Environmental Risk Assessment of a Diesel Fuel Tank: A Case Study

Abstract

1. Introduction

2. Materials and Methods

2.1. Researched Facility Characteristics

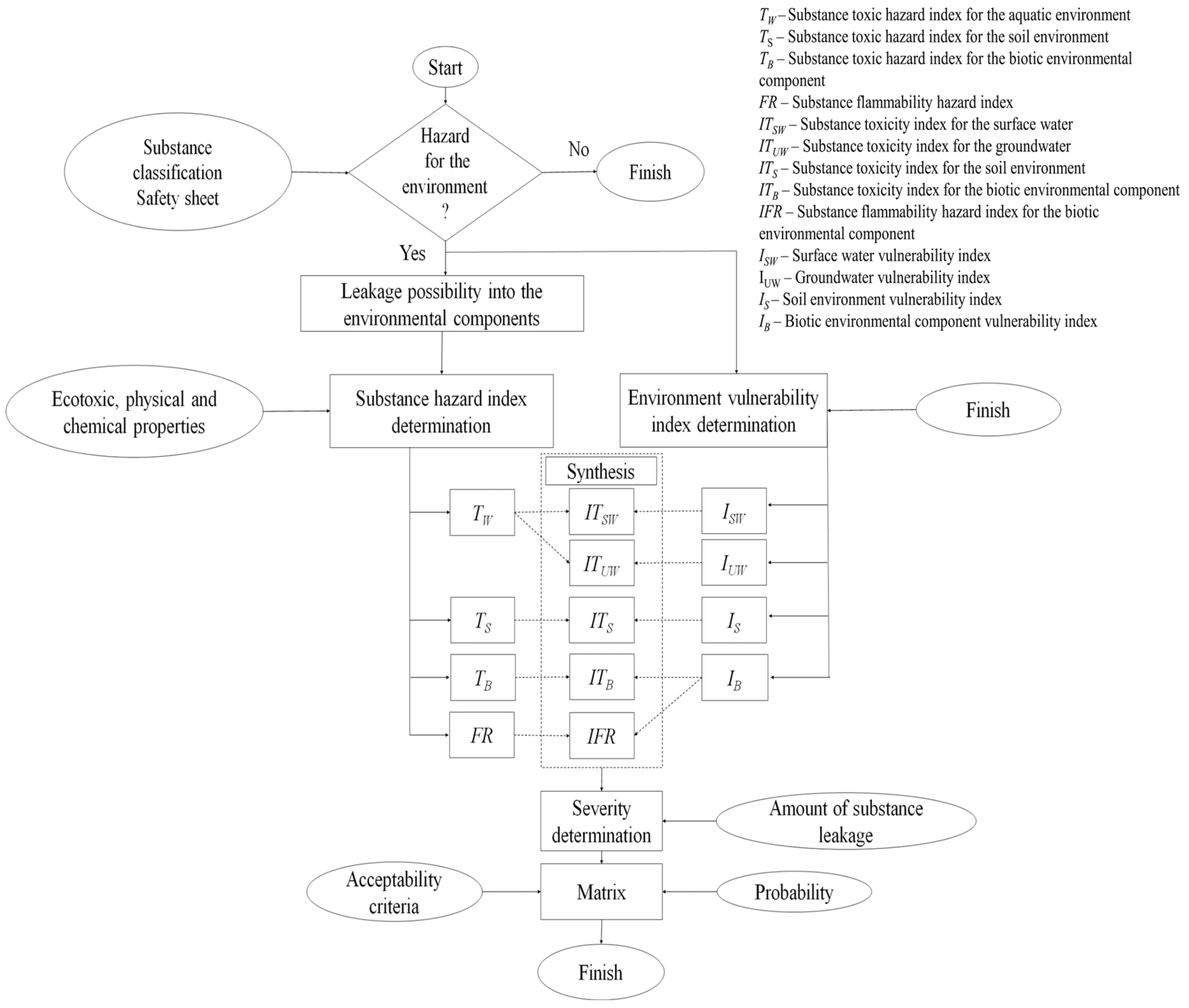

2.2. Environmental Risk Assessment Methods

3. Results and Discussion

3.1. Environmental Damage Assessment

3.2. Environmental Risk Assessment by the H&V Index II Method

3.2.1. Toxic Substance Assessment for the Environmental Components

- A substance is hazardous for the aquatic environment if classified as H400, H410, H411, H412, and H413. Diesel fuel is dangerous for the aquatic environment since H-statement H411 was listed in the safety data sheet.

- A substance is hazardous for acute toxicity for the biotic environment if classified as H300, H301, H302, H310, H311, H312, H330, H331, and H332. Diesel fuel is dangerous for the biotic environment and terrestrial ecosystems since H-statement H332 was listed.

- A substance is hazardous due to flammability if classified as H200, H201, H202, H203, H204, H205, H220, H221, H222, H223, H224, H225, H226, H228, H240, H241, H242, H250, H251, H252, H260, H261, H270, H271, H272, and H280. Diesel fuel is classified by H-statement H226 in accordance with normative legal acts.

3.2.2. Hazard Indices Determination

- Substance toxic hazard index:

- ○

- For the impact on the aquatic environment (TW), diesel fuel was classified by the standard hazard statement H411; therefore, it can be directly assigned the toxic hazard index for the aquatic environment. An index of 3 (TW = 3) was assigned on the basis of toxicity according to the determined values.

- ○

- For the impact on the soil environment (TS), diesel fuel was classified by the standard hazard statement H411, which was directly assigned the toxic hazard index for the soil environment according to toxicity codes at level 3 (TS = 3).

- ○

- For the impact on the biotic environmental component (TB), the index was determined according to the values of acute toxicity in combination with selected physical substance properties, which indicate its mobility (state, volatility). TB is the product of:

- ▪

- Partial index for the biotic environment (AB), diesel fuel is classified by the standard hazard statement H332 and LD50 oral for a rat at the level of 2000 mg.kg−1, low toxicity, thus it was possible to directly assign an index at level 1 (AB = 1).

- ▪

- Partial index BB, which represents the substance physical properties. Diesel fuel is a liquid with a vapor pressure at 20 °C < 0.005 MPa (specifically 0.0001 MPa). According to the table for the substance physical property assessment, the BB index was assigned at level 1.

- ▪

- The product of the indices AB and BB was the value of TB calculated at level 1.

- Substance flammable hazard index:

- ○

- For the impact on the environmental biotic component (FR), the ability of the substance to evaporate after leakage was assessed on the basis of a physical and chemical property scale, for flammable liquid vapor pressure at 20 °C < 0.03 MPa, the index was assigned at level 1.

3.2.3. Environmental Component Vulnerability Assessment

- Determination of surface water vulnerability (ISW)—individual surface water categories were assigned a specific index. The resulting index was given by the sum of the types of surface water in the surroundings. In the case of the researched facility, there was just surface backwater in the form of flooded mining pits, i.e., index 3. ISW was therefore assigned a value of 3.

- Groundwater vulnerability assessment (IUW) was carried out for:

- ○

- Rock environment of the collector—the rock environment at the evaluated location is porous and penetrable in the unpaved area, mostly gravel-sand sediments, with hydraulic connection to surface flow. In this case, contamination risk is very high and the point value assigned was 5.

- ○

- Cover character—the evaluated location is without a cover and with a permeable cover layer, which corresponds to a point value of 5.

- ○

- Protection degree—the assessed location belongs to the protected area of natural water accumulation, which was rated by 2 points.

- ○

- Collector water management importance (according to hydrological maps)—the use of groundwater in the location has the character of concentrated extractions of smaller regional importance (minor group waters). A point value of 4 was assigned to this characteristic.

- Determination of the soil environment vulnerability (IS)—the bonity of the soil-ecological unit was not determined in the location, as it is not agricultural land. The soil map of the Czech Republic was used as an alternative. It follows that these are highly susceptible alluvial soils with an IS index of a value of 4.

- Determination of the environmental biotic component vulnerability (IB)—vulnerability assesses the ecological value of the environment. The evaluated facility is located in the protected landscape area; therefore, the IB index was set at the value of 5.

3.2.4. Synthesis of Hazard and Vulnerability Indices

- Calculation of the substance toxicity index for the surface water (ITSW) was calculated using the Formula (1):

- ISW—Surface water vulnerability index

- TW—Substance toxic hazard index for the aquatic environment

- IS—Soil environment vulnerability index

- Calculation of the substance toxicity index for the groundwater (ITUW) was calculated using the Formula (2):

- IUW—Groundwater vulnerability index

- TW—Substance toxic hazard index for the aquatic environment

- IS—Soil environment vulnerability index

- Calculation of the substance toxicity index for the biotic environmental component (ITB) was calculated using the Formula (3):

- TB—Substance toxic hazard index for the biotic environmental component

- IB—Biotic environmental component vulnerability index

- Calculation of the substance toxicity index for the soil environment (ITS) was calculated using the Formula (4):

- TS—Substance toxic hazard index for the soil environment

- IS—Soil environment vulnerability index

- Calculation of the substance flammability impact index on the biotic environmental component (IFR) was calculated using the Formula (5):

- FR Substance flammability hazard index for the biotic environmental component

- IB Biotic environmental component vulnerability index

3.2.5. Assessment of the Substance Amount Leakage into the Environment, Accident Severity Determination, and Acceptability Assessment

3.2.6. Acceptability Determination

3.3. Suggestions and Recommendations

3.4. Discussion

4. Conclusions

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Padmalal, D.; Maya, K. Sand Mining: Environmental Impacts and Selected Case Studies, 1st ed.; Springer: Berlin, Germany, 2014; ISBN 978-94-017-9144-1. [Google Scholar]

- Peduzzi, P. Sand, Rarer than one thinks. Environ. Dev. 2014, 11, 208–218. [Google Scholar] [CrossRef]

- Baird, J.; Schultz, L.; Plummer, R.; Armitage, D.; Bodin, Ö. Emergence of Collaborative Environmental Governance: What are the Causal Mechanisms? Environ. Manag. 2019, 63, 16–31. [Google Scholar] [CrossRef] [PubMed]

- UNEP. Sand and Sustainability: Finding New Solutions for Environmental Governance of Global Sand Resources; United Nations Environment Programme: Geneva, Switzerland, 2019; ISBN 978-92-807. Available online: https://wedocs.unep.org/handle/20.500.11822/28163 (accessed on 10 February 2021).

- Gavriletea, M. Environmental Impacts of Sand Exploitation. Analysis of Sand Market. Sustainability 2017, 9, 1118. [Google Scholar] [CrossRef]

- Cousins, S.; Schultz, L.; Plummer, R.; Armitage, D.; Bodin, Ö. Shifting sand: Why we’re running out of aggregate. Constr. Res. Innov. 2019, 10, 69–71. [Google Scholar] [CrossRef]

- Mitterpach, J.; Hroncová, E.; Ladomerský, J.; Balco, K. Identification of Significant Impact of Silicon Foundry Sands Mining on LCIA: Why we’re running out of aggregate. Sustainability 2015, 7, 16408–16421. [Google Scholar] [CrossRef]

- Development Application—Environmental Effects Report and Planning Information; Manuka Park—Sand Extraction, Waterhouse Road. Environmental Protection Authority; Van Diemen Consulting: New Town, TAS, Australia, 2019; [cit. 2021-03-09]. Available online: https://epa.tas.gov.au/Documents/E%20J%20Hall%20-%20Sand%20Extraction%20-%201259%20Waterhouse%20Road%20-%20Waterhouse%20-%20EER.pdf (accessed on 10 February 2021).

- Kowalska, A.; Sobczyk, W. Negative and Positive Effects of the Exploitation of Gravel-Sand. Inżynieria Min. 2014, 15, 105–109. [Google Scholar]

- Bayram, A.; Önsoy, H. Sand and gravel mining impact on the surface water quality: A case study from the city of Tirebolu (Giresun Province, NE Turkey). Environ. Earth Sci. 2015, 73, 1997–2011. [Google Scholar] [CrossRef]

- Koehnken, L.; Rintoul, M. Impacts of Sand Mining on Ecosystem Structure, Process and Biodiversity in Rivers; WWF: Gland, Switzerland, 2018; ISBN 978-2-940529-88-9. [Google Scholar]

- Farahani, H.; Bayazidi, S. Modeling the assessment of socio-economic and environmental impacts of sand mining on local communities: A case study of Villages Tatao River Bank in North-western part of Iran. Resour. Policy 2018, 55, 87–95. [Google Scholar] [CrossRef]

- Tiainen, H.; Sairinen, R.; Novikov, V. Mining in the Chatkal Valley in Kyrgyzstan—Challenge of social sustainability. Resour. Policy 2014, 39, 80–87. [Google Scholar] [CrossRef]

- Grbeš, A. A Life Cycle Assessment of Silica Sand: Comparing the Beneficiation Processes. Sustainability 2016, 8, 11. [Google Scholar] [CrossRef]

- Bebbington, A.; Bebbington, D.H.; Bury, J.; Lingan, J.; Muñoz, J.P.; Scurrah, M. Mining and Social Movements: Struggles Over Livelihood and Rural Territorial Development in the Andes. World Dev. 2008, 36, 2888–2905. [Google Scholar] [CrossRef]

- Canel, E.; Idemudia, U.; North, L.L. Rethinking Extractive Industry: Regulation, Dispossession, and Emerging Claims. Can. J. Dev. Stud. Rev. Can. d’Études Dev. 2011, 30, 5–25. [Google Scholar] [CrossRef]

- Navrátil, J.; Sadovská, V.; Švarcová, I. Health Risk Assessment of Combustion Products from Simulated Residential Fire. In Mathematical-Statistical Models and Qualitative Theories for Economic and Social Sciences; Studies in Systems, Decision and Control; Springer International Publishing: Cham, Switzerland, 2017; pp. 15–23. [Google Scholar] [CrossRef]

- Le Bot, S.; Lafite, R.; Fournier, M.; Baltzer, A.; Desprez, M. Morphological and sedimentary impacts and recovery on a mixed sandy to pebbly seabed exposed to marine aggregate extraction (Eastern English Channel, France). Estuar. Coast. Shelf. Sci. 2010, 89, 221–233. [Google Scholar] [CrossRef]

- Kondolf, G.M. PROFILE: Hungry Water. Environ. Manag. 1997, 21, 533–551. [Google Scholar] [CrossRef]

- Koehnken, L.; Rintoul, M.S.; Goichot, M.; Tickner, D.; Loftus, A.-C.; Acreman, M.C. Impacts of riverine sand mining on freshwater ecosystems: A review of the scientific evidence and guidance for future research. River Res. Appl. 2020, 36, 362–370. [Google Scholar] [CrossRef]

- Lai, X.; Shankman, D.; Huber, C.; Yesou, H.; Huang, Q.; Jiang, J. Sand mining and increasing Poyang Lake’s discharge ability: A reassessment of causes for lake decline in China. J. Hydrol. 2014, 519, 1698–1706. [Google Scholar] [CrossRef]

- Nasrabadi, T.; Ruegner, H.; Sirdari, Z.Z.; Schwientek, M.; Grathwohl, P. Using total suspended solids (TSS) and turbidity as proxies for evaluation of metal transport in river water. Appl. Geochem. 2016, 68, 1–9. [Google Scholar] [CrossRef]

- Shegelman, I.R.; Vasilev, A.S.; Krupko, A.M. Logistics Linking Territories—Producers of Raw Materials and Territories—Producers of Final Products. J. Environ. Treat. Tech. 2020, 8, 727–734. [Google Scholar]

- Ranta, T.; Rinne, S. The profitability of transporting uncomminuted raw materials in Finland. Biomass Bioenergy 2006, 30, 231–237. [Google Scholar] [CrossRef]

- Al-Nuaimi, S.; Banawi, A.-A.A.; Al-Ghamdi, S.G. Environmental and Economic Life Cycle Analysis of Primary Construction Materials Sourcing under Geopolitical Uncertainties: A Case Study of Qatar. Sustainability 2019, 11, 6000. [Google Scholar] [CrossRef]

- Road Transport: Reducing CO2 Emissions from Vehicles; European Commission: Brussels, Belgium, 2020; Available online: https://ec.europa.eu/clima/policies/transport/vehicles_en (accessed on 5 March 2021).

- Kletz, T.; Amyotte, P. What Went Wrong? Case Histories of Process Plant Disasters and How They Could Have Been Avoided, 6th ed.; Elsevier: Oxford, UK, 2019; p. 840. ISBN 978-0-12-810539-9. [Google Scholar]

- Taveau, J. Explosion of fixed roof atmospheric storage tanks, part 1: Background and review of case histories. Process Saf. Prog. 2011, 30, 381–392. [Google Scholar] [CrossRef]

- Argyropoulos, C.D.; Christolis, M.N.; Nivolianitou, Z.; Markatos, N.C. A hazards assessment methodology for large liquid hydrocarbon fuel tanks. J. Loss Prev. Process Ind. 2012, 25, 329–335. [Google Scholar] [CrossRef]

- IEC 61882:2016 Hazard and Operability Studies (HAZOP Studies)—Application Guide, 2nd ed.; International Organization for Standardization: Geneva, Switzerland, 2016.

- ISO 31010:2019 Risk Management—Risk Management Techniques, 2nd ed.; International Organization for Standardization: Geneva, Switzerland, 2019.

- IEC 60812:2018 Failure Modes and Effects Analysiss (FMEA and FMECA), 2nd ed.; International Organization for Standardization: Geneva, Switzerland, 2018.

- IEC 61025:2006 Fault Tree Analysis (FTA), 1st ed.; International Organization for Standardization: Geneva, Switzerland, 2018.

- IEC 62502:2010 Analysis Techniques for Dependability—Event Tree Analysis (ETA), 1st ed.; International Organization for Standardization: Geneva, Switzerland, 2010.

- Lewis, D.J. The Mond Fire, Explosion and Toxicity Index Applied to Plant Layout and Spacing. Loss Prev. 1980, 13, 20–26. [Google Scholar]

- Pouyakian, M.; Jafari, M.J.; Laal, F.; Nourai, F.; Zarei, E. A comprehensive approach to analyze the risk of floating roof storage tanks. Process Saf. Environ. Prot. 2021, 146, 811–836. [Google Scholar] [CrossRef]

- Tejaswi, D.; Samuel, C. Techniques for Environmental Risk Assessment: A review. Rasayan J. Chem. 2017, 10, 499–506. [Google Scholar]

- Fuentes-Bargues, J.L.; Bastante-Ceca, M.J.; Ferrer-Gisbert, P.S.; González-Cruz, M.C. Study of Major-Accident Risk Assessment Techniques in the Environmental Impact Assessment Process. Sustainability 2020, 12, 5770. [Google Scholar] [CrossRef]

- Chen, F.-Z.; Zhang, M.-G.; Song, J.; Zheng, F. Risk Analysis on Domino Effect Caused by Pool Fire in Petroliferous Tank Farm. Procedia Eng. 2018, 211, 46–54. [Google Scholar] [CrossRef]

- Misuri, A.; Antonioni, G.; Cozzani, V. Quantitative risk assessment of domino effect in Natech scenarios triggered by lightning. J. Loss Prev. Process Ind. 2020, 64, 104095. [Google Scholar] [CrossRef]

- Baser, B.; Behnam, B. An emergency response plan for cascading post-earthquake fires in fuel storage facilities. J. Loss Prev. Process Ind. 2020, 65, 104155. [Google Scholar] [CrossRef]

- Korkmaz, K.A.; Sari, A.; Carhoglu, A.I. Seismic risk assessment of storage tanks in Turkish industrial facilities. J. Loss Prev. Process Ind. 2011, 24, 314–320. [Google Scholar] [CrossRef]

- Ahmadi, O. Survey of Accident Analysis Methods and Develop Optimal Method for Use in the Petroleum Industry. Ph.D. Thesis, Tarbiat Modares University, Tehran, Iran, August 2016; p. 210. Available online: https://parseh.modares.ac.ir/thesis/3203787 (accessed on 10 February 2021).

- Nasarwanji, M.F.; Sun, K. Burden associated with nonfatal slip and fall injuries in the surface stone, sand, and gravel mining industry. Saf. Sci. 2019, 120, 625–635. [Google Scholar] [CrossRef]

- Sikorova, K.; Bernatik, A.; Lunghi, E.; Fabiano, B. Lessons learned from environmental risk assessment within the framework of Seveso Directive in Czech Republic and Italy. J. Loss Prev. Process Ind. 2017, 49, 47–60. [Google Scholar] [CrossRef]

- Ecological Risk Assessment. Available online: https://www.epa.gov/risk/ecological-risk-assessment#self (accessed on 1 May 2021).

- Gormley, Á.; Pollard, S.; Rocks, S. Guidelines for Environmental Risk Assessment and Management: Green Leaves III, 1st ed.; Cranfield University: Cranfield, UK, 2011; Available online: https://assets.publishing.service.gov.uk/government/uploads/system/uploads/attachment_data/file/69450/pb13670-green-leaves-iii-1111071.pdf (accessed on 1 May 2021).

- Environmental Risk Assessment (ERA): An Approach for Assessing and Reporting Environmental Conditions, 1st ed.; Ministry of Environment, Habitat Branch: Victoria, BC, Canada, 2000; p. 70. ISBN 0-7726-4327-X.

- Environmental Risk Assessment: An Australian Perspective. Available online: https://www.environment.gov.au/science/supervising-scientist/publications/ssr/environmental-risk-assessment-australian-perspective (accessed on 1 May 2021).

- Vora, M.; Sanni, S.; Flage, R. An environmental risk assessment framework for enhanced oil recovery solutions from offshore oil and gas industry. Environ. Impact Assess. Rev. 2021, 88, 106512. [Google Scholar] [CrossRef]

- Robu, B.M.; Căliman, F.A.; Beţianu, C.; Gavrilescu, M. Methods and procedures for environmental risk assessment. Environ. Eng. Manag. J. 2007, 6, 573–592. [Google Scholar] [CrossRef]

- Tubis, A.; Werbińska-Wojciechowska, S.; Wroblewski, A. Risk Assessment Methods in Mining Industry—A Systematic Review. Appl. Sci. 2020, 10, 5172. [Google Scholar] [CrossRef]

- Kim, J.-H.; Yoo, S.-H. Public perspective on the environmental impacts of sea sand mining: Evidence from a choice experiment in South Korea. Resour. Policy 2020, 69, 101811. [Google Scholar] [CrossRef]

- Zeisl, Y. Salient Risk of Sand Mining: Consumption, Construction, and Compliance, 1st ed.; Global Risk Intelligence: Washington, DC, USA, 2019; p. 24. Available online: https://www.globalriskintel.com/reports/salient-risks-sand-mining-consumption-construction-and-compliance (accessed on 29 April 2021).

- Vukadinović, K.; Teodorović, D.; Pavković, G. A neural network approach to the vessel dispatching problém. Eur. J. Oper. Res. 1997, 102, 473–487. [Google Scholar] [CrossRef]

- Directive 2004/35/CE of the European Parliament and of the Council of 21 April 2004 on Environmental Liability with Regard to the Prevention and Remedying of Environmental Damage. Available online: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=CELEX:32004L0035&from=CS (accessed on 29 April 2021).

- Report on the Application of Directive 2004/35/EC of the European Parliament and of the Council of 21 April 2004 on Environmental Liability with Regard to the Prevention and Remedying of Environmental Damage (the ‘ELD’). Available online: https://www.europarl.europa.eu/doceo/document/A-8-2017-0297_EN.html (accessed on 29 April 2021).

- Act No. 167/2008 Sb., Act on Prevention and Remedying Environmental Damage. In Collection of Laws; Ministry of the Interior of the Czech Republic: Prague, Czech Republic, 2008. (In Czech)

- Government Regulation No. 295/2011 Sb., Government Regulation on the Method of Risk Assessment of Environmental Damage and Detailed Conditions for Financial Security. In Collection of Laws; Ministry of the Interior of the Czech Republic: Prague, Czech Republic, 2011. (In Czech)

- Leopold, L.B.; Clarke, F.E.; Hanshaw, B.B.; Balsley, J.R. A procedure for Evaluating Environment Impact, 1st ed.; Geological Survey: Washington, DC, USA, 1971. [Google Scholar]

- Al-Nasrawi, F.A.; Kareem, S.L.; Saleh, L.A. Using the Leopold Matrix Procedure to Assess the Environmental Impact of Pollution from Drinking Water Projects in Karbala City, Iraq. In Proceedings of the IOP Conference Series: Materials Science and Engineering, Kerbala, Iraq, 4–6 November 2019; Volume 671. 11p. [Google Scholar]

- Fanelli, P. Safety and Environmental Standards for Fuel Storage Sites: How to enhance the Safety Integrity of an Overfill Protection System for Flammable Fuel Storage Tanks. Chem. Eng. Trans. 2012, 26, 435–440. [Google Scholar]

- Center for Chemical Process Safety. Guidelines for Initiating Events and Independent Protection Layers in Layer of Protection Analysis, 1st ed.; Wiley: New York, NY, USA, 2014; ISBN 978-0-470-34385-2. [Google Scholar]

- Willey, R.J. Layer of Protection Analysis. Procedia Eng. 2014, 84, 12–22. [Google Scholar] [CrossRef]

- Danihelka, P.; Sikorova, K.; Tomasova, B. Analysis of chemical accident impact on environment. In Proceedings of the International Conference on Safety and Reliability ESREL, Estoril, Portugal, 18–22 September 2006; Taylor & Francis Group: London, UK, 2006; pp. 2233–2237. [Google Scholar]

- Blažková, K.; Danihelka, P. Methodology for Environmental Impact Assessment of Accidents Involving a Hazardous Substance on the Environment: The H&V Index II; Ministry of the Environment of the Czech Republic: Prague, Czech Republic, 2020. (In Czech)

- Andersson, A.S.; Tysklind, M.; Fangmark, I. A method to relate chemical accident properties and expert judgements in order to derive useful information for the development of Environment-Accident Index. J. Hazard. Mater. 2007, 147, 524–533. [Google Scholar] [CrossRef] [PubMed]

- Scott, Å. Environment–accident index: Validation of a model. J. Hazard. Mater. 1998, 61, 305–312. [Google Scholar] [CrossRef]

- Manual for the Classification and Prioritization of Risks due to Major Accidents in Process and Related Industries; IAEA: Vienna, Austria, 1996; ISSN 1011-4289.

- Act No. 224/2015 Sb., Act on the Prevention of Major Accidents. In Collection of Laws; Ministry of the Interior of the Czech Republic: Prague, Czech Republic, 2015. (In Czech)

- Catastrophic Floods in the Czech Republic in August 2002; Ministry of the Environment of the Czech Republic: Prague, Czech Republic, 2005; ISBN 80-7212-350-5. (In Czech)

- Albris, K.; Lauta, K.C.; Raju, E. Strengthening Governance for Disaster Prevention: The Enhancing Risk Management Capabilities Guidelines. Int. J. Disaster Risk Reduct. 2020, 47, 101647. [Google Scholar] [CrossRef]

- Zhang, Y.-L.; Byeon, H.-S.; Hong, W.-H.; Cha, G.-W.; Lee, Y.-H.; Kim, Y.-C. Risk assessment of asbestos containing materials in a deteriorated dwelling area using four different methods. J. Hazard. Mater. 2021, 410, 124645. [Google Scholar] [CrossRef]

- Prasad, D.; Reddy, A.R.; Balan, A.S.S.; Joel, J.; Thangaraja, J. Evaluation of Material Characteristics of Fuel Tank Material Utilized for Agricultural Applications with Biofuels. Mater. Today Proc. 2018, 5, 13682–13686. [Google Scholar] [CrossRef]

- Stewart, M. The application of life cycle assessment to mining, minerals and metals. In Report of the MMDS Workshop on Life Cycle Assessment; Minerals and Sustainable Development (MMSD) Project; International Institute for Environment and Development: London, UK, 2001; Available online: http://pubs.iied.org/pdfs/G00942.pdf (accessed on 1 May 2021).

| Environmental Component | Method | |||

|---|---|---|---|---|

| Leopold Matrix | Environmental Damage Assessment | H&V Index II | EAI | |

| Surface water | ✓ | ✓ | ✓ | ✓ |

| Groundwater | ✓ | ✓ | ✓ | ✓ |

| Soil | ✓ | ✓ | ✓ | ✓ |

| Biotic | ✓ | ✓ | ✓ | - |

| Athmosphere | ✓ | - | - | - |

| Amount of input data needed | 0, qualified estimate | >20 | >10 | 5–10 |

| Time demandingness | Easy | Medium | Time consuming | Easy |

| Assessment Part | Assessment Phase Characteristics | Points According to the Government Regulation | Assigned Points |

|---|---|---|---|

| Part B, Point 5 | Quantities of chemicals and mixtures (d) dangerous for the environment R51, R-52, R-53, R-54, R-55, and R-56, H411, H412, H413 | 10 | 0 |

| Subtotal of Part B | 0 | ||

| Part D, Point 18 | Identification of possible scenarios of environmental damage for the evaluated operational activity: leakage of a liquid substance into soil/water | 5 | 5 |

| Part D, Point 19 | The possible consequences of the scenario identified in Point 18 will manifest themselves as ecological damage to: | ||

| Water | 5 | 5 | |

| Soil | 2 | 2 | |

| Part D, Point 20 | The severity of possible consequences of environmental damage identified in Point 19: Significant | 5 | 5 |

| Subtotal of Part D | 17 | ||

| Part E, Point 21 | Existence of previous unauthorized interventions, accidents, or environmental damage that occurred in the past 10 years due to: | ||

| Technical defect | 5 | 0 | |

| Human factor failure | 3 | 0 | |

| External causes | 2 | 0 | |

| Part E, Point 22 | The consequences of previous unauthorized interventions, accidents, or environmental damage listed in Point 21 were reflected in: | ||

| Water | 5 | 0 | |

| Soil | 2 | 0 | |

| Protected species or natural habitat | 5 | 0 | |

| Part E, Point 23 | The consequences of previous unauthorized interventions, accidents, or environmental damage listed in Point 22 were: | ||

| Insignificant costs for liquidation of consequences below CZK 1 million | 2 | 0 | |

| Part E, Point 24 | The operator has not taken any preventive measures or does not have a detection device installed to prevent environmental damage | 5 | 0 |

| Subtotal of Part E | 0 | ||

| Part F | Total number of points achieved | 17 | |

| Index Value | Index Type | |||

|---|---|---|---|---|

| ISW | IUW | IS | IB | |

| 5 | X | |||

| 4 | X | X | ||

| 3 | X | |||

| 2 | ||||

| 1 | ||||

| Amount of Leaked Substance (t) | |||||||

|---|---|---|---|---|---|---|---|

| ˂1 | 1–5 | 5–10 | 10–50 | 50–200 | ˃200 | ||

| ITSW | 1 | A | A | A | B | B | C |

| 2 | A | B | B | C | C | D | |

| 3 | B | C | C | C | D | E | |

| 4 | B | C | C | D | E | E | |

| 5 | C | D | D | E | E | E | |

| Amount of Leaked Substance (t) | |||||||

|---|---|---|---|---|---|---|---|

| ˂1 | 1–5 | 5–10 | 10–50 | 50–200 | ˃200 | ||

| ITS | 1 | A | A | A | B | B | C |

| 2 | A | B | B | C | C | D | |

| 3 | B | C | C | C | D | E | |

| 4 | B | C | C | D | E | E | |

| 5 | C | D | D | E | E | E | |

| Amount of Leaked Substance (t) | |||||||

|---|---|---|---|---|---|---|---|

| ˂1 | 1–5 | 5–10 | 10–50 | 50–200 | ˃200 | ||

| ITUW | 1 | A | A | A | B | B | C |

| 2 | A | B | B | C | C | D | |

| 3 | B | C | C | C | D | E | |

| 4 | B | C | C | D | E | E | |

| 5 | C | D | D | E | E | E | |

| Amount of Leaked Substance (t) | |||||||

|---|---|---|---|---|---|---|---|

| ˂1 | 1–5 | 5–10 | 10–50 | 50–200 | ˃200 | ||

| ITB | 1 | A | A | A | B | B | C |

| 2 | A | B | B | C | C | D | |

| 3 | B | C | C | C | D | E | |

| 4 | B | C | C | D | E | E | |

| 5 | C | D | D | E | E | E | |

| Amount of Leaked Substance (t) | |||||||

|---|---|---|---|---|---|---|---|

| ˂1 | 1–5 | 5–10 | 10–50 | 50–200 | ˃200 | ||

| IFR | 1 | A | A | A | B | B | C |

| 2 | A | A | A | B | C | C | |

| 3 | A | A | A | B | C | C | |

| 4 | A | A | B | C | C | D | |

| 5 | A | B | B | C | D | E | |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Oulehlova, A.; Tušer, I.; Rehak, D. Environmental Risk Assessment of a Diesel Fuel Tank: A Case Study. Sustainability 2021, 13, 6537. https://doi.org/10.3390/su13126537

Oulehlova A, Tušer I, Rehak D. Environmental Risk Assessment of a Diesel Fuel Tank: A Case Study. Sustainability. 2021; 13(12):6537. https://doi.org/10.3390/su13126537

Chicago/Turabian StyleOulehlova, Alena, Irena Tušer, and David Rehak. 2021. "Environmental Risk Assessment of a Diesel Fuel Tank: A Case Study" Sustainability 13, no. 12: 6537. https://doi.org/10.3390/su13126537

APA StyleOulehlova, A., Tušer, I., & Rehak, D. (2021). Environmental Risk Assessment of a Diesel Fuel Tank: A Case Study. Sustainability, 13(12), 6537. https://doi.org/10.3390/su13126537