Developing a Resource Allocation Approach for Resource-Constrained Construction Operation under Multi-Objective Operation

Abstract

:1. Introduction

2. Literature Review

2.1. Resource Allocation Problem in Construction Project

2.2. Construction Multi-Objective Performances and Optimization

2.3. BIM Application in Construction

3. Materials and Method

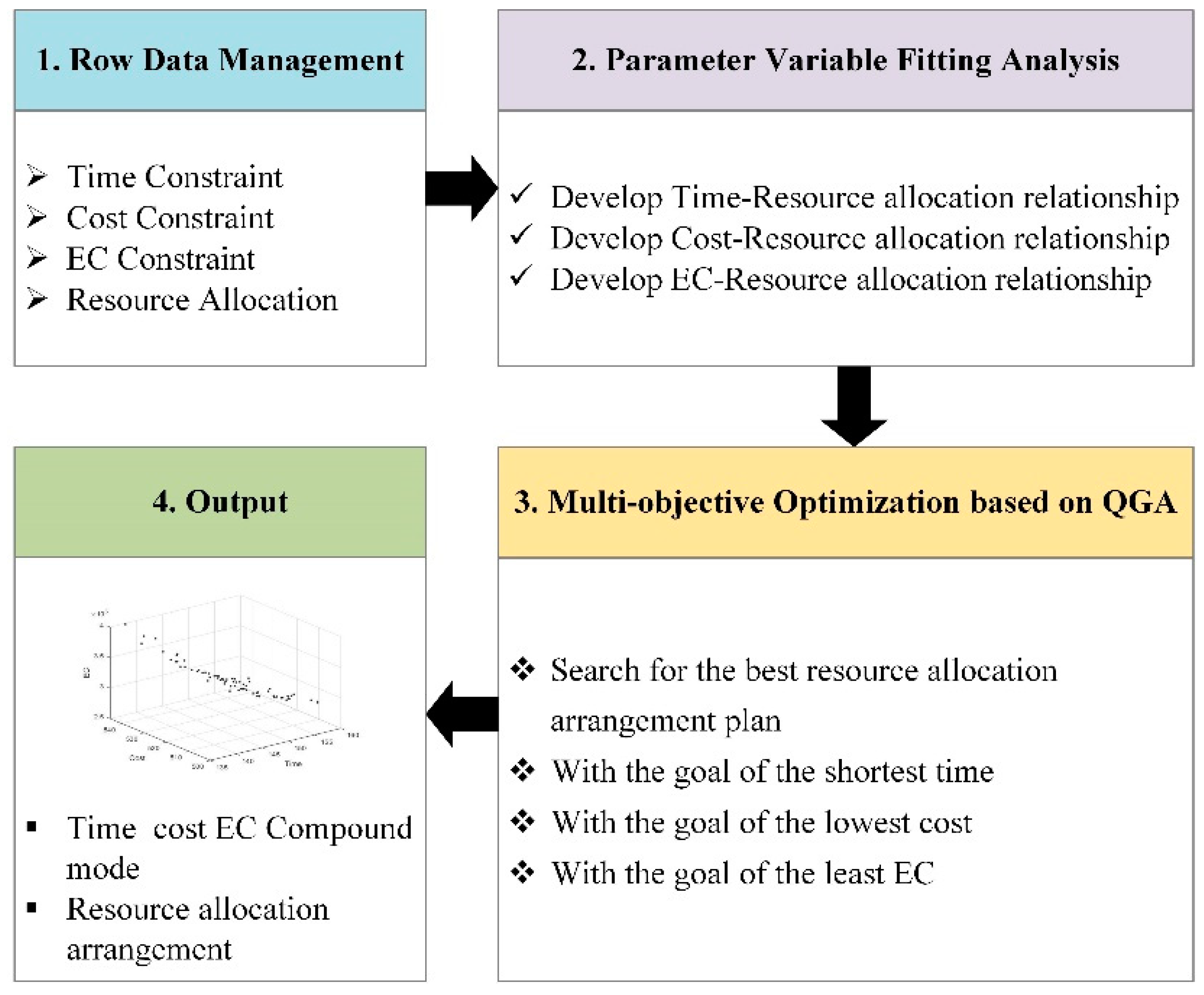

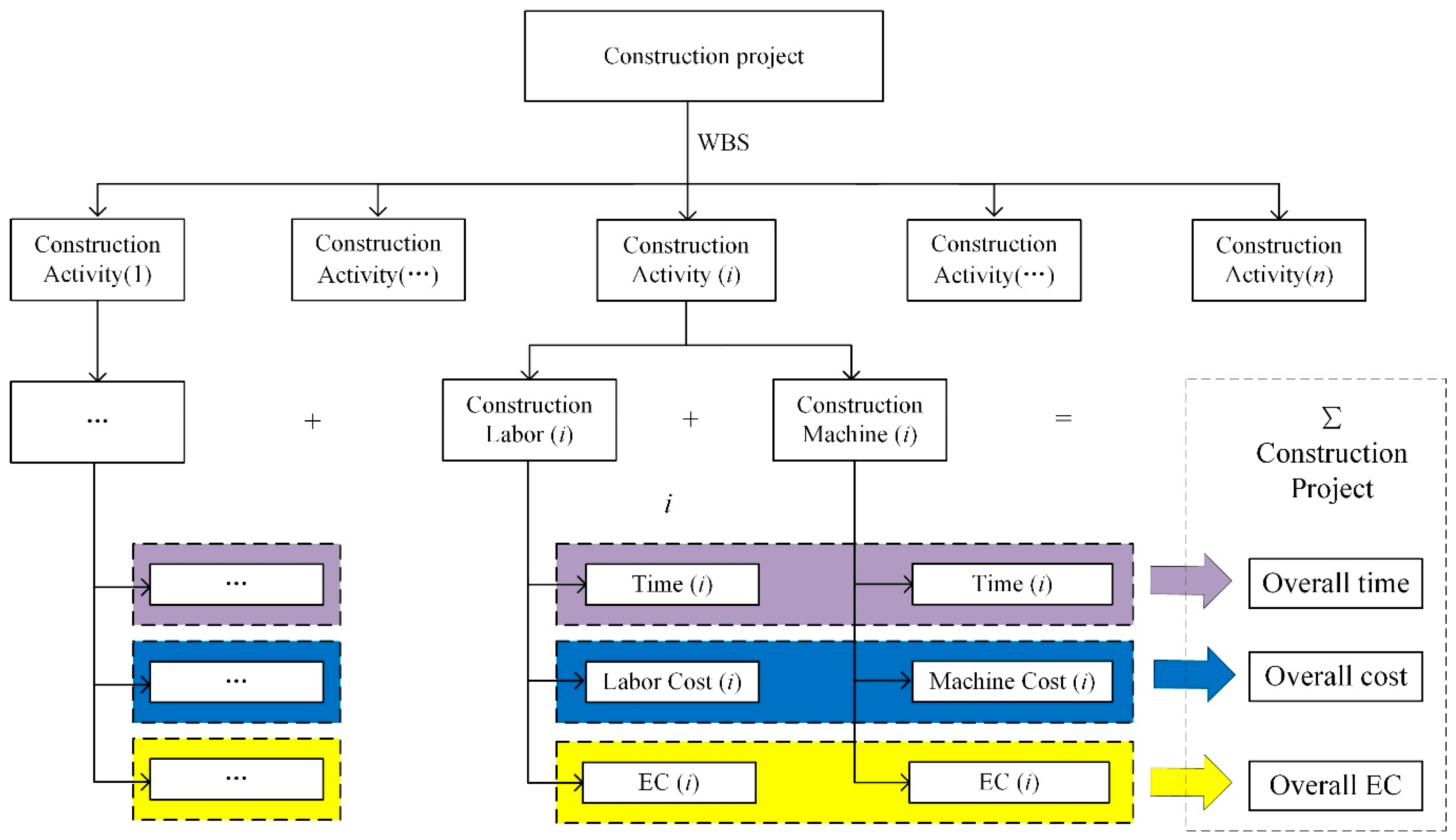

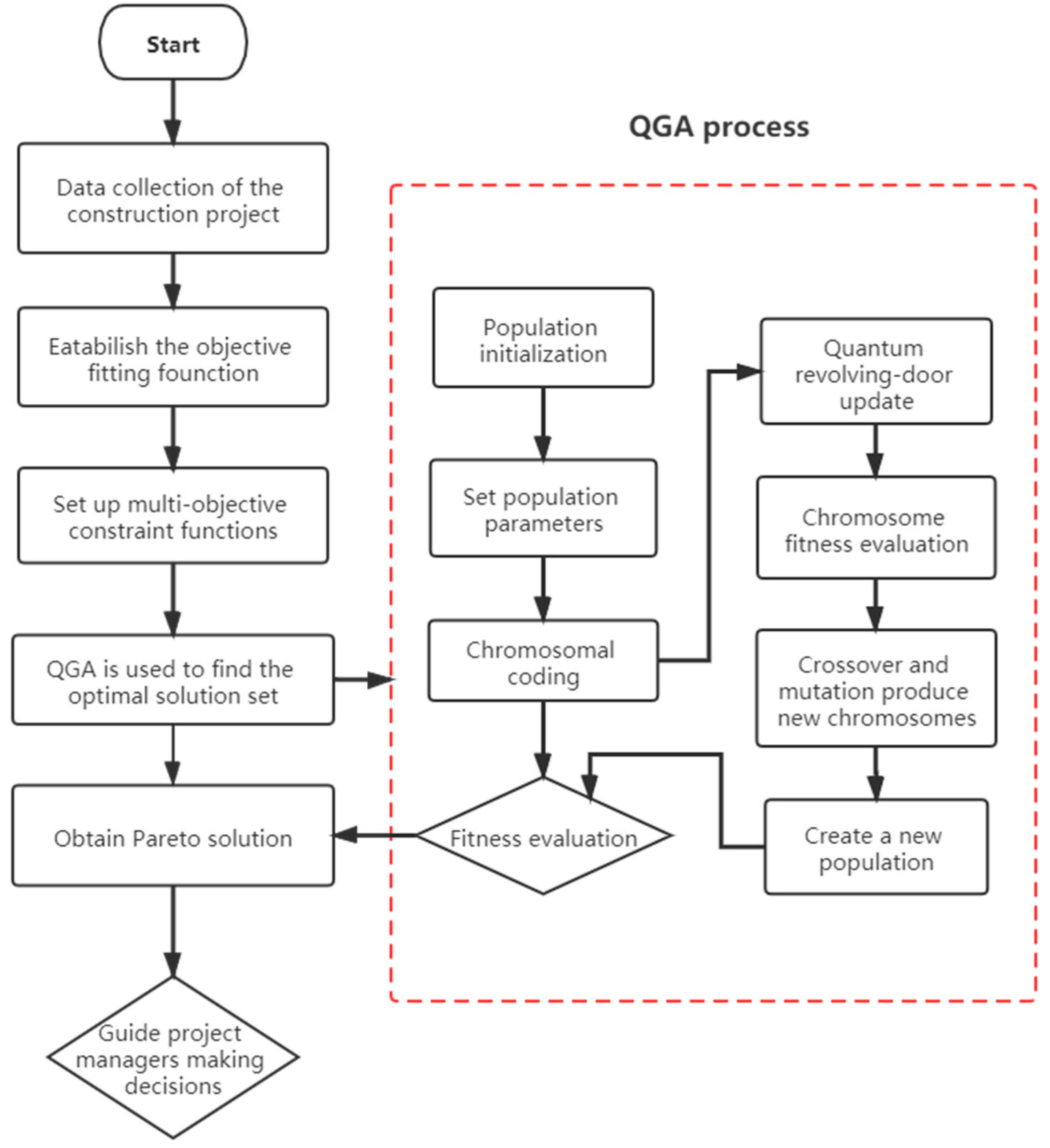

3.1. Modeling Approach

3.1.1. Raw Data Management

3.1.2. Variable Parameter Fitting Analysis

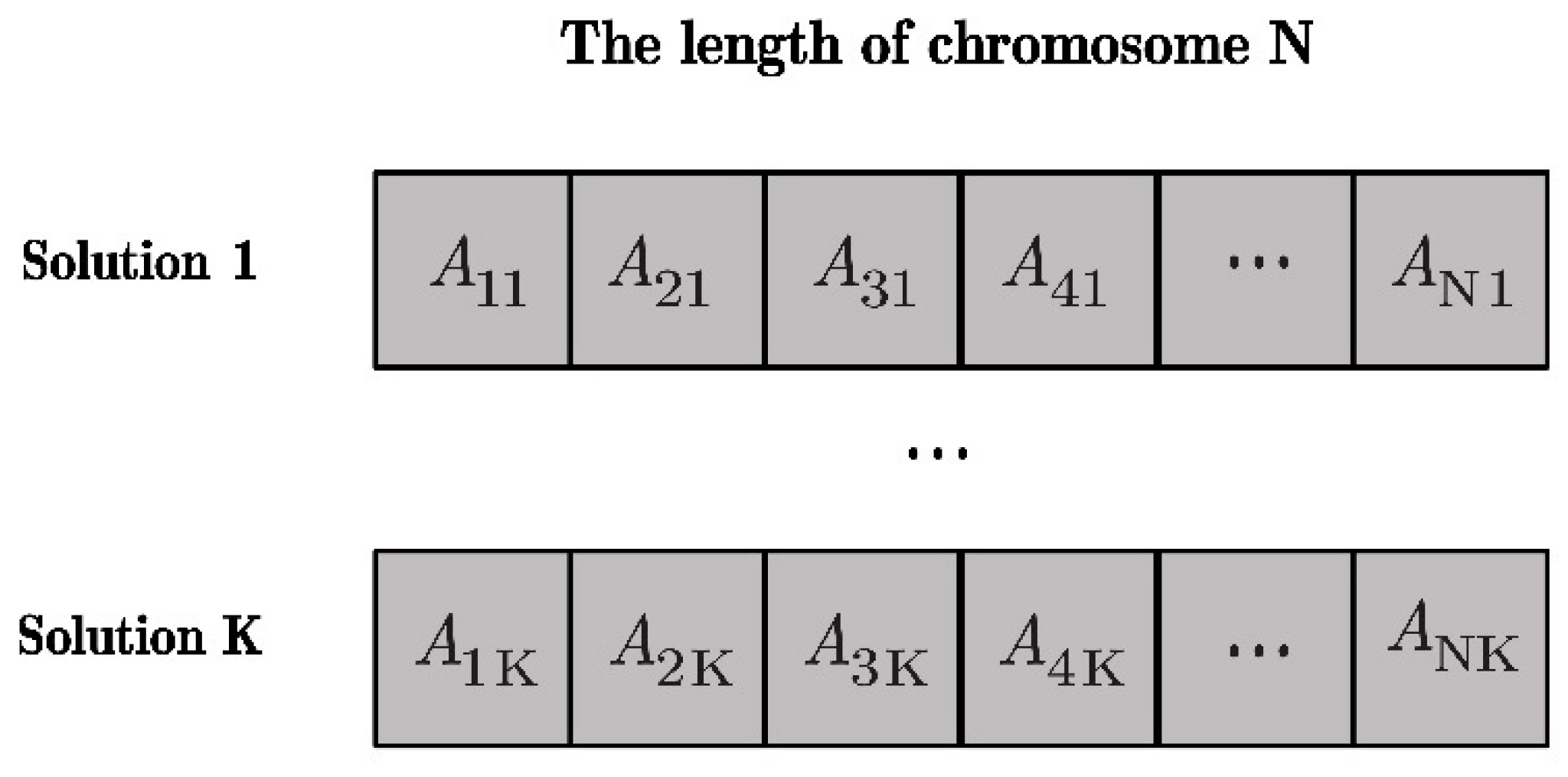

3.1.3. Multi-Objective Optimization Based on QGA

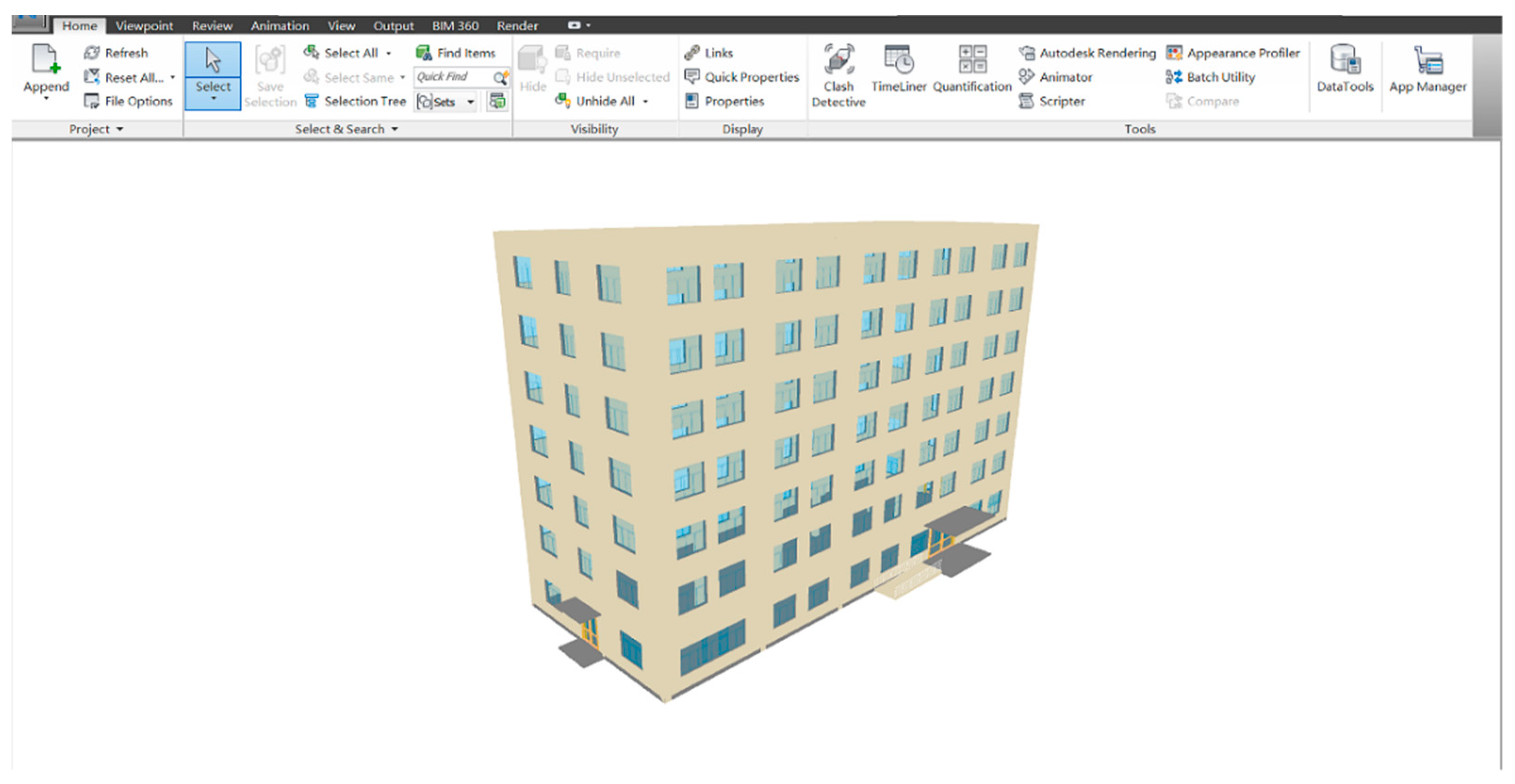

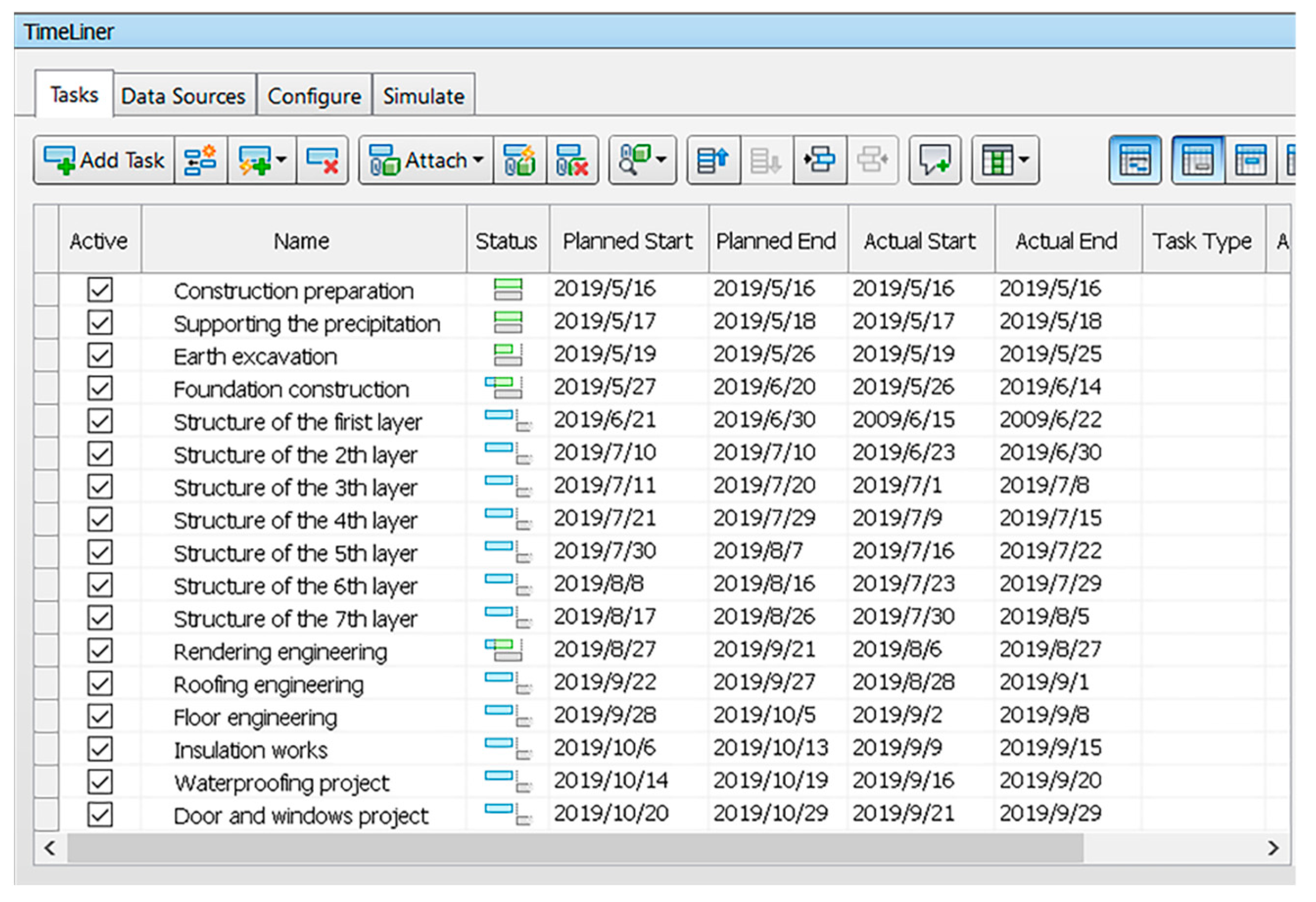

3.2. Object of Case Study

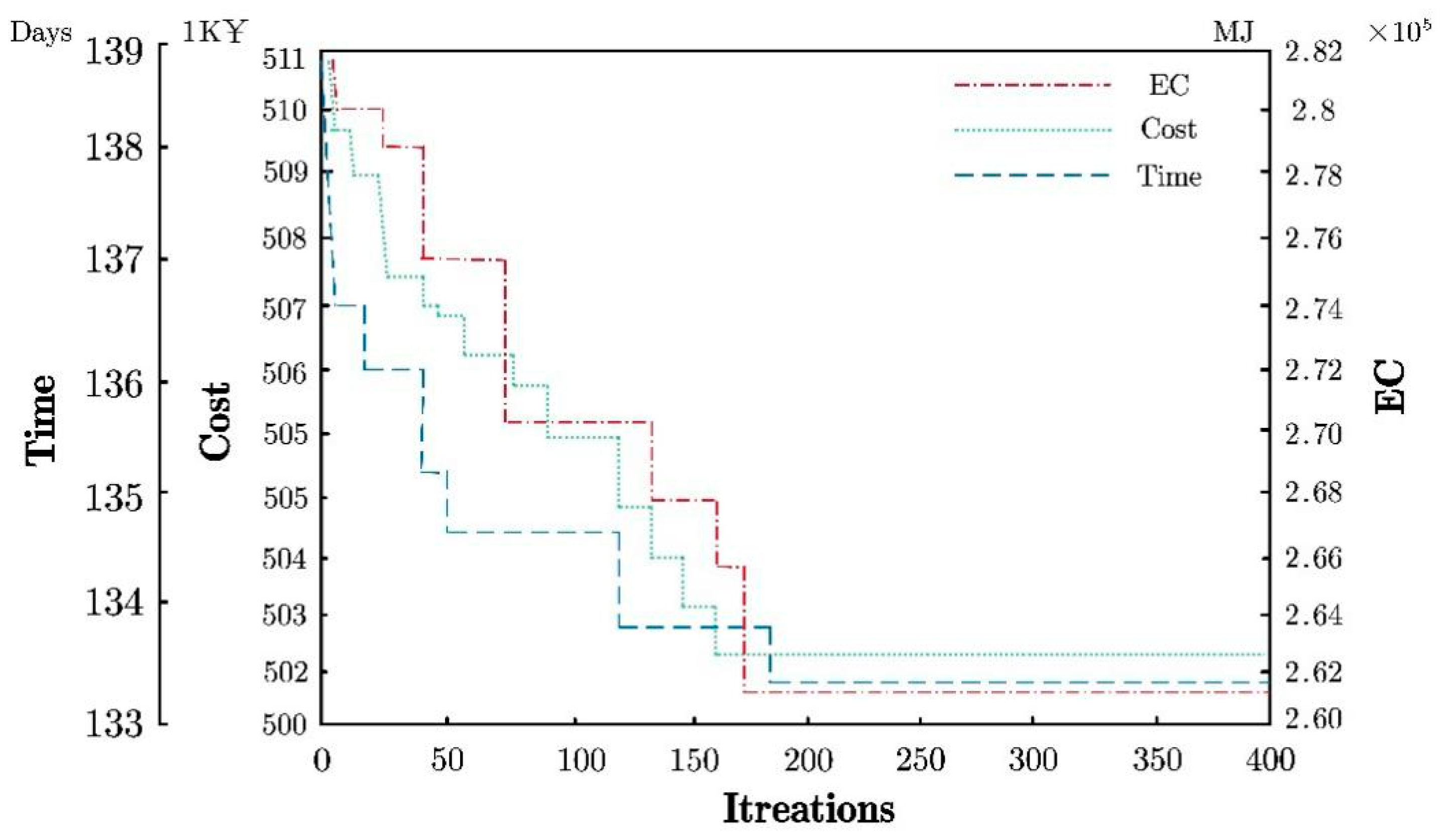

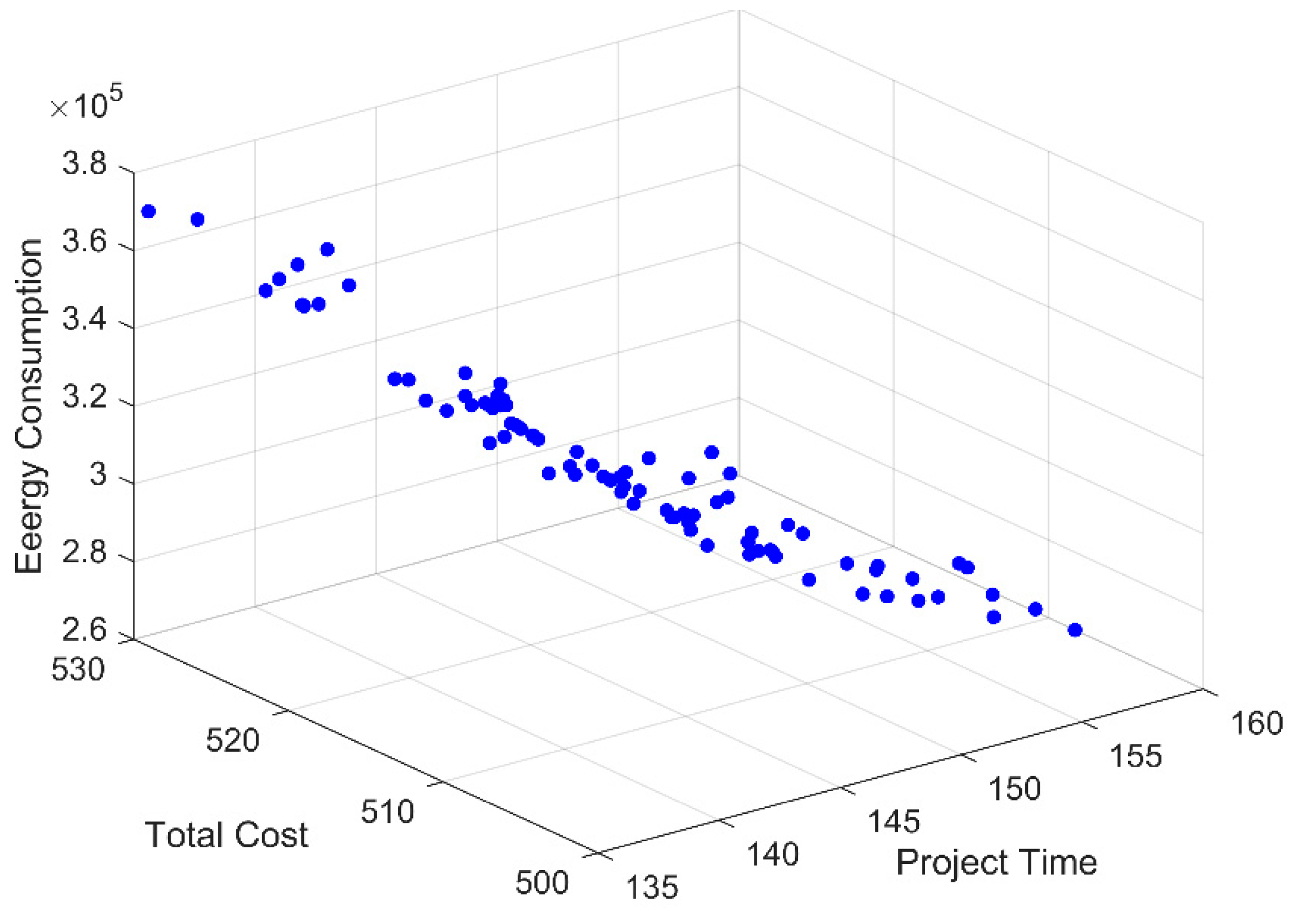

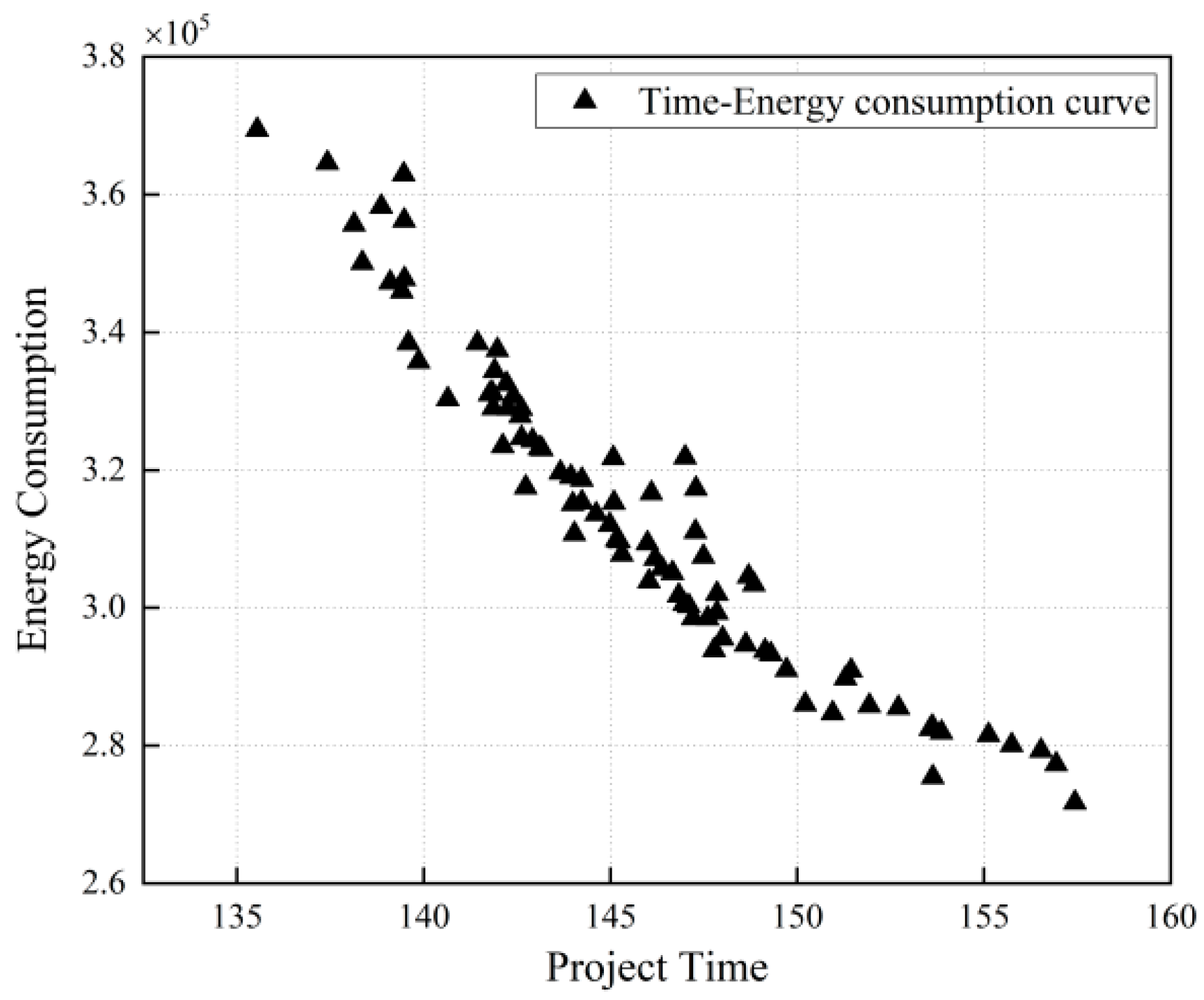

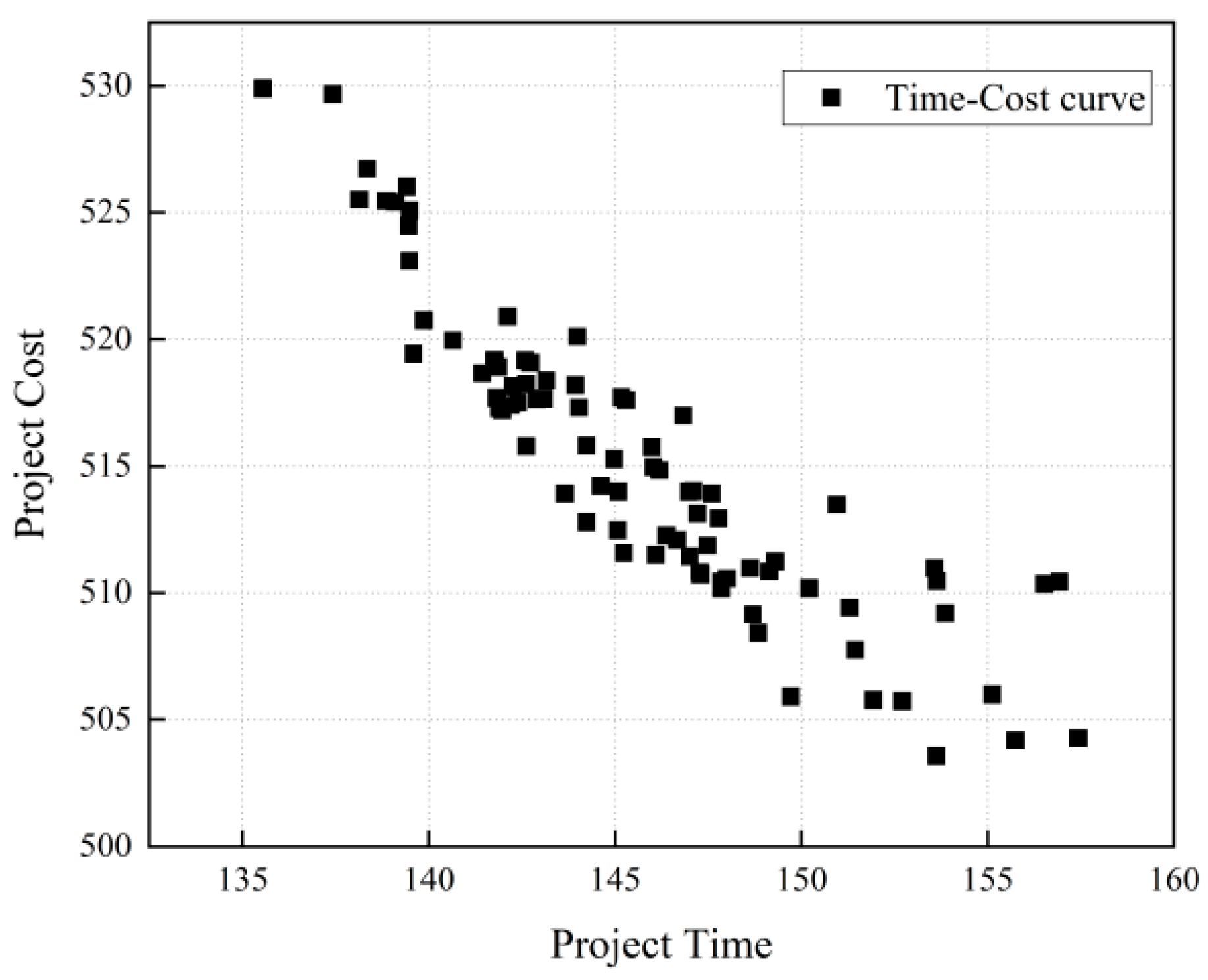

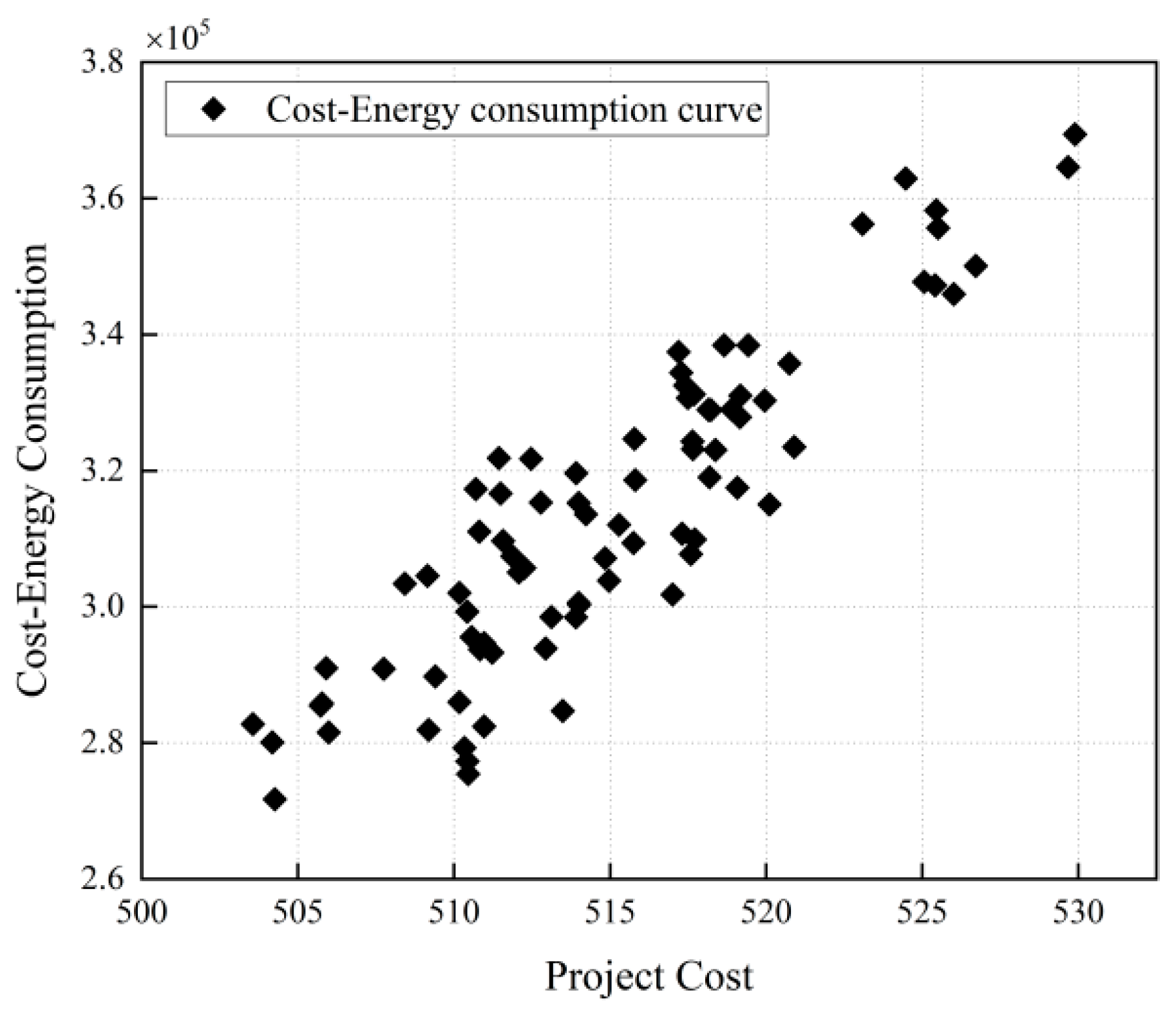

4. Results and Discussion

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Araújo, A.G.; Pereira Carneiro, A.M.; Palha, R.P. Sustainable Construction Management: A Systematic Review of the Literature with Meta-Analysis. J. Clean. Prod. 2020, 256, 120350. [Google Scholar] [CrossRef]

- Dayoub, N.; Fakhratov, M. The Mutual Influence Approach during the Resource Allocation Process in Construction Projects. IOP Conf. Ser. Mater. Sci. Eng. 2021, 1030, 012104. [Google Scholar] [CrossRef]

- Maghsoudi, S.; Duffield, C.; Wilson, D. In Pursuit of Innovation Value in Building Projects. Int. J. Innov. Sci. 2016, 8, 39–70. [Google Scholar] [CrossRef]

- Liu, Y.; Mohamed, Y. Modelling Industrial Construction Operations Using a Multi-agent Resource Allocation Framework. Eng. Constr. Archit. Manag. 2012, 19, 406–427. [Google Scholar] [CrossRef]

- Heon Jun, D.; El-Rayes, K. Multiobjective Optimization of Resource Leveling and Allocation during Construction Scheduling. J. Constr. Eng. Manag. 2011, 137, 1080–1088. [Google Scholar] [CrossRef]

- Li, Q.; Tao, S.; Chong, H.-Y.; Dong, Z.S. Robust Optimization for Integrated Construction Scheduling and Multiscale Resource Allocation. Complexity 2018, 2018, 1–17. [Google Scholar] [CrossRef]

- Leu, S.-S.; Yang, C.-H. A Genetic-Algorithm-Based Resource-Constrained Construction Scheduling System. Constr. Manag. Econ. 1999, 17, 767–776. [Google Scholar] [CrossRef]

- Chan, W.-T.; Chua, D.K.H.; Kannan, G. Construction Resource Scheduling with Genetic Algorithms. J. Constr. Eng. Manag. 1996, 122, 125–132. [Google Scholar] [CrossRef]

- Hegazy, T. Optimization of Resource Allocation and Leveling Using Genetic Algorithms. J. Constr. Eng. Manag. 1999, 125, 167–175. [Google Scholar] [CrossRef]

- Senouci, A.B.; Eldin, N.N. Use of Genetic Algorithms in Resource Scheduling of Construction Projects. J. Constr. Eng. Manag. 2004, 130, 869–877. [Google Scholar] [CrossRef]

- Feng, C.-W.; Liu, L.; Burns, S.A. Using Genetic Algorithms to Solve Construction Time-Cost Trade-Off Problems. J. Comput. Civ. Eng. 1997, 11, 184–189. [Google Scholar] [CrossRef]

- Elazouni, A.M.; Metwally, F.G. Expanding Finance-Based Scheduling to Devise Overall-Optimized Project Schedules. J. Constr. Eng. Manag. 2007, 133, 86–90. [Google Scholar] [CrossRef]

- Sonmez, R.; Iranagh, M.A.; Uysal, F. Critical Sequence Crashing Heuristic for Resource-Constrained Discrete Time–Cost Trade-Off Problem. J. Constr. Eng. Manag. 2016, 142, 04015090. [Google Scholar] [CrossRef]

- Ahmed, T.; Hossain, S.M.; Hossain, M.A. Reducing Completion Time and Optimizing Resource Use of Resource-Constrained Construction Operation by Means of Simulation Modeling. Int. J. Constr. Manag. 2021, 21, 404–415. [Google Scholar] [CrossRef]

- Banihashemi, S.A.; Khalilzadeh, M.; Shahraki, A.; Malkhalifeh, M.R.; Ahmadizadeh, S.S.R. Optimization of Environmental Impacts of Construction Projects: A Time-Cost-Quality Trade-off Approach. Int. J. Environ. Sci. Technol. 2021, 18, 631–646. [Google Scholar] [CrossRef]

- Liu, S.; Tao, R.; Tam, C.M. Optimizing Cost and CO2 Emission for Construction Projects Using Particle Swarm Optimization. Habitat Int. 2013, 37, 155–162. [Google Scholar] [CrossRef]

- Ozcan-Deniz, G.; Zhu, Y.; Ceron, V. Time, Cost, and Environmental Impact Analysis on Construction Operation Optimization Using Genetic Algorithms. J. Manag. Eng. 2012, 28, 265–272. [Google Scholar] [CrossRef]

- Bilec, M.; Ries, R.; Matthews, H.S.; Sharrard, A.L. Example of a Hybrid Life-Cycle Assessment of Construction Processes. J. Infrastruct. Syst. 2006, 12, 207–215. [Google Scholar] [CrossRef] [Green Version]

- Oreszczyn, T.; Lowe, R. Challenges for Energy and Buildings Research: Objectives, Methods and Funding Mechanisms. Build. Res. Inf. 2010, 38, 107–122. [Google Scholar] [CrossRef]

- Liu, X.; Chu, J.; Yin, P.; Sun, J. DEA Cross-Efficiency Evaluation Considering Undesirable Output and Ranking Priority: A Case Study of Eco-Efficiency Analysis of Coal-Fired Power Plants. J. Clean. Prod. 2017, 142, 877–885. [Google Scholar] [CrossRef]

- Ma, Y.X.; Yu, C. Impact of Meteorological Factors on High-Rise Office Building Energy Consumption in Hong Kong: From a Spatiotemporal Perspective. Energy Build. 2020, 228, 110468. [Google Scholar] [CrossRef]

- Van Peteghem, V.; Vanhoucke, M. An Experimental Investigation of Metaheuristics for the Multi-Mode Resource-Constrained Project Scheduling Problem on New Dataset Instances. Eur. J. Oper. Res. 2014, 235, 62–72. [Google Scholar] [CrossRef]

- Tao, S.; Dong, Z.S. Scheduling Resource-Constrained Project Problem with Alternative Activity Chains. Comput. Ind. Eng. 2017, 114, 288–296. [Google Scholar] [CrossRef]

- Khanzadi, M.; Attar, A.M.; Bagherpour, M. Finding Optimum Resource Allocation to Optimizing Construction Project Time/Cost through Combination of Artificial Agents CPM and GA. Period. Polytech. Civ. Eng. 2016, 60, 169–180. [Google Scholar] [CrossRef] [Green Version]

- Yeoh, J.K.W.; Chua, D.K.H. Optimizing Crane Selection and Location for Multistage Construction Using a Four-Dimensional Set Cover Approach. J. Constr. Eng. Manag. 2017, 143, 04017029. [Google Scholar] [CrossRef]

- Kim, K.; Kim, K.J. Multi-Agent-Based Simulation System for Construction Operations with Congested Flows. Autom. Constr. 2010, 19, 867–874. [Google Scholar] [CrossRef]

- Tao, S.; Wu, C.; Sheng, Z.; Wang, X. Space-Time Repetitive Project Scheduling Considering Location and Congestion. J. Comput. Civ. Eng. 2018, 32, 04018017. [Google Scholar] [CrossRef]

- Nabipoor Afruzi, E.; Roghanian, E.; Najafi, A.A.; Mazinani, M. A Multi-Mode Resource-Constrained Discrete Time–Cost Tradeoff Problem Solving Using an Adjusted Fuzzy Dominance Genetic Algorithm. Sci. Iran. 2013, S1026309812003070. [Google Scholar] [CrossRef]

- Wuliang, P.; Chengen, W. A Multi-Mode Resource-Constrained Discrete Time-Cost Tradeoff Problem and Its Genetic Algorithm Based Solution. Int. J. Proj. Manag. 2009, 27, 600–609. [Google Scholar] [CrossRef]

- Hegazy, T.; Menesi, W. Heuristic Method for Satisfying Both Deadlines and Resource Constraints. J. Constr. Eng. Manag. 2012, 138, 688–696. [Google Scholar] [CrossRef]

- Agdas, D.; Warne, D.J.; Osio-Norgaard, J.; Masters, F.J. Utility of Genetic Algorithms for Solving Large-Scale Construction Time-Cost Trade-Off Problems. J. Comput. Civ. Eng. 2018, 32, 04017072. [Google Scholar] [CrossRef] [Green Version]

- Afshar, A.; Ziaraty, A.K.; Kaveh, A.; Sharifi, F. Nondominated Archiving Multicolony Ant Algorithm in Time–Cost Trade-Off Optimization. J. Constr. Eng. Manag. 2009, 135, 668–674. [Google Scholar] [CrossRef]

- Zhang, Y.; Ng, S.T. An ant colony system based decision support system for construction time-cost optimization. J. Civ. Eng. Manag. 2012, 18, 580–589. [Google Scholar] [CrossRef]

- He, W.; Shi, Y.; Kong, D. Construction of a 5D Duration and Cost Optimisation Model Based on Genetic Algorithm and BIM. J. Eng. Des. Technol. 2019, 17, 929–942. [Google Scholar] [CrossRef]

- Toğan, V.; Eirgash, M.A. Time-Cost Trade-off Optimization of Construction Projects Using Teaching Learning Based Optimization. KSCE J. Civ. Eng. 2019, 23, 10–20. [Google Scholar] [CrossRef]

- Albayrak, G. Novel Hybrid Method in Time-Cost Trade-Off for Resource-Constrained Construction Projects. Iran. J. Sci. Technol. Trans. Civ. Eng. 2020, 44, 1295–1307. [Google Scholar] [CrossRef]

- Huang, Y.; Zou, X.; Zhang, L. Genetic Algorithm–Based Method for the Deadline Problem in Repetitive Construction Projects Considering Soft Logic. J. Manag. Eng. 2016, 32, 04016002. [Google Scholar] [CrossRef]

- Zou, X.; Fang, S.-C.; Huang, Y.-S.; Zhang, L.-H. Mixed-Integer Linear Programming Approach for Scheduling Repetitive Projects with Time-Cost Trade-Off Consideration. J. Comput. Civ. Eng. 2017, 31, 06016003. [Google Scholar] [CrossRef]

- Xu, J.; Zheng, H.; Zeng, Z.; Wu, S.; Shen, M. Discrete Time-Cost-Environment Trade-off Problem for Large-Scale Construction Systems with Multiple Modes under Fuzzy Uncertainty and Its Application to Jinping-II Hydroelectric Project. Int. J. Proj. Manag. 2012, 30, 950–966. [Google Scholar] [CrossRef]

- Marzouk, M.; Madany, M.; Abou-Zied, A.; El-said, M. Handling Construction Pollutions Using Multi-objective Optimization. Constr. Manag. Econ. 2008, 26, 1113–1125. [Google Scholar] [CrossRef]

- Ozcan-Deniz, G.; Zhu, Y. Multi-Objective Optimization of Greenhouse Gas Emissions in Highway Construction Projects. Sustain. Cities Soc. 2017, 28, 162–171. [Google Scholar] [CrossRef] [Green Version]

- Blazewicz, J.; Lenstra, J.K.; Kan, A.H.G.R. Scheduling Subject to Resource Constraints: Classification and Complexity. Discret. Appl. Math. 1983, 5, 11–24. [Google Scholar] [CrossRef] [Green Version]

- De, P.; Dunne, E.J.; Ghosh, J.B.; Wells, C.E. Complexity of the Discrete Time-Cost Tradeoff Problem for Project Networks. Oper. Res. 1997, 45, 302–306. [Google Scholar] [CrossRef] [Green Version]

- Zhang, H.; Xing, F. Fuzzy-Multi-Objective Particle Swarm Optimization for Time–Cost–Quality Tradeoff in Construction. Autom. Constr. 2010, 19, 1067–1075. [Google Scholar] [CrossRef]

- Wood, D.A. Gas and Oil Project Time-Cost-Quality Tradeoff: Integrated Stochastic and Fuzzy Multi-Objective Optimization Applying a Memetic, Nondominated, Sorting Algorithm. J. Nat. Gas Sci. Eng. 2017, 45, 143–164. [Google Scholar] [CrossRef]

- De, P.; Dunne, E.J.; Ghosh, J.B.; Wells, C.E. The Discrete Time-Cost Tradeoff Problem Revisited. Eur. J. Oper. Res. 1995, 81, 225–238. [Google Scholar] [CrossRef]

- Jiang, A.; Zhu, Y. A Multi-Stage Approach to Time-Cost Trade-Off Analysis Using Mathematical Programming. Int. J. Constr. Manag. 2010, 10, 13–27. [Google Scholar] [CrossRef]

- Burns, S.A.; Liu, L.; Feng, C.-W. The LP/IP Hybrid Method for Construction Time-Cost Trade-off Analysis. Constr. Manag. Econ. 1996, 14, 265–276. [Google Scholar] [CrossRef]

- Kalhor, E.; Khanzadi, M.; Eshtehardian, E.; Afshar, A. Stochastic Time–Cost Optimization Using Non-Dominated Archiving Ant Colony Approach. Autom. Constr. 2011, 20, 1193–1203. [Google Scholar] [CrossRef]

- Tormos, P.; Lova, A. A Competitive Heuristic Solution Technique for Resource-Constrained Project Scheduling. Ann. Oper. Res. 2001, 102, 65–81. [Google Scholar] [CrossRef]

- Sonmez, R.; Bettemir, Ö.H. A Hybrid Genetic Algorithm for the Discrete Time-Cost Trade-off Problem. Expert Syst. Appl. 2012, 39, 11428–11434. [Google Scholar] [CrossRef] [Green Version]

- Zheng, D.X.M.; Ng, S.T.; Kumaraswamy, M.M. Applying Pareto Ranking and Niche Formation to Genetic Algorithm-Based Multiobjective Time–Cost Optimization. J. Constr. Eng. Manag. 2005, 131, 81–91. [Google Scholar] [CrossRef]

- Sonmez, R.; Uysal, F. Backward-Forward Hybrid Genetic Algorithm for Resource-Constrained Multiproject Scheduling Problem. J. Comput. Civ. Eng. 2015, 29, 04014072. [Google Scholar] [CrossRef]

- Fallah-Mehdipour, E.; Bozorg Haddad, O.; Rezapour Tabari, M.M.; Mariño, M.A. Extraction of Decision Alternatives in Construction Management Projects: Application and Adaptation of NSGA-II and MOPSO. Expert Syst. Appl. 2012, 39, 2794–2803. [Google Scholar] [CrossRef]

- Bouleimen, K.; Lecocq, H. A New Efficient Simulated Annealing Algorithm for the Resource-Constrained Project Scheduling Problem and Its Multiple Mode Version. Eur. J. Oper. Res. 2003, 149, 268–281. [Google Scholar] [CrossRef]

- Valls, V.; Ballestín, F.; Quintanilla, S. Justification and RCPSP: A Technique That Pays. Eur. J. Oper. Res. 2005, 165, 375–386. [Google Scholar] [CrossRef]

- Chen, R.-M. Particle Swarm Optimization with Justification and Designed Mechanisms for Resource-Constrained Project Scheduling Problem. Expert Syst. Appl. 2011, 38, 7102–7111. [Google Scholar] [CrossRef]

- Elsayed, W.M.; Elmogy, M.; El-Desouky, B.S. DNA Sequence Reconstruction Based on Innovated Hybridization Technique of Probabilistic Cellular Automata and Particle Swarm Optimization. Inf. Sci. 2021, 547, 828–840. [Google Scholar] [CrossRef]

- Luong, D.-L.; Tran, D.-H.; Nguyen, P.T. Optimizing Multi-Mode Time-Cost-Quality Trade-off of Construction Project Using Opposition Multiple Objective Difference Evolution. Int. J. Constr. Manag. 2021, 21, 271–283. [Google Scholar] [CrossRef]

- Pan, Y.; Zhang, L. BIM Log Mining: Learning and Predicting Design Commands. Autom. Constr. 2020, 112, 103107. [Google Scholar] [CrossRef]

- Zhang, Q.; Guo, B. Discussion on the Development Barriers of BIM Construction Costs in China. Am. J. Civ. Eng. 2019, 7, 133. [Google Scholar] [CrossRef]

- Succar, B.; Kassem, M. Macro-BIM Adoption: Conceptual Structures. Autom. Constr. 2015, 57, 64–79. [Google Scholar] [CrossRef] [Green Version]

- Wong, A.K.D.; Wong, F.K.W.; Nadeem, A. Government Roles in Implementing Building Information Modelling Systems: Comparison between Hong Kong and the United States. Constr. Innov. 2011, 11, 61–76. [Google Scholar] [CrossRef]

- Dounas, T.; Lombardi, D.; Jabi, W. Framework for Decentralised Architectural Design BIM and Blockchain Integration. Int. J. Archit. Comput. 2021, 19, 157–173. [Google Scholar] [CrossRef]

- Boton, C. Supporting Constructability Analysis Meetings with Immersive Virtual Reality-Based Collaborative BIM 4D Simulation. Autom. Constr. 2018, 96, 1–15. [Google Scholar] [CrossRef]

- Hartmann, T.; Fischer, M. Supporting the Constructability Review with 3D/4D Models. Build. Res. Inf. 2007, 35, 70–80. [Google Scholar] [CrossRef]

- Zhang, C.; Zayed, T.; Hijazi, W.; Alkass, S. Quantitative Assessment of Building Constructability Using BIM and 4D Simulation. Open J. Civ. Eng. 2016, 06, 442–461. [Google Scholar] [CrossRef] [Green Version]

- Xu, J. Research on Application of BIM 5D Technology in Central Grand Project. Procedia Eng. 2017, 174, 600–610. [Google Scholar] [CrossRef]

- Ya-ping, K.; Ying, X. Construction time-cost trade-off analysis using ant colony optimization algorithm. In Proceedings of the 2006 International Conference on Management Science and Engineering, Lille, France, 5–7 October 2006; IEEE: Piscataway, NJ, USA; pp. 2039–2044. [Google Scholar] [CrossRef]

- Liu, D.; Li, H.; Wang, H.; Qi, C.; Rose, T. Discrete Symbiotic Organisms Search Method for Solving Large-Scale Time-Cost Trade-Off Problem in Construction Scheduling. Expert Syst. Appl. 2020, 148, 113230. [Google Scholar] [CrossRef]

- Sonmez, R.; Aminbakhsh, S.; Atan, T. Activity Uncrashing Heuristic with Noncritical Activity Rescheduling Method for the Discrete Time-Cost Trade-Off Problem. J. Constr. Eng. Manag. 2020, 146, 04020084. [Google Scholar] [CrossRef]

- He, W.; Shi, Y. Multiobjective Construction Optimization Model Based on Quantum Genetic Algorithm. Adv. Civ. Eng. 2019, 2019, 1–8. [Google Scholar] [CrossRef]

- Feng, K.; Lu, W.; Chen, S.; Wang, Y. An Integrated Environment–Cost–Time Optimisation Method for Construction Contractors Considering Global Warming. Sustainability 2018, 10, 4207. [Google Scholar] [CrossRef] [Green Version]

- Cheng, M.-Y.; Tran, D.-H. Opposition-Based Multiple-Objective Differential Evolution to Solve the Time–Cost–Environment Impact Trade-Off Problem in Construction Projects. J. Comput. Civ. Eng. 2015, 29, 04014074. [Google Scholar] [CrossRef]

- Dasović, B.; Galić, M.; Klanšek, U. A Survey on Integration of Optimization and Project Management Tools for Sustainable Construction Scheduling. Sustainability 2020, 12, 3405. [Google Scholar] [CrossRef] [Green Version]

- Aslam, M.; Baffoe-Twum, E.; Saleem, F. Design Changes in Construction Projects—Causes and Impact on the Cost. Civ. Eng. J. 2019, 5, 1647–1655. [Google Scholar] [CrossRef] [Green Version]

- Srdić, A.; Šelih, A.J. Delays in Construction Projects: Causes and Mitigation. Organ. Technol. Manag. Constr. Int. J. 2015, 7, 1383–1389. [Google Scholar] [CrossRef]

- Byun, N.; Han, W.S.; Kwon, Y.W.; Kang, Y.J. Development of BIM-Based Bridge Maintenance System Considering Maintenance Data Schema and Information System. Sustainability 2021, 13, 4858. [Google Scholar] [CrossRef]

- Chau, K.W.; Anson, M.; Zhang, J.P. Four-Dimensional Visualization of Construction Scheduling and Site Utilization. J. Constr. Eng. Manag. 2004, 130, 598–606. [Google Scholar] [CrossRef] [Green Version]

- Liao, L.; Teo, E.A.L.; Chang, R.; Li, L. Investigating Critical Non-Value Adding Activities and Their Resulting Wastes in BIM-Based Project Delivery. Sustainability 2020, 12, 355. [Google Scholar] [CrossRef] [Green Version]

- Lu, Q.; Chen, L.; Lee, S.; Zhao, X. Activity Theory-Based Analysis of BIM Implementation in Building O&M and First Response. Autom. Constr. 2018, 85, 317–332. [Google Scholar] [CrossRef]

| Name of Mechanical Equipment () | Machine Class () |

|---|---|

| Drilling machine | 5 |

| Truck-mounted crane | 3 |

| Lift pump (100 m) | 2 |

| Excavator | 1 |

| Muck truck | 1 |

| Motor pump | 2 |

| Reinforcing steel cutter (GQL40) | 1 |

| Reinforcement bar straightening machine | 1 |

| Steel bar bender (GJ40) | 1 |

| Electroslag pressure welder (630) | 1 |

| Electric welding machine | 1 |

| Tower crane (QTZ79) | 1 |

| Mortar mixer | 1 |

| Construction elevator (SC200/200) | 1 |

| Forklift truck (CPCD30C) | 1 |

| Floodlight | 1 |

| Water suction pump (QY-15) | 1 |

| Mist cannon truck (100 m) | 2 |

| Concrete seam cutting machine (handheld) | 1 |

| Portable pneumatic agitator | 1 |

| Concrete delivery pump truck | 3 |

| Water torch | 1 |

| Cleaning machine | 1 |

| Portable pneumatic agitator | 1 |

| Electric bucket car | 1 |

| Electric hand drill | 1 |

| No. | Activity | Time/Day | Cost/1 K¥ ($) | EC/GJ | |||

|---|---|---|---|---|---|---|---|

| Normal () | Emergency () | Normal () | Emergency () | Normal () | Emergency () | ||

| 1 | Construction preparation | 1 | 0.5 | 0.1 | 0.3 | 0.74 | 0.75 |

| 2 | Supporting the precipitation | 2 | 1 | 0.3 | 0.5 | 17.31 | 47.07 |

| 3 | Earth excavation | 8 | 6 | 6.2 | 8.5 | 8.42 | 19.1 |

| 4 | Foundation construction | 25 | 17 | 3.1 | 5.4 | 45.06 | 66.71 |

| 5 | Structure of the first layer | 10 | 7 | 52.35 | 59.37 | 37 | 68.49 |

| 6 | Structure of the 2nd layer | 10 | 7 | 52.35 | 59.37 | 34.48 | 52.81 |

| 7 | Structure of the 3rd layer | 10 | 7 | 52.35 | 59.37 | 26.68 | 50.81 |

| 8 | Structure of the 4th layer | 9 | 6 | 49.8 | 57.69 | 26.39 | 48.45 |

| 9 | Structure of the 5th layer | 9 | 6 | 51.8 | 57.69 | 26.893 | 48.45 |

| 10 | Structure of the 6th layer | 9 | 6 | 51.8 | 57.69 | 26.89 | 48.45 |

| 11 | Structure of the 7th layer | 9 | 6 | 51.8 | 57.69 | 28.31 | 50 |

| 12 | Rendering engineering | 26 | 20 | 14.7 | 16.6 | 8.72 | 18.37 |

| 13 | Roofing engineering | 6 | 5 | 15.1 | 17.5 | 4.79 | 6.25 |

| 14 | Floor engineering | 8 | 6 | 30.2 | 33.6 | 5.78 | 9.12 |

| 15 | Insulation works | 8 | 6 | 7.4 | 9.2 | 4.44 | 8.12 |

| 16 | Waterproofing project | 6 | 4 | 4.2 | 5.6 | 5.88 | 8.01 |

| 17 | Doors and windows project | 10 | 8 | 90 | 98 | 36 | 45.26 |

| No. | Activity | Labor ()/MT | Machine ()/MT | ||

|---|---|---|---|---|---|

| Normal | Emergency | Normal | Emergency | ||

| 1 | Construction preparation | 3 | 6 | 1 | 2 |

| 2 | Supporting the precipitation | 2 | 5 | 22 | 30 |

| 3 | Earth excavation | 10 | 16 | 20 | 32 |

| 4 | Foundation construction | 60 | 89 | 39 | 52 |

| 5 | Structure of the first layer | 56 | 84 | 34 | 48 |

| 6 | Structure of the 2nd layer | 56 | 84 | 34 | 48 |

| 7 | Structure of the 3rd layer | 56 | 84 | 34 | 48 |

| 8 | Structure of the 4th layer | 56 | 84 | 34 | 48 |

| 9 | Structure of the 5th layer | 56 | 84 | 34 | 48 |

| 10 | Structure of the 6th layer | 56 | 84 | 34 | 48 |

| 11 | Structure of the 7th layer | 56 | 84 | 34 | 48 |

| 12 | Rendering engineering | 12 | 20 | 3.5 | 5 |

| 13 | Roofing engineering | 15 | 25 | 4.5 | 7 |

| 14 | Floor engineering | 8 | 15 | 3 | 6 |

| 15 | Insulation works | 8 | 15 | 1 | 2 |

| 16 | Waterproofing project | 6 | 10 | 2 | 4 |

| 17 | Doors and windows project | 10 | 15 | 9 | 15 |

| Input Parameters | Notation | Setting |

|---|---|---|

| Initial Angle | IA | 0.01π |

| Population size | NP | 1000 |

| Variable dimension | D | 34 |

| Maximum generation | Gmax | 400 |

| Activity | Project Performance | |||||||||||||||||||||||||||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Solution | Partial Set | 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | Time | Cost | EC | |||||||||||||||||

| L | M | L | M | L | M | L | M | L | M | L | M | L | M | L | M | L | M | L | M | L | M | L | M | L | M | L | M | L | M | L | M | L | M | |||||

| 1 | Sorted by Time | 3 | 1 | 2 | 13 | 10 | 28 | 79 | 52 | 57 | 44 | 73 | 40 | 58 | 38 | 63 | 39 | 57 | 45 | 56 | 47 | 56 | 42 | 18 | 5 | 21 | 6 | 9 | 4 | 14 | 2 | 9 | 2 | 14 | 12 | 138.14 | 525.51 | 355,662.70 |

| 2 | 5 | 1 | 4 | 10 | 14 | 31 | 62 | 52 | 80 | 41 | 56 | 47 | 56 | 44 | 57 | 39 | 72 | 43 | 56 | 34 | 63 | 42 | 18 | 5 | 19 | 6 | 8 | 5 | 8 | 2 | 9 | 2 | 14 | 12 | 139.11 | 525.42 | 347,228.47 | |

| 3 | 5 | 1 | 4 | 11 | 12 | 29 | 70 | 51 | 56 | 43 | 56 | 42 | 65 | 45 | 78 | 44 | 56 | 43 | 56 | 45 | 73 | 42 | 18 | 5 | 15 | 5 | 8 | 5 | 11 | 2 | 9 | 2 | 11 | 14 | 139.41 | 526.01 | 345,932.44 | |

| 4 | Sorted by Cost | 4 | 1 | 3 | 12 | 16 | 20 | 63 | 51 | 56 | 36 | 58 | 41 | 57 | 36 | 57 | 35 | 57 | 36 | 56 | 44 | 56 | 35 | 18 | 4 | 15 | 6 | 9 | 5 | 9 | 2 | 7 | 3 | 10 | 9 | 153.62 | 503.56 | 282,754.93 |

| 5 | 5 | 1 | 4 | 13 | 11 | 22 | 63 | 43 | 56 | 34 | 56 | 37 | 56 | 36 | 56 | 37 | 56 | 43 | 56 | 40 | 56 | 34 | 19 | 5 | 18 | 5 | 9 | 5 | 12 | 1 | 6 | 2 | 10 | 13 | 155.74 | 504.18 | 280,071.75 | |

| 6 | 4 | 1 | 2 | 10 | 15 | 24 | 64 | 48 | 60 | 34 | 58 | 41 | 56 | 34 | 57 | 35 | 58 | 34 | 56 | 36 | 70 | 34 | 15 | 5 | 18 | 5 | 9 | 3 | 11 | 1 | 8 | 3 | 10 | 13 | 157.44 | 504.27 | 271,728.91 | |

| 7 | Sorted by EC | 4 | 1 | 2 | 10 | 15 | 24 | 64 | 48 | 60 | 34 | 58 | 41 | 56 | 34 | 57 | 35 | 58 | 34 | 56 | 36 | 70 | 34 | 15 | 5 | 18 | 5 | 9 | 3 | 11 | 1 | 8 | 3 | 10 | 13 | 157.44 | 504.27 | 271,728.91 |

| 8 | 5 | 1 | 3 | 13 | 13 | 25 | 60 | 48 | 56 | 44 | 56 | 47 | 58 | 34 | 57 | 34 | 57 | 36 | 64 | 34 | 64 | 34 | 14 | 4 | 16 | 6 | 10 | 5 | 12 | 2 | 9 | 2 | 10 | 10 | 153.63 | 510.34 | 2792.48 | |

| 9 | 4 | 1 | 2 | 11 | 13 | 20 | 68 | 40 | 58 | 47 | 61 | 43 | 56 | 35 | 65 | 34 | 56 | 36 | 57 | 38 | 58 | 39 | 20 | 4 | 16 | 5 | 8 | 5 | 13 | 2 | 8 | 2 | 10 | 14 | 156.93 | 510.43 | 277,281.17 | |

| 10 | Compromised | 3 | 1 | 4 | 10 | 12 | 28 | 65 | 51 | 56 | 35 | 56 | 44 | 56 | 37 | 59 | 46 | 56 | 36 | 72 | 38 | 72 | 36 | 19 | 5 | 20 | 4 | 9 | 3 | 12 | 2 | 8 | 2 | 10 | 13 | 1445.99 | 515.75 | 309,346.21 |

| 11 | 5 | 1 | 3 | 11 | 15 | 22 | 60 | 52 | 56 | 39 | 58 | 48 | 56 | 35 | 66 | 38 | 58 | 34 | 63 | 48 | 66 | 43 | 19 | 5 | 24 | 6 | 10 | 6 | 10 | 2 | 9 | 2 | 10 | 13 | 144.04 | 517.31 | 310,709.16 | |

| 12 | 5 | 1 | 2 | 13 | 15 | 24 | 79 | 52 | 56 | 36 | 58 | 43 | 56 | 42 | 58 | 36 | 56 | 44 | 56 | 42 | 58 | 39 | 15 | 5 | 17 | 6 | 9 | 5 | 9 | 1 | 10 | 2 | 13 | 13 | 147.28 | 510.81 | 311,016.29 | |

| Population Size | Iterative Convergence | Iterative Termination | Optimal Result | |||||

|---|---|---|---|---|---|---|---|---|

| Iteration | Time | Iteration | Time | Cost | Time | EC | ||

| GA | 1200 | 2300 | 30.2 min | 4500 | 41.6 min | 536.67 | 138.14 | 356,541.2 |

| QGA | 1000 | 160 | 21.1 min | 400 | 26.5min | 525.51 | 138.14 | 355,662.7 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

He, W.; Li, W.; Wang, W. Developing a Resource Allocation Approach for Resource-Constrained Construction Operation under Multi-Objective Operation. Sustainability 2021, 13, 7318. https://doi.org/10.3390/su13137318

He W, Li W, Wang W. Developing a Resource Allocation Approach for Resource-Constrained Construction Operation under Multi-Objective Operation. Sustainability. 2021; 13(13):7318. https://doi.org/10.3390/su13137318

Chicago/Turabian StyleHe, Wei, Wenjing Li, and Wei Wang. 2021. "Developing a Resource Allocation Approach for Resource-Constrained Construction Operation under Multi-Objective Operation" Sustainability 13, no. 13: 7318. https://doi.org/10.3390/su13137318

APA StyleHe, W., Li, W., & Wang, W. (2021). Developing a Resource Allocation Approach for Resource-Constrained Construction Operation under Multi-Objective Operation. Sustainability, 13(13), 7318. https://doi.org/10.3390/su13137318