4.1. Modeling Premise

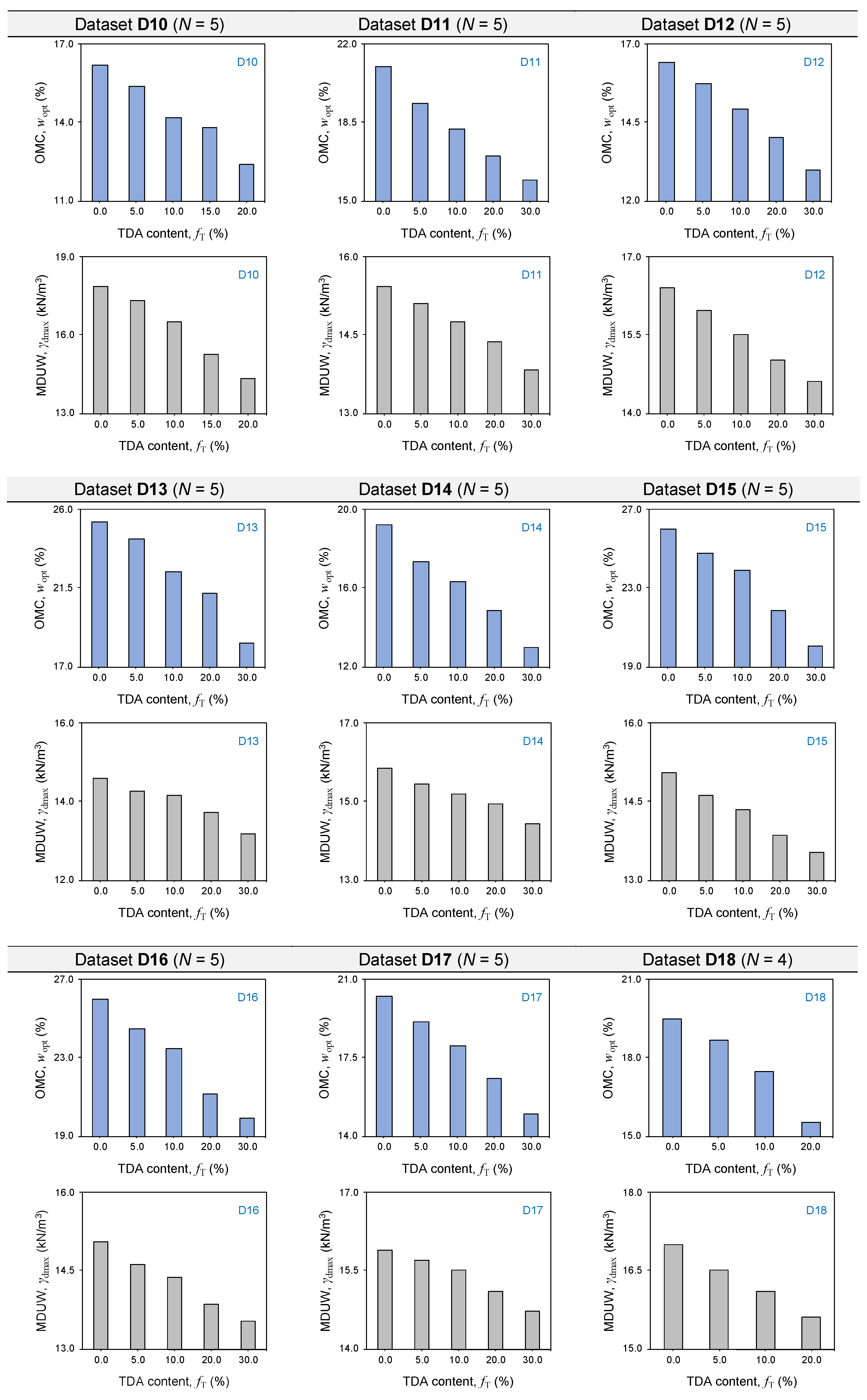

Following a comprehensive trial-and-error investigation employing the 21 soil–TDA compaction datasets (see

Table A1 and

Figure A1), it was observed that, for a given fine-grained soil mixed with a particular TDA material (constant particle size/shape), the conventional OMC and MDUW parameters (for the standard or modified Proctor energy level) can be expressed as follows:

where

and

= conventional OMC and MDUW for the soil–TDA mixture, respectively;

and

= intercept parameters for

fT = 0 (in % and kN/m

3, respectively); and

βM and

βD = reduction rate parameters (both < 0).

The dependent/input variable

/

selected for model development captures the combined effects of TDA content and TDA specific gravity; the latter well-established to vary (i.e., 0.85–1.14 for the present investigation, as outlined in

Table 2) depending on the source-tire composition, the adopted tire recycling process, and the TDA particle size/shape [

24,

26]. The intercept parameters

and

represent the OMC and MDUW of the unamended soil, since setting

fT = 0 in Equation (3) results in

=

. Note that these intercept parameters can be either fixed based on measured values or set as independent fitting parameters. Further, since the soil–TDA mixture specific gravity decreases with increasing the TDA content (i.e.,

fT−1 and hence

/

fT; see

Table A1), the parameters

βM and

βD (which are both negative) represent the rates of reduction in the OMC and MDUW, respectively, in relation to increasing the TDA content.

It should be mentioned that the trial-and-error investigation performed by the authors and leading to the proposal of Equations (4) and (5) involved applying various functional expressions (i.e., linear, logarithmic, polynomial, exponential and power) to the 21 soil–TDA compaction datasets and then cross-checking their predictive performances using routine fit-measure indices; namely, the mean absolute percentage error (MAPE) and the normalized root-mean-squared error (NRMSE), which were calculated as follows [

46]:

where RMSE = root-mean-squared error (in the same unit as OMC or MDUW);

yn = measured variable (OMC or MDUW);

= predicted variable (OMC or MDUW);

= arithmetic mean of

yn data; and

N = number of observations (or compaction tests) in each dataset, as reported in

Table 1.

The regression analysis outputs with respect to Equations (4) and (5) (with

and

set as independent fitting parameters) are presented in

Table 3 and

Table 4, respectively. Judging by the high R

2 (with median values of 0.989 and 0.987 for the OMC and MDUW predictions, respectively) and the low MAPE or NRMSE (unanimously less than 4%) values, the functional expressions proposed in Equations (4) and (5) can be deemed acceptable. Quite clearly, to employ Equations (4) and (5) for routine prediction purposes, the fitting parameters

βM and

βD should be calibrated. In view of their definitions, the intercept parameters

and

can be simply fixed based on the measured OMC and MDUW of the unamended soil (

fT = 0). Provided that the reduction rate parameters

βM and

βD can be practically calibrated without the need for obtaining any specific soil–TDA compaction test data, it would follow that, having established the OMC and MDUW of an unamended fine-grained soil (along with the soil and TDA specific gravities; the latter often provided by the TDA manufacturer), one can predict the OMC and MDUW of the same soil mixed with any specified TDA content. The following sections describe practical calibration frameworks for obtaining

βM and

βD.

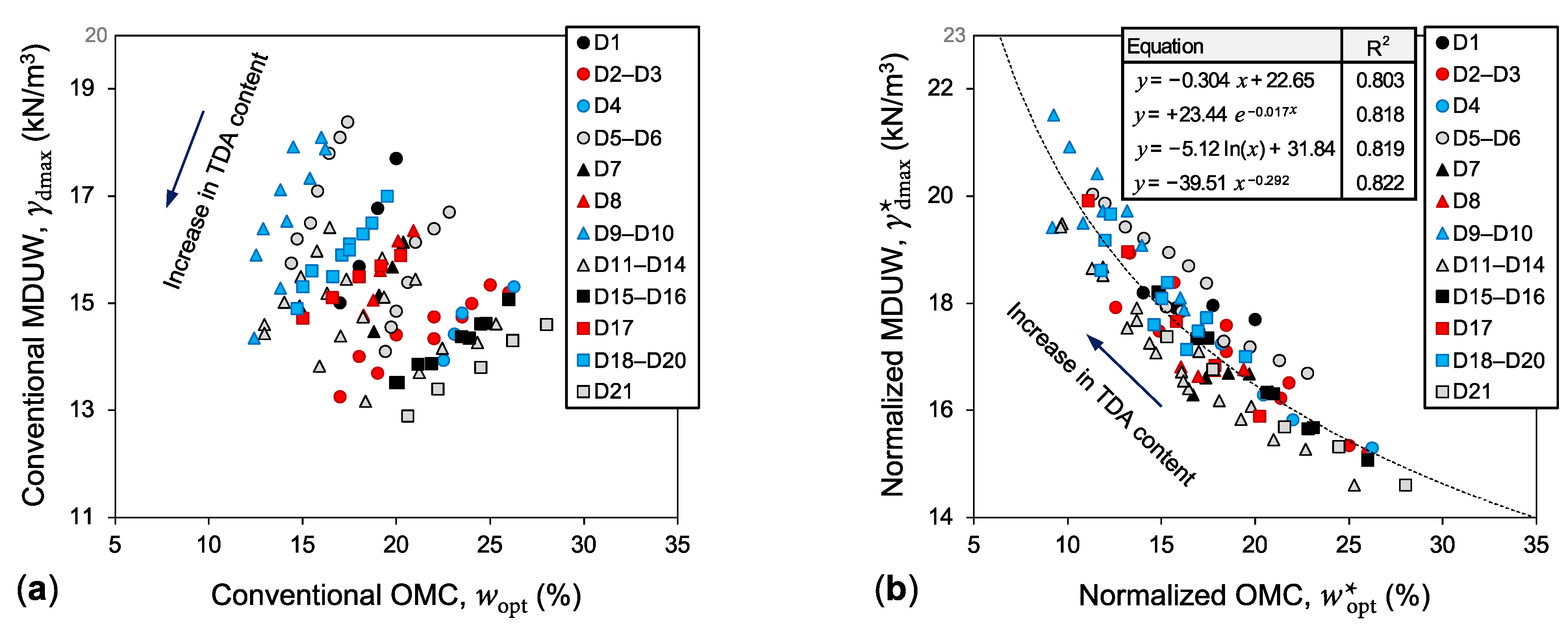

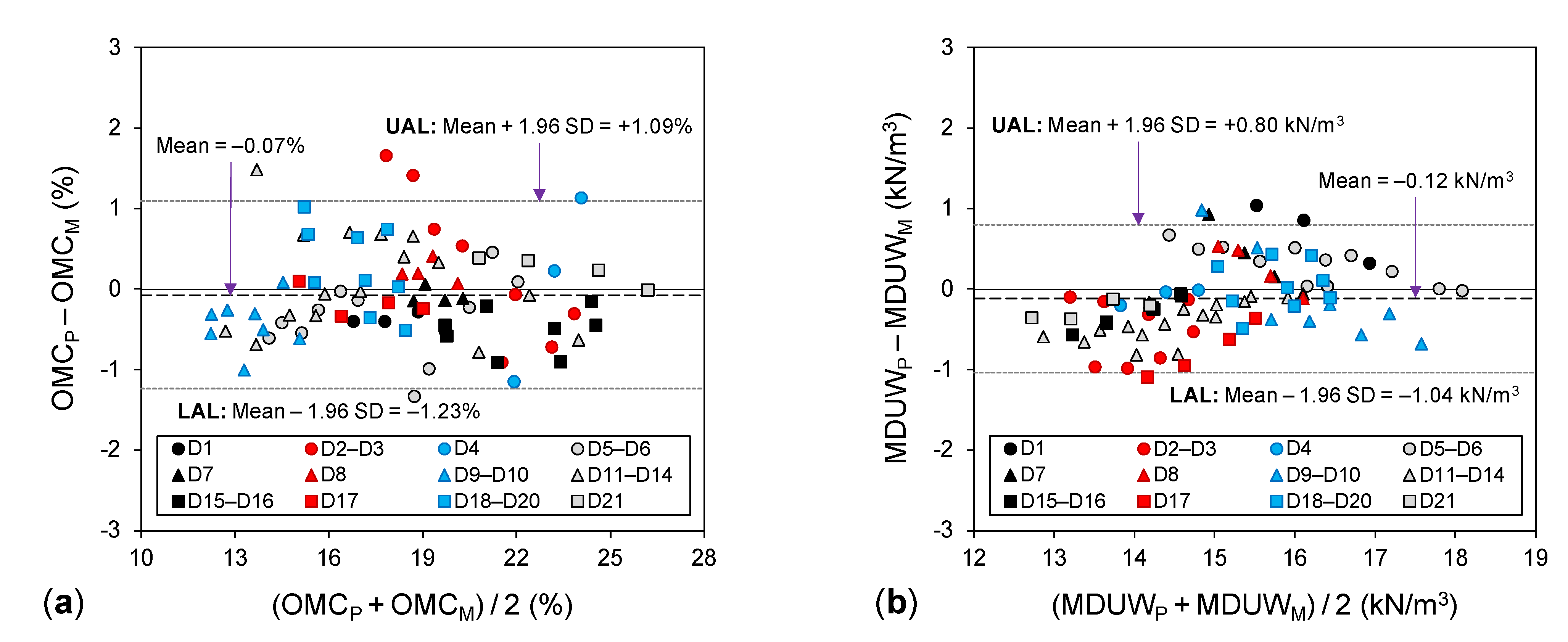

4.2. Predictive Models Employing Mean Reduction Rate Parameters

Figure 2a,b illustrates the variations of

βM and

βD for the 21 soil–TDA compaction datasets, respectively. In terms of absolute magnitude,

βM was found to be consistently greater than its

βD counterpart, indicating that the rate of OMC reduction with respect to increasing TDA content is greater than that of the MDUW. Judging by the low standard deviation (SD) for

βM and

βD (computed as 0.187 and 0.218, respectively), as well as the relatively small vertical distance between their upper and lower variation boundaries (see ‘UB’ and ‘LB’ in

Figure 2), it may be possible to achieve reliable OMC and MDUW predictions (across different fine-grained soil types, TDA particle sizes/shapes and compaction energy levels) by adopting mean values for the

βM and

βD parameters. To examine this hypothesis, the arithmetic means for the 21

βM and

βD values were calculated (i.e.,

= −0.967 and

= −0.509, as outlined in

Figure 2), and appointed to Equations (4) and (5), resulting in the following new relationships:

Scatter plots illustrating the variations of predicted (by Equations (9) and (10)) against measured OMC and MDUW values are presented in

Figure 3a,b, respectively. As is evident from these figures, the predicted and measured values, particularly for the OMC, are strongly correlated with each other. The R

2, MAPE and NRMSE associated with these predictions were, respectively, calculated as 0.970, 2.7% and 3.2% for the OMC, and 0.908, 2.6% and 3.2% for the MDUW.

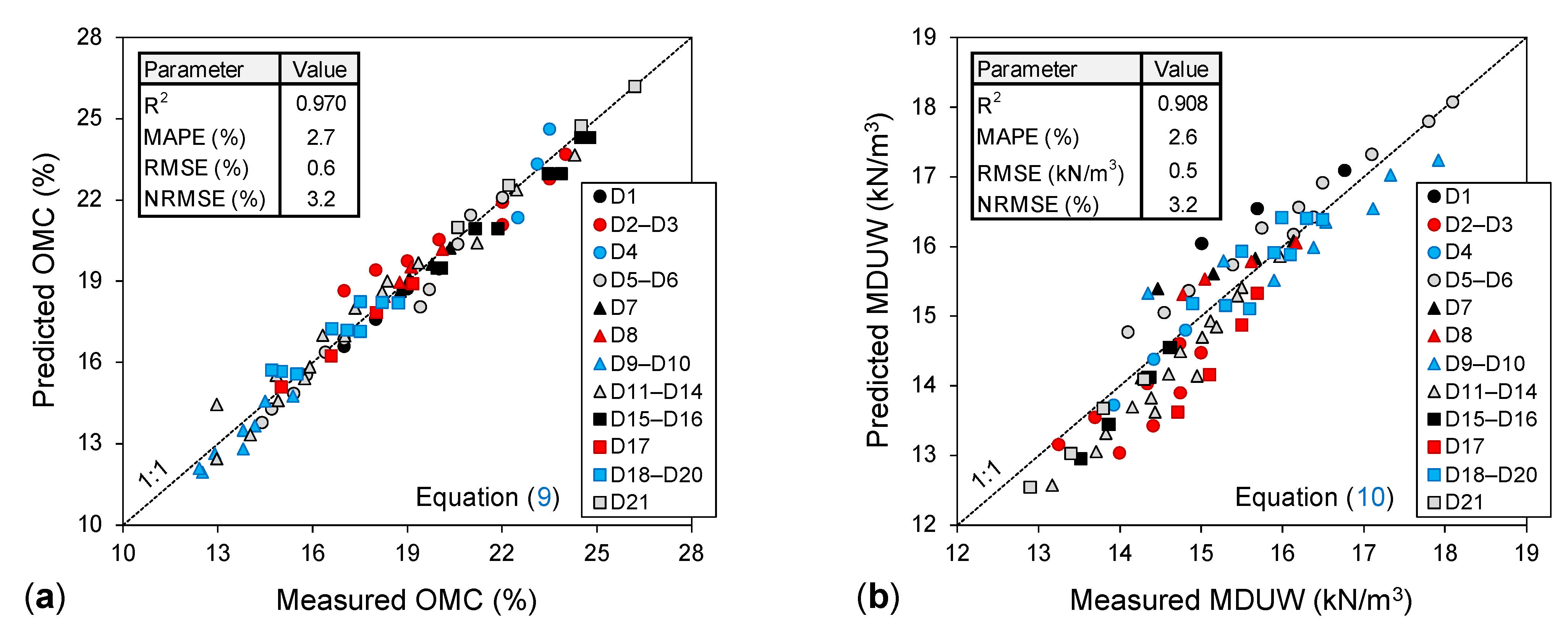

The excellent graphical correlation (high R

2), together with the low MAPE or NRMSE values, obtained for Equations (9) and (10) would normally lead to corroborating their predictive capability. However, a critical examination of the prediction residuals should also be performed to better perceive the true implications of these predictions for routine geotechnical engineering applications [

47]. This can be achieved by quantifying and critically examining the statistical ‘limits of agreement’ between the predicted and measured values, which was conducted using the Bland–Altman (BA) analysis [

48]. The BA analysis involves developing a scatter plot with the

y-axis representing the difference between the two compared variables (e.g., OMC

P − OMC

M, where the subscripts ‘P’ and ‘M’ denote predicted and measured variables, respectively) and the

x-axis showing the average of these variables (e.g., [OMC

P + OMC

M]/2). The 95% upper and lower agreement limits with respect to the BA plot can be, respectively, quantified as UAL = Mean + 1.96 × SD and LAL = Mean − 1.96 × SD (where ‘Mean’ and ‘SD’ are the arithmetic mean and standard deviation of the

y-axis data, respectively).

BA plots for the OMC and MDUW predictions (Equations (9) and (10)) are presented in

Figure 4a,b, respectively. The mean of differences between OMC

P and OMC

M was found to be −0.07%, indicating that the OMC predictions were on average 0.07% (water content) lower than their measured counterparts. The 95% agreement limits between OMC

P and OMC

M were calculated as UAL = +1.09% and LAL = −1.23%, implying that 95% of the predictions made by Equation (9) are associated with errors ranging between these two water content limits, both of which can be considered negligible for practical applications. As for the MDUW (see

Figure 4b), the mean of differences, UAL and LAL were obtained as −0.12, +0.80 and −1.04 kN/m

3, respectively. Taking into account the nature of the MDUW parameter and its variations across different fine-grained soil types and also with standard and modified compaction energy levels (these variations being relatively smaller compared with that of the OMC [

27,

31,

33]), the errors associated with Equation (10), though practically acceptable, may require further improvement. Alternatively, having predicted the OMC by Equation (9), the corresponding MDUW can be estimated with more accuracy through a practical single-point compaction test (performed at the predicted OMC).

4.3. Prediction Models Employing Empirical Reduction Rate Parameters

The authors postulate that the reduction rate parameters

βM and

βD may be systematically related to basic soil properties (namely those listed in

Table 1). Accordingly, attempts were made to explore the existence of potential links/correlations between these fitting parameters and other parameters reflective of the soil gradation, plasticity and mineralogy. Following a comprehensive statistical analysis of the data, no meaningful correlation was found for

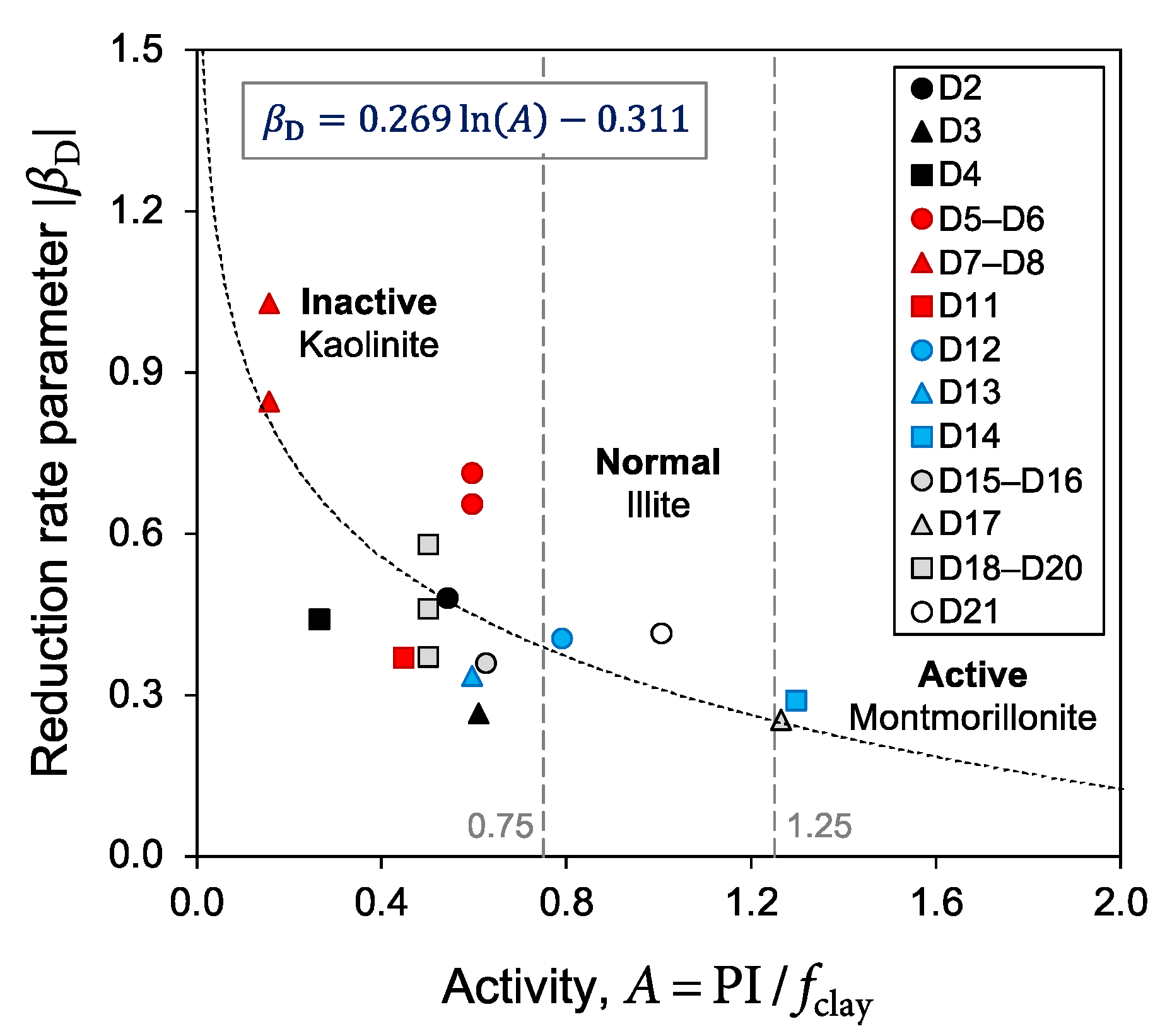

βM. However, it was observed that |

βD| systematically decreases with increasing the soil activity index (i.e., |

βD|

A−1). In other words, as the soil’s principal clay mineral becomes more active (e.g., kaolinite to montmorillonite), the rate of reduction in the MDUW (with respect to increasing TDA content) decreases.

Figure 5 illustrates the variations of |

βD| against the activity index for the compiled database (excluding datasets D1, D9 and D10 for which the clay contents were not reported). As demonstrated in this figure,

βD can be expressed as follows (for

fT ≤ 30%):

Accordingly, substituting Equation (11) into Equation (5) leads to the following new relationship for the MDUW:

Figure 6a illustrates the variations of predicted (by Equation (12)) against measured MDUW values for the compiled database. The R

2, MAPE and NRMSE for these new predictions were calculated as 0.936, 1.8% and 2.3%, respectively; corroborating the predictive capability of the newly proposed Equation (12). The 95% upper and lower agreement limits, as shown in

Figure 6b, were obtained as UAL = +0.67 kN/m

3 and LAL = −0.71 kN/m

3, indicating that 95% of the MDUW predictions are associated with errors ranging between these two small unit weight limits. Note that Equations (10) and (12) were developed based on different dataset sizes (i.e., 21 and 18 datasets, respectively); as such, their predictive performances cannot be directly compared. However, a reliable comparison can be performed if the R

2, MAPE, NRMSE, UAL and LAL parameters for Equation (10) are recalculated based on the same 18 datasets (i.e., D2–D8 and D11–D21) used for the development of Equation (12). The outcome of this recalculation was R

2 = 0.920, MAPE = 2.5%, NRMSE = 3.1%, UAL = +0.69 kN/m

3 and LAL = −1.0 kN/m

3, which appear to work (slightly) in favor of the more elaborate Equation (12). Even so, for prediction purposes, this performance improvement may not be sufficient to justify the use of Equation (12) over the more practical Equation (10); the latter making MDUW predictions without the need for PI and

fclay measurements.

In addition to fundamental soil properties, the authors speculated that

βM and

βD may also be related to other variables, such as the TDA mean particle size (or

D50) and the imparted compaction energy level. Even though the compiled database did not permit a critical investigation of these variables to be performed (i.e., since only a small number of the database soils included compaction results for varying

D50 and/or compaction energy levels), it is considered that both

D50 and compaction energy would likely have minor effects on

βM and

βD. As mentioned in

Section 4.1, for predominantly sand-sized TDA materials (0.075–4.75 mm), changes in the TDA mean particle size is normally reflected in the TDA specific gravity [

24,

26]. In other words, the dependent/input variable

/

not only captures the combined effects of TDA content and TDA density, but it is also expected to account, at least in part, for changes in the TDA mean particle size. Moreover, a review of the admittedly limited literature (including those listed in

Table 1 and

Table 2) indicates that, for TDA materials (i.e., powder, crumbs and buffings) having the same specific gravity but different

D50 values, the variations in OMC and MDUW across the two TDA sizes are relatively small.

The elastic-rebound recovery exhibited by TDA particles in compacted soil–TDA mixtures has been reported to increase with increasing the compactive effort. In other words, the higher the imparted compaction energy level (from standard to modified Proctor), the lower the compaction efficiency of the soil–TDA matrix [

25,

41]. This may explain the limited soil–TDA compaction data reported for the modified (heavy) Proctor energy level (accounting for only four of the twenty-one cases listed in

Table 1 and

Table 2). In view of this mechanism, it is speculated that the beneficial effects of compaction energy increase (from standard to modified Proctor) would likely be offset by the TDA material’s increased energy dissipation potential, allowing one to postulate that the reduction rate parameters, particularly

βD, may not be significantly influenced by compactive effort. As such, the modeling framework proposed in this investigation allocates similar OMC and MDUW reduction rates for standard and modified compaction energy levels. Given that the bulk of the compiled database used for model development consisted of standard Proctor compaction data (17 datasets out of 21 examined), the predictions made for modified Proctor should be taken with some caution. Nevertheless, a systematically controlled test program involving a variety of TDA particle sizes and a range of compaction energy levels should be performed with the dual aims of checking the above postulations and potentially developing improved empirical correlations for the reduction rate parameters

βM and

βD.