Circular Design of Composite Products: A Framework Based on Insights from Literature and Industry

Abstract

:1. Introduction

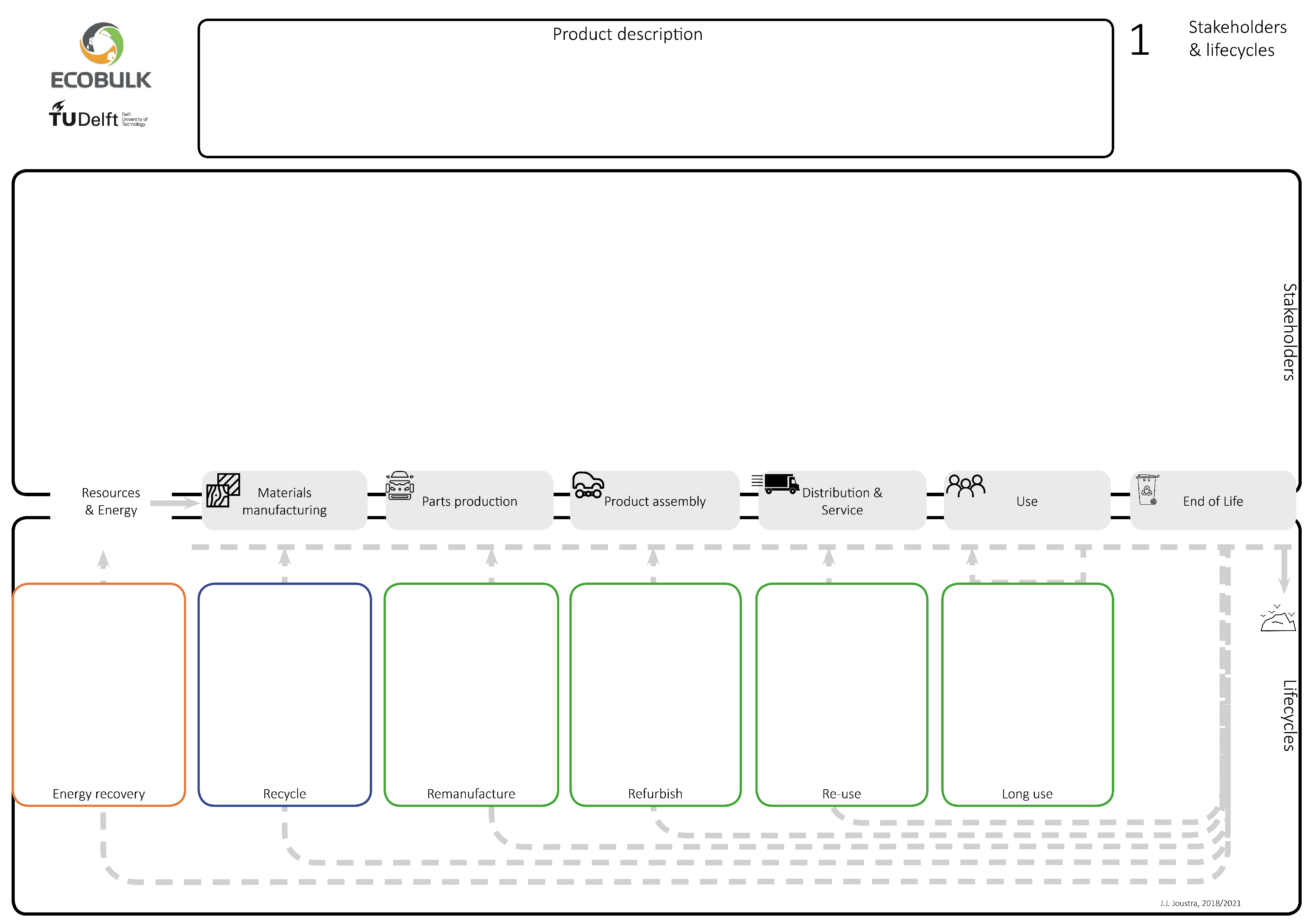

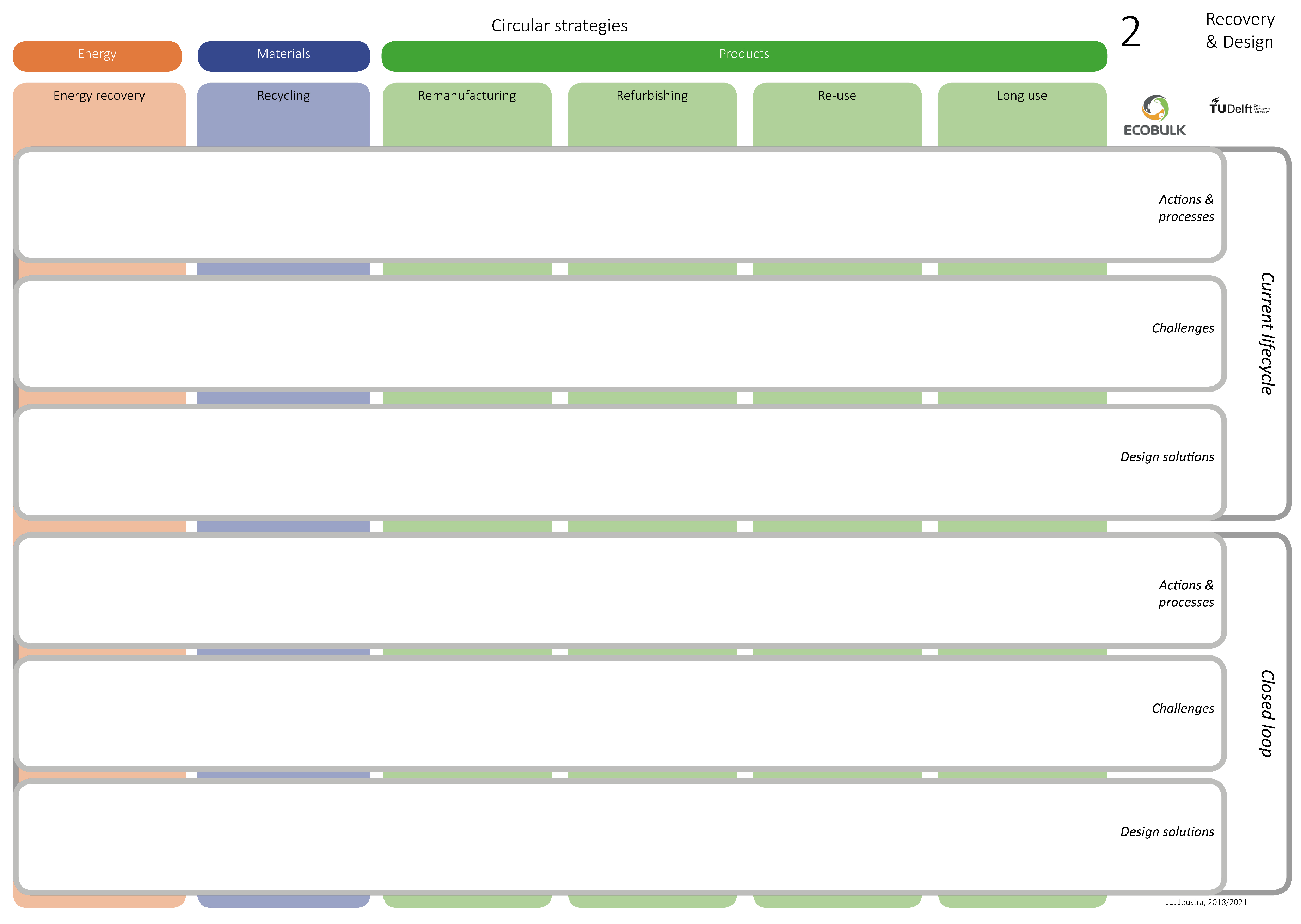

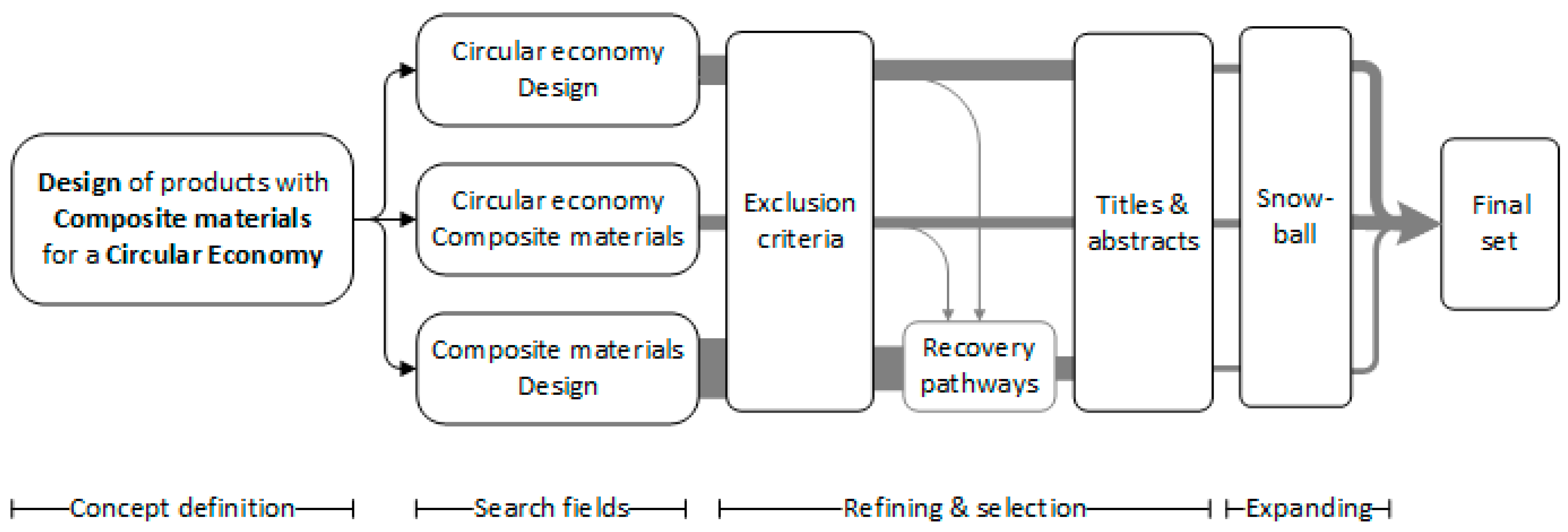

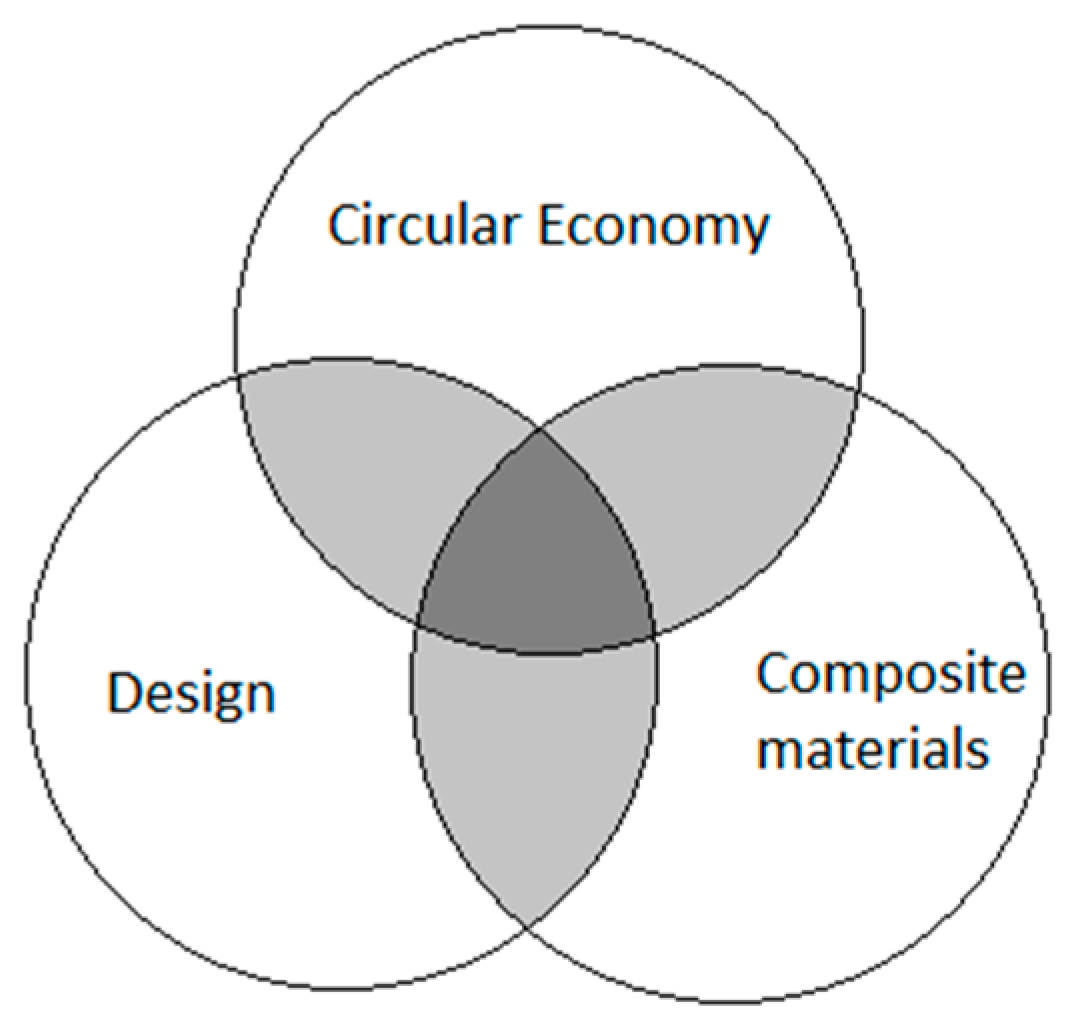

2. Methods

2.1. Literature Review

2.2. Expert Opinions

2.3. Analysis and Clustering of Quotations from Literature and Experts

3. Results

3.1. Circular Strategies for Composites

3.1.1. Long Life

3.1.2. Lifetime Extension

3.1.3. Structural Reuse

3.1.4. Material Recycling

3.2. Design Aspects Applicable to Composite Materials

3.2.1. Concept Design

3.2.2. Embodiment Design

3.2.3. Detail Design

4. Discussion

4.1. Circular Product Design Framework for Composites

- Seven design aspects were added, notably (1) Manufacturing process selection, (2) Structural design, (3) Connection selection (4) Documentation, (5) Monitoring, (6) Cleanability and (7) Function integration.

- One design aspect was omitted: Animacy, as the functional applications do not call for making the product behave as if it were alive.

4.2. Connections within the Circular Product Design Framework

4.3. Limitations and Recommendations

5. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Conflicts of Interest

Appendix A

| Circular Economy and Design | |

|---|---|

| Query | (TITLE-ABS-KEY ("circular economy" OR "circular product design") AND TITLE-ABS-KEY((design W/5 (method OR guideline OR strategy OR principle))) |

| Refine | AND NOT TITLE-ABS-KEY ("additive manufacturing") AND NOT TITLE-ABS-KEY ( biobased ) AND NOT TITLE-ABS-KEY ("consumer perception")) |

| Select | Read titles & abstracts |

| Result | [5,45,46,47,50,52,56,60,63] |

| Circular economy and Composite Materials | |

|---|---|

| Query | (TITLE-ABS-KEY ("circular economy" OR "circular product design") AND TITLE-ABS-KEY ("composite material*" OR (("fibre reinforced" OR "fiber reinforced") AND ( polymer OR plastic ))) |

| Refine | AND NOT TITLE-ABS-KEY ("additive manufacturing") AND NOT TITLE-ABS-KEY (biobased) AND NOT TITLE-ABS-KEY ("consumer perception")) |

| Select | Read titles & abstracts |

| Result | [7,8,12,13,16,29,32,48,49,57,62,65,67,78] |

| Composite Materials and Design | |

|---|---|

| Query | TITLE-ABS-KEY ("composite material*" OR (("fibre reinforced" OR "fiber reinforced") AND (polymer OR plastic))) AND TITLE-ABS-KEY ( ( design W/5 ( method OR guideline OR strategy OR principle))) |

| Refine | AND NOT TITLE-ABS-KEY ("additive manufacturing") AND NOT TITLE-ABS-KEY (biobased OR biopolymer) AND NOT TITLE-ABS-KEY ("consumer perception")) |

| Select | Design W/5 recycling |

| design W/5 "structur* reuse" | |

| design W/5 ("product recovery" OR remanufactur* OR refurbish* OR "parts harvest*")) | |

| design W/5 repair* | |

| design W/5 upgrade | |

| design W/5 maintenance | |

| design W/5 adapt | |

| design W/5 ( durability OR durable OR "long use" OR "long life" OR reuse))) | |

| Select | Read titles & abstracts |

| Result | [29,32,54,58,79,80] |

Appendix B

Appendix C

| 1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 | 12 | 13 | 14 | 15 | 16 | 17 | 18 | 19 | 20 | 21 | 22 | 23 | 24 | ||

| 1 | Accessibility | 0 | 6 | 2 | 4 | 26 | 0 | 7 | 9 | 0 | 8 | 9 | 11 | 7 | 8 | 0 | 13 | 13 | 0 | 6 | 3 | 10 | 10 | 0 | 6 |

| 2 | Adaptability | 6 | 0 | 0 | 0 | 7 | 0 | 6 | 6 | 1 | 6 | 6 | 7 | 6 | 6 | 0 | 6 | 9 | 0 | 6 | 3 | 6 | 8 | 0 | 7 |

| 3 | Cleanability | 2 | 0 | 0 | 2 | 5 | 0 | 0 | 1 | 0 | 2 | 3 | 0 | 1 | 1 | 0 | 3 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 4 | Connection selection | 4 | 0 | 2 | 0 | 34 | 2 | 1 | 2 | 0 | 2 | 2 | 0 | 0 | 0 | 0 | 13 | 5 | 1 | 0 | 0 | 2 | 6 | 2 | 1 |

| 5 | Dis & reassembly | 26 | 7 | 5 | 34 | 0 | 2 | 9 | 9 | 0 | 8 | 12 | 9 | 7 | 6 | 0 | 21 | 22 | 0 | 6 | 3 | 9 | 12 | 4 | 7 |

| 6 | Documentation | 0 | 0 | 0 | 2 | 2 | 0 | 0 | 1 | 0 | 1 | 5 | 0 | 0 | 1 | 0 | 7 | 3 | 0 | 0 | 0 | 1 | 6 | 3 | 0 |

| 7 | Ergonomics | 7 | 6 | 0 | 1 | 9 | 0 | 0 | 7 | 0 | 6 | 7 | 6 | 6 | 7 | 0 | 7 | 6 | 0 | 6 | 3 | 6 | 6 | 0 | 6 |

| 8 | Fault isolation | 9 | 6 | 1 | 2 | 9 | 1 | 7 | 0 | 0 | 8 | 8 | 8 | 6 | 8 | 0 | 7 | 9 | 1 | 7 | 3 | 7 | 9 | 1 | 6 |

| 9 | Function integration | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 |

| 10 | Functional packaging | 8 | 6 | 2 | 2 | 8 | 1 | 6 | 8 | 0 | 0 | 10 | 7 | 7 | 8 | 0 | 8 | 8 | 0 | 6 | 3 | 7 | 8 | 1 | 6 |

| 11 | Identification | 9 | 6 | 3 | 2 | 12 | 5 | 7 | 8 | 0 | 10 | 0 | 7 | 7 | 8 | 0 | 19 | 10 | 1 | 6 | 4 | 7 | 9 | 2 | 6 |

| 12 | Interchangeability | 11 | 7 | 0 | 0 | 9 | 0 | 6 | 8 | 0 | 7 | 7 | 0 | 6 | 7 | 0 | 7 | 12 | 0 | 6 | 3 | 8 | 10 | 0 | 6 |

| 13 | Keying | 7 | 6 | 1 | 0 | 7 | 0 | 6 | 6 | 0 | 7 | 7 | 6 | 0 | 7 | 0 | 7 | 7 | 0 | 6 | 3 | 6 | 6 | 0 | 6 |

| 14 | Malfunction signalling | 8 | 6 | 1 | 0 | 6 | 1 | 7 | 8 | 0 | 8 | 8 | 7 | 7 | 0 | 0 | 7 | 7 | 0 | 6 | 3 | 6 | 7 | 0 | 6 |

| 15 | Manufacturing | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 0 | 5 | 0 | 0 | 0 | 0 | 0 | 0 | 2 | 1 |

| 16 | Material selection | 13 | 6 | 3 | 13 | 21 | 7 | 7 | 7 | 2 | 8 | 19 | 7 | 7 | 7 | 5 | 0 | 15 | 0 | 7 | 3 | 9 | 13 | 8 | 15 |

| 17 | Modularity | 13 | 9 | 1 | 5 | 22 | 3 | 6 | 9 | 0 | 8 | 10 | 12 | 7 | 7 | 0 | 15 | 0 | 1 | 6 | 3 | 8 | 15 | 3 | 6 |

| 18 | Monitoring | 0 | 0 | 0 | 1 | 0 | 0 | 0 | 1 | 0 | 0 | 1 | 0 | 0 | 0 | 0 | 0 | 1 | 0 | 1 | 0 | 0 | 0 | 0 | 0 |

| 19 | Redundancy | 6 | 6 | 0 | 0 | 6 | 0 | 6 | 7 | 0 | 6 | 6 | 6 | 6 | 6 | 0 | 7 | 6 | 1 | 0 | 3 | 7 | 6 | 1 | 7 |

| 20 | Sacrificial elements | 3 | 3 | 0 | 0 | 3 | 0 | 3 | 3 | 0 | 3 | 4 | 3 | 3 | 3 | 0 | 3 | 3 | 0 | 3 | 0 | 3 | 3 | 1 | 3 |

| 21 | Simplification | 10 | 6 | 0 | 2 | 9 | 1 | 6 | 7 | 0 | 7 | 7 | 8 | 6 | 6 | 0 | 9 | 8 | 0 | 7 | 3 | 0 | 10 | 1 | 7 |

| 22 | Standardisation | 10 | 8 | 0 | 6 | 12 | 6 | 6 | 9 | 0 | 8 | 9 | 10 | 6 | 7 | 0 | 13 | 15 | 0 | 6 | 3 | 10 | 0 | 2 | 7 |

| 23 | Structural design | 0 | 0 | 0 | 2 | 4 | 3 | 0 | 1 | 0 | 1 | 2 | 0 | 0 | 0 | 2 | 8 | 3 | 0 | 1 | 1 | 1 | 2 | 0 | 1 |

| 24 | Surface treatment selection | 6 | 7 | 0 | 1 | 7 | 0 | 6 | 6 | 0 | 6 | 6 | 6 | 6 | 6 | 1 | 15 | 6 | 0 | 7 | 3 | 7 | 7 | 1 | 0 |

References

- Ellen MacArthur Foundation. Towards the Circular Economy 1: Economic and Business Rationale for an Accelerated Transition. Available online: https://www.ellenmacarthurfoundation.org/publications/towards-the-circular-economy-vol-1-an-economic-and-business-rationale-for-an-accelerated-Transition (accessed on 31 July 2019).

- Korhonen, J.; Honkasalo, A.; Seppälä, J. Circular Economy: The Concept and its Limitations. Ecol. Econ. 2018, 143, 37–46. [Google Scholar] [CrossRef]

- Balkenende, A.R.; Bocken, N.; Bakker, C.A. Design for the Circular Economy. In The Routledge Handbook of Sustainable Design; Egenhoefer, R.B., Ed.; Routledge International Handbooks: London, UK, 2017; pp. 498–513. ISBN 978-1138650176. [Google Scholar]

- Bakker, C.A.; Balkenende, A.R.; Poppelaars, F. Design for Product Integrity in a Circular Economy. In Designing for the Circular Economy; Charter, M., Ed.; Routledge International Handbooks: London, UK, 2018; ISBN 9781138081017. [Google Scholar]

- Bocken, N.; de Pauw, I.; Bakker, C.A.; van der Grinten, B. Product design and business model strategies for a circular economy. J. Ind. Prod. Eng. 2016, 33, 308–320. [Google Scholar] [CrossRef] [Green Version]

- Joustra, J.J.; Flipsen, S.F.; Balkenende, A.R. Circular Design of Composite Products: A Preliminary Framework Based on Insights from Literature and Industry. In Proceedings of the PLATE Product Lifetimes and The Environment 2019, Berlin, Germany, 18–20 September 2019. [Google Scholar]

- Yang, Y.; Boom, R.; Irion, B.; van Heerden, D.J.; Kuiper, P.; de Wit, H. Recycling of composite materials. Chem. Eng. Process. Process Intensif. 2012, 51, 53–68. [Google Scholar] [CrossRef]

- Jensen, J.P.; Skelton, K. Wind turbine blade recycling: Experiences, challenges and possibilities in a circular economy. Renew. Sustain. Energy Rev. 2018, 97, 165–176. [Google Scholar] [CrossRef]

- Beauson, J.; Brøndsted, P. Wind turbine blades: An End of Life Perspective. In MARE-WINT: New Materials and Reliability in Offshore Wind Turbine Technology; Ostachowicz, W., McGugan, M., Schröder-Hinrichs, J.U., Luczak, M., Eds.; Springer: Berlin/Heidelberg, Germany, 2016; pp. 421–432. ISBN 9783319390956. [Google Scholar]

- Nijssen, R.P.L. Composite Materials, 1st ed.; VKCN: Amsterdam, The Netherlands, 2015; Volume 3, ISBN 978-90-77812-471. [Google Scholar]

- Oliveux, G.; Dandy, L.O.; Leeke, G.A. Current status of recycling of fibre reinforced polymers: Review of technologies, reuse and resulting properties. Prog. Mater. Sci. 2015, 72, 61–99. [Google Scholar] [CrossRef] [Green Version]

- Mativenga, P.T.; Sultan, A.A.M.; Agwa-Ejon, J.; Mbohwa, C. Composites in a Circular Economy: A Study of United Kingdom and South Africa. Procedia CIRP 2017, 61, 691–696. [Google Scholar] [CrossRef]

- Zhang, J.; Chevali, V.S.; Wang, H.; Wang, C.H. Current status of carbon fibre and carbon fibre composites recycling. Compos. Part B Eng. 2020, 193, 108053. [Google Scholar] [CrossRef]

- Europen Parliament and Council. European Parliament and Council 2000/53/EC on end-of-life vehicles. Off. J. Eur. Union 2000, 269, 34–42. [Google Scholar]

- Cherrington, R.; Goodship, V.; Meredith, J.; Wood, B.M.; Coles, S.R.; Vuillaume, A.; Feito-Boirac, A.; Spee, F.; Kirwan, K. Producer responsibility: Defining the incentive for recycling composite wind turbine blades in Europe. Energy Policy 2012, 47, 13–21. [Google Scholar] [CrossRef] [Green Version]

- Longana, M.L.; Ong, N.; Yu, H.N.; Potter, K.D. Multiple closed loop recycling of carbon fibre composites with the HiPerDiF (High Performance Discontinuous Fibre) method. Compos. Struct. 2016, 153, 271–277. [Google Scholar] [CrossRef] [Green Version]

- Pickering, S.J.; Turner, T.A.; Meng, F.; Morris, C.N.; Heil, J.P.; Wong, K.H.; Melendi-Espina, S. Developments in the fluidised bed process for fibre recovery from thermoset composites. In Proceedings of the 2nd Annual Composites and Advanced Materials Expo, CAMX, Dallas, TX, USA, 26–29 October 2015. [Google Scholar]

- University of Delaware—Center for Composite Materials TuFF. Available online: https://www.ccm.udel.edu/research/program-highlights/tuff/ (accessed on 19 May 2021).

- DecomTools. Available online: https://northsearegion.eu/decomtools/about/ (accessed on 18 October 2019).

- Neowa. Our Contribution to a Clean Future: The Neocomp Project. Available online: https://www.neowa.de/en/references/neocomp-engl (accessed on 16 June 2020).

- Gen 2 Carbon (Former ELG Carbon Fibre). Available online: https://gen2carbon.com/ (accessed on 19 May 2021).

- EcoBulk Project. Available online: www.ecobulk.eu (accessed on 1 December 2017).

- FiberEUse Project. Available online: http://www.fibereuse.eu/ (accessed on 16 June 2020).

- Re-Wind Project. Available online: https://www.re-wind.info/ (accessed on 16 June 2020).

- Callister, W.; Rethwisch, D. Materials Science and Engineering: An Introduction; John Wiley and Sons: Hoboken, NJ, USA, 2007; ISBN 9780471736967. [Google Scholar]

- Witten, E.; Sauer, M.; Kühnel, M. Composites Market Report 2017; AVK: Frankfurt, Germany, 2017. [Google Scholar]

- Ashby, M.F. Materials Selection in Mechanical Design, 3rd ed.; Elsevier Butterworth-Heinemann: Oxford, UK, 2005; ISBN 0750661682. [Google Scholar]

- Effing, M. Expert insights in Europe’s booming composites market. Reinf. Plast. 2018, 62, 219–223. [Google Scholar] [CrossRef]

- Perry, N.; Bernard, A.; Laroche, F.; Pompidou, S. Improving design for recycling—Application to composites. CIRP Ann. 2012, 61, 151–154. [Google Scholar] [CrossRef] [Green Version]

- Grote, K.-H.; Fischer, N.; Schneider, U. Product design for recycling of structures with composite material. In Proceedings of the ICED: International Conference on Engineering Design 11, Tampere, Finland, 19–21 August 1997; pp. 347–350. [Google Scholar]

- Pahl, G.; Beitz, W.; Feldhusen, J.; Grote, K.H. Engineering Design: A Systematic Approach, 3rd ed.; Wallace, K., Blessing, L., Eds.; Springer: London, UK, 2007; Volume 11, ISBN 9781846283185. [Google Scholar]

- Perry, N.; Pompidou, S.; Mantaux, O. Information exchanges between experts for thermoset composites design for recycling. Int. J. Environ. Waste Manag. 2014, 13, 396–411. [Google Scholar] [CrossRef]

- Butenko, V.; Wilwer, J.; Spadinger, M.; Albers, A. A qualitative study to identify the need and requirements on further development of design guidelines for fibre-reinforced composites. In Proceedings of the 21st International Conference on Engineering Design (ICED17), Vancouver, BC, Canada, 21–25 August 2017; pp. 309–318. [Google Scholar]

- Leahy, P.G. End-of-life Options for Composite Material Wind Turbine Blades: Recover, Repurpose or Reuse? In Proceedings of the 14th SWEDES Conference, Dubrovnik, Croatia, 1–6 October 2019; pp. 1–9. [Google Scholar]

- Bank, L.C.; Arias, F.R.; Yazdanbakhsh, A.; Gentry, T.R.; Al-Haddad, T.; Chen, J.F.; Morrow, R. Concepts for reusing composite materials from decommissioned wind turbine blades in affordable housing. Recycling 2018, 3, 3. [Google Scholar] [CrossRef] [Green Version]

- Den Hollander, M. Design for Managing Obsolescence. Doctoral Thesis, Delft University of Technology, Delft, The Netherlands, 2018. [Google Scholar]

- Liu, Y.; Farnsworth, M.; Tiwari, A. A review of optimisation techniques used in the composite recycling area: State-of-the-art and steps towards a research agenda. J. Clean. Prod. 2017, 140, 1775–1781. [Google Scholar] [CrossRef] [Green Version]

- Ingemarsdotter, E.; Jamsin, E.; Kortuem, G.; Balkenende, R. Circular strategies enabled by the internet of things-a framework and analysis of current practice. Sustainability 2019, 11, 5689. [Google Scholar] [CrossRef] [Green Version]

- TU Delft Library Searching and Resources. Available online: https://tulib.tudelft.nl/ (accessed on 16 April 2020).

- Stewart, D.; Shamdasani, P.N. Focus Groups: Theory and Practice; SAGE: Thousand Oaks, CA, USA, 1990; ISBN 0803933894. [Google Scholar]

- Roozenburg, N.F.M.; Eekels, J. Productontwerpen, Structuur en Methoden, 2nd ed.; Lemma: Utrecht, The Netherlands, 1998; ISBN 9051897065. [Google Scholar]

- ATLAS.ti. Scientific Software Development Atlas.ti; ATLAS.ti: Berlin, Germany, 2020. [Google Scholar]

- Saldaña, J. The Coding Manual for Qualitative Researchers; Sage: Los Angeles, CA, USA, 2009; ISBN 9781446200353. [Google Scholar]

- Eck, N.J.V.; Waltman, L. VOSviewer Manual; Leiden University: Leiden, The Netherlands, 2020. [Google Scholar]

- Sassanelli, C.; Urbinati, A.; Rosa, P.; Chiaroni, D.; Terzi, S. Addressing circular economy through design for X approaches: A systematic literature review. Comput. Ind. 2020, 120, 103245. [Google Scholar] [CrossRef]

- Den Hollander, M.; Bakker, C.A.; Hultink, E. Product Design in a Circular Economy: Development of a Typology of Key Concepts and Terms. J. Ind. Ecol. 2017, 21, 517–525. [Google Scholar] [CrossRef]

- Moreno, M.; De los Rios, C.; Rowe, Z.; Charnley, F. A conceptual framework for circular design. Sustainability 2016, 8, 937. [Google Scholar] [CrossRef] [Green Version]

- Psomopoulos, C.S.; Kalkanis, K.; Kaminaris, S.; Ioannidis, G.C.; Pachos, P. A review of the potential for the recovery of wind turbine blade waste materials. Recycling 2019, 4, 7. [Google Scholar] [CrossRef] [Green Version]

- Ayre, D. Technology advancing polymers and polymer composites towards sustainability: A review. Curr. Opin. Green Sustain. Chem. 2018, 13, 108–112. [Google Scholar] [CrossRef]

- Mestre, A.; Cooper, T. Circular Product Design. A Multiple Loops Life Cycle Design Approach for the Circular Economy. Des. J. 2017, 20, S1620–S1635. [Google Scholar] [CrossRef] [Green Version]

- Van den Berg, M.R.; Bakker, C.A. A product design framework for a circular economy. In Proceedings of the PLATE Conference, Nottingham, UK, 17–19 June 2015; pp. 365–379. [Google Scholar]

- Shahbazi, S.; Jönbrink, A.K. Design guidelines to develop circular products: Action research on nordic industry. Sustaiability 2020, 12, 3679. [Google Scholar] [CrossRef]

- Post, N.L.; Bausano, J.V.; Lesko, J.J.; Case, S.W.; Duke, J.C. The role of durability in reliability-based design of composite materials for civil structures. Sci. Eng. Compos. Mater. 2005, 12, 153–158. [Google Scholar] [CrossRef]

- Kleemann, S.; Vietor, T. Design and dimensioning standards for multi-material components for the automotive industry considering their failure probability. In Proceedings of the 16th European Conference on Composite Materials ECCM 2014, Seville, Spain, 22–26 June 2014; pp. 22–26. [Google Scholar]

- Papadakis, N.; Ramírez, C.; Reynolds, N. 16—Designing composite wind turbine blades for disposal, recycling or reuse. In Management, Recycling and Reuse of Waste Composites; Elsevier: Amsterdam, The Netherlands, 2010; pp. 443–457. ISBN 9781845694623. [Google Scholar]

- Devadula, S.; Chakrabarti, A. Design strategies for circular economy. In Proceedings of the International Conference on Engineering Design 2015 (ICED 2015), Milan, Italy, 27–30 July 2015; pp. 1–9. [Google Scholar]

- Post, W.; Susa, A.; Blaauw, R.; Molenveld, K.; Knoop, R.J.I. A Review on the Potential and Limitations of Recyclable Thermosets for Structural Applications. Polym. Rev. 2020, 60, 359–388. [Google Scholar] [CrossRef]

- Alzeanidi, N.; Ghasemnejad, H. Analysis of the effect of impact damage on the repairability of composite panels. Compos. Struct. 2017, 176, 304–312. [Google Scholar] [CrossRef] [Green Version]

- Otheguy, M.E.; Gibson, A.G.; Findon, E.; Cripps, R.M. Repair technology for thermoplastic composite boats. Trans. R. Inst. Nav. Archit. Part B Int. J. Small Cr. Technol. 2010, 152, 33–40. [Google Scholar]

- Cong, L.; Zhao, F.; Sutherland, J.W. A Design Method to Improve End-of-Use Product Value Recovery for Circular Economy. J. Mech. Des. Trans. ASME 2019, 141, 1–10. [Google Scholar] [CrossRef]

- Asmatulu, E.; Twomey, J.; Overcash, M. Recycling of fiber-reinforced composites and direct structural composite recycling concept. J. Compos. Mater. 2014, 48. [Google Scholar] [CrossRef]

- Bank, L.C.; Arias, F.R.; Gentry, T.R.; Al-Haddad, T.; Tasistro-Hart, B.; Chen, J.-F. Structural Analysis of FRP Parts from Waste Wind Turbine Blades for Building Reuse Applications. In Proceedings of the Advances in Engineering Materials, Structures and Systems: Innovations, Mechanics and Applications, Cape Town, South Africa, 2–4 September 2019; Taylor and Francis Group: London, UK, 2019; pp. 1520–1524. [Google Scholar]

- Fivet, C.; Brütting, J. Nothing is lost, nothing is created, everything is reused: Structural design for a circular economy. Struct. Eng. 2020, 98, 74–81. [Google Scholar]

- Job, S.; Leeke, G.; Mativenga, P.T.; Oliveux, G.; Pickering, S.J.; Shuaib, N.A. Composites Recycling: Where Are We Now? Composites UK: Berkhamsted, UK; University of Birmingham: Birmingham, UK; The University of Notingham: Notingham, UK, 2016. [Google Scholar]

- Naqvi, S.R.R.; Prabhakara, H.M.M.; Bramer, E.A.A.; Dierkes, W.; Akkerman, R.; Brem, G. A critical review on recycling of end-of-life carbon fibre/glass fibre reinforced composites waste using pyrolysis towards a circular economy. Resour. Conserv. Recycl. 2018, 136, 118–129. [Google Scholar] [CrossRef] [Green Version]

- Pickering, S.J. Recycling Technologies For Thermoset Composite Materials. Compos. Part A 2006, 37, 1206–1215. [Google Scholar] [CrossRef]

- Hubka, V.; Eder, W. Design Science; Springer: London, UK, 1996; ISBN 978-3-540-19997-7. [Google Scholar]

- Pascoe, J.A. Slow-growth damage tolerance for fatigue after impact in FRP composites: Why current research won’t get us there. Procedia Struct. Integr. 2020, 28, 726–733. [Google Scholar] [CrossRef]

- Nijssen, R.P.L.; Brøndsted, P. Fatigue as a design driver for composite wind turbine blades. In Advances in Wind Turbine Blade Design and Materials; Woodhead Publishing: Cambridge, UK, 2013; pp. 175–209. ISBN 9780857094261. [Google Scholar]

- Joustra, J.J.J.; Flipsen, B.; Balkenende, R.; Flipsen, S.F.J.; Balkenende, A.R. Structural reuse of wind turbine blades through segmentation. Compos. Part C 2021, 5, 100137. [Google Scholar]

- CEN—European Committee for Standardisation. CEN/WS 113 Workshop on “Framework Linking Dismantled Parts with New Design Components for the Automotive Industry in a Circular Economy Model”. Available online: https://www.cen.eu/news/workshops/Pages/WS-2020-013.aspx (accessed on 25 May 2021).

- Castaldo, R.; Falco, F.D.; Avolio, R.; Bossanne, E.; Cicaroni Fernandes, F.; Cocca, M.; Di Pace, E.; Emanuela, E.M.; Gentile, G.; Jásinski, D.; et al. Critical Factors for the Recycling of Different End-of-Life Materials: Wood Wastes, Automotive, Turbine Blades. Polymers 2019, 11, 1604. [Google Scholar] [CrossRef] [Green Version]

- Zapelloni, G.; García Rellán, A.; Bello Bugallo, P.M. Sustainable production of marine equipment in a circular economy: Deepening in material and energy flows, best available techniques and toxicological impacts. Sci. Total Environ. 2019, 687, 991–1010. [Google Scholar] [CrossRef] [PubMed]

- Medici, P.; van den Dobbelsteen, A.; Peck, D. Safety and health concerns for the users of a playground, built with reused rotor blades from a dismantled wind turbine. Sustainability 2020, 12, 3626. [Google Scholar] [CrossRef]

- Shuaib, N.A.; Mativenga, P.T. Energy demand in mechanical recycling of glass fibre reinforced thermoset plastic composites. J. Clean. Prod. 2015, 120, 198–206. [Google Scholar] [CrossRef]

- Poulikidou, S.; Jerpdal, L.; Björklund, A.; Åkermo, M. Environmental performance of self-reinforced composites in automotive applications—Case study on a heavy truck component. Mater. Des. 2016, 103, 321–329. [Google Scholar] [CrossRef]

- Gao, C.; Yu, L.; Liu, H.; Chen, L. Development of self-reinforced polymer composites. Prog. Polym. Sci. 2012, 37, 767–780. [Google Scholar] [CrossRef]

- Karuppannan Gopalraj, S.; Kärki, T. A review on the recycling of waste carbon fibre/glass fibre-reinforced composites: Fibre recovery, properties and life-cycle analysis. SN Appl. Sci. 2020, 2, 1–21. [Google Scholar] [CrossRef] [Green Version]

- Xie, Z.H.; Li, X.; Yan, Q. Scarf repair of composite laminates. Testing and Measurement: Techniques and Applications; CRC Press: Boca Raton, FL, USA, 2015; pp. 1–4. [Google Scholar]

- Li, Z.; Gomez, J.M.; Pehlken, A. A systematic review of environmentally conscious product design. In Proceedings of the EnviroInfo and ICT for Sustainability, Copenhagen, Denmark, 7–9 September 2015; pp. 197–206. [Google Scholar]

- Bobovich, B.B. Glass-Fiber Reinforced Plastics—Construction Materials of the Sixth Technological Paradigm? Glas. Ceram. 2019, 76, 38–41. [Google Scholar] [CrossRef]

| Circular Strategies [References] | Description from the Literature | Quotes from Expert Consultation |

|---|---|---|

| Long life [3,4,5,8,9,31,36,46,47,48,49,50,51,52,53,54] | Ensuring long product lifetime by promoting long use and reuse of the product as a whole, through manufacturing physically durable products, resisting ageing, fatigue and corrosion, able to sustain wear and tear without failure. | “[incorporating] additives [in the material] to make the panel more scratch resistant” |

| Lifetime extension [3,4,5,7,8,9,12,31,32,34,36,45,46,47,50,51,52,55,56,57,58,59] | Extending the time in use through maintenance, repair, technical upgrading or adapting, by users or service personnel. This can be promoted by facilitating handling of the product and subsequent rework tasks. | “Repairing strategies favouring parts replacement and upgrades” “Design for disassembly (screws, reversible snapfits)” |

| Product recovery [3,4,5,7,9,31,32,34,36,45,46,47,50,51,52,56,60] | Returning products or parts to working condition, thereby increasing the number of use cycles. | “[Keep product parts] fixed so they don’t drop off during use but come off easily and quickly during reman/refurbish” |

| Structural reuse [8,9,31,32,34,61,62,63] | Retrieving structural elements, preserving the material composition, through repurposing, resizing or reshaping product parts for reuse in another context or construction. | “Remove panel elements for another furniture” “Structure made of linear components like truss structures so components could be re-used in other products” |

| Recycling [3,4,5,7,8,9,12,16,29,31,32,45,47,48,49,50,51,52,55,56,57,60,61,64,65,66] | Recovery of materials through thermal, chemical, or mechanical processes, resulting in raw materials (“recyclate”), aiming to close the materials loop. | “use of compatible materials [compatible with process and other materials in the product to warrant a good recyclate grade]” “[facilitate composite material] recovery from bulky waste” |

| Design Aim | Preserving Product Integrity | Preserving Material Integrity | |||

|---|---|---|---|---|---|

| Circular Economy Strategies | Long Life | Lifetime Extension | Product Recovery | Structural Reuse | Material Recycling |

| Actions/Processes | Physical- durability Long use Reuse | Repair Maintenance Adapt Upgrade | Refurbishment Remanufacture Parts-harvesting | Repurpose Resize Reshape | Remould Mechanical Thermal Chemical |

| Design Aspects [References] | Description from the Literature | Design Guidelines |

|---|---|---|

| Accessibility [3,31,36,45,51,52,56,60] | Ensuring (internal) parts and materials as well as their connections can be reached and/or removed easily, keeping them at maximum utility level, and facilitating separation and sorting. | Platform design Using a disassembly map Grouping parts and/or materials in modules Access from one side, using a single tool Connections/fasteners that are easily identifiable and removable |

| Adaptability [4,36,50,51,63] | Anticipating and enabling changes and adjustments to be made to the product during its (successive) use cycle(s). | Multifunctional design Facilitate DIY solutions/adaptations Versatile, customisable layout of the components; adaptable/changing the (surface) colour Transformable system, and reversible assembly |

| Cleanability [31,45,47,51,52] | Making products, parts, and surfaces so that they can be cleaned or prevent accumulation of dirt. | Smooth surfaces Accessible and demountable parts and modules, especially where dirt accumulates Use of the same cleaning method, and materials and surfaces withstanding the same chemicals |

| Ergonomics [29,31,36] | Ensuring the product can be used, maintained, reworked, and reprocessed in a safe and efficient way. | Dis- and reassembly as needed, with accessible component and connections |

| Fault isolation [3,29,31,36,45,52] | Enabling tracking an occurring fault to its cause, e.g., a worn component, for quick and easy repair. | Develop and promote repair diagnostics Making (approaching) failure noticeable for users or service inspections |

| Functional packaging [31,36,45,50,51] | Choosing packaging for the product and/or components to optimise transport and distribution. | Reducing packaging weight and volume, Improving stackability and handling Ensuring product/component protection |

| Interchangeability [3,36,45,52,63] | Making parts or subassemblies of the product readily replaceable or exchangeable. | Interfaces that allow exchange of parts Matching dimensions and functions of parts and replacements Standard, accessible and dismountable parts, modules, and connections |

| Malfunction signalling [36,45,52] | Indicating (imminent) product failure to facilitate inspection and subsequent actions. | Accessible parts Indicating elements, e.g., wearing strips Monitoring of components |

| Simplification [31,36,45,51] | Minimising the complexity of the product in terms of functionality, assembly, appearance, and materials composition. | Select the simplest design option available Reduce the number of material types, components, and assembly steps |

| Design Aspects [References] | Description from the Literature | Design Guidelines |

|---|---|---|

| Connection selection [3,7,8,45,48,50,51,52,60,63] | Selecting connections that can be accessed, opened, and reused where appropriate to facilitate use, rework, and recovery actions during product life. | Reversibility; e.g., screws, clips and several types of snapfits Recovery action, operator (e.g., user or service personnel), tool types (that need to be) available, Material compatibility and use resistance (e.g., wear and ageing) |

| Dis- and reassembly [3,5,7,29,31,36,45,50,51,56,60] | Facilitating manual or mechanical disassembly and reassembly of the product to enable reuse of parts to improve the recovery rate. | Using reversible connections (e.g., screws), and avoiding in-moulded inserts Mechanical assembly systems (e.g., form fits) Optimised and short component disassembly paths Use commonly available, standard, accessible tools, and connections. |

| Function integration [50] | Combining multiple functions and (sub)components into one part. | Integration of connectors with parts Combine structural design and other functions, e.g., aesthetic or aerodynamic |

| Keying [36,45] | Using product shape to facilitate alignment, e.g., holes and pins | Using pins, grooves, and other mating shapes for alignment and placing components |

| Modularity [3,4,7,8,29,36,45,50,51,52,60,63] | Grouping features within the product to create sub-assemblies that are accessible, removable, and interchangeable. | Match lifetime or maintenance intervals of components, Sort chemically similar materials, or isolate hazardous substances, Allow for (functional) customisation and adaptation |

| Redundancy [31,36,51] | Adding additional materials or functionality to ensure continued operation and safety, even when parts degrade or are (partially) removed. | Add materials on wearing areas Integrate multiple, redundant, load paths Add excess functionality |

| Sacrificial elements [36,50] | Defining replaceable components and surface treatments to take up wear and damage, thus protecting other parts. | Identify the areas subject to degradation Apply protective surface treatments Apply protective elements, e.g., covers |

| Design Aspects [References] | Description from the Literature | Design Guidelines |

|---|---|---|

| Material selection [5,7,8,16,29,36,45,48,50,51,52,55,56,57,60] | Selecting matrix, reinforcement, connections, and other materials to perform optimally for the use phase, as well as recovery stage of the product. For composites, this includes the type and orientation of reinforcements. | Consider reprocessing compatibility, by, e.g., using chemically similar matrix and reinforcement (self-reinforced composites), avoiding mix of biological and technological materials Using recycled and recyclable materials, thermoplastic or reversible thermoset matrices and short fibres, and limit the number of materials used within an assembly to promote recyclability Reconsider hazardous chemicals, effect of ageing (e.g., discolouring and loss of quality) Selection to cope with hostile conditions, to prolong lifetime |

| Manufacturing process selection [7,8,48,50,52,55] | Selecting and optimising the process to minimise emissions and meet the material, functional, shape and recovery criteria. | Optimise fibre architecture. Automate manufacturing for consistency Reduce waste and emissions of manufacturing process; consumables (foils, tapes, etc.) and material offcuts, especially when impregnated with resin Allow recycled content uptake |

| Structural design [7,8,29,31,51] | Optimising the material structure, shape, and product architecture to achieve the desired structural performance. | Use form stiffness and load bearing shapes Integrate form and material placement to meet load cases Consider reusable structural elements |

| Surface treatments [3,7,8,9,16,31,36,48,51,60] | Selecting coatings and other surface treatments appropriate for the use, reuse and reprocessing of the product and its materials. | Protective gelcoats, paints, tapes, foils, or other treatments to prevent material degradation by UV radiation, moisture, or erosion Use non-hazardous substances to support rework and reprocessing Ensure materials including surface treatments compatibility in the recycling process |

| Design Aspects [References] | Description from the Literature | Design Guidelines |

|---|---|---|

| Documentation [7,8,9,29,31,50,52,56,62,63] | Providing information about the product, components, and functions to stakeholders in the value chain and actors in the product and component lifecycle. | Identify which information the actors need, and how, e.g., Design specifications, e.g., dimensions, assembly, part id’s, material composition Service manuals and repair tutorials Certification and standards Material passports |

| Identification [7,8,9,29,31,36,45,52] | Using labels, tags etc. to facilitate recognition of the product, parts, materials and/or its specifications. | Labelling products and components Defining material characteristics for separation processes (i.e., IR scanning, density) Placing material markings on parts Mixing in markers into the materials |

| Monitoring [8,51,52] | Determining and logging of product properties and use conditions over the product lifetime. | Regular inspection intervals Embedded monitoring devices Sample or coupon testing (e.g., fatigue, strength) of used components Internet of Things solutions Digital measurement and identification systems |

| Standardisation [3,5,8,9,29,31,36,45,50,51,52,56,62,63] | Using well-known, defined, and widely used components, processes, dimensions, materials, etc., in the product design, or developing a standard layout for the product(range). This design aspect relates, but is not restricted to, industry standardisation. | Standardisation comes in many forms, e.g., Components (connections, bearings, etc.) Construction codes Dimensional tolerances Certification and inspection procedures Standard layout across product (range) Basic or standard available tools |

| Concept Design | Embodiment Design | Detail Design | |

|---|---|---|---|

| Cluster i: Handling and Rework | Cluster ii: Product Architecture | Cluster iii: Product Specifications | Cluster iv: Traceability |

| Accessibility Adaptability Cleanability Ergonomics Fault isolation Functional packaging Interchangeability Malfunction signalling Simplification | Connection selection Dis- and reassembly Modularity Keying Function Integration Redundancy Sacrificial elements | Material selection Structural design Manufacturing process Surface treatments | Documentation Identification Monitoring Standardisation |

| Design Aim | Product Integrity | Material Integrity | |||

|---|---|---|---|---|---|

| Circular Strategy | Long Life | Lifetime Extension | Product Recovery | Structural Reuse | Material Recycling |

| Design aspects | |||||

| Concept design | |||||

| Accessibility | |||||

| Adaptability | |||||

| Cleanability | |||||

| Dis- and reassembly | |||||

| Ergonomics | |||||

| Fault isolation | |||||

| Functional packaging | |||||

| Interchangeability | |||||

| Malfunction signaling | |||||

| Simplification | |||||

| Embodiment | |||||

| Connection selection | |||||

| Function integration | |||||

| Keying | |||||

| Material selection | |||||

| Manufacturing | |||||

| Modularity | |||||

| Redundancy | |||||

| Sacrificial elements | |||||

| Structural design | |||||

| Surface treatment selection | |||||

| Detail design | |||||

| Documentation | |||||

| Identification | |||||

| Monitoring | |||||

| Standardisation | |||||

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Joustra, J.; Flipsen, B.; Balkenende, R. Circular Design of Composite Products: A Framework Based on Insights from Literature and Industry. Sustainability 2021, 13, 7223. https://doi.org/10.3390/su13137223

Joustra J, Flipsen B, Balkenende R. Circular Design of Composite Products: A Framework Based on Insights from Literature and Industry. Sustainability. 2021; 13(13):7223. https://doi.org/10.3390/su13137223

Chicago/Turabian StyleJoustra, Jelle, Bas Flipsen, and Ruud Balkenende. 2021. "Circular Design of Composite Products: A Framework Based on Insights from Literature and Industry" Sustainability 13, no. 13: 7223. https://doi.org/10.3390/su13137223

APA StyleJoustra, J., Flipsen, B., & Balkenende, R. (2021). Circular Design of Composite Products: A Framework Based on Insights from Literature and Industry. Sustainability, 13(13), 7223. https://doi.org/10.3390/su13137223