Why Is the Construction Industry Killing More Workers Than the Offshore Petroleum Industry in Occupational Accidents?

Abstract

:1. Introduction

Theoretical Framework

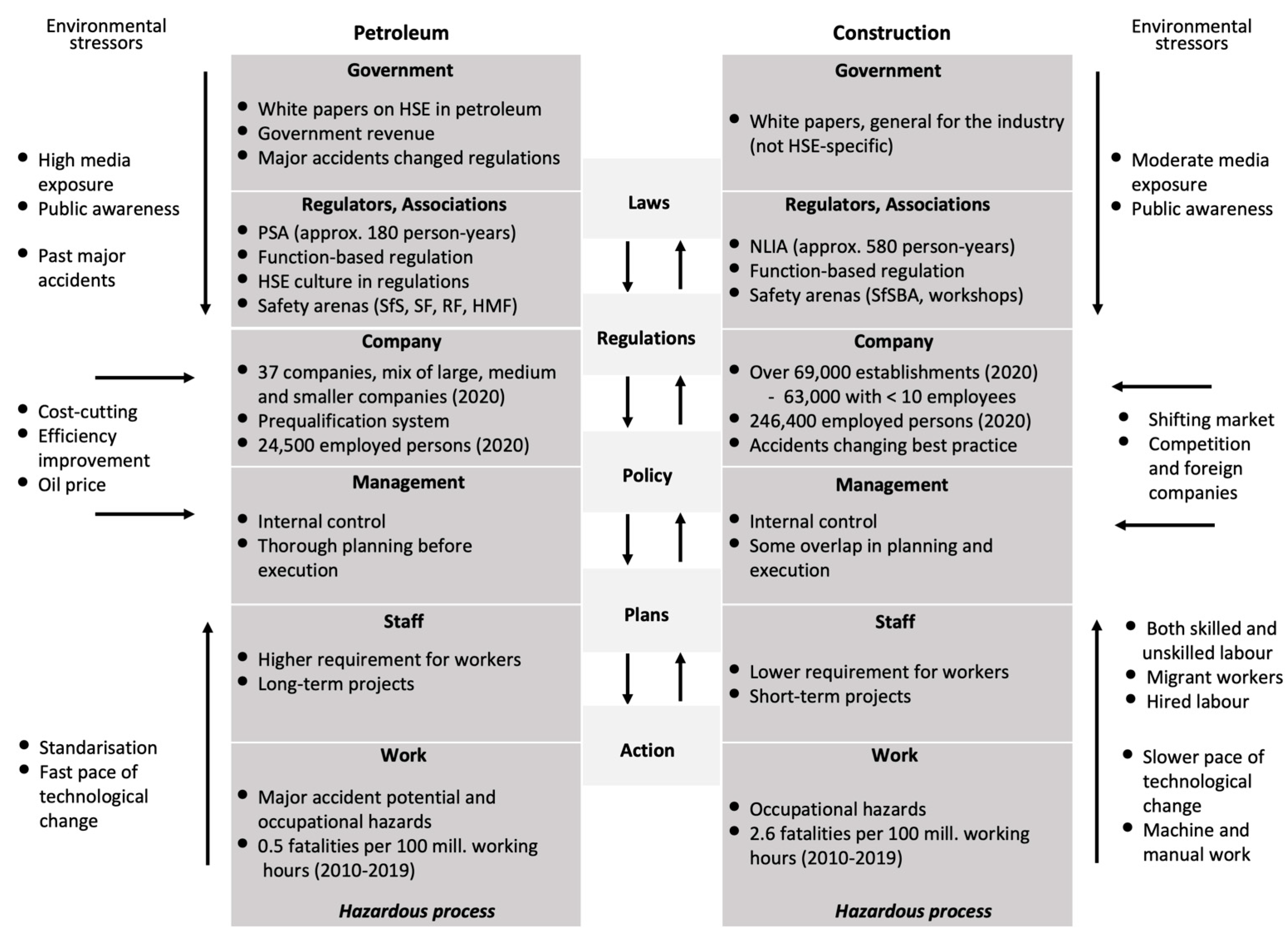

2. Characteristics and Framework Conditions of the Two Norwegian Industries

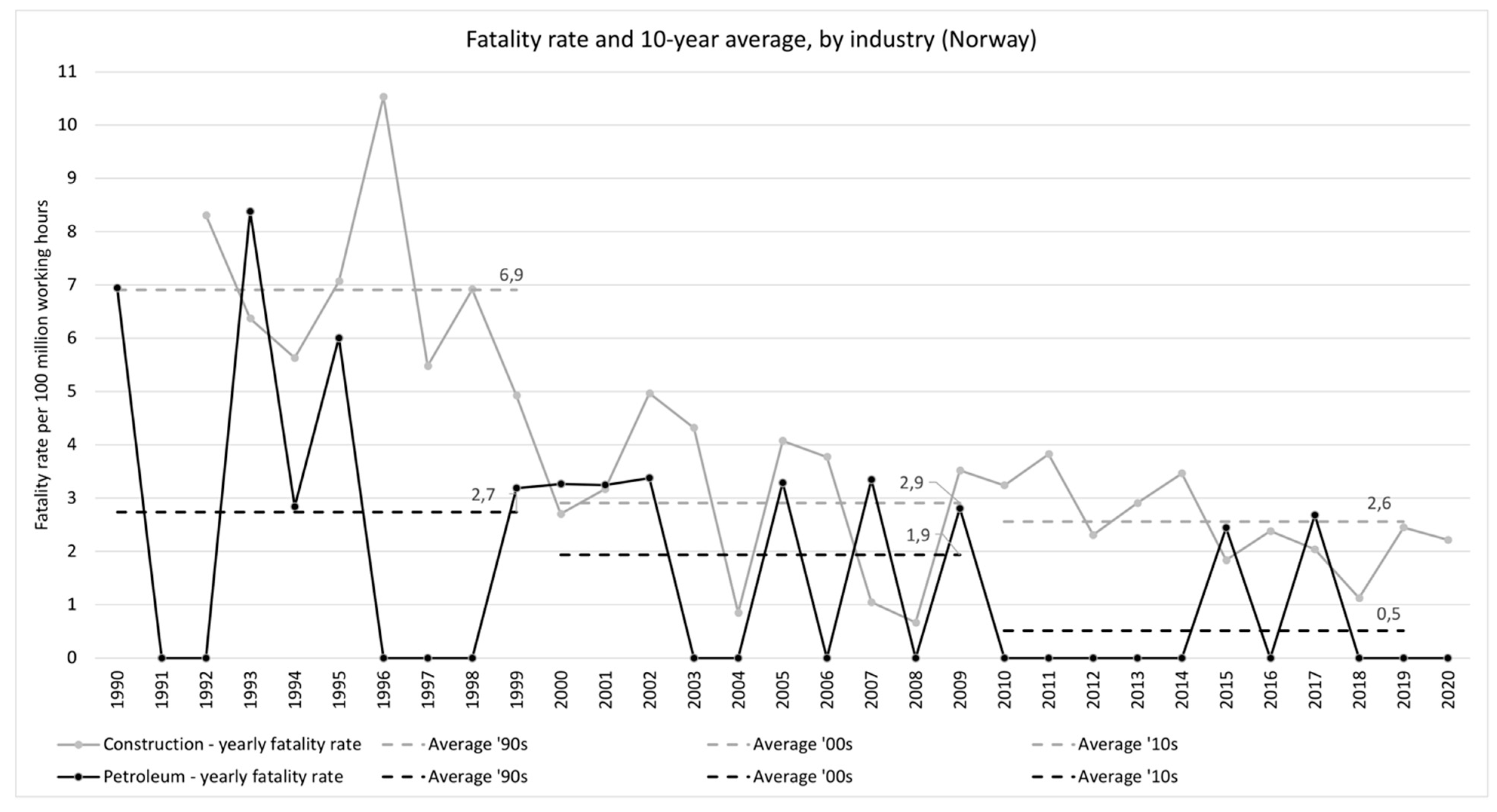

2.1. Accident Numbers

2.2. Work Characteristics

2.3. Regulators and Regulations

2.4. Environmental Stressors and Trends

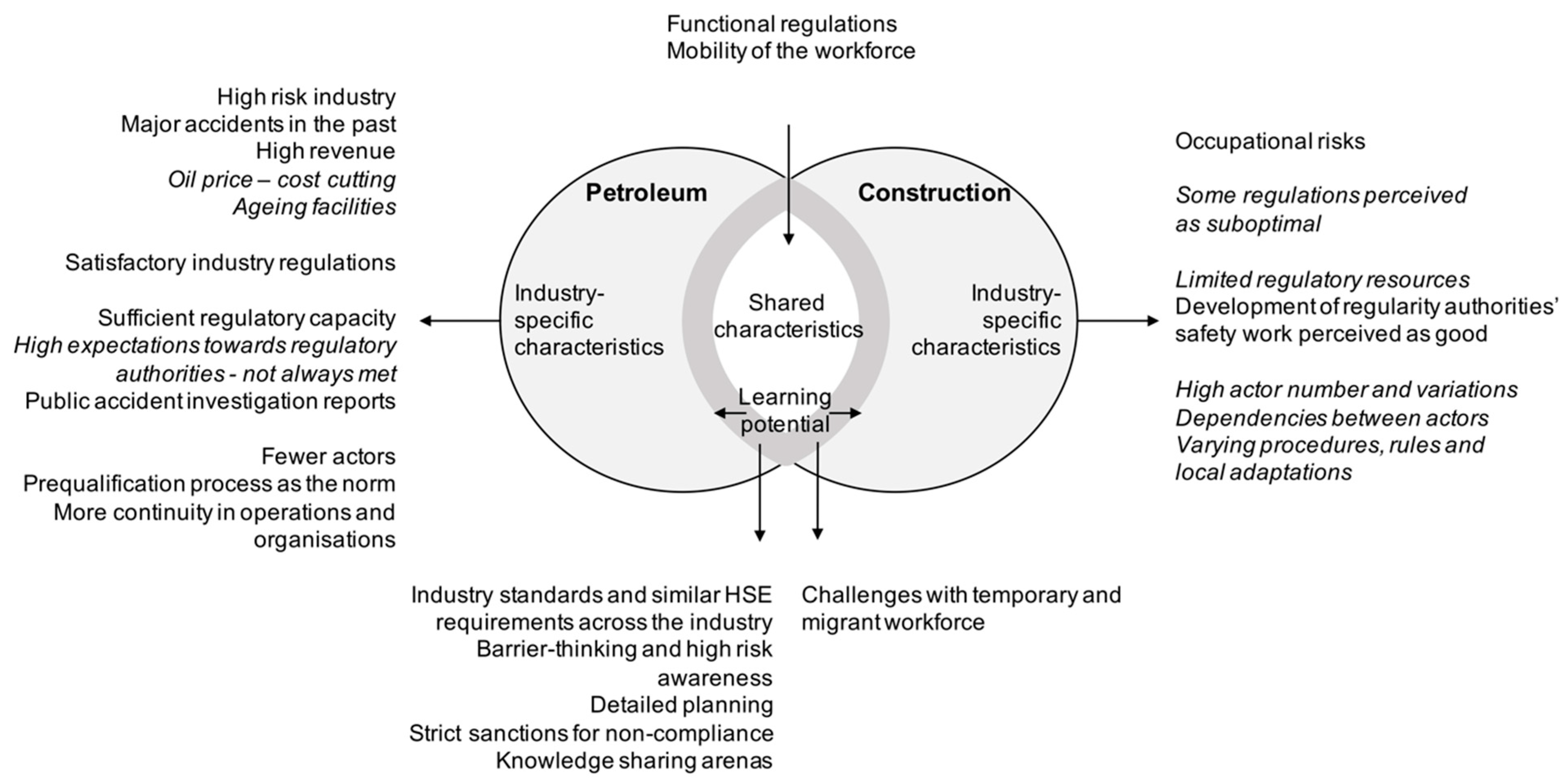

2.5. Summing Up Characteristics of the Two Industries

3. Materials and Methods

3.1. Data Collection and Analysis

3.2. Delimitations and Limitations

4. Results

4.1. The Safety Level in the Norwegian Petroleum and Construction Industries

4.2. Safety Influences from Different Actors

4.2.1. Government

4.2.2. Regulators and Associations

“They [PSA] are professionally good. […] They always come with some improvement points. We do not always agree with each other, but I find that the PSA helps to keep up the standard. They help to make us good. They are important to the industry, I think.”(Manager, Petroleum)

“If you look at the NLIA, they have stopped 50 workplaces in one year. The PSA has in the last 20 years barely stopped anything.”(Employee and employer organisation, Petroleum)

“It is the mainstay of the Norwegian industry—it [the tripartite collaboration] is seen as a success factor. But the truth is that we feel it has become more and more challenged. They want us not to have so much influence.”(Employer and employee organisation, Petroleum)

4.2.3. Company Level

“In the petroleum industry similar rules and procedures generally apply. In the construction industry, on the other hand, in my company we have an external HSE towards the contractor and so on, and an internal towards our own employees.”(Safety-responsible, Construction)

4.2.4. Management

“Something that characterises the construction industry is that there are no stable manger-employee relations.”(Manager, Construction)

4.2.5. Staff and Work

“I see a development where more and more unskilled workers are coming from Eastern Europe who are willing to do the job on conditions which Norwegians cannot live off. […] If we can’t turn this around and change this, then we will end up in a few years with the same conditions as they have in the construction industry.”(Employee, Petroleum)

4.3. Influences between the Industries

“At the end of the 1980s I would say a clear improvement happened, more systematising and routines for HSE. This happened in the contracting companies, and the reason was that the large contractors were getting building orders from the oil companies. The oil companies had requirements for systems and routines, which the construction contractors did not really have. So, the part of the construction industry that worked with the petroleum industry developed and improved HSE in construction.”(Employer and employee organisation, Construction)

“After the oil crisis we got many persons from petroleum. […] They may have many good systems for reporting, but they have never been in construction. […] Some think you can transfer everything one to one, but that does not work. We need to think what to do differently, not just copy.”(Manager, Construction)

5. Discussion

5.1. Development of Safety Work in the Two Industries

5.1.1. Major Accident Risk Prevention as a Driving Factor

5.1.2. Regulatory Resources and Tripartite Collaboration

5.1.3. Wide Range of Actors

5.1.4. Ensuring Continuous Improvement

5.2. Transferable Experiences and Knowledge

5.2.1. Petroleum as a Role Model

5.2.2. Adoption of Practices

5.2.3. Technological Innovations

5.2.4. Experiences from Construction to Petroleum

6. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

References

- SSB. Statistics from STATBANK: 10913: Fatal Accidents at Work, by Regulatory Authority and Industry (SIC2007) 2000–2019. Available online: https://www.ssb.no/en/statbank/table/10913 (accessed on 24 March 2021).

- NPD. Utvikling i Risikonivå-Norsk Sokkel. Pilotprosjektrapport for 2000 [Development of Risk Level—Norwegian Continental Shelf. Pilot Project Report for 2000]; Norwegian Petroleum Directorate: Stavanger, Norway, 2001. Available online: https://www.ptil.no/contentassets/08f11ad6277b4a248358350dc5221c6e/pilotprosjekt---hovedrapport2000.pdf (accessed on 24 March 2021).

- PSA. Risikonivå i Petroleumsvirksomheten. Hovedrapport, Utviklingstrekk 2019, Norsk Sokkel [Risk Level in the Petroleum Activities. Main Report. Development Trends 2019, Norwegian Continental Shelf]; Petroleum Safety Authority Norway: Stavanger, Norway, 2020; Available online: https://www.ptil.no/fagstoff/rnnp/rnnp-2019/hovedrapport/ (accessed on 24 March 2021).

- SSB. Construction etc. 1970–1977; Central Bureau of Statistics: Oslo, Norway, 1979. Available online: https://www.ssb.no/a/histstat/nos/nos_b028.pdf (accessed on 24 March 2021).

- SSB. Statistics from STATBANK: National Accounts. 09174: Wages and Salaries, Employment and Productivity, by Industry 1970–2020. Available online: https://www.ssb.no/en/statbank/table/09174 (accessed on 15 May 2021).

- SSB. Statistical Yearbook (1880–2013) Official Statistics of Norway; Central Bureau of Statistics: Oslo, Norway, 2013. Available online: https://www.ssb.no/a/histstat/aarbok/ (accessed on 11 March 2021).

- Winge, S.; Albrechtsen, E. Accident types and barrier failures in the construction industry. Saf. Sci. 2018, 105, 158–166. [Google Scholar] [CrossRef]

- Gravseth, H.M.; Mostue, B.A.; Winge, S. Ulykker i Bygg og Anlegg—Rapport 2019 [Accidents in Construction—Report 2019]; The Norwegian Labour Inspection Authority: Trondheim, Norway, 2019. Available online: https://arbeidsmandsforbundet.no/wp-content/uploads/2019/11/Ulykker-i-bygg-og-anlegg-Rapport-2019.pdf (accessed on 24 March 2021).

- PSA. Granskning av Hendelse «Mann over Bord med Dødelig Utfall på Saipem 7000 12.08.2007. [Investigation Report of Incidents ’Man Over Board with Fatal Result at Saipem 7000, 12 August 2007]; Petroleum Safety Authority Norway: Stavanger, Norway, 2007. [Google Scholar]

- PSA. Granskingsrapport Etter Ulykken på Oseberg B 7.5.2009 [Accident Investigation after the Accident at Oseberg B 5 May 2009]; Petroleum Safety Authority Norway: Stavanger, Norway, 2009; Available online: https://www.ptil.no/contentassets/d2fe2fb5adaa4e189e33a9b1017de224/granskingsrapport-doedsulykke-oseberg-nettversjon.pdf (accessed on 30 March 2021).

- PSA. Investigation of an Incident with Fatal Consequences on COSLInnovator, 30 December 2015; Petroleum Safety Authority Norway: Stavanger, Norway, 2016; Available online: https://www.ptil.no/contentassets/34ba6b722c0c44a3a137240bae06f623/investigation-report---cosl-drilling---cosl-innovator.pdf (accessed on 30 March 2021).

- NPD. Utvikling i Risikonivå-Norsk Sokkel. Hovedrapport Fase 3-2002 [Development in Risk Level at the Norwegian Continetal Shelf-Main Report Phase 3-2002]; Norwegian Petroleum Directorate: Stavanger, Norway, 2003. Available online: https://www.ptil.no/contentassets/7cb428e084454f7faf909712991e3e7b/risikonivhovedrapport2002.pdf (accessed on 24 March 2021).

- PSA. Investigation Report Following the Fatal Accident on Maersk Interceptor; Petroleum Safety Authority Norway: Stavanger, Norway, 2018; Available online: https://www.ptil.no/contentassets/370f70c8df9547c696172cf82d0bf712/2017_1321_eng-granskingsrapport-tambar-personskade-dodsulykke-maersk-interceptor.pdf (accessed on 30 March 2021).

- Health and Safety Executive. Offshore Statistics & Regulatory Activity Report 2019; Energy Division, Health and Safety Executive: Bootle, Merseyside, UK, 2020. Available online: https://www.hse.gov.uk/offshore/statistics/hsr2019.pdf (accessed on 30 March 2021).

- PSA. Risikonivå i Petroleumsvirksomheten. Hovedrapport, Utviklingstrekk 2020, Norsk Sokkel [Risk Level in the Petroleum Activities. Main Report. Development Trends 2010, Norwegian Continental Shelf]; Petroleum Safety Authority Norway: Stavanger, Norway, 2021; Available online: https://www.ptil.no/fagstoff/rnnp/rnnp-2020/hovedrapport/ (accessed on 24 March 2021).

- Mostue, B.A.; Nyrønning, C.Å.; Winge, S.; Gravseth, H.M. Ulykker i Bygg og Anlegg—Rapport 2020. [Accidents in Construction—Report 2020]; Norwegian Labour Inspection Authority: Trondheim, Norway, 2020. Available online: https://www.arbeidstilsynet.no/globalassets/om-oss/forskning-og-rapporter/kompass-tema-rapporter/2020/kompass-tema_nr2_2020-ulykker-i-bygg-og-anlegg.pdf (accessed on 24 March 2021).

- Høivik, D. HSE and Culture in the Petroleum Industry in Norway. In Proceedings of the SPE International Conference on Health, Safety and Environment in Oil and Gas Exploration and Production, Rio de Janeiro, Brazil, 12–14 April 2010. [Google Scholar] [CrossRef]

- Kjellén, U.; Albrechtsen, E. Prevention of Accidents and Unwanted Occurrences: Theory, Methods, and Tools in Safety Management, 2nd ed.; Taylor & Francis: Abingdon, UK, 2017. [Google Scholar]

- United Nations. Transforming our World: The 2030 Agenda for Sustainable Development; United Nations: New York, NY, USA, 2015; Available online: https://www.un.org/ga/search/view_doc.asp?symbol=A/RES/70/1&Lang=E (accessed on 25 May 2021).

- Osei-Asibey, D.; Ayarkwa, J.; Acheampong, A.; Adinyira, E.; Amoah, P. Impacts of accidents and hazards on the Ghanaian construction industry. Int. J. Constr. Manag. 2021, 1–20. [Google Scholar] [CrossRef]

- Lingard, H.; Wakefield, R.R. Integrating Work Health and Safety into Construction Project Management; Wiley Online Library: Hoboken, NJ, USA, 2019. [Google Scholar]

- Rasmussen, J. Risk management in a dynamic society: A modelling problem. Saf. Sci. 1997, 27, 183–213. [Google Scholar] [CrossRef]

- Rosness, R.; Blakstad, H.C.; Forseth, U.; Dahle, I.B.; Wiig, S. Environmental conditions for safety work—Theoretical foundations. Saf. Sci. 2012, 50, 1967–1976. [Google Scholar] [CrossRef]

- Le Coze, J.-C. Reflecting on Jens Rasmussen’s legacy. A strong program for a hard problem. Saf. Sci. 2015, 71, 123–141. [Google Scholar] [CrossRef]

- Le Coze, J.-C. New models for new times. An anti-dualist move. Saf. Sci. 2013, 59, 200–218. [Google Scholar] [CrossRef]

- Moan, T. Safety of Offshore Structures; CORE Report No. 2005-2004; National University of Singapore: Singapore, 2005. [Google Scholar]

- SSB. Statistics from STATBANK; 10914: Reported Accidents at Work, by Sex, Age, Absence and Industry (SIC2007) 2014–2019. Available online: https://www.ssb.no/en/statbank/table/10914 (accessed on 24 March 2021).

- Ministry of Petroleum and Energy. Norway’s Oil History in 5 Minutes. Available online: www.regjeringen.no/en/topics/energy/oil-and-gas/norways-oil-history-in-5-minutes/id440538/ (accessed on 8 May 2021).

- Vatne, E. Sysselsetting i Petroleumsvirksomhet 2017. Omfang og Lokalisering av Ansatte i Oljeselskap og den Spesialiserte Leveran-DØRINDUSTRIEN. [Employment in the Petroleum Industry 2017]; Centre for Applied Research at NHH: Bergen, Norway, 2018; Available online: https://www.regjeringen.no/contentassets/6cde1d4efca44c67a31c36ef98a1e4e8/r01_18.pdf (accessed on 25 March 2021).

- Norwegian Petroleum. Diversity and Competition. Available online: https://www.norskpetroleum.no/en/developments-and-operations/number-and-diversity-of-companies/ (accessed on 25 March 2021).

- Norwegian Petroleum. The Service and Supply Industry. Available online: https://www.norskpetroleum.no/en/developments-and-operations/service-and-supply-industry/ (accessed on 24 March 2021).

- SSB. Statistics from STATBANK-10309: Establishments, by Activity Codes (SIC2007) and Number of Employees (M) 2009–2021. Available online: https://www.ssb.no/en/statbank/table/10309 (accessed on 24 March 2021).

- Nykamp, H.; Skåholt, A.; Ørstavik, F. Sikkerhet i Komplekse Prosjekter [Safety in Complex Projects]; Nordic Institute for Studies in Innovation, Research and Education (NIFU): Oslo, Norway, 2011; Available online: https://www.nifu.no/publications/866060/ (accessed on 10 March 2021).

- PSA. Årsrapport 2020 [Annual Report 2020]; Petroleum Safety Authority Norway: Stavanger, Norway, 2021; Available online: https://www.ptil.no/fagstoff/utforsk-fagstoff/fagartikler/2021/arsrapport-2020-annerledesaret/ (accessed on 10 May 2021).

- Lindøe, P.H.; Engen, O.A. Offshore Safety Regimes—A Contested Terrain. In The Regulation of Continental Shelf Development; Brill|Nijhoff: Leiden, The Netherlands, 2013; pp. 195–212. [Google Scholar]

- Bang, P.; Thuestad, O. Government-Enforced Self-Regulation The Norwegian Case. In Risk Governance of Offshore Oil and Gas Operations; Baram, M., Renn, O., Lindøe, P.H., Eds.; Cambridge University Press: Cambridge, UK, 2013; pp. 243–273. [Google Scholar]

- NLIA. Årsrapport 2020. En Analyse av Arbeidstilsynets Innsats i 2020 [Annual Report 2020]; Norwegian Labour Inspection Authority: Trondheim, Norway, 2021. Available online: https://www.arbeidstilsynet.no/contentassets/7ec576afb75a45b69f8a74705ebe9c18/arsrapport-2020.pdf (accessed on 10 May 2021).

- NLIA. Arbeidstilsynets Satsing i bygg og Anlegg i Perioden 2013–2016 [The Norwegian Labour Inspection Authority’s Initiative in Construction in the Period 2013–2016]; Norwegian Labour Inspection Authority: Trondheim, Norway, 2017. Available online: https://www.arbeidstilsynet.no/globalassets/om-oss/forskning-og-rapporter/rapporter-fra-tilsynsprosjekter/arbeidstilsynets-satsing-i-bygg-og-anlegg-perioden-2013-2016-2108-2017.pdf (accessed on 24 March 2021).

- Hovden, J. The development of new safety regulations in the Norwegian oil and gas industry. In Changing Regulation: Controlling Risks in Society; Kirwan, B., Hale, A.R., Hopkins, A., Eds.; Elsevier Science Ltd.: Amsterdam, The Netherlands, 2002; pp. 57–78. [Google Scholar]

- Lindøe, P.H.; Engen, O.A.; Olsen, O.E. Responses to accidents in different industrial sectors. Saf. Sci. 2011, 49, 90–97. [Google Scholar] [CrossRef] [Green Version]

- Ryggvik, H. Offshore Safety Regulations in Norway: From Model to Systems in Erosion. NEW Solut. J. Environ. Occup. Health Policy 2000, 10, 67–116. [Google Scholar] [CrossRef] [PubMed]

- Lindøe, P.H.; Baram, M.; Braut, G.S. Empowered agents or empowered agencies? Assessing the risk regulatory regimes in the Norwegian and US offshore oil and gas industry. In Advances in Safety, Reliability and Risk Management, Proceedings of the European Safety and Reliability Conference, ESREL 2011, Troyes, France, 18–22 September 2011; Taylor & Francis Group: London, UK, 2012; pp. 1717–1724. [Google Scholar]

- Petroleum Act. Lov om Petroleumsvirksomhet (Petroleumsloven) (LOV-1996-11-29-72). Ministry of Petroleum and Energy, Oslo, Norway. 1996. Available online: https://lovdata.no/dokument/NL/lov/1996-11-29-72 (accessed on 24 March 2021).

- The Working Environment Act. Lov om Arbeidsmiljø, Arbeidstid og Stillingsvern mv. nr. 62 av 17. Juni 2005. Ministry of Labour and Social Affairs, Oslo, Norway. 2005. Available online: https://lovdata.no/dokument/NL/lov/2005-06-17-62 (accessed on 24 March 2021).

- Framework Regulations. Forskrift om Helse, Miljø og Sikkerhet i Petroleumsvirksomheten og på Enkelte Landanlegg. (FOR-2010-02-12-158). Ministry of Labour and Social Affairs, Oslo, Norway. 2010. Available online: https://lovdata.no/dokument/SF/forskrift/2010-02-12-158 (accessed on 24 March 2021).

- PSA. About the Regulations. Available online: https://www.ptil.no/en/regulations/acts/about-the-regulations/ (accessed on 24 March 2021).

- Ministry of Labour and Social Affairs. St.meld. nr. 7 (2001–2002) Om Helse, Miljø og Sikkerhet i Petroleumsvirksomheten. [Report No. 7 to the Storting (2001–2002). On Health, Environment and Safety in Petroleum Activities]. 2001. Available online: https://www.regjeringen.no/no/dokumenter/stmeld-nr-7-2001-2002-/ (accessed on 24 March 2021).

- Lindøe, P.H.; Laudal, T. Delingen av Oljedirektoratet–et Svar på Målkonflikter i Petroleumsindustrien? [The Division of the Norwegian Petroleum Directorate—A Response to Goal Conflicts in the Petroleum Industry?]; Rogalandsforskning: Stavanger, Norway, 2004; Available online: https://norceresearch.brage.unit.no/norceresearch-xmlui/handle/11250/2649678 (accessed on 25 March 2021).

- PSA. Barrier Memorandum 2017. In Principles for Barrier Management in the Petroleum Industry; Petroleum Safety Authority Norway: Stavanger, Norway, 2017; Available online: https://www.ptil.no/contentassets/43fc402b97e64a7cbabdf91c64b349cb/barriers-memorandum-2017-eng.pdf (accessed on 25 March 2021).

- Internal Control Regulations. Forskrift om Systematisk Helse-, Miljø- og Sikkerhetsarbeid i Virksomheter (Internkontrollforskriten) (FOR-1996-12-06-1127). Ministry of Labour and Social Affairs, Oslo, Norway. 1996. Available online: https://lovdata.no/dokument/SF/forskrift/1996-12-06-1127 (accessed on 24 March 2021).

- Construction Client Regulations. Forskrift om Sikkerhet, Helse og Arbeidsmiljø på Bygge- Eller Anleggsplasser (Byggherreforskriften) (FOR-2009-08-03-1028). Ministry of Labour and Social Affairs, Oslo, Norway. 2009. Available online: https://lovdata.no/dokument/SF/forskrift/2009-08-03-1028 (accessed on 24 March 2021).

- PSA. What Is Tripartite Collaboration? Available online: https://www.ptil.no/en/tripartite-cooperation/responsibility/tripartite-collaboration-explained/ (accessed on 30 March 2021).

- NOROG. Mandate for the Norwegian Oil and Gas Association Network for Safety and Emergency Response Training. Available online: https://www.norskoljeoggass.no/en/operations/mandate (accessed on 30 March 2021).

- SfS. Working Together for Safety. Available online: http://www.samarbeidforsikkerhet.no (accessed on 25 March 2021).

- SfSBA. Fra Charter til SFS BA [From Chater to SFS BA]. Available online: https://sfsba.no/om-oss/fra-charter-til-sfs-ba/ (accessed on 22 May 2021).

- Engen, O.A. Emergent Risk and New Technologies. In Risk Governance of Offshore Oil and Gas Operations; Lindøe, P.H., Baram, M., Renn, O., Eds.; Cambridge University Press: Cambridge, UK, 2015; pp. 340–359. [Google Scholar]

- SSB. Statistics from STATBANK-09170: Production Account and Income Generation, by Industry 1970–2020. Available online: https://www.ssb.no/en/statbank/table/09170 (accessed on 15 May 2021).

- PSA. Risikonivå i Petroleumsvirksomheten. Hovedrapport, Utviklingstrekk 2015, Norsk Sokkel [Risk Level in the Petroleum Activities. Main Report, Development Trends 2015, Norwegian Continental Shelf]; Petroleum Safety Authority Norway: Stavanger, Norway, 2016; Available online: https://www.ptil.no/fagstoff/rnnp/rnnp-2019/eldre-rapporter/rnnp-2015/hovedrapport/ (accessed on 24 March 2021).

- Bygballe, L.E.; Grimsby, G.; Engebretsen, B.E.; Reve, T. En Verdiskapende Bygg-, Anlegg- og Eiendomsnæring (BAE): Oppdatering 2019 [A Value Creating Construction Industry]; Centre for Construction Industry, Department of Strategy and Entrepreneurship, BI Norwegian Business School: Oslo, Norway, 2019; Available online: https://biopen.bi.no/bi-xmlui/handle/11250/2629396 (accessed on 30 March 2021).

- Andersen, R.K.; Jordfald, B. Arbeidstakere i Byggenæringen i 2008 og 2014 [Employees in the Construction Industry in 2008 and 2014]; Fafo: Oslo, Norway, 2016; Available online: https://fafo.no/en/publications/fafo-reports/item/arbeidstakere-i-byggenaeringen-i-2008-og-2014 (accessed on 25 March 2021).

- Skullerud, H.F. SSB Analyse 2019/31: Petroleumsnæringens Økonomiske Utvikling og Framtidsutsikter. Ettermiddagsbyger Eller Væromslag for Norsk Sokkel? [Statistics Norway Analysis 2019/31: The Petroleum Industry’s Economic Development and Future Prospects. Afternoon Showers or Weather Change for the Norwegian Shelf?]. Available online: https://www.ssb.no/energi-og-industri/artikler-og-publikasjoner/ettermiddagsbyger-eller-vaeromslag-for-norsk-sokkel (accessed on 30 March 2021).

- Ministry of Labour and Social Affairs. Meld. St. 12 (2017–2018) Report to the Storting (White Paper)—Health, Safety and Environment in the Petroleum Industry. 2018. Available online: https://www.regjeringen.no/contentassets/258cadcb3cca4e3c87c858fd787e0f75/en-gb/pdfs/stm201720180012000engpdfs.pdf (accessed on 25 March 2021).

- Kongsvik, T.; Albrechtsen, E.; Antonsen, S.; Herrera, I.A.; Hovden, J.; Schiefloe, P.M. Sikkerhet i Arbeidslivet [Safety in Working Life]; Fagbokforlaget: Bergen, Norway, 2018. [Google Scholar]

- Office of the Auditor General. The Office of the Auditor General’s Investigation of the PSA’s Follow-Up of Health, Safety, and Environment in the Petroleum Industry. 2019. Available online: https://www.riksrevisjonen.no/globalassets/reports/en-2018-2019/psafollowup.pdf (accessed on 30 March 2021).

- Renn, O. Risk Governance: Coping with Uncertainty in a Complex World; Earthscan: London, UK, 2008. [Google Scholar]

- Bryman, A. Social Research Methods, 4th ed.; Oxford University Press: Oxford, UK, 2012. [Google Scholar]

- Patton, M.Q. Qualitative Research & Evaluation Methods, 3rd ed.; Sage Publications: Thousand Oaks, CA, USA, 2002. [Google Scholar]

- Strauss, A.; Corbin, J.M. Basics of Qualitative Research: Grounded Theory Procedures and Techniques; Sage Publications, Inc.: Newbury Park, CA, USA, 1990. [Google Scholar]

- Haukelid, K. Theories of (safety) culture revisited—An anthropological approach. Saf. Sci. 2008, 46, 413–426. [Google Scholar] [CrossRef]

- Hudson, P. Applying the lessons of high risk industries to health care. BMJ Qual. Saf. 2003, 12 (Suppl. 1), i7–i12. [Google Scholar] [CrossRef] [PubMed] [Green Version]

- Drottz-Sjöberg, B.-M.; Sjöberg, L. The perception of risks of technology. In Risks in Technological Systems; Grimvall, G., Holmgren, Å., Jacobsson, P., Thedéen, T., Eds.; Springer: New York, NY, USA, 2009; pp. 255–271. [Google Scholar]

- Antonsen, S.; Skarholt, K.; Ringstad, A.J. The role of standardization in safety management—A case study of a major oil & gas company. Saf. Sci. 2012, 50, 2001–2009. [Google Scholar] [CrossRef]

- Milch, V.; Laumann, K. The influence of interorganizational factors on offshore incidents in the Norwegian petroleum industry: Challenges and future directions. Reliab. Eng. Syst. Saf. 2019, 181, 84–96. [Google Scholar] [CrossRef]

- Quinlan, M.; Mayhew, C.; Bohle, P. The Global Expansion of Precarious Employment, Work Disorganization, and Consequences for Occupational Health: A Review of Recent Research. Int. J. Health Serv. 2001, 31, 335–414. [Google Scholar] [CrossRef] [PubMed]

- Mohamed, S.; Chinda, T. System dynamics modelling of construction safety culture. Eng. Constr. Archit. Manag. 2011, 18, 266–281. [Google Scholar] [CrossRef]

- Carrillo, P. Managing knowledge: Lessons from the oil and gas sector. Constr. Manag. Econ. 2004, 22, 631–642. [Google Scholar] [CrossRef]

- Di Maggio, P.J.; Powell, W.W. The iron cage revisited: Institutional isomorphism and collective rationality. Am. Sociol. Rev. 1983, 48, 147–160. [Google Scholar] [CrossRef] [Green Version]

- Albrechtsen, E.; Solberg, I.; Svensli, E. The application and benefits of job safety analysis. Saf. Sci. 2019, 113, 425–437. [Google Scholar] [CrossRef]

| Petroleum Industry | Construction Industry | |

|---|---|---|

| Safety authorities | 3 | 2 |

| Employer and employee organisations | 7 | 3 |

| Top management | 3 | 4 |

| Safety personnel | 5 | 9 |

| Total | 18 | 18 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Edwin, K.W.; Nilsen, M.; Albrechtsen, E. Why Is the Construction Industry Killing More Workers Than the Offshore Petroleum Industry in Occupational Accidents? Sustainability 2021, 13, 7592. https://doi.org/10.3390/su13147592

Edwin KW, Nilsen M, Albrechtsen E. Why Is the Construction Industry Killing More Workers Than the Offshore Petroleum Industry in Occupational Accidents? Sustainability. 2021; 13(14):7592. https://doi.org/10.3390/su13147592

Chicago/Turabian StyleEdwin, Kinga Wasilkiewicz, Marie Nilsen, and Eirik Albrechtsen. 2021. "Why Is the Construction Industry Killing More Workers Than the Offshore Petroleum Industry in Occupational Accidents?" Sustainability 13, no. 14: 7592. https://doi.org/10.3390/su13147592

APA StyleEdwin, K. W., Nilsen, M., & Albrechtsen, E. (2021). Why Is the Construction Industry Killing More Workers Than the Offshore Petroleum Industry in Occupational Accidents? Sustainability, 13(14), 7592. https://doi.org/10.3390/su13147592