To give the procedure a formulaic-like structure, the general balancing equilibrium, modal balancing and Four-Run balancing method are described.

2.1.2. Modal Balancing

To obtain an accurate mass, the basic theory of modal balancing [

25,

34] and Kellenberger [

35] is a necessary tool to assist in accomplishing this. For an isotropic flexible rotor system with arbitrary distributed mass,

, the characteristic modal function can be obtained when the geometrical features and physical parameters of the system are given. The orthogonality condition between two modes can be defined as in the references, Yue et al. and Bishop et al. [

25,

34]:

where

is the

nth characteristic modal function and

is the location of the horizontal axis of the rotor bearing system and

is the

kth distributed mass. The distributions of initial unbalance mass eccentricity of shaft can be expressed as

The dynamic deflection

can be stated as

where

is the

nth critical angular speed. The critical rotation speeds in revolutions per minute (RPM),

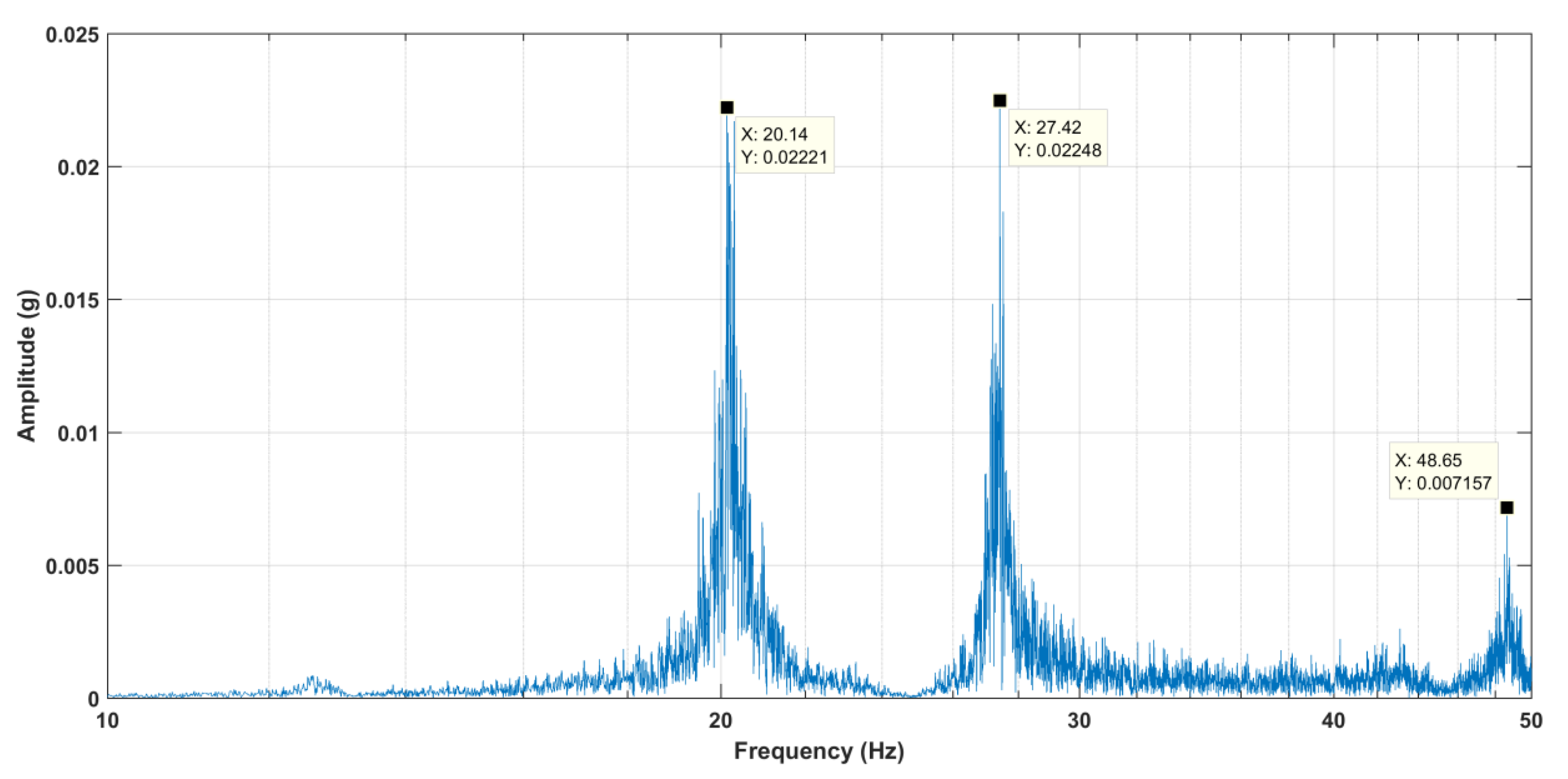

Figure 2, of the device are given by a simple relation in angular frequency

The actual values of the critical rotation speeds are presented a little later in the text, but it is clear here,

Figure 2, that critical speeds have been reached by consideration of the acceleration at a point measured on a rotation object during shut-down and run-up. The constant speed RPM is slightly above the critical speed encountered during run-up and is highlighted during Shut down, Zone A. Indeed, this example illustrates a possible increase in transient acceleration during shut down periods. Note that vibration acceleration is shown here and throughout in terms of g = 9.807 m/s

2 since this quantity is commonly used by test engineers in machine diagnostics.

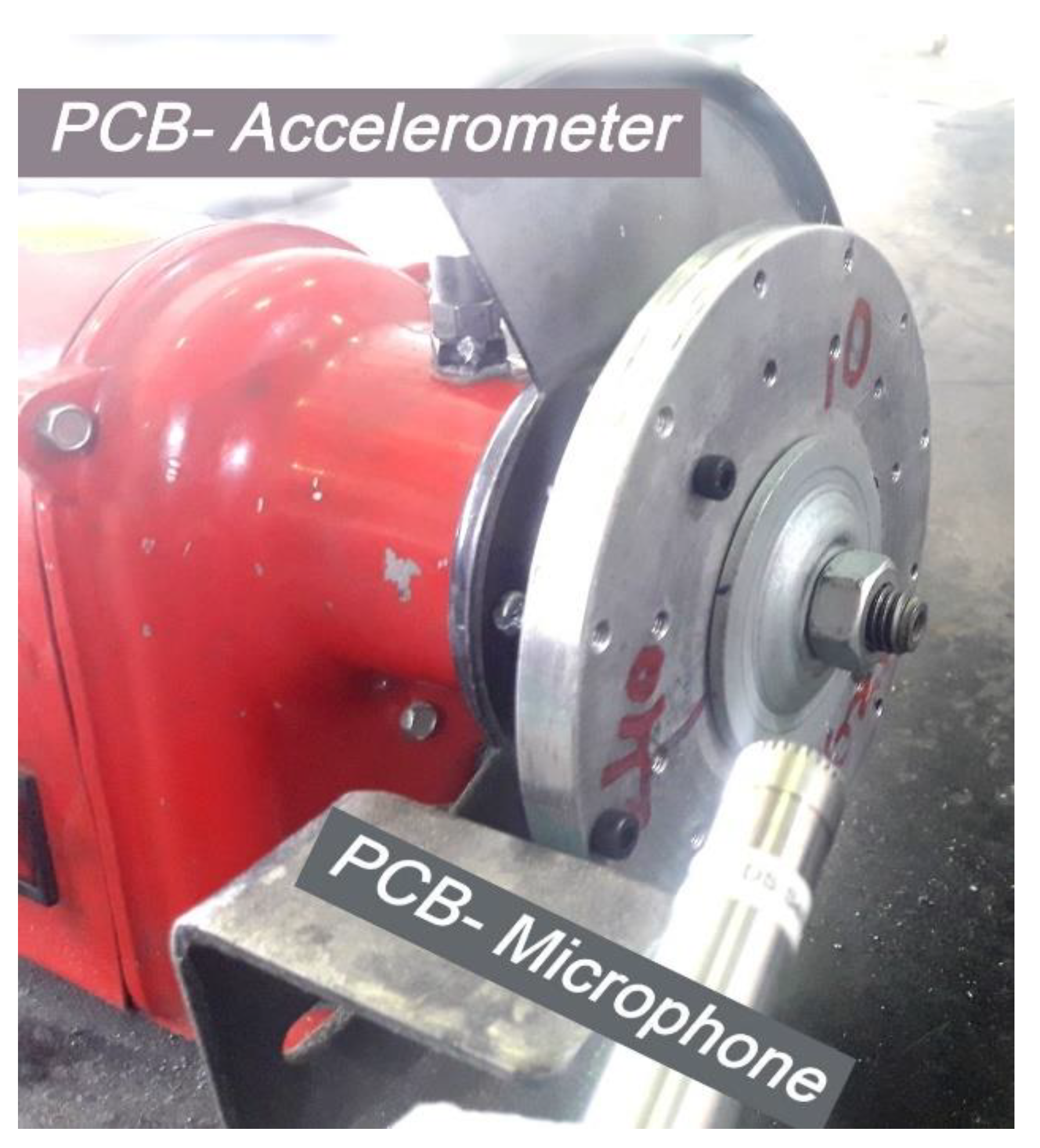

The original Four-Run balancing method is also known as the common phase-less method, Walker et al. [

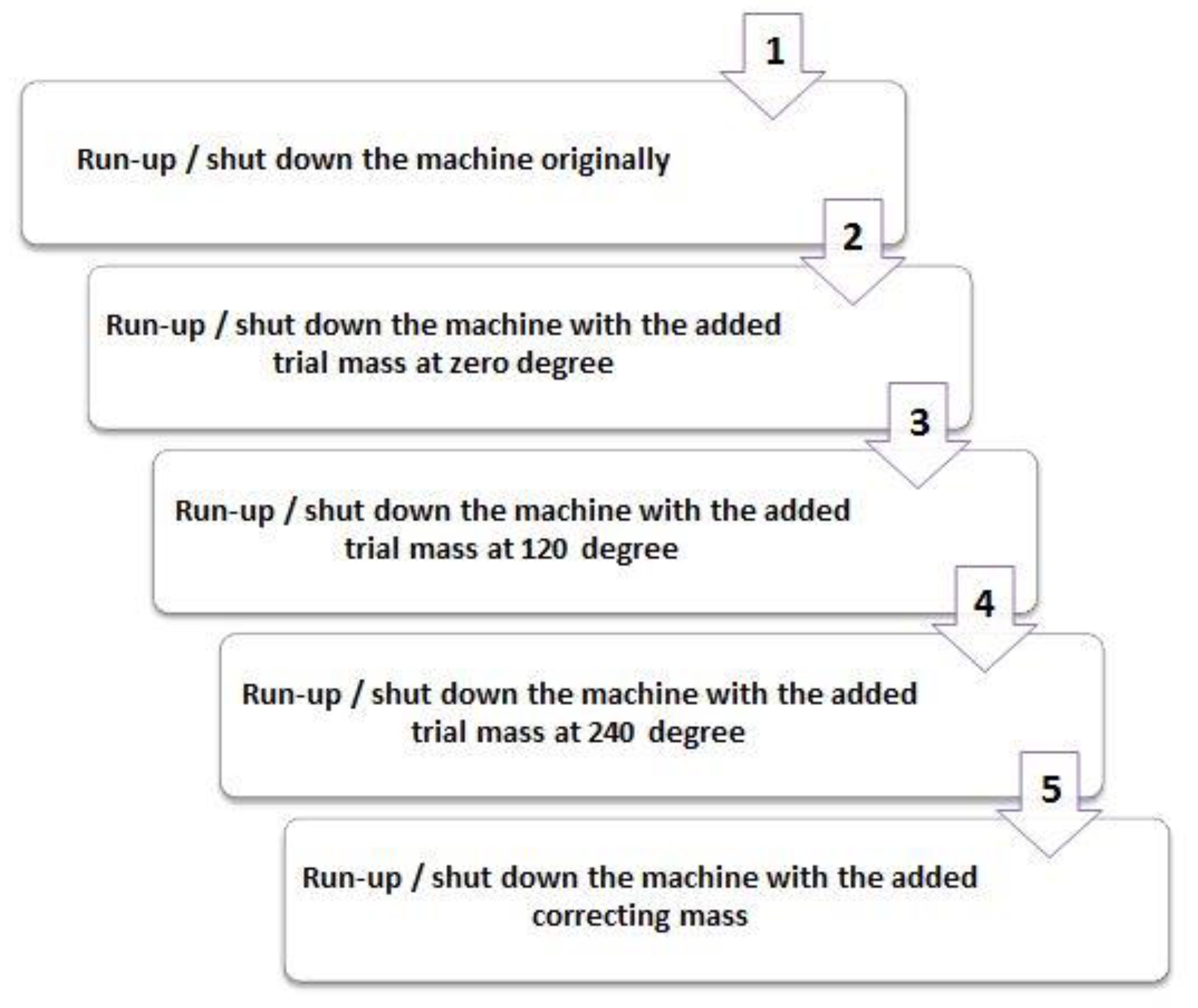

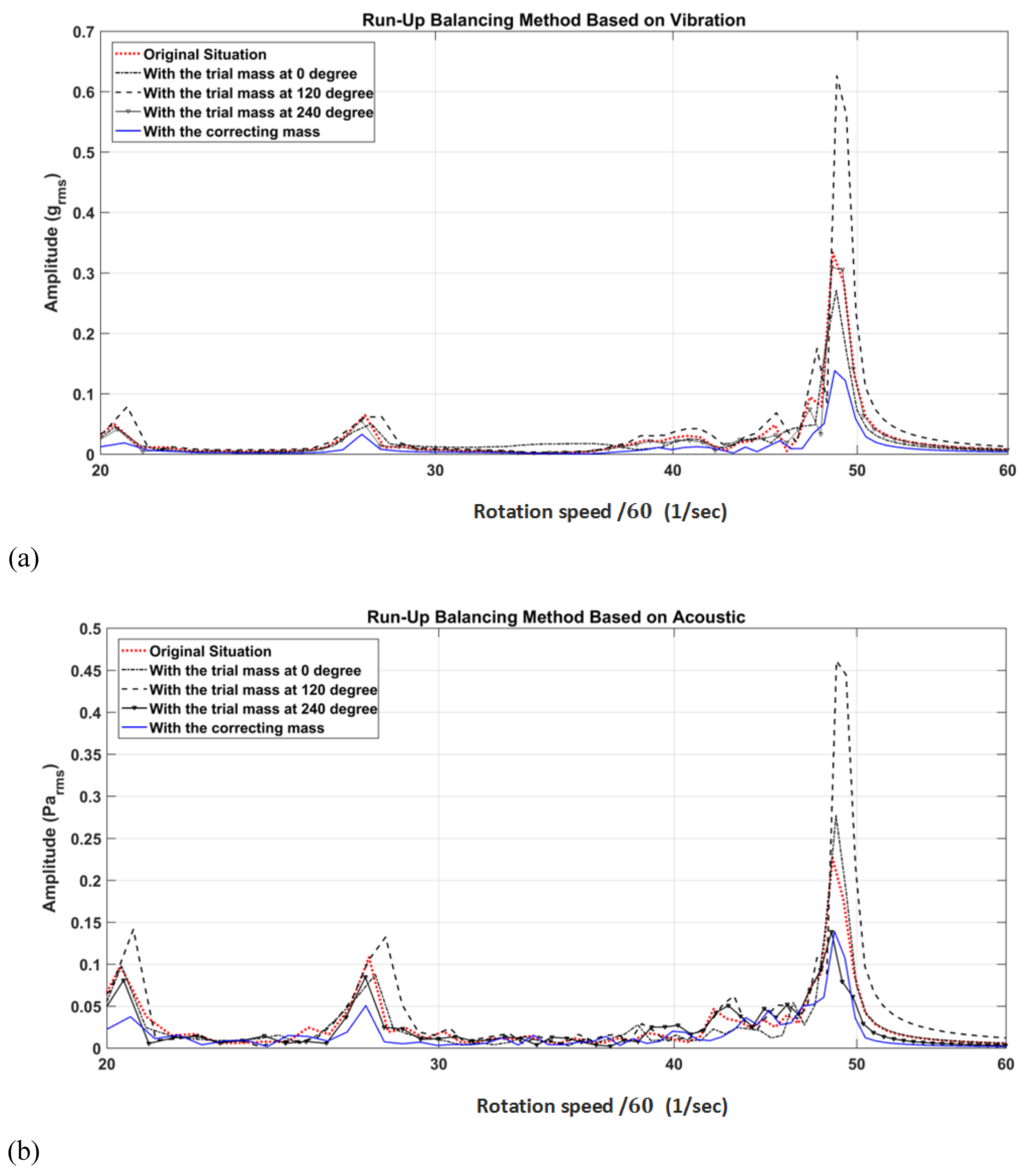

29]. Based on the fundamentals of regular Four-Run balancing method, the Peak to Peak of different Critical Speeds (PPCS) balancing method is proposed. Therefore, the PPCS method is simply based on the root mean square of the amplitude of vibration or acoustic responses of the device which are then recorded during running-up or free shutting-down operating processes in presence of critical speeds. However, this method requires preliminary assessment of run-up and shut-down Zones in which the PPCS method is required to assess independently. This means that the PPCS method can be applied to different types of disc data: the run-up test and the shut-down test. These provide enough information to calculate the position and properties of a required correction but arbitrary sized mass. The PPCS method requires several steps that, described briefly here, it is important to restate that these steps also apply to acoustic data which can be obtained from a single microphone or an array during an operational sample test. Using acoustic signature can be considered as an innovative idea to estimate the machine vibration contactless. This point is considered as the novelty of the method which brings simplicity to the balancing procedure. The outline steps of the method are illustrated in

Figure 3.

It must be stressed that the machine must reach a specific speed greater than the critical speeds during run-up or shut down operation. The acoustic response data of the machine could be considered from the run-up area, zone A or zone B of shut down process, according to

Figure 2. Zone A is related to the time from the beginning of the shut-down process to the time when the third and second critical speeds have been excited. Zone B consists of the time between excitation of the first and second critical speeds of the machine. Here, the root mean square (rms) values have been calculated within the response periods and considered as the representative values for the magnitude of the vibration and acoustic responses.

At the first step, a modal analysis test has been done to clarify the critical speeds of the machine. Then, the (faulty) device of interest is started normally and after reaching a specific speed higher than the critical speeds, the device is then switched off. Then, the root mean square of the amplitude of the machine response during the selected time range is calculated. Here, the acoustic response of the device is recorded via microphone. This type of recording also applies to the following steps. At the second run-up or shut-down test, a trial mass is added to a certain point of the rotating part. The process is repeated, and rms values are recorded. In the third and fourth run-up or shut-down tests, the same process is repeated but the trial mass is placed at angular positions which respectively differ by 120 and 240 degrees from the original point at the same radius.

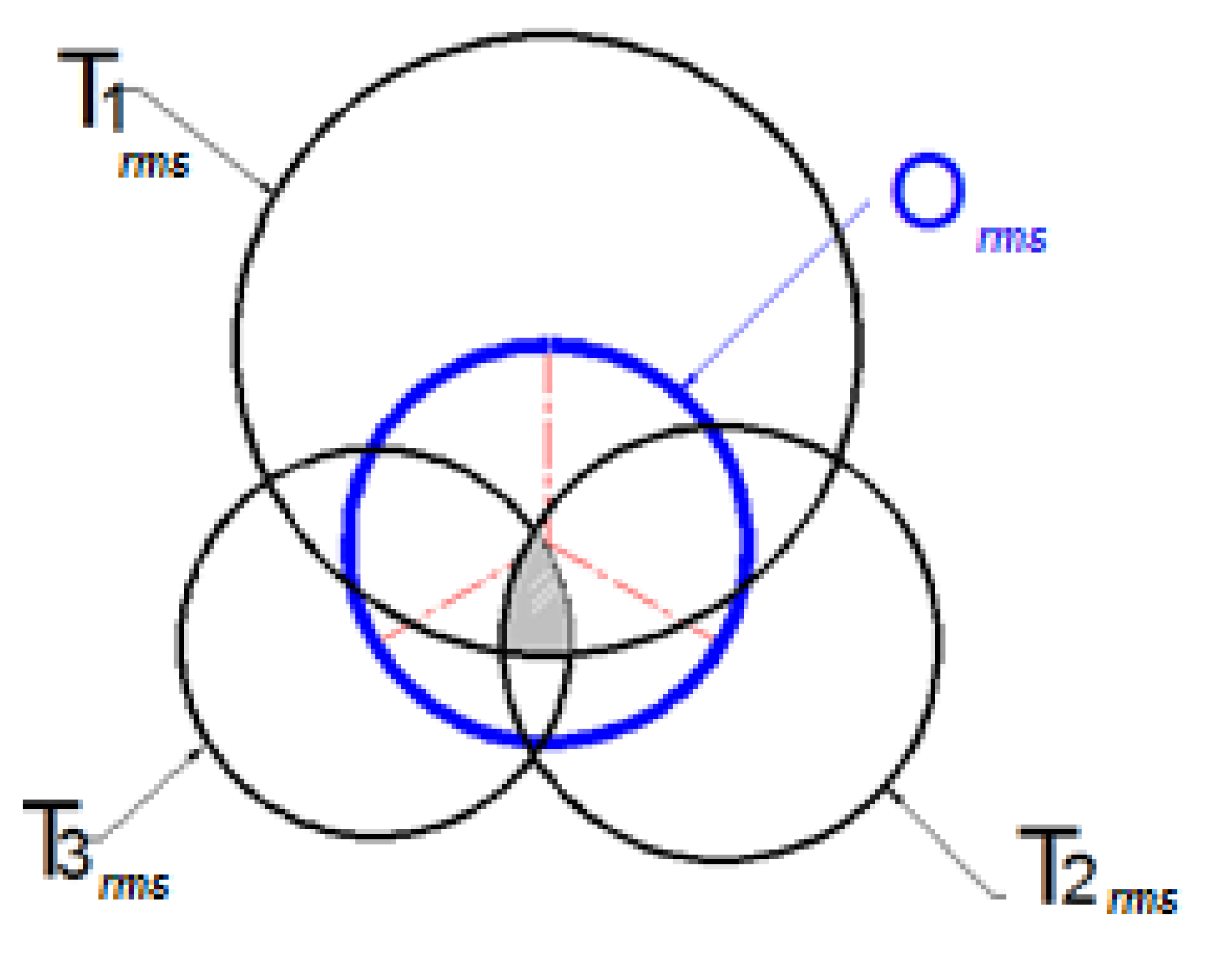

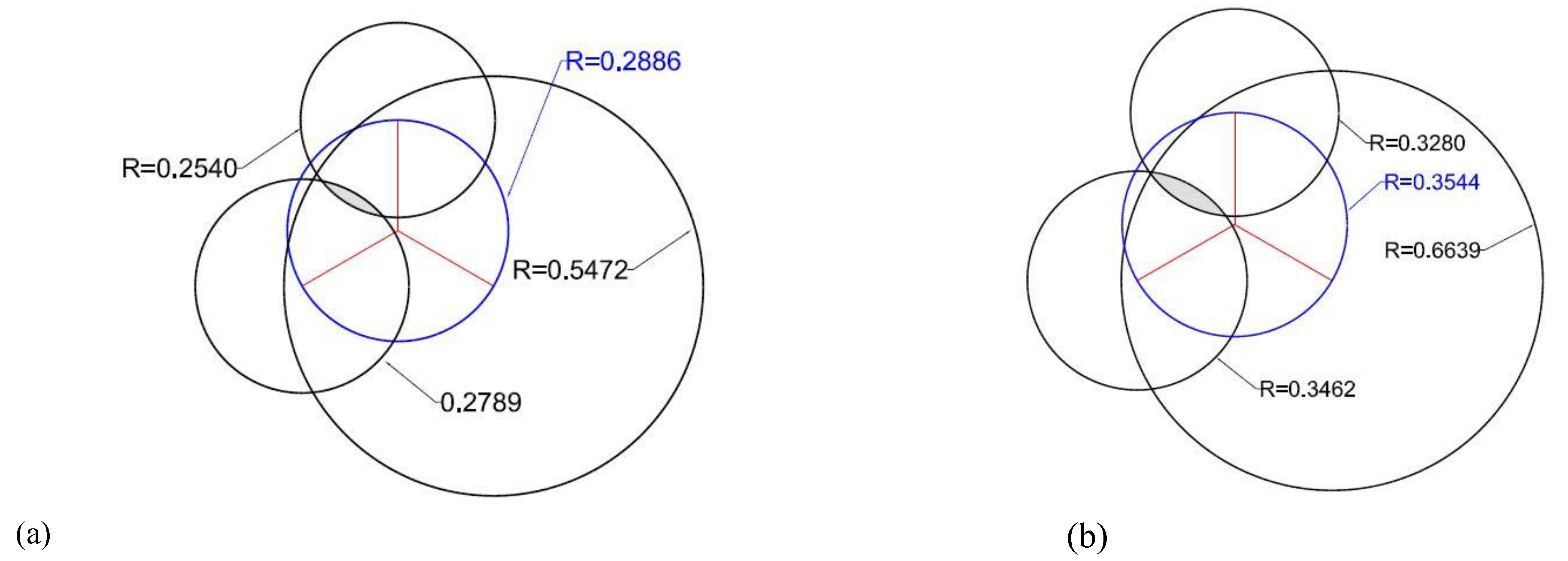

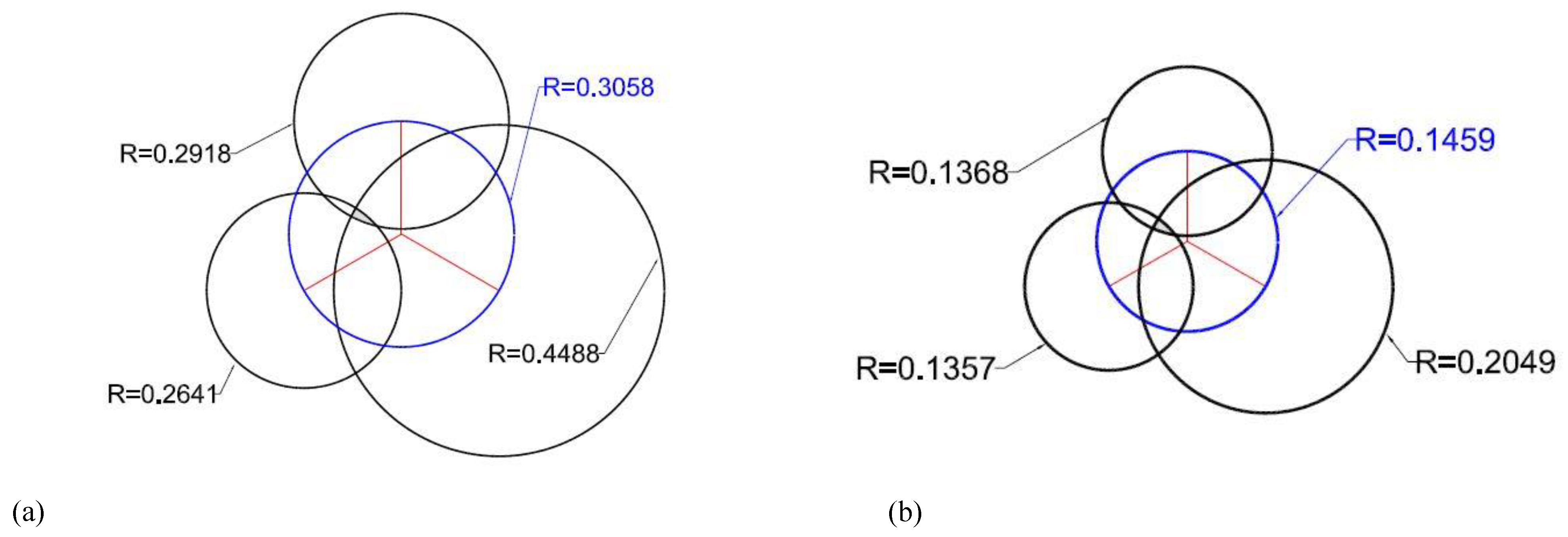

For calculating the position of a correcting mass which can, in principle, along with the zero-angle origin, be arbitrary, the first step is drawing a circle with the radius at the rms value of the vibration/acoustic response. By connecting the trial mass at zero position and acquiring the response, the next circle is drawn on the perimeter of the first circle at zero degree with the radius equal to the rms value of the second step. The third and fourth circles are drawn on the perimeter of the first circle at and respectively with the rms values related to third and fourth run-up or shut-down tests.

It should be noted that if there is no enclosed area between these four circles, the procedure must be done again with a heavier trial mass. The center of this enclosed area between circles is an important point to calculate the position and the final mass of the correcting mass. A schematic of drawn circles is shown in

Figure 4 and related information as listed in

Table 1. This schematic format is used to present the results of the experimental tests in this paper for both vibration and acoustic responses.

It should be added that, although the position of the trial mass at the second Run-up or Shut-down test is completely arbitrary, after selecting a zero angle the following positions are located based on this zero-angle point.