Abstract

In recent years, the circular economy and sustainability have gained attention in the food industry aimed at recycling food industrial waste and residues. For example, several plant-based materials are nowadays used in packaging and biofuel production. Among them, by-products and waste from coffee processing constitute a largely available, low cost, good quality resource. Coffee production includes many steps, in which by-products are generated including coffee pulp, coffee husks, silver skin and spent coffee. This review aims to analyze the reasons why coffee waste can be considered as a valuable source in recycling strategies for the sustainable production of bio-based chemicals, materials and fuels. It addresses the most recent advances in monomer, polymer and plastic filler productions and applications based on the development of viable biorefinery technologies. The exploration of strategies to unlock the potential of this biomass for fuel productions is also revised. Coffee by-products valorization is a clear example of waste biorefinery. Future applications in areas such as biomedicine, food packaging and material technology should be taken into consideration. However, further efforts in techno-economic analysis and the assessment of the feasibility of valorization processes on an industrial scale are needed.

1. Introduction

While the world experiences climate change and every year authorities adopt more sustainable policies, the scientific community is investigating more environmentally friendly solutions for the exploitation of food industrial residues.

Waste management encompasses reuse, repair and recycling. Food waste, either derived from the agri-food industry or produced at the household level, is a good source of renewable raw materials. A large amount of food waste is generated in the EU, an estimate of approximately 100 million tons per year, nearly 30% of which comes from the agri-food supply chain [1]. Such a production of waste and by-products induces high environmental impacts in terms of land use and a high carbon footprint and blue water footprint [2]. The global production of food waste is estimated to increase over 200 million tons by 2050 [3]. Therefore, an efficient waste management is necessary.

In parallel, it is known that today most commercially available organic chemicals, synthetic polymers and fuels are derived from oil resources. The use of fossil sources brings about a challenge in resource availability, cost fluctuation and very high impact in terms of carbon dioxide footprint and environmental consequences. For these reasons, chemical industries seek sustainable and innovative strategies in order to replace the traditional petroleum-based polymers and resins with new products that can still perform like their synthetic counterparts [4].

Indeed, the bio-based market keeps growing despite the fact that bio-sourced plastic represents only 1% of the 368 million tons of plastic produced annually. However, the total bioplastic production capacity is predicted to increase from 2.11 million tons in 2020 to 2.87 million tons in 2025 [5]. The most valuable alternative to fossil-based resources for the production of monomers and polymers is renewable biomass from vegetal and animal origin, preferably derived from agro-food waste and by-products, in order to avoid competition on the land use for the production of food and feed [2].

The search for sustainable alternatives to petro-sources has become increasingly interesting also in obtaining fuels from bioresources. The conversion of biomass to biofuels can be achieved via two major pathways, i.e., biochemical and thermochemical treatments [6]. A suitable biomass for biofuels production is characterised by a high content in sugar, starch or oils. Bioethanol and biodiesel constitute the main products, mostly meant for transport purposes. In this context, the energy produced from non-food/feed biomass would allow for a neutral carbon dioxide balance as natural ecosystems are currently unable to absorb CO2 and other greenhouse gas emissions in the natural cycle. In the European Union, the political targets for climate and energy by 2030 are: a 40% reduction in greenhouse gas emissions, 27% renewable energy installed capacity for the entire EU energy supply and a 27% improvement in energy efficiency [7,8].

It is clear that terms such as reuse, recycling and environmental sustainability are outlined as priorities of the European Union. In addition, citizens pay increasing attention to the ethical production of innovative and sustainable materials. These important new trends translate into a growing interest for education and training promoting the urgent need for sustainability and also by the increasing number of publications in international journals specialized in the circular economy and bioeconomy. Companies and stakeholders have realized the market value of sustainable materials and have turned their interest in such a direction. For example, many natural fibers and fillers have been tested for valorisation in biocomposites for a wide range of applications ranging from commodities such as packaging or agricultural items to more demanding applications such as automotive or construction panels, as well as energy production [4,6].

The increasing number of published studies on the use of plant-derived natural extracts or agricultural waste products addresses our need to both reduce waste and find new carbon resources. The low toxicity of plant-based materials favors their potential applications in food packaging and biomedicine [9,10,11]. Polysaccharide-based materials have been well investigated [12] and other renewable resources such as proteins and poly(lactic acid) (PLA) have also been examined [13]. Formulated composites with PLA as matrix and wastes deriving from the wine industry have shown improved mechanical properties [14], thus suggesting further applications and uses of wine waste [15,16]. The coffee plant is one of the agricultural resources for increased plant-based materials and its use includes a cycle from crop cultivation and processing to coffee beverage consumption.

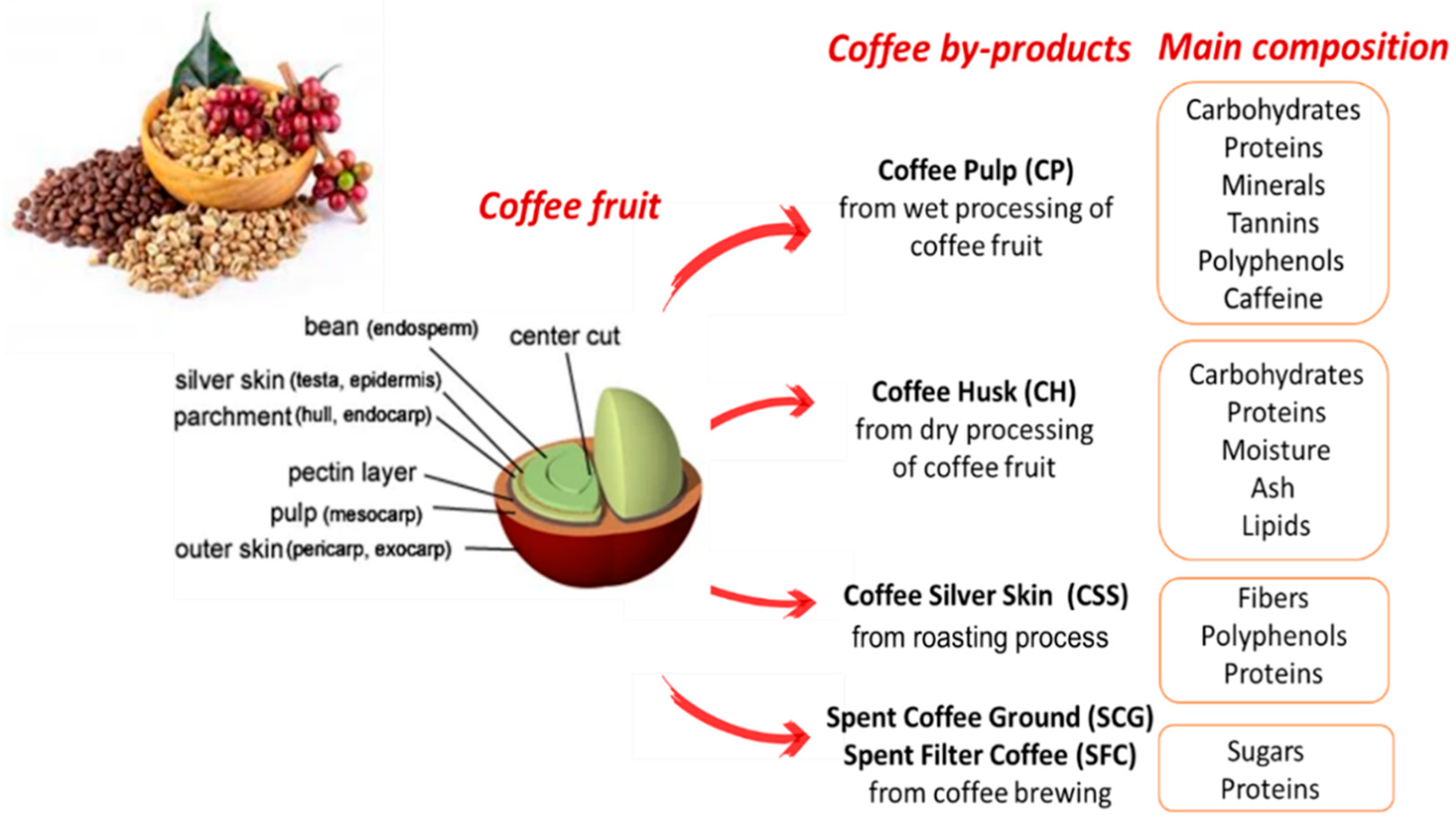

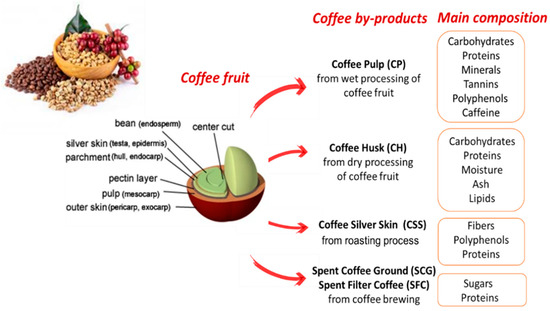

Considering that coffee is the second largest trade commodity with a global manufacture of 105 million tons per year worldwide, its industry generates enormous amounts of wastes during its processing from fruit to cup [17]. The annual coffee waste is estimated to exceed 23 million tons per year. By-products mainly arise from the removal of shells and mucilaginous parts from the fruits and depend on the processing method: wet or dry, roasting and brewing. Solid residues include coffee pulp, coffee husks, silver skin and spent coffee [18] (Figure 1). From a chemical point of view, coffee waste is an inexpensive raw material that contains fatty acids, which could be used as a sustainable carbon source, and it also represents an interesting source of bioactive compounds and fibers [18]. Indeed, coffee residues were proven to be an excellent resource for the production of high-value compounds [19,20]. The spent filter coffee (SFC) and the spent coffee grounds (SCG) [21], both widely produced at home or work, as well as the coffee husk (CH) and coffee pulp (CP), that is the solid fraction wastes derived from coffee industries, constitute coffee waste rich in polyphenols, carotenoids and organic acids [22,23,24,25]. The main compositions of the various fractions are reported in Figure 1.

Figure 1.

Schematic representation of coffee by-products and their main components.

Packaging production from coffee waste organic acids is a novel, quite promising research area, aimed at producing bio-based, low toxicity polymers [26]. In addition, coffee waste has been successfully used for the production of biocomposites [27,28,29,30]. Furthermore, biotechnological processes have been developed for biofuel production from coffee waste [31,32].

2. Challenges and Opportunities for Coffee Waste Utilization

A number of sustainable and low environmental impact technologies can be applied for converting biomass or waste from the food sector to traded chemicals and energy in a way that is similar to crude oil refinery [6]. In the last decade, the biorefinery concept has been well described. It integrates sustainability and includes environmental, economic and social aspects [33]. However, when focusing on coffee biorefinery systems, some issues are still unclear. The fact that the data collected show some inconsistency and that different methods were used in the various studies make it more complicate to assess the various biorefinery concepts. In addition, key stakeholders from different disciplines need to get together to deploy multidisciplinary knowledge. The novelty in this area makes for another important gap in appraising coffee biorefinery.

The price of polymers is gradually increasing, and plastic consumption exceeded 5 million tons in Germany and Italy in 2017. These two countries were ranked first in terms of coffee consumption in 2018 [34]. In their case, following a circular economy concept seems practicable. Coffee waste could easily be employed for polymer production, applying the ‘local production for local consumption’ concept.

Furthermore, European strategies such as the ‘EU Strategy for Plastics in a Circular Economy’ and ‘Plastics 2030’ aim to change ‘the way plastic products are designed, produced, used and recycled in the EU’. Plastic manufacturers are committed to ensure that 60% of their plastics for packaging will be re-used and recycled by 2030.

Biofuel production is also an opportunity to explore. Indeed, advanced biofuels can be produced from lignocellulosic and non-lignocellulosic sources (forestry and food or agro-derived residues) by means of thermochemical conversion, mainly based on gasification or pyrolysis [6].

Consequently, there is an urgent need for better understanding the benefits of establishing a coffee based biorefinery. In order to take part in such an effort, the present review aims at summarizing and describing in detail the most recent work carried out in monomer, material and fuel production from coffee waste.

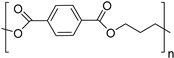

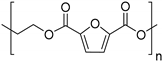

3. Sustainable Polymers from Coffee Waste

The need to move towards a circular economy requires rethinking the entire plastics value chain from raw material to recovery and recycling options at the end of polymer lifetimes. Several polymers based on renewable feedstocks (Table 1) were developed as an alternative to fossil-based products. There is a main advantage in bio-based plastic materials as compared to their conventional versions: they enable saving fossil resources by using biomass, which regenerates annually and has the unique potential of carbon neutrality [5]. The attractiveness of bio-based polymers has increased in recent decades. Thanks to the significant development of biorefineries, a wide variety of bio-based building blocks can be produced. The global production capacity of bio-based plastics was estimated at 2.1 million tons in 2019 [5]. Packaging remains the largest field of application for bioplastics with almost 53% (1.14 million tons) of the total bioplastics market in 2019. Two main classes of material can be produced starting from renewable biomass. One is related to the synthesis of traditional plastics such as bio-poly(ethylene) (bio-PE) and bio-poly(ethylene terephthalate) (bio-PET), which are almost non-biodegradable, but help replace fossil-based building blocks with identical molecules. The other class relates to the production of biodegradable materials, including thermoplastic starch, aliphatic polyesters like poly(lactic acid) (PLA), polyhydroxyalkanoates (PHAs) and poly(butylene succinate) (PBS). In addition, not all biodegradable bioplastics are readily degradable. In fact, the process of biodegradation depends on the surrounding environmental conditions (e.g., pH or temperature), on the material morphology and on the application (e.g., biomedical or agricultural) [35].

Table 1.

Commercial polymers obtained entirely or partially from renewable resources.

Today, bioplastics are mostly produced starting from carbohydrate-rich plants such as corn or sugar cane, the so-called food crops or first-generation feedstock. First-generation feedstock is currently the biomass that produces the highest yields of bioplastics [5], even if the competition with food and feed production is evident.

The bioplastics industry is also developing the use of non-food crops (second and third generation feedstocks). Innovative technologies are focusing on non-edible by-products from the production of food crops, which inevitably generates large amounts of waste. There are significant potential volumes for use in biotechnological processes to create platform chemicals for industrial purposes such as the production of bioplastics.

The valorisation of by-products and waste flows as raw materials in a biorefinery provides a great advantage and reduces pressure on arable land [36,37]. The use of food waste can be a solution for the development of sustainability by meeting environmental and resource challenges.

In recent years coffee by-products received much more attention as a promising renewable feedstock for various processes and for their conversion into high value-added products through biorefinery techniques.

Taking into consideration the presence of different chemicals in coffee by-products such as hydroxy acids, it is worth mentioning that some molecules such as caffeic acid represent interesting building blocks for the preparation of bio-based polymers such as polyesters, polyamides and poly (anhydride esters). Thus, valorizing coffee residues opens up new possibilities for a wide spectrum of applications [38].

Bio-active molecules derived from coffee by-products can also be valorized in polymer formulation in order to impart specific properties to the polymeric matrix such as antioxidative or biocidal properties. The content in valuable molecules such as caffeine or chlorogenic acid can be exploited by using coffee wastes as fillers in biocomposites [20]. The following sections highlight the recycling potential of coffee by-products for monomer and polymer production, material formulation as well as for biofuel and bioenergy production.

3.1. Monomer Production

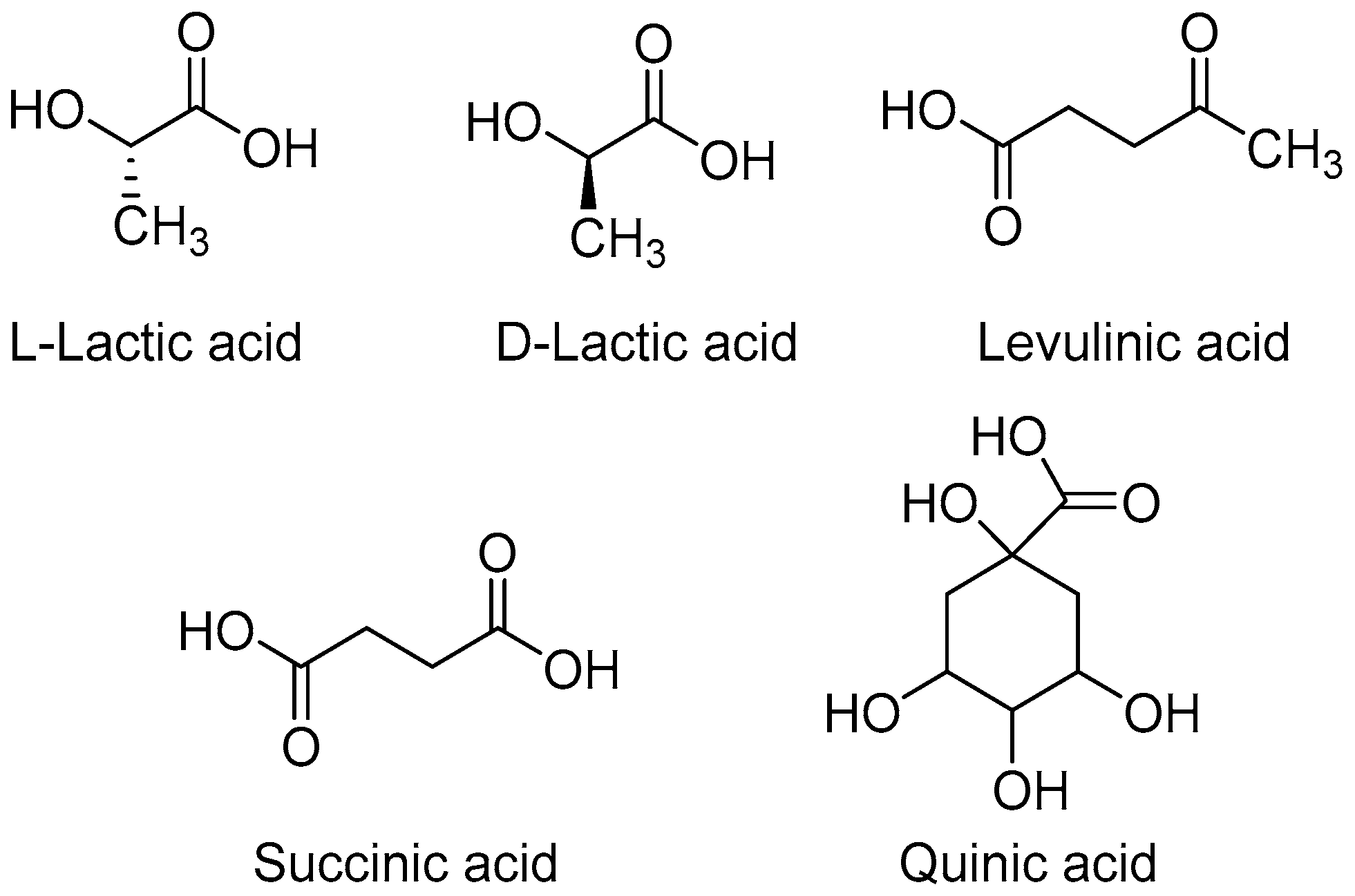

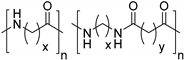

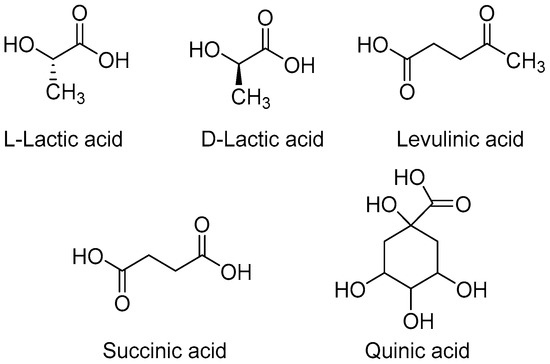

A number of integrated conversion technologies for the transformation of coffee by-products can result in the recovery of chemical building blocks that can be used for the production of monomeric units such as lactic acid, succinic acid, levulinic acid, alcohols and polyols.

3.1.1. Lactic Acid

Lactic acid (LA) is the simplest hydroxyl acid with an asymmetric carbon atom and two optically active configurations, namely the L and D isomers (Figure 2). LA is a well-established bio-based chemical and its global annual production amounts to approximately 270 kilo tons per year [39]. It finds applications in several sectors ranging from the food industry to cosmetics and pharmaceuticals, and it is also employed for the synthesis of PLA, which is by far the most commercially developed bio-based plastic that is mainly applied in packaging and in pharmaceutical industries. LA can be produced through a petrochemical route or biotechnologically by exploiting renewable feedstocks, mainly corn [40], but also food wastes and by-product streams [41,42,43]. Currently, the industrial production of LA is mostly carried out by microbial fermentation of carbohydrates, since higher purity products can be obtained. The majority of the fermentation processes use species of Lactobacilli, which give high yields of LA. Some organisms predominantly produce the L isomer, such as Lactobacilli amylophilus, L. bavaricus, L. casei and L. maltaromicus, whereas L. delbrueckii, L. jensenii or L. acidophilus produce the D isomer or a mixture of L and D [44].

Figure 2.

Monomeric units from coffee by-products.

Recently, it was reported that wastes from the coffee-processing industry such as coffee mucilage, CP and SCG were converted into LA trough Bacillus coagulans. B. coagulans is a very interesting L-lactic acid producer due to its ability to ferment pentoses. Furthermore, its thermotolerant nature (50–55 °C) minimises the need for sterile conditions. Hudeckova et al. [45] described the use of SCG as a promising raw material substrate for LA production. SCG was first hydrolyzed and then used as substrate for culturing several lactic acid bacteria and LA producing B. coagulans. Among them, Lactobacillus rhamnosus CCM 1825 was identified as the most promising producer of LA on SCG hydrolysate, giving a yield of 98% in LA. The same substrate was also investigated by Breton-Toral et al. [46] and compared with other food waste carbon sources such as potato peel and almond shells. They used an undefined mixed culture isolated from coffee mucilage and also studied the application of several biomass pretreatment and calcium carbonate as a buffer to increase the release of fermentable carbohydrates from the wastes.

Neu et al. [47] investigated the use of coffee mucilage as carbon source in the production of L-lactic acid with B. coagulans and yeast extract as an additional source of nitrogen. The raw material in this case was a liquid suspension containing several free sugars. The experiments resulted in the production of pure (99.8%) and highly concentrated (930 g/L L-LA) lactic acid formulation.

CP hydrolysate was investigated by Pleissner et al. [48] for the lab production of LA and in pilot scales using B. coagulans. The raw material, with a high content of lignocellulose was first hydrolysed by means of thermochemical treatments and a subsequent enzymatic digestion. The fermentation was performed in presence of yeast extract and gave rise, at both scales, to a highly concentrated (937 g/L) and pure (99.7%) L-lactic acid.

An engineered Saccharomices cerevisiae strain was used in a preliminary study as an alternative to B. coagulans for the fermentation of acid-pretreated SCG by Kim et al. [49]. The results proved the feasibility of using SCG for the selective production of LA, being the LA produced 0.11 g per g of SCG after 24 h.

3.1.2. Succinic Acid

Succinic acid (SA) (Figure 2), an intermediate in several chemical processes, has emerged as one of the most competitive bio-based chemicals. The major drivers for the growth of this market are the increasing applications using SA and the trend of the chemical industry to increasingly search for bio-based sustainable chemicals. Among industrial applications based on this building block, butanediol, PBS and its copolymers and polyurethanes (PUs) have the largest share of the market. The conventional process for SA production is carried out from petrochemical raw materials starting from n-butane or butadiene. Petrochemical production has remained stable for years, but recent advances in fermentation from different glucose sources, including mixed food waste, agricultural waste and textile waste [50,51,52], succeeded in making bio-based SA economically attractive, and now the fermentative SA production has outcompeted its conventional production.

It was recently reported [23] that coffee husk, i.e., a waste obtained from processing coffee cherries, could be used as substrate for bio-succinic acid production with A. succinogens. More specifically, three pre-treatment methods were compared (thermal, thermochemical and fungal hydrolysis). The thermochemical pre-treatment was proven to be the most effective and led to the highest SA yield (0.95 g SA per g of reducing sugars) and productivity (0.54 gL−1 h−1).

The use of CSS was investigated at lab scale by Niglio et al. [53] for the production of SA and butanol by fermentative process. CSS was first subjected to alkaline hydrolysis pre-treatment and enzymatic hydrolysis to maximize sugar release. The medium obtained was subjected to fermentation with Clostridium acetobutylicum to obtain a mixture of acetone, butanol and ethanol (ABE) in the molar ratio of 2:5:1, respectively, a yield of 7.3% in butanol per g of sugars and a productivity in ABE of 0.06 gL−1 h−1. The same medium, subjected to fermentation with A. succinogens, gave a SA production yield of 84% per g of sugars and a productivity of 0.15 gL−1 h−1.

3.1.3. Levulinic Acid

Levulinic acid (Figure 2) is considered as a promising platform chemical due to its high reactivity conferred by the presence of carboxylic acid and ketone functional groups. Levulinic acid is a versatile building block for the production of pharmaceutical, plasticizer and several chemical derivatives such as SA, γ-valerolactone and 1,4-pentanediol [24,54].

Up to now, levulinic acid is exclusively produced from petroleum sources. The conventional production of levulinic acid is based on chemical conversion employing mineral acids or heterogeneous catalysts like zeolites. In recent years, several biomass wastes, such as rice straw, corn stover, microalgae, etc., [55,56,57] were used for its production. In particular, Tukacs et al. [24] reported the use of SCG and cooked tea leaves for the production of levulinic acid, valorising their lignocellulosic content. They studied the influence of water presence and microwave pre-treatment. Interestingly, they discovered that the drying process of biomass can be avoided, and the microwave technique can drastically reduce reaction times while enabling the same conversion yields. In particular, in the case of a commercial arabica-based SCG, the yield in levulinic acid, calculated on the average cellulose content of biomass waste, was 12.9%, while in the case of robusta-based SCG, the yield was 14.6%.

SCG was also used as a starting raw material by Kim et al. [58] to produce levulinic acid and formic acid by using a catalyst-free hydrothermal biphasic system, thus avoiding corrosion and undesirable side reactions. A single and a double steps conversion consisting in a lipid separation, followed by the conversion of levulinic and formic acids were investigated. In addition, several other parameters (pre-treatment conditions, temperature, reaction time, solvent amount and moisture content) affecting reaction yields were investigated and optimized. Thus, the yields of the two acids were maximized when SCG was used with water in a molar ratio of 1:8.33 at 180 °C for 3 h and a maximum yield of 47 and 29 wt.% (based on convertible monosaccharides in raw SCG) in levulinic and formic acid, respectively, was obtained.

3.1.4. Quinic Acid

Quinic acid is a polyhydroxy molecule (Figure 2) with interesting biological activity (growth promoting property) and chirality that is useful in pharmaceutical applications. It can be extracted from several plant sources and from coffee beans [59].

Besset et al. [9] reported for the first time the use of quinic acid as a monomer for the synthesis of polycarbonates from renewable sources as an alternative to polycarbonates obtained using bisphenol A, which is a highly toxic and hormonally active compound.

3.1.5. n-Butanol, Isopropanol and Polyols

Today, alcohols and polyols are produced almost exclusively from petrochemicals, but the industrial production of these chemicals by fermentation from renewable and sustainable resources has recently increased worldwide. n-Butanol can find broad applications as an intermediate in pharmaceuticals and polymers production, as food grade solvent in the food and flavor industry and, recently, as fuel [60]. Isopropanol is one of the main short alcohols for industrial application. In addition to its use as a solvent, it is also employed as a chemical intermediate and a fuel additive. Polyols instead became increasingly interesting for the preparation of polyurethane, and several researchers are exploring different biomass residues to obtain bio-based polyols [61]. Thus far, Clostridium beijerinckii is the most widely used strain for fermentation to produce n-butanol and isopropanol from biomass [62]. Procentese et al. [32] investigated for the first time the use of alkali pre-treated and enzymatically hydrolysed coffee silverskin as a carbon source for Clostridium beijerinckii fermentation for the production of n-butanol and isopropanol. Low yields were obtained for both alcohols in aqueous medium: 0.86 g and 1.66 g per 100 g of dry CSS for isopropanol and butanol, respectively.

Spent coffee grounds were used to obtain liquefied polyols via sulfuric acid treatment using polyhydric solvents (polyethylene glycol and glycerol) at moderate temperatures [37]. Three key parameters were optimized to increase conversion, namely temperature, sulfuric acid concentration and reaction time. From an industrial point of view, the established process proved to be very interesting, as it only generated 8 wt.% of residue per total mass of polyols with 70 wt.% of conversion. Moreover, the obtained polyols showed adequate characteristics for the substitution of existing commercial polyols (produced from petrochemicals) in the synthesis of polyurethane foams. To this aim, isocyanates were reacted with the polyols obtained from spent coffee grounds [63].

In Table 2, the main examples discussed in Section 3.1 are summarized.

Table 2.

Example of monomers from coffee by-products.

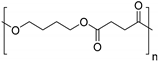

3.2. Polymer Production

As stated above, bio-based polymers have become increasingly attractive in recent decades thanks to the significant development of biorefineries, which allow the production of a wide variety of bio-based building blocks or the exploitation of naturally produced biopolymers. The production of polyhydroxyalkanoates (PHAs) directly from coffee by-products is described here as a main example of polymer production.

PHAs are a family of biopolyesters synthesised as intracellular products by various microorganisms. These microorganisms use PHA as a form of carbon and energy storage. They are very versatile polymers, mostly used in the packaging industry. Due to their biocompatibility and biodegradability, they are also employed in the medical field and as carrier materials in agriculture, food technology or pharmaceutical sectors.

PHAs can be produced from natural resources, classically from highly nutritional substrates such as glucose, starch or edible oils. Several researchers recently approached the possibility of using a broad range of industrial- and agro-waste as well as wastewater. The description of conversion of SCG or oils extracted from SCG into PHAs is well documented in the scientific literature.

Kovalcik et al. [64] investigated the potential of Halomonas halophile to produce PHA from three different acid-treated SCG hydrolysates: unmodified, defatted and defatted without phenols. It was shown that all the different samples gave rise to high carbohydrate releases. However, the presence of phenols negatively affected the cultivation of the bacterial strain. The purified sample, without phenolic contaminants, enabled the production of high molecular weight poly(3-hydroxybutyrate) (27 wt.% of dry cell weight).

Obruca et al. [25] studied several strains for the production of PHAs from SCG: Cupriavidus necator H16, Bacillus megaterium or Burkholderia cepacia. In particular, oil extracted from SCG proved to be the best substrate for the poly(hydroxybutyrate) homopolymer production among the waste oils tested. C. necator H16. B. megaterium or B. cepacia were tested for their capacity to use SCG hydrolysates. B. cepacia demonstrated higher PHAs yields and production coefficients. In addition, this strain was able to accumulate the copolymer poly(3-hydroxybutyrate-co-3-hydroxyvalerate), which possesses better mechanical properties as compared to the homopolymer produced by B. megaterium. Probably, the presence of levulinic acid in the substrate induced the biosynthesis of valerate units by B. cepacia. The same authors also investigated various detoxification methods prior to hydrolysis for the removal of microbial inhibitors such as phenols present in SCG in order to improve PHAs production yield.

Bathia et al. [65] studied the use of coffee waste oil as a source of fatty acid for the production of (3-hydroxybutyrate-co-3-hydroxyhexanoate) copolymer by genetically engineered Ralstonia eutropha without additional precursor feeding. Several parameters, such as the solvent for coffee extraction, concentration of coffee oil and concentration of nitrogen source and time, were optimized. The final production of PHA copolymer obtained was 69 wt.% based on cell dry weight.

The use of oil extracts from SCG for the production of poly(3-hydroxybutyrate) by wild type Ralstonia eutropha was previously investigated by Obruca et al. [66]. The authors reported that copolymers could be obtained with the wild strain only by feeding additional precursors, such as propionate.

Finally, Cruz et al. [67] reported the application of supercritical carbon dioxide extraction to improve oil extraction from SCG to be used as a substrate for C. necator strain culture for the production of poly(3-hydroxybutyrate). The final yield was 77% of PHA based on SCG oil weight.

3.3. Composite Materials Production

Coffee silver skin (CSS), also called spent coffee chaff, is the tegument of green coffee beans. CSS is obtained as a main by-product from the roasting process [68] and consists principally of lignin (29 wt.%), polysaccharides such as cellulose (24 wt.%) and hemicellulose (17 wt.%) [69]. Silver skin may be valorised as poultry feed and/or as a raw material for paper production. None of these methods used for the valorisation of CSS is an ideal solution in terms of value addition, especially if one considers the large availability of such residue. Therefore, to date, most CSS is simply disposed in landfills as industrial waste [28].

A potential low-cost and largely available alternative for the sustainable exploitation of this residue is its use as a filler in polymeric matrices. Actually, silver skin turns out to be a suitable starting material for obtaining high value polysaccharide derivatives such as cellulose nanocrystals (CNCs), which have attracted a lot of attention given their interesting and remarkable mechanical properties such as high specific resistance (10 GPa) and relatively high elastic modulus (150 GPa) [70].

Furthermore, their low cost, availability, renewable nature, ease of chemical and mechanical modification and high aspect ratio have led to the use of CNCs as reinforcing fillers for polymeric composites. In the work of Sung et al. [28] bio-nanocomposite films based on a PLA matrix reinforced with CNCs were produced by using a twin-screw extruder. These CNCs were extracted from coffee silver skin by alkali treatment followed by sulfuric acid hydrolysis. The nanocomposites were prepared at different concentrations (1%, 3% and 5% of CNCs), resulting in increasing tensile strength, Young’s modulus and barrier to oxygen, while barrier to water was lowered.

Some examples of biocomposites with silver skin fibers are reported. Zarrinbakhsh et al. [71] prepared composites with silver skin and spent coffee ground in a polypropylene (PP) polymeric matrix, resulting in non-biodegradable composites due to their polyolefin content. The morphology, mechanical and thermal properties of such composites were investigated with up to a content of 25% by weight of filler in a homo-polymeric matrix. The analysis of the biocomposite’s properties showed that coffee silver skin is a better reinforcing agent than spent coffee ground given its denser fibrous structure, lower fatty acid content and higher thermal stability. Poor interfacial adhesion between both coffee silver skin and spent coffee ground with polypropylene was observed due to the hydrophilic nature of coffee by-products and hydrophobic nature of PP. Thus, the use of a compatibilizer, such as maleic anhydride, was recommended to improve the final properties. Considering the possibility to achieve production of PP from renewable resources, these biocomposites have potential for a high bio-based content. In the work of Essabir et al. [27] PP and spent ground coffee (SCG) were prepared by extrusion compounding and injection molding using different SCG contents (0, 5, 10, 15 and 20 wt.%). The authors investigated the effect of particle loading on the thermal, rheological and mechanical properties. In this study, the effect of the use of compatibilizers such as silane and styrene-ethylene-butene-styrene-graft-maleic anhydride on the properties of the biocomposite prepared at 15 wt.% was also examined. As expected, bleaching and the use of a coupling agent improved the adhesion between the matrix and fibers resulting in improved tensile strength.

In the work of Dominici et al. [72], the use of BioPE-based composites containing CSS was evaluated. To improve the adhesion properties, a grafted PE was used as a compatibiliser. Moreover, a hydrophobic treatment of CSS with palmitoyl chloride showed a positive effect in promoting the interfacial adhesion, consequently improving mechanical properties and in particular increasing the strain at break values. The amount of CSS was up to 20 wt.%, which resulted in an adequate compromise between tensile strength and Young’s modulus.

When the polymeric matrix is compostable, the use of coffee by-products allows for the production of potentially biodegradable composites. The biodegradable and petro-derived polymer, poly(butylene adipate-co-terephthalate) (PBAT), was blended with coffee by-products and the resulting composites were adapted for rigid food packaging applications [26]. In this work, the torrefaction process (a mild thermal treatment occurring at 200−300 °C under nitrogen atmosphere) was optimised in order to increase the hydrophobicity of the coffee grounds (CG), thus improving adhesion with PBAT matrix. The torrefaction process highlighted a significant enhancement in thermo-mechanical properties for PBAT/torrefied coffee grounds as compared to PBAT/coffee grounds composites. In the PBAT-based composites with untreated coffee grounds, a consistent decrease in tensile strength values was observed. In contrast, the addition of 10 wt.% of torrefied coffee grounds to PBAT conferred better tensile properties as compared to neat PBAT, while the strain at break was slightly decreased. Beyond 10 wt.%, the tensile strength and strain at break began to decrease gradually but their values were still better than the untreated CG/PBAT composites. The water contact angle values were clearly increased proportionally to the torrefied CG content in the matrix, resulting in highly hydrophobic biocomposites. Considering the high biodegradability of PBAT, such composites are valuable for the production of biodegradable rigid items usable in the packaging or agricultural sectors.

Of note, Sarasini et al. [30] studied the effect of coffee silver skin size, variety, distribution and content on the processability, thermal and mechanical properties of biocomposites based on a biodegradable blend of PBAT and poly(3-hydroxybutyrate-co-3-hydroxyvalerate) (PHB-HV). The authors showed the feasible use of coffee silver skin in the production of biodegradable composites with improved stiffness and tensile strength compared to the blend without coffee silver skin. Recently, coffee capsules, based on PHB-HV copolymers and CSS, have been produced by injection molding; the migration properties in contact with simulants are very promising for applications of these composites as plastic materials for food contact [73].

Composite materials based on PLA and torrefied SCG (TSCG) were also reported in the literature [74]. In order to improve the compatibility, maleic anhydride-grafted polylactide (PLA-g-MA) and cross-linked spent coffee grounds were used. Compatibilised materials exhibited improved mechanical properties. This effect was attributed to great compatibility of the grafted polymer and the natural filler. The dispersion of spent coffee grounds in the PLA-g-MA matrix was homogeneous due to ester formation and resulted in branched and cross-linked macromolecules. Moreover, the PLA-g-MA/TSCG composites exhibited low melt viscosities and were therefore easy to process. The water resistance of the PLA-g-MA/TSCG composite was greater than that of PLA/SCG and the mass losses following burial in soil compost indicated that both materials were able to disintegrate, especially at high levels of coffee ground content.

Biocomposites containing PBS have also been reported [75]. Their production from renewable resources is possible with up to 30% by weight of silver skin. In PBS-based composites, silver skin increased tensile strength and Young’s modulus and had negligible effect on crystallinity.

Table 3 presents some examples of biocomposites containing coffee by-products.

Table 3.

Example of biocomposites with coffee by-products as filler.

4. Biofuels Production from Coffee Waste

According to the Food and Agricultural Organisation (FAO), biofuels are classified in wood fuels and agro-fuels. The latter are fuels obtained as a product of agricultural biomass and by-products at farming level, and/or the industrial processing of raw material (agro-industries). The term covers mainly biomass that is derived directly from fuel crops (see Table 4 for examples) and agricultural, agro-industrial and animal by-products [76].

Table 4.

Fuel crops and agriculture derived main product.

Thus, advanced biofuels can be produced from lignocellulosic and non-lignocellulosic sources (forestry and food or agro-derived residues) by means of thermochemical conversion, mainly based on gasification or pyrolysis plus a potential catalytic fuel production stage [77]. Biorefinery schemes based on this approach may vary, as well as their efficiency as per the configuration of the process itself and the final products.

Spent coffee grounds after a thermal water extraction still possess more than 700 volatile compounds, insoluble and un-extractable, with high quality, organic and energy content. Moreover, spent coffee grounds contain tannins, polyphenol and caffeine that can result toxic if disposed into the environment [78].

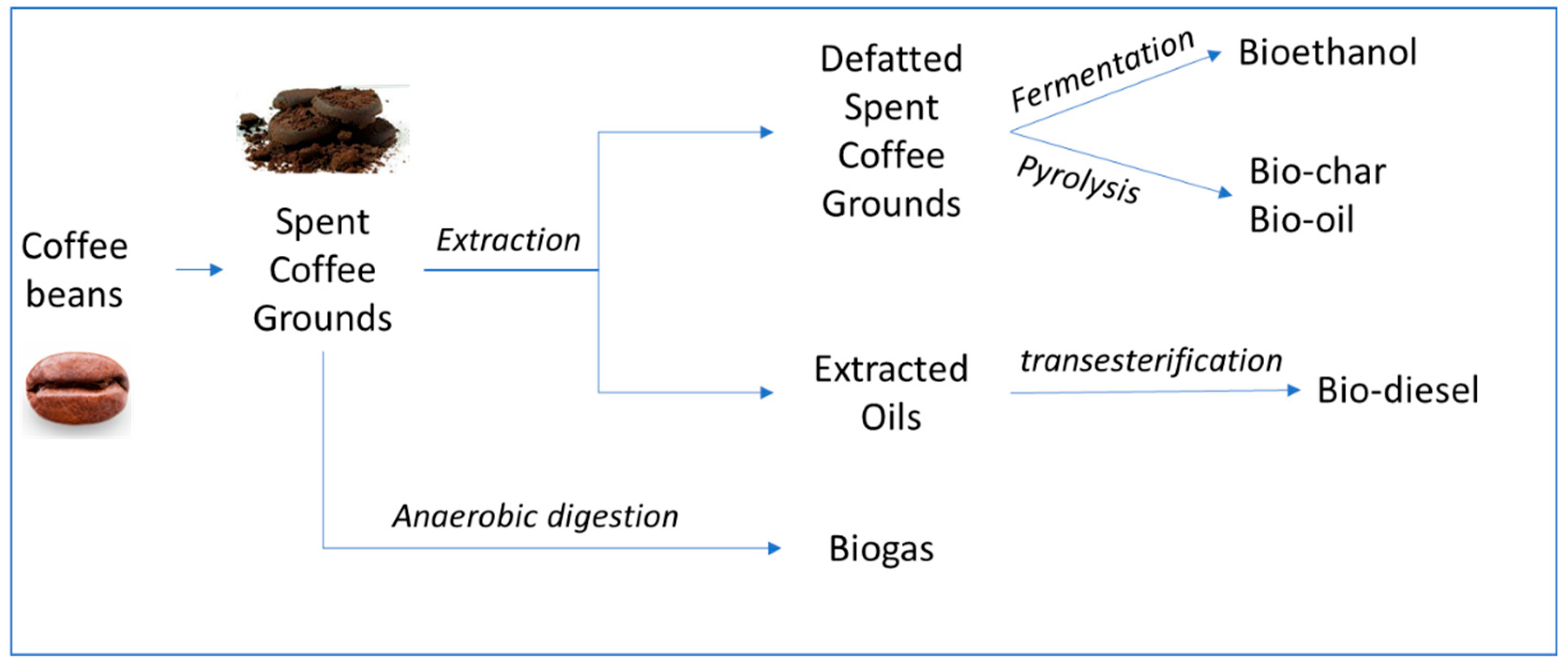

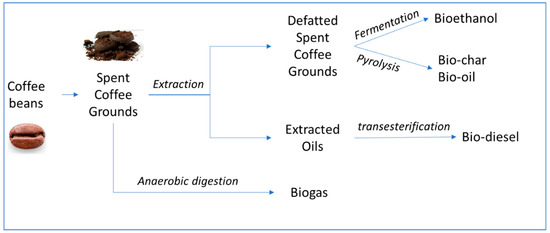

Even spent coffee waste can be used for bioethanol, biodiesel, bio-oil, biochar, renewable diesel or biogas production by anaerobic digestion, hydrogenation, esterification-transesterification, fermentation or pyrolytic reactions [79]. There are several references addressing the valorisation of spent coffee grounds for the production of different types of biofuels such as bioethanol, biodiesel, fuel pellets, biohydrogen, bio-oil, biogas and hydrocarbon fuels [80,81].

Table 5 reports some examples of coffee by-products valorisation in energy production, the methods used and the secondary products obtained.

Table 5.

Some examples of coffee by-products valorisation in energy production.

As summarised in Figure 3 and described in the next paragraphs, several approaches can be used to valorise coffee by-products for the production of fuels and energy.

Figure 3.

Schematic examples of coffee by-products valorization in energy production.

4.1. Biodiesel

In the literature, several studies report how coffee crops can result in more oil per unit of land area than other traditional biodiesel crops with e.g., 386 kg/ha compared to 375 kg/ha for soybean [81,82].

For SCG, an oil yield of 21.5% is reported to be converted into biodiesel with an 82% yield [83].

Kondamudi et al. [84] suggested to extract the oil from spent coffee grounds and then convert it to spent coffee grounds oil methyl ester (biodiesel), while glycerin can be further processed into biohydrogen. The spent coffee grounds can be represented as triolein with formula C57H104O6, which can be transesterified using methanol to form methyl oleate (C19H36O2) and glycerol. Being low in caffeine (C8H10N4O2), spent ground coffee has limited NOx production. Another process [83] converts spent coffee ground oils into fatty acid methyl ester or fatty acid ethyl ester via a non-catalytic transesterification process.

Most recent studies have focused on oil extraction from SCG with different types of non-polar (hexane, toluene, n-pentane, etc.) or polar solvents (alcohols, acetone). Innovative technologies such as two-phase oil extraction [85], ultrasound-assisted solvent extraction [86] and supercritical fluid extraction using CO2 [87] achieved about 0.61–0.81 of n-hexane soxhlet extraction value.

Transesterification can be carried out with catalytic alkaline-based transesterification or acid-catalysed esterification using methanol/carbon dioxide mixtures or with enzymatic catalysis; with a catalytic two-step reaction of acid-catalysed esterification followed by alkaline-based transesterification; by non-catalytic esterification; or by in situ transesterification [88]. In the last process, the production of biodiesel from spent coffee ground oils can be carried out by reacting directly spent coffee ground (in-situ) with no need for the solvent extraction process, followed by pyrolysis with biochar production [89].

4.2. Bioethanol

The direct conversion of SCG to bioethanol (without oil extraction) was reported as unfeasible due to the existence of triglyceride and fatty acids, which inhibits the activity of the enzymatic saccharification process [90].

In the work of Go et al. [91] the SCG was first hydrolysed with sulfuric acid extracting sugars, that can be then fermented to bioethanol. Lipids remained intact even after hydrolysis and were successfully recovered from the hydrolysed SCG known as spent coffee grounds oil (SCGO) to produce biodiesel and glycerin. The solid residues after hydrolysis were ~68% of the initial biomass having a moisture content of ~65%, thus reducing the total amount of moisture to be removed as well as the energy required in the drying step prior to lipid extraction [92]. The obtained bioethanol can be converted to bioesters for the EU gasoline market.

The defatted spent coffee grounds (DSCG) can be valorised as fuel pellets or soil amendment agents. In the work of Haile et al. [93], oil was extracted from dry SCG up to 19.73% w/w and further used to produce biodiesel with a yield of about 73.4% w/w. The solid remaining after extraction was used to produce bioethanol through acid hydrolysis (H2SO4) and fermentation (Saccharomyces cerevisiae), which resulted in a 8.3% v/v yield. The biomass remaining after bioethanol production can be used for the production of compost and solid fuel pellets with a 21.9:1 carbon to nitrogen ratio (C/N) and a 20.8 MJ/kg heating value, respectively.

4.3. Bio-Oil

Spent coffee grounds and defatted SCG are a potential source for bio-oil and biochar obtained by means of pyrolysis. The process of pyrolysis is based on thermal decomposition of biomass under inert atmosphere (nitrogen), with limited oxygen and at relatively high temperatures in the range of 500 to 1000 °C. The biomass degradation produces bio-oil, water phase, biochar and syngas.

These bio-oils are used as fuels or chemicals [94] while biochar can be used as energy source or soil amendment [95]. The co-pyrolysis process was investigated and led to improved oil yield and crude oil quality. The best performing conditions were set at 250 °C and a mixing ratio of 1:1 of SCG.

The co-pyrolysis (co-liquefaction) of SCG with PP [96], paper filter, corn stalk and white pine has been reported to lead to interesting results [97].

4.4. Biogas

SCG is a valuable material for fermentation in both mesophilic and thermophilic processes due to its suitable elemental composition, C/N ratio and chemical composition (content in polysaccharides, proteins and minerals). Several papers report the production of biogas from SCG by anaerobic digestion. For example, in the study of Vítez et al. [98], methane production ranged from 0.271–0.325 m3/kg dry organic matter under mesophilic conditions. To improve the methane recovery, an alkaline pre-treatment was applied to SCG through anaerobic digestion. The highest concentration of NaOH (8% w/w) led to the best anaerobic digestion performances (392 mL CH4/gVS, calculated by dividing total volume of methane by measured total Volatile Solids) as a consequence of the slightly higher lignin degradation, which was 24% higher than that of the untreated substrate, and of the higher dissolved organic carbon concentration [99].

Integrated biological and physico-chemical process was studied by Lee et al. [100] for the production of fatty acid methyl ester, lignin and biogas from SCG. A maximum recovery of 62.4% and 55.5% of fatty acid methyl ester and lignin was obtained. The solid remaining after extraction was anaerobically digested and had a maximal methane yield of 36.0 mL CH4/gVS.

Due to their reduced O/C and H/C ratios, torrefied coffee grounds are an interesting feedstock for the production of syngas. Torrefaction is actually a good process to enhance the efficiency of biomass and waste uses for renewable energy applications [101].

5. Conclusions and Future Perspectives

This review summarizes the most recent studies concerning monomer, material and fuel production from coffee waste. Through a series of integrated conversion technologies, chemical building blocks can be recovered from coffee by-products and used for the production of monomers such as lactic acid, succinic acid, levulinic acid, alcohols, etc., obtaining especially high yields for lactic acid. Polymers such as polyhydroxyalkanoates can also be directly produced from coffee waste with adequate yields. In parallel, coffee by-products can be used as fillers in composite materials leading to an improvement of the final properties if a good interfacial adhesion is achieved, and, in any case, composite materials with very high bio-based content can be obtained. Provided these materials contain the appropriate co-polymeric matrix, they are potentially compostable or degradable in soil.

Coffee by-products can even find a very valuable exploitation in energy production. Indeed, biomass derived from spent ground coffee can be used for the production of biodiesel, by transesterification of the extracted lipids. Then, the defatted SCG can be converted in bioethanol by means of fermentation or in bio-oil and biochar through pyrolysis with no waste material. SCG can also be used directly for the production of biogas by means of anaerobic digestion.

Future applications might involve the development of new materials for application in biomedicine, active food packaging and smart materials. However, research must also focus on a techno-economic analysis and feasibility of industrial scale production.

Author Contributions

Conceptualization, L.N.; writing—original draft preparation, P.C. (Philippe Corvini), M.B., L.S. and A.C.; writing—review and editing, L.S., A.C., P.C. (Patrizia Cinelli)., F.S., A.L., L.N., P.C. (Philippe Corvini), A.T. and M.B.; supervision, G.T. and M.F.; funding acquisition, all authors. All authors have read and agreed to the published version of the manuscript.

Funding

This work was supported by the PROLIFIC project (“Integrated cascades of processes for the extraction and valorization of protein and bioactive molecules from legumes, fungi and coffee agro-industrial side streams”), which receives funding from the Bio Based Industries Joint Undertaking under the European Union’s Horizon 2020 research and innovation program, under grant agreement No 790157.

Conflicts of Interest

The authors declare no conflict of interest.

Abbreviations

| ABE | mixture of acetone, butanol and ethanol |

| CH | coffee husk |

| CG | coffee grounds |

| CNCs | cellulose nanocrystals |

| CP | coffee pulp |

| CSS | coffee silver skin |

| DSCG | defatted spent coffee grounds |

| LA | lactic acid |

| PBAT | poly(butylene adipate-co-terephthalate) |

| PBS | poly(butylene succinate) |

| PE | poly(ethylene) |

| PEF | poly(ethylene 2,5-furandicarboxylate) |

| PET | poly(ethylene terephthalate) |

| PHA | polyhydroxyalkanoates |

| PHB-HV | poly(3-hydroxybutyrate-co-3-hydroxyvalerate) |

| PLA | poly(lactic acid) |

| PLA-g-MA | maleic anhydride-grafted-polylactide |

| PP | poly(propylene) |

| PTT | poly(trimethylene terephthalate) |

| PUs | polyurethanes |

| SA | succinic acid |

| SCGO | spent coffee grounds oil |

| SFC | spent filter coffee |

| SCG | spent coffee grounds |

| TSCG | torrefied spent coffee grounds |

| VS | volatile solid |

References

- Gustavsson, J.; Cederberg, C.; Sonesson, U.; van Ottedijk, R.; Meybeck, A. Global food losses and food waste: Extent, causes and prevention. In Save Food, Proceedings of the Interpack2011, Düsseldorf, Germany, 12–18 May 2011; FAO: Rome, Italy, 2011. [Google Scholar]

- Vermeulen, S.J.; Campbell, B.M.; Ingram, J.S.I. Climate change and food systems. Annu. Rev. Environ. Resour. 2012, 37, 195–222. [Google Scholar] [CrossRef]

- Scialabba, N. Food Wastage Footprint: Impacts on Natural Resources-Summary Report; FAO, Food and Agricultural Organization of the United Nations: Rome, Italy, 2013. [Google Scholar]

- Hatti-Kaul, R.; Nilsson, L.J.; Zhang, B.; Rehnberg, N.; Lundmark, S. Designing Biobased recyclable polymers for plastics. Trends Biotechnol. 2020, 38, 50–67. [Google Scholar] [CrossRef]

- European Bioplastics. Available online: https://www.european-bioplastics.org/market/ (accessed on 5 January 2021).

- Cherubini, F. The biorefinery concept: Using biomass instead of oil for producing energy and chemicals. Energy Convers. Manag. 2010, 51, 1412–1421. [Google Scholar] [CrossRef]

- European Commission. Press Release-Energy Union: Secure, Sustainable, Competitive, Affordable Energy for Every European; European Commission: Brussels, Belgium, 2015. [Google Scholar]

- European Commission. Communication from the Commission to the European Parliament, the European Council, the Council, the European Economic and Social Committee, the Committee of the Regions and the European Investment Bank; European Commission: Brussels, Belgium, 2018. [Google Scholar]

- Besset, C.J.; Lonnecker, A.T.; Streff, J.M.; Wooley, K.L. Polycarbonates from the polyhydroxy natural product quinic acid. Biomacromolecules 2011, 12, 2512–2517. [Google Scholar] [CrossRef] [PubMed]

- Shogren, R.; Wood, D.; Orts, W.; Glenn, G. Plant-based materials and transitioning to a circular economy. Sustain. Prod. Consum. 2019, 19, 194–215. [Google Scholar] [CrossRef]

- Monari, S.; Ferri, M.; Vannini, M.; Sisti, L.; Marchese, P.; Ehrnell, M.; Xanthakis, E.; Celli, A.; Tassoni, A. Cascade strategies for the full valorisation of Garganega white grape pomace towards bioactive extracts and bio-based materials. PLoS ONE 2020, 15, e0239629. [Google Scholar] [CrossRef] [PubMed]

- Cazón, P.; Velazquez, G.; Ramírez, J.A.; Vázquez, M. Polysaccharide-based films and coatings for food packaging: A review. Food Hydrocoll. 2017, 68, 136–148. [Google Scholar] [CrossRef]

- Weber, C.J.; Haugaard, V.; Festersen, R.; Bertelsen, G. Production and applications of biobased packaging materials for the food industry. Food Addit. Contam. 2002, 19, 172–177. [Google Scholar] [CrossRef] [PubMed]

- Saccani, A.; Sisti, L.; Manzi, S.; Fiorini, M. PLA Composites formulated recycling residuals of the winery industry. Polym. Compos. 2019, 40, 1378–1383. [Google Scholar] [CrossRef]

- Arvanitoyannis, I.S.; Ladas, D.; Mavromatis, A. Potential uses and applications of treated wine waste: A review. Int. J. Food Sci. Tech. 2006, 41, 475–487. [Google Scholar] [CrossRef]

- Ferri, M.; Vannini, M.; Ehrnell, M.; Eliasson, L.; Xanthakis, E.; Monari, S.; Sisti, L.; Marchese, P.; Celli, A.; Tassoni, A. From winery waste to bioactive compounds and new polymeric biocomposites: A contribution to the circular economy concept. J. Adv. Res. 2020, 24, 1–11. [Google Scholar] [CrossRef]

- Toschi, T.G.; Cardenia, V.; Bonaga, G.; Mandrioli, M.; Rodriguez-Estrada, M.T. Coffee silverskin: Characterization, possible uses, and safety aspects. J. Agric. Food Chem. 2014, 62, 10836–10844. [Google Scholar] [CrossRef] [PubMed]

- Murthy, P.S.; Naidu, M.M. Sustainable management of coffee industry by-products and value addition-A Review. Resour. Conserv. Recycl. 2012, 66, 45–58. [Google Scholar] [CrossRef]

- Bonilla-Hermosa, V.A.; Duarte, W.F.; Schwan, R.F. Utilization of coffee by-products obtained from semi-washed process for production of value-added compounds. Bioresour. Technol. 2014, 166, 142–150. [Google Scholar] [CrossRef]

- Janissen, B.; Huynh, T. Chemical composition and value adding applications of coffee industry by-products: A review. Resour. Conserv. Recycl. 2018, 128, 110–117. [Google Scholar] [CrossRef]

- Michail, A.; Sigala, P.; Grigorakis, S.; Makris, D.P. Kinetics of ultrasound-assisted polyphenol extraction from spent filter coffee using aqueous glycerol. Chem. Eng. Commun. 2016, 203, 407–413. [Google Scholar] [CrossRef]

- Karmee, S.K. A spent coffee grounds based biorefinery for the production of biofuels, biopolymers, antioxidants and biocomposites. Waste Manag. 2018, 72, 240–254. [Google Scholar] [CrossRef]

- Dessie, W.; Zhu, J.; Xin, F.; Zhang, W.; Jiang, Y.; Wu, H.; Ma, J.; Jiang, M. Bio-succinic acid production from coffee husk treated with thermochemical and fungal hydrolysis. Bioprocess Biosyst. Eng. 2018, 41, 1461–1470. [Google Scholar] [CrossRef]

- Tukacs, J.M.; Holló, A.T.; Rétfalvi, N.; Cséfalvay, E.; Dibó, G.; Havasi, D.; Mika, L.T. Microwave-assisted valorization of biowastes to levulinic acid. Chem. Sel. 2017, 2, 1375–1380. [Google Scholar] [CrossRef]

- Obruca, S.; Benesova, P.; Kucera, D.; Petrik, S.; Marova, I. Biotechnological conversion of spent coffee grounds into polyhydroxyalkanoates and carotenoids. New Biotechnol. 2015, 32, 569–574. [Google Scholar] [CrossRef]

- Moustafa, H.; Guizani, C.; Dupont, C.; Martin, V.; Jeguirim, M.; Dufresne, A. Utilization of torrefied coffee grounds as reinforcing agent to produce high-quality biodegradable PBAT composites for food packaging applications. ACS Sustain. Chem. Eng. 2017, 5, 1906–1916. [Google Scholar] [CrossRef]

- Essabir, H.; Rajia, M.; Ait Laaziza, S.; Rodrique, D.; Bouhfid, R.; el kacem Qaiss, A. Thermo-mechanical performances of polypropylene biocomposites based on untreated, treated and compatibilized spent coffee grounds. Comp. Part B 2018, 149, 1–11. [Google Scholar] [CrossRef]

- Sung, S.H.; Chang, Y.; Han, J. Development of polylactic acid nanocomposite films reinforced with cellulose nanocrystals derived from coffee silverskin. Carbohydr. Polym. 2017, 169, 495–503. [Google Scholar] [CrossRef] [PubMed]

- Sarasini, F.; Luzi, F.; Dominici, F.; Maffei, G.; Iannone, A.; Zuorro, A.; Lavecchia, R.; Torre, L.; Carbonell-Verdu, A.; Balart, R.; et al. Effect of Different Compatibilizers on Sustainable Composites Based on a PHBV/PBAT Matrix Filled with Coffee Silverskin. Polymers 2018, 10, 1256. [Google Scholar] [CrossRef] [PubMed]

- Sarasini, F.; Tirillò, J.; Zuorro, A.; Maffei, G.; Lavecchia, R.; Puglia, D.; Dominici, F.; Luzi, F.; Valente, T.; Torre, L. Recycling coffee silverskin in sustainable composites based on a poly(butylene adipate-co-terephthalate)/poly(3-hydroxybutyrate-co-3-hydroxyvalerate) matrix. Ind. Crops Prod. 2018, 118, 311–320. [Google Scholar] [CrossRef]

- Dadi, D.; Beyene, A.; Simoens, K.; Soares, J.; Demeke, M.M.; Thevelein, J.M.; Bernaerts, K.; Luis, P.; Van der Bruggen, B. Valorization of coffee for bioethanol production using lignocellulosic yeast fermentation and pervaporation. Int. J. Environ. Sci. Technol. 2018, 15, 821–832. [Google Scholar] [CrossRef]

- Procentese, A.; Raganati, F.; Navarini, L.; Olivieri, G.; Russo, M.E.; Marzocchella, A. Coffee silver skin as a renewable resource to produce butanol and isopropanol. Chem Eng. Trans. 2018, 64, 139–144. [Google Scholar]

- Lin, C.S.K.; Pfaltzgraff, L.A.; Herrero-Davila, L.; Mubofu, E.B.; Abderrahim, S.; Clark, J.H.; Koutinas, A.A.; Kopsahelis, N.; Stamatelatou, K.; Dickson, F.; et al. Food waste as a valuable resource for the production of chemicals, materials and fuels. Current situation and global perspective. Energy Environ. Sci. 2013, 6, 426–464. [Google Scholar] [CrossRef]

- European Commission, Eurostat: Some Statistics for Coffee Time. 2019. Available online: https://ec.europa.eu/eurostat/web/products-eurostat-news/-/EDN-20191001-1 (accessed on 15 January 2021).

- Iwata, T. Biodegradable and bio-based polymers: Future prospects of eco-friendly plastics. Angew. Chem. Int. Ed. 2015, 54, 3210–3215. [Google Scholar] [CrossRef]

- Cherubini, F.; Ulgiati, S. Crop residues as raw materials for biorefinery systems. Appl. Energy 2010, 87, 47–57. [Google Scholar] [CrossRef]

- Ahorsu, R.; Medina, F.; Constantí, M. Significance and challenges of biomass as a suitable feedstock for bioenergy and biochemical production: A review. Energies 2018, 11, 3366. [Google Scholar] [CrossRef]

- Fonseca, A.C.; Lima, M.; Sousa, A.F.; Silvestre, A.J.; Coelho, J.F.J.; Serra, A.C. Cinnamic acid derivatives as promising building blocks for advanced polymers: Synthesis, properties and applications. Polym. Chem. 2019, 10, 1696–1723. [Google Scholar] [CrossRef]

- Alexandri, M.; Schneider, R.; Mehlmann, K.; Venus, J. Recent advances in D-Lactic Acid production from renewable resources: Case studies on agro-industrial waste streams. Food Technol. Biotech. 2019, 57, 293–304. [Google Scholar] [CrossRef] [PubMed]

- Abdel-Rahman, M.A.; Tashiro, Y.; Sonomoto, K. Recent advances in lactic acid production by microbial fermentation processes. Biotechnol. Adv. 2013, 31, 877–902. [Google Scholar] [CrossRef] [PubMed]

- Tarraran, L.; Mazzoli, R. Alternative strategies for lignocellulose fermentation through lactic acid bacteria: The state of the art and perspectives. FEMS Microbiol. Lett. 2018, 365, 1–14. [Google Scholar] [CrossRef]

- Nguyen, C.M.; Kim, J.S.; Nguyen, T.N.; Kim, S.K.; Choi, G.J.; Choi, Y.H.; Jang, K.S.; Kim, J.C. Production of L- and D-lactic acid from waste Curcuma longa biomass through simultaneous saccharification and cofermentation. Bioresour. Technol. 2013, 146, 35–43. [Google Scholar] [CrossRef]

- De la Torre, I.; Ladero, M.; Santos, V.E. Production of D-lactic acid by Lactobacillus delbrueckii ssp. delbrueckii from orange peel waste: Techno-economical assessment of nitrogen sources. Appl. Microbiol. Biotechnol. 2018, 102, 10511–10521. [Google Scholar] [CrossRef]

- Hartmann, H. High molecular weight polylactic acid polymers. In Biopolymers from Renewable Resources, 1st ed.; Kaplan, D.L., Ed.; Springer: Berlin, Germany, 1998; pp. 367–411. [Google Scholar]

- Hudeckova, H.; Neureiter, M.; Obruca, S.; Frühauf, S.; Marova, I. Biotechnological conversion of spent coffee grounds into lactic acid. Lett. Appl. Microbiol. 2018, 66, 306–312. [Google Scholar] [CrossRef]

- Bretón-Toral, A.; Trejo-Estrada, S.R.; McDonald, A.G. Lactic acid production from potato peel waste, spent coffee grounds and almond shells with undefined mixed cultures isolated from coffee mucilage from Coatepec Mexico. Ferment. Technol. 2017, 6, 1000139–1000145. [Google Scholar] [CrossRef]

- Neu, A.K.; Pleissner, D.; Mehlmann, K.; Schneider, R.; Puerta-Quintero, G.I.; Venus, J. Fermentative utilization of coffee mucilage using Bacillus coagulans and investigation of down-stream processing of fermentation broth for optically pure L(+)-lactic acid production. Bioresour. Technol. 2016, 211, 398–405. [Google Scholar] [CrossRef]

- Pleissner, D.; Neu, A.K.; Mehlmann, K.; Schneider, R.; Puerta-Quintero, G.I.; Venus, J. Fermentative lactic acid production from coffee pulp hydrolysate using Bacillus coagulans at laboratory and pilot scales. Bioresour. Technol. 2016, 218, 167–173. [Google Scholar] [CrossRef]

- Kim, J.; Jang, J.H.; Yeo, H.J.; Seol, J.; Kim, S.R.; Jung, Y.H. Lactic Acid Production from a whole slurry of acid-pretreated spent coffee grounds by engineered Saccharomyces cerevisiae. Appl. Biochem. Biotechnol. 2019, 189, 206–216. [Google Scholar] [CrossRef] [PubMed]

- Sisti, L.; Totaro, G.; Marchese, P. PBS makes its entrance into the family of biobased plastics. In Biodegradable and Biobased, Polymers for Environmental and Biomedical Applications; Kalia, S., Averous, L., Eds.; John Wiley & Sons: Hoboken, NJ, USA, 2016; pp. 225–285. [Google Scholar]

- Li, C.; Ong, K.L.; Yang, X.; Lin, C.S.K. Bio-refinery of waste streams for green and efficient succinic acid production by engineered Yarrowia lipolytica without pH control. Chem. Eng. J. 2019, 371, 804–812. [Google Scholar] [CrossRef]

- Li, C.; Ong, K.L.; Cui, Z.; Sang, Z.; Li, X.; Patria, R.D.; Qi, Q.; Fickers, P.; Yan, J.; Lin, C.S.K. Promising advancement in fermentative succinic production by yeast hosts. J. Hazard. Mater. 2021, 401, 123414. [Google Scholar] [CrossRef] [PubMed]

- Niglio, S.; Procentese, A.; Russo, M.E.; Sannia, G.; Marzocchella, A. Investigation of enzymatic hydrolysis of coffee silverskin aimed at the production of butanol and succinic acid by fermentative processes. Bioenergy Res. 2019, 12, 312–324. [Google Scholar] [CrossRef]

- Pileidis, F.D.; Titirici, M.M. Levulinic acid biorefineries: New challenges for efficient utilization of biomass. ChemSusChem 2016, 9, 562–582. [Google Scholar] [CrossRef]

- Kang, S.; Fu, J.; Zhang, G. From lignocellulosic biomass to levulinic acid: A review on acid-catalyzed hydrolysis. Renew. Sustain. Energy Rev. 2018, 94, 340–362. [Google Scholar] [CrossRef]

- Qin, K.; Yan, Y.; Zhang, Y.; Tang, Y. Direct production of levulinic acid in high yield from cellulose: Joint effect of high ion strength and microwave field. RSC Adv. 2016, 6, 39131–39136. [Google Scholar] [CrossRef]

- Im, H.; Kim, B.; Lee, J.W. Concurrent production of biodiesel and chemicals through wet in situ transesterification of microalgae. Bioresour. Technol. 2015, 193, 386–392. [Google Scholar] [CrossRef]

- Kim, B.; Yang, J.; Kim, M.; Lee, J.W. One-pot selective production of levulinic acid and formic acid from spent coffee grounds in a catalyst-free biphasic system. Bioresour. Technol. 2020, 303, 122898–122906. [Google Scholar] [CrossRef]

- Sato, Y.; Itagaki, S.; Kurokawa, T.; Ogura, J.; Kobayashi, M.; Hirano, T.; Sugawara, M.; Iseki, K. In vitro and in vivo antioxidant properties of chlorogenic acid and caffeic acid. Int. J. Pharm. 2011, 403, 136–138. [Google Scholar] [CrossRef]

- Youn, S.H.; Lee, K.M.; Kim, K.Y.; Lee, S.M.; Woo, H.M.; Um, Y. Effective isopropanol–butanol (IB) fermentation with high butanol content using a newly isolated Clostridium sp. A1424. Biotechnol. Biofuels 2016, 9, 230–245. [Google Scholar] [CrossRef]

- Soares, B.; Gama, N.; Freire, C.S.R.; Barros-Timmons, A.; Brandão, I.; Silva, R.; Neto, C.P.; Ferreira, A. Spent coffee grounds as a renewable source for ecopolyols production. J. Chem. Technol. Biotechnol. 2015, 90, 1480–1488. [Google Scholar] [CrossRef]

- Yang, Y.; Hoogewind, A.; Moon, Y.H.; Day, D. Bioprocess Production of butanol and isopropanol with an immobilized Clostridium. Biosyst. Eng. 2016, 39, 421–428. [Google Scholar]

- Gama, N.V.; Soares, B.; Freire, C.S.R.; Silva, R.; Neto, C.P.; Barros-Timmons, A.; Ferreira, A. Bio-based polyurethane foams toward applications beyond thermal insulation. Mater. Des. 2015, 76, 77–85. [Google Scholar] [CrossRef]

- Kovalcik, A.; Kucera, D.; Matouskova, P.; Pernicova, I.; Obruca, S.; Kalina, M.; Enev, K.; Marova, I. Influence of removal of microbial inhibitors on PHA production from spent coffee grounds employing Halomonas halophila. J. Environ. Chem. Eng. 2018, 6, 3495–3501. [Google Scholar] [CrossRef]

- Bathia, S.K.; Kim, J.H.; Kim, M.S.; Kim, J.; Hong, J.W.; Hong, Y.G.; Kim, H.J.; Jeon, J.M.; Kim, S.H.; Ahn, J.; et al. Production of (3-hydroxybutyrate-co-3-hydroxyhexanoate) copolymer from coffee waste oil using engineered Ralstonia eutropha. Bioprocess Biosyst. Eng. 2018, 41, 229–235. [Google Scholar]

- Obruca, S.; Petrik, S.; Benesova, P.; Svoboda, Z.; Eremka, L.; Marova, I. Utilization of oil extracted from spent coffee grounds for sustainable production of polyhydroxyalkanoates. Appl. Microbiol. Biotechol. 2014, 98, 5883–5890. [Google Scholar] [CrossRef] [PubMed]

- Cruz, M.V.; Paiva, A.; Lisboa, P.; Freitas, F.; Alves, V.D.; Simões, P.; Barreiros, S.; Reis, M.A.M. Production of polyhydroxyalkanoates from spent coffee grounds oil obtained by supercritical fluid extraction technology. Bioresour. Technol. 2014, 157, 360–363. [Google Scholar] [CrossRef] [PubMed]

- Ballesteros, L.F.; Teixeira, J.A.; Mussatto, S.I. Chemical, functional, and structural properties of spent coffee grounds and coffee silverskin. Food Bioprocess Technol. 2014, 7, 3493–3503. [Google Scholar] [CrossRef]

- Iriondo-De Hond, A.; Haza, A.I.; Ávalos, A.; del Castillo, M.D.; Morales, P. Validation of coffee silverskin extract as a food ingredient by the analysis of cytotoxicity and genotoxicity. Food Res. Int. 2017, 100, 791–797. [Google Scholar] [CrossRef]

- Trache, D.; Donnot, A.; Khimeche, K.; Benelmir, R.; Brosse, N. Physico-chemical properties and thermal stability of microcrystalline cellulose isolated from Alfa fibres. Carbohydr. Polym. 2014, 104, 223–230. [Google Scholar] [CrossRef]

- Zarrinbakhsh, N.; Wang, T.; Rodriguez-Uribe, A.; Misra, M.; Mohanty, A.K. Characterization of wastes and coproducts from the coffee industry for composite material production. BioResources 2016, 11, 7637–7653. [Google Scholar] [CrossRef]

- Dominici, F.; García García, D.; Fombuena, V.; Luzi, F.; Puglia, D.; Torre, L.; Balart, R. Bio-Polyethylene-based composites reinforced with alkali and palmitoyl chloride-treated coffee Silverskin. Molecules 2019, 24, 3113. [Google Scholar] [CrossRef]

- Gigante, V.; Seggiani, M.; Cinelli, P.; Signori, F.; Vania, A.; Navarini, L.; Amato, G.; Lazzeri, A. Utilization of coffee silverskin in the production of Poly(3-hydroxybutyrate-co-3-hydroxyvalerate) biopolymer-based thermoplastic biocomposites for food contact applications. Compos. Part A Appl. Sci. Manuf. 2021, 140, 106172–106182. [Google Scholar] [CrossRef]

- Wu, C.S. Renewable resource-based green composites of surface-treated spent coffee grounds and polylactide: Characterisation and biodegradability. Polym. Deg. Stab. 2015, 121, 51–59. [Google Scholar] [CrossRef]

- Totaro, G.; Sisti, L.; Fiorini, M.; Lancellotti, M.; Andreola, F.N.; Saccani, A. Formulation of green particulate composites from PLA and PBS matrix and wastes deriving from the coffee production. J. Polym. Environm. 2019, 27, 1488–1496. [Google Scholar] [CrossRef]

- Food and Agricultural Organization of the United Nations, “Ubet Unified Bioenergy Terminology”. 2004. Available online: http://www.fao.org/3/j4504E/j4504e07.htm#P731_40655 (accessed on 1 June 2020).

- Simell, P.; Hannula, S.; Toumi, S.; Nieminen, M.; Kurkela, E.; Hiltunen, I. Clean syngas from biomass-Process development and concept assessment. Biomass Convers. Biorefinery 2014, 4, 357–370. [Google Scholar] [CrossRef]

- Scully, D.S.; Jalswal, A.K.; Abu-Ghannam, N. An investigation into spent coffee waste as a renewable source of bioactive compounds and industrially important sugars. Bioengineering 2016, 3, 33. [Google Scholar] [CrossRef]

- Atabani, A.E.; Al-Muhtaseb, A.H.; Kumar, G.; Saratale, G.D.; Aslam, M.; Khan, H.A.; Said, Z.; Mahmoud, E. Valorization of spent coffee grounds into biofuels and value-added products: Pathway towards integrated bio-refinery. Fuel 2019, 254, 115640–115660. [Google Scholar] [CrossRef]

- Banu, J.R.; Kavitha, S.; Yukesh Kannah, R.; Dinesh Kumar, M.; Preethi; Atabani, A.E.; Kumar, G. Biorefinery of spent coffee grounds waste: Viable pathway towards circular bioeconomy. Bioresour. Technol. 2020, 302, 122821–122836. [Google Scholar] [CrossRef] [PubMed]

- Jenkins, R.W. Renewable Liquid Transport Fuels from Microbes and Waste Resources. Ph.D. Thesis, Centre for Sustainable Chemical Technologies, Department of Chemical Engineering, University of Bath, Bath, UK, 2014; p. 252. [Google Scholar]

- Ferrario, V.; Veny, H.; De Angelis, E.; Navarini, L.; Ebert, C.; Gardossi, L. Lipases immobilization for effective synthesis of biodiesel starting from coffee waste oils. Biomolecules 2013, 3, 514. [Google Scholar] [CrossRef]

- Haile, M. Integrated valorization of spent coffee grounds to biofuels. Biofuel Res. J. 2014, 1, 65–69. [Google Scholar] [CrossRef]

- Kondamudi, N.; Mohapatra, S.K.; Misra, M. Spent coffee grounds as a versatile source of green energy. J. Agric. Food Chem. 2008, 56, 11757–11760. [Google Scholar] [CrossRef]

- Abdullah, M.; Koc, A.B. Oil removal from waste coffee grounds using two-phase solvent extraction enhanced with ultrasonication. Renew. Energy 2013, 50, 965–970. [Google Scholar] [CrossRef]

- Rocha, M.V.P.; de Matos, L.J.B.L.; de Lima, L.P.; da Silva Figueiredo, P.M.; Lucena, I.L.; Fernandes, F.A.N.; Gonçalves, L.R.B. Ultrasound-assisted production of biodiesel and ethanol from spent coffee grounds. Bioresour. Technol. 2014, 167, 343–348. [Google Scholar] [CrossRef] [PubMed]

- de Melo, M.M.R.; Barbosa, H.M.A.; Passos, C.P.; Silva, C.M. Supercritical fluid extraction of spent coffee grounds: Measurement of extraction curves, oil characterization and economic analysis. J. Supercrit. Fluids 2014, 86, 150–159. [Google Scholar] [CrossRef]

- Liu, Y.; Tu, Q.; Knothe, G.; Lu, M. Direct transesterification of spent coffee grounds for biodiesel production. Fuel 2017, 199, 157–161. [Google Scholar] [CrossRef]

- Tongcumpou, C.; Usapein, P.; Tuntiwiwattanapun, N. Complete utilization of wet spent coffee grounds waste as a novel feedstock for antioxidant, biodiesel, and biochar production. Ind. Crops Prod. 2019, 138, 111484–111491. [Google Scholar] [CrossRef]

- Kwon, E.E.; Yi, H.; Jeon, Y.J. Sequential co-production of biodiesel and bioethanol with spent coffee grounds. Bioresour. Technol. 2013, 136, 475–480. [Google Scholar] [CrossRef]

- Go, Y.W.; Yeom, S.H. Statistical analysis and optimization of biodiesel production from waste coffee grounds by a two-step process. Biotechnol. Bioprocess Eng. 2017, 22, 440–449. [Google Scholar] [CrossRef]

- Juarez, G.F.Y.; Pabiloña, K.B.C.; Manlangit, K.B.L.; Go, A.W. Direct dilute acid hydrolysis of Spent Coffee Grounds: A new approach in sugar and lipid recovery. Waste Biomass Valor. 2018, 9, 235–246. [Google Scholar] [CrossRef]

- Haile, M.; Asfaw, A.; Asfaw, N. Investigation of waste coffee ground as a potential raw material for biodiesel production. Int. J. Renew. Energy Res. 2013, 3, 854–860. [Google Scholar]

- Primaz, C.T.; Schena, T.; Lazzari, E.; Caramãoa, E.B.; Jacques, R.A. Influence of the temperature in the yield and composition of the bio-oil from the pyrolysis of spent coffee grounds: Characterization by comprehensive two dimensional gas chromatography. Fuel 2018, 232, 572–580. [Google Scholar] [CrossRef]

- Kelkar, S.; Saffron, C.M.; Chai, L.; Bovee, J.; Stuecken, T.R.; Garedew, M.; Li, Z.; Kriegeld, R.M. Pyrolysis of spent coffee grounds using a screw-conveyor reactor. Fuel Process Technol. 2015, 137, 170–178. [Google Scholar] [CrossRef]

- Zanella, E.; Della Zassa, M.; Navarini, L.; Canu, P. Low-temperature co-pyrolysis of polypropylene and coffee wastes to fuels. Energy Fuels 2013, 27, 1357–1364. [Google Scholar] [CrossRef]

- Yang, L.; He, Q.; Havard, P.; Corscadden, K.; Xu, C.; Wang, X. Co-liquefaction of spent coffee grounds and lignocellulosic feedstocks. Bioresour. Technol. 2017, 237, 108–121. [Google Scholar] [CrossRef]

- Vítez, T.; Koutny, T.; Sotnar, M.; Chovanec, J. On the spent coffee grounds biogas production. Acta Univ. Agric. Silvicult. Mendel. Brun. 2016, 64, 1279–1282. [Google Scholar] [CrossRef]

- Girotto, F.; Lavagnolo, M.C.; Pivato, A. Spent coffee grounds alkaline pre-treatment as biorefinery option to enhance their anaerobic digestion yield. Waste Biomass Valor. 2018, 9, 2565–2570. [Google Scholar] [CrossRef]

- Lee, M.; Yang, M.; Choi, S.; Shin, J.; Park, C.; Cho, S.K.; Kim, Y.M. Sequential production of lignin, fatty acid methyl esters and biogas from Spent Coffee Grounds via an integrated physicochemical and biological process. Energies 2019, 12, 2360. [Google Scholar] [CrossRef]

- Chen, Y.; Yang, H.; Yang, Q.; Hao, H.; Zhu, B.; Chen, H. Torrefaction of agriculture straws and its application on biomass pyrolysis poly-generation. Bioresour. Technol. 2014, 156, 70–77. [Google Scholar] [CrossRef] [PubMed]

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).