1. Introduction

The EN590 specification [

1] is used to control automotive diesel fuel quality in Europe to ensure the reliable operation of road vehicles. The current specification is the culmination of three decades of development driven by and enabling the introduction of sophisticated emissions aftertreatment devices such as diesel oxidation catalyst (DOC), diesel particulate filters (DPF), lean NO

x traps (LNT) and selective catalytic reduction catalysts (SCR) to achieve low emissions performance of the incumbent vehicles. Going forward, fuels used in diesel engines are likely to develop further and diversify to help meet future targets for carbon dioxide (CO

2) and other emissions associated with road vehicle use.

The current EN590 specification allows up to 7%

v/

v fatty acid methyl ester by volume (FAME), meeting the EN14214 specification to be blended into conventional petroleum diesel fuel. In addition, EN16709 provides a standard for B20 and B30 (petroleum diesel containing 20% and 30% biodiesel) fuels for use in captive fleets. It is anticipated that higher renewables levels will be needed in order to meet the future renewable energy targets mandated by the recast renewable energy directive (RED2), while the use of biofuels made from food and feed crops will be capped [

2].

In this study, two fuels containing 30%

v/

v FAME (B30, one including cetane number improver, (CNI)) were tested and their results compared to a fuel containing 5%

v/

v FAME (B5). This was in order to determine the impact of using FAME at levels much higher than currently permissible in EN590 compared with those typical of current European diesel fuels. The addition of FAME into diesel fuel is well known to decrease the engine-out particulate matter (PM) emissions of diesel engines [

3,

4,

5]. This effect is largely attributed to the presence of oxygenated compounds in the fuel which increases the local oxygen concentration in the rich area of the diesel flame, facilitating the oxidation of soot [

6] and diluting aromatic hydrocarbons and especially polycyclic aromatic hydrocarbons in the diesel fuel with an aromatics-free blending component where the FAME is splash-blended. Previous Concawe work confirmed that the addition of FAME in diesel fuel decreases the engine-out PM emissions and noted a reduction in fuel consumption penalty associated with reducing the frequency of DPF regenerations [

7]. Another study showed that the vehicles’ volumetric consumption increased due to the reduced energy content of FAME/diesel blends, which could not be compensated for through better engine efficiency on the oxygenated fuels [

8]. In general, previous studies have shown that increasing FAME reduces engine-out hydrocarbon (HC) and carbon monoxide (CO) and increases oxides of nitrogen (NO

x) emissions to a lesser degree, all this being consistent with the presence of oxygenated compounds within the diffusion flame. However, it should be remembered that these results are from a collection of published studies that predominantly focused on heavy-duty engines (and primarily on US market engines) that were not equipped with NO

x exhaust aftertreatment and were tested only over hot-start test cycles. It may not be reasonable to assume that these results will be representative of modern European vehicles that are equipped with a variety of aftertreatment technologies and are certified over a cold-start test cycle. There are considerably fewer publications related to modern light-duty diesel vehicles and the results that have been reported are generally less consistent than those from the heavy-duty tests. One study on light-duty engines [

9] demonstrated that vehicle effects became stronger than fuel effects when emissions started to become very low. A later Concawe study examined the consumption and emissions effects of 10% FAME vs. FAME-free fuel on emissions and consumption in Euro 4, 5 and 6 vehicles. This showed that increasing FAME content had the expected effect of increasing volumetric fuel consumption whereas it had no consistent negative or positive effects on emissions and NO

x penalties and PM benefits were only observed in the Euro 4 (non-DPF) vehicle [

10].

Studies sponsored by California Air Resources Board (CARB) showed that use of more paraffinic fuels as blending components and addition of cetane number improvers could mitigate the NO

x penalties experienced when using high FAME content fuels in US heavy-duty (HD) engines and trucks manufactured between 1998 and 2010 and subsequently some blends and fuel additives were certified for use in California for NO

x mitigation in high FAME content fuels [

11].

There are a number of EN590 specification properties defined to be environmental parameters according to the European Fuel Quality Directive [

12] and previous regulations. The aforementioned Concawe study [

10] considered other fuel properties as well as FAME: density, polycyclic aromatic hydrocarbons (PAH), cetane number. It showed that in diesel cars certified to Euro 4, 5 and 6 standards, increasing density above the current EN590 specification limit increased tailpipe CO

2 emissions in all cases, with varied effects observed for other regulated emissions. Emissions effects of cetane number were inconsistent except for HC and CO benefits in New European Driving Cycle (NEDC), and not Worldwide harmonized Light-duty Test Cycle (WLTC); for all vehicles indicating cetane number (CN), effects are vehicle- and test-cycle-dependent. Effects of higher PAH levels on tailpipe emissions were largely insignificant and a PM increase observed in the non-DPF car was not observed in the Euro 5 or Euro 6 vehicles. Overall, the effect of engine emission controls, vehicle calibration and test cycle clearly dominated fuel effects on emissions and efficiency.

Paraffinic diesel fuels (PDFs) can be derived from natural gas (gas-to-liquids, GTL), biological sources (such as so-called hydrotreated vegetable oil, (HVO), biomass-to-liquids, (BTL)) and power-to-liquids, (PTL). As some PDFs have become more abundant in the market (GTL, HVO), a European specification describing the quality for PDFs for use in automotive applications, EN15940, has been developed in recent years [

13]. PDFs have been proven to have beneficial effects on vehicle tailpipe emissions, including PM, NO

x, CO and HC [

14,

15], although some studies have shown that PN can be increased [

16]. As well as the tailpipe or “tank-to-wheel” (TTW) benefits, these fuels can provide overall lifecycle CO

2 benefits when derived from renewable sources [

17].

As both vehicle technology and emissions legislation in Europe continue to evolve, Concawe conducted a study (in 2019) to examine the opportunities that fuels can provide to further reduce emissions from light-duty diesel passenger cars [

18]. Three European specification diesel cars spanning Euro 5, Euro 6b and Euro 6d-TEMP emissions certification levels were tested over the cold-start WLTC with six fuels: EN590-compliant B5, bioderived paraffinic diesel (HVO), a 50:50 blend of the aforementioned fuels, low-density petroleum-derived B5, B30 and B30 including a high dose of cetane number improver. It was concluded that low-density hydrocarbon fuels can offer benefits in TTW CO

2 and other GHG emissions and emissions impacting local air quality. Although paraffinic diesel fuels offer emissions benefits when used as a neat fuel, using paraffinic diesel as a blend component can give disproportionally large benefits in these emissions. This bodes well for cases where PDFs are in short supply and in the future when HVO, BTL and PTL fuels become more widely available. Advanced exhaust aftertreatment was found to suppress the negative NO

x effects associated with the use of high FAME content fuels, opening the door to the use of such fuels in markets dominated by advanced vehicles, thereby enabling increased use of such renewables without local air quality drawbacks. In the European passenger cars tested, the use of high levels of CNI did not mitigate any NO

x penalty traditionally associated with the use of high FAME content fuels. Deleterious fuel effects were not evident in the emissions slated for future regulation (<23 nm PN, NH

3); however, some additional benefits were noted from application of specific fuel qualities (CH

4, N

2O). It was evident that some traditional benefits of fuel quality on emissions were reduced or even eliminated in the tailpipe emissions of cars using advanced aftertreatment.

To complement the results of the aforementioned LD study, in 2020 Concawe commissioned a study of the effects of the same fuel set on emissions from two commercial vehicles. A heavy-duty (HD) bus certified to Euro VI emissions level and a medium-duty (MD) delivery truck certified to Euro V emissions level have been tested on a chassis-dyno over the World Harmonized Vehicle Cycle (WHVC) and Transport for London Urban Inter-Peak (TfL UIP) test cycle.

The objective of the study is to provide understanding of the effects that diesel fuels operable in current automotive technology applications could offer to both emissions affecting local air quality and to greenhouse gas emissions, with the focus on TTW effects. The fuels tested do not necessarily comply with the current EN590 specification and therefore it is recognized that compatibility of these fuels with the existing vehicle fleet would require further specific consideration which is outside the scope of the study.

Tests over the WHVC and TfL UIP chassis dynamometer test cycles rather than the Real Driving Emissions (RDE) protocol were appropriate to obtain the experimental repeatability required to analyze fuel effects, given that in a previous Concawe study, fuel differences spanning EN590 in terms of density were undetectable over RDE [

19].

Testing was limited to one example each of a heavy-duty (HD) bus certified to Euro VI emissions level and a medium-duty (MD) delivery truck certified to Euro V emissions level due to resource constraints. These vehicles were chosen with consideration of the typical age of vehicles in different commercial vehicle segments in Europe.

2. Materials and Method

2.1. Test Fuels

The test fuel set comprised commercially available fuels and fuel components already used in vehicles in demonstration fleets or commercial applications without modifications. The rationale for selecting such fuels was to consider fuel options that could be applied to, and potentially achieve, benefits in the existing as well as future fleets. The fuels were selected for their expected potential to provide benefits to both emissions affecting local air quality and to greenhouse gas emissions, with the focus on TTW effects. The fuels, F1–F6 (Fuel 1–6) are described in the following subsections, key fuel properties are listed in

Table 1 and full properties are given in

Appendix A.

Fuel 1—EN590 B5

The EN590 B5 fuel was selected to represent a current European diesel road fuel complying with EN590 and it provided a reference fuel for some of the other fuels in the set. This fuel comprised crude-derived petroleum diesel (95% v/v) and FAME type biodiesel derived from used cooking oil (UCOME, 5% v/v) which complied with EN14214. Density for this fuel was at the top of the density range permitted in the EN590 specification: 845 g/L and cetane number was close to the EN590 minimum at 52.

Fuel 2—Low-Density B5 (LD B5)

The Low-Density B5 (LD B5) was selected to represent a lower than EN590 specification density fuel derived from refinery streams normally used for jet and diesel fuel to enable the impact of reduced density and higher hydrogen-to-carbon (H/C) ratio on emissions to be evaluated while still using conventional refinery streams. The LD B5 fuel also acted as a reference fuel for some other fuels in the set and the biodiesel component was UCOME, complying with EN14214.

Fuel 3—Paraffinic Diesel Fuel (PDF)

The PDF was chosen to represent paraffinic fuels derived from natural gas (GTL), biological sources (such as HVO, BTL) and PTL fuels. In this case, Fuel 3 was HVO targeted at the lower end of the EN15940, class A specification in terms of density and, as such, enabled the impact of low density, high H/C ratio, low aromatics and high cetane number on emissions to be evaluated.

Fuel 4—50:50 Blend of Fuels 1 and 3 (PDF50)

The 50:50 blend of PDF and EN590 B5 (PDF50) enabled the impact of a paraffinic blend component on emissions to be evaluated. This fuel was included to represent scenarios in which availability of paraffinic fuels is limited, to cater for scenarios where vehicles are not compatible with pure PDF fuel and to determine in these cases whether or not emissions benefits can be expected to be proportional to the paraffinic fuel content. It was also postulated that paraffinic fuel blends could offer the opportunity to provide emissions benefits while remaining nearer to the existing EN590 specification.

Fuel 5—B30 based on LD B5 (B30)

The B30 fuel was configured from an altered ratio of the components in Fuel 2, low-density petroleum-based diesel (70% v/v) and UCOME (30% v/v). This fuel was designed to enable the evaluation of the impact of high FAME content levels, so far only used in Europe in captive fleets, on emissions. It was postulated that the increased NOx emissions historically associated with the use of high FAME fuels could be mitigated by the sophisticated exhaust aftertreatment used in the latest vehicles.

Fuel 6—B30 + Cetane Number Improver (B30+CNI)

Fuel 6 comprised Fuel 5 with a high dose of 2-ethylhexyl nitrate (2-EHN) CNI of 0.52%

v/

v, (B30+CNI). The rationale was that the addition of CNI was found to be effective at mitigating NO

x penalties associated with the use of high biodiesel blends used in HD trucks in California [

11] and could also yield some other emission benefits.

Key Fuel Properties

Key properties of the test fuels are summarized in

Table 1 and full properties are listed in

Appendix A. It is notable that there is an anomalous measured difference in PAH and total aromatics between F5 and F6, which is in fact within the reproducibility of the measurement method.

2.2. Test Vehicles

The test vehicles were chosen based on representation of:

Vehicle types currently common in the European market;

Engine and emission control technologies currently common in the European market;

Vehicles certified to Euro V and Euro VI standards;

Different parent original equipment manufacturers (OEMs);

The typical age of vehicles in different commercial vehicle segments in Europe.

The test vehicles were rented by the test provider, VTT Technical Research Centre of Finland, from the Finnish market.

Key test vehicle details are given in

Table 2.

2.3. Experimental Program

Experimental work was carried out at the VTT Technical Research Centre of Finland. Specifically, testing was conducted in a temperature-controlled heavy-duty chassis dynamometer (CD) with ambient temperature controlled to 23 °C, ±2 °C. Relative humidity was not controlled and varied between 10 and 30% in the test period. Humidity corrections (KH) were applied to NOx results.

2.3.1. Vehicle Preparation

Ahead of testing, the serviceability of each vehicle and OBD were checked for existing faults and identified faults were rectified. The vehicles were within their recommended service intervals for the duration of the test program, thereby avoiding the need for servicing mid-program. Inertia based on the 50% payload level vehicle mass along with coast down times on reference vehicles of similar mass and size was used to derive road load models for testing. Fuel lines from and to the vehicle tanks were rerouted to enable fueling from external canisters and both delivery and return lines were routed via heat exchangers to control fuel temperature.

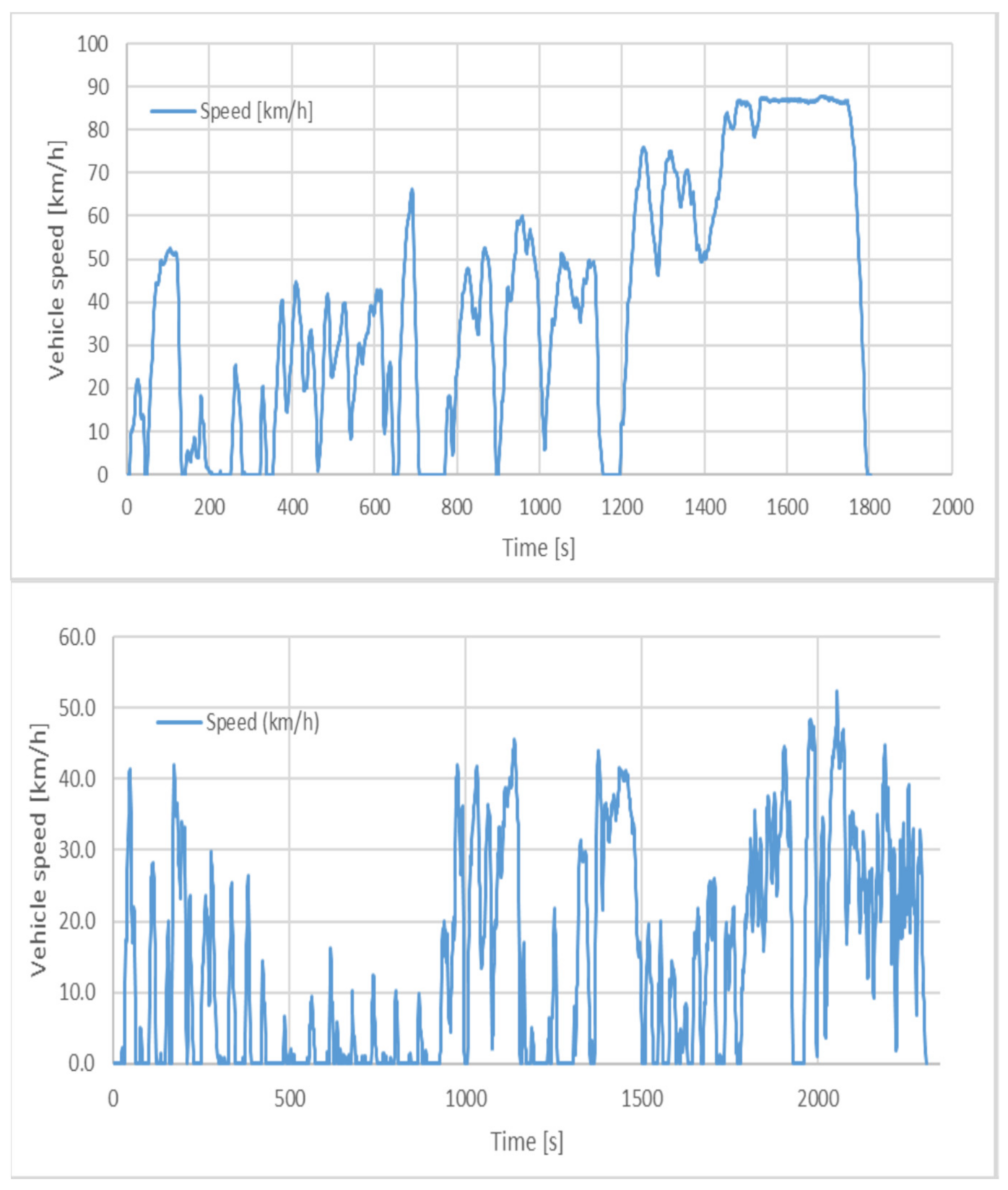

2.3.2. Test Cycles

Tests were conducted over World Harmonized Vehicle Cycle (WHVC) and Transport for London Urban Inter-Peak (TfL UIP) test cycles. The WHVC was developed from the World Harmonized Transient Cycle (WHTC) for emissions certification of heavy-duty engines to provide an equivalent for testing in vehicles and includes sections representing urban, rural and highway driving [

20,

21]. The TfL UIP cycle was chosen to investigate emissions performance over severe urban conditions. This is a congested-traffic cycle modelled on real bus driving between the morning and evening rush hours in London (NB: morning and evening rush hours are even more congested). The cycle takes around 40 min and covers approximately 9 km. The cycle has a low average speed, but is highly dynamic and features frequent idling, thereby presenting a challenging combination for the emissions control systems of low exhaust gas temperature quickly transitioning to high pollutant throughput [

22]. The key features of the WHVC and TfL UIP cycles are compared in

Table 3 and the speed profiles are illustrated in

Figure 1.

2.3.3. Measurements

Test measurements were collected via the CD monitoring system, vehicle and environmental data loggers and emissions analyzer equipment as listed in

Table 4. The emissions measurement system implements a full flow constant volume sampler dilution tunnel (CVS). A bag sampling system was used for determining cycle average gaseous exhaust results. PM was measured using a filter paper sampling method. PN (in the range >23 nm) was measured using a CPC with a diluter. FTIR units were used both pre- and post-engine after treatment (EAT) for determining the EAT effect on the emissions. The engine exhaust mass flow was determined for the purpose of FTIR calculations from exhaust dilution rate in the CVS. Carbon balance fuel consumption (FC) was calculated from CO

2, CO and HC results acquired from exhaust bag sampling in combination with fuel carbon content proportioned to total determined exhaust mass flow. As HC emissions were generally very low, they had an insubstantial impact on fuel consumption. These FC calculations were then double checked and compared with values from physical FC measurement. Total FC for each test cycle was derived from change in fuel mass measured on a balance. Vehicle urea consumption was likewise measured using a balance. Vehicle controller area network (CAN) messages (J1939 protocol) were acquired using a CAN-logger and obtained via the on-board diagnostics (OBD) port. Truck EGR position was measured directly from EGR-valve as this message was excluded from the standardized CAN-protocol. Voltage was directly measured from the EGR valve’s control unit, therefore relative EGR valve position, rather than actual EGR rate being observed, but this was deemed sufficient to check that no differences in EGR level were being applied with different fuels.

2.3.4. Test Protocol

Each daily test sequence was executed in a predefined, consistent task order. Either 1, 2 or 3 passes through the test sequence were made depending on the operational circumstances (see

Section 2.3.5 and

Table 5). The test sequence tasks are listed chronologically in

Table 6. In order to ensure consistent initial vehicle conditions in every test, the vehicle was conditioned by running on the CD at 80 km/h for 30 min before the initial test (WHVC) and 10 min before the subsequent TfL UIP cycle. These preconditioning steps were found to be sufficient to attain consistent and stable engine coolant and oil temperatures. The target triggering temperature for coolant was set at thermostat opening temperature: 89 °C (±1 °C) for the bus and 84 °C (±1 °C) for the truck, along with 100 °C (±1.5 °C) engine oil temperature for both vehicles. Switching test fuel was performed during the initial conditioning phase of each day. After switching, the fuel return line was diverted to waste with the engine running to ensure the system was sufficiently flushed. At the end of each test day, a coast down curve was run to check that changes in vehicle frictional losses were not occurring that could confound detection of fuel differences.

Throughout the program, exhaust gas temperature was monitored from the Euro VI bus to detect and respond to DPF regeneration events; however, none were detected during testing.

Engine lubricant levels were checked at SOT and thereafter the dashboard level indicators were relied upon to ensure that levels did not fall outside recommended limits.

2.3.5. Test Schedule

The test order was designed so that the three repeats on each fuel were positioned approximately symmetrically about the mid-point of the test sequence. This ensures that the fuel means would have experienced minimal adjustment had (linear) drift been present in the data and a correction applied. Each fuel was followed by a test on a different fuel and repeated pairings of the same fuels were also avoided so that, in the very unlikely event that the effects of a fuel carried over into the following test, any impact would be distributed across multiple fuels. Another consideration was to avoid, as far as practicable, all tests on any fuel being run in the same position within the test day. As Fuel 1 was used as a main reference, more tests were carried out on this fuel to increase the statistical power of the fuel comparisons. (Fuel 2 was also a reference for Fuels 5 and 6, but because three repeats were already scheduled on each fuel, no additional tests were deemed necessary.) Tests identified as invalid at the time of running were repeated in-sequence, whereas those identified later as non-conforming were repeated in a position in the sequence subject to the constraint of avoiding successive tests on the same fuel. The detailed formulation of the fuels was not disclosed to the test facility until after the test program was complete (details required for the correct calculation of fuel and energy consumption were disclosed). This ensured that all testing was blind and that the decision to omit any test as invalid on operational grounds and to repeat it was made without any knowledge of expected performance.

The actual test order (

Table 6) deviated from the planned test order due to some tests being identified as potentially non-conforming or, in the case of the first test on the truck and the first four tests on the bus, affected by vehicle settling; these tests were repeated at the end of the planned test sequence in reverse order. Two more valid tests were run on the truck rather than the bus because some tests earlier in the sequence that appeared to be outliers were confirmed not to be so when the additional repeats were run.

2.4. Data Analysis

2.4.1. Data Quality

As mentioned under “Test Schedule”, some tests were rejected from the analysis due to unusual high emissions, notably in CO2, in the initial tests. Specifically this was the first test sequence (of WHVC+TfL UIP) on the truck and first four test sequences (of WHVC+TfL UIP) on the bus and the cause was attributed to vehicle settling.

No usable CH4 data were generated; readings were below the detection limit and so CH4 was not included in calculation of GHG emissions.

Some PN and PM data were missing due to equipment malfunctions. In the respective tests this was the only omission and so the tests were not repeated.

2.4.2. Statistical Analysis

The statistical analysis was carried out separately for each vehicle and is based on a simple one-way analysis of variance (ANOVA) with fuel as the factor. Standard statistical methods such as ANOVA assume that the variation in the data is constant regardless of the level of the mean, but many emissions measurements exhibit proportional variation where the variability of the measurements increases with its mean level. This is not a concern for CO

2 emissions, fuel consumption and the related GHG CO

2 equivalent (CO

2e) and energy consumption measurements, as these are predominantly determined by the vehicle and fuel effects are small in relative terms. However, for other emissions where large proportional differences can arise between fuels, a weighted analysis has been applied where the weights correspond to 1/(Mean

2). This weighting has no effect on the fuel means but gives more weight to smaller measurements, which are more precise, and smaller fuel means will therefore have smaller confidence intervals than larger fuel means. Additionally, in line with other studies [

18], PN was analyzed on the logarithmic scale with the results presented as geometric means.

The study was designed to evaluate the impact of fuel properties, namely density, paraffinic fuel content, B30 and B30 with CNI, via a small fuel matrix using a predefined set of fuel comparisons. With more than one reference fuel involved, fuel differences have been assessed for significance using the Holm–Bonferroni method, which protects the family-wise error to provide protection against the risk of false positives but offers greater statistical power than other, more severe, multiple comparison tests.

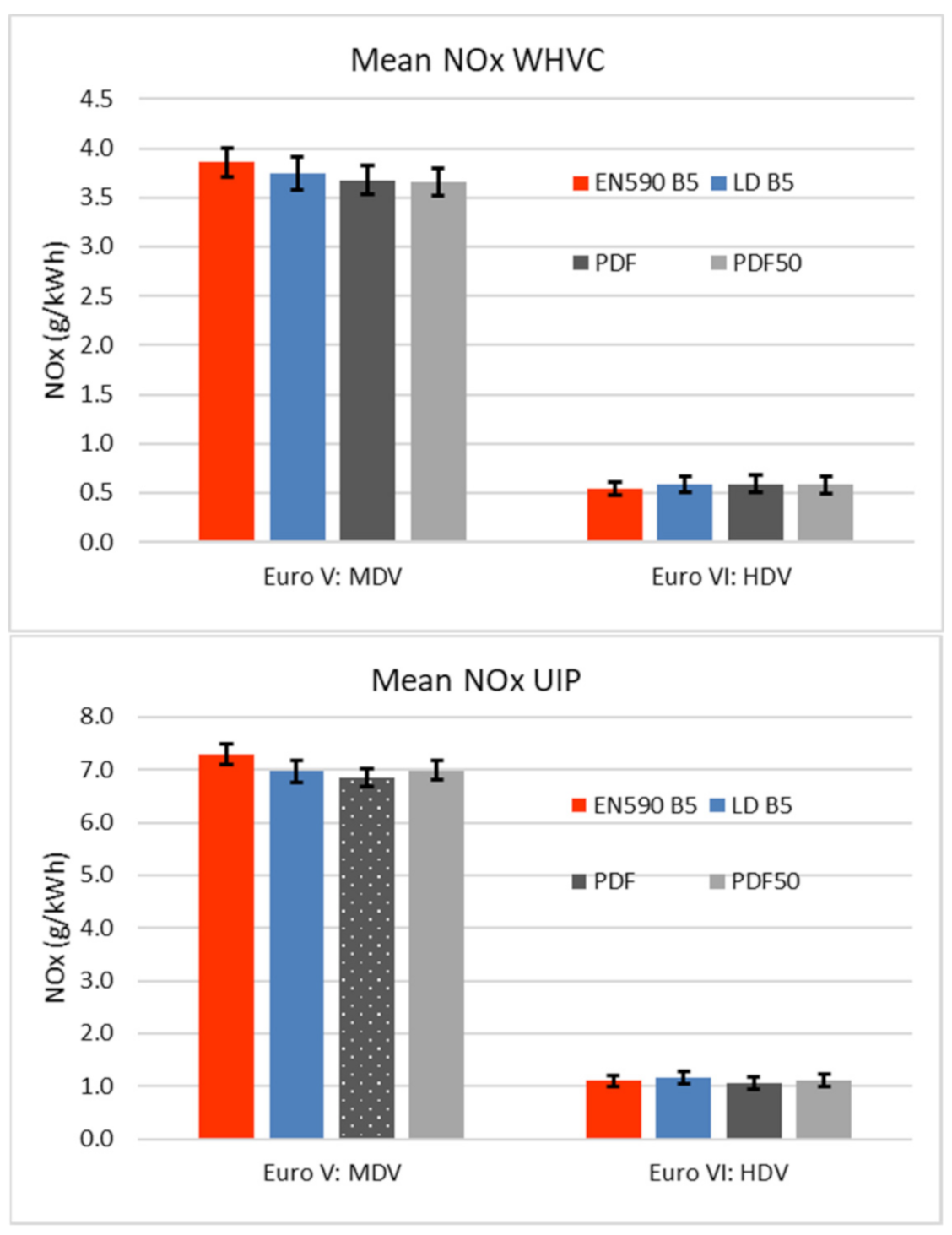

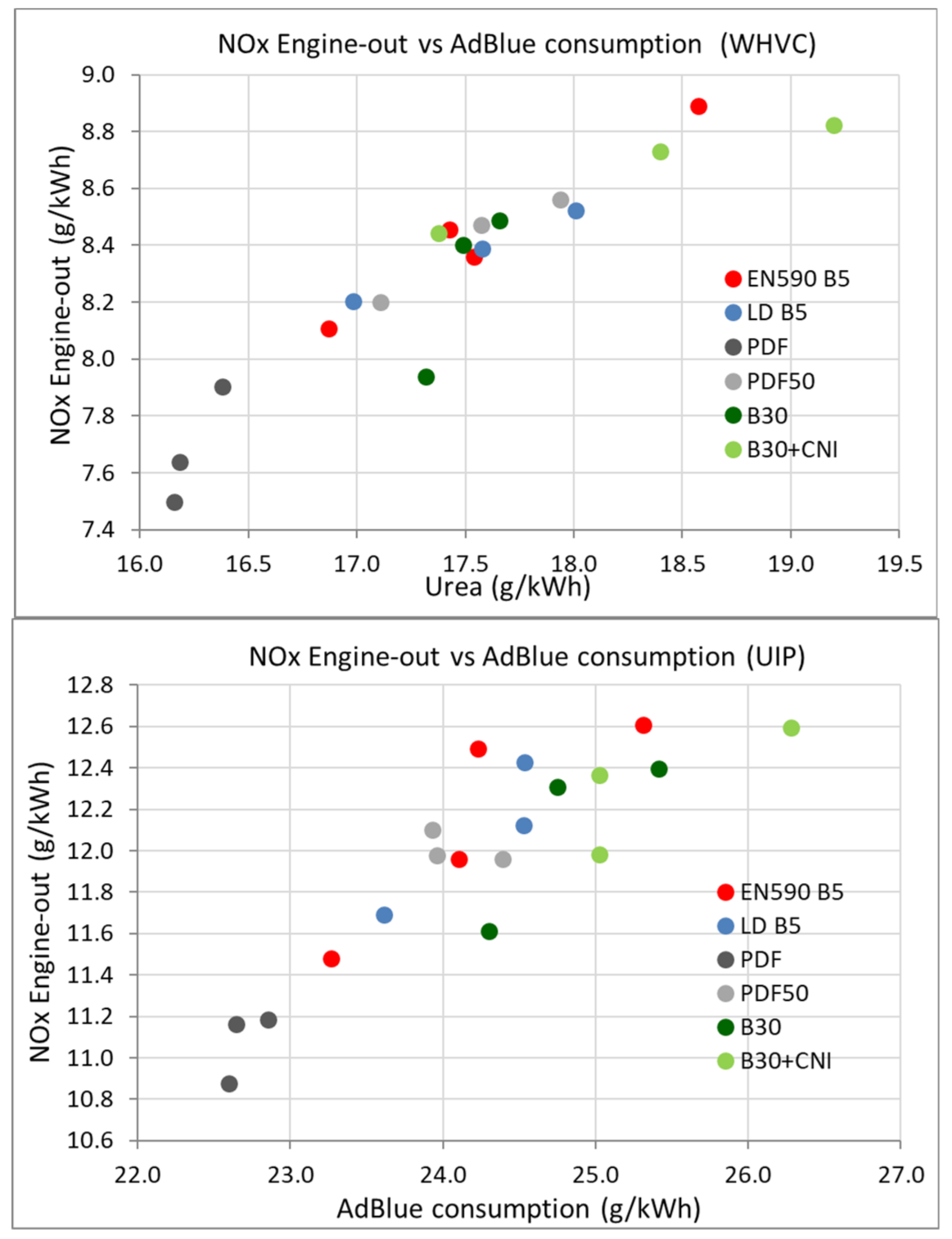

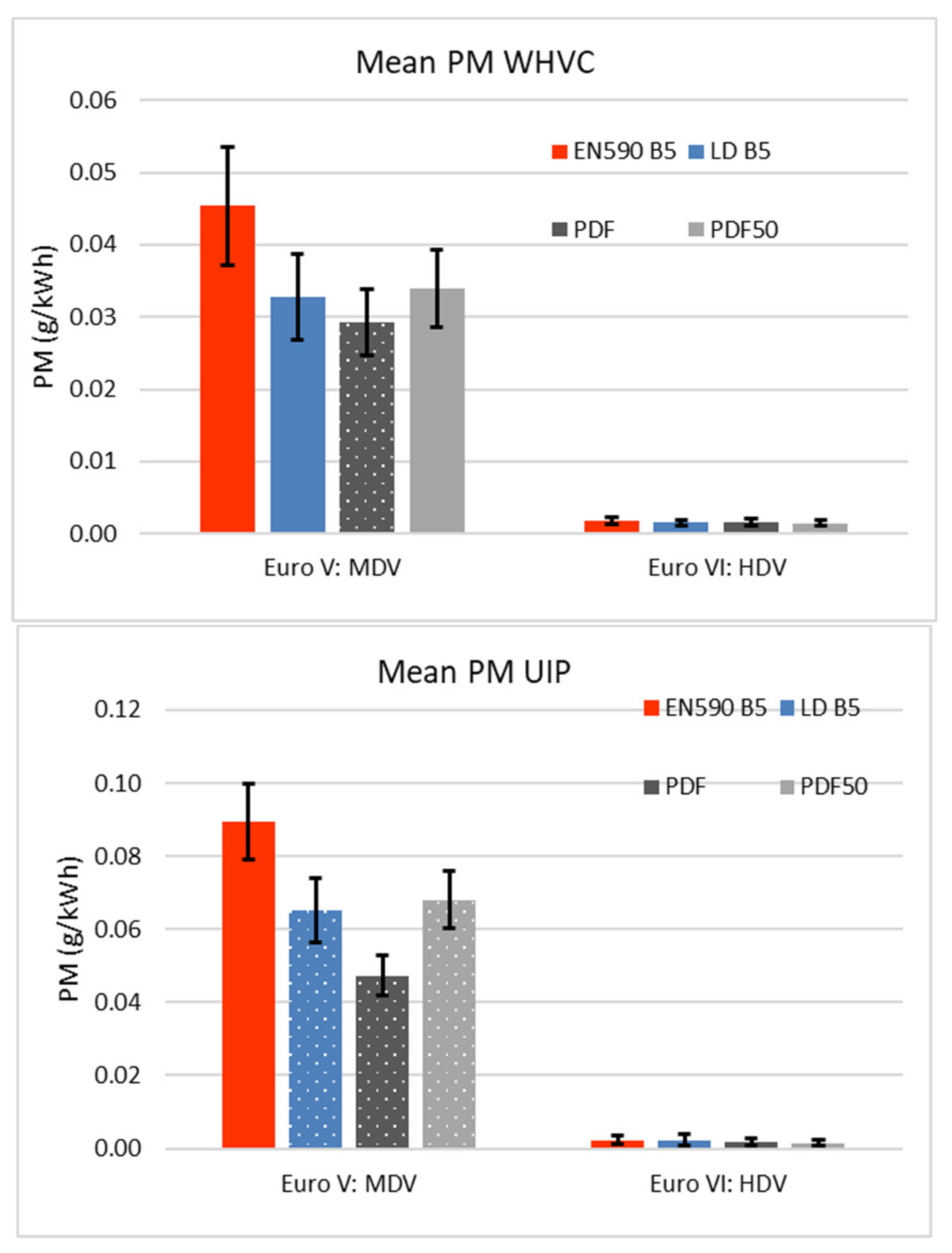

4. Discussion

The emissions and fuel consumption performance of six diesel fuels have been tested over hot-start WHVC and TfL UIP test cycles in two European commercial vehicles—one HD Euro VI bus and one MD Euro V truck—to determine their potential benefits. Most of the fuels tested have potential to be renewable, with WTT benefits as well as the TTW effects studied, but in many cases additional OEM certification would be required to deploy such fuels for general use in the European market.

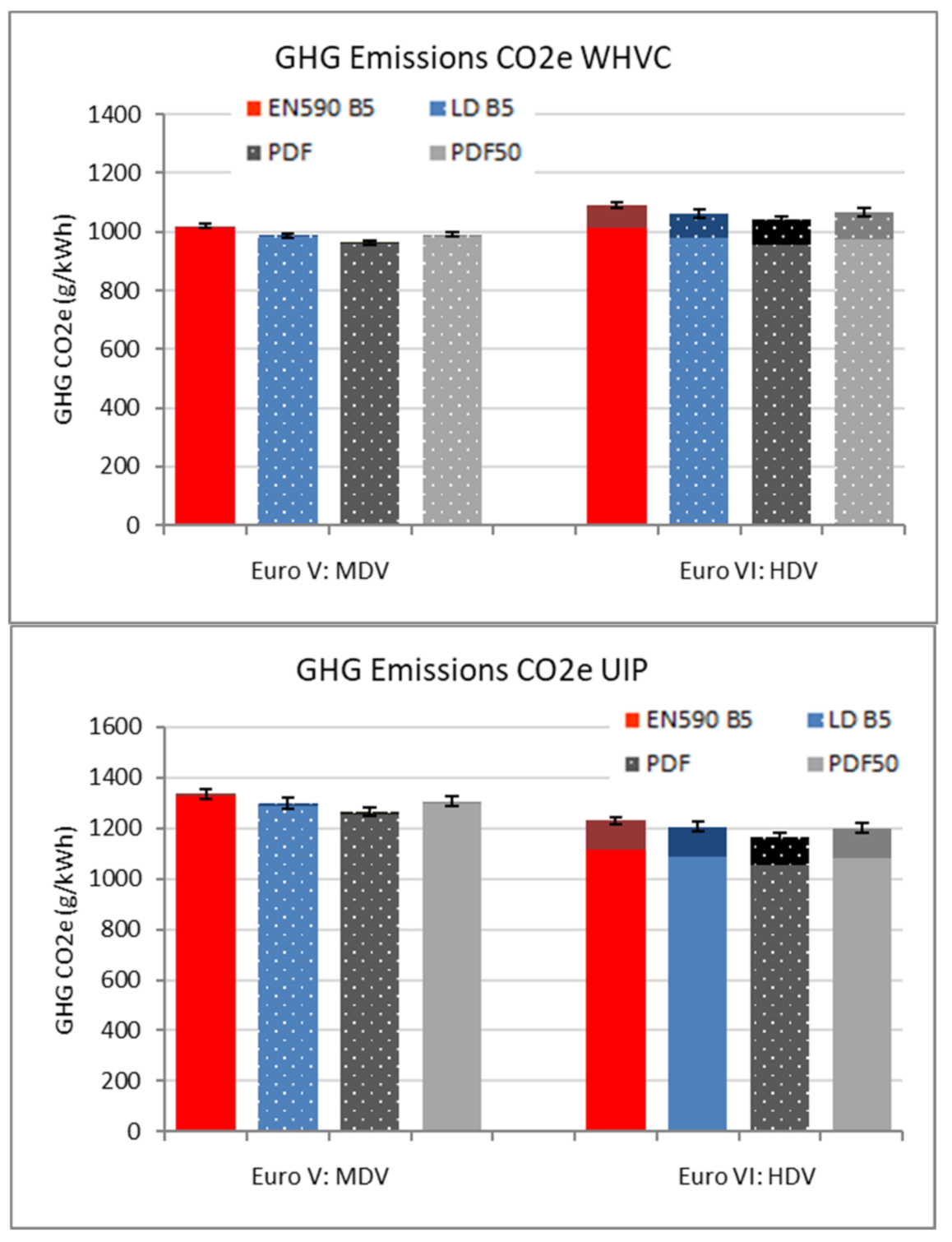

Results showed that low-density hydrocarbon fuels can offer TTW CO2 benefits in the range of 2 to 6%, but with an accompanying increase in volumetric fuel consumption and no difference in energy consumption, meaning that the fuels did not affect engine efficiency. The differences in volumetric fuel consumption were consistent with expectations based on the fuels’ lower heating value and density; so were the CO2 emissions consistent with the fuels’ carbon intensities. When combining CO2 and N2O emissions, these fuels also offer total TTW GHG benefits (with methane emissions being immeasurably low in this experiment).

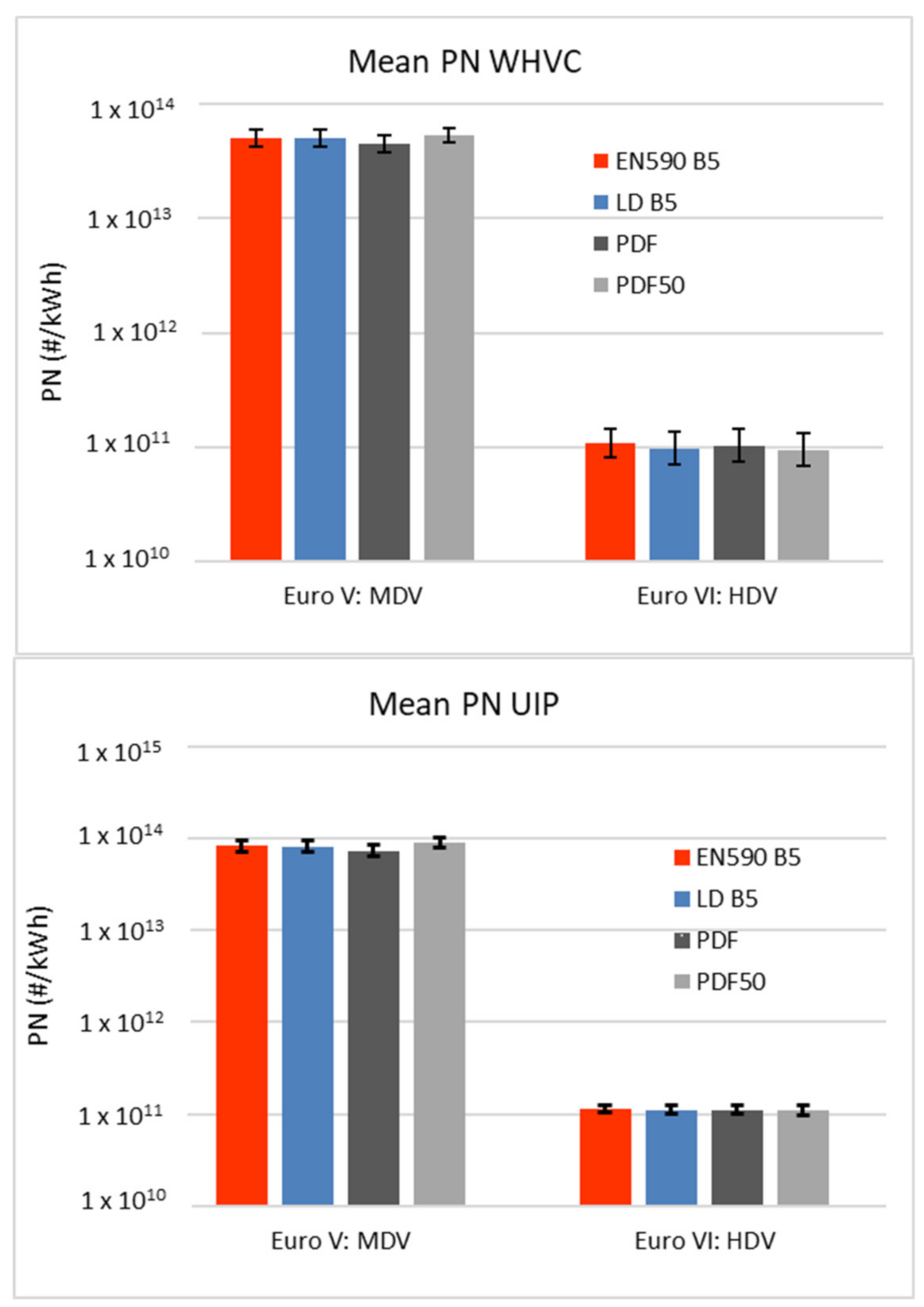

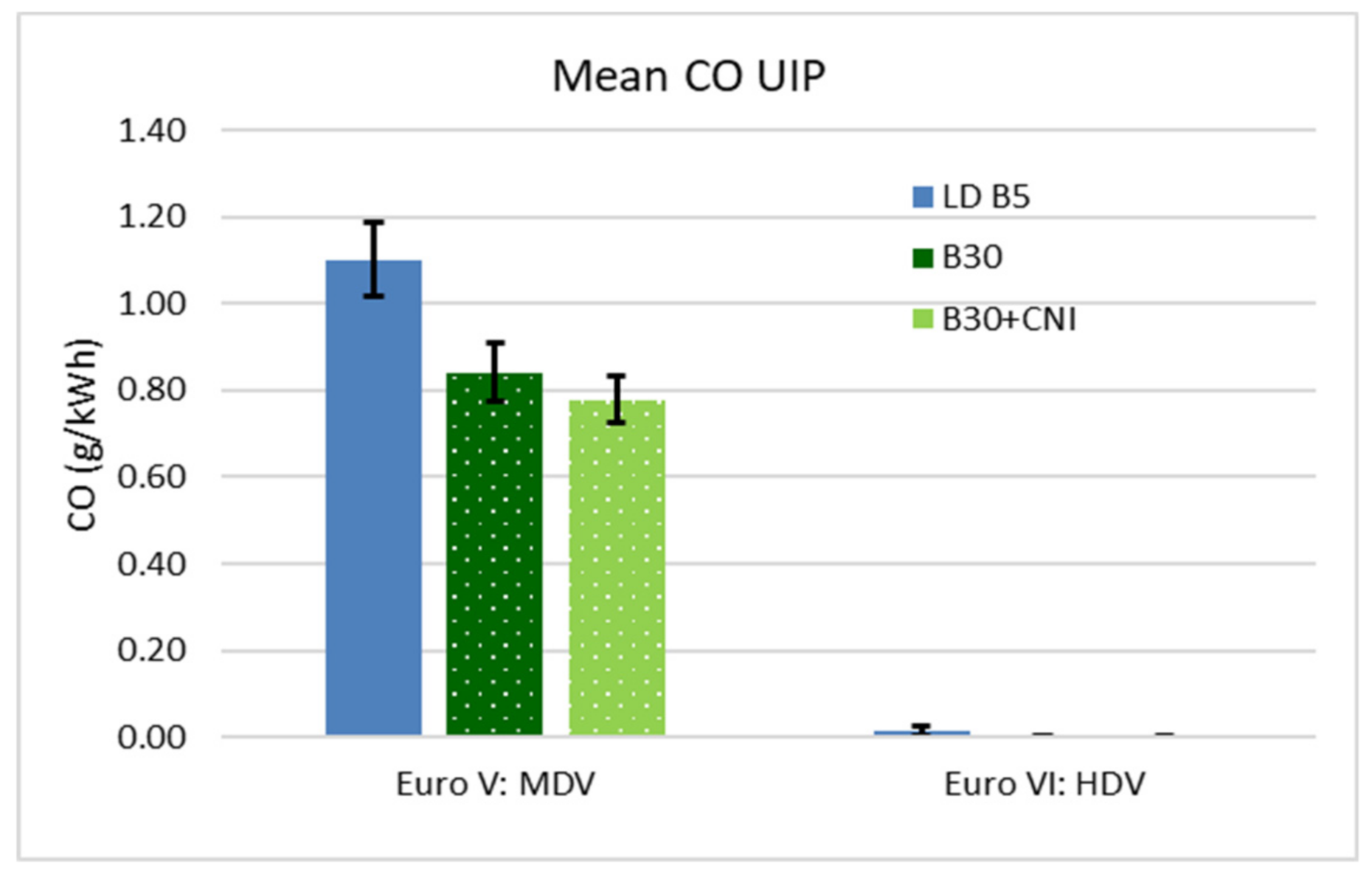

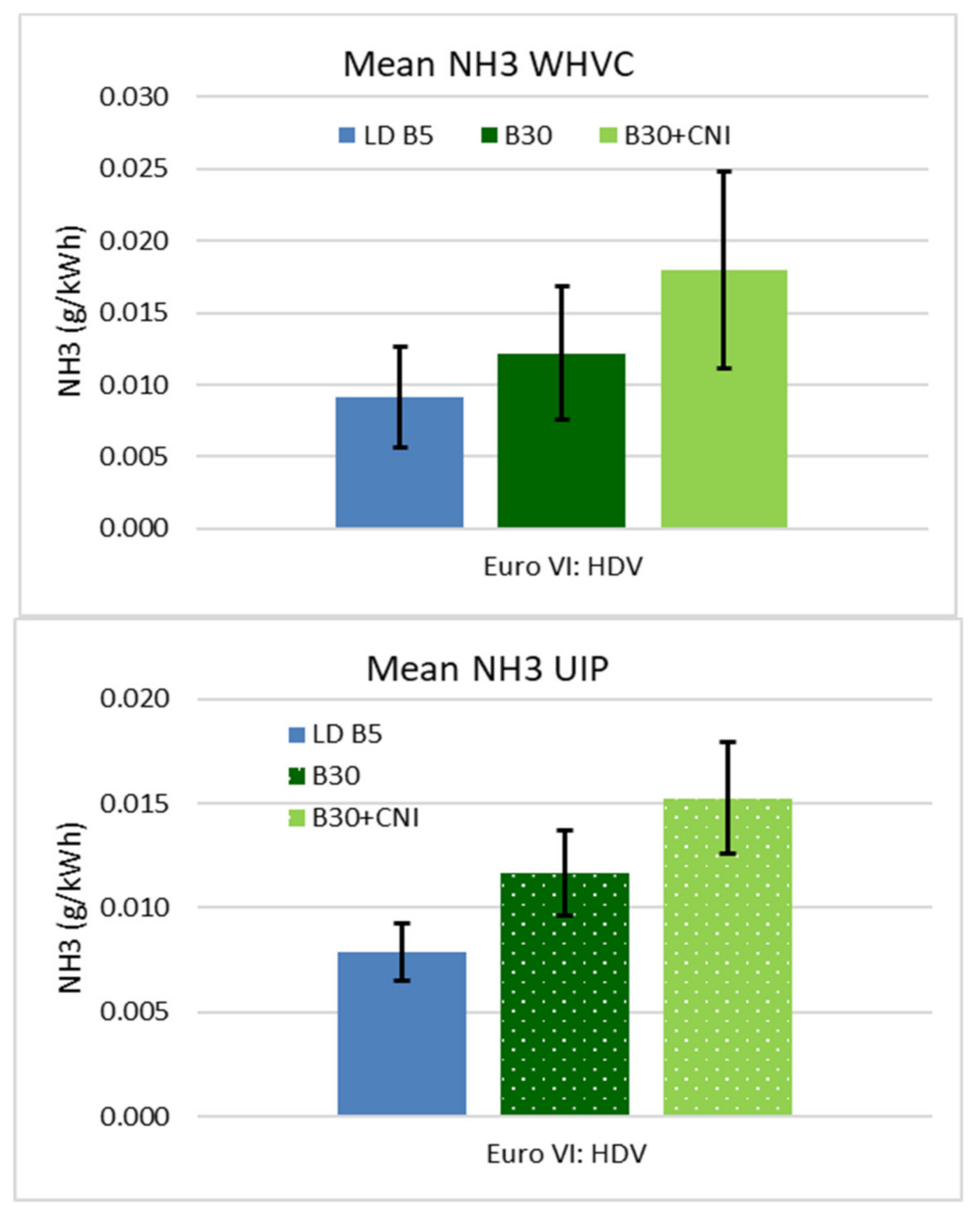

In terms of emissions that could affect local air quality, significant fuel effects on tailpipe emissions from the low-density hydrocarbon fuels were only observed in the Euro V vehicle. The impact of modern exhaust aftertreatment is illustrated in this respect, given that beneficial fuel effects on NOx were observed in engine-out emissions from the Euro VI vehicle (with paraffinic diesel fuel) but were absent in the tailpipe emissions and lower engine-out NOx was instead translated into lower consumption of AdBlue SCR reductant due to closed-loop control of tailpipe NOx. Tailpipe levels of PM, PN, NOx, CO and HC were all substantially lower for the Euro VI vehicle than for the Euro V vehicle; however, due to the application of urea-SCR, measurable ammonia emissions were observed from the Euro VI vehicle. N2O and the fraction of NO2 in the total NOx emissions were higher although absolute levels of NO2 were similar in both vehicles. For the Euro VI vehicle, N2O contributed to approximately 10% of the GHG emissions, showing a possible weakness in the current CO2 regulation which is aimed at GHG emissions reduction.

In the Euro V vehicle, low-density hydrocarbon fuels gave some benefits in PM and CO, especially in the TfL UIP urban cycle, whereas, surprisingly, HC emissions were higher for these fuels in some cases and lower in one case. The surprising increases in HC oppose trends observed in other studies [

11,

18,

24,

25,

26] and could be an artefact of the calibration of the specific vehicle used. It is postulated that low-density fuels led to longer injection durations being applied to deliver the required fuel mass to meet torque demands. This in turn could have been interpreted by the vehicle EMS as different load points leading to a different point on the engine operating map being adopted, which affected engine-out emissions. There were no significant fuel effects on tailpipe NO

x or PN except in one case in the TfL UIP test where the PDF reduced NO

x in the Euro V vehicle.

The B30+CNI fuel was included primarily to determine if the addition of CNI could mitigate any NO

x penalties arising from the high FAME level in B30 (as practiced historically for HD vehicles in California [

11]). In the current study, there were no significant effects of B30 and B30+CNI on NO

x (engine or tailpipe) or indeed any significant differences in CO

2, volumetric fuel consumption or energy consumption compared to LD B5. This difference between the former Californian study and the outcomes of the current study possibly results from advances in fuel injection equipment capable of delivering improved fuel-air mixing and multiple injection strategies. Older engines using fewer fuel injection events per engine cycle created long auto-ignition delays, in particular with low CN fuels (which is often the case in the USA), consequently leading to a substantial premixed flame which with rapid heat release and consequent high temperatures is known to be a source of NO

x. In this context, increasing the CN by using CNI was likely to reduce the auto-ignition delay, hence the premixed flame, hence the NO

x emissions. The modern vehicles in this study would systematically apply multiple injection regimes, primarily to control the auto-ignition delay with pilot injections, and may be less sensitive to CN for the control of the premixed flame, hence less sensitive to CNI for NO

x emissions.

The B30 and B30+CNI fuels produced similar results in most cases, only differing in two cases: where B30+CNI increased N2O in the Euro VI WHVC tests compared to LD B5 also leading to an overall higher GHG total emission and where B30+CNI reduced PM in the Euro V TfL UIP tests. Both B30 and B30+CNI reduced CO in the TfL UIP and HC in both cycles in the Euro V vehicle relative to LD B5. As was the case for the low-density hydrocarbon fuels, more fuel effects were observed in emissions relevant to local air quality in the Euro V vehicle.

Overall, it appeared that test cycle influenced the detection of fuel effects in some cases, with effects on PM and CO being more readily detected in the TfL UIP cycle than in the WHVC cycle despite similar directional trends, with improved repeatability in the UIP test along with higher absolute emission values. The TfL UIP cycle represents congested urban driving, where pollutant emissions are most relevant and so it is fitting to appraise fuel effects using this cycle. It was also apparent that vehicle technology impacted the detection of fuel effects, for example, in the cases of PM, CO and HC where the low absolute tailpipe levels from the Euro VI vehicle would make detecting fuel differences unfeasible and in the case of NOx where closed loop control of tailpipe emissions compensated for fuel effects on engine-out emissions.