Numerical Analysis and Parametric Study of a 7 kW Tubular Permanent Magnet Linear Alternator

Abstract

:1. Introduction

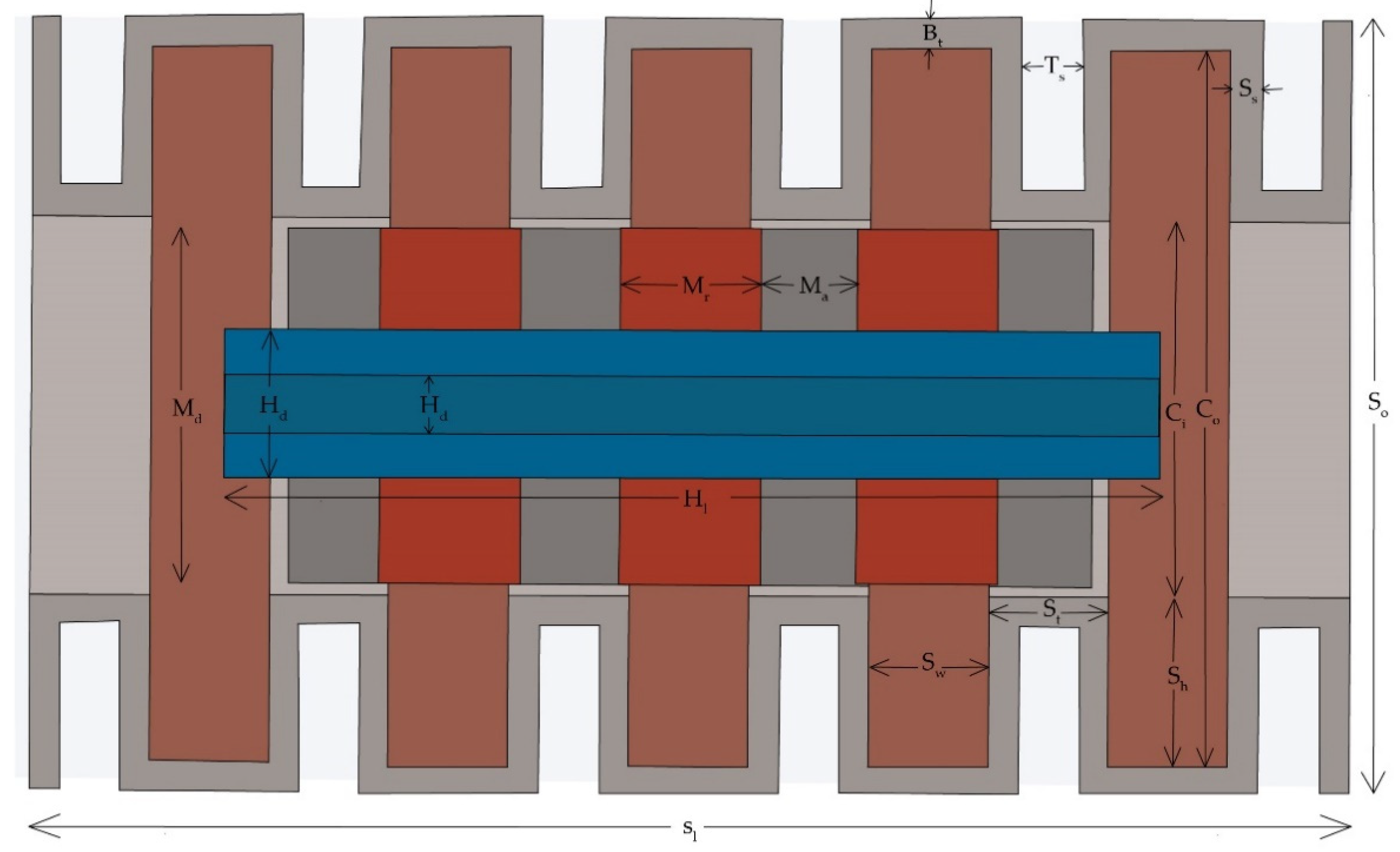

2. PMLA Design

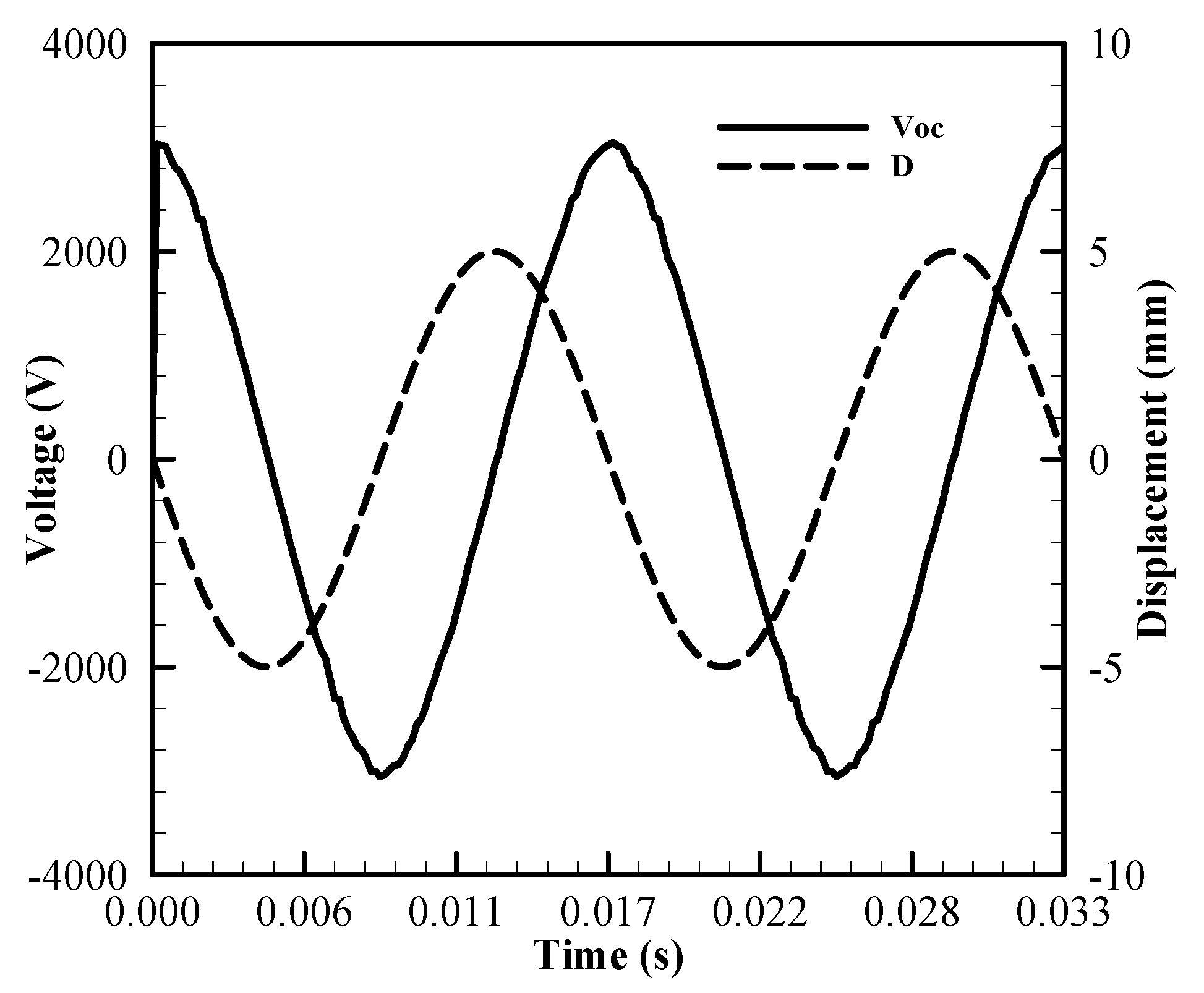

3. Baseline Case

4. Parametric Study

5. Results and Discussion

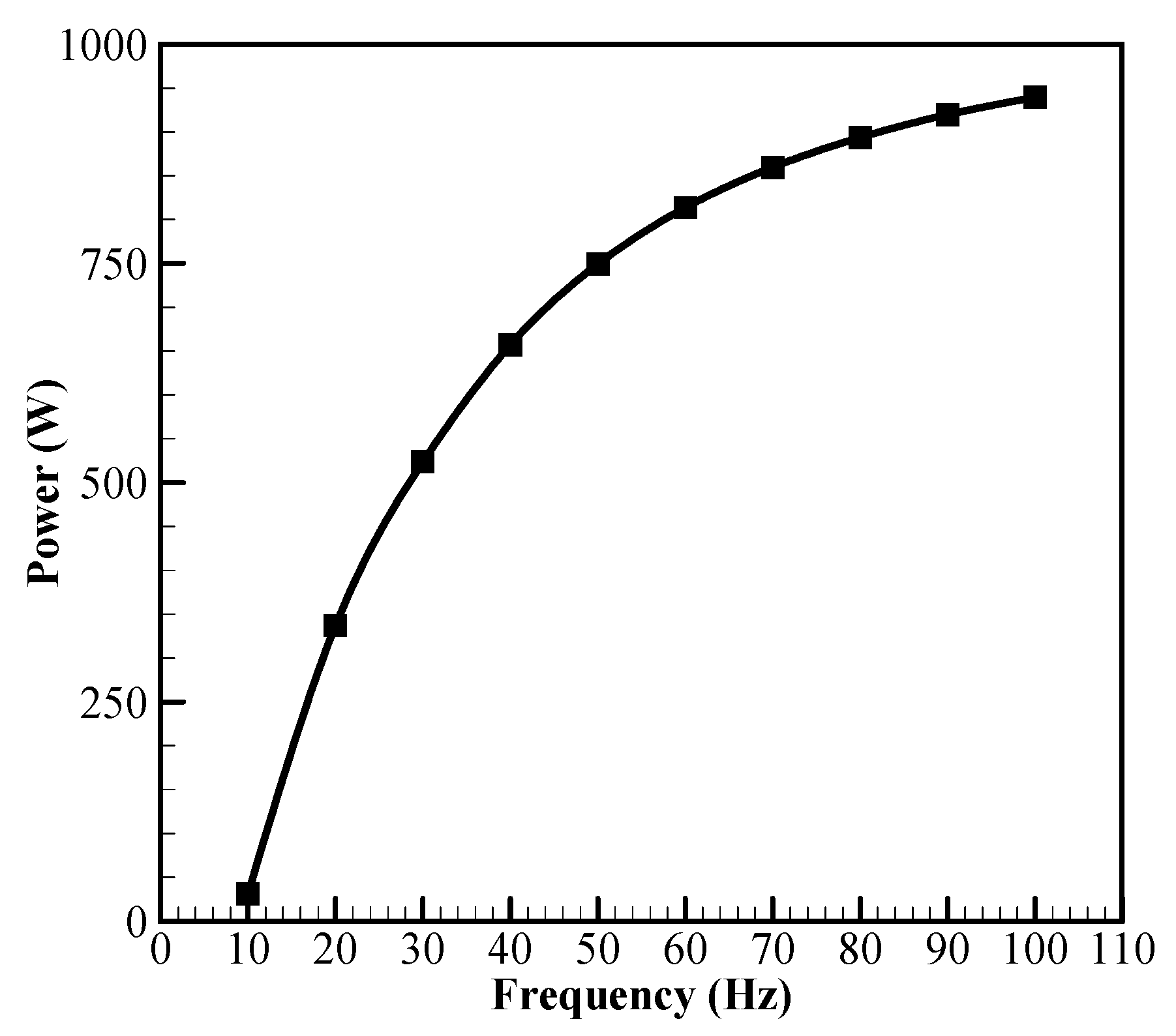

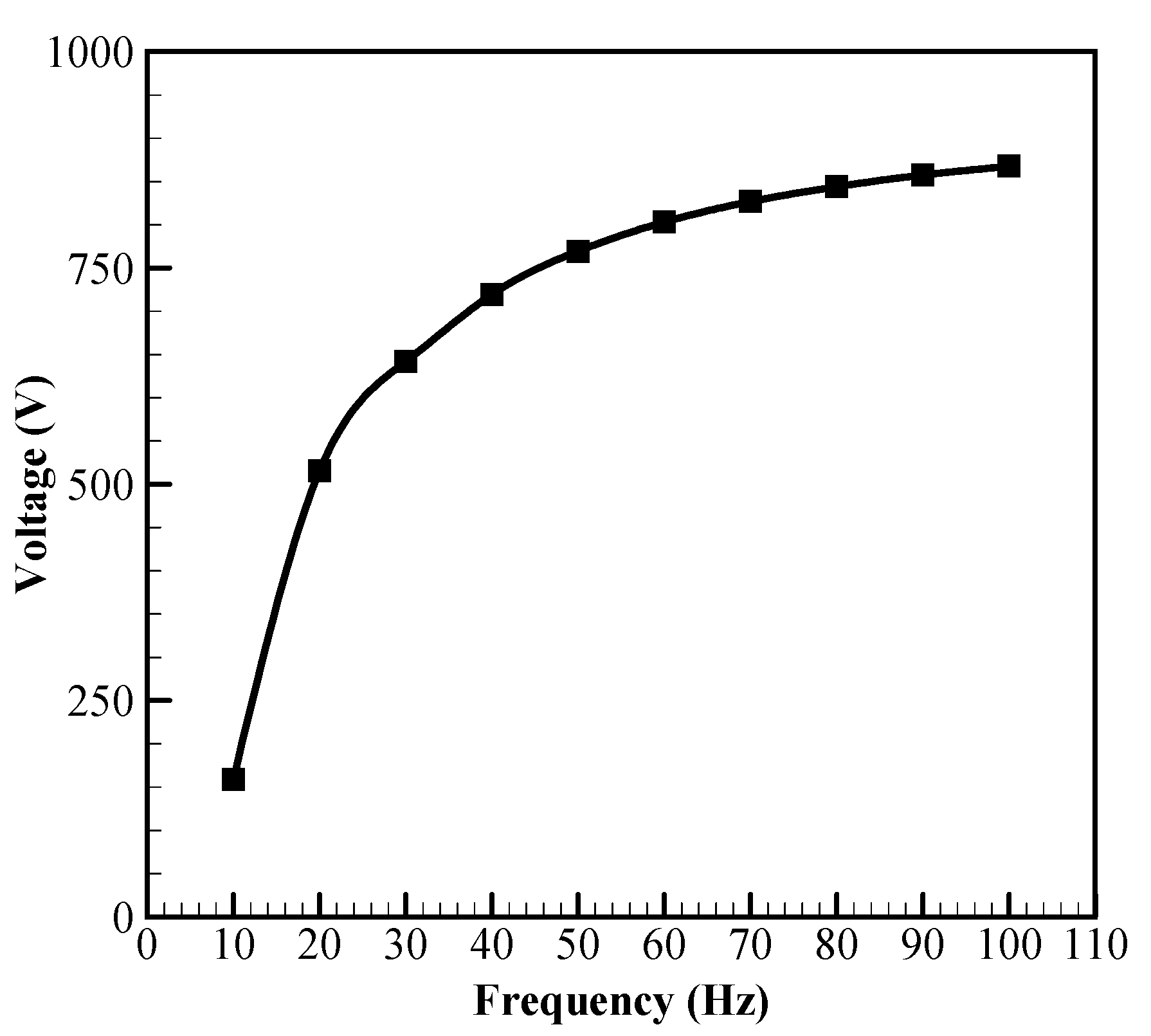

5.1. Effects of Frequency

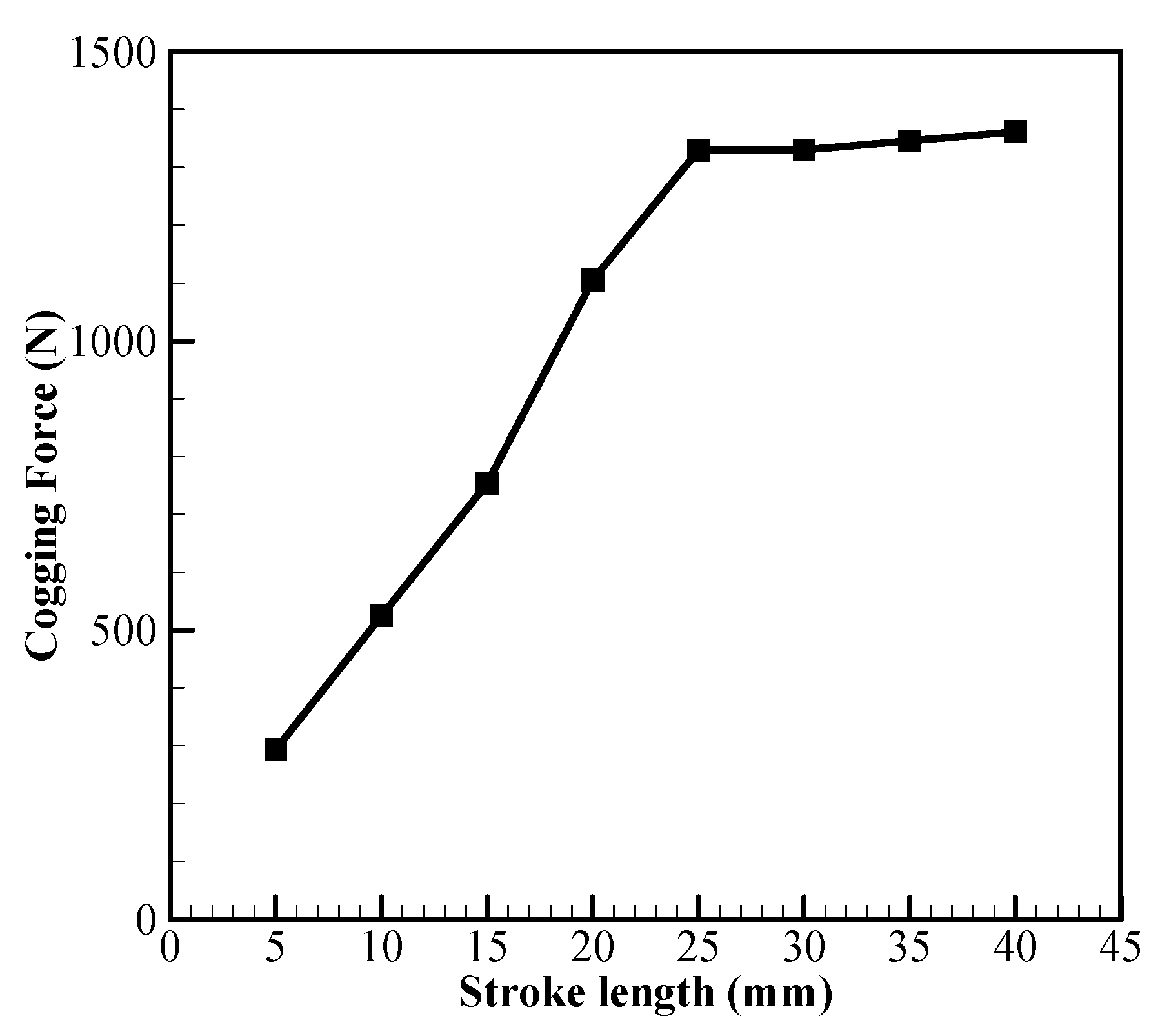

5.2. Effects of Stroke Length

5.3. Effects of Magnet Material

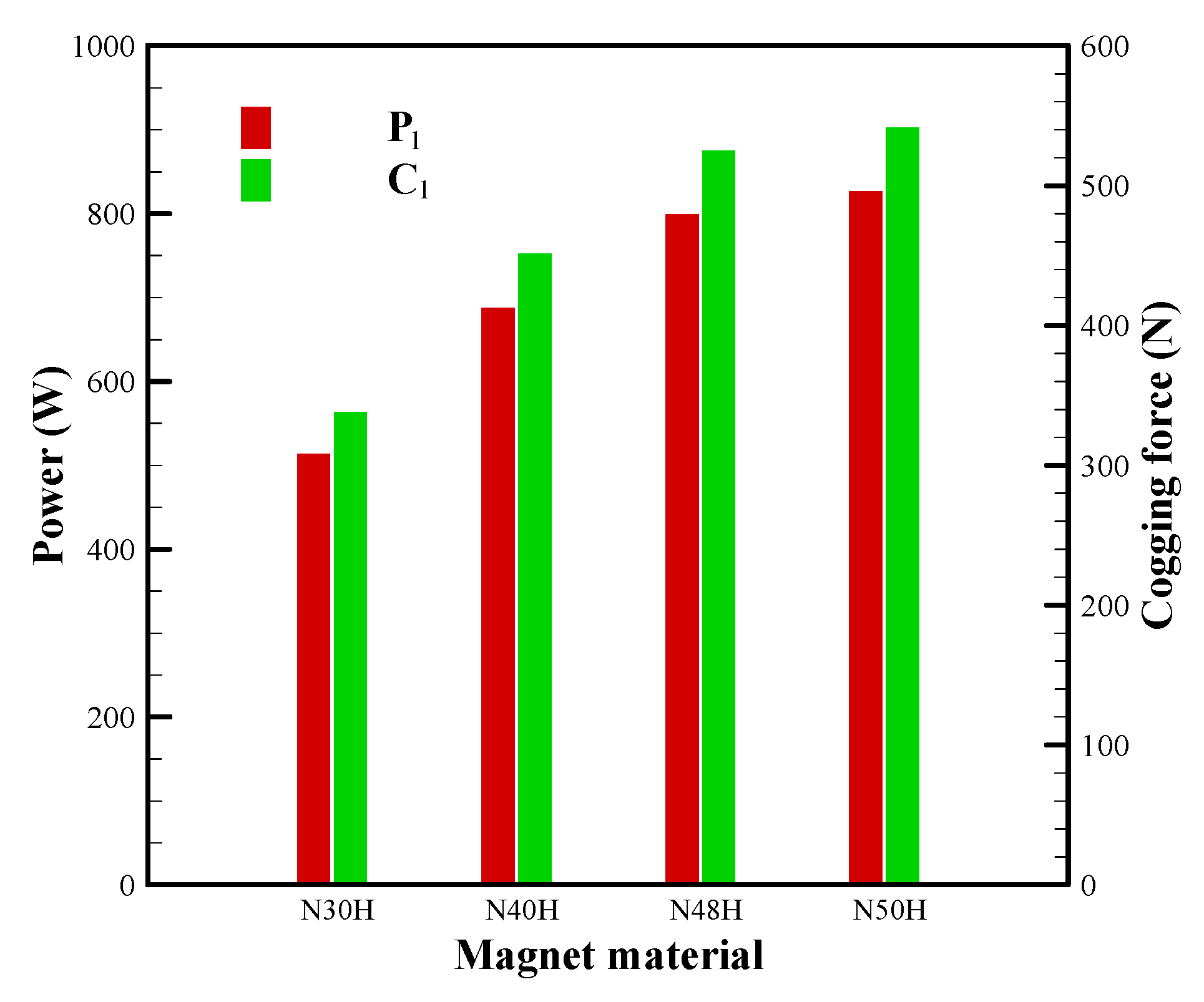

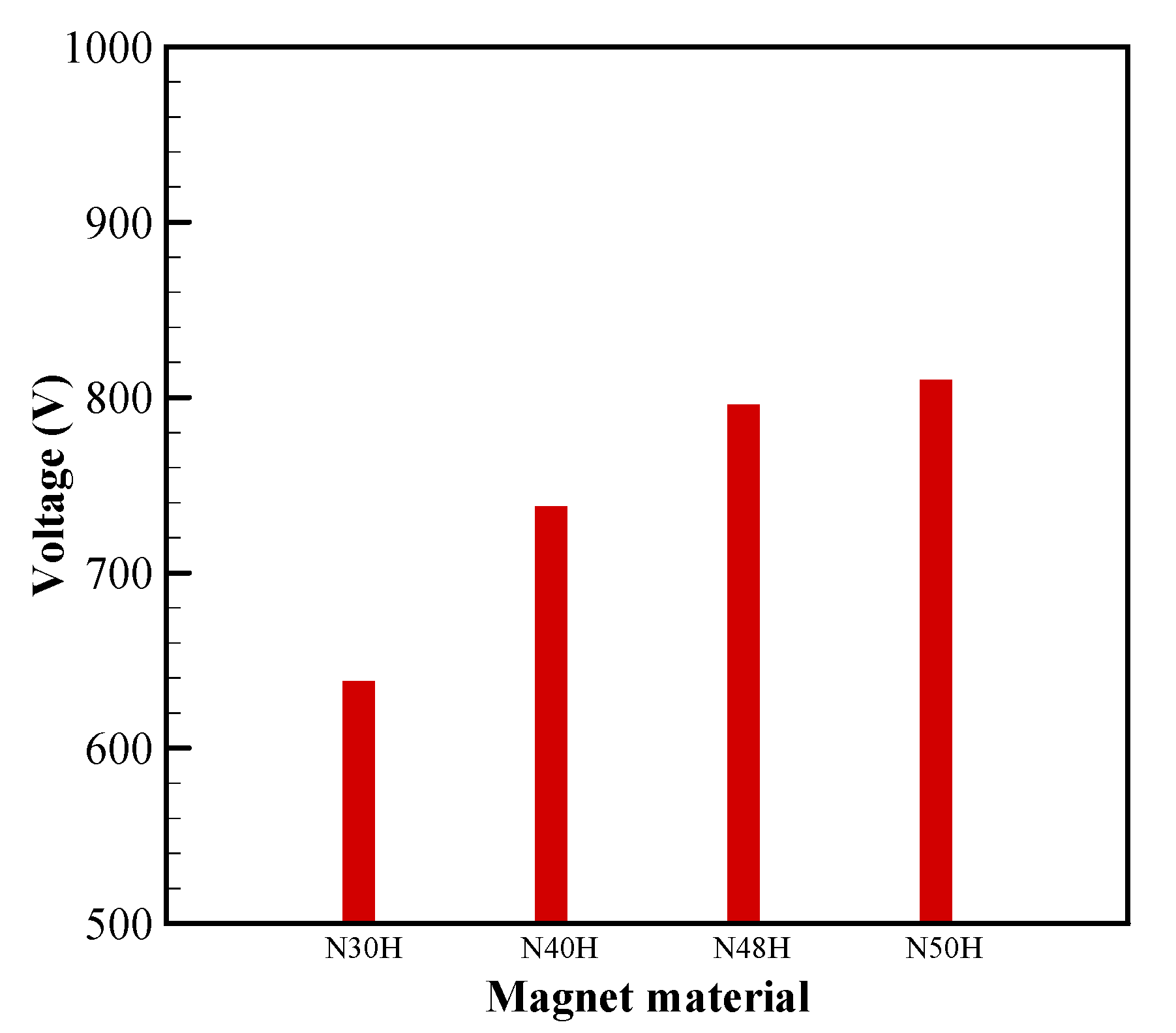

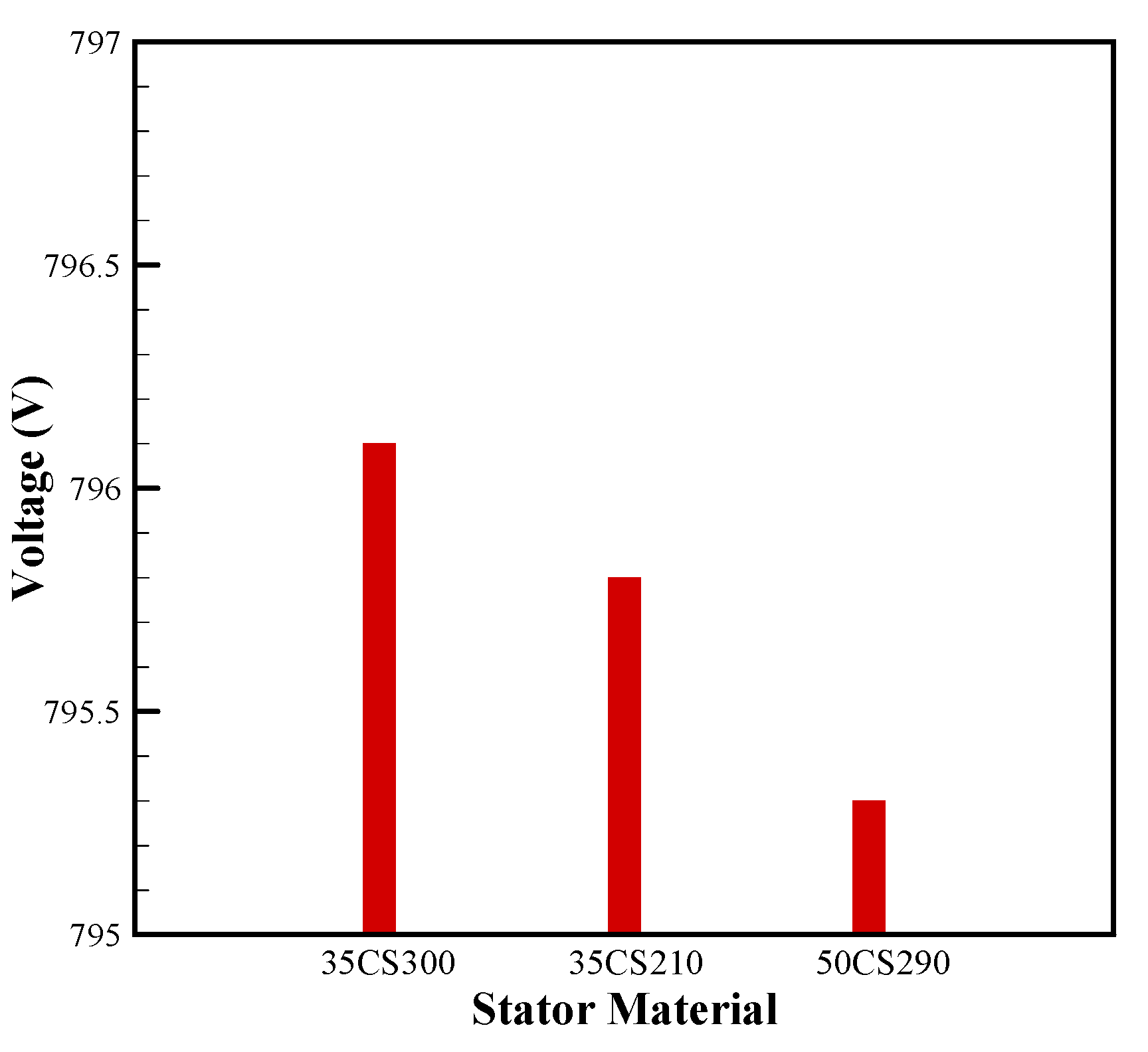

5.4. Effects of Stator Material

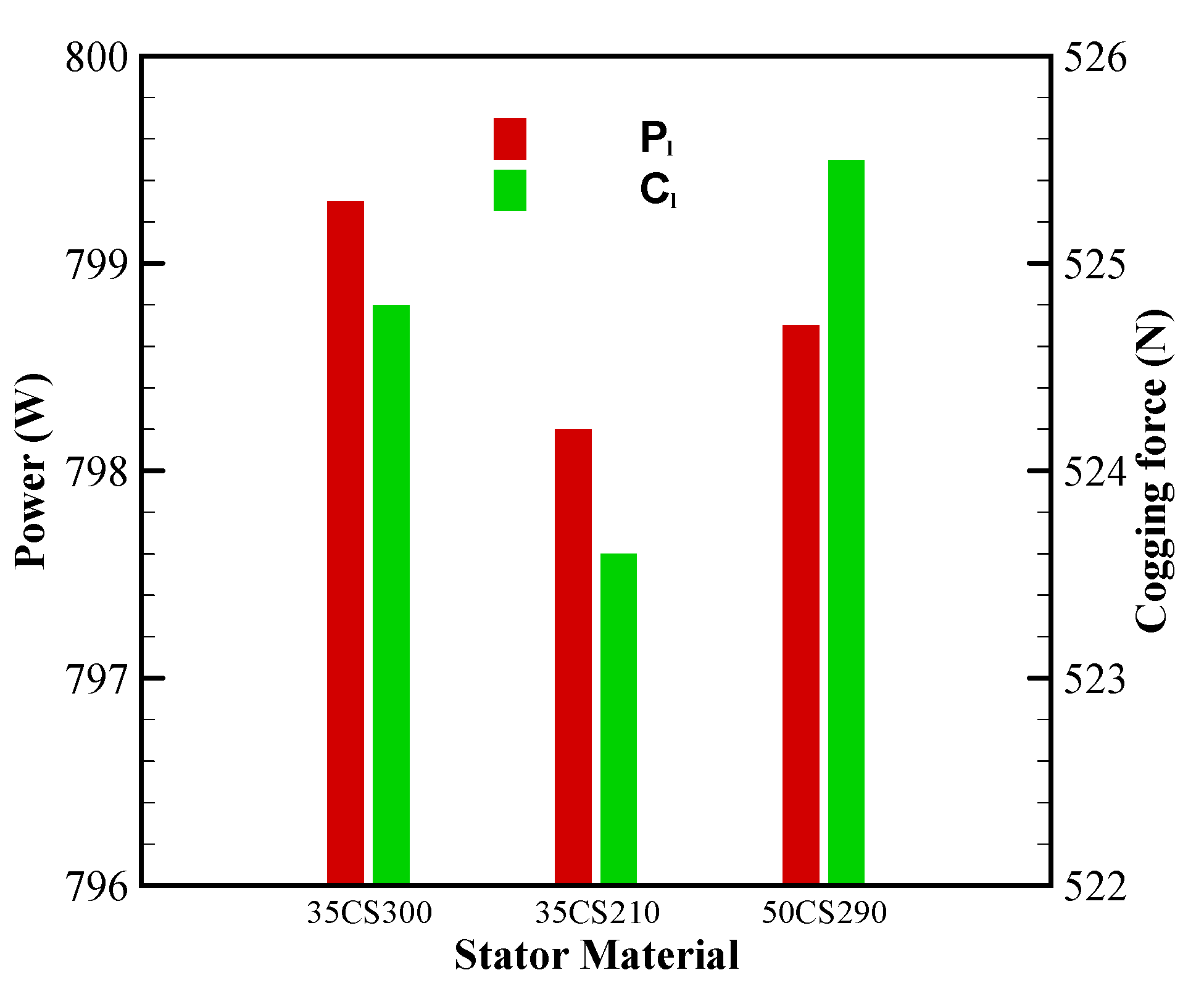

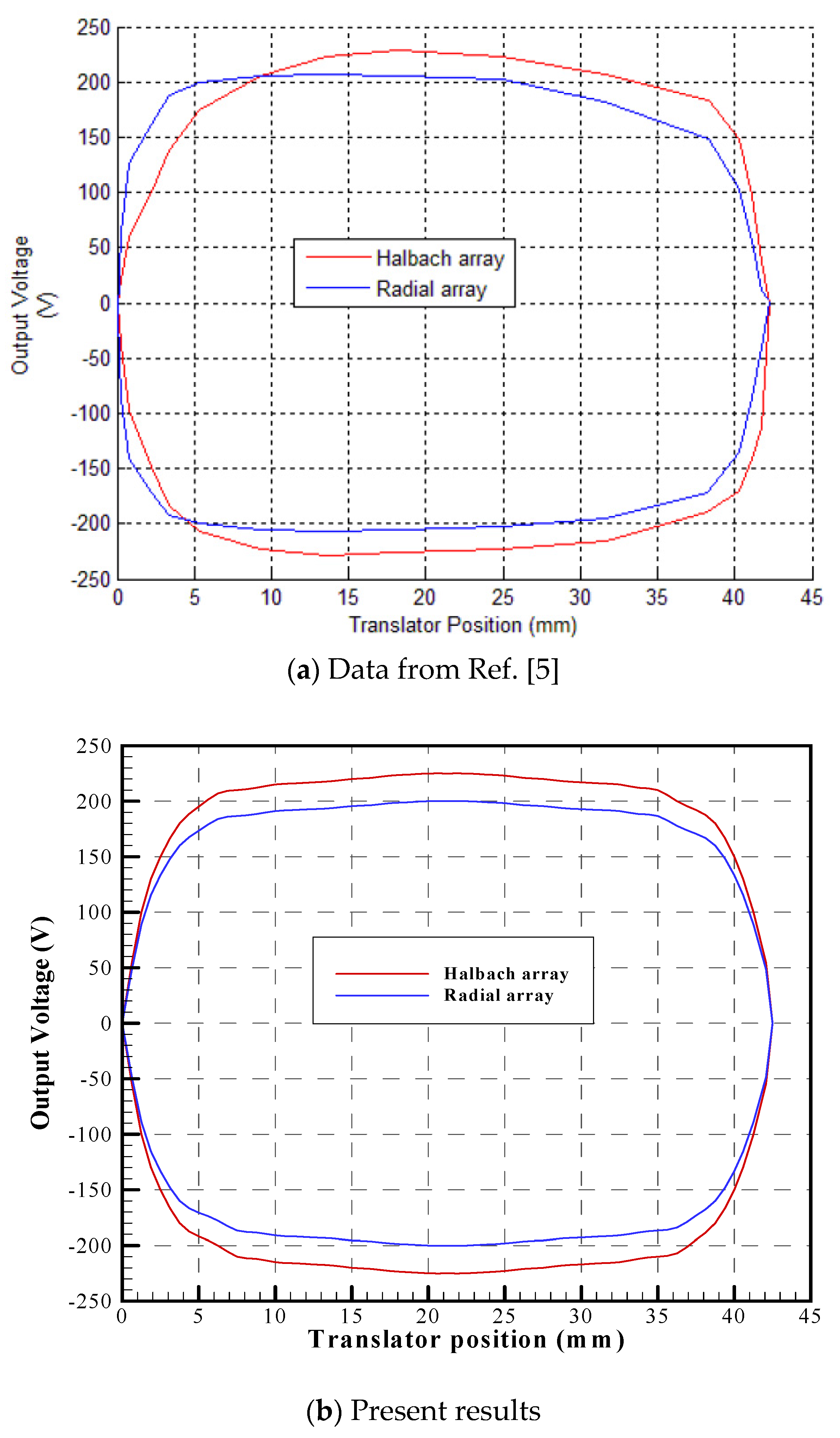

6. Validation

7. Conclusions

- (1)

- A level of saturation was seen after 60 Hz in the frequency variation. However, the domestic supply of Taiwan is fixed at 60 Hz, and hence was found to be a suitable solution that avoids post-processing of the induced EMF; most FPSEs operate within this range. The cogging force on the translator had a minuscule change due to the frequency variation and 939 W of power on the load in frequency variation.

- (2)

- With stroke length variation, there is a linear rise in induced voltage, varying beyond 40 mm, which is a design limitation, and applications with such inappropriate lengths are hard to find. A peak power of 7.1 kW was obtained for a 40 mm stroke, with the highest cogging force of 1.36 kN acting on the translator.

- (3)

- There was a linear rise in the induced power in the variation of magnetic material, and thus the cogging force. Hence, a balance between the required power delivery and an application to withstand the maximum cogging force felt on the translator should be chosen for specific applications.

- (4)

- The 35 series material has proven to be a better choice for the stator and shaft material, of which 35CS300 was found to have better-induced EMF than 35CS210. The iron loss in 35CS210 is comparatively lower, but the cogging force does not make a significant difference; hence, 35CS300 has proven to be a better material choice. Though having a considerable number of material choices for comparison, it was limited to a small number due to similar previous research [32].

- (5)

- Having values as low as 31 W and as high as 7116 W, the specific power varies from 1.4 W/kg to 313.5 W/kg. There is a wide band of power availability with this PMLA. Power-dense machines of such proportions have been possible in the past with suitable integrations.

- (6)

- Considering four parameters, a newer, lighter model from an existing conventional model has been developed which can provide more power under the same operating conditions. We came up with a PMLA that can produce a 7.1 kW peak power which is numerically analyzed and validated.

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Allen, M.; Antwi-Agyei, P.; Aragon-Durand, F.; Babiker, M.; Bertoldi, P.; Bind, M.; Brown, S.; Buckeridge, M.; Camilloni, I.; Cartwright, A.; et al. Technical Summary: Global Warming of 1.5 °C. An IPCC Special Report on the Impacts of Global Warming of 1.5 °C above Pre-Industrial Levels and Related Global Greenhouse Gas Emission Pathways, in the Context of Strengthening the Global Response to the Threat of Climate Change, Sustainable Development, and Efforts to Eradicate Poverty; IIASA: Laxenburg, Austria, 2019. [Google Scholar]

- Boldea, I.; Nasar, S.A. Linear Electric Actuators and Generators; Cambridge University Press (CUP): Cambridge, UK, 1999; pp. 3–43. [Google Scholar]

- Hung, N.B.; Lim, O. A review of free-piston linear engines. Appl. Energy 2016, 178, 78–97. [Google Scholar] [CrossRef]

- Gargov, N.P.; Zobaa, A.F.; Pisica, I. Investigation of multi-phase tubular permanent magnet linear generator for wave energy converters. Electr. Power Components Syst. 2014, 42, 124–131. [Google Scholar] [CrossRef] [Green Version]

- Rezaeealam, B. Permanent Magnet Tubular Generator with Quasi-Halbach Array for Free-Piston Generator System. Int. J. Power Electron. Drive Syst. (IJPEDS) 2017, 8, 1663–1672. [Google Scholar] [CrossRef] [Green Version]

- Loktionov, E.; Martirosyan, A.A.; Shcherbina, M.D. Solar Powered Free-Piston Stirling-Linear Alternator Module for the Lunar Base. In Proceedings of the 2016 2nd International Conference on Industrial Engineering, Applications and Manufacturing (ICIEAM), Piscataway, NJ, USA, 19–20 May 2016; pp. 1–6. [Google Scholar]

- Durcansky, P.; Nosek, R.; Jandačka, J. Use of Stirling Engine for Waste Heat Recovery. Energies 2020, 13, 4133. [Google Scholar] [CrossRef]

- Zhou, Y.; Sofianopoulos, A.; Lawler, B.; Mamalis, S. Advanced combustion free-piston engines: A comprehensive review. Int. J. Engine Res. 2018, 21, 1205–1230. [Google Scholar] [CrossRef] [Green Version]

- Wang, D.; Shuttleworth, R. Linear Alternator Design for Use in Heat Energy Recovery System. In Proceedings of the 6th IET International Conference on Power Electronics, Machines and Drives (PEMD 2012), London, UK, 27–29 March 2012; pp. 1–6. [Google Scholar]

- Dhar, M. Stirling Space Engine Program; National Aeronautics and Space Administration Glenn Research Center: Washington, DC, USA, 1999. [Google Scholar]

- Wood, J.G.; Buffalino, A.; Holliday, E.; Penswick, B.; Gedeon, D. Free-Piston Stirling Power Conversion Unit for Fission Surface Power, Phase I Final Report; NASA: Washington, DC, USA, 2010. [Google Scholar]

- Gecha, V.Y.; Goncharov, V.I.; Chirkin, V.G.; Shirinskii, S.V.; Petrichenko, D.A. Linear Alternator with Reciprocating Mover: Review of Designs and Machine Types. Biosci. Biotechnol. Res. Asia 2015, 12, 409–418. [Google Scholar] [CrossRef]

- Famouri, P.; Cawthorne, W.R.; Clark, N.; Nandkumar, S.; Atkinson, C.; Atkinson, R.; McDaniel, T.; Petreanu, S. Design and testing of a novel linear alternator and engine system for remote electrical power generation. In Proceedings of the IEEE Power Engineering Society. 1999 Winter Meeting (Cat. No. 99CH36233), New York, NY, USA, 31 January–4 February 1999; Volume 1, pp. 108–112. [Google Scholar]

- Cawthorne, W.; Famouri, P.; Chen, J.; Clark, N.; McDaniel, T.; Atkinson, R.; Nandkumar, S.; Atkinson, C.; Petreanu, S. Development of a linear alternator-engine for hybrid electric vehicle applications. IEEE Trans. Veh. Technol. 1999, 48, 1797–1802. [Google Scholar] [CrossRef]

- Ferrari, C.; Friedrich, H.E. Development of a free-piston linear generator for use in an extended-range electric vehicle. In Proceedings of the EVS26 International Battery, Hybrid and Fuel Cell Electric Vehicle Symposium, Los Angeles, CA, USA, 6–9 May 2012; pp. 1–6. [Google Scholar]

- Hodgins, N.; Keysan, O.; McDonald, A.; Mueller, M.A. Design and Testing of a Linear Generator for Wave-Energy Applications. IEEE Trans. Ind. Electron. 2011, 59, 2094–2103. [Google Scholar] [CrossRef]

- Brown, D.; Bao-Min, M.; Zhongmin, C. Developments in the processing and properties of NdFeb-type perma-nent magnets. J. Magn. Magn. Mater. 2002, 248, 432–440. [Google Scholar] [CrossRef]

- Ma, B.M.; Herchenroeder, J.W.; Smith, B.; Suda, M.; Brown, D.N.; Chen, Z. Recent development in bonded NdFeB magnets. J. Magn. Magn. Mater. 2002, 239, 418–423. [Google Scholar] [CrossRef]

- Eckert, P.R.; Igor, P.W.; Flores Filho, A.F. Design Aspects of Quasi-Halbach Arrays Applied to Linear Tubular Actuators. In Proceedings of the 10th International Symposium on Linear Drives for Industry Applications, Aachen, Germany, 27–29 July 2015; pp. 27–29. [Google Scholar]

- Lee, K.-S.; Lee, S.-H.; Park, J.-H.; Choi, J.-Y.; Sim, K.-H. Design and Experimental Analysis of a 3 kW Single-Phase Linear Permanent Magnet Generator for Stirling Engines. IEEE Trans. Magn. 2018, 54, 1–5. [Google Scholar] [CrossRef]

- Kumar, M.; Santosh, M.; Krishna, A.R.; Manisha, D. Permanent magnet linear generator design. IOSR J. Electr. Electron. Eng. 2015, 10, 86–90. [Google Scholar]

- Park, J.; Ko, J.; Kim, H.; Hong, Y.; Yeom, H.; Park, S.; In, S. The design and testing of a kW-class free-piston Stirling engine for microcombined heat and power applications. Appl. Therm. Eng. 2020, 164, 114504. [Google Scholar] [CrossRef]

- Sugiyantoro, B.; Rafsanjani, S.A.; Susilo, W.Y. Slotless Tubular Linear Permanent Magnet Generator Using Halbach-Array Excitation. In Proceedings of the 2018 10th International Conference on Information Technology and Electrical Engineering (ICITEE), Piscataway, NJ, USA, 24–26 July 2018; pp. 573–576. [Google Scholar]

- Li, Q.-F.; Xiao, J.; Huang, Z. Parametric study of a free piston linear alternator. Int. J. Automot. Technol. 2010, 11, 111–117. [Google Scholar] [CrossRef]

- Joubert, L.H.; Strauss, J.M. Optimisation of a Transverse Flux Linear Oscillating Generator by Transient 3D Finite Element Analysis. In Proceedings of the 2014 International Conference on Electrical Machines (ICEM), Piscataway, NJ, USA, 2–5 September 2014; pp. 602–608. [Google Scholar]

- de la Bat, B.; Dobson, R.; Harms, T.; Bell, A. Simulation, manufacture and experimental validation of a novel single-acting free-piston Stirling engine electric generator. Appl. Energy 2020, 263, 114585. [Google Scholar] [CrossRef]

- Lim, K.-C.; Woo, J.-K.; Kang, G.-H.; Hong, J.-P.; Kim, G.-T. Detent force minimization techniques in permanent magnet linear synchronous motors. IEEE Trans. Magn. 2002, 38, 1157–1160. [Google Scholar] [CrossRef]

- Eid, A.M.; Lee, H.W.; Nakaoka, M. Detent force reduction of a tubular linear generator using an axial stepped permanent magnet structure. J. Power Electron. 2006, 6, 290–297. [Google Scholar]

- Rezaeealam, B. Losses Computation in Reciprocating Tubular Permanent Magnet Generator with SMC Core. Int. J. Power Electron. Drive Syst. (IJPEDS) 2018, 9, 1545–1551. [Google Scholar] [CrossRef]

- Cawthorne, W.R. Optimization of a Brushless Permanent Magnet Linear Alternator for Use with A Linear Internal Combustion Engine. Ph.D. Thesis, West Virginia University, Morgantown, VA, USA, 1999. [Google Scholar]

- Mahmudzadeh, F.; Subramanian, J.; Famouri, P. Experimental Implementation of PLL for Free-Piston Engine Application. In Proceedings of the 2021 IEEE Texas Power and Energy Conference (TPEC), College Station, TX, USA, 2–5 February 2021. [Google Scholar]

- Yi-Jia, C. Integrated Model Analysis of a Free-Piston Stirling Engine Incorporated with a Linear Alternator. Master Thesis, National Cheng-Kung University, Tainan, Taiwan, January 2021. [Google Scholar]

- Schlune, H.; Plos, M.; Gylltoft, K. Safety formats for non-linear analysis of concrete structures. Mag. Concr. Res. 2012, 64, 563–574. [Google Scholar] [CrossRef]

- Castaldo, P.; Gino, D.; Mancini, G. Safety formats for non-linear finite element analysis of reinforced concrete structures: Dis-cussion, comparison and proposals. Eng. Struct. 2019, 193, 136–153. [Google Scholar] [CrossRef]

| Parameters | Dimensions (mm) |

|---|---|

| Stator Outer Diameter, So | 136 |

| Slot Width, Sw | 21 |

| Slot Height, Sh | 30 |

| Back Iron Thickness, Bt | 5 |

| Tooth Slot Thickness, Ss | 5 |

| Tooth Slot Gap, Ts | 10.5 |

| Stator Stack Length, Sl | 230.5 |

| Magnet Outer Diameter, Md | 63 |

| QH (Axial) Magnet Thickness, Ma | 16.5 |

| QH (Radial) Magnet Thickness, Mr | 25 |

| Coil Inner Diameter, Ci | 66 |

| Coil Outer Diameter, Co | 125 |

| Shaft Stack Length, Hl | 163.5 |

| Shaft Inner Diameter, Hi | 16 |

| Shaft Outer Diameter, Hd | 26 |

| Air Gap | 1.5 |

| Part | Mass (kg) |

|---|---|

| Stator | 7.6 |

| Shaft | 4.1 |

| Magnets | 2.7 |

| Coils | 8.3 |

| Baseline Parameters | Parameter |

|---|---|

| Stator material | 35CS300 |

| Magnet material | N48H |

| Stroke length (mm) | 10 |

| Frequency (Hz) | 60 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Cheng, C.-H.; Dhanasekaran, S. Numerical Analysis and Parametric Study of a 7 kW Tubular Permanent Magnet Linear Alternator. Sustainability 2021, 13, 7192. https://doi.org/10.3390/su13137192

Cheng C-H, Dhanasekaran S. Numerical Analysis and Parametric Study of a 7 kW Tubular Permanent Magnet Linear Alternator. Sustainability. 2021; 13(13):7192. https://doi.org/10.3390/su13137192

Chicago/Turabian StyleCheng, Chin-Hsiang, and Surender Dhanasekaran. 2021. "Numerical Analysis and Parametric Study of a 7 kW Tubular Permanent Magnet Linear Alternator" Sustainability 13, no. 13: 7192. https://doi.org/10.3390/su13137192

APA StyleCheng, C.-H., & Dhanasekaran, S. (2021). Numerical Analysis and Parametric Study of a 7 kW Tubular Permanent Magnet Linear Alternator. Sustainability, 13(13), 7192. https://doi.org/10.3390/su13137192