Abstract

In this study, interviewer-based questionnaires of 67 variables were administered to local fabricators and end-users of single-pot biomass stoves (SPBS) in Ghana. Additionally, two randomly selected traditional and improved SPBS were lab-tested using standard performance metrics. From the study, the relationship between fabricators and end-users was conceptualized based on selected indicators and assumptions. The study results indicated that the primary design resources for fabrication were patterns and templates, and that major challenges to fabrication were lack of training in design principles, standards and safety, poor emission efficiency and financial sustainability. Whereas end-users of improved SPBS were less affected by heat and smoke, end-users of traditional SPBS were mostly affected. From hypothesis test, because the calculated χ2cal = 24.05, and is greater than the tabulated χ2crit = 3.841, it is concluded that there is a relationship between heat, smoke effect and gender, and that female end-users of traditional SPBS were particularly affected during cooking. The traditional SPBS emitted more CO2 and CO than improved SPBS. Comparatively, 38% more end-users of traditional SPBS observed charcoal ash residue in the cooking area than improved SPBS users. Four basic practices of managing ashes from SPBS are developed. Finally, a fabricator and end-user framework are developed for energy sustainability and quality improvement.

1. Introduction

Locally fabricated single-pot biomass stoves (SPBS) are mainly developed and produced by fabricators who use locally available raw materials and skills [1]. These stoves are generally customized for household or commercial uses. In several African communities, cooking is for the most part done by women [2] who normally use single-pot biomass stoves, while the stoves that are used for cooking are typically fabricated by men [3]. Household and commercial stoves are typically fabricated as single-pot/burner stoves, although double burners can also be found on the market. Single-pot stoves are relatively affordable; hence, a significant number of end-users depend on them for cooking and heating. However, there is a lack of uniformity in the design and fabrication of SPBS and this affects their thermal efficiency, fuel consumption, and emissions. A poorly designed and fabricated stove can easily burn food before it finishes cooking [4]. It is widely acknowledged that well-designed stoves contribute to improve thermal efficiency, remove smoke from indoor living space, and lessen the drudgery of cooking duties [5,6].

In spite of the realization of the multiple concerns about locally fabricated SPBS, the issue of product quality has not significantly improved for most end-users [7], hence affecting marketing dynamics and revenue generation. Again, owing to decades of absence of standards for local fabrication of SPBS, effective regulation and certification by relevant institutions are not implemented. This could be a potential source of risk to fabricators as a result of drudgery in production and risk to end-users’ comfort due to emissions. Inefficient burning of solid biomass fuels including charcoal and firewood caused by fabrication problems could lead to indoor air pollution, which affects human health and the environment. Each year, close to four million people die prematurely from illness attributable to air pollution from inefficient cooking practices using polluting stoves paired with solid biomass fuels [8]. In poorly aerated places, indoor air smoke can be many times higher than acceptable levels for fine particles [8]. Exposure is particularly high among women and young children, who spend most of their time near the domestic fireside [8,9].

Although several studies have been conducted on cookstove design and commercialization in Africa, there is the lack of in-depth study on the interdependent relationship between local fabricators and end-users of SPBS. To gain insight and understanding, the relationship can be conceptualized in a framework. Understanding the relationship will help the continuous generation of new knowledge and skills that will match stove performance to end-user requirements [10]. This will contribute to addressing specific issues and concerns end-users consider important and critical for energy sustainable and quality improvement.

Therefore, this study assesses the fabricator and end-user relationship using SPBS to develop a sustainability framework that will contribute to sustainable biomass energy management and product improvement. The study is guided by the following research questions:

- (1)

- How do we conceptualize the relationship between local fabricators and end-users of SPBS for understanding and sustainable improvement?

- (2)

- What issues and challenges are faced by local fabricators and end-users of SPBS?

- (3)

- To what extent do smoke and heat affect local fabricators and end-users of SPBS and does heat and smoke effect have a relationship with gender?

- (4)

- How do we validate the performance metrics of SPBS?

- (5)

- What framework can be developed from the study to ensure sustainable energy management and product improvement?

2. Approach and Methodology

2.1. Survey of Local Fabricators and End-Users

An interviewer-administered questionnaire was designed and administered to 25 male fabricators and 15 female end-users of single-pot biomass stoves that were randomly selected in the light industrial cluster of Suame in the Kumasi Metropolis, Ghana. Research assistants from the Kwame Nkrumah University of Science and Technology, Kumasi who speak the local language were engaged in the administration of the questionnaires. The questionnaires contained 67 variables including demographic data, challenges and issues associated with stove design and fabrication, standards and safety, training and measures to ensure safety, marketing, pricing, and stove/fuel stacking, thermal efficiency, emissions, environmental awareness, etc.

2.2. Survey Data Analysis

In order to analyze the data, IBM SPSS 22.0 (IBM Corp. New York, NY, USA) for Windows was used. The data were cleaned by visually cross-checking the data base with the individual questionnaires to find out wrong entries, and by using a box plot to identify extreme values and outliers. To assess the challenges being faced by the fabricators and end-users so as to develop methods and tools for improvement of the production process and usage, both qualitative and quantitative analysis were employed. The qualitative analysis focused on interpretative understandings and relations that explained the challenges and issues. Statistical significant difference was computed at the probability p < 0.05.

2.3. Hypothesis Testing Using Chi-Square Test for Independence

In order to answer the research question on whether heat and smoke effect have a relationship with gender, the following hypotheses on two categories of variables were considered: (1) heat and smoke effect; and (2) gender (male fabricators and female end-users). Using chi-square test, the hypotheses were tested for independence [11]. This test is a nonparametric test that uses the observed data of the two variables, which are tabulated in a contingency table [12].

The null hypothesis (H0) and the alternative hypothesis (H1) are stated as follows:

H0: Smoke effect is independent of gender.

H1: Smoke effect is not independent of gender.

Chi-square (χ2) is determined using Equation (1)

where,

O = the observed frequency of any value.

E = the expected frequency of any value.

The degree of freedom at a significance level = 0.05 is determined using the equation

2.4. Performance Testing

Improved single-pot biomass stove and traditional single-pot biomass stove were the two locally fabricated stoves used for the laboratory testing. The stoves were randomly sampled from the open market. Charcoal of moisture content 8% was used as the fuel for the two stoves. Standard 5 L stainless steel cooking pots were used for boiling 5 L of water.

Parameters including thermal performance, fuel consumption, emissions etc. were measured using the hood and duct system, laboratory emissions monitoring system (LEMS) set supplied by Aprovecho Research Centre, Cottage Grove, OR, USA and other equipment including weighing scale CTS 3000 (Precision Weighing Balances, Bradford, MA, USA), moisture meter (Delmhorst J-10 Delmhorst Instruments Company, Towaco, NJ, USA, gravimetric particulate matter measurement (Aprovecho Research Centre, Cottage Grove, OR, USA) at the Cookstove Testing and Expertise Laboratory (C-Lab) of Technology Consultancy Centre (TCC), KNUST, Kumasi.

The protocol used for the test was the Water Boiling Test (WBT). This is a standardized test in which 5 L of water was boiled at high power with the stoves starting cold or “cold start”, hot or “hot start” and simmered for 45 min at low power (3 °C to 6 °C below full-boiling temperature). The WBT was carried out to find the characteristics of the stoves under controlled operating procedures. Three replicates were carried out for each stove. Analog signals from the sensors were read by a data acquisition board connected to a computer. Concentration data are displayed in real time on the computer monitor.

Data were analyzed in conjunction with WBT data calculation spreadsheet 4.2.3 software developed by Aprovecho Research Centre, Cottage Grove, OR, USA.. Statistical averages of the three replicate tests were computed from the spreadsheet. When a standard WBT, representing a cooking task, is done under the hood, it was possible to determine how much charcoal fuel was consumed and how much pollutant emissions were generated in performing the test.

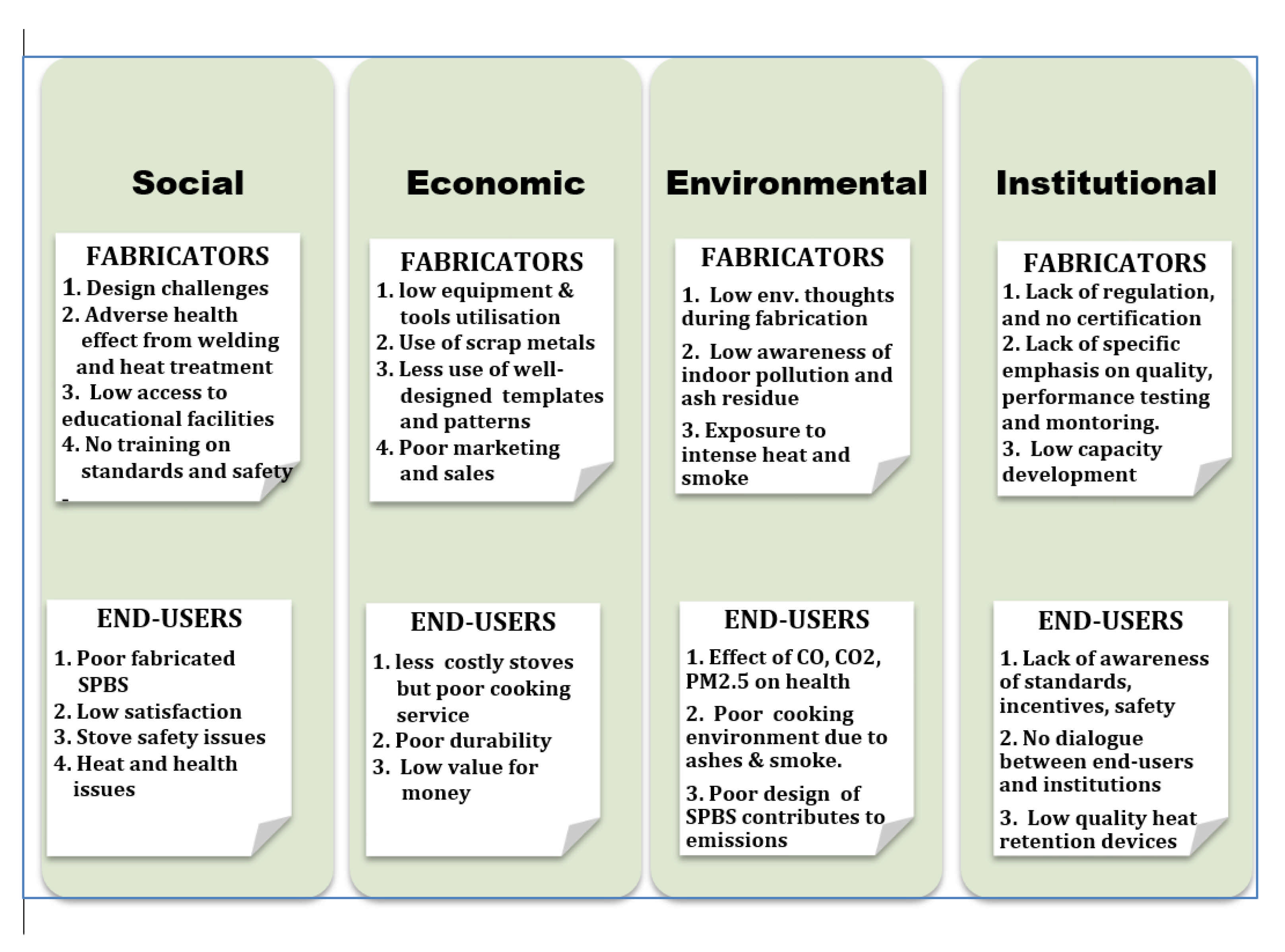

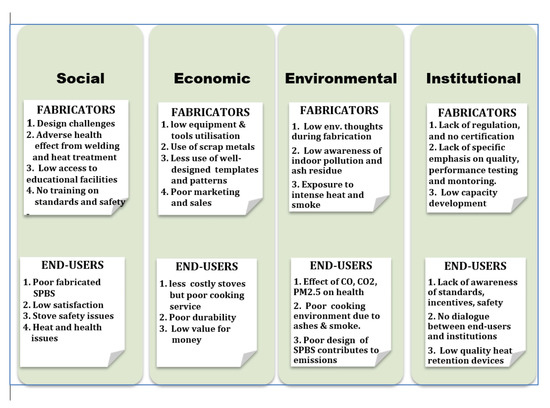

2.5. Development of Energy Sustainability Framework

To guide the development of the energy sustainability framework, the pillars of sustainability, namely, social, economic, environmental and institutional were used as the guiding framework. Four rectangular pillars were developed to analyze the sustainability-related issues and challenges faced by both the local fabricators and end-users of SPBS. On the one hand, the framework provides understanding of the technical and marketing issues SPBS fabricators. On the other hand, end-users’ perspectives are analyzed for understanding and generation of information for product quality improvement. End-users are the direct users of the fabricated stoves whose demand influences continuous supply; hence, their perspectives and reflections are of relevance to local fabricators.

3. Results and Discussion

3.1. Conceptualizing the Fabricator and End-User Relationship

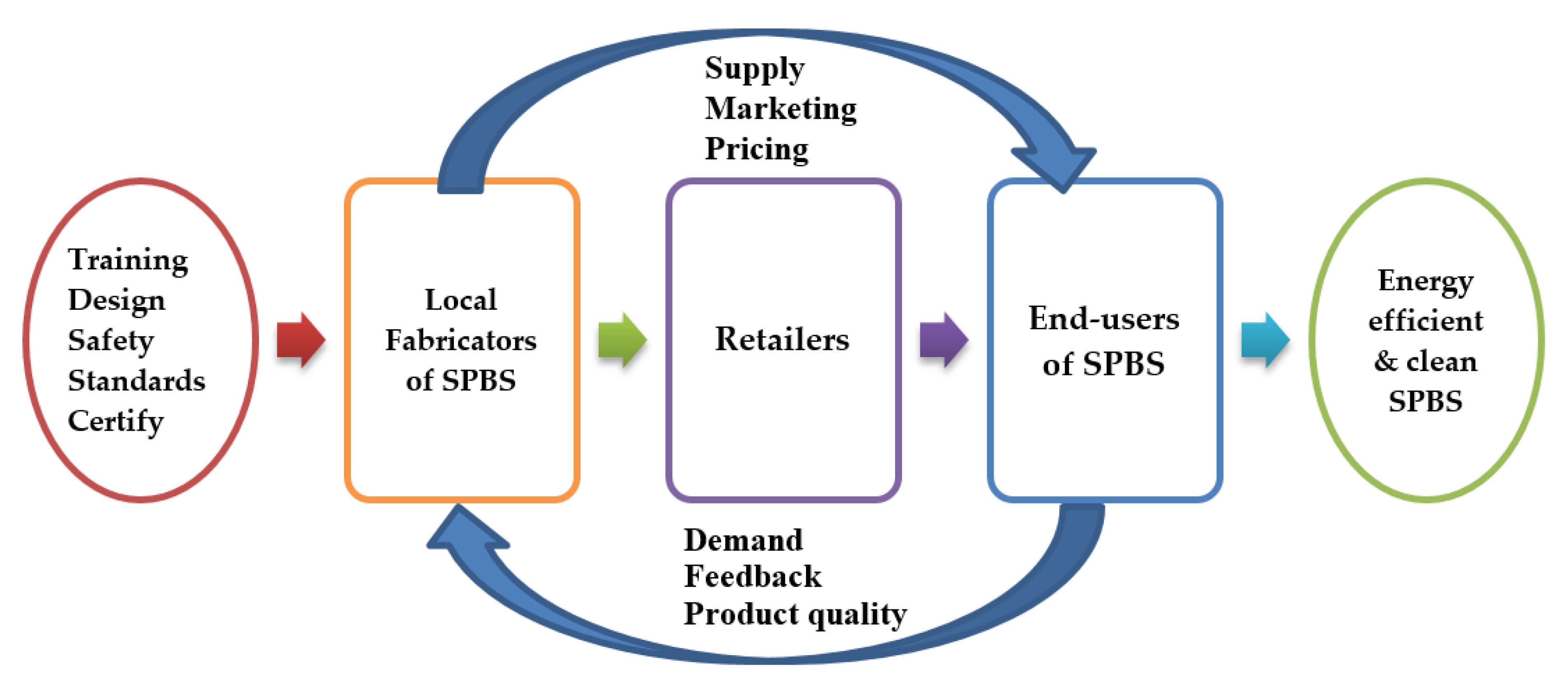

The relationship between fabricators of SPBS and end-users can be conceptualized for understanding and improvement. One end of the conceptual framework focuses on understanding the practices that are carried out to fabricate and market the stoves and their outcomes. The other end concentrates on the end-users who are direct and immediate users of the fabricated stoves whose demand, feedback and input for continuous improvement influence market supply, sometimes through retailers, that are of relevance to fabricators. Continuous demand for the stoves and feedback on functionality and performance improvement would help improve the design and fabrication processes. Understanding the relationship based on the knowledge and information that may well be generated and shared between fabricators and end-users would go a long way to addressing issues which end-users see as important and critical for sustainable quality improvement of energy efficient and clean SPBS (see Figure 1).

Figure 1.

Conceptualizing the fabricator and end-user relationship.

To measure the difference in social, economic and environmental effects associated with SPBS, a number of key fabricators and end-user level indicators were developed. The indicators sought to measure the change in output (improved functionality, improved performance and energy efficient and clean) associated with SPBS. Table 1 shows the indicators and assumptions that were used to measure change.

Table 1.

The Fabricator and end-user indicators and assumptions.

There is a link between the indicators and assumptions. While the indicators are meant to provide data to show the situation, the assumptions serve as expectations for the performance of activities that would lead to the results of the study. To analyze the data from the study, it is necessary to outline the clear path in which the indicators of change and assumptions are linked and valid. In the context of this study, the indicators and assumptions presented in Table 1 are quantitative metrics that provide information and expectations that are necessary for measuring challenges, performance and quality aspects of SPBSs.

3.2. The Fabricators

The fabricator side of the conceptual framework focuses on the stove fabrication metrics including design challenges, problems faced during fabrication, safety standards, certification and training, marketing and pricing.

3.2.1. Design Challenges

Table 2 indicates that 60% of the local fabricators designed their stoves before production, while 40% did not design their stoves. In trying to find out the procedures involved in the design of the existing SPBS, about 56% mentioned that they use patterns and templates as the main design resources. It is interesting to note that patterns and templates are the tools the fabricators used when they were undertaking their apprenticeship training [13]. These templates and patterns are not modified from time to time to reflect the changing needs and requirements of end-users. Using old templates and patterns that are not consistently modified implies that the fabricators produce the same stoves without innovation. From the study results, it is clear that at the level of fabrication of the local stoves, not much attention is given to capacity building of the fabricators to facilitate the creation and development of new designs with quality attributes of good functionality and aesthetics to meet new needs of customers [10]. To design the stove means to use engineering drawings and specifications that can be transformed into templates and patterns to build stoves that meet end-users’ needs and satisfy planned criteria including functionality, quality performance, safety, and aesthetics. Such engineering drawings and specifications are standard methods and approach for fabricating standard stoves.

Table 2.

Designing stoves before production and procedures for designing.

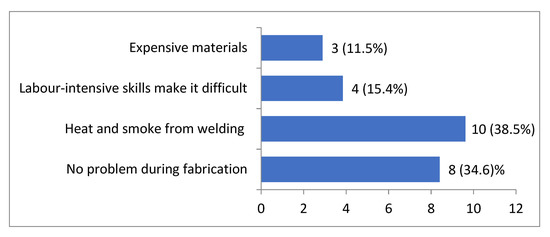

3.2.2. Problems Faced during Fabrication

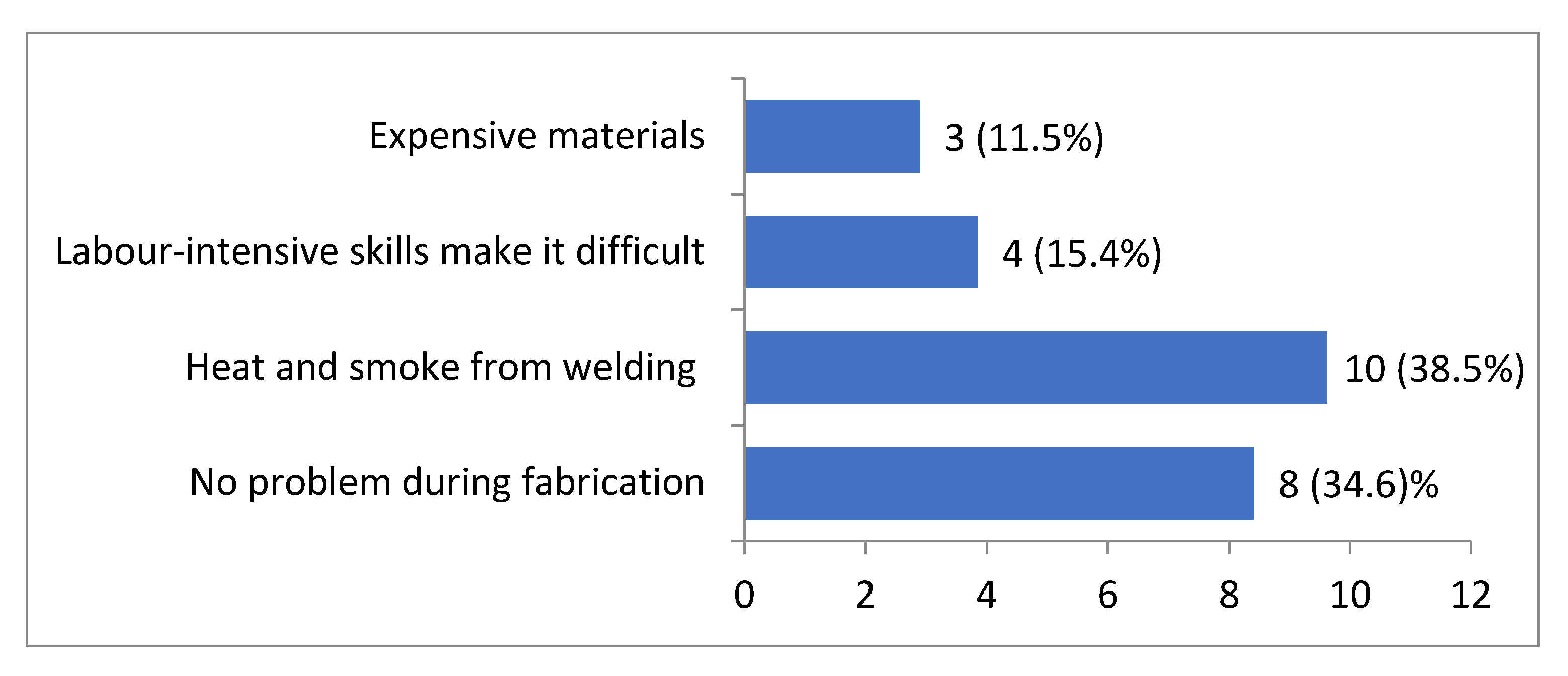

In Figure 2, the results revealed that nearly 65% of the local fabricators face a number of problems during the fabrication of the stoves. Problems such as heat and smoke from welding (about 39%), labor-intensive skills (about 15%), and high cost of engineering materials (about 12%) were reported as the major difficulties being faced during fabrication of the stoves. The data indicate that the fabricators are exposed to intense heat and smoke. Intense heat and smoke have adverse effects on the health of the stove fabricators, particularly in poorly ventilated workplaces, where indoor smoke can be higher than acceptable levels for fine particles [9,14].

Figure 2.

Problems faced during fabrication.

3.2.3. Safety Standards, Certification and Training

Although locally fabricated single-pot stoves play a very significant role in the economy of Ghana, there are currently no gazetted standards for the fabrication of stoves. The results in Table 3 indicate that a majority of stove fabricators (about 92%) do not follow any safety standards during fabrication. Only 8% reported that they follow some safety standards, and these are likely to be those who fabricate both biomass-based and gas stoves who might be aware of the risks posed by gas systems. It is reported that the absence of mandatory standards and enforcement result in poor design and fabrication of systems as well as their wrong operation [15].

Table 3.

Certification and training on standards and safety of stoves.

As a result of lack of standards and safety, there is a lack of training on standards and safety of stove fabrication. It is presented in Table 3 that nearly 96% of the local stove fabricators have not been trained on standards and safety. The only fabricator who reported having had some training was a stove and oven manufacturer who had training from a foreign company in the Netherlands. In the absence of formal training, a few of the fabricators reported that among the standards they adopt include use of quality materials (8%) and use of template and patterns as design tools.

The results presented in Table 3 indicate that the products being fabricated by 96% of the local fabricators are not certified by the relevant authorities. A whopping 96% of the fabricators have not been trained on standards and safety of stoves. The results show that in general locally fabricated stoves are not trained and certified by the relevant institutions and authorities. The lack of certification, which stems from the lack of standard procedures and production methods, could be a potential source of risk that can affect end-users and the environment [15].

Standards ensure that products and services are safe, reliable and are of good quality [16]. For businesses, they are a strategic tool that reduces costs by minimizing waste and errors, and increasing productivity. They help companies to access new markets, level the playing field for developing countries and facilitate free and fair global trade [16]. Although locally fabricated cooking stoves play a very significant role in the economy of Ghana, there are no gazetted standards for fabrication. However, under the group title-engineering and basic standards (renewable energy), standards for improved cookstoves are at the draft preparation stage for technical committee discussion [17]. The purchasing pattern of consumers of local stoves can be influenced by factors including environmental certification and adoption of standard production methods [18].

3.2.4. Marketing and Pricing

The quantity of stoves sold per week by the fabricators is presented in Table 4. The results revealed that on average the fabricators could sell the following number of stoves per week: small-size (min = 3; max = 100); medium-size (min = 2, max = 100); and large-size (min = 2, max = 70). On average, a majority of the fabricators sold 48 small-size stoves, 46 medium-size stoves and 18 large-size stoves per week. This was so partly because small-size stoves are mainly used for domestic purposes, while the medium and large-size stoves are used for commercial purpose. Moreover, small-size stoves are the cheapest, and hence could be afforded by most end-users (see Table 5). Further, commercial users of medium and large-size stoves also have small-size stoves, which they use for preparing stews and sauces in small cooking pots. In Ghana three different sizes of traditional single-pot biomass stove (coalpot) can be found on the market: small-size, medium-size and large-size.

Table 4.

Quantity of stoves sold per week.

Table 5.

Stove prices, means of getting customers and retail outlets.

When asked about prices, the respondents indicated that the price of stoves available on the market depends on several factors including: size, type of metal, thickness of metal, and quality of finish product. The small charcoal stoves priced at US$5–10 are usually bought by single or small families; medium-size charcoal stoves priced at US$6.5–13 are the normal household version, and the larger stoves costing US$16–20 are commercial (Table 5). Since most improved cookstove programmes are designed so that even the poorest customers can afford them, its price of US$4–7 appears to be reasonable. It is reported that Toyola, a stove company in Ghana, sold its improved cookstove that is 40% efficient at US$7 [19]. Valued at about US$5 or less in the early stages of most stove programmes, the best of improved stoves represented an improvement over a three-stone open fire [20]. There is a wide range of locally fabricated liquefied petroleum gas (LPG) stoves on the market and hence their prices vary depending on the number of burners, quality of burner, robustness of stove etc.

In Table 5 the results revealed that standard locally fabricated gas stoves are valued at US$13–26. This is relatively expensive because gas stoves are considered modern and are usually used by people whose incomes are higher than those who rely heavily on traditional biomass stoves. As incomes rise, end-users in developing countries generally switch to LPG fuel and various types of specialized electric cooking appliances [1,20]. More people use LPG directly than any other gaseous fuel because it is considered as a cleaner energy source with relatively high thermal energy [21,22,23].

The results presented in Table 5 demonstrate how cheap or expensive locally fabricated stoves compare to foreign ones. From the results about 80% of the respondents indicated that locally fabricated stoves are cheaper compared to the foreign ones, while close to 20% of them are of the view that the foreign ones are relatively cheap. In general, prices of local and/or foreign products are influenced by factors including production environment, cost of materials, cost of labor, quality of product, local taxes etc.

Therefore, it is not surprising that since the locally fabricated stoves are produced from scrap materials by people whose labor cost is relatively cheap and virtually pay no taxes on their manufactured products, the price of such stoves/ovens will be cheaper than foreign ones. The means of getting customers to buy stoves is presented in Table 5. The results indicate that (40%) is through word of mouth and (60%) said they sent samples to the market. From the results, it is understood that one out of every three customers who purchase locally fabricated stoves help in promoting the sale of the stoves they have used before, while two out of three purchase the stoves when they see samples on the market.

The results also indicate that 56% of the fabricators sell their locally fabricated stoves at the local marketplace, while 44% generally sell at both the fabrication shop and the local marketplace. Local fabricators of stoves who sell at the marketplace usually cut off middlemen and work with retailers who in turn sell directly to the end-users (see Figure 1—conceptual framework). The process of cutting off the middleman is known as disintermediation [24]. It has the advantage of reduction in the sales and infrastructural cost of selling through the channel [25]. In the case of fabricators who sell their stoves at the fabricator’s shop, they also bypass both the wholesalers and the retailers and sell to the end-users (consumer).

3.3. The End-Users

The end-user side of the conceptual framework focuses on the operational-related metrics of the stoves including stove/fuel stacking, number of stoves used, years of usage, smoke and ash emissions, ashes management, and smoke and heat effect on gender. It is recognized that usability and performance of the stoves are essential as performance is dependent on several factors including user behavior, cultural acceptance and operating conditions [26]. These factors are assessed in order to fully understand their effect on the end-users. End-users’ perspective in the form of operating conditions can be used to understand how the stoves perform when being utilized in the kitchen by people who usually cook. In this study, the perspectives and reflections of female end-users who usually cook in the kitchen were measured and analyzed.

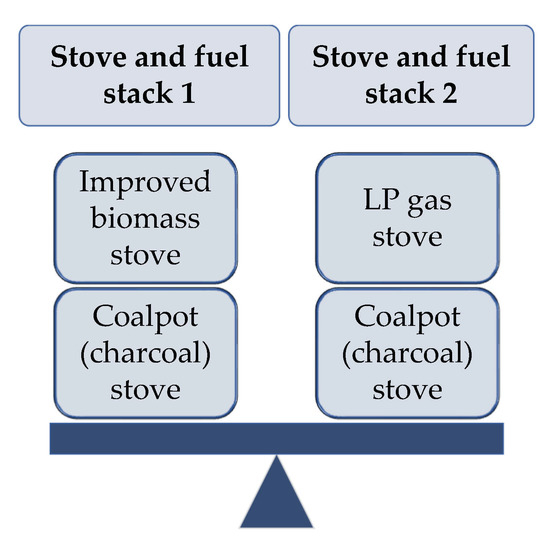

3.3.1. Stove and Fuel Stacking

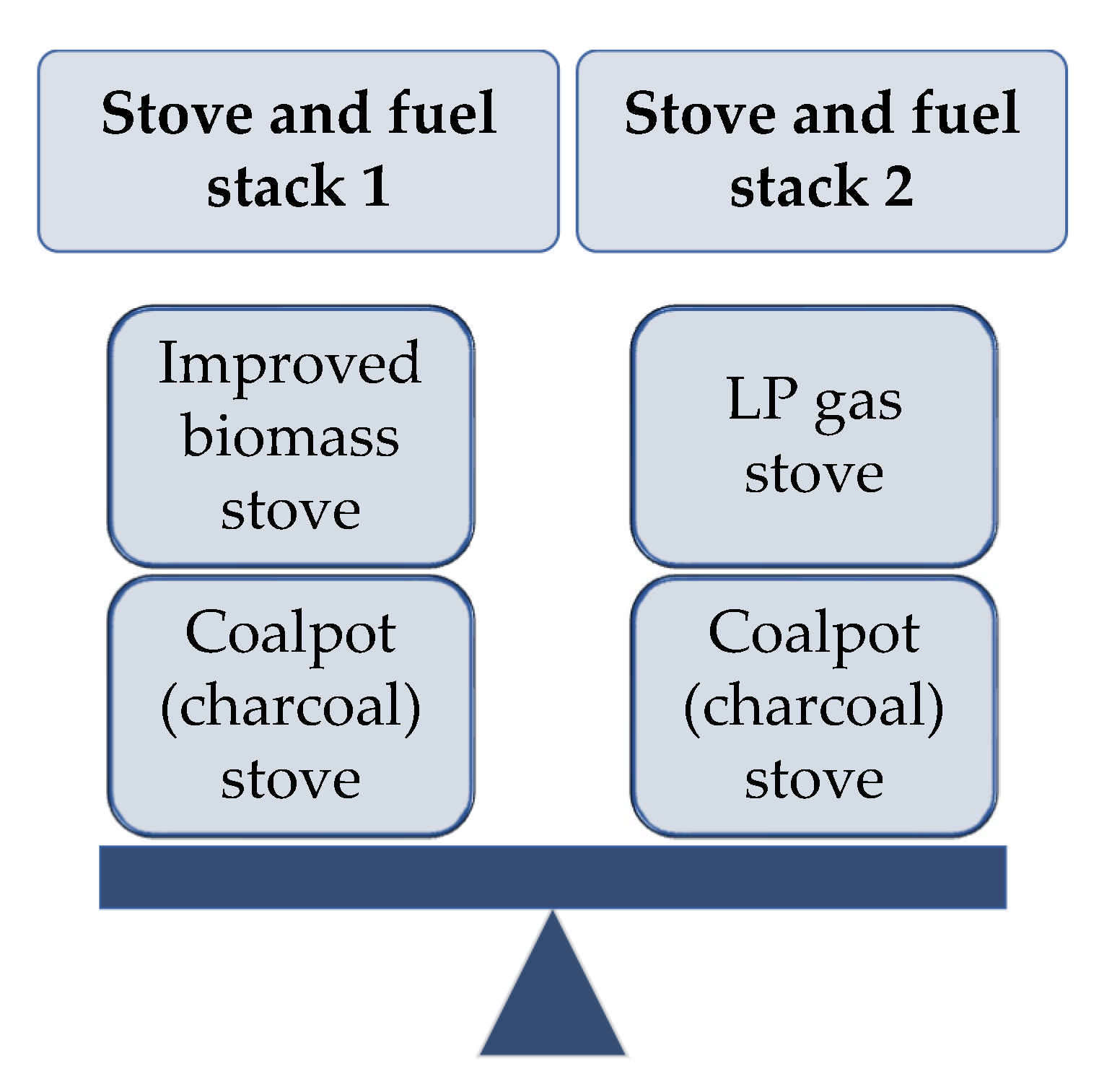

It is common for end-users to practice stove and fuel stacking because of different cooking tasks, availability of fuel, time constraints etc. The more local fabricators of stoves understand such preferences and constraints on end-users, the better they can modify their stoves to meet end-users’ choice and needs. Fuel stacking is the method of mixing the use of different stoves and fuels to meet a single energy need [27].

Figure 3 shows two groups of stove/fuel stacking that were determined in the study. Stove/fuel stack 1 is a combination of traditional coalpot stove and improved biomass stove that are both fueled with charcoal. Charcoal is preferred by many end-users in the urban areas because it is cheaper than other domestic fuels such as kerosene and LPG [28]. Stove/fuel stack 2 is a combination of traditional coalpot stove and LP gas stove. In a few cases, some end-users may use a combination of LP gas stove, charcoal stove, and woodfuel stove. Gas stoves provide more clean and efficient heating with less smoke than charcoal or wood stoves [23,29,30]. Stove and fuel stacking strategically position people who cook to meet their cooking and fuel needs [31]. It is driven by factors including fuel prices and the perceived suitability of specific stoves for different cooking tasks [31]. It is interesting to know that end-users prefer to use LPG so as to increase their cooking options, using several fuels alongside [28]. Such pieces of information will help local fabricators to understand the end-user’s needs and this will help to convert the information into design requirements.

Figure 3.

Two groups of stove and fuel stacking.

3.3.2. Number of Stoves Used and Years of Usage (Durability)

In Table 6, the results revealed that 40% of the end-users had one stove, 33% had two stoves and 27% had three stoves. The number of stoves used depends on factors such as number of people served, wealth and meal variety, as well as cooking practices and preferences [32]. However, typically, most end-users of SPBS have two separate stoves that are either used simultaneously or individually. What usually happens is that the main food is cooked on one stove, while sauces and soups are cooked on the other so that a complete meal can be ready in a short time.

Table 6.

Number of stoves being used and years of usage.

From the study, 40% of the end-users used their traditional SPBS for 3–7 years, while 13% used it for 8–11 years and another 13% used their stoves for 12–15 years. Number of years of usage is an indicator that is used for evaluating durability of cooking stoves [33]. Durability testing helps the designer, fabricator, and end-users to understand how consistently a stove will perform over an extended period of time. Information on durability is an essential input required for design and selection of engineering materials for a cookstove [34].

At the initial design stage, the selection of an appropriate material for the fabrication of the stove is very important since cookstoves undergo a substantial amount of stress due to high heat cycles [34]. End-users stand to benefit if their cooking stoves can be utilized for an extended period of time. Traditional charcoal stoves made from cast metal have lifetime of about 2–3 years, while welded coalpots can have lifetime of 3–10 years depending on the type and thickness of the metal used [35]. Traditional coalpot stoves are usually fabricated out of mild steel of 2–6 mm thickness that is cut into four trapezoidal shapes whose ends are welded together to form a pot rest. The pot rest is also welded to form a stove body that is welded to a base plate that collects the ashes and provides support for the base of the stove.

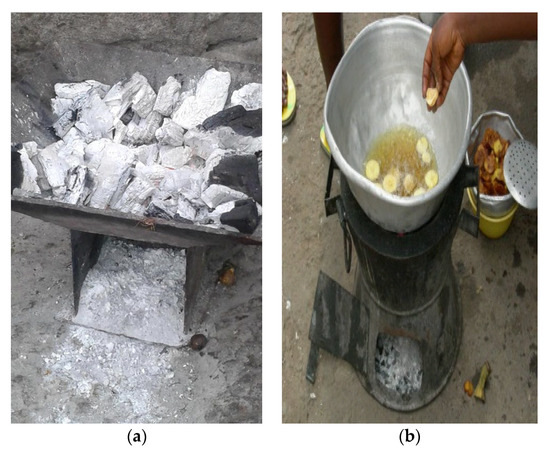

3.3.3. Smoke and Ash Emissions

In Table 7, the study revealed that all the traditional stove users (who formed about half of the respondents) indicated they are affected by smoke during cooking, while users of improved cooking stoves are not affected by smoke during cooking. Again, the results indicated that 60% of end-users of traditional SPBS said their stoves generate charcoal ash that affects the cleanness of their cooking zone. Only 22% who use improved SPBS said their cooking zones are affected by ashes. The results indicated that 38% more end-users of traditional SPBS observed charcoal ash deposition in the cooking area than end-users of improved SPBS (see Figure 4).

Table 7.

Smoke and ashes during cooking and environmental awareness.

Figure 4.

(a) Traditional single-pot biomass stove with ashes on the cooking environment and (b) improved single-pot biomass stove with clean cooking environment.

Charcoal ash is the non-combustible residue remaining after combustion of a fuel under specified conditions, typically expressed as a percentage of the mass of dry matter in fuel [33]. Several studies have reported that biomass fuels burned in traditional cooking stoves contribute to an accumulation of greenhouse gases (GHGs) and black carbon in the atmosphere [36,37]. Improved cookstoves and gas stoves are regarded as clean cooking devices by most end-users in Ghana [35].

Awareness of environmental changes was about 80%. With increasing environmental awareness, ecologically friendly alternatives, such as the application of charcoal ash to serve as compost for fruit and vegetable farms are becoming more popular [38]. Further, because wood ash has high char content, it can be used as an odor control agent, especially in composting operations [39]. In order for ash disposal not to be an environmental hazard, there is the need to put in place effective environmental monitoring measures [39].

When using traditional SPBS to cook food, some quantity of ashes gets discharged on the floor of the cooking area, hence resulting in a littered environment. Figure 4 shows pictures of two types of SPBS—traditional coalpot and improved cookstoves and the cooking area with drop of ashes. At both the household and commercial levels, charcoal ashes are commonly disposed of by women and children as part of kitchen waste management. The primary concerns for ashes are storage, disposal, use and the presence of unburned carbon [39].

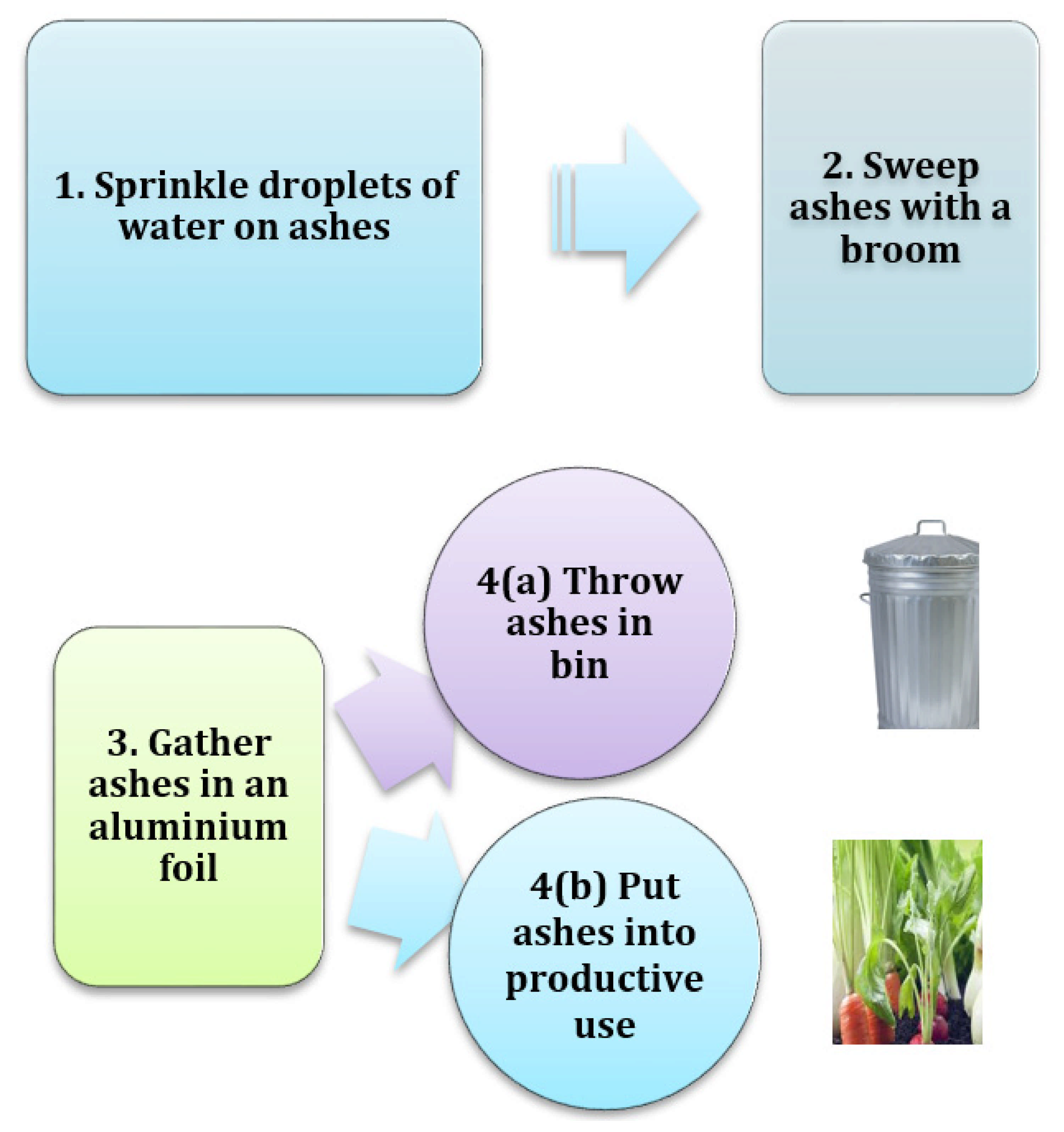

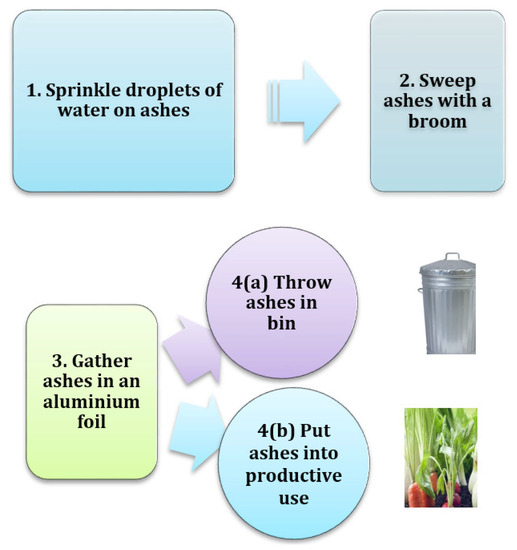

3.3.4. Managing Ashes from Single-Pot Biomass Cookstoves

To manage and dispose of charcoal ashes from biomass cookstoves, four basic practices are developed and presented in Figure 5. They are essentially to: (1) sprinkle droplets of water on the ashes; (2) sweep the ashes with a broom; (3) gather the ashes in aluminum foil; and (4) throw the ashes in a bin or put the ashes into productive use. The usual practice is that droplets of water are sprinkled on the ashes to quench any hidden flame and also reduce the dry dusty texture so as to make sweeping much easier and less dusty. Ash meant to be thrown into the bin is normally gathered onto dustpans or aluminum foil and carefully thrown into the bin or dumped outside, ensuring that there is no hidden fire. For ashes that are going to be used to enhance the soil for gardening, it is important that aluminum foil is used to gather the ash for productive uses, particularly for soil amendment in vegetable and fruit cultivation [38].

Figure 5.

Four basic practices of managing ashes from biomass stoves.

3.4. Hypotheses Testing: Smoke and Heat Effect on Gender

This test is a nonparametric test that uses the frequencies of the two variables—smoke and heat effect and gender (male fabricators, women end-users). The null hypothesis (H0) and the alternative hypothesis (H1) are stated as follows: Table 8 presents the actual observed numbers of people who were affected and not affected by smoke and heat. It is required to test at the 5% significant level. The null and alternative hypotheses are stated as follows:

Table 8.

Smoke and heat effect and gender.

Null hypothesis (H0): Heat and smoke effect is independent of gender.

Alternative hypothesis (H1): Heat and smoke effect is not independent of gender.

Chi-square (χ2), df and Er,c are determined using Equations (1)–(3)

From Equation (3), the expected frequency values are calculated:

Further, from the observed and expected frequencies, the results of the χ2 calculations are presented in Table 9.

Table 9.

Table required for calculating chi-square χ2.

According to the reference table, the critical chi-square value given df = (r−1) (c−1) degrees of freedom. This gives df = (2−1) (2−1) = 1 and α = 0.05 is 3.841. Because χ2 = 24.05 is greater than χ2 = 3.841, we reject the null hypothesis (H0) and accept that there is a relationship between heat and smoke effect and gender. Female end-users who use traditional coalpot stoves are affected by heat and smoke during cooking. Heat loss occurs in several ways, namely due to stove material, from stove surface, and in flue gases [5]. Male fabricators of traditional coalpot stoves are also affected by heat and smoke during the stove fabrication, particularly when they anneal the stove materials tin in order to easily chisel out the needed parts for fabrication.

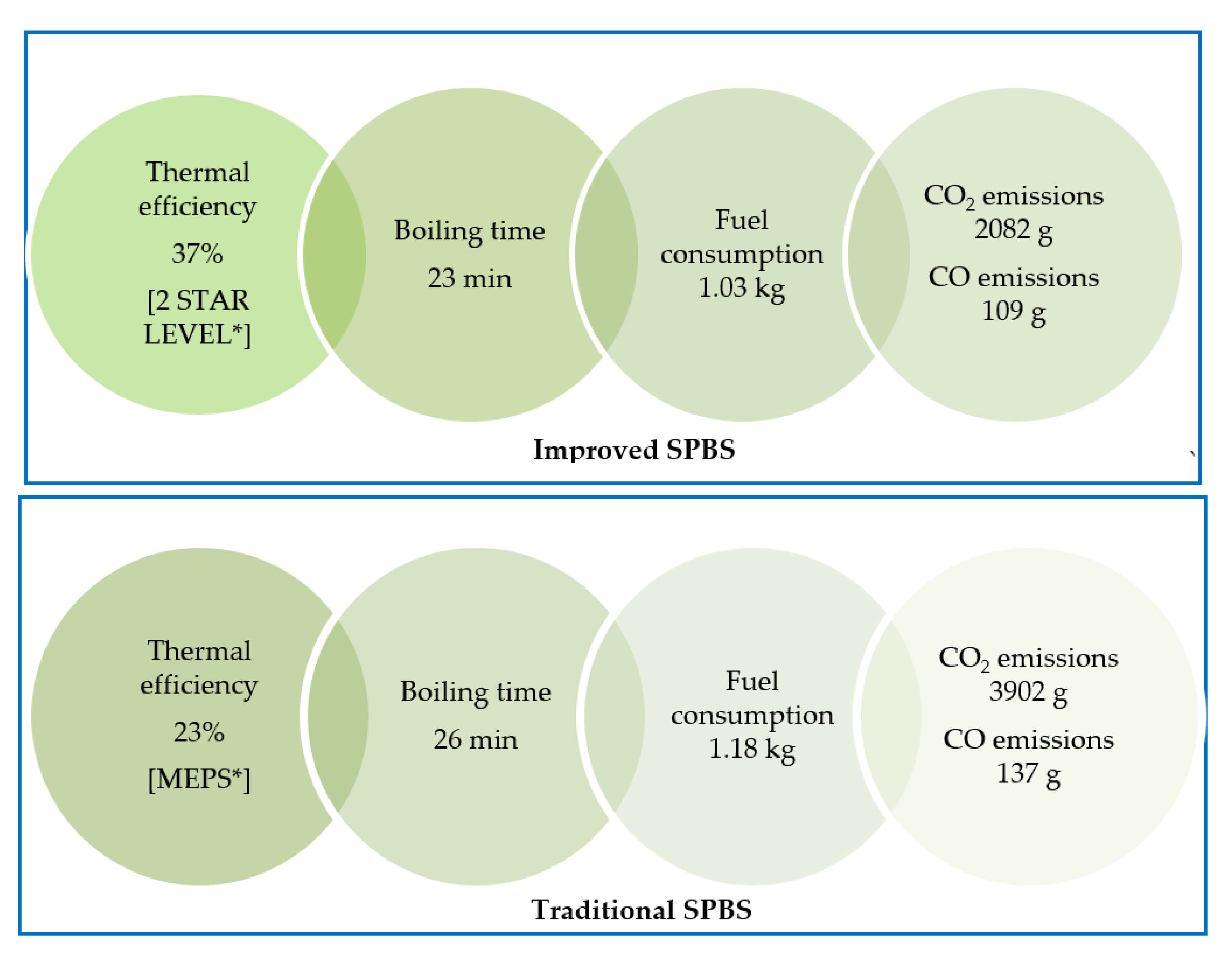

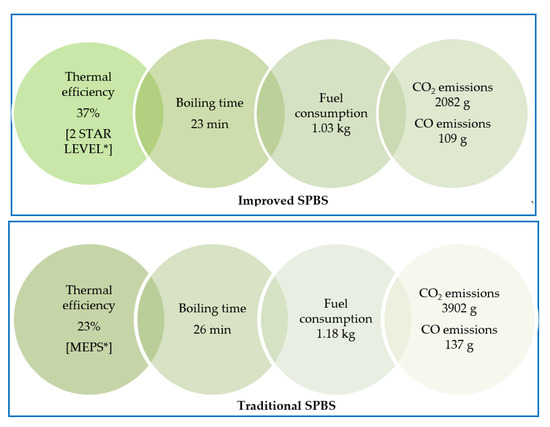

3.5. Performance Metrics

In order to evaluate the performance of SPBS, laboratory-based measurements were taken to validate the usability of both improved and traditional SPBS. Performance metrics used as a guide for measurements and decision making were thermal efficiency, boiling time, fuel consumption, and emissions. The results on performance metrics presented in Figure 6 indicate thermal efficiency of 37% for the improved single-pot biomass stove, which is higher than that for the traditional single-pot biomass stove of 23%. Thermal efficiency (>30%) is rated Two (2) Star Level, while thermal efficiency (>20% but less than 30%) is One (1) Star Level, which is the minimum energy performance standard (MEPS) [35,40]. Thermal efficiency measures the proportion of heat given by the fuel that was transferred directly to useful heat into the pot [5,41]. The left-over energy is lost to the surroundings. A higher thermal efficiency of a stove indicates a greater ability to transfer the heat produced into the pot [42].

Figure 6.

Laboratory performance test results. * (1) The 2 Star Level is based on ISO 19867 Harmonized laboratory test protocols [33]. (2) MEPS = Minimum Energy Performance Standard. (3) Full data on laboratory performance test was published in Obeng et al. [4].

Considering the boiling time, the improved single-pot biomass stove was the fastest (23 min) compared to 26 min for traditional single-pot biomass stove. It is interesting to note that Aprovecho Research Center designers have accepted a limit of 25 min to boil 5 L of water when designing a stove for the reason that in most cases cooks do not like a slower stove [43]. Boiling time is one of the key performance outputs of every stove that is appreciated by end-users; shorter time for cooking is always preferred [43]. The results further indicated that the improved charcoal cookstove used 1036 g of fuel to cook, while the traditional biomass stove used 1178 g of fuel. The heat created in the stove has to be high enough to cook local foods in acceptable times. To boil water quickly, as much heat as possible has to get from the fire into the pot. It is important to make sure the flame and hot gases are directed right at the pot.

Further, fuel consumed by the improved SPBS was low (1.03 g) compared to the fuel consumed by the traditional SPBS (1.18 g). More fuel consumed to boil 5 L of water might have contributed to relatively more emissions of carbon dioxide (CO2) and carbon monoxide (CO) when compared to the improved charcoal stove. In general, the lower the emissions, the higher the thermal efficiency of stoves [44]. Therefore, stove designers, fabricators, energy experts and practitioners should work together to ensure continuous capacity building in the areas of design process, use of standards and adherence to safety and environmentally friendly practices in local stove fabrication to achieve the goal of affordability and clean energy production.

3.6. Developing Energy Sustainability Framework

The energy sustainability framework developed from the study is shown in Figure 7. It has four rectangular pillars, which are created to analyze the sustainability-related issues and challenges faced by both fabricators and end-users of SPBS. The four pillars are distinct aspects of social, economic, environmental and institutional.

Figure 7.

Fabricator and end-user sustainability framework.

- (1)

- Social—The social aspects, perspectives and reflections contained in the information provided by the fabricators are characterized by low access to educational facilities, low earning capacity of the stove fabrication business, and lack of continuous training on stove design principles and standards. The implication is that end-users buy poorly designed stoves that give them less satisfaction with regard to energy efficiency, emissions and safety as poorly fabricated stoves are not properly insulated and so they lose a substantial amount of heat to the metal of the stove body as well as to the surroundings. Cooking with stoves that pose a safety risk is connected with a substantial share of the global burden of severe burns and injury occurring in low- and middle-income countries [8,45].

- (2)

- Economic—Data on economic aspects that were provided by the stove fabricators, which are captured in the framework include low equipment and tools utilization, use of scrap metals, less use of well-designed templates/patterns, and poor marketing and sales. Equipment and tools utilization is a measure of availability and how effectively they are used to produce the stoves within the time available to the fabricators. Traditional stove manufacturers tend to use basic hand tools such as hammers, chisels, files, clamps etc., to fabricate the stoves. Such tools are useful in the production of stoves; however, they are labor-intensive, slow to work with, and difficult to use as volume of production increases from small to medium and large scale. With regard to scrap metals, they are used principally because they are less costly compared to new sheet metals, which are not always readily available on the market, depending on the gauge. Typically, stove producers have patterns that are used for cutting of materials. However, they do not use the patterns for every cutting, particularly as they gain on-the-job experience with time. The result of such practice is that the parts are not of uniform standard and this affects interchangeability, which results in non-conformance to standards and low quality. Low quality products in turn attract low pricing and low market penetration. It is particularly important for manufacturers to understand the products that are preferred by consumers and hence, should be produced [46]. In general, end-users prefer affordable and clean cooking stoves of acceptable standard; hence, the transition from traditional cookstoves to clean cooking stoves is likely to enhance the income earning potential of local fabricators [47].

- (3)

- Environmental—The environmental aspects and perspectives from the standpoint of the fabricators include low environmental thoughts during fabrication; low awareness of indoor air pollution during heat treatment of scrap metals, particularly those who fabricate traditional SPBS using thicker gauge metals; and lack of instruments and testing devices for measuring and monitoring indoor emissions and energy efficiency. End-users are concerned with heat and smoke effects on their health, dirty cooking environment due to smoke emissions and fall of ashes on cooking area. Poorly fabricated stoves contribute to environmental challenges, and hence provide the justification for continuous development of emission efficient and clean SPBS.

- (4)

- Institutional—National level institutions responsible for the promotion, regulation and enforcement of clean cooking standards are less interested in the activities of local stove manufacturers; hence, they do not involve them in capacity development programmes and product certification to enhance their operations. However, it is said that the responsibility to guide on a sustainable path lies with resilient institutions to develop, train and retrain the human capital available [48,49]. Again, there is a lack of specific policy, plans and incentives for clean cooking stove development owing to the fact that stove fabricators are typically informal sector players who are not organized into formidable trade associations with a collective voice on issues that would significantly contribute to the growth of their business. End-user perspectives focused on concerns such as: lack of awareness of standards, incentives, and safety; no dialogue between end-users and institutions and the institutional challenge of relatively little emphasis on quality or performance testing and monitoring [50]. The energy sustainability framework presented in Figure 7 serves as a guide that provides information and opportunity for continuous research in clean energy cooking stove design, development and commercialization for sustainable production.

4. Conclusions and Recommendations

This study sought to analyze the relationship between local fabricators and end-users of SPBS for energy sustainability and quality improvement. The predominant issues assessed and analyzed were challenges related to design and fabrication, standards and safety, energy and emission efficiency, marketing related considerations, sustainability etc. The following conclusions and recommendations arose out of the study:

- (1)

- The relationship between fabricators and end-users of SPBS is conceptualized for understanding and quality improvement. Knowledge and information generated from the study will contribute to an optimal match of stove performance and end-user requirements that are considered important for performance improvement and achievement of clean energy efficiency. To improve quality and transition to clean energy stoves, templates and patterns being used should be created from engineering design that can be continually modified to reflect the changing needs of the market. Further, continuous training of local fabricators on measurements, drawings and specification and standards will help the fabricators to develop new stoves to achieve quality performance, safety, and aesthetics. In order to improve the quality of the stoves, fabricators should have access to modern equipment and tools, and be able to afford new materials for fabrication with good surface finish, which can result in good marketing and increased sales.

- (2)

- From the fabricators, issues that need to be solved include: heat and smoke effect from welding and heat treatment, low intensive-skills, low awareness of indoor air pollution during heat treatment of scrap metals of thicker gauge, and lack of instrumentation and testing devices for measuring and monitoring of indoor emissions and stove efficiency. The concerns of the end-users were: fuel and stove stacking, heat and smoke effects on their health, dirty cooking environment due to smoke emissions, and ash drops on cooking surroundings. To manage and dispose of charcoal ashes from biomass cooking stoves, four basic management practices were developed and presented.

- (3)

- From the hypothesis testing, it is concluded that heat and smoke effect have a relationship with gender. Hence, both male fabricators and female end-users must be protected in order that they can live healthy lifestyles free from heat and smoke associated with fabrication and use of stoves.

- (4)

- From the laboratory test results, the traditional SPBS emitted more CO and CO2 than the improved SPBS. The data suggest that traditional SPBS have more global warming impact than improved SPBS. Decades of lack of standards for local stove manufacture have resulted in emission concerns. Hence, there is a need for policies and programmes to support mandatory standards and enforcement to achieve enhanced design, fabrication and operational related outcomes.

- (5)

- An energy sustainability framework to ensure clean energy transition is developed out of which the following recommendations are made: (a) SPBS fabricators should work closely with end-users and other stakeholders to design stoves with well-structured features to obtain clean energy burning and high heat transfer; (b) design and fabrication of stoves should be guided by the goal of affordability, clean energy and low emissions; (c) there is the need to produce quality fabricated stoves and adopt innovative marketing strategies to get samples on the market; (d) continuous innovation in cleaner burning stoves and fuels is needed because such stoves have less global warming impact and, therefore, are the preferred choice for end-users.

- (6)

- Future research should consider the following: development of metrics to assess quality improvement efforts in design and fabrication of local stoves; model development for continuous quality improvement of SPBS; and optimization of design parameters to meet affordability, heat transfer and clean burning criteria.

Author Contributions

Conceptualization, G.Y.O. and E.M.; methodology, G.Y.O., E.M. and R.O.; data collection and acquisition, G.Y.O., E.M., R.O.; formal analysis, G.Y.O., E.M. and R.O.; resources, G.Y.O. and E.M.; draft preparation, G.Y.O. and E.M.; writing—review and editing, G.Y.O. and R.O.; supervision, G.Y.O. and E.M.; project administration, G.Y.O.; funding for fieldwork, G.Y.O. and E.M. All authors have read and agreed to the published version of the manuscript.

Funding

The fieldwork was supported by the Danish International Development Agency (DANIDA) sponsored Building Stronger Universities (BSU II) project under the theme Entrepreneurship and Job Creation (WP 2) of the Kwame Nkrumah University of Science and Technology, Kumasi, Ghana. However, the APC was self-funded by the authors.

Institutional Review Board Statement

Not applicable.

Informed Consent Statement

Not applicable.

Data Availability Statement

Not applicable.

Acknowledgments

We thank all the research assistants who helped in the field data collection. Laboratory equipment used for testing and measurements was financed by UNDP Ghana and supported by the USAID/MIT D-Lab IDIN program.

Conflicts of Interest

No conflict of interest.

References

- USAID. Clean and Efficient Cooking Technologies and Fuels: 5. Technological Innovation in Cookstoves and Fuels. A Publication Prepared by Winrock International for the Review of USAID; USAID/Winrock International, 2017. Available online: https://www.usaid.gov/sites/default/files/documents/1865/cookstoves-toolkit-2017-mod5-technological-innovation.pdf (accessed on 15 May 2020).

- Gitau, J.K.; Mendum, R.; Njenga, M. Gender and improvement of cooking systems with biochar-producing gasifier stoves. In Recovering Bioenergy in Sub-Saharan Africa: Gender Dimensions, Lessons and Challenges; Njenga, M., Mendum, R., Eds.; CGIAR Research Program on Water, Land and Ecosystems (WLE), Resource Recovery & Reuse: Colombo, Sri Lanka, 2018; 96p, ISBN 978-92-9090-877-7. [Google Scholar] [CrossRef]

- Adeya, N. Knowledge, Technology and Growth: The Case Study of Suame Manufacturing Enterprise Cluster in Ghana; Knowledge for development (K4D) Program; World Bank: Washington, DC, USA, 2006. [Google Scholar]

- Obeng, G.Y.; Mensah, E.; Ashiagbor, G.; Owusu, B.; Sweeney, D.J. Watching the Smoke Rise Up: Thermal Efficiency, Pollutant Emissions and Global Warming Impact of Three Biomass Stoves in Ghana. Energies 2017, 10, 641. [Google Scholar] [CrossRef] [Green Version]

- Raman, P.; Ram, N.K.; Murali, J. Improved test method for evaluation of bio-mass cook-stoves. Energy 2014, 71, 479–495. [Google Scholar] [CrossRef]

- Bantu, A.A.; Nuwagaba, G.; Kizza, S.; Turinayo, Y.K. Design of an Improved Cooking Stove Using High Density Heated Rocks and Heat Retaining Techniques. J. Ren. Energy 2018, 2018, 9620103. [Google Scholar] [CrossRef] [Green Version]

- Kodgule, R.; Salvi, S. Exposure to biomass smoke as a cause for airway disease in women and children. Curr. Opin. Allergy Clin. Immunol. 2012, 12, 82–90. [Google Scholar] [CrossRef] [PubMed]

- WHO. Household Air Pollution and Health. Key Facts; World Health Organisation (WHO): Geneva, Switzerland, 2018; Available online: https://www.who.int/news-room/fact-sheets/detail/household-air-pollution-and-health (accessed on 11 May 2020).

- Jerneck, A.; Olsson, L. A smoke-free kitchen: Initiating community based co-production for cleaner cooking and cuts in carbon emissions. J. Clean Prod. 2013, 60, 208–215. [Google Scholar] [CrossRef] [Green Version]

- Kshirsagar, M.P.; Kalamkar, V.R. User-centric approach for the design and sizing of natural convection biomass cookstoves for lower emissions. Energy 2016, 115, 1202–1215. [Google Scholar] [CrossRef]

- Kelly, M.; Donnelly, R.A. The Humongous Book of Statistics Problems; Penguin Group: New York, NY, USA, 2009; ISBN 978-1-59257-865-8. [Google Scholar]

- Lucey, T. Quantitative Techniques, 6th ed.; BookPower/ELTS: London, UK, 2002; ISBN 1-84480-111-X. [Google Scholar]

- Obeng, G.Y.; Adjaloo, M.K.; Amrago, D.K. Analysis of Skills and Training Needs of Metalwork Enterprises in Ghana. Int. J. Eng. Sci. 2013, 2, 102–112. [Google Scholar]

- WHO. Household Air Pollution and Health. Media Centre Fact Sheet N°292; World Health Organisation (WHO): Geneva, Switzerland, 2016; Available online: http://www.who.int/mediacentre/factsheets/fs292/en/ (accessed on 15 May 2020).

- Brew-Hammond, A.; Darkwah, L.; Obeng, G.; Kemausuor, F. Renewable Energy Technology, Capacity Building and R&D in Africa. Thematic Background Paper for International Conference on Renewable Energy in Africa. In Proceedings of the Jointly Organised by the Government of Senegal, the African Union, German Federal Ministry of Economic Cooperation and Development, Dakar, Senegal, 16–18 April 2008; Available online: http://energycenter.knust.edu.gh/downloads/5/52.pdf (accessed on 15 May 2020).

- GSA. Standards; Ghana Standards Authority (GSA): Accra, Ghana, 2016. Available online: http://www.gsa.gov.gh/ (accessed on 1 January 2016).

- GSA. GSA Standards Work Programme Bulletin January; Ghana Standards Authority (GSA): Accra, Ghana, 2016. [Google Scholar]

- Noelke, C.M.; Caswell, J.A. A Model of the Implementation of Quality Management Systems for Credence Attributes. In Proceedings of the Annual Meetings of the American Agricultural Economics Association, Tampa, FL, USA, 30 July–2 August 2000. [Google Scholar] [CrossRef]

- Smith, J. Protecting Health and the Planet with Clean Stoves Carbon Market Helps Boost African Energy Project. National Geographic News. 2011. Available online: http://news.nationalgeographic.com/news/energy/2011/02/110215-stoves-sustainable-development-ghana/ (accessed on 17 May 2020).

- World Bank. Household stoves, environment, health, and climate Change: A new look at an old problem. In The Environment Department (Climate Change); World Bank: Washington, DC, USA, 2011; Available online: http://documents.worldbank.org/curated/en/732691468177236006/pdf/632170WP0House00Box0361508B0PUBLIC0.pdf (accessed on 18 May 2020).

- Inkoom, D.K.B.; Biney, B.S. The potential of liquefied petroleum gas (LPG) as a viable energy option for the industrial sector in Ghana. J. Sustain. Dev. Afr. 2010, 12, 34–61. [Google Scholar]

- Prasad, B.; Baidurja, R.; Ravikrishna, R.V. Thermal Efficiency of LPG and PNG-fired burners: Experimental and numerical studies. Fuel 2014, 116, 709–715. [Google Scholar]

- WLPGA. World LPG Association Annual Report 2019; World LPG Association (WLPGA): Neuilly-sur-Seine, France, 2019; Available online: https://www.wlpga.org/wp-content/uploads/2019/12/WLPGA-Annual-Report-2019.pdf (accessed on 12 May 2020).

- Sander, P.J.; Haley, J. Value Investing for Dummies, 2nd ed.; Wiley Publishing Inc.: Indianapolis, IN, USA, 2008; ISBN 978-0-470-23222-4. [Google Scholar]

- InvestorWords. Disintermediation. 2002. Available online: http://www.investorwords.com/1488/disintermediation.html (accessed on 12 May 2020).

- PCIA. Test Results of Cook Stove Performance, Partnership for Clean Indoor Air (PCIA); Aprovecho Research Center, Shell Foundation, and United States Environmental Protection Agency: Cottage Grove, OR, USA, 2011. [Google Scholar]

- ESMAP. Beyond Connections Energy Access Redefined—Conceptualisation Report, Technical Report 008/15; Energy Sector Management Assistance Program (ESMAP) World Bank: Washington, DC, USA, 2015. [Google Scholar]

- Energypedia. Cooking Fuel. 2020. Available online: https://energypedia.info/wiki/Cooking_Fuels (accessed on 10 May 2020).

- EPA. Burn Wise. United States Environmental Protection Agency (US EPA); EPA: Washington, DC, USA, 2011. Available online: http://www.epa.gov/burnwise/healtheffects.html (accessed on 25 February 2016).

- Bruce, N.; Pope, D.; Rehfuess, E.; Balakrishnan, K.; Adair-Rohani, H.; Dora, C. WHO indoor air quality guidelines on household fuel combustion: Strategy implications of new evidence on interventions and exposure risk functions. Atmos. Environ. 2015, 106, 451–457. [Google Scholar] [CrossRef]

- Quinn, A.K.; Bruce, N.; Puzzolo, E.; Dickinson, K.; Sturke, R.; Jack, D.W.; Mehta, S.; Shankar, A.; Sherr, K.; Joshua, P.; et al. An analysis of efforts to scale up clean household energy for cooking around the world. Energy Sustain. Dev. 2018, 46, 1–10. [Google Scholar] [CrossRef] [PubMed]

- Wang, Y.; Bailis, R. The revolution from the kitchen: Social processes of the removal of traditional cookstoves in Himachal Pradesh, India. Energy Sustain. Dev. 2015, 27, 127–136. [Google Scholar] [CrossRef]

- ISO. ISO 19867-1:2018(en). Clean Cookstoves and Clean Cooking Solutions—Harmonized Laboratory Test Protocols—Part 1: Standard Test Sequence for Emissions and Performance, Safety and Durability. 2018. Available online: https://www.iso.org/obp/ui/#iso:std:iso:19867:-1:ed-1:v1:en (accessed on 18 May 2020).

- GACC. Cookstove Durability Testing. Global Alliance for Clean Cookstove (GACC). January 2013. Available online: https://www.cleancookingalliance.org/events/28.html (accessed on 18 May 2020).

- ENERGICA. Pre-Feasibility Study for an Improved Cook Stoves Project in Northern Ghana; Report submitted to CARE Denmark; Danish Energy Agency: Copenhagen, Denmark, 2009. [Google Scholar]

- Venkataraman, C.; Sagar, A.D.; Habib, G.; Smith, K. The national initiative for advanced biomass cookstoves: The benefits of clean combustion. Energy Sustain. Dev. 2010, 14, 63–72. [Google Scholar] [CrossRef]

- Urmeen, T.; Gyamfi, S. A review of improved Cookstove technologies and programs. Renew. Sust. Energ. Rev. 2014, 33, 625–635. [Google Scholar] [CrossRef] [Green Version]

- Demeyer, A.; Voundi Nkana, J.C.; Verloo, M.G. Characteristics of wood ash and influence on soil properties and nutrient uptake: An overview. Bioresour. Technol. 2001, 77, 287–295. [Google Scholar] [CrossRef]

- James, K.A.; Thring, W.R.; Helle, S.; Ghuman, S.H. Ash Management Review—Applications of Biomass Bottom Ash. Energies 2012, 5, 3856–3873. [Google Scholar] [CrossRef]

- Yu, Y.; Edze, P.; Spiak, M.; Kearney, N. Tier-Setting for Ghana Cookstove Labeling Program. CLASP. September 2017. Available online: http://eedal2017.uci.edu/wp-content/uploads/Wednesday-6-Yu.pdf (accessed on 16 May 2020).

- Bryden, M.; Still, D.; Scott, P.; Hoffa, G.; Ogle, D.; Bailis, R.; Goyer, K. Design Principles for Wood Burning Stoves; Aprovecho Research Center: Cottage Grove, OR, USA, 2011. [Google Scholar]

- GACC. The Water Boiling Test. Version 4.2.3. Cookstove Emissions and Efficiency in a Controlled Laboratory Setting. Global Alliance for Clean Cookstove (GACC) Released 19 March 2014. Available online: https://cleanstoves.org/binary-data/DOCUMENT/file/000/000/399-1.pdf (accessed on 15 May 2014).

- Still, D.; Bentson, S.; Lawrence, R.H.; Adams, E.; Andreatta, D.; Evitt, D.; Attenweiler, C.; Harris, K. Clean Burning Biomass Cookstoves, 2nd ed.; Aprovecho Research Center (ARC): Cottage Grove, OR, USA, 2021; Available online: http://aprovecho.org/publications-3/ (accessed on 31 May 2021).

- EPA. Air Quality Guide for Particle Pollution. Office of Air Quality and Radiation, February. (6301A) US EPA-456/F-15-005. 2015. Available online: www.airnow.org (accessed on 18 May 2020).

- Diekman, S.T.; Pope, D. WHO indoor air quality guidelines: Household fuel combustion. In Review 10: Burns and Poisoning; World Health Organization: Geneva, Switzerland, 2014. [Google Scholar]

- Han, Q.; Wang, Y. Decision and Coordination in a Low-Carbon E-Supply Chain Considering the Manufacturer’s Carbon Emission Reduction Behavior. Sustainability 2018, 10, 1686. [Google Scholar] [CrossRef] [Green Version]

- Brinkmann, V.; Klingshirn, A. Stove producers assess their impact. In Methodology and Results of a ProBEC Participatory Impact Assessment; Programme for biomass energy conservation (ProBEC), GTZ: Pretoria, South Africa, 2005. [Google Scholar]

- Ruiz-Mallén, I.; Heras, M. What Sustainability? Higher Education Institutions’ Pathways to Reach the Agenda 2030 Goals. Sustainability 2020, 12, 1290. [Google Scholar] [CrossRef] [Green Version]

- Association of African Universities. AAU Strategic Plan 2016–2020 (August 2016). Available online: https://www.aau.org/wp-content/uploads/sites/9/2016/10/AAU-STRATEGIC-PLAN-2016-2020-FINAL.pdf (accessed on 31 May 2021).

- World Bank. Accelerating Access to Clean Cooking: The Efficient, Clean Cooking and Heating Program and the Clean Cooking Fund, Results Brief; World Bank: Washington, DC, USA, 2020; Available online: https://www.worldbank.org/en/results/2020/11/10/accelerating-access-to-clean-cooking-the-efficient-clean-cooking-and-heating-program-and-the-clean-cooking-fund (accessed on 1 June 2021).

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).