GHG Emissions Assessment of Civil Construction Waste Disposal and Transportation Process in the Eastern Amazon

Abstract

1. Introduction

2. Literature Review

2.1. Construction Waste

2.2. Life Cycle Carbon Emissions Assessment (LCCO2A) in Building Construction

2.3. CO2 Emission in Transportation

3. Research Methodology

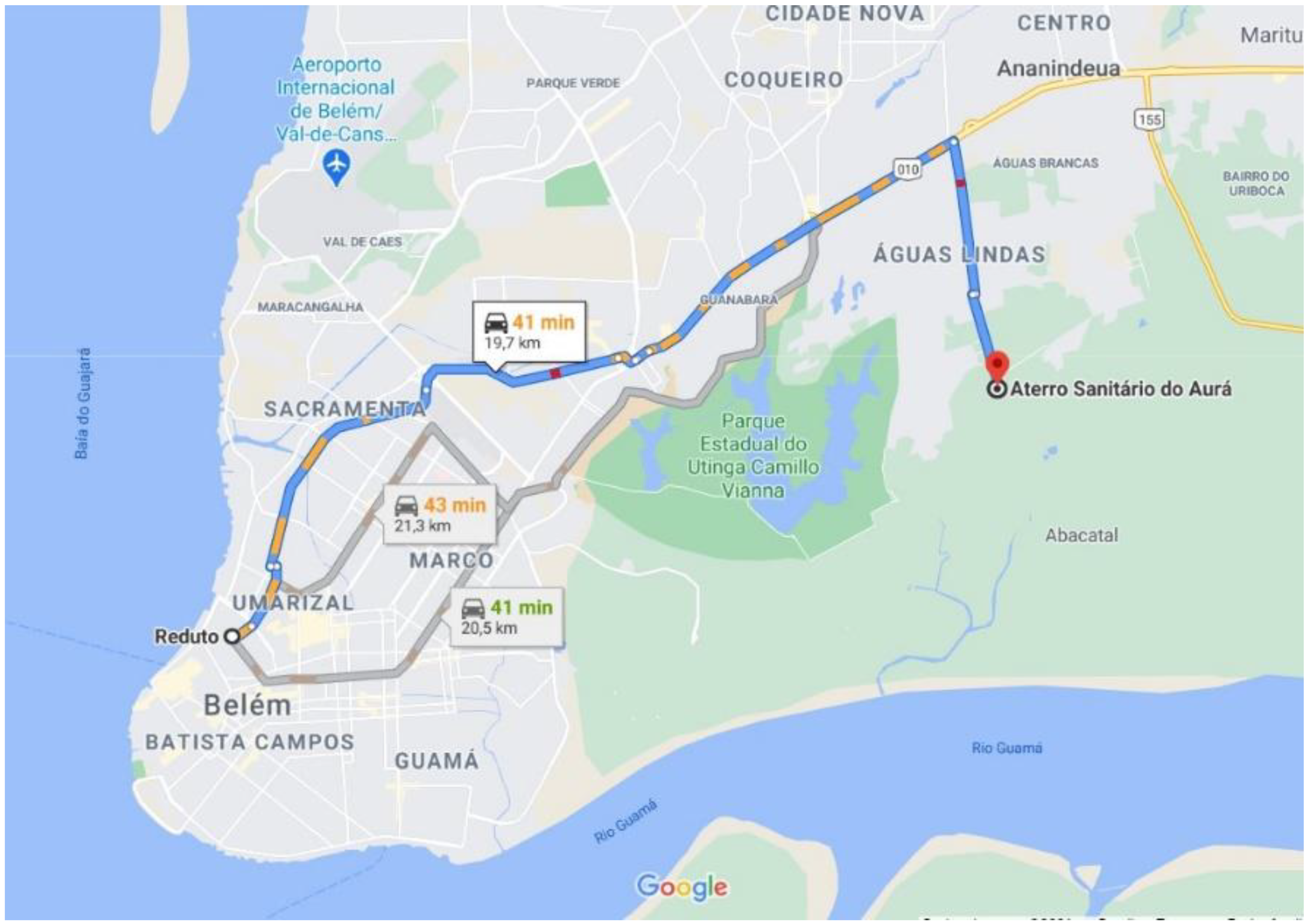

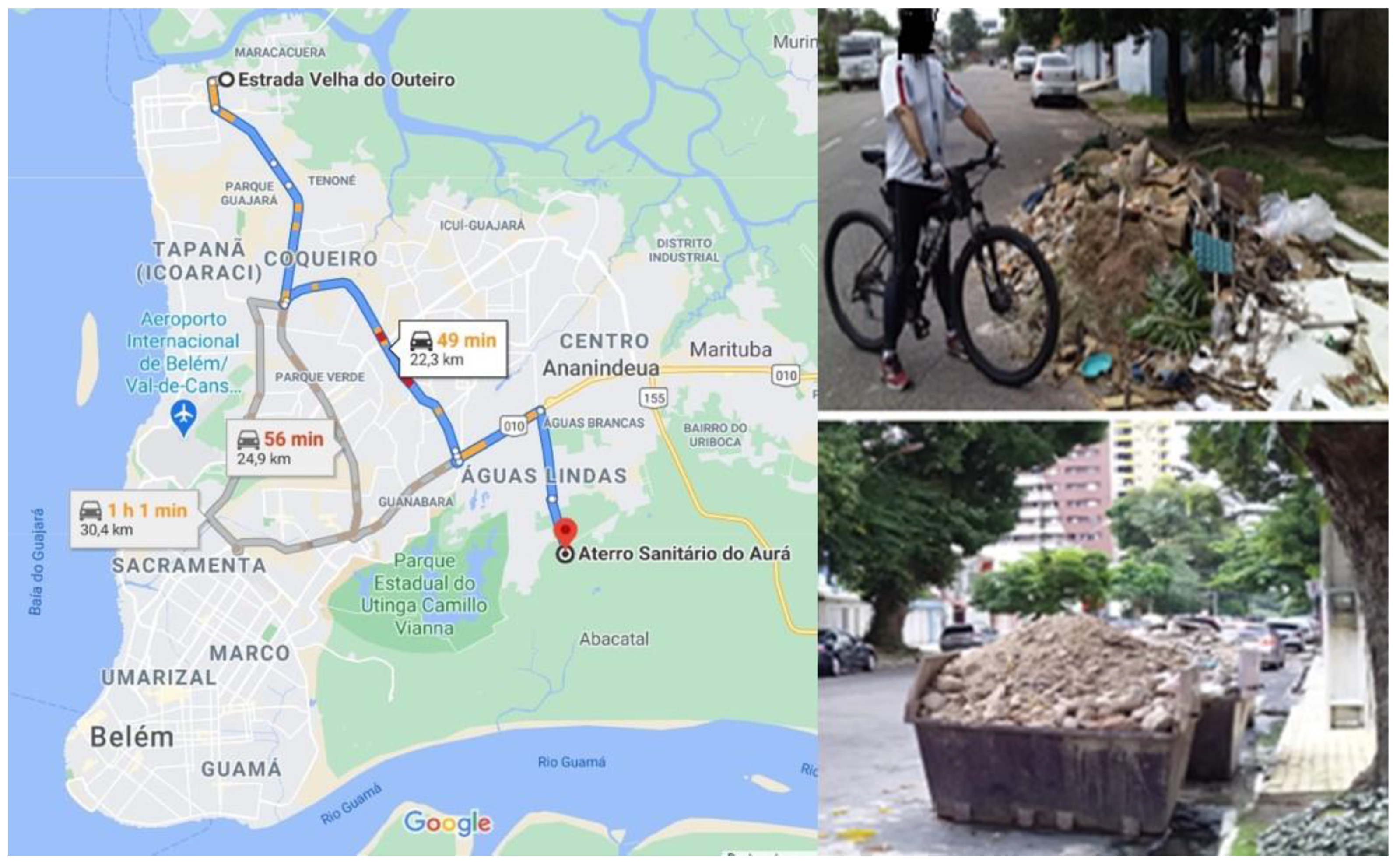

3.1. Data Collection

3.2. Quantification of Greenhouse Gases in the Transportation of Waste

3.3. Identification of Impacts Caused by Waste in the City

4. Case Description

5. Results and Findings

Greenhouse Gas Emissions

6. Conclusions and Future Work

Author Contributions

Funding

Institutional Review Board Statement

Informed Consent Statement

Data Availability Statement

Acknowledgments

Conflicts of Interest

Appendix A

| Transport Distance to Aurá Landfill—Small Generators | Transport Distance to Aurá Landfill—Large Generators | ||||||

|---|---|---|---|---|---|---|---|

| Container (Units) | District | Geographic Coordinates | Distance (km) | Container (Units) | District | Geographic Coordinates | Distance (km) |

| 2 | Batista Campos | 1°27′35.6″ S 48°29′19.8″ W | 27.7 | 4 | Guamá | 1°28′15.5″ S 48°27′32.7″ W | 27.1 |

| 1 | Batista Campos | 1°27′29.5″ S 48°29′52.9″ W | 28 | 6 | Guamá | 1°28′14.0″ S 48°27′19.4″ W | 27.6 |

| 1 | Batista Campos | 1°27′21.3″ S 48°29′40.2″ W | 27.6 | 2 | Guamá | 1°28′05.2″ S 48°27′15.0″ W | 27.3 |

| 1 | Fátima | 1°27′18.7″ S 48°28′14.4″ W | 25.7 | 1 | Guamá | 1°28′06.4″ S 48°28′03.0″ W | 28.6 |

| 1 | Guamá | 1°27′40.2″ S 48°28′07.8″ W | 25.7 | 4 | Guamá | 1°27′35.4″ S 48°28′13.2″ W | 24.3 |

| 1 | Marambaia | 1°23′59.0″ S 48°27′13.0″ W | 19.6 | 8 | Terra firme | 1°28′04.6″ S 48°27′10.6″ W | 27.1 |

| 1 | Marambaia | 1°23′57.5″ S 48°26′54.7″ W | 20.3 | 1 | Terra firme | 1°27′06.6″ S 48°27′02.1″ W | 24.2 |

| 1 | Marco | 1°25′42.7″ S 48°27′47.9″ W | 21.8 | 1 | Terra firme | 1°27′04.69″ S 48°27′02.26″ W | 24.3 |

| 1 | Nazaré | 1°27′07.9″ S 48°29′04.7″ W | 26.4 | 1 | Terra firme | 1°26′56.5″ S 48°27′10.3″ W | 24.6 |

| 2 | Nazaré | 1°26′56.1″ S 48°28′45.3″ W | 26.6 | 1 | Marco | 1°26′33.1″ S 48°27′07.4″ W | 23 |

| 1 | Nazaré | 1°26′58.7″ S 48°29′11.5″ W | 27 | 1 | Marco | 1°25′55.0″ S 48°27′05.8″ W | 21.4 |

| 1 | Nazaré | 1°26′45.5″ S 48°28′41.3″ W | 25.9 | 1 | Marco | 1°26′33.9″ S 48°27′31.8″ W | 22.8 |

| 1 | Nazaré | 1°26′45.6″ S 48°28′33.6″ W | 25.6 | 2 | Marco | 1°26′11.2″ S 48°27′25.4″ W | 22.6 |

| 1 | Pedreira | 1°24′58.3″ S 48°27′50.2″ W | 21.3 | 2 | Pedreira | 1°26′42.0″ S 48°27′55.1″ W | 22.9 |

| 2 | Pedreira | 1°25′38.6″ S 48°27′44.4″ W | 22 | 2 | Marco | 1°26′07.2″ S 48°27′43.0″ W | 21.8 |

| 2 | Sacramenta | 1°24′47.0″ S 48°28′12.8″ W | 21.4 | 1 | Marco | 1°25′48.6″ S 48°27′10.6″ W | 20.3 |

| 1 | São Brás | 1°27′32.0″ S 48°28′14.2″ W | 25.9 | 4 | Pedreira | 1°25′53.3″ S 48°27′42.1″ W | 21.8 |

| 3 | São Brás | 1°27′12.0″ S 48°28′26.7″ W | 25.7 | 1 | Castanheira | 1°25′46.1″ S 48°26′53.6″ W | 22.4 |

| 2 | São Brás | 1°27′20.5″ S 48°28′26.3″ W | 26.2 | 1 | Castanheira | 1°24′13.7″ S 48°25′55.3″ W | 17.7 |

| 1 | São Brás | 1°27′17.2″ S 48°28′23.1″ W | 25.4 | 2 | Curió utinga | 1°25′10.5″ S 48°26′20.6″ W | 21.5 |

| 1 | São Brás | 1°27′16.8″ S 48°28′17.3″ W | 25.3 | 1 | Marambaia | 1°23′54.6″ S 48°26′11.1″ W | 18.1 |

| 1 | São Brás | 1°27′11.2″ S 48°28′20.6″ W | 25.2 | 4 | Maracangalha | 1°24′27.1″ S 48°28′43.6″ W | 23.5 |

| 1 | São Brás | 1°27′13.6″ S 48°28′32.4″ W | 25.6 | 8 | Bonfim | 1°06′49.1″ S 48°23′17.1″ W | 48 |

| 1 | São Brás | 1°27′06.8″ S 48°28′33.5″ W | 25.4 | 6 | Itaiteua | 1°15′48.3″ S 48°27′01.3″ W | 36 |

| 2 | São Brás | 1°27′15.8″ S 48°28′20.5″ W | 25.3 | 1 | Campina de icoaraci | 1°17′37.8″ S 48°28′00.3″ W | 28.9 |

| 3 | Umarizal | 1°26′34.6″ S 48°28′38.3″ W | 26 | 2 | Cruzeiro | 1°18′16.8″ S 48°28′39.2″ W | 29 |

| 2 | Umarizal | 1°26′45.3″ S 48°28′25.6″ W | 25.1 | 8 | Tenoné | 1°17′43.5″ S 48°26′15.3″ W | 30.2 |

| 1 | Umarizal | 1°26′16.7″ S 48°28′50.1″ W | 26.4 | 1 | Tapanã | 1°21′09.4″ S 48°27′49.3″ W | 23.3 |

| 1 | Nazaré | 1°27′10.9″ S 48°28′57.9″ W | 26.8 | 1 | Tapanã | 1°21′05.9″ S 48°28′07.3″ W | 23.7 |

| 1 | São Brás | 1°27′09.1″ S 48°28′07.9″ W | 23.3 | 3 | Maguari | 1°21′06.1″ S 48°22′44.0″ W | 10.7 |

| 1 | Nazaré | 1°26′56.6″ S 48°28′45.5″ W | 25.1 | 5 | Coqueiro | 1°21′13.7″ S 48°25′06.9″ W | 17.9 |

| 1 | Campina | 1°26′41.9″ S 48°29′43.8″ W | 26.4 | 4 | 40 horas | 1°21′25.5″ S 48°25′10.7″ W | 17.5 |

| 1 | Campina | 1°26′55.2″ S 48°29′53.7″ W | 26.7 | 4 | Coqueiro | 1°21′37.7″ S 48°25′06.9″ W | 18.1 |

| 1 | Campina | 1°26′59.2″ S 48°30′02.0″ W | 27.1 | 4 | 40 horas | 1°21′50.2″ S 48°25′13.0″ W | 16.7 |

| 1 | Umarizal | 1°26′31.8″ S 48°29′02.7″ W | 25.6 | 2 | Maguari | 1°20′28.2″ S 48°23′37.5″ W | 14.1 |

| 1 | São Brás | 1°27′12.4″ S 48°28′20.3″ W | 23.7 | 1 | Paar | 1°20′30.5″ S 48°23′43.7″ W | 15.1 |

| 1 | Umarizal | 1°26′08.8″ S 48°29′28.7″ W | 25.3 | 2 | Icuí guajará | 1°20′17.8″ S 48°24′40.4″ W | 16.5 |

| 1 | Reduto | 1°26′48.0″ S 48°29′31.9″ W | 26.1 | 1 | Cidade nova | 1°21′20.8″ S 48°24′18.3″ W | 15.2 |

| 1 | Reduto | 1°26′52.3″ S 48°29′33.8″ W | 27 | 1 | Pedreirinha | 1°21′31.5″ S 48°20′55.9″ W | 7.6 |

| 1 | Nazaré | 1°27′07.7″ S 48°28′42.6″ W | 24.2 | 1 | Novo horizonte | 1°21′35.8″ S 48°19′55.4″ W | 6.4 |

| 1 | Umarizal | 1°26′33.0″ S 48°29′06.1″ W | 25.7 | 1 | Bairro novo | 1°21′27.3″ S 48°20′19.4″ W | 6.3 |

| 1 | Umarizal | 1°26′29.7″ S 48°29′07.7″ W | 25.6 | 1 | Tapanã | 1°21′38.1″ S 48°27′44.6″ W | 24.2 |

| 1 | Canudos | 1°27′06.6″ S 48°27′32.0″ W | 23.3 | 2 | Parque verde | 1°21′56.9″ S 48°26′06.0″ W | 20.1 |

| 1 | Souza | 1°24′46.0″ S 48°26′33.6″ W | 17.9 | 1 | Cabanagem | 1°21′39.8″ S 48°26′26.4″ W | 20.4 |

| 1 | Coqueiro | 1°20′45.5″ S 48°26′55.7″ W | 20.7 | 1 | Cabanagem | 1°21′39.8″ S 48°26′26.4″ W | 20.4 |

| 2 | Marambaia | 1°24′27.9″ S 48°27′39.1″ W | 22.6 | 1 | Águas lindas | 1°23′55.2″ S 48°23′04.1″ W | 13.7 |

| 1 | Julia seffer | 1°23′23.2″ S 48°23′27.1″ W | 12.5 | ||||

| 1 | Atalaia | 1°23′05.2″ S 48°26′03.0″ W | 18 | ||||

| 1 | Guanabara | 1°23′36.1″ S 48°24′43.0″ W | 14.1 | ||||

| 1 | Souza | 1°24′37.2″ S 48°26′36.1″ W | 18.9 | ||||

| 2 | Pedreira | 1°26′09.0″ S 48°28′39.2″ W | 24.6 | ||||

| 1 | Pedreira | 1°25′58.8″ S 48°28′12.0″ W | 23 | ||||

| 3 | Pedreira | 1°25′32.6″ S 48°28′32.1″ W | 23.8 | ||||

| 4 | Telégrafo | 1°25′42.1″ S 48°29′28.4″ W | 25.1 | ||||

| 1 | Marco | 1°26′26.5″ S 48°28′04.4″ W | 23.1 | ||||

| 1 | Umarizal | 1°26′44.0″ S 48°28′53.4″ W | 24.8 | ||||

| 1 | Umarizal | 1°26′48.8″ S 48°29′01.5″ W | 25.1 | ||||

| 2 | Umarizal | 1°26′43.2″ S 48°29′07.1″ W | 25.5 | ||||

| 2 | Umarizal | 1°26′20.4″ S 48°29′06.6″ W | 25 | ||||

| 3 | Umarizal | 1°26′26.1″ S 48°29′35.0″ W | 25.9 | ||||

| 1 | Reduto | 1°26′36.1″ S 48°29′41.2″ W | 26.1 | ||||

| 2 | São braz | 1°26′54.0″ S 48°28′11.8″ W | 23.8 | ||||

| 1 | São braz | 1°26′57.1″ S 48°29′06.1″ W | 25.9 | ||||

| 2 | Umarizal | 1°26′52.4″ S 48°29′04.3″ W | 25.3 | ||||

| 2 | Umarizal | 1°26′51.8″ S 48°28′47.7″ W | 25.1 | ||||

| 2 | Nazaré | 1°26′47.4″ S 48°28′48.2″ W | 24.8 | ||||

| 1 | Umarizal | 1°26′48.0″ S 48°28′50.4″ W | 24.8 | ||||

| 1 | Cidade velha | 1°28′01.8″ S 48°29′49.9″ W | 27.6 | ||||

| 2 | Umarizal | 1°26′48.0″ S 48°29′05.8″ W | 18.7 | ||||

| 2 | Umarizal | 1°26′25.6″ S 48°29′07.8″ W | 18.9 | ||||

| 2 | Umarizal | 1°26′35.9″ S 48°28′46.4″ W | 19.1 | ||||

| 2 | Umarizal | 1°26′34.7″ S 48°29′17.7″ W | 19.1 | ||||

| 2 | Marco | 1°26′07.1″ S 48°27′43.5″ W | 16.8 | ||||

| 2 | Jurunas | 1°27′57.7″ S 48°29′18.7″ W | 22.1 | ||||

| 2 | Val-de-caes | 1°23′21.5″ S 48°28′09.6″ W | 17.1 | ||||

| 2 | Val-de-caes | 1°23′21.9″ S 48°28′07.9″ W | 17.1 | ||||

| 2 | Val-de-caes | 1°23′28.4″ S 48°28′08.3″ W | 17.2 | ||||

| 2 | Val-de-caes | 1°23′28.6″ S 48°28′10.8″ W | 17.2 | ||||

| 4 | Val-de-caes | 1°23′28.8″ S 48°28′09.7″ W | 17.2 | ||||

Appendix B

| Company | Truck Model | PBT | Category–CONTRAN | Year of Manufacture | Waste Volume of the Container-m3 | Load per Container per Trip | Number of Trips per Day per Truck | Number of Containers per Truck per Day | Phase Proconave * | Autonomy (km/L) * |

|---|---|---|---|---|---|---|---|---|---|---|

| 1 | Ford Cargo 6232 | 23 | Heavy | 2011 | 5 | 2 | 3 | 6 | P5 | 3.4 |

| Ford 13180 | 16 | Heavy | 2012 | 4 | 1 | 2 | 4 | P7 | 3.6 | |

| 2 | Volkswagen 13.190 | 16 | Heavy | 2012 | 5 | 2 | 4 | 8 | P7 | 3.6 |

| Volkswagen 13.190 | 16 | Heavy | 2012 | 5 | 2 | 4 | 8 | P7 | 3.6 | |

| 3 | Mercedes Benz ATEGO 1718 | 16 | Heavy | 2012 | 4 | 2 | 4 | 8 | P7 | 3.6 |

| Mercedes Benz L-1319 | 23 | Heavy | 2012 | 5 | 2 | 4 | 8 | P7 | 3.6 | |

| 4 | Ford 13180 | 16 | Heavy | 2012 | 1 | 5 | 2 | 4 | P7 | 3.6 |

| Volkswagen 13.190 | 16 | Heavy | 2012 | 5 | 2 | 4 | 8 | P7 | 3.6 | |

| 5 | Volkswagen 17190 | 16 | Heavy | 2015 | 5 | 1 | 3 | 3 | P7 | 3.6 |

| Volkswagen 17191 | 16 | Heavy | 2015 | 5 | 2 | 3 | 6 | P7 | 3.6 | |

| 6 | Volkswagen 17190 | 16 | Heavy | 2015 | 5 | 1 | 3 | 3 | P7 | 3.6 |

| Volkswagen 17190 | 16 | Heavy | 2015 | 5 | 1 | 3 | 3 | P7 | 3.6 | |

| 7 | Volkswagen 24280 | 16 | Heavy | 2013 | 5 | 2 | 3 | 6 | P7 | 3.6 |

| Volkswagen 24280 | 16 | Heavy | 2013 | 5 | 2 | 3 | 6 | P7 | 3.6 | |

| 8 | Volkswagen 13.190 | 16 | Heavy | 2012 | 5 | 2 | 4 | 8 | P7 | 3.6 |

| Volkswagen 13.190 | 16 | Heavy | 2012 | 5 | 2 | 4 | 8 | P7 | 3.6 | |

| 9 | Ford Cargo 1418 | 23 | Heavy | 1989 | 5 | 2 | 3 | 6 | P2/P3/P4 | 3.5 |

| Volkswagen 17190 | 16 | Heavy | 2011 | 4 | 2 | 3 | 6 | P5 | 3.4 | |

| 10 | C- 1119, FORD | 16 | Heavy | 2014 | 5 | 2 | 3 | 6 | P7 | 3.6 |

| C- 1119, FORD | 16 | Heavy | 2014 | 5 | 2 | 3 | 6 | P7 | 3.6 | |

| 11 | Volkswagen 24280 | 16 | Heavy | 2013 | 5 | 2 | 3 | 6 | P7 | 3.6 |

| Volkswagen 13180 | 16 | Heavy | 2008 | 5 | 2 | 3 | 6 | P5 | 3.4 | |

| Iveco /EUROCARGO 170E22 | 23 | Heavy | 2019 | 5 | 2 | 3 | 6 | P7 | 3.6 | |

| 12 | Volkswagen 1710 | 23 | Heavy | 2005 | 5 | 1 | 3 | 3 | P5 | 3.5 |

| Mercedes 1113 | 16 | Heavy | 1970 | 5 | 2 | 3 | 6 | P2/P3/P4 | 3.5 | |

| Atego 1419 Mercedes Benz | 16 | Heavy | 2013 | 5 | 2 | 3 | 6 | P7 | 3.6 | |

| 13 | Atego 1419 Mercedes Benz | 16 | Heavy | 2019 | 5 | 2 | 3 | 6 | P7 | 3.6 |

| Mercedes Benz 1319 | 16 | Heavy | 2013 | 5 | 2 | 3 | 6 | P7 | 3.6 | |

| Mercedes Benz 1320 | 16 | Heavy | 2013 | 5 | 2 | 3 | 6 | P7 | 3.6 | |

| 14 | Mercedes Benz 1319 | 16 | Heavy | 2013 | 5 | 1 | 1 | 1 | P7 | 3.6 |

| 15 | Volkswagen 17190 | 16 | Heavy | 2017 | 5 | 2 | 3 | 6 | P7 | 3.6 |

| Mercedez Benz Atego 1719 | 16 | Heavy | 2016 | 5 | 2 | 3 | 6 | P7 | 3.6 | |

| Mercedez Benz Atego 1720 | 16 | Heavy | 2019 | 5 | 2 | 3 | 6 | P7 | 3.6 | |

| Mercedez Benz Atego 1721 | 16 | Heavy | 2019 | 5 | 2 | 3 | 6 | P7 | 3.6 | |

| 16 | Mercedez Benz Atego 1418 | 23 | Heavy | 2005 | 4 | 2 | 4 | 8 | P5 | 3.5 |

| Mercedez Benz Atego 1718 | 16 | Heavy | 2009 | 4 | 2 | 4 | 8 | P5 | 3.4 | |

| 17 | Volkswagen 14150 | 16 | Heavy | 1996 | 5 | 1 | 3 | 3 | P2/P3/P4 | 3.5 |

| 18 | FORD/CARGO 1215 | 16 | Heavy | 1988 | 5 | 2 | 3 | 6 | P2/P3/P4 | 3.5 |

| 19 | Mercedes Benz 1320 | 16 | Heavy | 2013 | 5 | 2 | 3 | 6 | P7 | 3.6 |

| Mercedes Benz 1320 | 16 | Heavy | 2013 | 5 | 2 | 3 | 6 | P7 | 3.6 | |

| 20 | Volkswagen 24280 | 16 | Heavy | 2013 | 5 | 2 | 3 | 6 | P7 | 3.6 |

| Volkswagen 24280 | 16 | Heavy | 2013 | 5 | 2 | 3 | 6 | P7 | 3.6 | |

| 21 | Mercedez Benz Atego 1718 | 16 | Heavy | 2009 | 4 | 2 | 4 | 8 | P5 | 3.4 |

| Mercedez Benz Atego 1718 | 16 | Heavy | 2009 | 4 | 2 | 4 | 8 | P5 | 3.4 |

Appendix C

| Inputs | Atmosphere Gas Emissions (g) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Container (und.) | District | Average Transport Distance (km) | Number of Trips (und.) | Fuel Consumption (L/KM) | Total Fuel Consumption (L) | CO2 | CO | HC | NOx | MP | CH4 | N2O | Total CO2eq (kg) |

| 4 | Batista Campos | 27.8 | 2 | 0.42 | 23.35 | 60,781 | 14.82 | 3.28 | 89.02 | 2.56 | 1.67 | 0.83 | 61 |

| 1 | Fátima | 25.7 | 1 | 0.42 | 10.79 | 28,087 | 13.7 | 3.03 | 82.29 | 2.36 | 1.54 | 0.77 | 28 |

| 1 | Guamá | 25.7 | 1 | 0.42 | 10.79 | 28,087 | 13.7 | 3.03 | 82.29 | 2.36 | 1.54 | 0.77 | 28 |

| 4 | Marambaia | 20.8 | 2 | 0.42 | 17.47 | 45,475 | 11.09 | 2.45 | 66.6 | 1.91 | 1.25 | 0.62 | 46 |

| 1 | Marco | 21.8 | 1 | 0.42 | 9.16 | 23,844 | 11.62 | 2.57 | 69.8 | 2.01 | 1.31 | 0.65 | 24 |

| 9 | Nazaré | 26 | 5 | 0.42 | 54.6 | 142,124 | 13.86 | 3.07 | 83.25 | 2.39 | 1.56 | 0.78 | 142 |

| 3 | Pedreira | 21.7 | 2 | 0.42 | 18.23 | 47,453 | 11.57 | 2.56 | 69.48 | 2 | 1.3 | 0.65 | 48 |

| 2 | Sacramenta | 21.4 | 1 | 0.42 | 8.99 | 23,401 | 11.41 | 2.53 | 68.52 | 1.97 | 1.28 | 0.64 | 24 |

| 15 | São Brás | 25.2 | 8 | 0.42 | 84.67 | 220,397 | 13.43 | 2.97 | 80.69 | 2.32 | 1.51 | 0.76 | 221 |

| 10 | Umarizal | 25.7 | 5 | 0.42 | 53.97 | 140,484 | 13.7 | 3.03 | 82.29 | 2.36 | 1.54 | 0.77 | 141 |

| 2 | Reduto | 26.6 | 1 | 0.42 | 11.17 | 29,076 | 14.18 | 3.14 | 85.17 | 2.45 | 1.6 | 0.8 | 29 |

| 1 | Canudos | 23.3 | 1 | 0.42 | 9.79 | 25,484 | 12.42 | 2.75 | 74.61 | 2.14 | 1.4 | 0.7 | 26 |

| 1 | Souza | 17.9 | 1 | 0.42 | 7.52 | 19,575 | 9.54 | 2.11 | 57.32 | 1.65 | 1.07 | 0.54 | 20 |

| 1 | Coqueiro | 20.7 | 1 | 0.42 | 8.69 | 22,621 | 11.03 | 2.44 | 66.28 | 1.9 | 1.24 | 0.62 | 23 |

| 3 | Campina | 26.7 | 2 | 0.42 | 22.43 | 58,386 | 14.23 | 3.15 | 85.49 | 2.46 | 1.6 | 0.8 | 59 |

| Total | 357.0 | 351.6 | 915,275.0 | 190.3 | 42.1 | 1143.1 | 32.8 | 21.4 | 10.7 | 920.0 | |||

Appendix D

| Inputs | Atmosphere Gas Emissions (g) | ||||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|---|---|

| Container (und.) | District | Average Transport Distance (km) | Number of Trips (und.) | Fuel Consumption (L/KM) | Total Fuel Consumption (L) | CO2 | CO | HC | NOx | MP | CH4 | N2O | Total CO2eq (kg) |

| 17 | Guamá | 26.98 | 9 | 0.42 | 101.98 | 265,454 | 14.38 | 3.18 | 86.39 | 2.48 | 1.62 | 0.81 | 266 |

| 11 | Terra Firme | 25.05 | 6 | 0.42 | 63.13 | 164,327 | 13.35 | 2.96 | 80.21 | 2.3 | 1.5 | 0.75 | 165 |

| 11 | Marco | 21.48 | 6 | 0.42 | 54.13 | 140,900 | 11.45 | 2.53 | 68.78 | 1.98 | 1.29 | 0.64 | 141 |

| 12 | Pedreira | 23.22 | 6 | 0.42 | 58.51 | 152,302 | 12.38 | 2.74 | 74.35 | 2.14 | 1.39 | 0.7 | 153 |

| 2 | Castanheira | 20.05 | 1 | 0.42 | 8.42 | 21,917 | 10.69 | 2.37 | 64.2 | 1.84 | 1.2 | 0.6 | 22 |

| 2 | Curió Utinga | 21.5 | 1 | 0.42 | 9.03 | 23,505 | 11.46 | 2.54 | 68.84 | 1.98 | 1.29 | 0.65 | 24 |

| 1 | Marambaia | 18.1 | 1 | 0.42 | 7.6 | 19,783 | 9.65 | 2.14 | 57.96 | 1.67 | 1.09 | 0.54 | 20 |

| 4 | Maracangalha | 23.5 | 2 | 0.42 | 19.74 | 51,383 | 12.53 | 2.77 | 75.25 | 2.16 | 1.41 | 0.71 | 52 |

| 8 | Bonfim | 48 | 4 | 0.42 | 80.64 | 209,906 | 25.58 | 5.66 | 153.7 | 4.42 | 2.88 | 1.44 | 210 |

| 6 | Itaiteua | 36 | 3 | 0.42 | 45.36 | 118,072 | 19.19 | 4.25 | 115.27 | 3.31 | 2.16 | 1.08 | 118 |

| 1 | Campina Icoaraci | 28.9 | 1 | 0.42 | 12.14 | 31,600 | 15.4 | 3.41 | 92.54 | 2.66 | 1.73 | 0.87 | 32 |

| 2 | Cruzeiro | 29 | 1 | 0.42 | 12.18 | 31,705 | 15.46 | 3.42 | 92.86 | 2.67 | 1.74 | 0.87 | 32 |

| 8 | Tenoné | 30.2 | 4 | 0.42 | 50.74 | 132,076 | 16.1 | 3.56 | 96.7 | 2.78 | 1.81 | 0.91 | 132 |

| 9 | Coqueiro | 18 | 5 | 0.42 | 37.8 | 98,393 | 9.59 | 2.12 | 57.64 | 1.66 | 1.08 | 0.54 | 99 |

| 8 | Quarenta Horas | 17.1 | 4 | 0.42 | 28.73 | 74,784 | 9.11 | 2.02 | 54.75 | 1.57 | 1.03 | 0.51 | 75 |

| 5 | Maguari | 12.4 | 3 | 0.42 | 15.62 | 40,659 | 6.61 | 1.46 | 39.7 | 1.14 | 0.74 | 0.37 | 41 |

| 1 | Paar | 15.1 | 1 | 0.42 | 6.34 | 16,503 | 8.05 | 1.78 | 48.35 | 1.39 | 0.91 | 0.45 | 17 |

| 2 | Icuí Guajará | 16.5 | 1 | 0.42 | 6.93 | 18,039 | 8.79 | 1.95 | 52.83 | 1.52 | 0.99 | 0.5 | 18 |

| 1 | Cidade Nova | 15.2 | 1 | 0.42 | 6.38 | 16,607 | 8.1 | 1.79 | 48.67 | 1.4 | 0.91 | 0.46 | 17 |

| 1 | Pedreirinha | 7.6 | 1 | 0.42 | 3.19 | 8304 | 4.05 | 0.9 | 24.34 | 0.7 | 0.46 | 0.23 | 8 |

| 1 | Novo Horizonte | 6.4 | 1 | 0.42 | 2.69 | 7002 | 3.41 | 0.76 | 20.49 | 0.59 | 0.38 | 0.19 | 7 |

| 1 | Bairro Novo | 6.3 | 1 | 0.42 | 2.65 | 6898 | 3.36 | 0.74 | 20.17 | 0.58 | 0.38 | 0.19 | 7 |

| 3 | Tapanã | 23.73 | 2 | 0.42 | 19.93 | 51,878 | 12.65 | 2.8 | 75.98 | 2.18 | 1.42 | 0.71 | 52 |

| 2 | Parque Verde | 20.1 | 1 | 0.42 | 8.44 | 21,969 | 10.71 | 2.37 | 64.36 | 1.85 | 1.21 | 0.6 | 22 |

| 2 | Cabanagem | 20.4 | 1 | 0.42 | 8.57 | 22,308 | 10.87 | 2.41 | 65.32 | 1.88 | 1.22 | 0.61 | 23 |

| 1 | Águas Lindas | 13.7 | 1 | 0.42 | 5.75 | 14,967 | 7.3 | 1.62 | 43.87 | 1.26 | 0.82 | 0.41 | 15 |

| 1 | Julia Seffer | 12.5 | 1 | 0.42 | 5.25 | 13,666 | 6.66 | 1.48 | 40.03 | 1.15 | 0.75 | 0.38 | 14 |

| 1 | Atalaia | 18 | 1 | 0.42 | 7.56 | 19,679 | 9.59 | 2.12 | 57.64 | 1.66 | 1.08 | 0.54 | 20 |

| 1 | Guanabara | 14.1 | 1 | 0.42 | 5.92 | 15,410 | 7.52 | 1.66 | 45.15 | 1.3 | 0.85 | 0.42 | 16 |

| 1 | Souza | 18.9 | 1 | 0.42 | 7.94 | 20,668 | 10.07 | 2.23 | 60.52 | 1.74 | 1.13 | 0.57 | 21 |

| 4 | Telégrafo | 25.1 | 2 | 0.42 | 21.08 | 54,871 | 13.38 | 2.96 | 80.37 | 2.31 | 1.51 | 0.75 | 55 |

| 1 | Reduto | 26.1 | 1 | 0.42 | 10.96 | 28,529 | 13.91 | 3.08 | 83.57 | 2.4 | 1.57 | 0.78 | 29 |

| 3 | São Braz | 24.85 | 2 | 0.42 | 20.87 | 54,325 | 13.25 | 2.93 | 79.57 | 2.29 | 1.49 | 0.75 | 55 |

| 2 | Nazaré | 24.8 | 1 | 0.42 | 10.42 | 27,123 | 13.22 | 2.93 | 79.41 | 2.28 | 1.49 | 0.74 | 27 |

| 1 | Cidade Velha | 27.6 | 1 | 0.42 | 11.59 | 30,169 | 14.71 | 3.26 | 88.38 | 2.54 | 1.66 | 0.83 | 30 |

| 22 | Umarizal | 23.11 | 11 | 0.42 | 106.77 | 277,922 | 12.32 | 2.73 | 74 | 2.13 | 1.39 | 0.69 | 278 |

| 2 | Jurunas | 22.1 | 1 | 0.42 | 9.28 | 24,156 | 11.78 | 2.61 | 70.76 | 2.03 | 1.33 | 0.66 | 24 |

| 12 | Val-De-Cães | 17.16 | 6 | 0.42 | 43.24 | 112,554 | 9.15 | 2.02 | 54.95 | 1.58 | 1.03 | 0.51 | 113 |

| TOTAL | 799 | 938 | 2,440,313 | 425.78 | 94.26 | 2557.87 | 73.52 | 47.94 | 23.96 | 2450 | |||

References

- Luangcharoenrat, C.; Intrachooto, S.; Peansupap, V.; Sutthinarakorn, W. Factors influencing construction waste generation in building construction: Thailand’s perspective. Sustainability 2019, 11, 3638. [Google Scholar] [CrossRef]

- Xiao, W.; Yang, J.; Fang, H.; Zhuang, J.; Ku, Y. Development of online classification system for construction waste based on industrial camera and hyperspectral camera. PLoS ONE 2019, 14, e0208706. [Google Scholar] [CrossRef]

- Kern, P.; Perreira, M.; Piva, M.; Gomes, L. Waste generated in high-rise buildings construction: A quantification model based on statistical multiple regression. J. Clean. Prod. 2015, 39, 35–44. [Google Scholar]

- Maués, L.; Nascimento, B.; Lu, W.; Xue, F. Estimating construction waste generation in residential buildings: A fuzzy set theory approach in the Brazilian Amazon. J. Clean. Prod. 2020, 265, 121779. [Google Scholar] [CrossRef]

- Bergsdal, H.; Bohne, R.A.; Bratteb, H. Projection of Construction and Demolition Waste in Norway. J. Ind. Ecol. 2007, 11, 27–39. [Google Scholar] [CrossRef]

- Debrah, J.; Vidal, D.; Dinis, M. Innovative Use of Plastic for a Clean and Sustainable Environmental Management: Learning Cases from Ghana, Africa. Urban Sci. 2021, 5, 1–12. [Google Scholar] [CrossRef]

- Joensuu, T.; Edelman, H.; Saari, A. Circular economy practices in the built environment. J. Clean. Prod. 2020, 276, 124215. [Google Scholar] [CrossRef]

- Pomponi, F.; Moncaster, A. Circular economy for the built environment: A research framework. J. Clean. Prod. 2017, 143, 710–718. [Google Scholar] [CrossRef]

- Gravagnuolo, A.; Angrisano, M.; Fusco Girard, L. Circular economy strategies in eight historic port cities: Criteria and indicators towards a circular city assessment framework. Sustainability 2019, 11, 3512. [Google Scholar] [CrossRef]

- Wang, J.; Wu, H.; Tam, V.W.Y.; Zuo, J. Considering life-cycle environmental impacts and society’s willingness for optimizing construction and demolition waste management fee: An empirical study of China. J. Clean. Prod. 2019, 206, 1004–1014. [Google Scholar] [CrossRef]

- Bao, Z.; Lu, W. Developing efficient circularity for construction and demolition waste management in fast emerging economies: Lessons learned from Shenzhen, China. Sci. Total Environ. 2020, 724, 138264. [Google Scholar] [CrossRef] [PubMed]

- Kwofie, T.E.; Aigbavboa, C.O.; Thwala, W.D. Measures to improve the adoption of life cycle assessment in the South African construction industry. J. Eng. Des. Technol. 2019, 18, 480–494. [Google Scholar] [CrossRef]

- Daoud, A.O.; Othman, A.A.E.; Robinson, H.; Bayyati, A. An investigation into solid waste problem in the Egyptian construction industry: A mini-review. Waste Manag. Res. 2020, 38, 371–382. [Google Scholar] [CrossRef]

- Orhorhoro, E.K.; Oghoghorie, O. Review on Solid Waste Generation and Management in Sub-Saharan Africa: A Case Study of Nigeria. J. Appl. Sci. Environ. Manag. 2019, 23, 1729–1737. [Google Scholar] [CrossRef]

- Mak, T.M.W.; Yu, I.K.M.; Wang, L.; Hsu, S.-C.; Tsang, D.C.W.; Li, C.N.; Yeung, T.L.Y.; Zhang, R.; Poon, C.S. Extended theory of planned behaviour for promoting construction waste recycling in Hong Kong. Waste Manag. 2019, 83, 161–170. [Google Scholar] [CrossRef] [PubMed]

- Wu, H.; Zuo, J.; Yuan, H.; Zillante, G.; Wang, J. Cross-regional mobility of construction and demolition waste in Australia: An exploratory study. Resour. Conserv. Recycl. 2020, 156, 104710. [Google Scholar] [CrossRef]

- Wang, J.; Li, Z.; Tam, V.W.Y. Identifying best design strategies for construction waste minimization. J. Clean. Prod. 2015, 92, 237–247. [Google Scholar] [CrossRef]

- Zanna, C.D.; Fernandes, F.; Gasparine, J.C. Solid construction waste management in large civil construction companies through use of specific software—case study. Acta Sci. Technol. 2017, 39, 169–176. [Google Scholar] [CrossRef]

- Ferreiro-Cabello, J.; Fraile-Garcia, E.; Martinez-Camara, E.; Perez-de-la-Parte, M. Sensitivity analysis of Life Cycle Assessment to select reinforced concrete structures with one-way slabs. Eng. Struct. 2017, 132, 586–596. [Google Scholar] [CrossRef]

- Correia Gomes, P.C.; Alencar Pereira, F.; Uchôa, S.B.B.; Oliveira, F.C.; de Almeida, L.H. Obtenção de blocos de concreto com utilização de resíduos reciclados da própria fabricação dos blocos. Ambient. Construído 2017, 17, 267–280. [Google Scholar] [CrossRef]

- Martínez, E.; Nuñez, Y.; Sobaberas, E. End of life of buildings: Three alternatives, two scenarios. A case study. Int. J. Life Cycle Assess. 2013, 18, 1082–1088. [Google Scholar] [CrossRef]

- Lima, A.S.; Cabral, A.E.B. Caracterização e classificação dos resíduos de construção civil da cidade de Fortaleza (CE). Eng. Sanit. Ambient. 2013, 18, 169–176. [Google Scholar] [CrossRef]

- Ulsen, C.; John, V.M. Composição química de agregados mistos de resíduos de construção e demolição do Estado de São Paulo. Rev. Esc. Minas 2010, 63, 339–346. [Google Scholar] [CrossRef]

- Yang, H.; Xia, J.; Thompson, J.R.; Flower, R.J. Urban construction and demolition waste and landfill failure in Shenzhen, China. Waste Manag. 2017, 63, 393–396. [Google Scholar] [CrossRef]

- Ferronato, N.; Torretta, V. Waste mismanagement in developing countries: A review of global issues. Int. J. Environ. Res. Public Health 2019, 16, 1060. [Google Scholar] [CrossRef]

- Ibáñez-Forés, V.; Bovea, M.D.; Coutinho-Nóbrega, C.; de Medeiros, H.R. Assessing the social performance of municipal solid waste management systems in developing countries: Proposal of indicators and a case study. Ecol. Indic. 2019, 98, 164–178. [Google Scholar] [CrossRef]

- Azevedo, B.D.; Scavarda, L.F.; Caiado, R.G.G. Urban solid waste management in developing countries from the sustainable supply chain management perspective: A case study of Brazil’s largest slum. J. Clean. Prod. 2019, 233, 1377–1386. [Google Scholar] [CrossRef]

- Sauve, G.; Van Acker, K. The environmental impacts of municipal solid waste landfills in Europe: A life cycle assessment of proper reference cases to support decision making. J. Environ. Manag. 2020, 261, 110216. [Google Scholar] [CrossRef]

- Brand, J.H.; Spencer, K.L. Potential contamination of the coastal zone by eroding historic landfills. Mar. Pollut. Bull. 2019, 146, 282–291. [Google Scholar] [CrossRef]

- Singh, C.K.; Kumar, A.; Roy, S.S. Estimating potential methane emission from municipal solid waste and a site suitability analysis of existing landfills in Delhi, India. Technologies 2017, 5, 62. [Google Scholar] [CrossRef]

- Liu, J.; Liu, Y.; Wang, X. An environmental assessment model of construction and demolition waste based on system dynamics: A case study in Guangzhou. Environ. Sci. Pollut. Res. 2020, 27, 37237–37259. [Google Scholar] [CrossRef]

- Periotto, A.J.; Furlan, L.A. Um estudo sobre a gestão de resíduos sólidos no município de Cidade Gaúcha–PR. Cad. Adm. 2012, 20, 66–82. [Google Scholar]

- Imbiriba, B.C.d.O.; Ramos, J.R.d.S.; de Sousa Silva, R.; Cattanio, J.H.; do Couto, L.L.; Mitschein, T.A. Estimates of methane emissions and comparison with gas mass burned in CDM action in a large landfill in Eastern Amazon. Waste Manag. 2020, 101, 28–34. [Google Scholar] [CrossRef]

- Kahn, H.; Ulsen, C.; Hawlitschek, G. Automated Image Analysis on the Quantification of Recycled Aggregates Phases 2 Materiais E Métodos. Holos 2014, 3, 44–52. [Google Scholar]

- Klamt, R.A.; Fontoura, P.R.; Budney, J.; dos Santos, F.F. Estudo da utilização da reciclagem de concreto asfáltico como camada de pavimento. Rev. Gestão Ambient. Sustentabilidade 2018, 7, 539–553. [Google Scholar] [CrossRef]

- Ossa, A.; García, J.L.; Botero, E. Use of recycled construction and demolition waste (CDW) aggregates: A sustainable alternative for the pavement construction industry. J. Clean. Prod. 2016, 135, 379–386. [Google Scholar] [CrossRef]

- Xuan, D.X.; Molenaar, A.A.A.; Houben, L.J.M. Evaluation of cement treatment of reclaimed construction and demolition waste as road bases. J. Clean. Prod. 2015, 100, 77–83. [Google Scholar] [CrossRef]

- Dos Santos, R.A.; Lira, B.B.; Marinho Ribeiro, A.C. Argamassa Com Substituição De Agregado Natural Por Resíduo De Britagem De Granito. Holos 2012, 5, 125. [Google Scholar] [CrossRef]

- Brandão, A.; Barreto, P.; Lenti, F.; Shimbo, J.; Alencar, A. 2018. Emissões do setor mudança do uso da terra. Amazon Institute of People and the Environment. [Google Scholar] [CrossRef]

- Pérez-Martnez, P.J. Energy consumption and emissions from the road transport in Spain: A conceptual approach. Transport 2012, 27, 383–396. [Google Scholar] [CrossRef]

- Lu, W.; Webster, C.; Peng, Y.; Chen, X.; Zhang, X. Estimating and calibrating the amount of building-related construction and demolition waste in urban China Weisheng. Int. J. Constr. Manag. 2017, 17, 13–24. [Google Scholar]

- Villoria Sáez, P.; del Río Merino, M.; Porras-Amores, C. Estimation of construction and demolition waste volume generation in new residential buildings in Spain. Waste Manag. Res. 2012, 30, 137–146. [Google Scholar] [CrossRef] [PubMed]

- Fernandez, J.A.B.; ROMA, J.C.; MOURA, A.A.M. Diagnóstico dos resíduos sólidos da construção civil; Instituto de Pesquisa Econômica Aplicada–IPEA: Brasília, Brazil, 2012. [Google Scholar]

- Diniz, I.d.C.; Vinagre, M.V.d.A.; Bello, L.A.L.; Maia, É.M.; Gaia, A. Impactos ambientais causados por resíduos de construção na cidade de Belém, “a metrópole da amazônia”. Educ. Ambient. Ação 2015, 54, 70–95. [Google Scholar]

- Lu, W.; Yuan, H. A framework for understanding waste management studies in construction. Waste Manag. 2011, 31, 1252–1260. [Google Scholar] [CrossRef]

- Ministério do Meio Ambiente. Resolução CONAMA no 307, de 5 de julho de 2002; Diário Oficial da União: Brasilia, Brasil, 2002. [Google Scholar]

- Debrah, J.; Vidal, D.; Dinis, M. Raising Awareness on Solid Waste Management through Formal Education for Sustainability: A Developing Countries Evidence Review. Recycling 2021, 6, 1–21. [Google Scholar] [CrossRef]

- Caldas, L.R.; Sposto, R.M. Emissões de CO2 referentes ao transporte de materiais de construção no Brasil: Estudo comparativo entre blocos estruturais cerâmicos e de concreto. Ambient. Construído 2017, 17, 91–108. [Google Scholar] [CrossRef]

- Severo, E.; Sousa, H. Ferramentas Quantitativas e Qualitativas para Avaliação da Sustentabilidade das Edificações. Ciaiq 2016, 4, 13–21. [Google Scholar]

- Chau, C.K.; Leung, T.M.; Ng, W.Y. A review on life cycle assessment, life cycle energy assessment and life cycle carbon emissions assessment on buildings. Appl. Energy 2015, 143, 395–413. [Google Scholar] [CrossRef]

- Maués, L.M.F.; de Freitas, A.C.A.; Barbosa, A.R. Quantificação da emissão de CO2 para edificações residenciais do programa minha casa minha vida. In III Encuentro Latinoamericano y Europeu Sobre Edificações e Comunidades Sostenibles; ANTAC y EcoUrbano, Ed.; ANTAC y EcoUrbano: Santa Fe, Argentina, 2019; pp. 1340–1349. [Google Scholar]

- Campos, É.F.; Punhagui, K.R.G.; John, V.M. Emissão de CO2 do transporte da madeira nativa da Amazônia. Ambient. Construído 2011, 11, 157–172. [Google Scholar] [CrossRef][Green Version]

- Dossche, C.; Boel, V.; De Corte, W. Comparative material-based life cycle analysis of structural beam-floor systems. J. Clean. Prod. 2018, 194, 327–341. [Google Scholar] [CrossRef]

- UNFCCC. Adoption of the Paris Agreement (Report No. FCCC/CP/2015/L.9/Rev.1). 2015. Available online: http://unfccc.int/resource/docs/2015/cop21/eng/l09r01.pdf (accessed on 19 August 2020).

- Del Bianco, S.; Carli, B.; Gai, M.; Laurenza, L.M.; Cortesi, U. XCO 2 retrieved from IASI using KLIMA algorithm. In ANNALS OF GEOPHYSICS; INGV, Istituto Nazionale di Geofisica e Vulcanologia: Firenze, Italy; pp. 1–10. 2013; ISSN 2037-416X. [Google Scholar]

- Brewer, T.L. Black carbon emissions and regulatory policies in transportation. Energy Policy 2019, 129, 1047–1055. [Google Scholar] [CrossRef]

- Mohd Yasin, N.H.; Maeda, T.; Hu, A.; Yu, C.P.; Wood, T.K. CO2 sequestration by methanogens in activated sludge for methane production. Appl. Energy 2015, 142, 426–434. [Google Scholar] [CrossRef]

- Waldron, C.D.; Harnisch, J.; Lucon, O.; Mckibbon, R.S.; Saile, S.B.; Wagner, F.; Walsh, M.P. MOBILE COMBUSTION. In IPCC Guidelines for National Greenhouse Gas Inventories; The National Greenhouse Gas Inventories Programme: Hayama, Japan, 2006; p. 78. [Google Scholar]

- Solaymani, S. CO2 emissions patterns in 7 top carbon emitter economies: The case of transport sector. Energy 2019, 168, 989–1001. [Google Scholar] [CrossRef]

- Glock, C.H.; Kim, T. Coordinating a supply chain with a heterogeneous vehicle fleet under greenhouse gas emissions. Int. J. Logist. Manag. 2015, 26, 494–516. [Google Scholar] [CrossRef]

- Wahab, M.I.M.; Mamun, S.M.H.; Ongkunaruk, P. EOQ models for a coordinated two-level international supply chain considering imperfect items and environmental impact. Int. J. Prod. Econ. 2011, 134, 151–158. [Google Scholar] [CrossRef]

- Malarvizhi, K.; Kumar, S.V.; Porchelvan, P. Use of high resolution Google Earth satellite imagery in landuse map preparation for urban related applications. Procedia Technol. 2016, 24, 1835–1842. [Google Scholar] [CrossRef]

- Instituto Brasileiro de Geografia e Estatística [WWW Document], IBGE. 2019. Available online: https://cidades.ibge.gov.br/ (accessed on 1 September 2020).

- Institute for Global Environmental Strategis—IGES. IPCC Guidelines for National Greenhouse Inventories; IGES: Hayama, Japan, 2006. [Google Scholar]

| Emission Factors of GHG Generated by Vehicles | ||||||

|---|---|---|---|---|---|---|

| CO2 (g/l) | CO(g/km) | HC (g/km) | NOx (g/km) | MP | CH4 (g/km) | N2O (g/km) |

| 2603 | 0.533 | 0.118 | 3.202 | 0.092 | 0.06 | 0.03 |

| Global Warming Factors | ||||||

| CO2 (g/l) | CO(g/km) | HC (g/km) | NOx (g/km) | MP | CH4 (g/km) | N2O (g/km) |

| 1 | 0 | 0 | 0 | 0 | 25 | 298 |

Publisher’s Note: MDPI stays neutral with regard to jurisdictional claims in published maps and institutional affiliations. |

© 2021 by the authors. Licensee MDPI, Basel, Switzerland. This article is an open access article distributed under the terms and conditions of the Creative Commons Attribution (CC BY) license (https://creativecommons.org/licenses/by/4.0/).

Share and Cite

Maués, L.M.; Beltrão, N.; Silva, I. GHG Emissions Assessment of Civil Construction Waste Disposal and Transportation Process in the Eastern Amazon. Sustainability 2021, 13, 5666. https://doi.org/10.3390/su13105666

Maués LM, Beltrão N, Silva I. GHG Emissions Assessment of Civil Construction Waste Disposal and Transportation Process in the Eastern Amazon. Sustainability. 2021; 13(10):5666. https://doi.org/10.3390/su13105666

Chicago/Turabian StyleMaués, Luiz Maurício, Norma Beltrão, and Isabela Silva. 2021. "GHG Emissions Assessment of Civil Construction Waste Disposal and Transportation Process in the Eastern Amazon" Sustainability 13, no. 10: 5666. https://doi.org/10.3390/su13105666

APA StyleMaués, L. M., Beltrão, N., & Silva, I. (2021). GHG Emissions Assessment of Civil Construction Waste Disposal and Transportation Process in the Eastern Amazon. Sustainability, 13(10), 5666. https://doi.org/10.3390/su13105666