Abstract

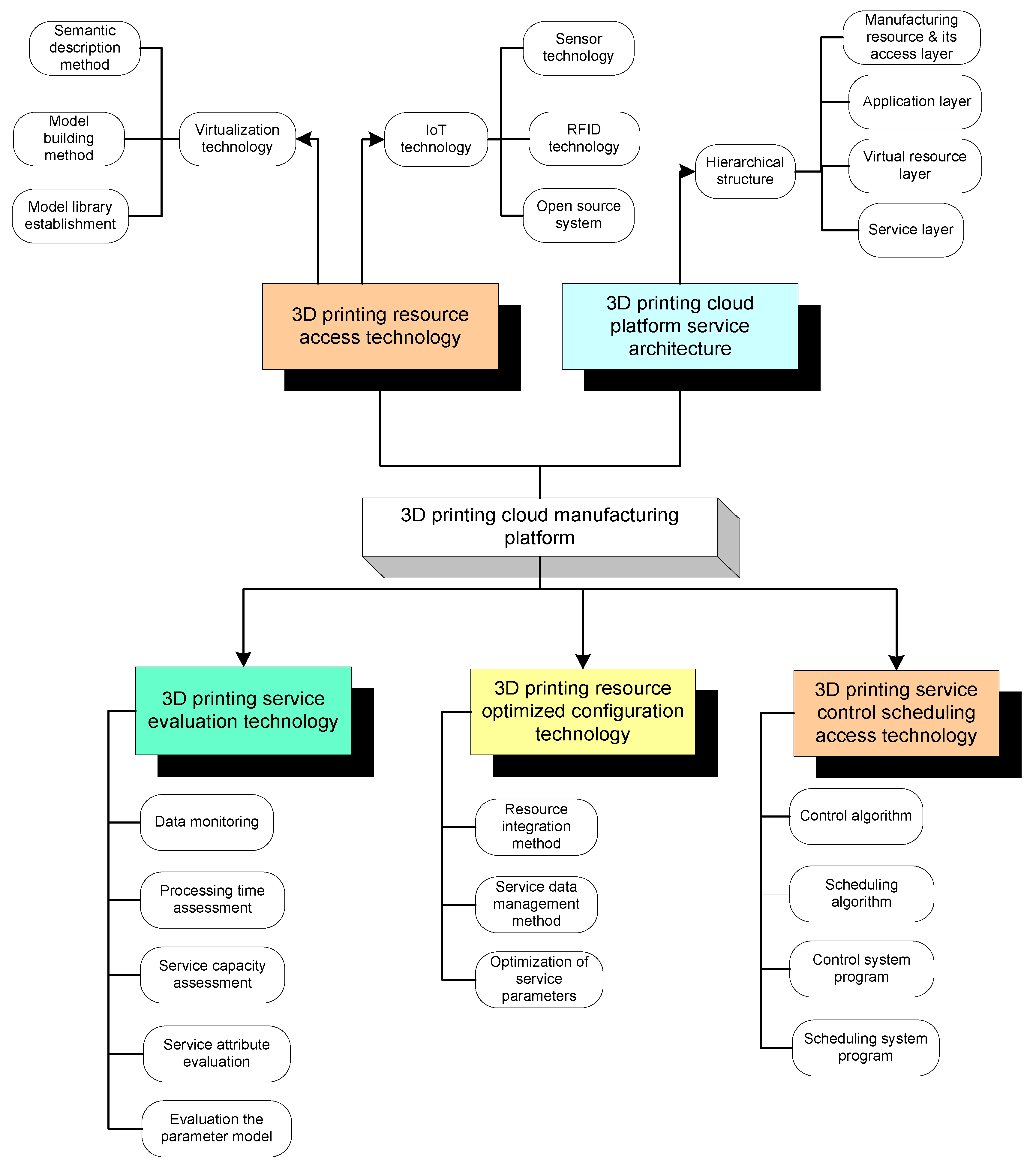

The United Nations (UN) 2030 agenda on sustainable development goals (SDGs) encourages us to implement sustainable infrastructure and services for confronting challenges such as large energy consumption, solid waste generation, depletion of water resources and emission of greenhouse gases in the construction industry. Therefore, to overcome challenges and establishing sustainable construction, there is a requirement to integrate information technology with innovative manufacturing processes and materials science. Moreover, the wide implementation of three-dimensional printing (3DP) technology in constructing monuments, artistic objects, and residential buildings has gained attention. The integration of the Internet of Things (IoT), cloud manufacturing (CM), and 3DP allows us to digitalize the construction for providing reliable and digitalized features to the users. In this review article, we discuss the opportunities and challenges of implementing the IoT, CM, and 3D printing (3DP) technologies in building constructions for achieving sustainability. The recent convergence research of cloud development and 3D printing (3DP) are being explored in the article by categorizing them into multiple sections including 3D printing resource access technology, 3D printing cloud platform (3D–PCP) service architectures, 3D printing service optimized configuration technology, 3D printing service evaluation technology, and 3D service control and monitoring technology. This paper also examines and analyzes the limitations of existing research and, moreover, the article provides key recommendations such as automation with robotics, predictive analytics in 3DP, eco-friendly 3DP, and 5G technology-based IoT-based CM for future enhancements.

1. Introduction

The United Nations has set a target of achieving the sustainable development goals (SDGs) by 2030 in order to establish a sustainable environment [1]. Concerning the construction industry, the SDGs are “Build resilient infrastructure, promote inclusive and sustainable industrialization and foster innovation (SDG 9)”, “Make cities and human settlements inclusive, safe, resilient and sustainable (SDG 11)”, “Ensure sustainable consumption and production patterns” (SDG 12), and “Take urgent action to combat climate change and its impacts (SDG 13)” [2]. Moreover, the construction industry is contributing approximately 13% of the world’s gross domestic product (GDP) [3,4]. As per the United Nations (UN), the construction industry is responsible for 12% of global drinking water consumption, 40% of global energy consumption, 40% of solid waste production, and 28% of global greenhouse gas emissions (GHG) [5,6]. The reports indicate that there is a necessity to implement sustainable technology for reducing the impact on the environment. Generally, in the construction industry, the amount of waste and energy generated is high [7], so with the evolution of 3D printing (3DP), some of the work processed in traditional mechanisms, such as concrete mixing, building blocks, and labor, can be replaced with 3DP. Professionals, government officials, and academics conclude that sustainability in the construction industry is a top priority [8] in dealing with environmental and ecological issues, as well as social, economic, and technological sustainability issues for sustainable development [9]. Therefore, sustainability in construction is typically viewed in terms of the tripartite domains: environment, society, and the economy. Unlike the traditional construction process, 3DP technology has been proven to be an efficient approach in architecture, engineering, and construction (AEC). Moreover, 3DP is of significant assistance in terms of economic development, environmental safety, manpower, time reduction, and customization of the complex architectural designs [10]. At present, 3DP technology (also called additive manufacturing or rapid prototyping) has emerged as a fast-growing technology due to its efficient manufacturing abilities and wide applications in different sectors. This technology creates physical objects by layering the materials based on the digital model [11,12]. As such, 3D printing services are feasible for geometrically complex and small-batch products. Moreover, the necessity for design information in 3DP to be available in a digitized format (.STL file), encourages us to realize digitization more generally. Moreover, the Internet of Things (IoT) and cloud manufacturing (CM) empowers us to implement digitization throughout the 3DP process [13] Additionally, to expand the efficiency of 3DP resource utilization and the variety of 3DP services, a cloud platform has been established [14,15,16]. CM is a modern network manufacturing mechanism that combines manufacturing technology and IT, including cloud computing [17,18] Big Data [19,20], and the IoT. Depending upon the concept of collaboration, intellectualization, materialization, servitization, and virtualization [21], CM provides high-quality, reliable, on-demand and cost-effective services across the network of manufacturing for complete cycle [22]. The most significant aspect of cloud manufacturing is the accumulation and vast exchange of manufacturing tools. Contemporary manufacturing methods require process design from design to machining, but the design of processes does not require standardization and several iterations for the team of design and machining. Complex computing in conventional manufacturing encounters significant challenges in the in-depth research of CM [23].

This article discusses the importance of the integration of 3DP and CM in the construction field. Moreover, research directions and trending applications of 3D printing and CM are summarized. The structure of this paper is as follows: Section 2 covers the overview of construction. Section 3 discusses the brief background of 3D printing. Section 4 addresses 3D concrete printing (3DCP) for sustainability in the construction, with the parameters involved in concrete printing. Section 5 discusses real-time 3D manufacturing. Section 6 presents the integration of CM and 3DP in construction and covers the architecture for 3D printing cloud platform services, the advantages of 3DP and CM for construction, and the cloud printing service system. Section 7 addresses the challenges and also provides recommendations for the extensive implementation of 3DP for construction.

2. Overview of Construction

Construction is a primitive industry that combines extensive equipment with manual work. The rate of building automation is considerably lower than that of other sectors, which ultimately hinders efficiency and establishes risky environments for working. The impact of implementing semi-automated technology in construction has been considered a significant transformation in construction. Steam cylinders, machinery for drilling the piles, hydraulic excavator, bulldozers, conveyors, and pumps are significant semi-automated technology implemented to optimize the workforce with maximum throughput. However, the evolution of new and advanced technologies has encouraged the implementation of vision, mapping, sensing, and localization features to automate construction activities. Predominantly, robots are utilized for different construction activities such as wall construction, cleaning, inspecting, prefabrication and beam assembly, etc. The implementation of robots in the construction industry has led to automation in the industry; however, a few challenges still hinder the progress of this implementation. Generally, in the construction of walls, the precise placement of the brick is necessary. However, the challenge arises to a robot when the orientation and size of the brick need to be changed. Here, the coordination between the human and robot plays a crucial role for effective, widespread implementation of robots in construction.

Moreover, the adoption of robots requires high-end technology which causes costs to increase, so it is not affordable for small- and medium-scale industries. The other challenges of utilizing the robots are the incompatibility of the technologies, the nature of the construction industry, technological usability, technology adoption by workers, resources, and retraining of workers. However, the challenges of working with robots can be overcome with emerging technology, i.e., 3DP, which utilizes a 3D printer for making each block required for the construction of the building.

3. 3D Printing (3DP)

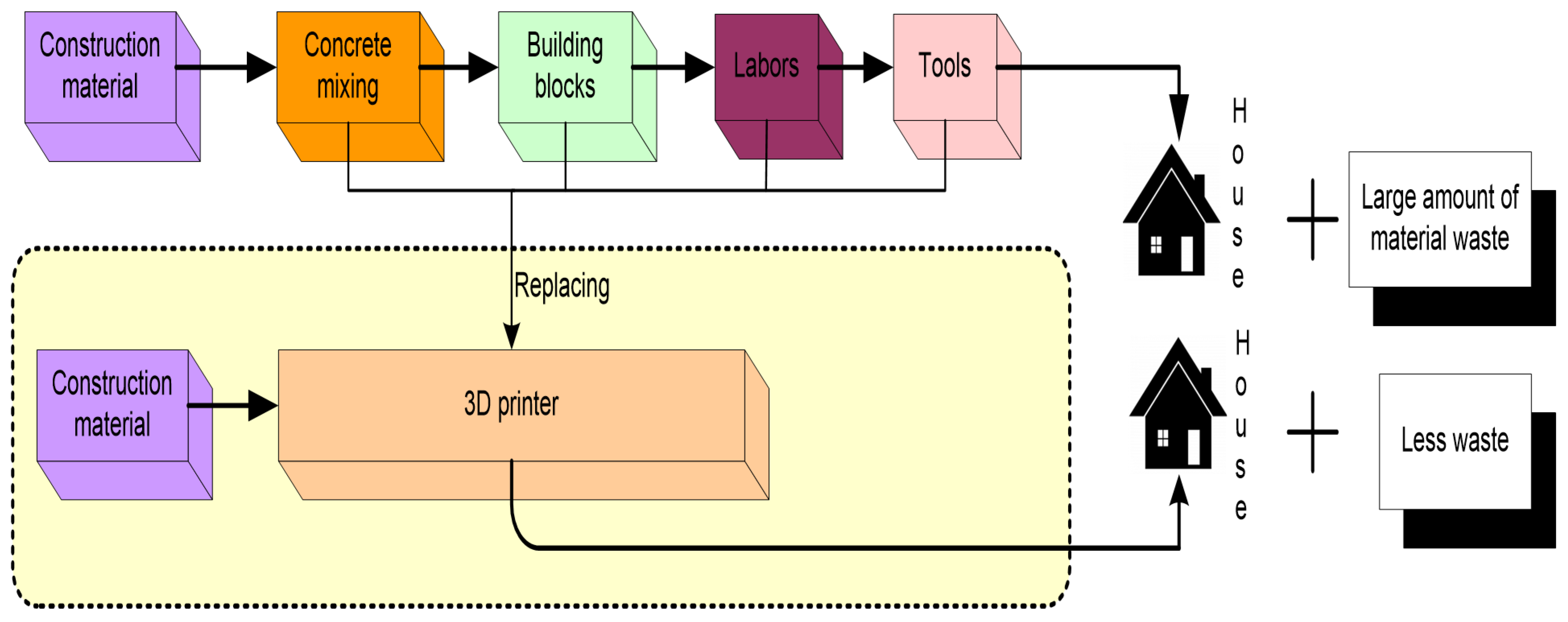

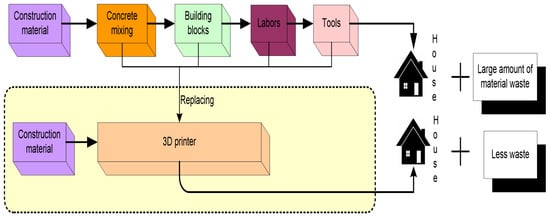

The construction industry requires a technology that could enhance productivity and automation with minimum impact on the environment. At present, the mechanism and method following in the construction industry are generating a large amount of waste that has a considerable effect on the environment and the cost of the projects. Formworks in traditional construction are a major source of expenses due to higher labor costs, machinery, material costs, and waste materials. Generally, forming a basic geometrical configuration during a formwork costs around 35% of the total cost of the project [24]. The productivity of the workforce for formwork faces challenges during the establishment of complex geometrical shapes. The fundamental activities involved in the conventional construction are presented in Figure 1. Given the amount of concrete mixing, the number of blocks is not accurately measured during their construction and, moreover, this requires a skilled workforce and many tools.

Figure 1.

Conventional mechanism vs. 3D printing (3DP) mechanism in construction.

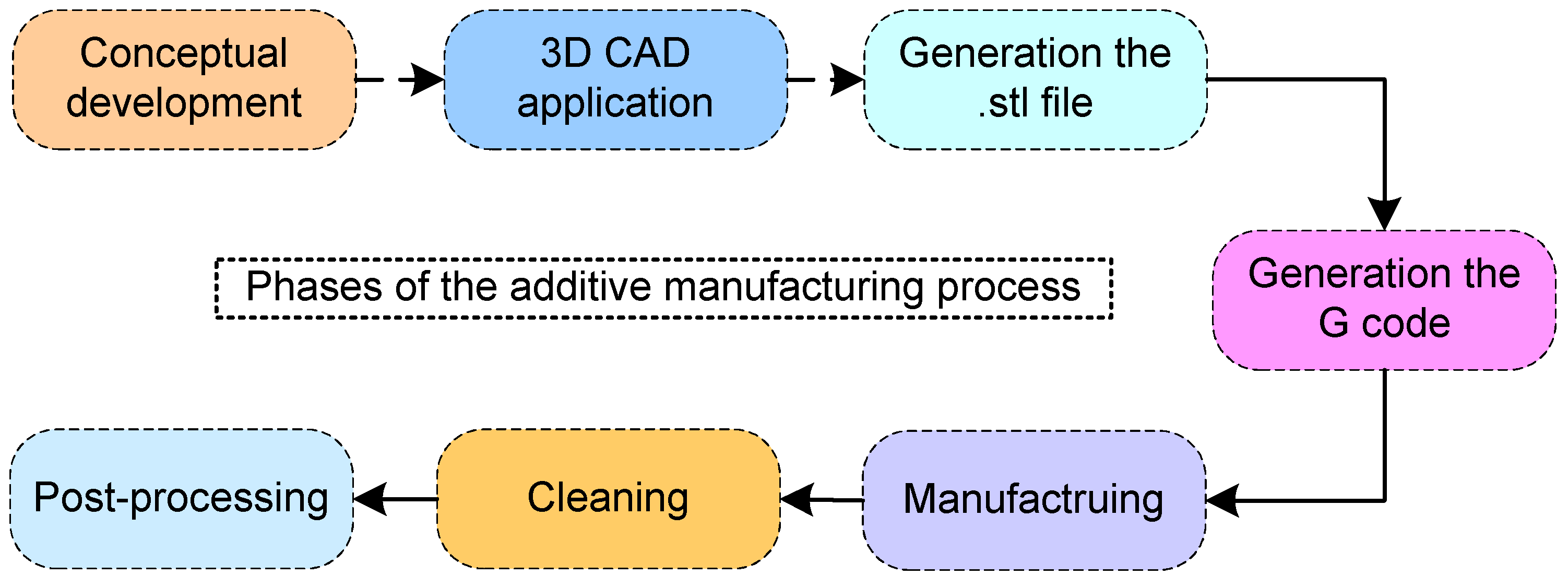

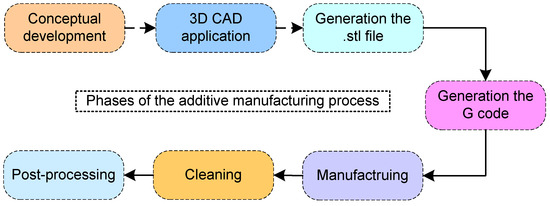

A large amount of the waste is generated due to inaccurate calculation and planning during the construction. The rise of 3D printing technology provides assistance for replacing concrete mixing, building blocks, labor, and tools, as these activities are the primary causes of increases in cost and the generation of large amounts of waste. 3DP technology cuts down the cost of the workforce on the project by 25% [25] and cuts the material cost by 65% compared to conventional construction methods [26] The widespread utilization of the 3DP also enhances the workers’ productivity and safety in high-risk activities. 3DP’s primary reliability rests on printing technologies, material properties, and the expert management of the work [27,28]. A typical feature of the various processes in the additive manufacture is the development of a limited number of steps in the fabrication process for transforming the ‘idea’ from the production to a finished product [29]. Figure 2 illustrates the phases/steps that are involved in the 3DP process. Initially, we need a conceptual model on the 3D CAD application; after that, a .STL file (Standard Triangle Language or Standard Tessellation Language) and G code are generated. After these stages, the manufacturing process is initiated and, in the final stage, cleaning and post-processing will be completed.

Figure 2.

Phases of the 3DP process [27].

3DP technology can be regarded as eco-friendly technology that offers infinite opportunities to realize geometric complexity [30,31]. 3DP can be used in the construction sector to print whole houses or to produce building parts [32,33]. With 3DP, organizations facilitate the following features: quick, inexpensive design and visualization of the virtual building, prevention of delays, and help identifying any problem areas [34]. Simultaneously, 3D printing technology allows construction engineers and their clients to interact more quickly and clearly. Many of a customer’s demands are derived from an idea, and 3D printing makes it easy to manifest the concept beyond the outdated system of paper and pencil [35] Apis Cor Printed House in Russia [36] and Canal House in Amsterdam are two examples of 3D printed houses.

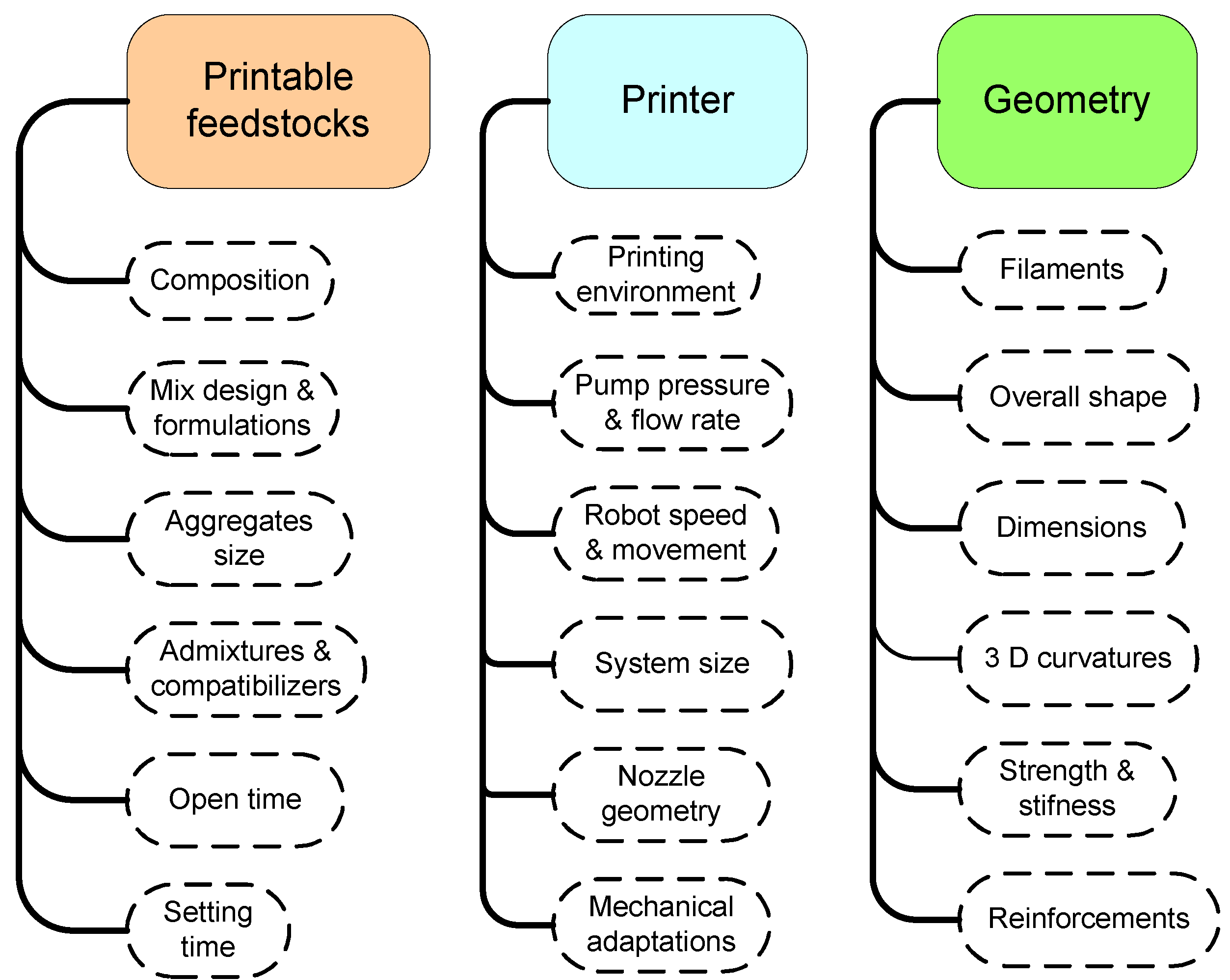

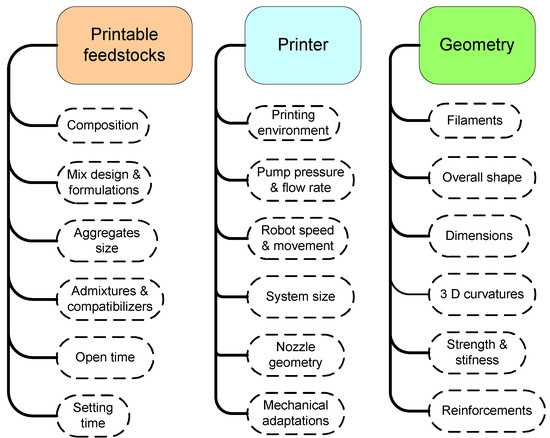

Figure 3 presents the significant interdependency of multiple parameters of 3DP for construction. To effectively enforce 3DP in a large-scale structure, the following are three primary parameters to be discussed.

Figure 3.

Relationship of systematic parameters for large-scale AM implementation in construction.

- (a)

- Printable feedstocks: In the context of the essence of feedstock developments, the source structure, mix model with various additives, and specific size contribute to the effect. To maximize the effectiveness of mixing materials, an accurate opening time and setting time are needed for allowing the continuous extrusion and distribution to the dust. For maximizing the mixing of feedstocks, it is essential to provide the required open period and time to allow continuous extrusion and distribution to the nozzle.

- (b)

- Printer: Pump-integrated printers are essential for the scale of production in the construction industry. The pressure and flow rate must then be examined following the various mixing designs. To obtain a reasonable output, i.e., smooth finish, square edge, and dimensional accuracy, the printer’s speed, and size are also essential. The deposition rate of feedstocks determines construction speed, and the reduction in the setting time will lead to a significant risk of hardness inside the printer system. An integrated printing device should continuously extrude the material with continuous feedstock materials to avoid the interface between the layers.

- (c)

- Geometry: The custom design and the effects of the existing two criteria will be used for specifically applying smart self-reinforced geometry to complete realization of scaling building blocks/objects. The strength and rigidity of the printed object/blocks could then be obtained by the type of stiffness, deposited filaments and 3D curvatures, and truss-like structure [37].

4. 3D Concrete Printing in Sustainable Construction

In this section, the significance of 3D concrete printing for sustainable construction is presented. Moreover, this section also presents the parameters related to 3D concrete printing.

4.1. 3D Concrete Printing (3DCP)

3DCP has been studied more intensively to provide the sustainable construction process with more durability to the buildings, recycling of the printed materials, and also to protect the environment and economy relating to the construction process. A recent study revealed many aspects of sustainability for 3DCP with more focus on extrusion printing [38]. This study discussed the appropriate mix design of the cementitious materials concerning permeability, buildability, materials consistency, flowability, and workability parameters to maintain sustainability. Different reactive and inert mineral additives were trialed in this experiment and evaluated regarding the mechanical properties and their effect on the environment. Significant findings were achieved with the desired modification of material mixes, which can negatively impact the environment without compromising the construction quality [38]. The material plays a crucial role in 3DP for building the building blocks. It is categorized into three distinct categories: green and sustainable materials, functional construction materials, and functionally graded materials. Green and sustainable materials are materials that significantly reduce the impact on the environment.

These materials also support the establishment of a green environment. Furthermore, new building materials such as fiber-reinforced concrete (FRC) and extremely bendable engineered cementitious composite (ECC) can be substituted in place of conventional concrete for sophisticated architecture design while maintaining energy efficiency, resilience, and protection [39]. Furthermore, functional materials such as FRC and ECC can be advantageous for 3D concrete printing because they have higher tensile and flexural strength than standard concrete. These properties are critical for the structural integrity of concrete structures. Due to high complexity and contradictory property requirements, functionally graded materials can be extended to AM [40]. By changing the printing technique, heavy and thicker content can be printed on the ground, and lighter materials can be printed on top of the structure, thereby lowering prices and materials as contrasted with structuring uniformly. At present, large-scale industries are utilizing the following materials for 3DP and they are concrete mix, natural material mix consisting of 25% rice husk, 40% straw chopped rice, 25% soil, and 10% hydraulic lime and concrete mix made up of geopolymer, cement, sand, sand and other additives.

If we look back at the historical perspectives of 3D concrete printing technology, it was developed for the first time with contour crafting by the researchers of South California university [41]. Another team of researchers from Loughborough University worked thoroughly on concrete printing and developed a printing method from the nozzle without troweling blades [42,43,44]. The major issue with 3DCP is the determination of the mix properties. After extrusion, the materials continue to harden, thus enhancing the compressive strength and stiffness over time. One of the parameters called buildability determines the quantity of stress transferred by lower layers due to the printing of subsequent layers over the lower layers. The buildability of the mixture can be determined by calculating the yield stress in rheometric tests; however, unanimous results were not observed by this analysis [45]. Extrusion caulking is an alternative approach for calculating buildability, which is a combination of extrudability and buildability assessment methods.

Moreover, it determines the correlation between the rheological and mechanical properties [46]. The loading of the subsequent layers depends upon the speed of extrusion and other printing parameters. Besides the load-taking capacity and material stiffness, the stability of the constructed structures should also be considered. The stability can be maintained within the range by maintaining the thickness of the deposited materials, or some additives can be mixed with the concrete material to enhance the stiffness.

Another issue presented in the building construction with 3DP is buckling due to self-weight during the printing process, which must be sorted out by choosing the appropriate concrete mix. The printing speed should also be considered as a critical parameter for a successful construction process. If the speed is more than the desired value, there will be a shorter time between the layers, and when the speed is less, the interlayer adhesion will be hampered. The adverse effect on the environment due to the traditional construction practices can be avoided by adopting 3D concrete printing technology. For this purpose, a concrete mix should be designed by the appropriate pathway. Sometimes, high cement content is used in the mixture. Still, it adds to the negative environmental impact and, to avoid this circumstance, mineral additives such as silica fume, fly ash, metakaolin, quartz powder, etc., can be used [47].

Moreover, chemical admixtures like superplasticizers, accelerators, retarders, or viscosity modifying components can be used to gain the required properties of the concrete mix [48]. Again, too many admixtures will add more cost to the concrete mixture. Hence, there should be a proper balance of different components to safeguard the environment without compromising the buildability value.

The compressive strength of the deposited concrete through the 3D printing method can be assessed by measuring the load-bearing capacity by implementing Linear Variable Differential Transformer (LVDT) displacement transducers, force transducers, and related software use [38]. The LVDT is an electromechanical sensor that converts mechanical motion or vibrations, especially rectilinear motion, into a variable electrical current, voltage, or electric signals. This study revealed that longer printing time and increased cycle time enhances the load-bearing capacity. Additionally, the concrete mixes modified with limestone powder showed a tangential rise in compressive strength. The 3D-printing technology is more reliable than the traditional approach of housing constructions in terms of sustainability because of its environmentally friendly executions, more opportunities for recycling of materials, ample possibilities for geometric complexity realizations, less cost and time involvement, minimal injuries on construction site, and minimal pollution to the environment. The contour crafting technique is expected to revolutionize the construction industry in the near future, producing vast opportunities for further progress [10]. One more advantage of 3D printing lies in eliminating the need for formwork, which ultimately decreases the material consumption, the time required for the construction process, labor requirement, impact of materials on the environment, and the cost involved [49] The accessibility of easy printing of the hollow core also provides opportunities for hybrid printing from the 3D printing technique and the conventional method of construction. Both the 3D printing and conventional construction process are comparable when the reinforced structures are developed as both approaches require a manual method of placing reinforcement [50].

Another advantage of 3DP is the continuous printing process with the minimal time required for the cleaning and maintenance protocols. However, time is used to set up, pump calibration, test the materials, and calibrate the printer [51]. Normally, after 45 min of printing, the materials solidify. One more advantage of 3DP technology is the ability to simplify construction logistics and management through shortening of the supply chain [30]. This technology replaces many tools and heavy pieces of equipment required for traditional construction, with the well-designed 3D printer device and a pump that can be transported to anywhere we want.

Moreover, through automation, there is a reduction in transport cost, manpower requirement, food, fuel, and energy consumption. Besides these advantages, the technology has minimal negative environmental impacts due to waste of materials, consumption of energy, and emission of greenhouse gases [52]. The material waste is eliminated as this technology is an additive process, using only the materials required for the structure and eliminating the need for material formwork. Electric printers rely on solar power or a generator for operation. Thus, this equipment can be used in isolated and remote areas, whereas the traditional approach needs more energy consumption, mostly relying on diesel-driven equipment. Additionally, the 3DP process can be driven by locally available resources or recycled materials, so fewer greenhouse gas emissions are associated with the construction technology [50].

4.2. Parameters of Concrete 3D Printing

Some specific parameters are related to scale, support, assembly strategies, and the environment, which are discussed below:

4.2.1. Cementitious Paste Extrusion

A system is required to develop the cementitious paste out of mortar and concrete by continuously flowing out through a moving opening process. Three steps are involved in this process such as mixing, transporting or pumping, and shaping. As with the layered extrusion technique and the slip forming technique, two approaches follow the cementitious paste extrusion process. However, there exists a difference in the extrusion scale, and this value for the layered extrusion technique is 1/1000 of the printed object size, whereas its value is 1/10 in the slip forming technique [53,54].

4.2.2. Extrusion Speed

Another critical parameter of concrete 3DP is the speed of extrusion, which is decided by the speed of the nozzle giving shape to the paste. This parameter is scale-dependent and has a direct link to the behavior of the concrete. As discussed in the last parameter, suppose slip forming extrusion technique is adopted for concrete printing. A large amount of paste is released in a short period through the nozzle; hence, more time is needed for the setting process. For this reason, the speed of the nozzle should be kept slow to the tune of few meters per day in the slip forming technique. However, if the extruding mortar laces around 1 mm, it is preferred to maintain the nozzle speed high and the high flow pumping methods. In this way, precise printing can be done quickly and can be implemented in the building industry.

4.2.3. Automation

Minimum human interference should be there, which will save manpower and expenditure. Robotic systems have tremendous potential in this aspect, and complex robots can be utilized to perform the functions of 3DP technology. The robotic system plays a vital role in the fabrication process in architecture with quality construction and expanded design in building constructions [55]. In housing constructions, robotics can be applied in the nozzles for smoothening, cutting, and handling large-sized or specially designed printed materials. The authors of [56] revealed the use of robotics in the construction industry to efficiently manufacture buildings by 3DP technology. In this study, more focus is given to the engagement of on-site robotics in the construction area. Cable robots are used with the 3D printers with Adobe, whereas drones are applied for real-time observation and monitoring of the construction works. This study revealed the tremendous potential for fusing robotics with 3DP technology for sustainable construction processes on site.

4.2.4. Environment

The printing environment can be of printing directly on-site. It can also be off-site printing with defined environmental conditions (such as temperature, hygrometry, etc.) and assembly of the printed materials in the desired site. The third category can be a prefab factory that imposes handling and transporting the printed materials to the site. On-site printing is categorized under direct printing, whereas the other two categories are indirect printing [57].

5. Real-Time 3D Manufacturing

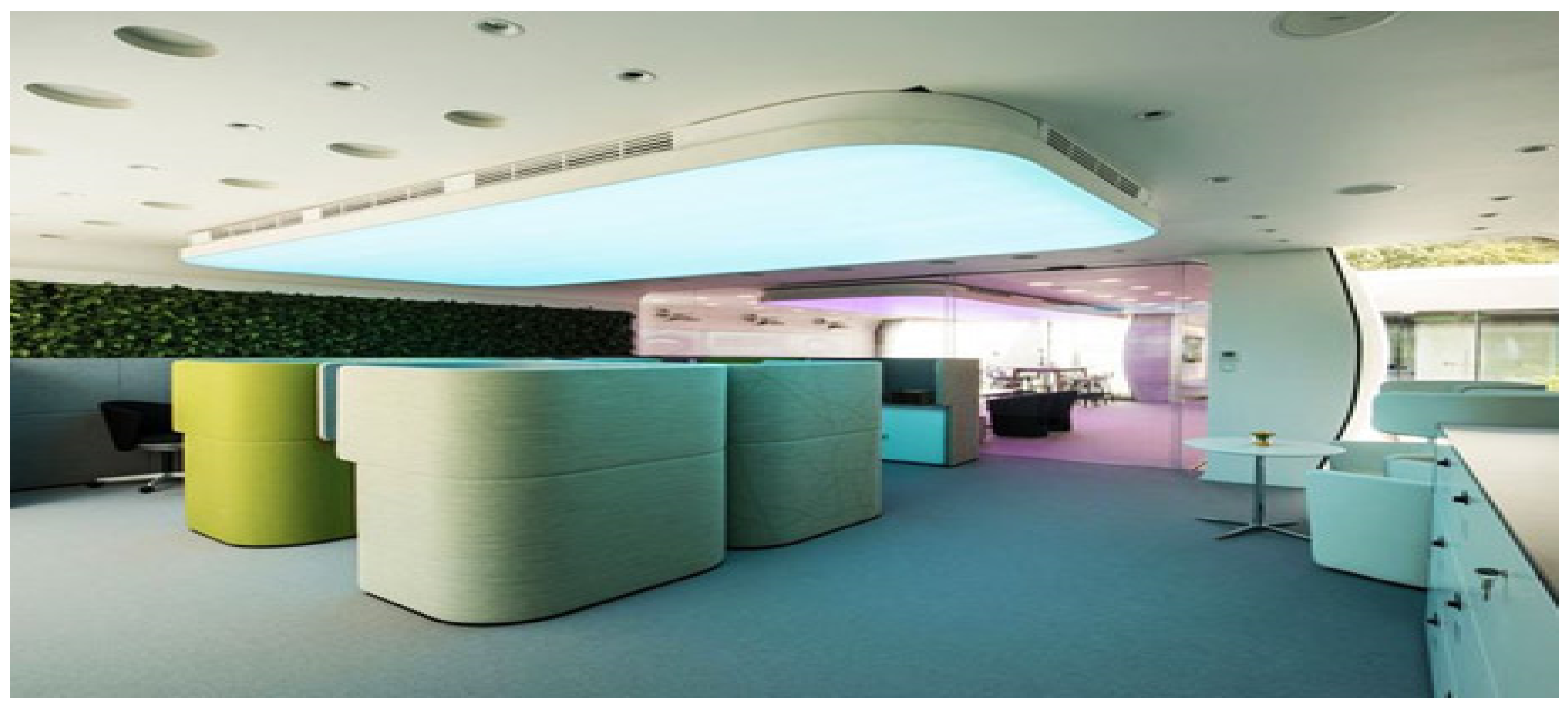

The significance of 3D manufacturing means that it is replacing the traditional mechanism of constructing buildings. Many countries are adopting 3D manufacturing to meet the target of establishing sustainable infrastructure. Saudi Arabia was the first country to use 3D printing technology to develop a two-story building in its capital, Dubai. The 3D printed office (also called Office of the Future) at Dubai (Figure 4 and Figure 5) is a milestone achieved in the construction industry, revolutionizing construction technology.

Figure 4.

Front view and side view of “Office of the Future” in Dubai, manufactured by 3D printing technology [11].

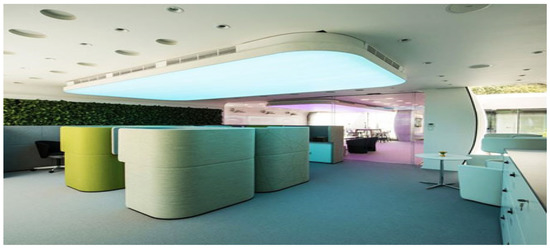

Figure 5.

Interior view of “Office of the Future” in Dubai, manufactured by 3D printing technology [58].

Figure 5.

Interior view of “Office of the Future” in Dubai, manufactured by 3D printing technology [58].

Similarly, on-site construction of the “Apis Cor house” in Russia represents a remarkable achievement for this technology, and its ability to push the boundaries beyond expectation (Figure 6). This building was made in 24 h with an estimated cost of USD 10,000, which is far cheaper than the traditional methods of housing construction.

Figure 6.

The 3D-printed building “Apis Cor House” was constructed in Russia [11].

6. CM and 3DP Based Construction of Buildings

CM and 3D printing show tremendous impact in the design and manufacturing process and trending research areas in innovative manufacturing technology. In this section, initially, we will discuss the importance and working of CM and 3D printing. After that, we will address the 3D printing-based service architectures clearly, and finally, the section concludes with the cloud printing service system.

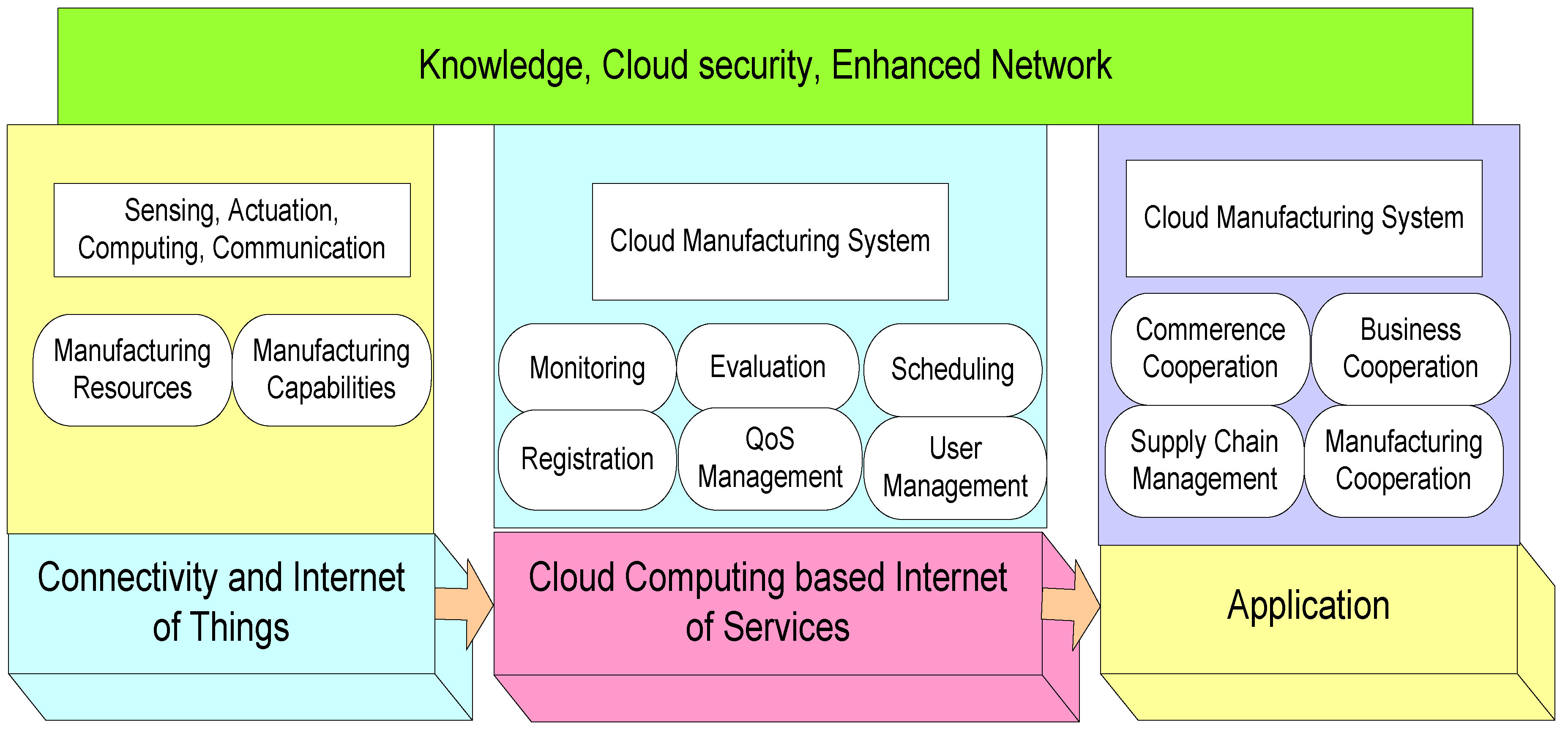

6.1. Cloud Manufacturing (CM)

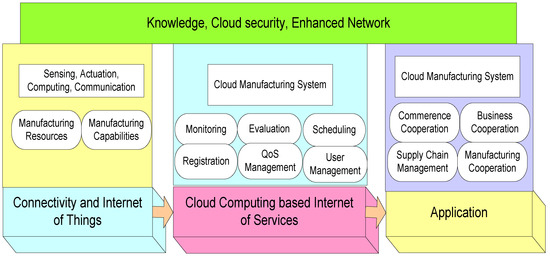

CM is a network manufacturing mode that provides users various on-demand manufacturing services according to users’ needs [59,60]. This mode uses the network to organize the online manufacturing resources. CM is an Internet-based manufacturing mode that delivers users with a spectrum of on-demand manufacturing services to meet users’ needs [61,62]. This approach utilizes the network to coordinate online manufacturing tools. Figure 7 shows a representative CM architecture in current researches. The manufacturing service providers deliver all sorts of development tools in cloud service through perception and virtualization technology for the entire product life cycle [63,64]. Manufacturing service applicants apply manufacturing specifications for each level or different granularity development service requirements for the complete product life cycle to the cloud platform, seeking to identify manufacturing services that already exist on the cloud platform [65,66]. The customer’s responsibility as a manufacturing service provider or a requesting organization is dynamically evolving [66,67,68,69]. When one offers a production service, he is a retailer of services in the CM system. The cloud platform administrators control and run the cloud platform effectively and organize the interaction between the manufacturing service requesters and the manufacturing service providers. Operators can dynamically and flexibly ensure that service for resource users is based on access requests by resource users. The essence of the CM process is the delivery of production resources between supply and demand, and the operation of the cloud is primarily to manufacture as a service [38,60,70].

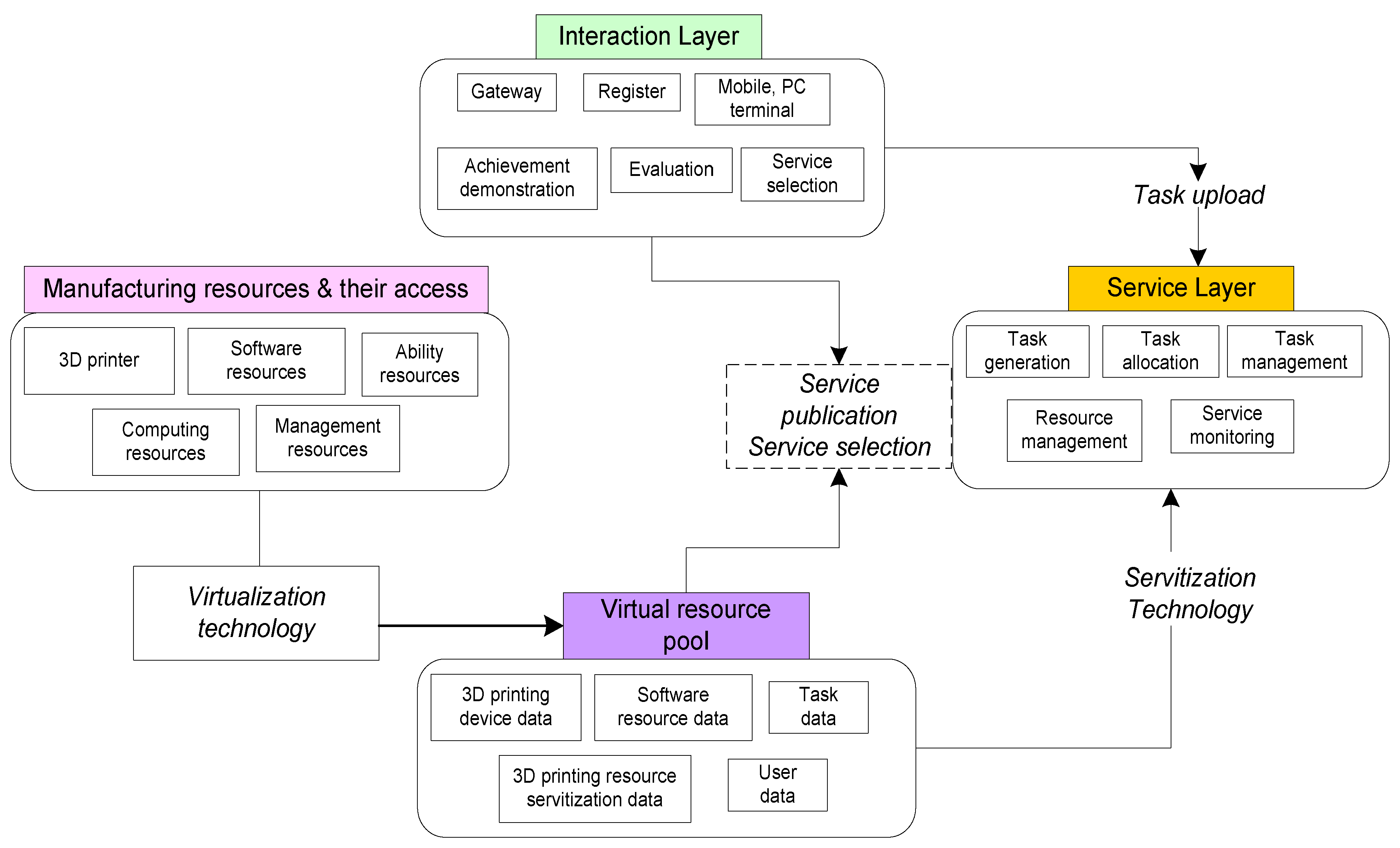

Figure 7.

Architecture of CM system.

6.2. CM Assisted 3DP

Globally, the impact of the construction industry on the environment is very high in terms of energy consumption, waste generation and emissions of greenhouse gases [71]. Currently, society is aiming to find sustainable technologies which can reduce the burdens of traditional construction approaches. 3D printing has emerged as a sustainable technique for this purpose. More innovations will bring this technology into the mainstream of buildings formation and construction processes [72]. Through this technology, the additive construction strategies facilitate topology optimization, reduce the use of materials, produce complex geometries without supporting structures and, more importantly, accumulate and integrate complex technologies in a single platform. This practice is not possible in traditional construction mechanisms [73]. Customization is achieved in complex structures by computer-aided design and improved fabrication processes. The construction complexes have been possible through digital technologies and improved material science [74]. The industries involved in building construction are moving towards digitization and adopting the 3D printing technology to convert the virtual model into an accurate model. Productivity has been increased with a reduction in operating cost by this technology for building construction [53,75].

CM and 3DP research have been a topic of extensive research in recent years in manufacturing. The 3D printer-based cloud development system and underlying manufacturing equipment are essentially a modern mode of manufacturing that substitutes mass production.

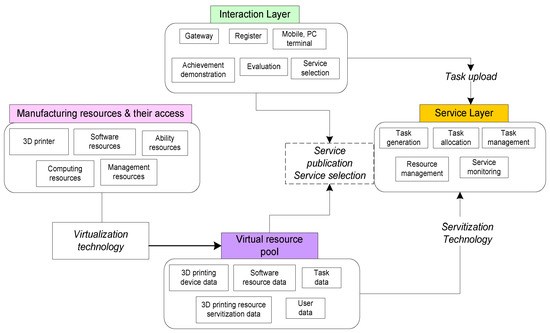

6.3. Architecture for 3D Printing Cloud Platform Service

3DP integration with CM will foster the growth of potential intelligent networks of virtual 3D cloud printing and establish a modern service-driven 3D printing manufacturing mode to accomplish the mass customization options. The service mode demonstrates the cloud printing device architecture and service flow. 3D-PCP device architecture was classified into six layers based on parameters of resources and their access, layer CM application system, and task management and execution. The first layer comprises cloud scheduling, QoS management, evaluation monitoring manufacturing, and registry allocation. The second layer includes supply chain co-operation, portals commerce co-operation, manufacturing (Mfg) co-operation, and business co-operation. The third layer comprises communication Mfg resources, Mfg resources and capability perception, connection, and layer application on-demand use and co-operation. The fourth layer includes management service, interface service generation and aggression, IoT connection and communication knowledge, cloud security, wider network, and cloud computing-based Internet services. The system architecture is divided into five layers: the interaction layer, service layer, the core layer, task layer, and applications layer, in Selection Distributions Manufacturing mode (CDM) [76] suggested by the Academic Lu team of the Chinese Academy of Engineering.

The physical layer comprises the manufacturing resources, access, and virtualization, while the service layer operates in a similar context as the control layer, core layer, and task layer. At the same time, several architectures on the 3D cloud Printing Platform consider virtual resource layers as the core components of virtual resource pools for multiple homogenous nodes. The service aggregation layer permits the configuration of service and internal calls for virtual resource pools while delivering lifecycle resources, including workflows. In another architecture, all physical and interface devices are differentiated on distinct levels. The user tool layer is assigned as part of the service layer’s functionality [77]. In [78] an agent layer to the architecture establishes a bridge between the resource demand side and the supplier. The agent layer contains the supplier of the cloud output and the demand side of the operation, the system operating connection as shown in Figure 8. A service integration architecture was developed to complete service integration [79] and it includes a physical system layer, adapter layer, service layer, control layer, and application layer. The architecture is only for the convergence of services, and the first four layers include the virtualization, servitization, and control of manufacturing infrastructure and fulfil the resource layout and compete. On the other hand, the architecture of 3DP OS [80] and 3D framework [81] for manufacturing tools have been built based on IoT and presented; namely, the resource layer, perception layer, network layer, service layer, and application layer. Furthermore, several researchers have suggested the architecture of the associated service models in the field of training [82] conventional valve manufacture [83] miniature manufacturing [84] and other areas.

Figure 8.

3D-PCP framework in recent studies.

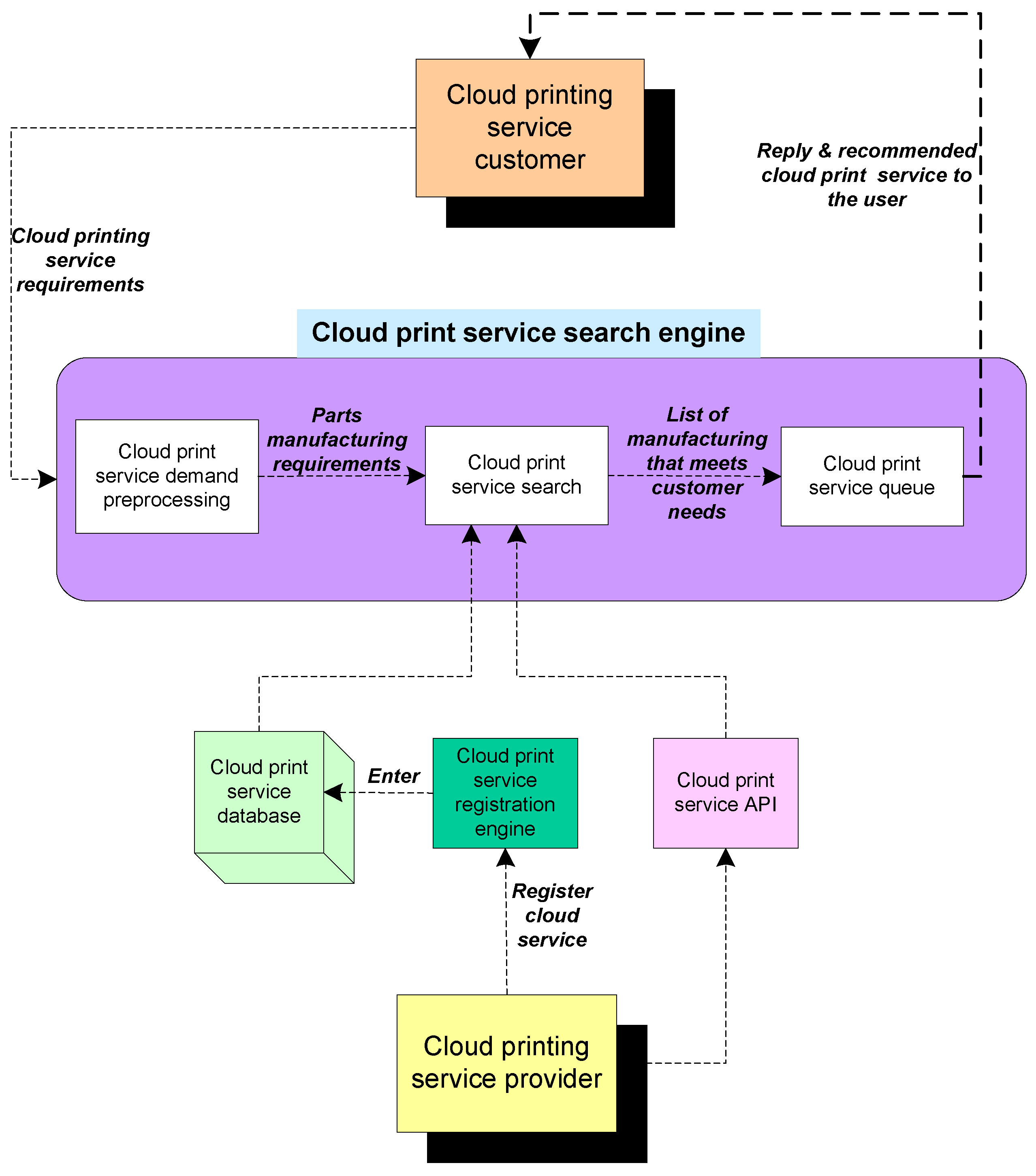

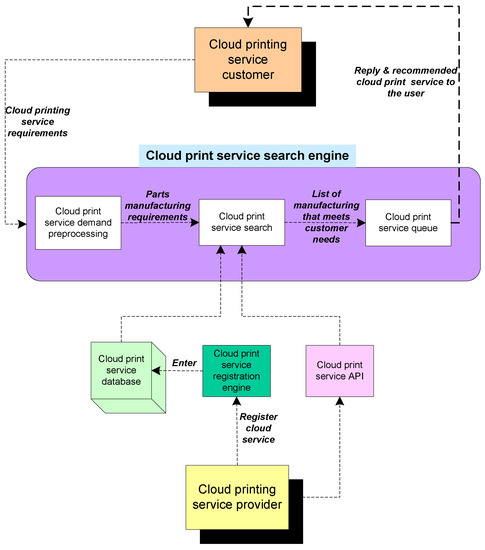

Figure 9 provides the detailed mechanism of the cloud printing service system. Cloud printing service customers and cloud printing service providers are represented as the users in this system [85]. Cloud printing service customers request the printing of a model by providing the printing requirements. The request is sent to the cloud print service search engine for pre-processing and the details are sent to the cloud print service search to initiate the printing [86]. The cloud service provider delivers a database, application interface (API), and registration support for utilizing the services. Here, the cloud print search sends the request to the database and API, where it receives a message for continuing the process further on in the system. The cloud service queue refers to an order or line of these tasks that are waiting to be handled.

Figure 9.

Cloud printing service system operation relationships [32].

3DP is adopted in various industries that are a part of Industry 4.0. The advantages of 3DP include less reduction in building time, reduced waste generation, and more flexibility in the manufacturing process to develop a complex design, which ultimately leads to a reduction of cost [87,88]. Additionally, automation in the construction process will help with better monitoring of the work, reduce manpower and manual labor involvement, and increase safety during the manufacturing process [89]. In addition, there are opportunities for the recycling and reuse of the printed materials when it is desired. Researchers have predicted that adopting this technology in the construction sector will open up incomparable design opportunities and merge construction technology with digital technology [90].

The 3DP process can be made more innovative by focusing on the technology-based research work with innovation, developing expertise in this sector, financial sustainability, unification, and encouragement of territorial equality [36]. The IoT can be incorporated in the construction technology for real-time monitoring of different parameters and the work area, enhancing safety precautions while the construction work goes on [37,91].

A sensor-based integration system is achieved in the IoT technology to gather and monitor the data remotely. There are many pieces of evidence that exist regarding the incorporation of IoT technology for smart building construction. Another digital technology that can help build construction is the artificial intelligence (AI) network [92]. AI in construction refers to machines involved in undertaking tasks as though they have human skills, planning, self-correcting, reasoning, etc.

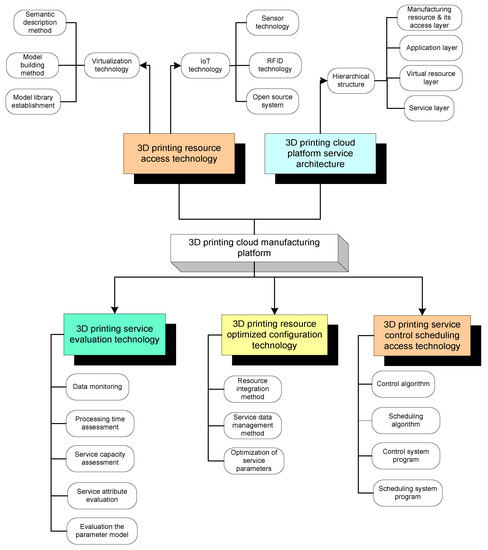

One more piece of technology that can revolutionize the construction industry is big data analysis (BDA). Big data includes the information that the existing tools cannot store, retrieve, or analyze concerning the processing speed, volume, and the range of data [93,94]. It is predicted that big data can be used to improve the output of the BIM model and thus increase its efficiency [95]. Almost all core technologies in the 3D–PCP service period are included, as seen in Figure 10, in the five aspects of the study. The next section summarizes the emerging trends and service structures in the successful 3D–PCP global sector. We include a resource for researching 3D printing platforms via comparisons of each platform.

Figure 10.

CM based 3DP platform.

7. Challenges and Recommendations

In this section, we will be addressing the challenges and recommendations associated with 3DP technology and CM. Section ‘a’ addresses the challenges, and section ‘b’ address the recommendations associated with 3DP and CM.

7.1. Challenges

There are many challenges associated with 3DP technology, although it has widespread applications in various industries. Some of the challenges concerning the construction industry are discussed here.

- The fourth industrial revolution, known as Industry 4.0, deals with computer technology and automation, which can revolutionize the construction processes by incorporating 3DP technology in the near future. Complex architectural design, precise execution of the design through 3D printing technology and computer technology will be the driving force of Industry 4.0. However, the present scenario has some challenges that need to be addressed to adopt this technology in the mainstream of developmental processes.

- In the last three industrial revolutions, many developments have occurred with ignorance of the environment, leading to a major industrial contribution to global warming. The time has come to adopt changes through Industry 4.0 with more focus on sustainable development, without affecting the fine balance in the environment and the ecosystem. Some more challenges involve the lack of availability of skilled personnel to operate 3D printers in the construction of buildings, less investment in the AEC sector, and slow progress in the adoption of cyber-physical systems (CPS) for the fourth industrial revolution [96,97,98]. The operation of the CPS system is controlled and coordinated by computer algorithms integrated with the Internet. Thus, real-time data can be gathered and assessed with automatic linking to the virtual models allowing the collaborated work in the whole chain [99,100].

- Exploring the printing materials for building constructions with the appropriate material mixture, buildability, pumpability, and printability is important [74]. Commercially produced ready-made material mix has disadvantages such as greater expense and difficulty in procurement in remote areas. The drawbacks associated with the structural design are the lack of codes and standards regulating the industry’s existing designs and construction standards which cannot be applied to 3D printing technology [101].

- When we discuss process efficiency, the 3D-printed constructions are more susceptible to changes in environmental conditions than conventional construction processes. To cite an example, if it is a rainy weather condition, it will be more convenient to place a framework made up of wood in a traditional approach, rather than using printable concrete materials for the purpose [50]. Although automation has many advantages, there are certain circumstances where the demand for manual labor is more for socio-economic sustainability. This is necessary for the people who get their daily work from the construction industry [102]. Automation will reduce the employability opportunities in society. There are some studies where bagged materials are used for printing, but this approach lacks most of the logistical benefits under 3D printing construction technology. The transportation cost is added to the total cost, and there is additional manpower, labor, and time required, besides the cost involved in this process. Additionally, the bagged material mix can affect some of the benefits gained with 3D printing technology, such as the scope of cutting down the emissions by using fewer industrialized raw materials [5].

7.2. Recommendations

This article presents a detailed overview and analysis of the 3D–PCP in the global market and addresses issues in the existing operation mode and infrastructure, such as the lack of cloud technology and 3D printer network research and the constraint of advanced configuration technology. Eventually, there is evidence of future trends in service mode fusion, unit encapsulation technology analysis, and the macro-and micro-level phase of service processes. Indeed, several key technological problems need to be investigated on the 3D cloud printing platform [23]. Based on the studies on the role of 3D printing technology in the construction industry, some recommendations are highlighted here, which can further enhance the prospects of this technology in various sectors while safeguarding the environment and maintaining sustainable growth and development of society.

7.2.1. Automation with Robotics

Automation should be prioritized with the incorporation of robotics in 3D printing technology. Construction-scale robotic systems can be employed for complex formwork production through this technology. Significant benefits will be achieved in freeform manufacturing, cost, and reduced generation of waste materials by implementing robotics in 3D printing technology.

7.2.2. Predictive Analytics for 3DP

Monitoring the machinery’s performance in 3DP is necessary for detecting the imperfections in it. Here, the inclusion of sensor technology provides an opportunity for predicting the imperfections through data analytics. Data analytics with artificial intelligence (AI) techniques are applied to the sensors data for predicting the imperfections in machinery [103,104,105] Predicting the imperfections at an instant time avoids the degradation of the machinery with minimum cost.

7.2.3. Research for Integration of CM with 3DP

Integration of the CM with 3DP will be delivering high potentiality in the future for replacing traditional manufacturing. However, extensive research is required for overcoming the challenges; namely, 3DP service process control, 3DP service optimized configuration, and 3D printer networks. In 3D printers, enhancing the 3D printer access to the cloud platform is an area open to further research.

7.2.4. Eco-Friendly Printing

For sustainable growth, the printing processes should be more eco-friendly, safeguarding our environment and ecosystems. Overall, the 3D printing technology has ample opportunities to explore different manufacturing sectors further, and now society is moving towards 4D printing technology. Perhaps, in the near future, advanced versions will be adopted for holistic growth and development.

7.2.5. 5G Technology for IoT-Based Cloud Manufacturing

IoT-based cloud manufacturing requires continuous, fast, and reliable intercommunication between the machines and users. To meet the above requirements, 5G technology is the prominent solution for implementing high-end predictive analytics on the 3D printing machinery [106,107]. 5G technology provides less latency and allows more data to travel faster. 5G facilitates a secure means of transmitting the time-critical events in manufacturing, even in the predictive analytics of 3D printing.

8. Conclusions

The sustainable development goals (SDGs) were formulated by the UN, aiming to achieve a sustainable environment for global citizens by 2030. Concerning this goal, the construction industry requires more focus on sustainability in order to combat GHG emissions, generation of waste, and consumption of water and energy resources. Sustainability in the construction industry is possible with innovative 3DP technology and IoT-based CM. 3D printing technology has been proven to revolutionize the construction industry with more automation, less cost involvement, more design complexity, and, more importantly, an environmentally friendly approach. As the building model of the 3DP in the digitalized format, it provides an opportunity to utilize the IoT and cloud for establishing the digitalized services and environment. This paper highlights the research and development of core 3DP CM platform technologies; namely, access technology for 3D printers, 3D–PCP service architecture, optimization technology for 3D printing services, control, and scheduling technology for 3DP services, and assessment technology for 3D printing services. Additional important topics mentioned here include automation with robotics, predictive analytics for 3DP, research for enhancement of integrating CM with 3DP, eco-friendly printing and 5G technology for reliable and fast connectivity for IoT-based CM.

Author Contributions

Conceptualization, R.S., A.G. and S.V.A.; methodology, L.R.G., M.K.J.; writing—R.S., A.G., C.P., S.S. and R.K.; writing—review and editing, R.S., A.G., C.P. and L.R.G.; visualization, R.S. and M.K.J.; supervision, L.R.G., C.P. and S.S.; project administration, R.S., A.G., L.R.G., C.P. and S.S. All authors have read and agreed to the published version of the manuscript.

Funding

This research received no external funding.

Institutional Review Board Statement

No applicable.

Informed Consent Statement

No applicable.

Data Availability Statement

No applicable.

Conflicts of Interest

The authors declare no conflict of interest.

References

- Social Development for Sustainable Development. DISD. Available online: https://www.un.org/development/desa/dspd/2030agenda-sdgs.html (accessed on 15 March 2021).

- THE 17 GOALS. Sustainable Development. Available online: https://sdgs.un.org/goals (accessed on 15 March 2021).

- Bamgbade, J.A.; Kamaruddeen, A.M.; Nawi, M.N.M. Malaysian construction firms’ social sustainability via organizational innovativeness and government support: The mediating role of market culture. J. Clean. Prod. 2017, 154, 114–124. [Google Scholar] [CrossRef]

- Mavi, R.K.; Gengatharen, D.; Mavi, N.K.; Hughes, R.; Campbell, A.; Yates, R. Sustainability in Construction Projects: A Systematic Literature Review. Sustainability 2021, 13, 1932. [Google Scholar] [CrossRef]

- Agustí-Juan, I.; Habert, G. Environmental design guidelines for digital fabrication. J. Clean. Prod. 2017, 142, 2780–2791. [Google Scholar] [CrossRef]

- 2019 Global Status Report for Buildings and Construction Sector. UNEP—UN Environment Programme. Available online: https://www.unep.org/resources/publication/2019-global-status-report-buildings-and-construction-sector (accessed on 15 March 2021).

- Marzouk, M.; Azab, S. Environmental and economic impact assessment of construction and demolition waste disposal using system dynamics. Resour. Conserv. Recycl. 2014, 82, 41–49. [Google Scholar]

- Weng, Y.; Li, M.; Ruan, S.; Wong, T.N.; Tan, M.J.; Yeong, K.L.O.; Qian, S. Comparative economic, environmental and productivity assessment of a concrete bathroom unit fabricated through 3D printing and a precast approach. J. Clean. Prod. 2020, 261, 121245. [Google Scholar] [CrossRef]

- Hill, R.C.; Bowen, P.A. Sustainable construction: Principles and a framework for attainment. Constr. Manag. Econ. 1997, 15, 223–239. [Google Scholar]

- Hager, I.; Golonka, A.; Putanowicz, R. 3D printing of buildings and building components as the future of sustainable construction? Procedia Eng. 2016, 151, 292–299. [Google Scholar]

- Sakin, M.; Kiroglu, Y.C. 3D Printing of Buildings: Construction of the Sustainable Houses of the Future by BIM. Energy Procedia 2017, 134, 702–711. [Google Scholar] [CrossRef]

- Cameli, S.A. 3D Printing of Cities: Is Urban Planning Ready? Plan. Theory Pract. 2019, 20, 776–784. [Google Scholar]

- Wang, Y.; Zheng, P.; Xu, X.; Yang, H.; Zou, J. Production planning for cloud-based additive manufacturing—A computer vision-based approach. Robot. Comput. Integr. Manuf. 2019, 58, 145–157. [Google Scholar] [CrossRef]

- Wang, Y.; Lin, Y.; Zhong, R.Y.; Xu, X. IoT-enabled cloud-based additive manufacturing platform to support rapid product development. Int. J. Prod. Res. 2019, 57, 3975–3991. [Google Scholar] [CrossRef]

- Rossi, E.; di Nicolantonio, M.; Barcarolo, P.; Lagatta, J. Sustainable 3D printing: Design opportunities and research perspectives. Adv. Intell. Syst. Comput. 2020, 975, 3–15. [Google Scholar] [CrossRef]

- Mintsaev, M.S.; Bataev, D.S.; Mazhiev, K.K.; Mazhiev, A.K.; Mazhieva, A.K.; Mazhiev, A.K.; Mazhiev, M.K. Prospects for Using 3D-Printing Technologies in Construction of Buildings in Seismic Areas. ISEES 2019, 311–315. [Google Scholar] [CrossRef]

- Rosenthal, A.; Mork, P.; Li, M.H.; Stanford, J.; Koester, D.; Reynolds, P. Cloud computing: A new business paradigm for biomedical information sharing. J. Biomed. Inform. 2010, 43, 342–353. [Google Scholar] [CrossRef] [PubMed]

- Tao, F.; Li, C.; Liao, T.W.; Laili, Y. BGM-BLA: A new algorithm for dynamic migration of virtual machines in cloud computing. IEEE Trans. Serv. Comput. 2015, 9, 910–925. [Google Scholar] [CrossRef]

- Manyika, J.; Chui, M.; Brown, B.; Bughin, J.; Dobbs, R.; Roxburgh, C.; Byers, A.H. Big Data: The Next Frontier for Innovation, Competition, and Productivity; McKinsey Global Institute: Washington, DC, USA, 2011. [Google Scholar]

- Bughin, J.; Chui, M.; Manyika, J. Clouds, big data, and smart assets: Ten tech-enabled business trends to watch. McKinsey Q. 2010, 56, 75–86. [Google Scholar]

- Li, B.H.; Zhang, L.; Wang, S.L.; Tao, F.; Cao, J.W.; Jiang, X.D.; Song, X.; Chai, X.D. Cloud manufacturing: A new service-oriented networked manufacturing model. Comput. Integr. Manuf. Syst. 2010, 16, 1–7. [Google Scholar]

- Tao, F.; Zhang, L.; Guo, H.; Luo, Y.-L.; Ren, L. Typical characteristics of cloud manufacturing and several key issues of cloud service composition. Comput. Integr. Manuf. Syst. 2011, 17, 477–486. [Google Scholar]

- Guo, L.; Qiu, J. Combination of cloud manufacturing and 3D printing: Research progress and prospect. Int. J. Adv. Manuf. Technol. 2018, 96, 1929–1942. [Google Scholar] [CrossRef]

- Mechtcherine, V.; Nerella, V.N.; Will, F.; Näther, M.; Otto, J.; Krause, M. Large-scale digital concrete construction—CONPrint3D concept for on-site, monolithic 3D-printing. Autom. Constr. 2019, 107, 102933. [Google Scholar] [CrossRef]

- Jang, H.; Kim, K.; Kim, J.H.; Kim, J. Labour productivity model for reinforced concrete construction projects. Constr. Innov. Inf. Process. Manag. 2011, 11, 92–113. [Google Scholar] [CrossRef]

- Allouzi, R.; Al-Azhari, W.; Allouzi, R. Conventional Construction and 3D Printing: A Comparison Study on Material Cost in Jordan. J. Eng. 2020, 2020, 1424682. [Google Scholar]

- Hossain, M.; Zhumabekova, A.; Paul, S.C.; Kim, J.R. A Review of 3D Printing in Construction and its Impact on the Labor Market. Sustainability 2020, 12, 8492. [Google Scholar] [CrossRef]

- Furet, B.; Poullain, P.; Garnier, S. 3D printing for construction based on a complex wall of polymer-foam and concrete. Addit. Manuf. 2019, 28, 58–64. [Google Scholar] [CrossRef]

- Marchon, D.; Kawashima, S.; Bessaies-Bey, H.; Mantellato, S.; Ng, S. Hydration and rheology control of concrete for digital fabrication: Potential admixtures and cement chemistry. Cem. Concr. Res. 2018, 112, 96–110. [Google Scholar] [CrossRef]

- Ghaffar, S.H.; Corker, J.; Fan, M. Additive manufacturing technology and its implementation in construction as an eco-innovative solution. Autom. Constr. 2018, 93, 1–11. [Google Scholar] [CrossRef]

- Ngo, T.D.; Kashani, A.; Imbalzano, G.; Nguyen, K.T.Q.; Hui, D. Additive manufacturing (3D printing): A review of materials, methods, applications and challenges. Compos. Part. B Eng. 2018, 143, 172–196. [Google Scholar] [CrossRef]

- Zuo, Z.; Gong, J.; Huang, Y.; Zhan, Y.; Gong, M.; Zhang, L. Experimental research on transition from scale 3D printing to full-size printing in construction. Constr. Build. Mater. 2019, 208, 350–360. [Google Scholar] [CrossRef]

- Buchanan, C.; Gardner, L. Metal 3D printing in construction: A review of methods, research, applications, opportunities and challenges. Eng. Struct. 2019, 180, 332–348. [Google Scholar] [CrossRef]

- Asprone, D.; Auricchio, F.; Menna, C.; Mercuri, V. 3D printing of reinforced concrete elements: Technology and design approach. Constr. Build. Mater. 2018, 165, 218–231. [Google Scholar] [CrossRef]

- Jia, M.; Komeily, A.; Wang, Y.; Srinivasan, R.S. Adopting Internet of Things for the development of smart buildings: A review of enabling technologies and applications. Autom. Constr. 2019, 101, 111–126. [Google Scholar] [CrossRef]

- Deloitte. Plano Estratégico de Inovação e Competitividade 2030 Para o Setor AEC; Plataforma Tecnológica Port. da Construção: Lisboa, Portugal, 2018; p. 93. [Google Scholar]

- Tao, F.; Cheng, Y.; da Xu, L.; Zhang, L.; Li, B.H. CCIoT-CMfg: Cloud computing and internet of things-based cloud manufacturing service system. IEEE Trans. Ind. Inform. 2014, 10, 1435–1442. [Google Scholar] [CrossRef]

- Kaszyńska, M.; Skibicki, S.; Hoffmann, M. 3D Concrete Printing for Sustainable Construction. Energies 2020, 13, 6351. [Google Scholar] [CrossRef]

- Yahya MY, B.; Hui, Y.L.; Yassin AB, M.; Omar, R.; anak Robin, R.O.; Kasim, N. The Challenges of the Implementation of Construction Robotics Technologies in the Construction. MATEC Web Conf. 2019, 266, 05012. [Google Scholar] [CrossRef]

- Mahamood, R.M.; Akinlabi, E.T.; Shukla, M.; Pityana, S.L. Functionally graded material: An overview. In Proceedings of the World Congress on Engineering 2012 Vol III (WCE 2012), London, UK, 4–6 July 2012. [Google Scholar]

- Khoshnevis, B. Automated construction by contour crafting—Related robotics and information technologies. Autom. Constr. 2004, 13, 5–19. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Gibb, A.G.F.; Thorpe, T. Mix design and fresh properties for high-performance printing concrete. Mater. Struct. 2012, 45, 1221–1232. [Google Scholar] [CrossRef]

- Lim, S.; Buswell, R.A.; Le, T.T.; Austin, S.A.; Gibb, A.G.F.; Thorpe, T. Developments in construction-scale additive manufacturing processes. Autom. Constr. 2012, 21, 262–268. [Google Scholar] [CrossRef]

- Le, T.T.; Austin, S.A.; Lim, S.; Buswell, R.A.; Law, R.; Gibb, A.G.; Thorpe, T. Hardened properties of high-performance printing concrete. Cem. Concr. Res. 2012, 42, 558–566. [Google Scholar] [CrossRef]

- Wangler, T.; Roussel, N.; Bos, F.P.; Salet, T.A.M.; Flatt, R.J. Digital concrete: A review. Cem. Concr. Res. 2019, 123, 105780. [Google Scholar] [CrossRef]

- Lafhaj, Z.; Rabenantoandro, A.Z.; el Moussaoui, S.; Dakhli, Z.; Youssef, N. Experimental Approach for Printability Assessment: Toward a Practical Decision-Making Framework of Printability for Cementitious Materials. Buildings 2019, 9, 245. [Google Scholar] [CrossRef]

- Kaszyńska, M.; Hoffmann, M.; Skibicki, S.; Zieliński, A.; Techman, M.; Olczyk, N.; Wróblewski, T. Evaluation of suitability for 3D printing of high performance concretes. MATEC Web Conf. 2018, 163, 1002. [Google Scholar] [CrossRef]

- Khoshnevis, B.; Hwang, D. Contour Crafting. In Rapid Prototyping; Kamrani, A., Nasr, E.A., Eds.; Springer: Berlin/Heidelberg, Germany, 2006; pp. 221–251. [Google Scholar]

- Ma, G.; Zhang, J.; Wang, L.; Li, Z.; Sun, J. Mechanical characterization of 3D printed anisotropic cementitious material by the electromechanical transducer. Smart Mater. Struct. 2018, 27, 75036. [Google Scholar] [CrossRef]

- Jagoda, J.; Diggs-McGee, B.; Kreiger, M.; Schuldt, S. The Viability and Simplicity of 3D-Printed Construction: A Military Case Study. Infrastructures 2020, 5, 35. [Google Scholar] [CrossRef]

- Geneidy, O.; Ismaeel, W.S.E.; Abbas, A. A critical review for applying three-dimensional concrete wall printing technology in Egypt. Archit. Sci. Rev. 2019, 62, 438–452. [Google Scholar] [CrossRef]

- De Schutter, G.; Lesage, K.; Mechtcherine, V.; Nerella, V.N.; Habert, G.; Agusti-Juan, I. Vision of 3D printing with concrete—technical, economic and environmental potentials. Cem. Concr. Res. 2018, 112, 25–36. [Google Scholar] [CrossRef]

- Lloret, E.; Shahab, A.R.; Linus, M.; Flatt, R.J.; Gramazio, F.; Kohler, M.; Langenberg, S. Complex concrete structures: Merging existing casting techniques with digital fabrication. Comput. Des. 2015, 60, 40–49. [Google Scholar]

- Wangler, T.; Lloret, E.; Reiter, L.; Hack, N.; Gramazio, F.; Kohler, M.; Bernhard, M.; Dillenburger, B.; Buchli, J.; Roussel, N.; et al. Digital concrete: Opportunities and challenges. Rilem Tech. Lett. 2016, 1, 67–75. [Google Scholar] [CrossRef]

- Willette, A.; Brell-Cokcan, S.; Braumann, J. Robotic Fabrication in Architecture, Art and Design; Springer: Berlin/Heidelberg, Germany, 2014. [Google Scholar]

- Dubor, A.; Izard, J.-B.; Cabay, E.; Sollazzo, A.; Markopoulou, A.; Rodriguez, M. On-Site Robotics for Sustainable Construction. In Robotic Fabrication in Architecture, Art and Design; Springer: Berlin/Heidelberg, Germany, 2018; pp. 390–401. [Google Scholar]

- Duballet, R.; Baverel, O.; Dirrenberger, J. Classification of building systems for concrete 3D printing. Autom. Constr. 2017, 83, 247–258. [Google Scholar] [CrossRef]

- Zhang, J.; Wang, J.; Dong, S.; Yu, X.; Han, B. A review of the current progress and application of 3D printed concrete. Compos. Part. A Appl. Sci. Manuf. 2019, 125, 105533. [Google Scholar] [CrossRef]

- Fisher, O.; Watson, N.; Porcu, L.; Bacon, D.; Rigley, M.; Gomes, R.L. Cloud manufacturing as a sustainable process manufacturing route. J. Manuf. Syst. 2018, 47, 53–68. [Google Scholar] [CrossRef]

- Siderska, J.; Jadaan, K.S. Cloud manufacturing: A service-oriented manufacturing paradigm. A review paper. Eng. Manag. Prod. Serv. 2018, 10, 22–31. [Google Scholar] [CrossRef]

- Ren, L.; Zhang, L.; Wang, L.; Tao, F.; Chai, X. Cloud manufacturing: Key characteristics and applications. Int. J. Comput. Integr. Manuf. 2017, 30, 501–515. [Google Scholar] [CrossRef]

- Cloud Manufacturing: A New Service-Oriented Networked Manufacturing Model–Computer Integrated Manufacturing Systems. Available online: https://en.cnki.com.cn/Article_en/CJFDTotal-JSJJ201001001.htm (accessed on 17 March 2021).

- Ren, L.; Zhang, L.; Tao, F.; Zhao, C.; Chai, X.; Zhao, X. Cloud manufacturing: From concept to practice. Enterp. Inf. Syst. 2015, 9, 186–209. [Google Scholar] [CrossRef]

- Zhang, L.; Luo, Y.; Tao, F.; Li, B.H.; Ren, L.; Zhang, X.; Guo, H.; Cheng, Y.; Hu, A.; Liu, Y. Cloud manufacturing: A new manufacturing paradigm. Enterp. Inf. Syst. 2014, 8, 167–187. [Google Scholar] [CrossRef]

- Simeone, A.; Caggiano, A.; Boun, L.; Deng, B. Intelligent cloud manufacturing platform for efficient resource sharing in smart manufacturing networks. Procedia CIRP 2019, 79, 233–238. [Google Scholar] [CrossRef]

- Liu, Y.; Xu, X. Industry 4.0 and cloud manufacturing: A comparative analysis. J. Manuf. Sci. Eng. Trans. ASME 2017, 139. [Google Scholar] [CrossRef]

- Zhou, L.; Zhang, L.; Laili, Y.; Zhao, C.; Xiao, Y. Multi-task scheduling of distributed 3D printing services in cloud manufacturing. Int. J. Adv. Manuf. Technol. 2018, 96, 3003–3017. [Google Scholar] [CrossRef]

- Wang, X.V.; Xu, X.W. ICMS: A Cloud-Based Manufacturing System; Springer: London, UK, 2013; pp. 1–22. [Google Scholar]

- Chen, J.; Huang, G.Q.; Wang, J.Q.; Yang, C. A cooperative approach to service booking and scheduling in cloud manufacturing. Eur. J. Oper. Res. 2019, 273, 861–873. [Google Scholar] [CrossRef]

- Liu, Y.; Wang, L.; Wang, X.V.; Xu, X.; Jiang, P. Cloud manufacturing: Key issues and future perspectives. Int. J. Comput. Integr. Manuf. 2019, 32, 858–874. [Google Scholar] [CrossRef]

- Sustainable Buildings|UNEP—UN Environment Programme. Available online: https://www.unep.org/explore-topics/resource-efficiency/what-we-do/cities/sustainable-buildings (accessed on 25 February 2021).

- Lao, W.; Li, M.; Wong, T.N.; Tan, M.J.; Tjahjowidodo, T. Improving surface finish quality in extrusion-based 3D concrete printing using machine learning-based extrudate geometry control. Virtual Phys. Prototyp. 2020, 15, 178–193. [Google Scholar] [CrossRef]

- Labonnote, N.; Rønnquist, A.; Manum, B.; Rüther, P. Additive construction: State-of-the-art, challenges and opportunities. Autom. Constr. 2016, 72, 347–366. [Google Scholar] [CrossRef]

- Al Jassmi, H.; Al Najjar, F.; Mourad, A.-H.I. Large-Scale 3D printing: The way forward. IOP Conf. Ser. Mater. Sci. Eng. 2018, 324, 12088. [Google Scholar] [CrossRef]

- Buswell, R.A.; de Silva, W.R.L.; Jones, S.Z.; Dirrenberger, J. 3D printing using concrete extrusion: A roadmap for research. Cem. Concr. Res. 2018, 112, 37–49. [Google Scholar] [CrossRef]

- Jiang, Y.; Lu, B.; Fang, X.; Long, H. 3D printing-based Internet collect-manufacturing mode. Comput. Integr. Manuf. Syst. 2016, 22, 1424–1433. [Google Scholar]

- Ren, L.; Wang, S.; Shen, Y.; Hong, S.; Chen, Y.; Zhang, L. 3D printing in cloud manufacturing: Model and platform design. In Proceedings of the ASME 2016 11th International Manufacturing Science and Engineering Conference, MSEC, Blacksburg, VA, USA, 27 June–1 July 2016; Volume 2. [Google Scholar] [CrossRef]

- Modekurthy, V.P.; Liu, X.F.; Fletcher, K.K.; Leu, M.C. Design and implementation of a broker for cloud additive manufacturing services. J. Manuf. Sci. Eng. 2015, 137, 040904. [Google Scholar] [CrossRef]

- Mai, J.; Zhang, L.; Tao, F.; Ren, L. Customized production based on distributed 3D printing services in cloud manufacturing. Int. J. Adv. Manuf. Technol. 2016, 84, 71–83. [Google Scholar] [CrossRef]

- Wu, J.J.; Tan, Y.G.; Ma, G.F. 3D printing monitoring platform based on the Internet of Things. IET 2015. [Google Scholar] [CrossRef]

- Tao, F.; Zuo, Y.; da Xu, L.; Zhang, L. IoT-based intelligent perception and access of manufacturing resource toward cloud manufacturing. IEEE Trans. Ind. Inf. 2014, 10, 1547–1557. [Google Scholar]

- Liu, X.M.; Huang, J.F. Education-oriented 3Dprinting and networked communication platform. Chin. J. Eng. Mach. 2015, 13, 82–87. [Google Scholar]

- Jun, Z.; Wen-jie, D. The research on service of valve with cloud manufacturing and 3D printing. Manuf. Autom. 2015, 37, 108–111. [Google Scholar]

- Brant, A.; Sundaram, M.M. A novel system for cloud-based micro additive manufacturing of metal structures. J. Manuf. Process. 2015, 20, 478–484. [Google Scholar] [CrossRef]

- Li, F.; Liao, T.W.; Zhang, L. Two-level multi-task scheduling in a cloud manufacturing environment. Robot. Comput. Integr. Manuf. 2019, 56, 127–139. [Google Scholar] [CrossRef]

- Bag, S.; Pretorius, J.H.C. Relationships between industry 4.0, sustainable manufacturing and circular economy: Proposal of a research framework. Int. J. Organ. Anal. 2020. [Google Scholar] [CrossRef]

- De Soto, B.G.; Agustí-Juan, I.; Hunhevicz, J.; Joss, S.; Graser, K.; Habert, G.; Adey, B.T. Productivity of digital fabrication in construction: Cost and time analysis of a robotically built wall. Autom. Constr. 2018, 92, 297–311. [Google Scholar] [CrossRef]

- Shaping the Future of Construction: A Breakthrough in Mindset and Technology. World Economic Forum. Available online: https://www.weforum.org/reports/shaping-the-future-of-construction-a-breakthrough-in-mindset-and-technology (accessed on 25 February 2021).

- Pacewicz, K.; Sobotka, A.; Gołek, Ł. Characteristic of materials for the 3D printed building constructions by additive printing. MATEC Web Conf. 2018, 222, 1013. [Google Scholar] [CrossRef]

- Labonnote, N.; Rüther, P. Additive manufacturing: An opportunity for functional and sustainable constructions. In Challenges for Technology Innovation: An Agenda for the Future, Proceedings of the International Conference on Sustainable Smart Manufacturing, S2M 2016; CRC Press: Boca Raton, FL, USA, 2017; pp. 201–206. [Google Scholar] [CrossRef]

- Zhong, D.; Lv, H.; Han, J.; Wei, Q. A practical application combining wireless sensor networks and internet of things: Safety management system for tower crane groups. Sensors 2014, 14, 13794–13814. [Google Scholar] [CrossRef] [PubMed]

- Hansen, E.B.; Bøgh, S. Artificial intelligence and internet of things in small and medium-sized enterprises: A survey. J. Manuf. Syst. 2020, 58, 362–372. [Google Scholar] [CrossRef]

- Ajayi, S.; Akinade, O.; Al-Hasan, A.; Alaka, H.; Ambituuni, A.; Amezaga, J.M.; Ball, P.; Bandera, C.; Bao, L.; Basole, R.C. Index Transactions on Engineering Management. IEEE Trans. Eng. Manag. 2019, 66. Available online: https://ieeexplore.ieee.org/stamp/stamp.jsp?arnumber=9031584 (accessed on 20 June 2021).

- Bilal, M.; Oyedele, L.O.; Qadir, J.; Munir, K.; Ajayi, S.O.; Akinade, O.O.; Owolabi, H.A.; Alaka, H.A.; Pasha, M. Big Data in the construction industry: A review of present status, opportunities, and future trends. Adv. Eng. Inform. 2016, 30, 500–521. [Google Scholar] [CrossRef]

- Ram, J.; Afridi, N.K.; Khan, K.A. Adoption of Big Data analytics in construction: Development of a conceptual model. Built Environ. Proj. Asset Manag. 2019, 9, 564–579. [Google Scholar] [CrossRef]

- Nowotarski, P.; Paslawski, J. Industry 4.0 Concept Introduction into Construction SMEs. IOP Conf. Ser. Mater. Sci. Eng. 2017, 245, 052043. [Google Scholar] [CrossRef]

- Maskuriy, R.; Selamat, A.; Ali, K.N.; Maresova, P.; Krejcar, O. Industry 4.0 for the construction industry—How ready is the industry? Appl. Sci. 2019, 9, 2819. [Google Scholar] [CrossRef]

- CIRP Encyclopedia of Production Engineering|Springer. Available online: https://www.springer.com/gp/book/9783662531198 (accessed on 25 February 2021).

- Alaloul, W.S.; Liew, M.S.; Zawawi, N.A.W.A.; Kennedy, I.B. Industrial Revolution 4.0 in the construction industry: Challenges and opportunities for stakeholders. Ain Shams Eng. J. 2020, 11, 225–230. [Google Scholar] [CrossRef]

- Correa, F.R. Cyber-physical systems for construction industry. In Proceedings of the 2018 IEEE Industrial Cyber-Physical Systems (ICPS), St. Petersburg, Russia, 15–18 May 2018; pp. 392–397. [Google Scholar]

- Paul, S.C.; van Zijl, G.P.A.G.; Tan, M.J.; Gibson, I. A review of 3D concrete printing systems and materials properties: Current status and future research prospects. Rapid Prototyp. J. 2018, 24, 784–798. [Google Scholar] [CrossRef]

- Gebler, M.; Uiterkamp, A.J.M.S.; Visser, C. A global sustainability perspective on 3D printing technologies. Energy Policy 2014, 74, 158–167. [Google Scholar] [CrossRef]

- Rodríguez-Espíndola, O.; Chowdhury, S.; Beltagui, A.; Albores, P. The potential of emergent disruptive technologies for humanitarian supply chains: The integration of blockchain, Artificial Intelligence and 3D printing. Int. J. Prod. Res. 2020, 58, 4610–4630. [Google Scholar] [CrossRef]

- Li, B.H.; Hou, B.C.; Yu, W.T.; Lu, X.B.; Yang, C.W. Applications of artificial intelligence in intelligent manufacturing: A review. Front. Inf. Technol. Electron. Eng. 2017, 18, 86–96. [Google Scholar] [CrossRef]

- Delli, U.; Chang, S. Automated Process Monitoring in 3D Printing Using Supervised Machine Learning. Procedia Manuf. 2018, 26, 865–870. [Google Scholar] [CrossRef]

- Wang, Y. Industrial structure technology upgrade based on 5G network service and IoT intelligent manufacturing. Microprocess. Microsyst. 2021, 81, 103696. [Google Scholar] [CrossRef]

- Cheng, J.; Chen, W.; Tao, F.; Lin, C.L. Industrial IoT in 5G environment towards smart manufacturing. J. Ind. Inf. Integr. 2018, 10, 10–19. [Google Scholar] [CrossRef]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).