3.1.1. Results of the Laboratory Tests

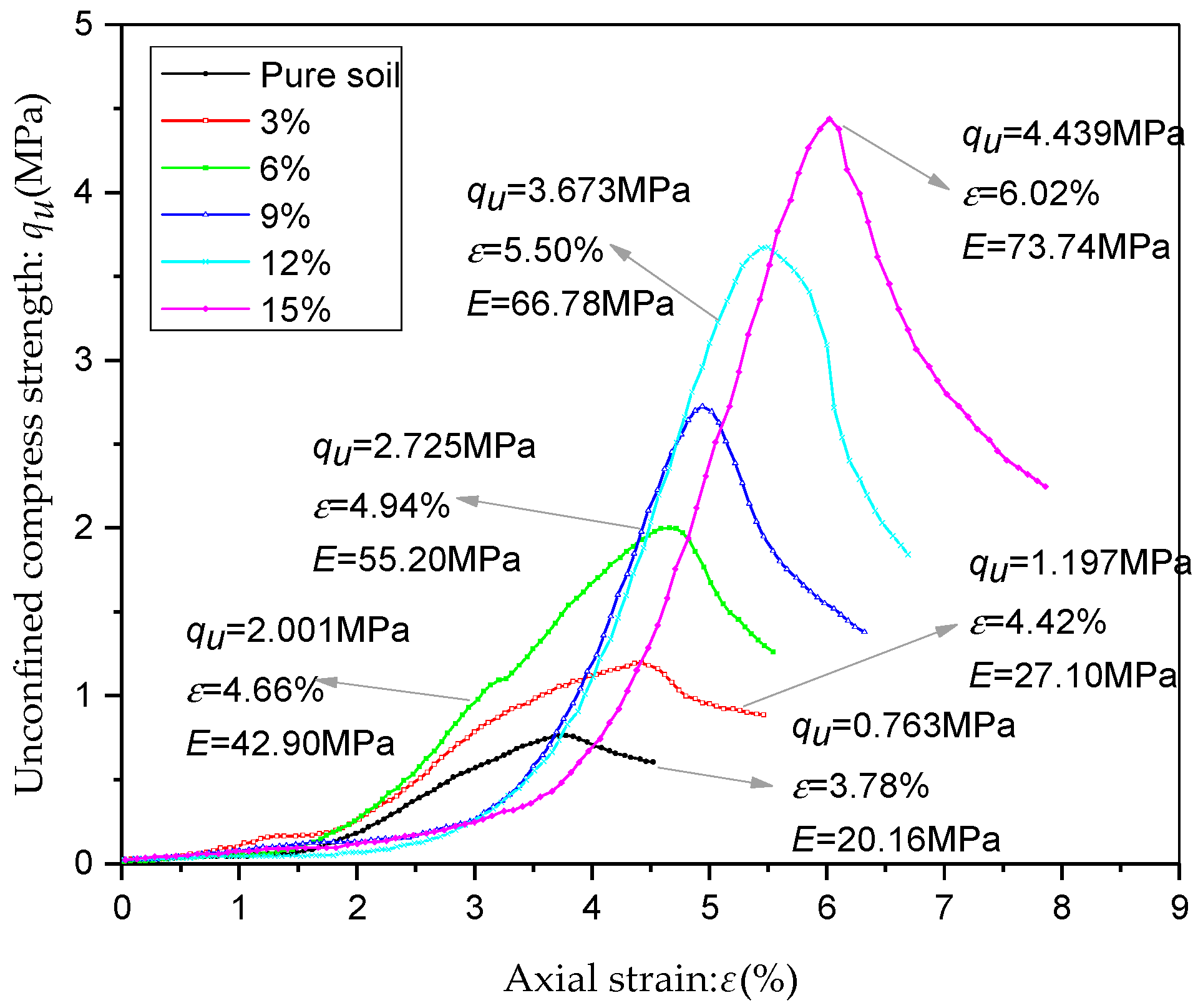

For pure soil and various inorganic stable soils, their stress–strain curves of UCS tests are shown in

Figure 5 and

Figure 6. It can be seen that when the pure soil’s curing age was 7 days and 28 days, respectively, the unconfined compressive strength

qu was 0.696 MPa and 0.763 MPa, and Young’s modulus

E was 20.16 MPa and 19.22 MPa.

For the two curing ages, the strength and stiffness were closely related to the content of inorganic material; the greater the inorganic material’s total content, the greater the qu and E of the inorganic stabilized soil was. When the total proportion of the inorganic stable material was 15% (5% cement, 5% quicklime and 5% fly ash), the peak values of qu and E were reached. At the 7th curing day, qu1max = 4.439 MPa, E1max = 73.74 MPa, and at 28th curing day, qu2max = 5.903 MPa, E2max = 89.18 MPa.

As the curing age increased, the

qu and

E gradually increased; in the actual construction process, the strength growth ratio from 7 to 28 days is an important guarantee for the project’s continuously stable and efficient progress. Assuming the

G represents the growth ratio of the

qu and

E from the 7th curing day to the 28th curing day, the growth ratio of

qu and

E can be calculated using Equations (1) and (2). When the proportion of the inorganic material was 15%,

Gqumax = 32.98% and

GEmax = 20.94%. For other groups, their variations of

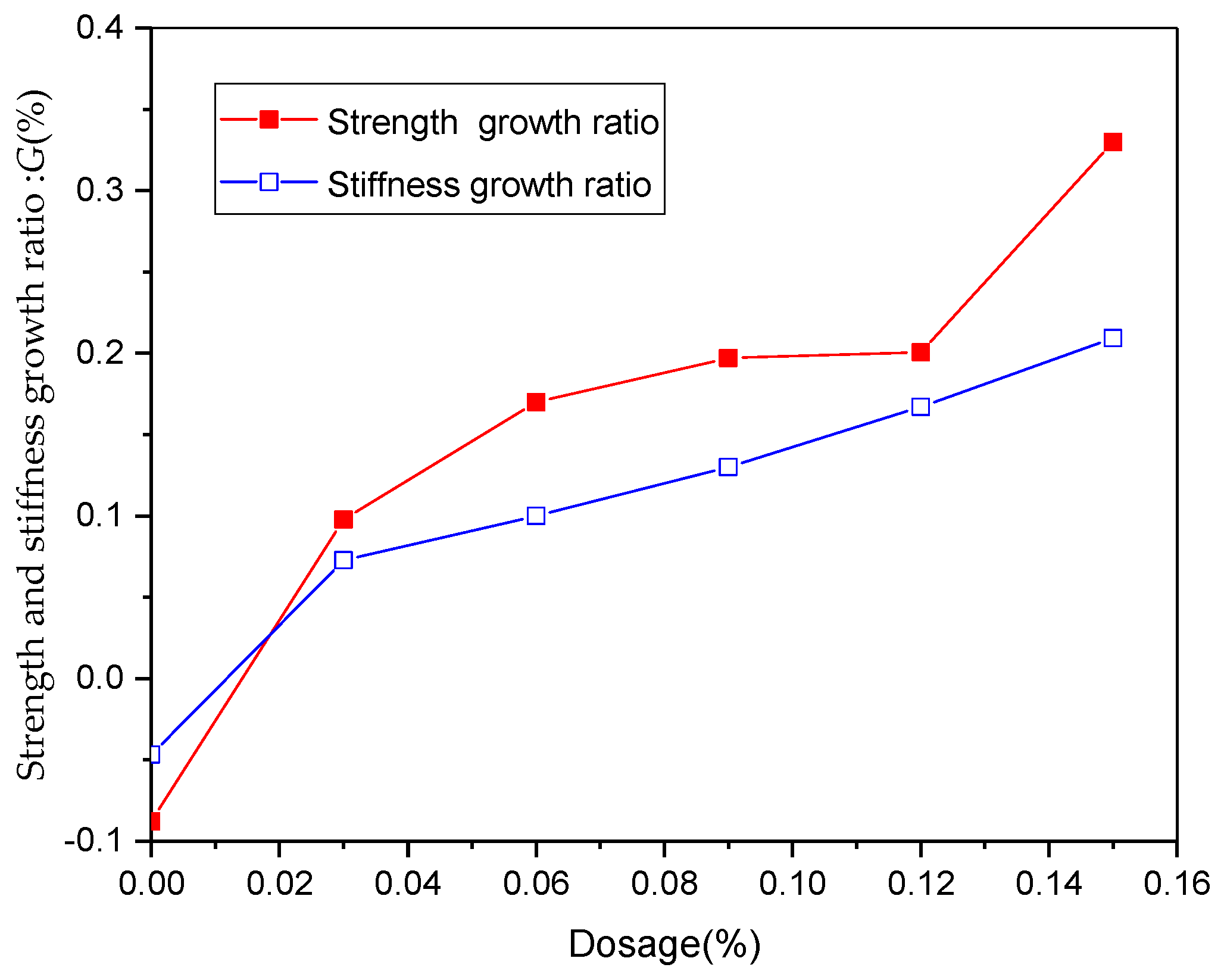

G are shown in

Figure 7.

where the

qu1 is the value of

qu on the 7th curing day, and

qu2 is the value of

qu on the 28th curing day.

where

E1 is the value of

E on the 7th curing day, and

E2 is the value of

E on the 28th curing day.

As shown in

Figure 7, the pure soil’s

Gqu and

GE were both less than 0%, and this is because, under the condition of unconfined wet nutrient, the montmorillonite in the soil sample made the soil structure slightly swell after absorbing water, reducing the strength and rigidity. As the addition content increased, the

Gqu and

GE of the stabilized soil both increased. Under the reasonable curing condition, as the curing time increased, the three kinds of inorganic materials’ strength and stiffness increased, and the growth rate gradually increased and eventually stabilized.

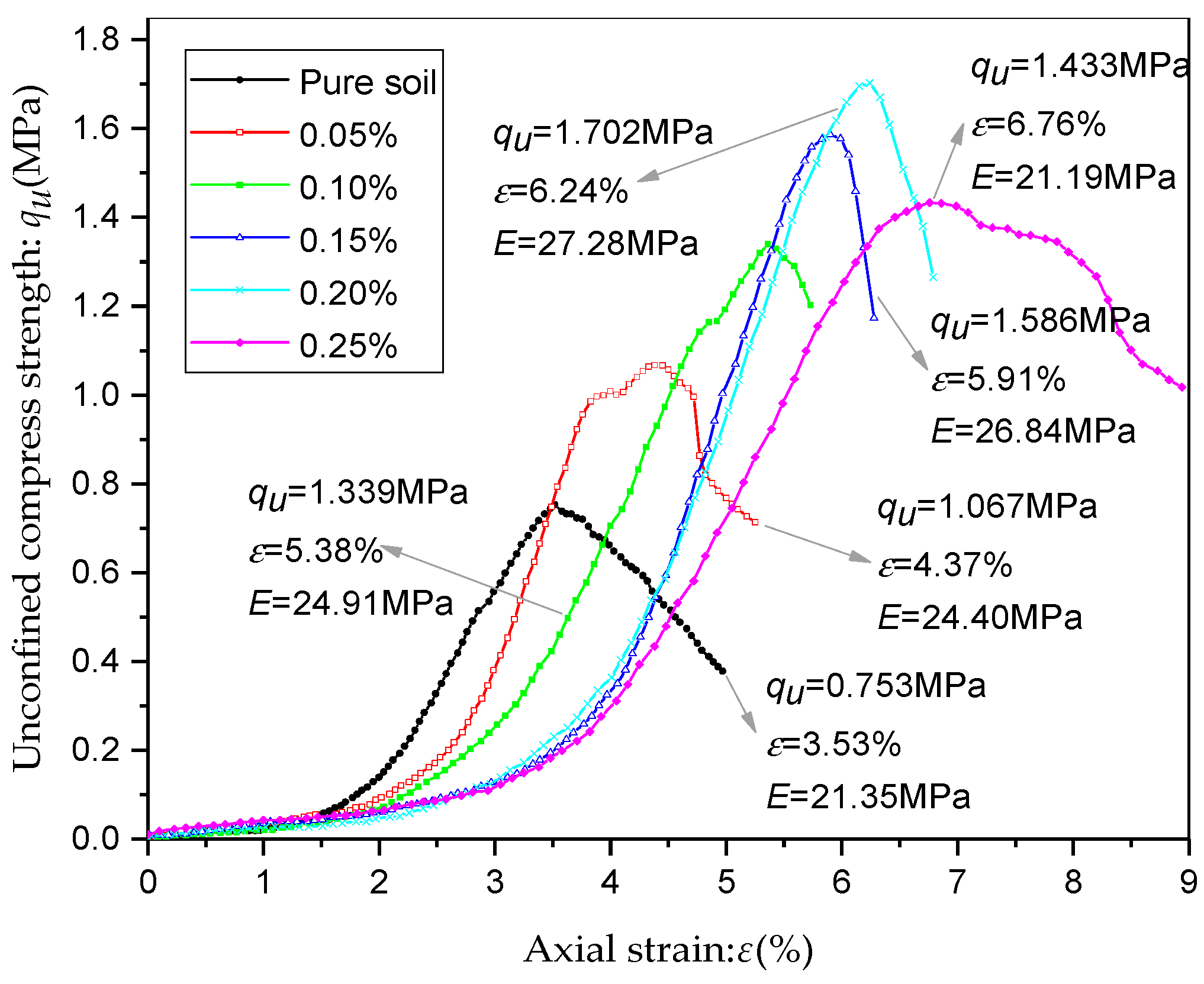

As for the pure soil and various SO-stabilized soils, the stress–strain curves in the UCS test on the 7th and 28th curing days are shown in

Figure 8 and

Figure 9. It was indicated that when the SO content was less than 0.2%; the SO content presents a strong positive correlation with the strength and stiffness of the stabilized soil. By contrast, when the SO content reached 0.25%, the strength and stiffness of stabilized soil decreased but is still slightly better than that of pure soil; compared with inorganic materials, the strain

ε corresponding to the strength peak point of the SO modified sample increased to avoid brittle failure. It was also indicated that, as the SO content increased, this ε also gradually increased.

The peak values of qu and E were the largest when the SO content was 0.2%, qu1max = 1.787 MPa, E1max = 28.37 MPa at the 7th curing day, qu2max = 1.702 MPa, E2max = 21.19 MPa at the 28th curing day. According to the test results, When the SO content was less than 0.2%, as the curing time increased, the strength and stiffness at the 28th day were slightly reduced compared with that at the 7th day for the same set of tests. On the contrary, the strength and stiffness were slightly increased when the SO content was 0.25%.

In order to verify the reliability of this conclusion, the author added a test with 0.3% SO content to prove it. The supporting test shows that when the SO content is 0.3%, the strength is 1.052 MPa, and the elastic modulus is 15.73 MPa. Compared with the solidified soil with the SO content of 0.25%, the strength and stiffness are further reduced. The test proves that the above conclusion is reliable.

When the SO content was less than 0.2%, qu and E increased with the increase in the content, indicating that the primary effect of SO on strengthening the soil structure is the physical and chemical effect. However, when the SO content reached 0.25%, qu and E began to decrease, ε significantly increased, suggesting that the lubrication effect was dominant at this time. It was found that the SO content was in charge of the transition of these two effects. When the SO content was low than 0.2%, the soil particles were not completely covered with SO molecules; combined with the soil particles, the SO molecules played a role in enlarging the soil’s structure. At this time, there was no excess SO molecule in the soil particles’ pore, the physical and chemical effect was greater than the lubricating effect, and the strength and rigidity of the soil were improved.

However, with the increase in the content, the strength and rigidity were increased to the extreme value because the soil particles were gradually covered with SO molecules; as SO continuously increased, the excess SO molecules entered the soil particle pore and the lubrication effect appeared, then the strength and stiffness of the soil gradually decrease, and the ductility was improved. Moreover, in the process of curing, SO is inevitably partly lost due to volatilization or other reasons. When the SO content was less than 0.2%, the loss of SO molecules reduced the sulfonated oil molecules around the soil particles, and the physical and chemical effects decayed and limited the enhancement of the stabilized soil strength and stiffness.

Nevertheless, when the SO content was equal to 0.25%, the SO molecules in the pores of the soil particles were lost first, weakening the lubrication effect, but the SO molecular around the soil particles remained unchanged or even reached an appropriate amount, and the physical and chemical effects were not significantly weakened. Therefore, the strength and stiffness of the stabilized soil did not weaken in the later stage, which also explains the differences in the variation of strength and stiffness of stabilized soils. Considering the loss of SO, it is recommended that when SO is selected as a single stabilizer in the project, a sealing treatment or an appropriate increase in the amount should be used to ensure the effectiveness of SO.

The results of the two single-mixing tests showed that, compared with SO, inorganic materials were more prominent in improving the strength and stiffness of high-liquid-limit soil. However, except for the strength and stiffness as the improvement indicators, water stability is even more essential. Water stability refers to the stability of the strength and stiffness before and after immersion, which is generally represented by the water stability coefficient

HS; its calculation is shown in Equation (3).

where

qu’ is the unconfined compressive strength after the sample is immersed for 24 h at the one-day point before the specified curing time;

qu is the unconfined compressive strength at the specified curing day.

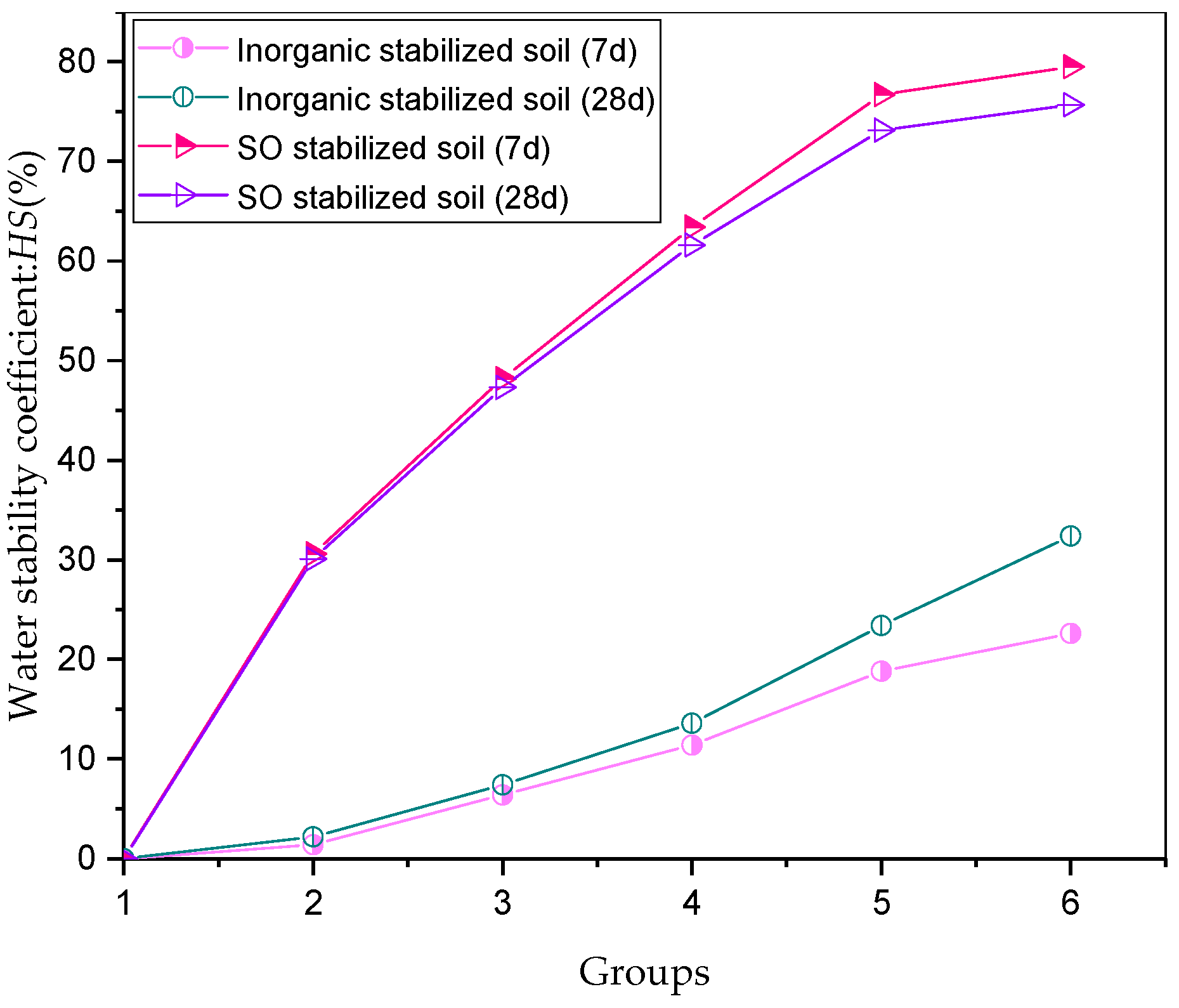

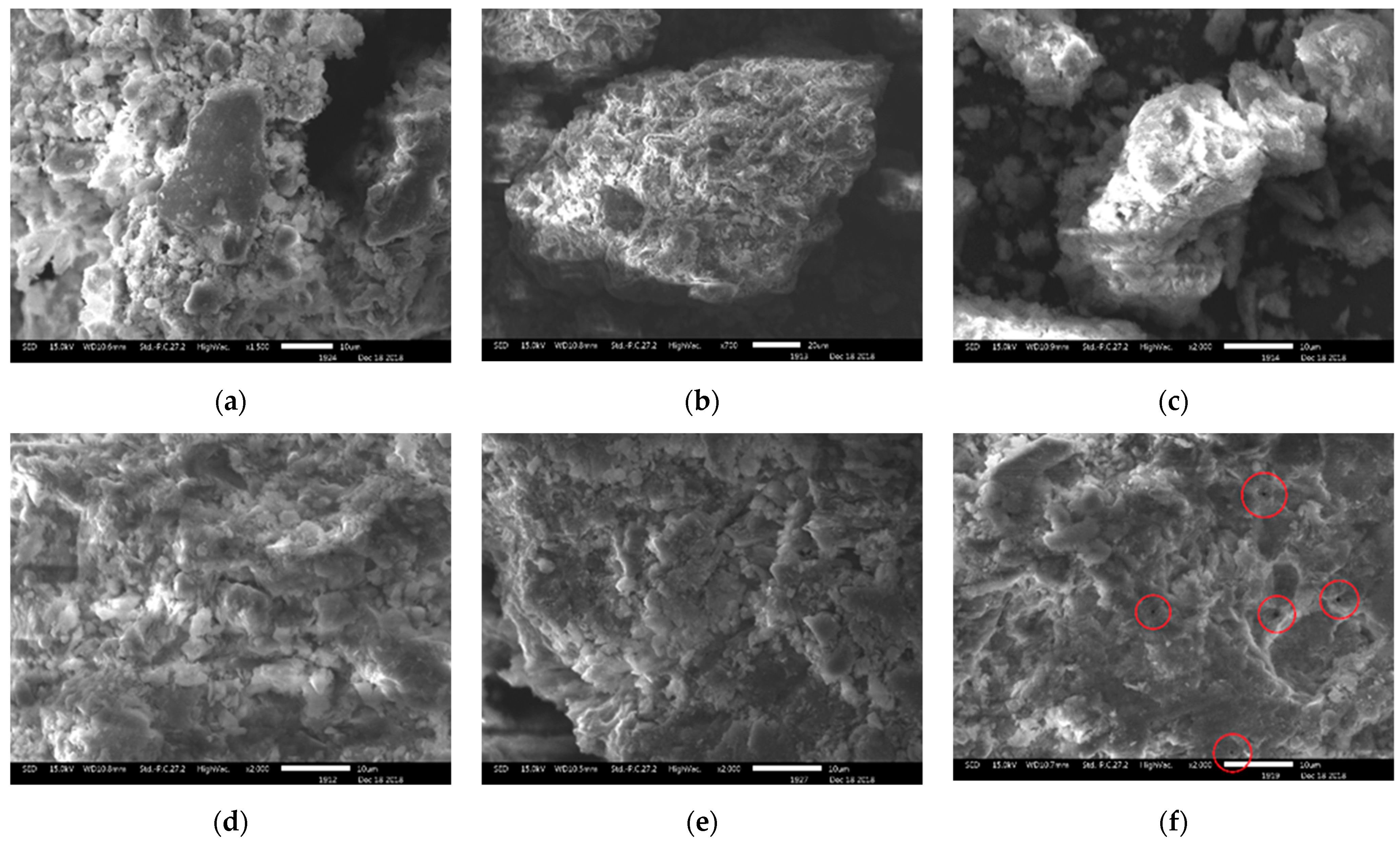

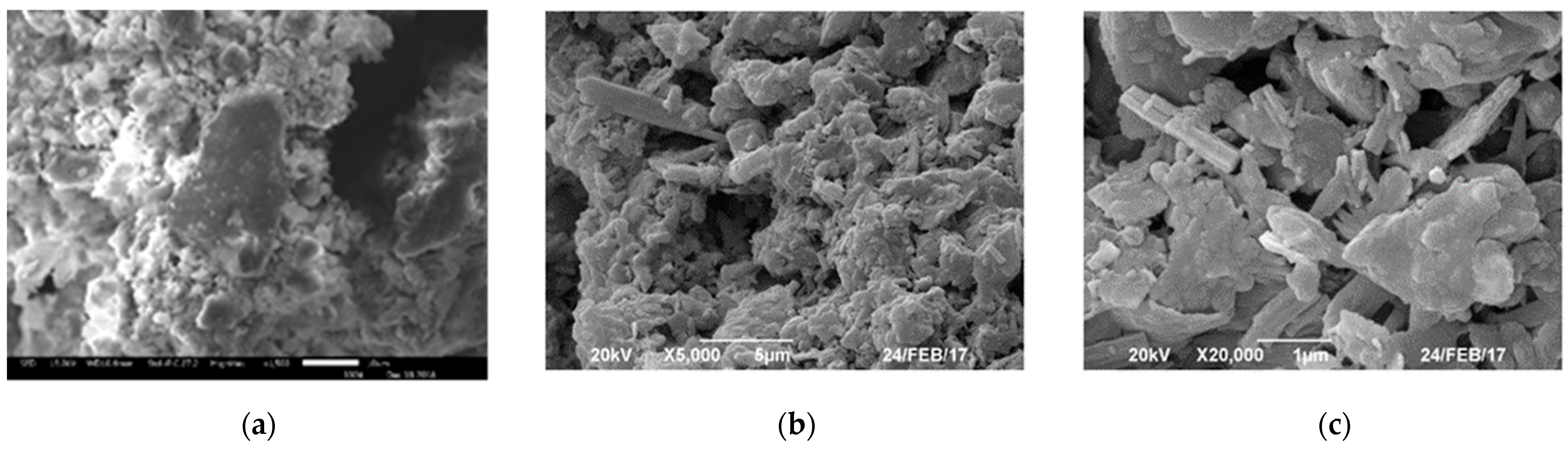

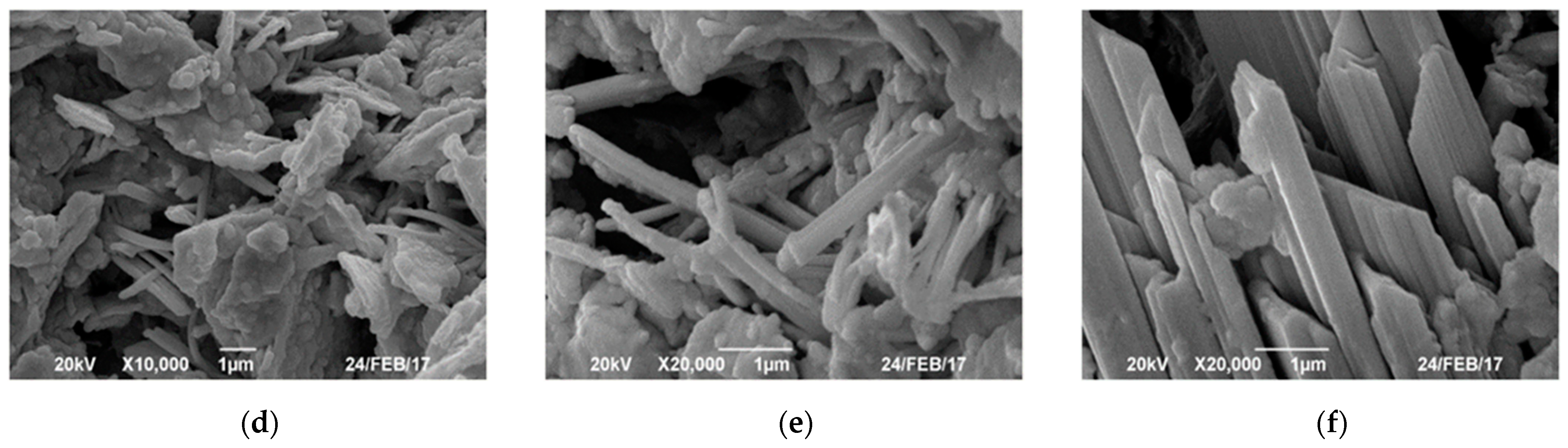

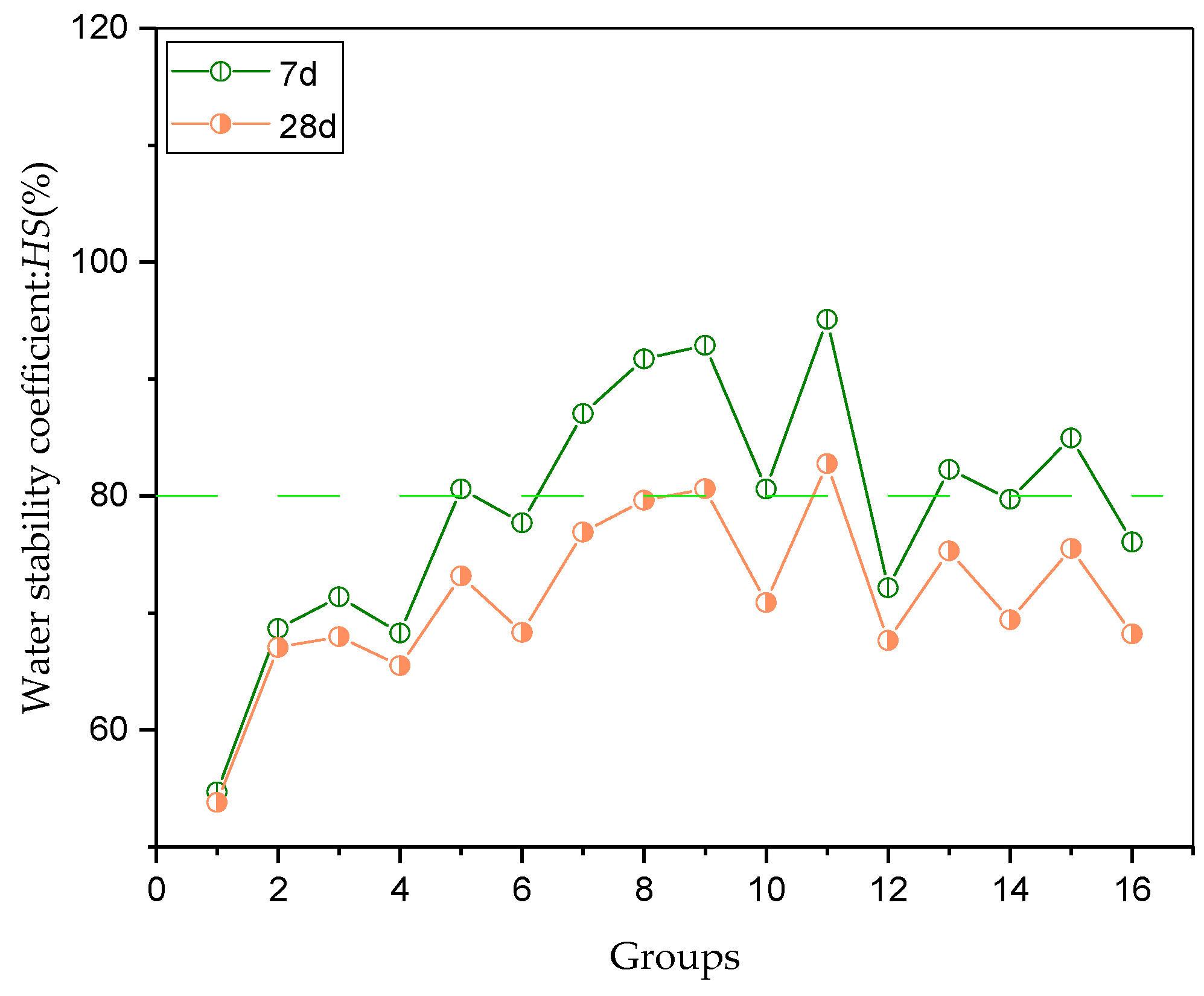

Figure 10 shows the water stability coefficient curves of the pure soil, inorganic stabilized soil, and SO-stabilized soil at 7 d and 28 d. Numbers from one to six represent the six different contents of two stabilizers ranging from 0% to the maximum in the uniaxial unconfined compressive strength test.

It was found that the pure soil sample disintegrated quickly after being immersed, and the HS was 0%. The strength after immersion was considered to be 0MPa because the strength test cannot be carried out. Inorganic materials and SO have a certain effect on improving water stability of the high liquid limit soil. At the 7th curing day, with the increase in inorganic material content, the HS increased from 0% to 33.9%; with the increase in SO content, the HS increased from 0% to 79.5%. At the 28th curing day, the HS of inorganic stabilized soil can reach up to 48.6%, and the HS of SO-stabilized soil can reach up to 75.7%, indicating that SO had a more significant effect on water stability.

As for the single material stabilized soil, no matter the inorganic stabilized soil or SO-stabilized soil, the HS at the 7th day and 28th day is positively correlated with the material content. From the perspective of curing time, from the 7th day and 28th day, the HS of soil increased at the same inorganic stabilizer content, while the HS of SO-stabilized soil decreased.

It was found that, for the inorganic stabilized soil, only when the total addition content was greater than 12% can the specimens maintain their integrity after immersion for 24 h. When the total addition content was less than 12%, the specimens after immersion would disintegrate, or soil particles fall off to some degree.

According to the water stability test results, SO can significantly improve the water stability of high-liquid-limit soil compared to inorganic stabilizer. However, according to the strength test results, SO stabilizer was found to be unable to improve the mechanical properties significantly. The mechanical properties and water stability are two indispensable indicators of high-liquid-limit soil in subgrade filling. Therefore, in order to explore the effect of using the inorganic stabilizer and OS at the same time, this study further conducted an orthogonal experiment on the composite soil stabilizer composed of inorganic stabilizing materials and SO.