Digital Product–Service Innovation and Sustainability: A Multiple-Case Study in the Capital Goods Industry

Abstract

1. Introduction

2. Literature Review

2.1. Product–Service Innovation and Service Categorisation

2.2. Digitalisation and Product–Service Innovation

2.3. Supply-Chain Integration and PSI

2.4. Sustainability in Digital PSI

2.4.1. Economic Sustainability

2.4.2. Environmental Sustainability

2.4.3. Social Sustainability

3. Methodology

3.1. Research Framework

3.2. Case Selection

3.3. Data Collection and Analysis Process

4. Results: Impact of Digital Services on Sustainability for Manufacturing Companies

4.1. Identification of the Services

4.2. Impact of Digitalisation on Services

4.3. Role of SCI Dimensions in the Different Services

4.4. Sustainability

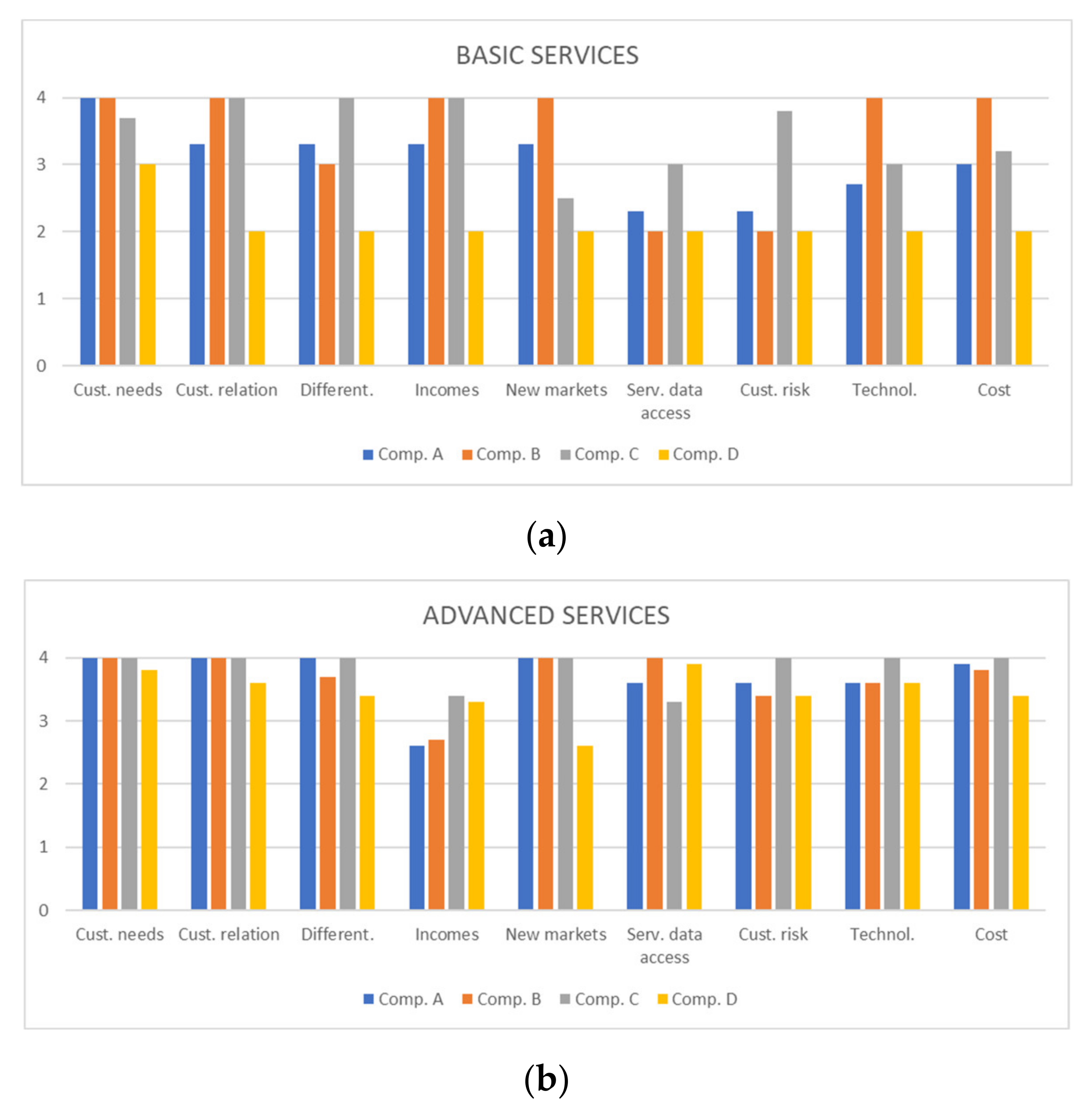

4.4.1. Economic Sustainability

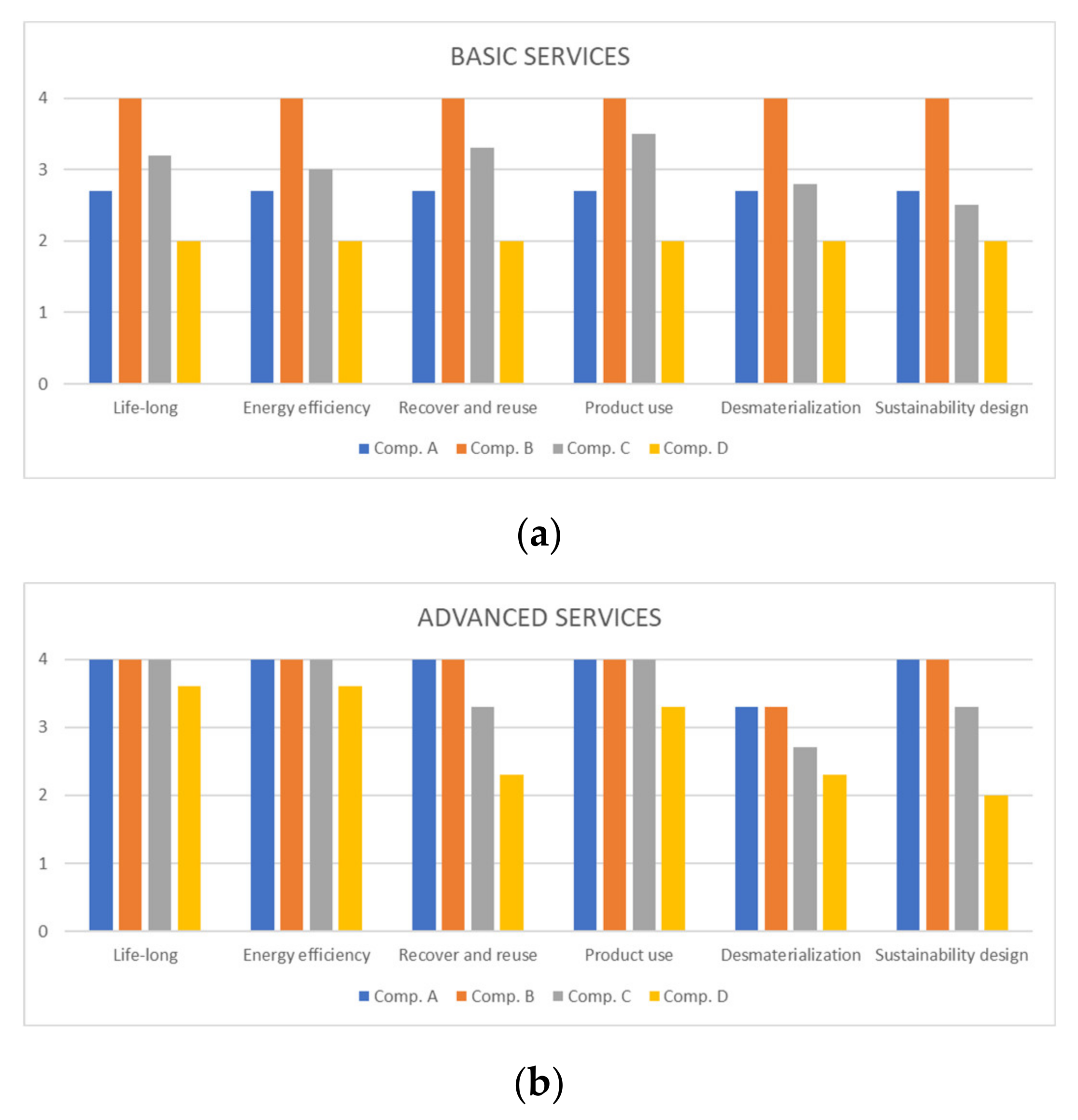

4.4.2. Environmental Sustainability

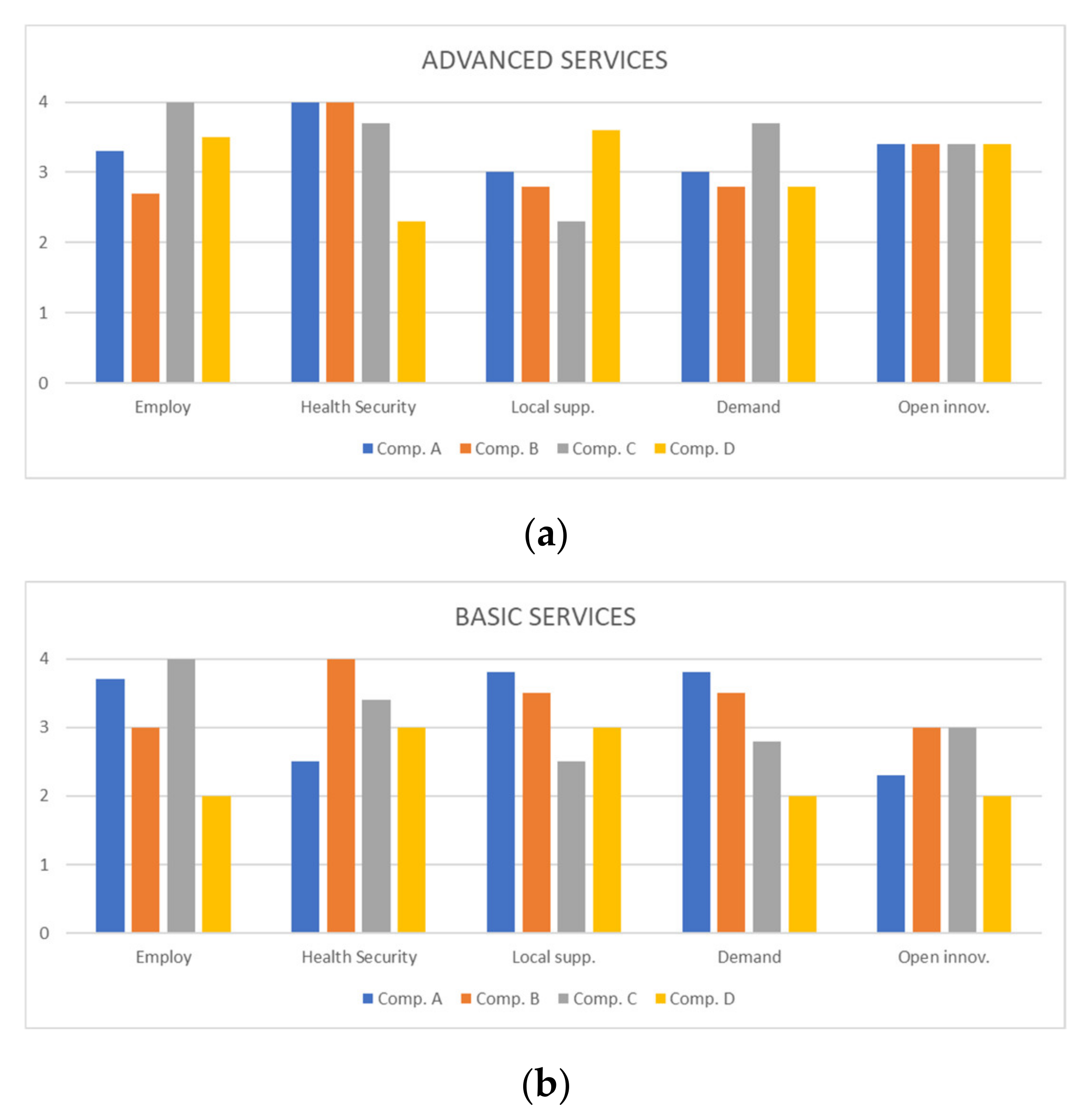

4.4.3. Social Sustainability

5. Conclusions

5.1. Theoretical Implications

5.2. Managerial and Policy Implications

5.3. Limitations and Future Research

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Conflicts of Interest

References

- Goedkoop, M.J.; Van Halen, C.J.; Te Riele, H.R.; Rommens, P.J. Product service systems, ecological and economic basics. Rep. Dutch Minist. Environ. (VROM) Econ. Aff. (EZ) 1999, 36, 1–122. [Google Scholar]

- Porter, M.E.; Heppelmann, J.E. How smart, connected products are transforming competition. Harv. Bus. Rev. 2014, 92, 64–88. [Google Scholar]

- Parida, V.; Sjödin, D.R.; Lenka, S.; Wincent, J. Developing Global Service Innovation Capabilities: How Global Manufacturers Address the Challenges of Market Heterogeneity. Res. Technol. Manag. 2015, 58, 35–44. [Google Scholar] [CrossRef]

- Parida, V.; Wincent, J. Why and how to compete through sustainability: A review and outline of trends influencing firm and network-level transformation. Int. Entrep. Manag. J. 2019, 15, 1–19. [Google Scholar] [CrossRef]

- Lundvall, B.-A. Innovation as an interactive process: From user-producer interaction to the national system of innovation. In Technical Change and Economic Theory; Dosi, G., Freeman, C., Nelson, R., Silverberg, G., Soete, L., Eds.; Pinter Publishers: London, UK, 1988; pp. 349–369. [Google Scholar]

- Matthyssens, P.; Vandenbempt, K. Moving from basic offerings to value-added solutions: Strategies, barriers and alignment. Ind. Mark. Manag. 2008, 37, 316–328. [Google Scholar] [CrossRef]

- Manzini, E.; Vezzoli, C. A strategic design approach to develop sustainable product service systems: Examples taken from the ‘environmentally friendly innovation’ Italian prize. J. Clean. Prod. 2003, 11, 851–857. [Google Scholar] [CrossRef]

- Tukker, A. Product services for a resource-efficient and circular economy—A review. J. Clean. Prod. 2015, 97, 76–91. [Google Scholar] [CrossRef]

- Hallstedt, S.I.; Isaksson, O.; Öhrwall Rönnbäck, A. The Need for New Product Development Capabilities from Digitalization, Sustainability, and Servitization Trends. Sustainability 2020, 12, 10222. [Google Scholar] [CrossRef]

- Vandermerwe, S.; Rada, J. Servitization of business: Adding value by adding services. Eur. Manag. J. 1988, 6, 314–324. [Google Scholar] [CrossRef]

- Suarez, F.F.; Cusumano, M.A.; Kahl, S. Services and the business models of product firms: An empirical analysis of the software industry. Manag. Sci. 2013, 59, 420–435. [Google Scholar] [CrossRef]

- Bustinza, O.F.; Gomes, E.; Vendrell-Herrero, F.; Baines, T. Product–service innovation and performance: The role of collaborative partnerships and R&D intensity. R&D Manag. 2019, 49, 33–45. [Google Scholar] [CrossRef]

- Carlborg, P.; Kindström, D.; Kowalkowski, C. The evolution of service innovation research: A critical review and synthesis. Serv. Ind. J. 2014, 34, 373–398. [Google Scholar] [CrossRef]

- Martinez, V.; Bastl, M.; Kingston, J.; Evans, S. Challenges in transforming manufacturing organisations into product-service providers. J. Manuf. Technol. Manag. 2010, 21, 449–469. [Google Scholar] [CrossRef]

- Visnjic, I.K.; van Looy, B. Servitization: Disentangling the impact of service business model innovation on manufacturing firm performance. J. Oper. Manag. 2013, 31, 169–180. [Google Scholar] [CrossRef]

- Golara, S. Product-Service Bundling in Manufacturing Firms. Ph.D. Thesis, Arizona State University, Tempe, AZ, USA, 2018. [Google Scholar]

- Dachs, B.; Biege, S.; Borowiecki, M.; Lay, G.; Jäger, A.; Schartinger, D. Servitisation of European manufacturing: Evidence from a large scale database. Serv. Ind. J. 2014, 34, 5–23. [Google Scholar] [CrossRef]

- Cusumano, M.A. Staying Power; Oxford University Press: Oxford, UK, 2010. [Google Scholar]

- Cusumano, M.A.; Kahl, S.J.; Suarez, F.F. Services, industry evolution, and the competitive strategies of product firms. Strateg. Manag. J. 2015, 36, 559–575. [Google Scholar] [CrossRef]

- Gebauer, H.; Haldimann, M.; Saul, C.J. Competing in business-to-business sectors through pay-per-use services. J. Serv. Manag. 2017, 28, 914–935. [Google Scholar] [CrossRef]

- Mont, O.K. Clarifying the concept of product–service system. J. Clean. Prod. 2002, 10, 237–245. [Google Scholar] [CrossRef]

- Baines, T.S.; Lightfoot, H.W.; Evans, S.; Neely, A.; Greenough, R.; Peppard, J.; Roy, R.; Shehab, E.; Braganza, A.; Tiwari, A.; et al. State-of-the-art in product-service systems. Proc. Inst. Mech. Eng. J. Eng. Manuf. 2007, 221, 1543–1552. [Google Scholar] [CrossRef]

- Tukker, A.; Tischner, U. Product-services as a research field: Past, present and future. Reflections from a decade of research. J. Clean. Prod. 2006, 14, 1552–1556. [Google Scholar] [CrossRef]

- Kohtamäki, M.; Parida, V.; Oghazi, P.; Gebauer, H.; Baines, T. Digital servitization business models in ecosystems: A theory of the firm. J. Bus. Res. 2019, 104, 380–392. [Google Scholar] [CrossRef]

- Mastrogiacomo, L.; Barravecchia, F.; Franceschini, F. Definition of a conceptual scale of servitization: Proposal and preliminary results. CIRP J. Manuf. Sci. Technol. 2018, 29, 141–156. [Google Scholar] [CrossRef]

- Mathieu, V. Product Services: From a Service Supporting the Product to a Service Supporting the Client. J. Bus. Ind. Mark. 2001, 16, 39–61. [Google Scholar] [CrossRef]

- Tukker, A. Eight Types of Product-service System: Eight Ways to Sustainability? Experiences from Suspronet. Bus. Strategy Environ. 2004, 13, 246–260. [Google Scholar] [CrossRef]

- Baines, T.; Lightfoot, H. Made to Serve: How Manufacturers Can Compete through Servitization and Product Service Systems; John Wiley and Sons: Chichester, UK, 2013; pp. 1–270. [Google Scholar]

- Brax, S.A.; Visintin, F. Value Constellations in Servitization. In Practices and Tools for Servitization; Kohtamäki, M., Baines, T., Rabetino, R., Bigdeli, A., Eds.; Palgrave Macmillan: Cham, Switzerland, 2018. [Google Scholar] [CrossRef]

- Brax, S.A.; Visintin, F. Meta-model of servitization: The integrative profiling approach. Ind. Mark. Manag. 2017, 60, 17–32. [Google Scholar] [CrossRef]

- Bustinza, O.F.; Vendrell-Herrero, F.; Sánchez-Montesinos, F.J.; Campos-Granados, J.A. Should Manufacturers Support the Entire Product Lifecycle with Services? Sustainability 2021, 13, 2493. [Google Scholar] [CrossRef]

- Oliva, R.; Kallenberg, R. Managing the transition from products to services. Int. J. Serv. Ind. Manag. 2003, 14, 160–172. [Google Scholar] [CrossRef]

- Kindström, D.; Kowalkowski, C. Service innovation in product-centric firms: A multidimensional business model perspective. J. Bus. Ind. Mark. 2014, 29, 96–111. [Google Scholar] [CrossRef]

- Martinez, V.; Neely, A.; Velu, C.; Leinster-Evans, S.; Bisessar, D. Exploring the journey to services. Int. J. Prod. Econ. 2017, 192, 66–80. [Google Scholar] [CrossRef]

- Mastrogiacomo, L.; Barravecchia, F.; Franceschini, F. A General Overview of Manufacturing Servitization in Italy. Procedia CIRP 2017, 64, 121–126. [Google Scholar] [CrossRef]

- Paschou, T.; Adrodegari, F.; Perona, M.; Sacceni, N. The digital servitization of manufacturing: Literature review and research agenda. In Proceedings of the 27th RESER Conference Bilbao, Bilbao, Spain, 7–9 September 2017; Available online: https://www.researchgate.net/publication/319628925_The_digital_servitization_of_manufacturing_a_literature_review_and_research_agenda (accessed on 5 March 2021).

- Kowalkowski, C.; Gebauer, H.; Oliva, R. Service growth in product firms: Past, present and future. Ind. Mark. Manag. 2017, 60, 82–88. [Google Scholar] [CrossRef]

- Porter, M.E.; Heppelmann, J.E. How smart, connected products are transforming companies. Harv. Bus. Rev. 2015, 93, 96–114. [Google Scholar]

- Khan, M.A.; West, S.; Wuest, T. Midlife upgrade of capital equipment: A servitization-enabled, value-adding alternative to traditional equipment replacement strategies. CIRP J. Manuf. Sci. Technol. 2020, 29, 232–244. [Google Scholar] [CrossRef]

- Opazo, M.; Vendrell-Herrero, F.; Bustinza, O.F. Uncovering productivity gains of digital and green servitization: Implications from the automotive industry. Sustainability 2018, 10, 1524. [Google Scholar] [CrossRef]

- Schroeder, A.; Kotlarsky, J. Digital resources and their role in advanced service provision: A VRIN analysis’. In Proceedings of the Spring Servitization Conference, SSC2015, Birmingham, UK, 18–19 May 2015; Available online: https://research.aston.ac.uk/portal/files/17919118/Proceedings_of_the_Spring_Servitization_Conference_SSC2015.pdf (accessed on 5 March 2021).

- Reim, W.; Parida, V.; Örtqvist, D. Producte Service Systems (PSS) business models and tactics-a systematic literature review. J. Clean. Prod. 2015, 97, 61–75. [Google Scholar] [CrossRef]

- Grubic, T. Servitization and remote monitoring technology: A literature review and research agenda. J. Manuf. Technol. Manag. 2014, 25, 100–124. [Google Scholar] [CrossRef]

- Lerch, C.; Gotsch, M. Digitalized Product-Service Systems in Manufacturing Firms: A Case Study Analysis. Res. Technol. Manag. 2015, 58, 45–52. [Google Scholar] [CrossRef]

- Benedettini, O.; Davies, J.; Neely, A. A Capability-Based View of Service Transitions; Working paper; University of Cambridge: Cambridge, UK, 2015; Available online: http://cambridgeservicealliance.eng.cam.ac.uk/Resources/Downloads/Monthly%20Papers/2015April_Capabilitybasedviewofservicetransition.pdf (accessed on 8 March 2021).

- Kowalkowski, C.; Witell, L.; Gustafsson, A. Any way goes: Identifying value constellations for service infusion in SMEs. Ind. Mark. Manag. 2013, 42, 18–30. [Google Scholar] [CrossRef]

- Coreynen, W.; Matthyssens, P.; Van Bockhaven, W. Boosting servitization through digitization: Pathways and dynamic resource configurations for manufacturers. Ind. Mark. Manag. 2016, 60, 42–53. [Google Scholar] [CrossRef]

- Lenka, S.; Parida, V.; Wincent, J. Digitalization capabilities as enablers of value co-creation in servitizing firms. Psychol. Mark. 2017, 34, 92–100. [Google Scholar] [CrossRef]

- De la Calle, A.; Freije, I.; Ugarte, J.V.; Larrinaga, M.Á. Measuring the impact of digital capabilities on product-service innovation in Spanish industries. Int. J. Bus. Environ. 2020, 11, 254–274. [Google Scholar] [CrossRef]

- Nuutinen, M.; Lappalainen, I. Towards service-oriented organisational culture in manufacturing companies. Int. J. Qual. Serv. Sci. 2012, 4, 137–155. [Google Scholar] [CrossRef]

- Flynn, B.; Huo, B.; Zhao, X. The impact of supply chain integration on performance: A contingency and configuration approach. J. Oper. Manag. 2010, 28, 58–71. [Google Scholar] [CrossRef]

- Zhao, X.; Huo, B.; Flynn, B.B.; Yeung, J.H.Y. The impact of power and relationship commitment on the integration between manufacturers and customers in a supply chain. J. Oper. Manag. 2008, 26, 368–388. [Google Scholar] [CrossRef]

- Tarifa-Fernandez, J.; De Burgos-Jiménez, J. Supply chain integration and performance relationship: A moderating effects review. Int. J. Logist. Manag. 2017, 28, 1243–1271. [Google Scholar] [CrossRef]

- Huo, B. The impact of supply chain integration on company performance: An organizational capability perspective. Supply Chain Manag. Int. J. 2012, 17, 596–610. [Google Scholar] [CrossRef]

- Chen, I.J.; Paulraj, A. Towards a theory of supply chain management: The constructs and measurements. J. Oper. Manag. 2004, 22, 119–150. [Google Scholar] [CrossRef]

- Zhao, X.; Huo, B.; Selen, W.; Yeung, J.H.Y. The impact of internal integration and relationship commitment on external integration. J. Oper. Manag. 2011, 29, 17–32. [Google Scholar] [CrossRef]

- Shah, S.A.A.; Jajja, M.S.S.; Chatha, K.A.; Farooq, S. Servitization and supply chain integration: An empirical analysis. Int. J. Prod. Econ. 2020, 229, 107765. [Google Scholar] [CrossRef]

- Spekman, R.E.; Kamauff, J.W., Jr.; Myhr, N. An empirical investigation into supply chain management: A perspective on partnerships. Supply Chain Manag. Int. J. 1998, 3, 53–67. [Google Scholar] [CrossRef]

- Lambert, D.M.; Emmelhainz, M.A.; Gardner, J.T. Developing and implementing supply chain partnerships. Int. J. Logist. Manag. 1996, 7, 1–18. [Google Scholar] [CrossRef]

- Whipple, J.M.; Russell, D. Building supply chain collaboration: A typology of collaborative approaches. Int. J. Logist. Manag. 2007, 18, 174–196. [Google Scholar] [CrossRef]

- Bagchi, P.K.; Ha, B.C.; Skjoett-Larsen, T.; Soerensen, L.B. Supply chain integration: A European survey. Int. J. Logist. Manag. 2005, 16, 275–294. [Google Scholar] [CrossRef]

- Soosay, C.A.; Hyland, P.W.; Ferrer, M. Supply chain collaboration: Capabilities for continuous innovation. Supply Chain Manag. Int. J. 2008, 13, 160–169. [Google Scholar] [CrossRef]

- Lambert, D.M.; Cooper, M.C. Issues in supply chain management. Ind. Mark. Manag. 2000, 29, 65–83. [Google Scholar] [CrossRef]

- Huo, B.; Qi, Y.; Wang, Z.; Zhao, X. The impact of supply chain integration on firm performance. Supply Chain Manag. Int. J. 2014. [Google Scholar] [CrossRef]

- Leuschner, R.; Rogers, D.S.; Charvet, F.F. A meta-analysis of supply chain integration and firm performance. J. Supply Chain Manag. 2013, 49, 34–57. [Google Scholar] [CrossRef]

- Adams, R.; Jeanrenaud, S.; Bessant, J.; Denyer, D.; Overy, P. Sustainability-oriented innovation: A systematic review. Int. J. Manag. Rev. 2016, 18, 180–205. [Google Scholar] [CrossRef]

- Zailani, S.; Iranmanesh, M.; Foroughi, B.; Kim, K.; Hyun, S.S. Effects of supply chain practices, integration and closed-loop supply chain activities on cost-containment of biodiesel. Rev. Manag. Sci. 2019, 1–21. [Google Scholar] [CrossRef]

- Mondragon, A.E.C.; Lalwani, C.; Mondragon, C.E.C. Measures for auditing performance and integration in closed-loop supply chains. Supply Chain Manag. Int. J. 2011, 43–56. [Google Scholar] [CrossRef]

- Elkington, J. Cannibals with Forks: The Triple Bottom Line of 21st Century Business, 1st ed.; Capstone Publishing: Oxford, UK, 1997. [Google Scholar]

- Hristov, I.; Chirico, A. The role of sustainability key performance indicators (KPIs) in implementing sustainable strategies. Sustainability 2019, 11, 5742. [Google Scholar] [CrossRef]

- Neely, A.D. Exploring the financial consequences of the servitization of manufacturing. Oper. Manag. Res. 2008, 2, 103–118. [Google Scholar] [CrossRef]

- Barney, J.B.; Arikan, A.M. The resource-based view: Origins and implications. Blackwell Handb. Strateg. Manag. 2001, 5, 124–188. [Google Scholar] [CrossRef]

- Anderson, E.W.; Fornell, C.; Rust, R.T. Customer satisfaction, productivity, and profitability: Differences between goods and services. Mark. Sci. 1997, 16, 129–145. [Google Scholar] [CrossRef]

- Quinn, J.B.; Doorley, T.L.; Paquette, P.C. Beyond products: Services-based strategy. Harv. Bus. Rev. 1990, 68, 58–67. [Google Scholar]

- Wise, R.; Baumgartner, P. Go downstream: The new imperative in manufacturing. Harv. Bus. Rev. 1999, 77, 133–141. [Google Scholar]

- Potts, G.W. Exploiting your product’s service life cycle. Harv. Bus. Rev. 1988, 66, 32–36. [Google Scholar]

- Kamp, B.; Parry, G. Servitization and advanced business services as levers for competitiveness. Ind. Mark. Manag. 2017, 60, 11–16. [Google Scholar] [CrossRef]

- Porter, M.E. Competitive Advantage: Creating and Sustaining Superior Performance; The Free Press: New York, NY, USA, 1985. [Google Scholar]

- Heskett, J.L. Lessons in the service sector. Harv. Bus. Rev. 1987, 65, 164–174. [Google Scholar]

- Doni, F.; Corvino, A.; Martini, S.B. Servitization and sustainability actions. Evidence from European manufacturing companies. J. Environ. Manag. 2019, 234, 367–378. [Google Scholar] [CrossRef]

- Szász, L.; Seer, L. Towards an operations strategy model of servitization: The role of sustainability pressure. Oper. Manag. Res. 2018, 11, 51–66. [Google Scholar] [CrossRef]

- Khan, M.A.; Mittal, S.; West, S.; Wuest, T. Review on upgradability–A product lifetime extension strategy in the context of product service systems. J. Clean. Prod. 2018, 204, 1154–1168. [Google Scholar] [CrossRef]

- Hojnik, J. Ecological modernization through servitization: EU regulatory support for sustainable product–service systems. Rev. Eur. Comp. Int. Environ. Law 2018, 27, 162–175. [Google Scholar] [CrossRef]

- Corvellec, H.; Stål, H.I. Evidencing the waste effect of product-service systems (PSSs). J. Clean. Prod. 2017, 145, 14–24. [Google Scholar] [CrossRef]

- Yang, M.; Evans, S. Product-service system business model archetypes and sustainability. J. Clean. Prod. 2019, 220, 1156–1166. [Google Scholar] [CrossRef]

- Vezzoli, C.; Ceschin, F.; Diehl, J.C.; Kohtala, C. New design challenges to widely implement sustainable product-service systems. J. Clean. Prod. 2015, 97, 1–12. [Google Scholar] [CrossRef]

- Mebratu, D. Sustainability and sustainable development: Historical and conceptual review. Environ. Impact Assess. Rev. 1998, 18, 493–520. [Google Scholar] [CrossRef]

- Annarelli, A.; Battistella, C.; Nonino, F. Product service system: A conceptual framework from a systematic review. J. Clean. Prod. 2016, 139, 1011–1032. [Google Scholar] [CrossRef]

- Moreno, R.; Marques, L.; Arkader, R. Servitization impact on performance moderated by country development. Benchmarking Int. J. 2019, 27, 302–318. [Google Scholar] [CrossRef]

- Tseng, M.L.; Lin, S.; Chen, C.C.; Sarmiento, L.S.C.; Tan, C.L. A causal sustainable product-service system using hierarchical structure with linguistic preferences in the Ecuadorian construction industry. J. Clean. Prod. 2019, 230, 477–487. [Google Scholar] [CrossRef]

- Porter, M.E.; Kramer, M.R. Creating Shared Value. How to reinvent capitalism—and unleash a wave of innovation and growth. Harv. Bus. Rev. 2011, 89, 2–17. [Google Scholar]

- Chesbrough, H. Open innovation: A new paradigm for understanding industrial innovation. In Open Innovation: Researching a New Paradigm; Chesbrough, H., Vanhaverbeke, W., West, J., Eds.; Oxford University Press: New York, NY, USA, 2006; pp. 1–19. [Google Scholar]

- Yin, R.K. Case Study Research. Design and Methods, 5th ed.; Sage Publications: Thousand Oaks, CA, USA, 2014. [Google Scholar]

- Vendrell-Herrero, F.; Bustinza, O.F.; Parry, G.; Georgantzis, N. Servitization, digitization and supply chain interdependency. Ind. Mark. Manag. 2017, 60, 69–81. [Google Scholar] [CrossRef]

- MacCarthy, B.L.; Lewis, M.; Voss, C.; Narasimhan, R. The same old methodologies? Perspectives on OM research in the post-lean age. Int. J. Oper. Prod. Manag. 2013, 33, 934–956. [Google Scholar] [CrossRef]

- Larrinaga, O.V. Is it desirable, necessary and possible to perform research using case studies? Cuad. Gest. 2017, 17, 147–171. [Google Scholar] [CrossRef]

- Hillebrand, B.; Kok, R.A.; Biemans, W.G. Theory-testing using case studies: A comment on Johnston, Leach, and Liu. Ind. Mark. Manag. 2001, 30, 651–657. [Google Scholar] [CrossRef]

- De la Calle, A.; Alvarez, E.; Freije, I. Supply chain integration, a key strategic capability for improving product and service value propositions: Empirical evidence. Int. J. Eng. Manag. Econ. 2015, 5, 89–103. [Google Scholar] [CrossRef]

- Freije, I.; de la Calle, A.; Ugarte, J.V. Role of supply chain integration in the product innovation capability of servitized manufacturing companies. Technovation 2021, 102216. [Google Scholar] [CrossRef]

- Grönroos, C. Value co-creation in service logic: A critical analysis. Mark. Theory 2011, 11, 279–301. [Google Scholar] [CrossRef]

- Adrodegari, F.; Bacchetti, A.; Saccani, N.; Arnaiz, A.; Meiren, T. The transition towards service-oriented business models: A European survey on capital goods manufacturers. Int. J. Eng. Bus. Manag. 2018, 10, 1–10. [Google Scholar] [CrossRef]

- Cenamor, J.; Sjödin, D.R.; Parida, V. Adopting a platform approach in servitization: Leveraging the value of digitalization. Int. J. Prod. Econ. 2017, 192, 54–65. [Google Scholar] [CrossRef]

- Chen, J.S.; Kerr, D.; Tsang, S.S.; Sung, Y.C. Co-production of service innovations through dynamic capability enhancement. Serv. Ind. J. 2015, 35, 96–114. [Google Scholar] [CrossRef]

- Koufteros, X.; Vonderembse, M.; Jayaram, J. Internal and external integration for product development: The contingency effects of uncertainty, equivocality, and platform strategy. Decis. Sci. 2005, 36, 97–133. [Google Scholar] [CrossRef]

- Cheng, Y.; Chaudhuri, A.; Farooq, S. Interplant coordination, supply chain integration, and operational performance of a plant in a manufacturing network: A mediation analysis. Supply Chain Manag. Int. J. 2016, 21, 550–568. [Google Scholar] [CrossRef]

- Witell, L.; Löfgren, M. From service for free to service for fee: Business model innovation in manufacturing firms. J. Serv. Manag. 2013, 5, 520–533. [Google Scholar] [CrossRef]

- Visnjic, I.; Wiengarten, F.; Neely, A. Only the brave: Product innovation, service business model innovation, and their impact on performance. J. Prod. Innov. Manag. 2016, 33, 36–52. [Google Scholar] [CrossRef]

- Beuren, F.H.; Ferreira, M.G.G.; Miguel, P.A.C. Product-service systems: A literature review on integrated products and services. J. Clean. Prod. 2013, 47, 222–231. [Google Scholar] [CrossRef]

- Vifell, Å.C.; Soneryd, L. Organizing matters: How ‘the social dimension’gets lost in sustainability projects. Sustain. Dev. 2012, 20, 18–27. [Google Scholar] [CrossRef]

- Lafuente, E.; Vaillant, Y.; Vendrell-Herrero, F. Territorial servitization: Exploring the virtuous circle connecting knowledge-intensive services and new manufacturing businesses. Int. J. Prod. Econ. 2017, 192, 19–28. [Google Scholar] [CrossRef]

- Mpinganjira, M.; Roberts-Lombard, M.; Svensson, G. Validating the relationship between trust, commitment, economic and non-economic satisfaction in South African buyer-supplier relationships. J. Bus. Ind. Mark. 2017, 32, 421–431. [Google Scholar] [CrossRef]

- Gölgeci, I.; Gligor, D.M.; Lacka, E.; Raja, J.Z. Understanding the influence of servitization on global value chains: A conceptual framework. Int. J. Oper. Prod. Manag. 2021, 1–23. [Google Scholar] [CrossRef]

- Castelló, I.; Lozano, J.M. Searching for new forms of legitimacy through corporate responsibility rhetoric. J. Bus. Ethics 2011, 100, 11–29. [Google Scholar] [CrossRef]

| Domain of Analysis | Analysed Dimensions | References |

|---|---|---|

| Servitisation taxonomy | Digital services and consultancy Customisation Financial services Logistic services Installation and setup services Management and operation services Maintenance and support services Disposal and conversion services | Mastrogiacomo et al. (2017) |

| Digitalisation | Efficiency improvement Cost reduction New functionalities New service | Adapted from Cenamor et al. (2017); Kindström and Kowalkowski (2014); Porter and Heppelmann (2014); Coreynen et al. (2016) |

| Supply-chain integration | Supplier integration Customer integration Internal integration | Adapted from Zhao et al. (2011) |

| Economical sustainability | Strategy type: Defensive strategy Differentiating Growth and new opportunities Source of economic sustainability Better fulfilment of customer needs Stronger customer relationships Differentiation and lockout competitors Increased revenues Identification of new markets and better response agility Access to service data Reduced customer risk Improved technology Reduced life-cycle costs | Adapted from Neely, 2008; Suarez et al., 2013; Kohtamaäki et al., 2013; Cusumano, 2010; Oliva &Kalenberg, 2003 Adapted from Yang and Evans, 2019 |

| Environmental sustainability | Resources efficiency Longer product life Increased product usage Reuse and recycling Dematerialisation Liberty for sustainable design | Adapted from Yang and Evans, 2019 |

| Social sustainability | Increased employment Local supplier development Induced demand Health and security Open innovation | Adapted from Yang and Evans (2019); Beuren et al. (2013) and United Nations (Sustainable Development Goals) |

| Companies | Industry (NACE Codes) | Age of the Firm (Years) | Size (Employees) | Operating Markets |

|---|---|---|---|---|

| Company A | C29—Manufacture of motor vehicles, trailers, and semitrailers | >100 | >250 | B2B |

| Company B | C30—Manufacture of other transport equipment | >100 | >250 | B2B |

| Company C | C28—Manufacture of machinery and equipment n.e.c. | >40 | >250 | B2B |

| Company D | C28—Manufacture of machinery and equipment n.e.c. | >30 | <250 | B2B and B2C |

| Companies | Interviewee | Gender/Years at the Company |

|---|---|---|

| Company A | Head of Corporate Human Resources and Corporate Social Responsibility | Male/>10 |

| Company B | Head of Corporate Human Resources and experience in other Managerial positions: Strategic Unit director and Commercial responsible | Male/>20 |

| Company C | CTO—Chief Technology Officer | Male/>25 |

| Company D | R&D Manager | Male/>15 |

| Services Adapted from [19] | PSS [27] | Servitisation Level [14,28,32] |

|---|---|---|

| 1. Digital services and consultancy. Advice and assistance related to the firm’s expertise and data | Product-oriented PSS | Advanced/relationship-based |

| 2. Product customisation | Product-oriented PSS | Advanced/relationship-based |

| Customised product design and development services 3. Financial services Long-term credits related to the products, rental contracts, leasing, etc. | Use-oriented PSS | Advanced/relationship-based |

| 4. Logistic services The company provides delivery, transport, and/or storage services for its customer’s products, components, or raw materials | Product-oriented PSS | Basic-intermediate/transaction-based |

| 5. Installation and setup services | Product-oriented PSS | Intermediate/transaction-based |

| The company installs and tests its products and trains the personnel in charge of their use. 6. Management and operation services The customer receives only the benefits of product use without having to execute it | Result-oriented and use-oriented PSS | Advanced/relationship-based |

| 7. Maintenance and support services Not only corrective maintenance and support services during the life cycle of the product, offering spare parts, but also predictive. | Product-oriented PSS | Basic/intermediate (usually)/transaction based/advanced (seldom)/relationship-based |

| 8. Disposal and conversion services Recycling or conversion services usually at the end of the product life cycle. | Product-oriented PSS | Intermediate/transaction-based |

| Services | Company A | Company B | Company C | Company D |

|---|---|---|---|---|

| 1. Digital services and consultancy | Connected products (IOT) and more competitive services for operators and maintainers through data collection, storage, processing, and analysis, such as geolocation, remote human machine interface, remote condition monitoring, condition-based maintenance, energy efficiency (i.e., to reduce energy and fuel costs by calculating the optimum operating patterns and providing the operator with real-time suggestions. | Connected products (IOT) and more competitive services for operators and maintainers through data collection, storage, processing, and analysis, such as diagnostic tool for the different systems working in the product, training for dealers and distributors, fleet manager to optimise the performance and profitability of customers’ fleets, ad fuel efficiency and carbon dioxide emissions data directly from the vehicle, to make decisions and optimise resources. | Connected products (IOT) through an on-premise platform and more competitive services for customers and maintainers through collection, storage, processing, and analysis of data. Integral advisory service (compliance with local/global regulatory norms and specifications) and simulation models to demonstrate all key features (mechanical, thermal, electrical, etc.) considering real case scenarios. It leads to a proposal of different alternatives of energy conversion, generation, or consumption. In some cases, global engineering integration of the complete solution (complete project management). | Connected products (IOT) through an on-premise platform and more competitive services for customers and maintainers through collection, storage, processing, and analysis of data. Service of simulation models for comparing the current performance with the potential performance of their products. Integral advisory service (use of building information modelling and virtual reality for visualising the product in the place it will operate in the customer installation). |

| 2. Product customisation | All products are customised. It is not considered a separate service. The weight of the design is crucial in the project (lasts months). | Customised product design and development through the combination and adaptation of modules. | All products are customised as a part of the integral design of the solution. In some sectors, that design can be invoiced separately (small batches). Key parts of the product are modular. | Customised product design and development through the combination and adaptation of modules (they have standard products, generally focused on the end customer, B2C). They have software to select and size the equipment on the basis of the customer’s requirements. |

| 3. Financial services | They form part of the capital of the shared company, which may be a financial entity that remains in operation for 30 years. The client receives the service, by kilometres or fixed price: quota. | Service not provided by the firm. | Service not provided by the firm. | Service not provided by the firm. |

| 4. Logistic services | Management of the collection and sale of spare parts. Logistics management for materials in the workshop. Delivery planning according to workshop activities. Delivery planning according to workshop activities. Warehouse management. Vendor-managed inventory (VMI) service. | Service not provided by the firm. | Service not provided by the firm. | Service not provided by the firm. |

| 5. Installation and setup services | Complete solutions and integrated or turnkey systems. | Service not provided by the firm. | Complete solutions and integrated or turnkey systems. | They do not install but setup the product. |

| 6. Management and operation services | System operation. | Vehicle operation. | Service not provided by the firm. | System operation (an incipient area, mainly in the hotel sector) and fundamentally through the digital service platform. |

| 7. Maintenance and support services | Preventive and corrective maintenance for their own branded and for other-branded products. | Preventive and corrective maintenance for their branded products. 24 h assistance in more than 1000 official assistance points in the five continents). Digital service platform. | All business units offer both preventive (through advanced digital services and local operators) and corrective maintenance for the products they supply. 24 h assistance and ‘on-site’ placement (when required) are common in more than 1000 official assistance points on the five continents. | Preventive and corrective maintenance but not 24/7 and for their own branded products. The digital platform is the key to make up, in a way, for not having a 24/7 maintenance service. |

| 8. Disposal and conversion services | Product end-of-life refurbishment and service upgrades. | Refurbishment and modernisation of the product. | Refurbishment and modernisation of the product. | Service not provided by the firm. |

| 1. Digital Services and Consultancy | 2. Product Customisation | 3. Financial Services | 4. Logistic Services | 5. Installation and Setup Services | 6. Management and Operation Services | 7. Maintenance and Support Services | 8. Disposal and Conversion Services | ||

|---|---|---|---|---|---|---|---|---|---|

| Company A | EFFIC | Yes | Yes | Yes | Yes | Yes | Yes | Yes | Yes |

| COST | Yes | Yes | No | Yes | Yes | Yes | Yes | Yes | |

| FUNCT | Yes | Yes | No | No | Yes | Yes | Yes | Yes | |

| NEWS | Yes | Yes | No | No | No | Yes | Yes | Yes | |

| Company B | EFFIC | Yes | Yes | --- | --- | --- | Yes | Yes | Yes |

| COST | Yes | Yes | --- | --- | --- | Yes | Yes | Yes | |

| FUNCT | Yes | Yes | --- | --- | --- | Yes | Yes | Yes | |

| NEWS | Yes | Yes | --- | --- | --- | Yes | Yes | Yes | |

| Company C | EFFIC | Yes | Yes | --- | --- | Yes | --- | Yes | Yes |

| COST | Yes | Yes | --- | --- | Yes | --- | Yes | Yes | |

| FUNCT | Yes | Yes | --- | --- | Yes | --- | Yes | No | |

| NEWS | Yes | Yes | --- | --- | No | --- | Yes | Yes | |

| Company D | EFFIC | Yes | Yes | --- | --- | Yes | Yes | Yes | --- |

| COST | Yes | Yes | --- | --- | Yes | Yes | Yes | --- | |

| FUNCT | Yes | Yes | --- | --- | No | No | No | --- | |

| NEWS | Yes | Yes | --- | --- | No | No | No | --- |

| Service Categorisation | Company | Supp. Int. | Cust. Int. | Int. Int. |

|---|---|---|---|---|

| 1. Digital services and consultancy | Company A | CP | CP | CP |

| Company B | PB | PB | PB | |

| Company C | CP | CP | CP | |

| Company D | CP | PB | CP | |

| 2. Product customisation | Company A | CP | CP | CP |

| Company B | CP | CP | CP | |

| Company C | CP | CP | CP | |

| Company D | Irrelevant | ARM | CP | |

| 3. Financial services | Company A | CP | CP | CP |

| 4. Logistic services | Company A | ARM | ARM | ARM |

| 5. Installation and setup services | Company A | CP | CP | CP |

| Company C | PB | CP | CP | |

| Company D | ARM | ARM | CP | |

| 6. Management and operation services | Company A | CP | CP | CP |

| Company B | CPM | CP | CP | |

| Company D | PB | CP | CP | |

| 7. Maintenance and support services | Company A | PB | PB | PB |

| Company B | ARM | ARM | ARM | |

| Company C | PB | PB | PB | |

| Company D | PB | CP | PB | |

| 8. Disposal and conversion services | Company A | PB | CP | PB |

| Company B | PB | CP | PB | |

| Company C | CP | PB | CP |

| Services | Company A | Company B | Company C | Company D |

|---|---|---|---|---|

| 1. Digital services and consultancy | ALL | ALL | ALL | ALL |

| 2. Product customisation | DEFF It is required | DEFF It is not separated invoiced Typically modularity | DEFF It is not separated invoiced Includes both integration and customisation | DEFF It is required |

| 3. Financial services | DEFF DIFFER Facing smallest competitors | Service not provided | Service not provided | DEFF DIFFER Facing smallest competitors |

| 4. Logistic services | ALL | Service not provided | Service not provided | ALL |

| 5. Installation and setup services | DEFF It is required | Service not provided | DEFF It is required | DEFF It is required |

| 6. Management and operation services | ALL | DEFF It is used primarily for product promotion to key customers and product development, for example, public service fleets | DEFF | ALL |

| 7. Maintenance and support services | DEFF | ALL May be necessary for the sale of new products or may serve to win the sale (differentiate), as well as products already owned by the customer and additional services | ALL It is a key aspect that may serve to win the sale (differentiate) or, more frequently, to obtain new sales. | DEFF |

| 8. Disposal and conversion services | NEW_OPP | ALL Sometimes is part of the sales agreement: repurchasing | ALL Compulsory in some sectors, but can be an opportunity to renew products during lifecycle time for more recent technological ones | NEW_OPP |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

de la Calle, A.; Freije, I.; Oyarbide, A. Digital Product–Service Innovation and Sustainability: A Multiple-Case Study in the Capital Goods Industry. Sustainability 2021, 13, 6342. https://doi.org/10.3390/su13116342

de la Calle A, Freije I, Oyarbide A. Digital Product–Service Innovation and Sustainability: A Multiple-Case Study in the Capital Goods Industry. Sustainability. 2021; 13(11):6342. https://doi.org/10.3390/su13116342

Chicago/Turabian Stylede la Calle, Alberto, Inmaculada Freije, and Aitor Oyarbide. 2021. "Digital Product–Service Innovation and Sustainability: A Multiple-Case Study in the Capital Goods Industry" Sustainability 13, no. 11: 6342. https://doi.org/10.3390/su13116342

APA Stylede la Calle, A., Freije, I., & Oyarbide, A. (2021). Digital Product–Service Innovation and Sustainability: A Multiple-Case Study in the Capital Goods Industry. Sustainability, 13(11), 6342. https://doi.org/10.3390/su13116342