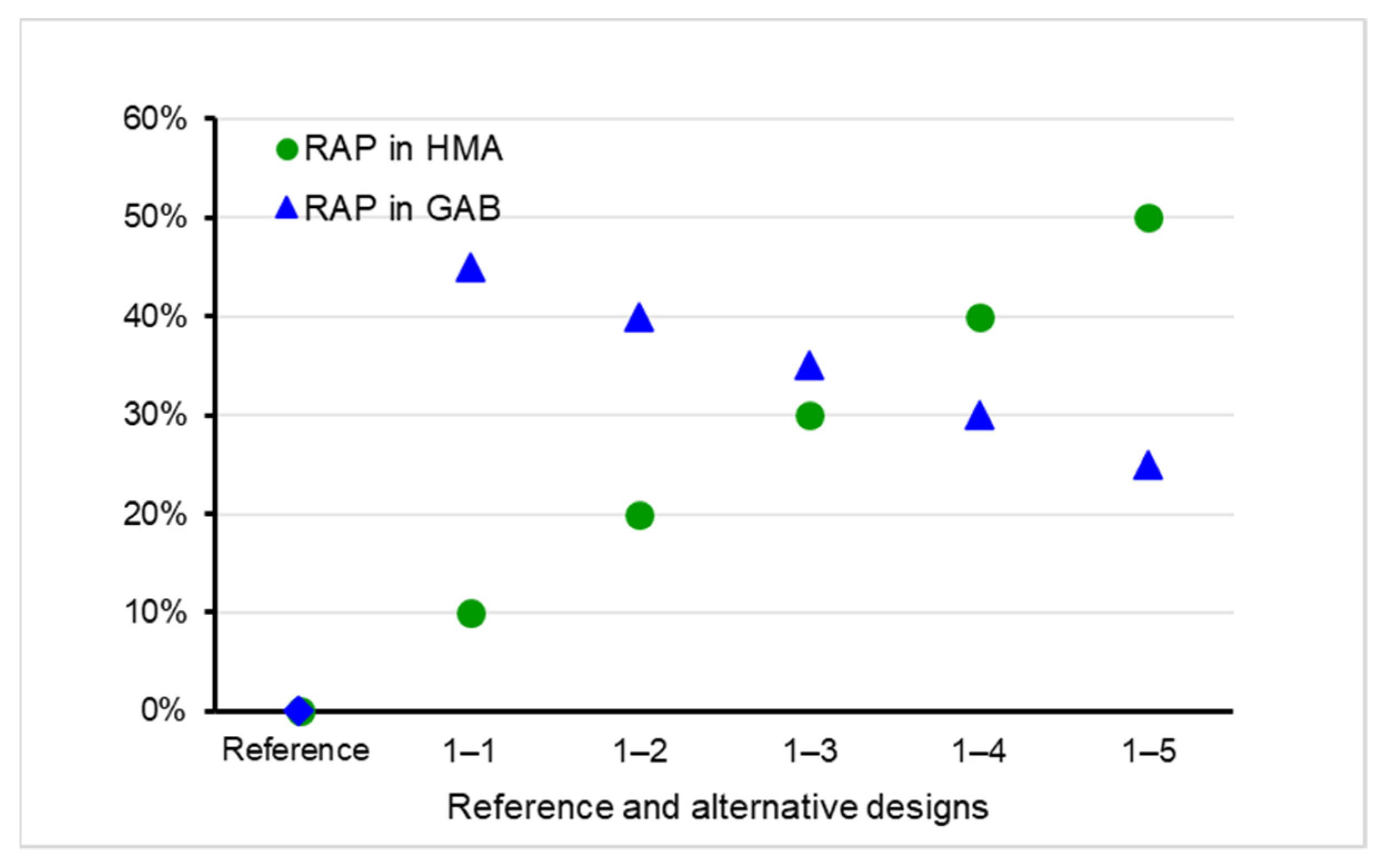

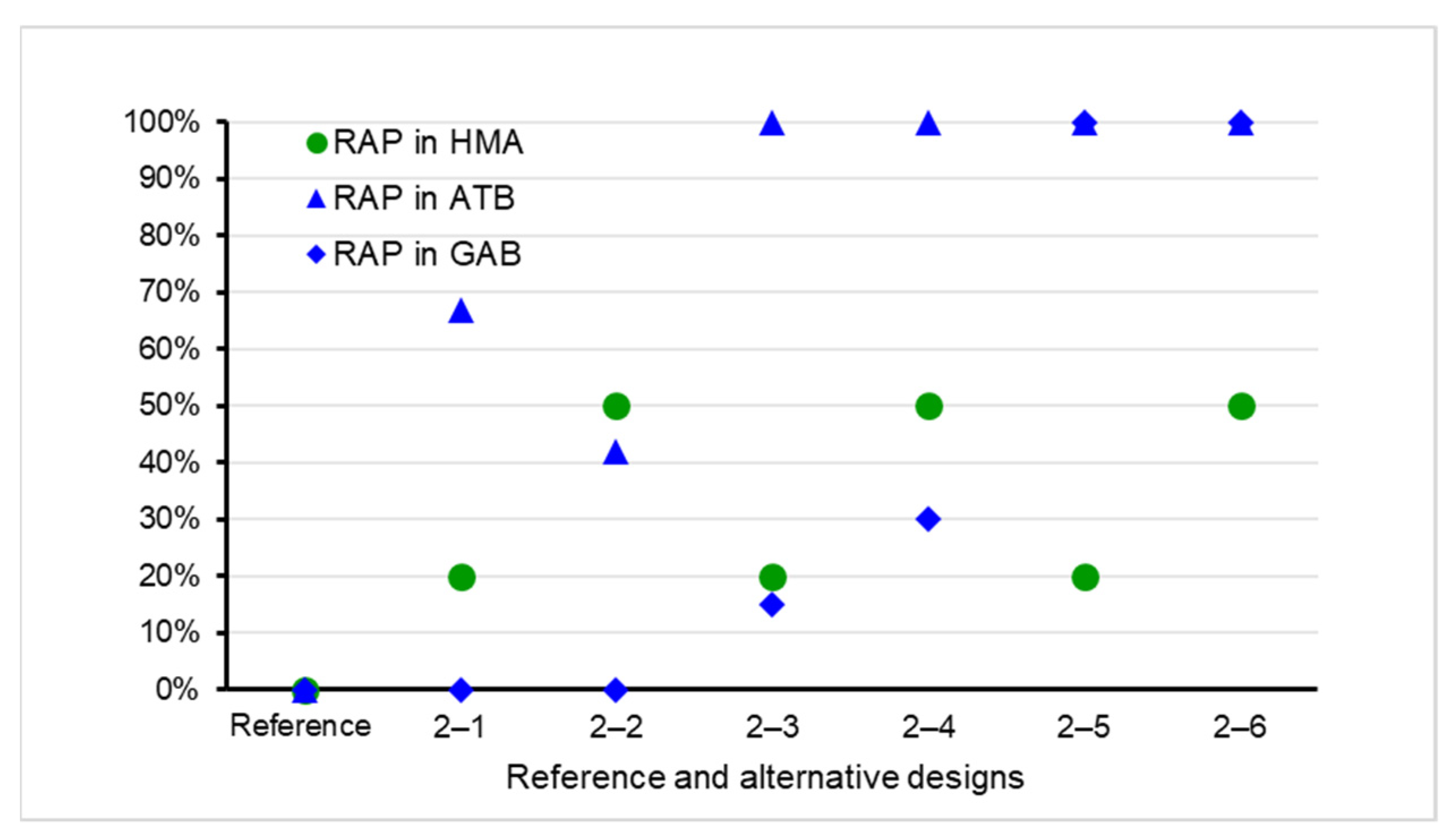

2.2. Identify Conventional and Alternative Strategies

2.3. Determine Equivalent Thicknesses for Alternative Designs

2.4. Predict Pavement Service Life

2.5. Identifying Rehabilitation Strategies

2.6. Life Cycle Assessment

3. Case Studies

4. Results and Analysis

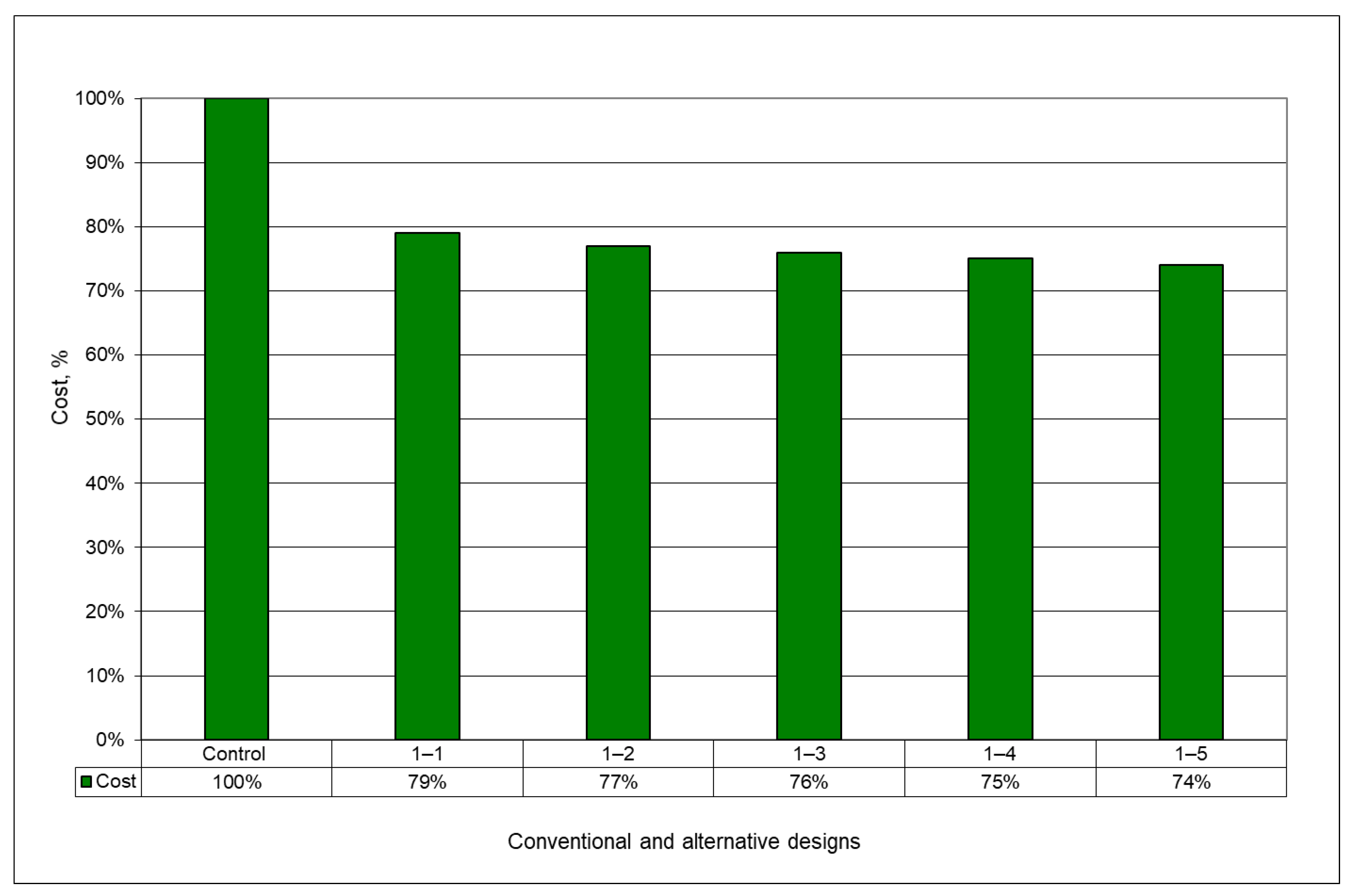

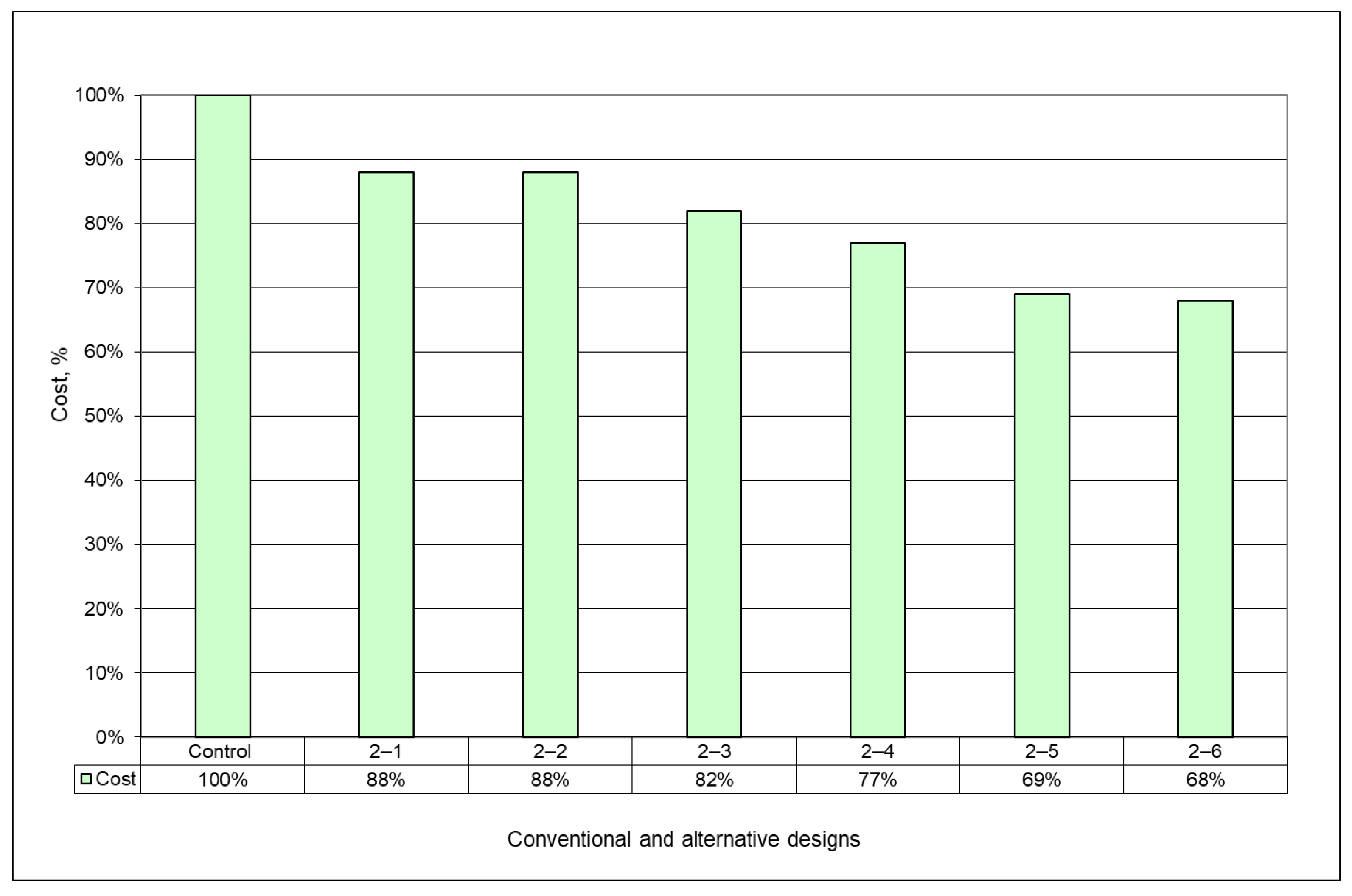

4.1. Economic Implications

4.2. Environmental Impact

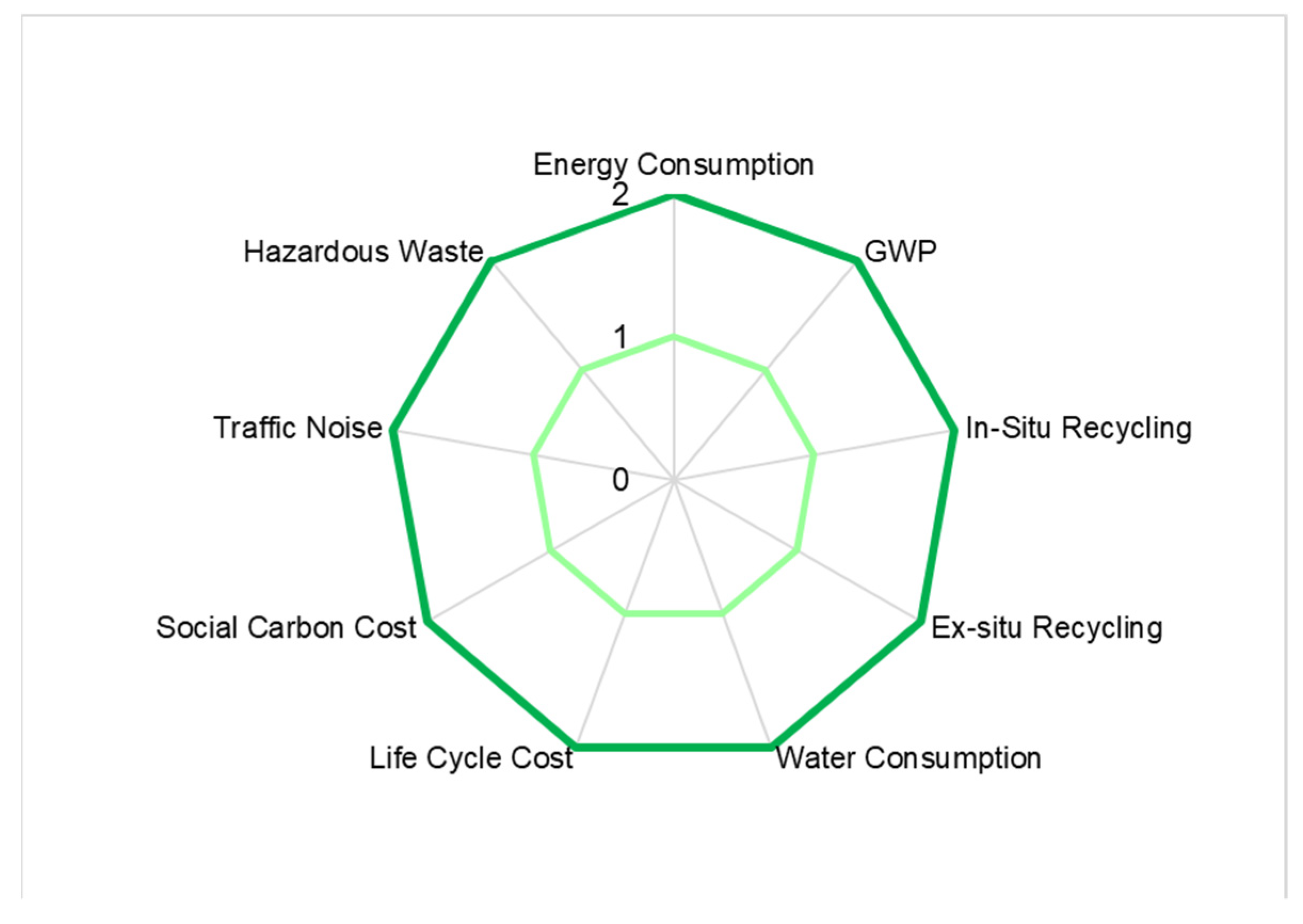

4.3. Sustainability Rating

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

References

- Lee, J.; Edil, T.B.; Benson, C.H.; Tinjum, J.M. Building Environmentally and Economically Sustainable Transportation Infrastructure: Green Highway. J. Constr. Eng. Manag. 2013, 139. [Google Scholar] [CrossRef]

- Lee, J.C.; Edil, T.B.; Tinjum, J.M.; Benson, C.H. Quantitative Assessment of Environmental and Economic Benefits of Recycled Materials in Highway Construction. Transp. Res. Rec. 2010, 2158, 138–142. [Google Scholar] [CrossRef] [Green Version]

- National Academies of Sciences, Engineering, and Medicine. Recycling and Reclamation of Asphalt Pavements Using In-Place Methods; The National Academies Press: Washington, DC, USA, 2011. [Google Scholar] [CrossRef]

- Chesner, W.; Collins, R.; MacKay, M. User Guidelines for Waste and By-Product Materials in Pavement Construction; FHWA-RD-97-148; Federal Highway Administration: McLean, VA, USA, 1998. [Google Scholar]

- Horvath, A. A Life-Cycle Analysis Model and Decision-Support Tool for Selecting Recycled Versus Virgin Materials for Highway Applications; RMRC Research Project No 23; Federal Highway Administration: Washington, DC, USA, 2004. [Google Scholar]

- Ventura, A.; Monéron, P.; Jullien, A. Environmental Impact of a Binding Course Pavement Section, with Asphalt Recycled at Varying Rates. Road Mater. Pavement Des. 2008, 9, 319–338. [Google Scholar] [CrossRef]

- Al-Qadi, I.L.; Elseifi, M.; Carpenter, S.H. Reclaimed Asphalt Pavement—A Literature Review; FHWA-ICT-07-001; Illinois Department of Transportation: Springfield, IL, USA, 2007. [Google Scholar]

- Aurangzeb, Q.; Al-Qadi, I.L.; Ozer, H.; Yang, R. Hybrid Life Cycle Assessment for Asphalt Mixtures with High RAP Content. Resources, Conservation and Recycling; Elsevier: Philadelphia, PA, USA, 2014; Volume 83. [Google Scholar]

- Del Ponte, K.; Madras Natarajan, B.; Pakes Ahlman, A.; Baker, A.; Elliott, E.; Edil, T.B. Life-Cycle Benefits of Recycled Material in Highway Construction. Transp. Res. Rec. 2017, 2628, 1–11. [Google Scholar] [CrossRef]

- Goulias, D.D.; Zhang, Y.; Aydilek, A. Sustainability Assessment of Roadways through Economic and Environmental Impact Life Cycle Analysis. Int. J. Comput. Eng. Res. 2018, 8, 1–8. [Google Scholar]

- Pavement Life-Cycle Assessment Tool for Environmental and Economic Effects Version 2.0. Consortium on Green Design and Manufacturing, University of California, Berkeley. Available online: https://rmrc.wisc.edu/palate/ (accessed on 14 May 2021).

- ASTM D6433-20. Standard Practice for Roads and Parking Lots Pavement Condition Index Surveys; ASTM International: West Conshohocken, PA, USA, 2020. [Google Scholar]

- Solla, M.; Pérez-Gracia, V.; Fontul, S. A Review of GPR Application on Transport Infrastructures: Troubleshooting and Best Practices. Remote Sens. 2021, 13, 672. [Google Scholar] [CrossRef]

- Goulias, D.G.; Cafiso, S.; di Graziano, A.; Saremi, S.G.; Currao, V. Condition Assessment of Bridge Decks through Ground-Penetrating Radar in Bridge Management Systems. J. Perform. Constr. Facil. 2020, 34, 1–13. [Google Scholar] [CrossRef]

- Scott, M.; Goulias, D. Effective use of GPR Data in PMS for Identification of Homogeneous Sections with Uniform Pavement Thickness & Assessing Thickness Variability: A Multi-Scale Approach. In Proceedings of the 9th International Conference on Managing Pavement Assets (ICMPA9), Washington, DC, USA, 18–21 May 2015. [Google Scholar]

- Gomes, A.; Winter, M.G.; Puppala, A.J. A Review of Sustainable Approaches in Transport Infrastructure Geotechnics. Transp. Geotech. 2016, 7, 21–28. [Google Scholar] [CrossRef] [Green Version]

- Reyes, O.; Berardinelli, E.; Alvarez, A.; Carvajal, J.; Fuentes, L. Evaluation of Hot Mix Asphalt Mixtures with Replacement of Aggregates by Reclaimed Asphalt Pavement (RAP) Material. Procedia—Soc. Behav. Sci. 2012, 53, 379–388. [Google Scholar] [CrossRef] [Green Version]

- Vislavičius, K.; Sivilevičius, H. Effect of reclaimed asphalt pavement gradation variation on the homogeneity of recycled hot-mix asphalt. Arch. Civ. Mech. Eng. 2013, 13, 345–353. [Google Scholar] [CrossRef]

- Association of State Highway and Transportation Officials (AASHTO). Guide for Design of Pavement Structures; AASHTO: Washington, DC, USA, 1993. [Google Scholar]

- National Cooperative Highway Research Program (NCHRP). Guide for Mechanistic-Empirical Design of New and Rehabilitated Pavement Structures; NCHRP, Transportation Research Board, National Research Council: Washington, DC, USA, 2004. [Google Scholar]

- Copeland, A. Reclaimed Asphalt Pavement in Asphalt Mixtures: State of the Practice; Publication FHWA-HRT-11-021; Turner-Fairbank Highway Research Center, Federal Highway Administration: McLean, VA, USA, 2011. [Google Scholar]

- Baladi, G.Y.; Dawson, T.; Musunuru, G.; Prohaska, M.; Thomas, K. Pavement Performance Measures and Forecasting and the Effects of Maintenance and Rehabilitation Strategy on Treatment Effectiveness; Report No. FHWA-HRT-17-095; United States Federal Highway Administration: Washington, DC, USA, 2017. [Google Scholar]

- Cafiso, S.; Di Graziano, A.; Goulias, D.; D’Agostino, C. Distress and Profile Data Analysis for Condition Assessment in Pavement Management Systems. Int. J. Pavement Res. Technol. 2019, 12, 527–536. [Google Scholar] [CrossRef]

- Schwartz, C.W.; Andrews, J.; Stephanos, P.; Goulias, D. Laboratory Evaluation of Inertial Profiler Accuracy. In Proceedings of the 2002 Pavement Evaluation, TRB, National Academies, Roanoke, VA, USA, 21–25 October 2002. [Google Scholar]

- Life-Cycle Cost Analysis in Pavement Design. Pavement Division Interim Technical Bulletin FHWA-SA-98-079, FHWA; U.S. Department of Transportation: Washington, DC, USA, 1998.

- Recycled Materials Resource Centre. RMRC. Building Environmentally and Economically Sustainable Transportation-Infrastructure-Highways. BE2ST-in-Highways User’s Manual; University of Wisconsin-Madison: Madison, WI, USA, 2012. [Google Scholar]

- Filho, W.U.; Klinsky, L.M.G.; Motta, R.; Bernucci, L.L.B. Cold Recycled Asphalt Mixture using 100% RAP with Emulsified Asphalt-Recycling Agent as a New Pavement Base Course. Adv. Mater. Sci. Eng. 2020, 2020, 5863458. [Google Scholar] [CrossRef] [Green Version]

| Pavement Condition | PCI Scale |

|---|---|

| Good | 85–100 |

| Satisfactory | 70–85 |

| Fair | 55–70 |

| Poor | 40–55 |

| Very Poor | 25–40 |

| Serious | 10–25 |

| Failed | 0–10 |

| Pavement Condition | Recycling Method |

|---|---|

| Satisfactory to Good | HIR |

| Fair | CIR |

| Poor or Lower | FDR |

| Parameter | Value |

|---|---|

| Road Width | 7.3 m |

| Road Length | 1.6 km |

| Wearing Course Depth | 10.16 cm |

| Graded Aggregate Base | 20.32 cm |

| Analysis Period | 40 years |

| Overlay (50 mm) | @ year 10 & 30 |

| Reconstruction | @ year 20 & 40 |

| Criteria | Reference (Conventional) | Alternative Strategy 1–5 | Performance | Normalized Score |

|---|---|---|---|---|

| Energy Use (MJ) | 10,342,136 | 8,229,633 | 20.43% | 2 |

| GWP (Mg) | 573 | 447 | 21.99% | 2 |

| In-Situ Recycling (%) | 0 | 1 | 100.00% | 2 |

| Ex-Situ Recycling (%) | 0 | - | - | - |

| Water Consumption (kg) | 2290 | 2009 | 12.27% | 2 |

| Life Cycle Cost (USD) | 2,552,620 | 1,952,232 | 23.52% | 2 |

| Social Carbon Cost (USD) | USD 27,446.65 | USD 21,411.26 | USD 6.035 | 0.15 |

| Traffic Noise | - | 1 | 1 | 1 |

| Hazardous Waste (kg) | 78,161 | 75,597 | 3.28% | 0.33 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Zhao, Y.; Goulias, D.; Peterson, D. Recycled Asphalt Pavement Materials in Transport Pavement Infrastructure: Sustainability Analysis & Metrics. Sustainability 2021, 13, 8071. https://doi.org/10.3390/su13148071

Zhao Y, Goulias D, Peterson D. Recycled Asphalt Pavement Materials in Transport Pavement Infrastructure: Sustainability Analysis & Metrics. Sustainability. 2021; 13(14):8071. https://doi.org/10.3390/su13148071

Chicago/Turabian StyleZhao, Yunpeng, Dimitrios Goulias, and Dominique Peterson. 2021. "Recycled Asphalt Pavement Materials in Transport Pavement Infrastructure: Sustainability Analysis & Metrics" Sustainability 13, no. 14: 8071. https://doi.org/10.3390/su13148071

APA StyleZhao, Y., Goulias, D., & Peterson, D. (2021). Recycled Asphalt Pavement Materials in Transport Pavement Infrastructure: Sustainability Analysis & Metrics. Sustainability, 13(14), 8071. https://doi.org/10.3390/su13148071